Page 1

WARNING: THIS MACHINE CAN CAUSE SERIOUS INJURY OR DEATH!

THOROUGHLY READ INSTRUCTIONS BEFORE INSTALLING OR OPERATING TRAP!

TM

WHEELYBIRD

AUTO-FEED TRAP

Part No. 40909

Instruction Manual

Page 2

Table of Contents

Section Page

I. Introduction ............................................................................ 1

II. Safety ..................................................................................... 2

III. Assembly and Installation ...................................................... 4

1. Unpacking ...................................................................................... 4

2. Contents ......................................................................................... 5

3. Assembly ........................................................................................ 7

A. Assemble Frame ......................................................................... 7

B. Attach the Trap to the Frame....................................................... 8

C. Install the Mainspring .................................................................. 9

D. Attach the Throwing Arm Path Indicator ..................................... 10

E. Attach the Magazine Assembly .................................................... 11

F. Setup .......................................................................................... 11

IV. Operation ................................................................................ 12

V. Adjustments ............................................................................ 13

1. Throwing arm limit switch .............................................................. 13

2. Elevation Adjustment ...................................................................... 15

3. Distance Adjustment ....................................................................... 16

VI. Troubleshooting ...................................................................... 17

VII. Maintenance ........................................................................... 18

VIII. Replacement Parts ............................................................................... 19

IX. Warranty Information .......................................................................... 19

X. Contact Information ............................................................................. 20

Page 3

I. Introduction

The WheelyBird

skeet shooter looking for an automatic, lightweight, and portable machine for

practice/fun shooting.

Features and benefits of the WheelyBird

Safety

ON-OFF-SAFE RELEASE switch provides safe method to uncock throwing arm

Arm path indicator ring provides visual indication of throwing arm path for safety

20 amp circuit breaker protects electrical wires and motor

Convenience

Lightweight and portable - approximately 48 lbs

Detachable magazine holds 50 targets

Thro

25 ft. release cord with foot pedal release

Two-wheeled frame with handle for easy movement

Performance

Fast, 2-second cycle time

Standard throwing range of 55yds at 25 deg elevation angle

Runs off 12 volt battery (deep cycle type recommended)

Balanced throwing arm with replaceable flight rail

TM

Auto-Feed Trap is designed for the active sporting clays, trap, and

TM

Auto-Feed Trap:

ws standard 108 mm or 110mm international clay targets

1

Page 4

II. Safety

WARNING: THIS MACHINE CAN CAUSE SERIOUS INJURY OR DEATH!!!!

THOROUGHLY READ INSTRUCTIONS BEFORE INSTALLING OR OPERATING TRAP!

DO NOT STAND IN FRONT OF THE TRAP WHEN IT IS IN THE COCKED POSITION.

SERIOUS INJURY OR DEATH CAN RESULT.

THIS TRAP IS CAPABLE OF THROWING TARGETS A DISTANCE OF OVER 65 YARDS.

USE ONLY IN AREAS WHERE THERE IS NO RISK OF CAUSING DAMAGE, OR HITTING

A PERSON WITH A TARGET.

KNOW YOUR BACKSTOP. ENSURE THERE IS A SAFE PERIMETER THROUGHOUT

TARGET FLIGHT PATH SUFFICIENT FOR AMMUNITION USED.

WARNING: IF THERE IS A TARGET ON THE THROWING ARM, SAFE RELEASING

THE ARM WILL THROW THE TARGET. DO NOT STAND IN FRONT OF THE TRAP WHILE

SAFE RELEASING THE THROWING ARM.

CAUTION: THE TRAP MUST HAVE AMPLE CLEARANCE AROUND THE TRAP. THE

ON/OFF/SAFE RELEASE SWITCH FOR THE TRAP IS LOCATED ON THE REAR OF THE

TRAP AND ALLOWS THE TRAP TO BE UNCOCKED BEFORE APPROACHING IT.

DO NOT INSTALL THE TRAP IN AN AREA THAT DOES NOT ALLOW SAFE (REAR)

ACCESS TO THE TRAP AND THE ON/OFF/SAFE RELEASE SWITCH DURING LOADING

AND USE.

1. All personnel operating the trap should be thoroughly familiar with the

operating instructions and the safety issues relating to the trap.

2. Do not leave trap in the cocked position. Not only is this potentially dangerous,

but it puts undue stress on the mainspring.

3. Always load and operate the trap from the rear (switch end).

4. Keep hands and body outside the trap and throwing arm path indicator areas

while the trap is operating. This ring shows the throwing arm‟s path when

throwing a target, and should always be attached to the trap when it is in use.

5. Be aware that a cracked or broken target thrown from the trap will sometimes

scatter pieces out the right side of the machine as the arm throws. These

pieces may hit nearby unsuspecting bystanders.

6. Always wear eye and hearing protection when shooting.

2

Page 5

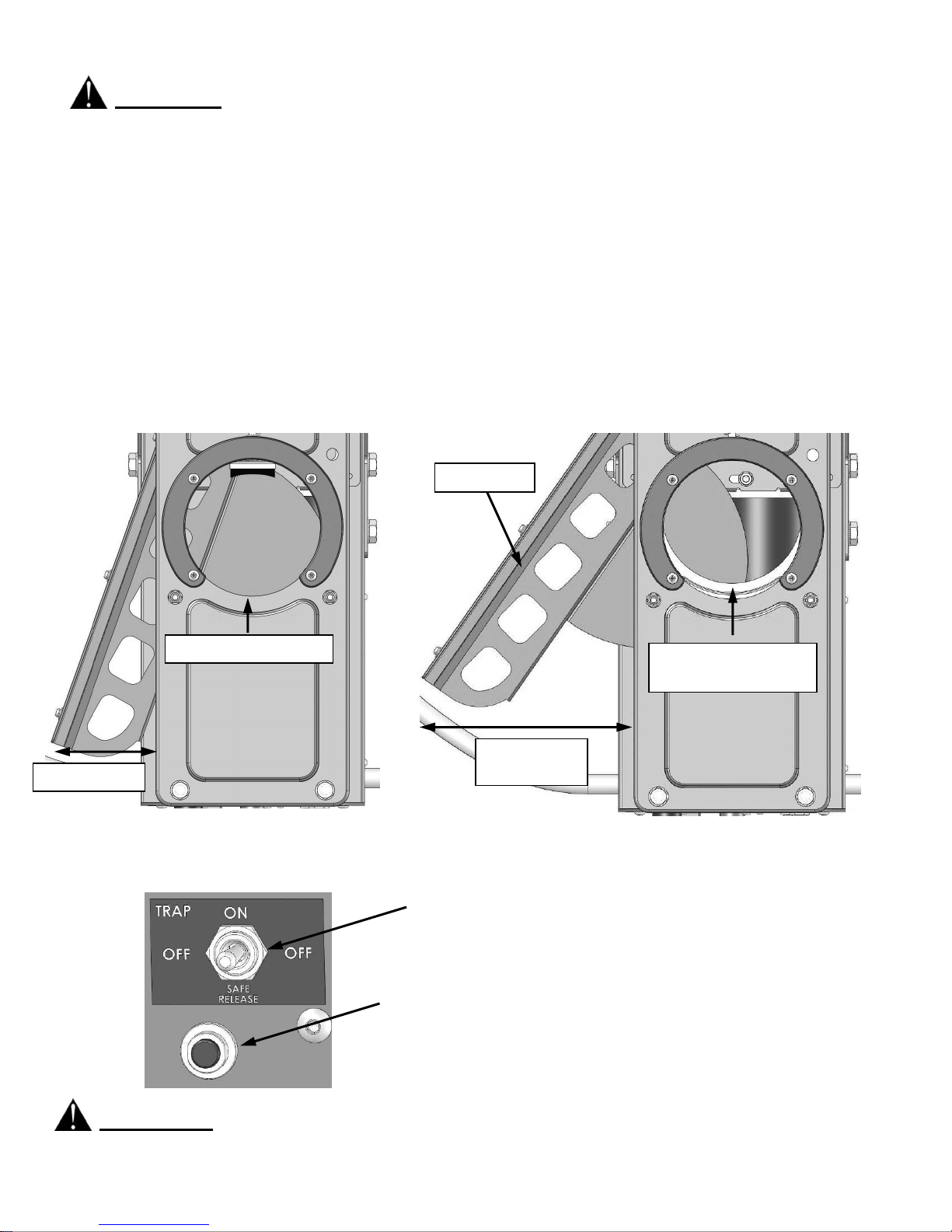

WARNING: BEFORE PERFORMING ANY REPAIR, MAINTENANCE, OR ASSEMBLY,

Cocked Arm Position

(Ready to Launch Target)

Uncocked Arm Position

(Ready to Load Targets)

Circuit Breaker

ON/OFF/SAFE RELEASE

Switch

Drop Hole Open

Drop Hole

Partially Closed

2.5” to 4.5“

more than

4.5“

Flight Rail

MAKE SURE THE THROWING ARM IS IN THE UNCOCKED POSITION (SEE BELOW),

THE ON/OFF/SAFE RELEASE SWITCH LOCATED ON THE REAR OF THE TRAP IS IN

THE „OFF„ POSITION (SEE PHOTO BELOW) , AND THE BATTERY IS DISCONNECTED

FROM THE TRAP.

If the throwing arm is in the cocked arm position (see photo below), uncock

the throwing arm by first connecting the red battery lead to the positive (+)

terminal and the black battery lead to the negative (-) terminal on the battery.

Momentarily press the on/off/safe release switch to the “SAFE RELEASE”

position to release the throwing arm. After the trap fires, release the

ON/OFF/SAFE RELEASE switch allowing it to return to the “OFF” position. The

throwing arm should now be in the uncocked position. Disconnect the battery

from the trap.

WARNING: FAILURE TO FOLLOW SAFETY RULES CAN RESULT IN SERIOUS

INJURY OR DEATH!

3

Page 6

III. Assembly

1. Unpacking

1. Carefully inspect the carton and trap machine to be sure that damage hasn’t

occurred during shipping. Report any damage found immediately to the

shipper.

2. Carefully remove trap assembly and all other components from cardboard

shipping box and other smaller boxes. Remove all hardware from bags.

3. Check that all parts were included. If any parts are missing, call the

CHAMPION Customer Service Department at (800) 379-1732 to obtainreplacement parts.

4. Save all packing material and box if trap should ever need to be returned for

service or replacement.

4

Page 7

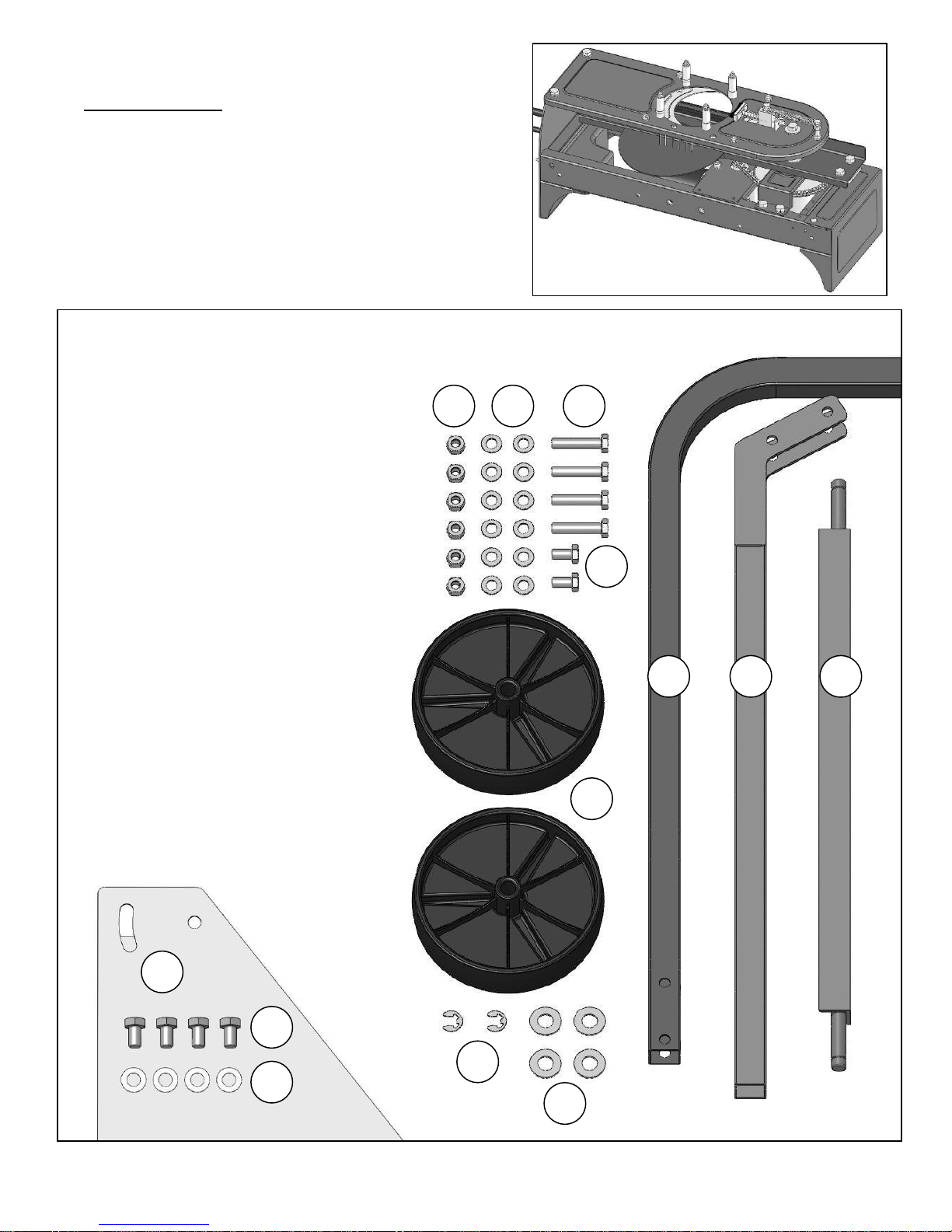

2. Contents

F1 - Axle

F3 - Handle

F2 - Bracket Support Bar

F4 - 8mm x 45mm Bolt (4)

F5 - 8mm x 16mm Bolt (2)

F6 - 8mm Washer (12)

F7 - 8mm Lock Nut (6)

F8 - Plastic Wheel (2)

F9 - Large Axle Washer (4)

F11 - Mounting Bracket

F10 - Axle Clip (2)

F12 - 10mm x 16mm Bolt (4)

F13 - 10mm Washer (4)

Frame Parts

F12

F13

F11

F1

F9

F8

F7

F6

F5

F4

F3

F2

F10

Trap Assembly

5

Page 8

S1 - Mainspring

A1 - Arm Path Tube

Supports (2)

M1 - Magazine Rods (4)

M2 - Magazine Top Plate

M3 - 5mm x 10mm Screws (4)

S2 - Mainspring Bolt

S3 - 10mm Flat Washer

S4 - 10mm Flange Nut

S5 - 10mm Hex Nut

A2 - Arm Path Tube

Studs (2)

A3 - Arm Path Tubing

A4 - 5mm x 10mm Screws (4)

A5 - 5mm Washers (4)

Mainspring Assembly

Arm Path Tubing Parts

Magazine Parts

S2

S5

S4

S3

S1

A4

A5

A1

A3

A2

M1

M3

M2

6

Page 9

3. Assembly

F2

F1

F3

F3

F11

F8

F8

F5

Caution: Provide ample clearance around the trap.

DO NOT OPERATE THE TRAP IN AN AREA THAT DOES NOT ALLOW SAFE

(REAR) ACCESS TO THE TRAP AND THE ON/OFF/SAFE RELEASE SWITCH

DURING LOADING AND USE.

A. Assemble Frame

1. Assemble F1 (Axle) and F2 (Bracket Support Bar) to F11 (Mounting Bracket) using F4

(8mm x 45mm Bolt), F5 (8mm x 16mm bolt) with F6 (8mm Washers) and F7 (8mm Nut).

2. Attach F3 (Handle) to F2 (Bracket Support Bar) using F4 (8mm x 45mm Bolt) with F6 (8mm

Washers) and F7 (8mm Nut). F3 Handle end can point back or to the left as shown.

3. Assemble F8 (Plastic Wheel) to each end of F1 (Axle) with F9 (Large Axle Washer) on

each side of wheel. Install F10 (Axle Clip) in groove on each end of Axle.

7

Page 10

B. Attach Trap to Frame

F12

F13

1. Stand and support trap assembly on front panel as shown.

2. Attach F11 (Mounting Bracket) to trap using F12 (10mm x 16mm Bolt) and F13 (10mm

Washer) as shown.

3. Pivot trap and frame back when finished.

8

Page 11

C. Install Mainspring

S1

S2

S5

S4

S3

1. Remove the plastic tie holding the throwing arm in place and rotate the arm counter

clockwise 180 so it is facing forward of the trap in the 12 o‟clock position.

2. Remove the wire tie holding the crankshaft eyebolt.

3. Attach the hook on one end of the S1 (Mainspring) through the crankshaft eyebolt.

(Eyebolt should be pointing toward rear of trap.)

4. Push threaded end of S2 (Mainspring Bolt) through hole in rear of body.

5. Attach the hook on other end of S1 (Mainspring) through the hole in end of S2 (Mainspring

Bolt).

6. Attach S3 (10mm Flat Washer) and S4 (10mm Flange Nut) to S2 (Mainspring Bolt).

7. With the throwing arm still facing forward of the trap, tighten S4 until all the slack is taken

up in the spring and the bolt is tight. Add S5 (10mm Hex Nut) and tighten against S4.

8. The throwing arm is now in the uncocked position and is under standard tension.

9

Page 12

D. Attach the Throwing Arm Path Indicator

A1

A3

A2

A5

A4

1. Attach A1 (Arm Path Tube Support) to each front side of trap using A4 (5mm x 10 Bolt) and

A5 (5mm Washer).

2. Thread A2 (Arm Path Tube Stud) into each rear tapped side hole of trap and tighten

securely.

3. Unwind A3 (Arm Path Tubing) and thread thru each A1 and connect each end to A2.

WARNING: FAILURE TO KEEP HANDS AND BODY OUTSIDE THE THROWING ARM

PATH INDICATOR AREA CAN RESULT IN SERIOUS INJURY OR DEATH

FROM BEING STRUCK BY THE THROWING ARM DURING USE.

Caution: Do not lift trap by throwing arm path tubing, or front arm path

tube supports, these were not designed to be a lifting point.

10

Page 13

E. Attach the Magazine

Magazine Rods

Rear of Machine

Magazine Top Plate

M1

M2

1. Slide M1 (Magazine Rod) over each magazine stud as shown.

2. Attach M2 (Magazine Top Plate) using M3 (5mm x 10 Screws). Opening of M2 should be

toward rear of machine.

F. Setup

WARNING: MAKE SURE THAT THE “ON-OFF-SAFE RELEASE” SWITCH IS SET TO

THE “OFF” POSITION BEFORE CONNECTING POWER TO THE TRAP.

DO NOT OPERATE THE TRAP IN AN AREA THAT DOES NOT ALLOW SAFE (REAR)

ACCESS TO THE TRAP AND THE ON/OFF/SAFE RELEASE SWITCH DURING LOADING

AND USE.

1. Connect the red battery lead to the positive (+) terminal and the black battery lead to the

negative (-) terminal of a charged deep cycle 12V battery.

2. Remove wire ties from foot pedal release cable and unwind cable as needed and place foot

pedal switch on ground.

3. For additional stability of trap, a large screwdriver or stake can be placed through rear hole

of F2 (Bracket Support Bar) and driven into the ground (see below).

11

Page 14

IV. Operation

Target Retainer

Loading Bar

Rubber

Target Retainer

WARNING: DO NOT STAND IN FRONT OF TRAP OR IN THE PATH OF THE THROWING

ARM ! SERIOUS INJURY OR DEATH MAY RESULT !

1. The throwing arm path indicator must be mounted properly before using trap.

2. Make sure that the trap is located to allow ample clearance around machine and provides

safe access to the rear of the trap during operation. The trap must be located so that the

user has safe access to the rear to operate the On/Off/Safe Release switch and reload the

trap.

3. Make sure that the On/Off/Safe Release switch is in the “OFF” position, and the arm is in

the uncocked position (page 3).

4. Place six (6) targets into magazine and hold them flat. Pull back on Target Retainer

Loading Bar if the Rubber Target Retainer interferes with the targets.

5. Release the Target Retainer Loading Bar if it was being held. The rubber target retainer

should be pressing on the 2nd target. Release the targets. Continue to load targets into the

magazine column.

6. Make sure that there is a fully charged 12VDC battery connected to the trap and that the

remote release cord is safely away from and behind the trap.

7. Turn the On/Off/Safe Release switch to the “ON” position.

8. The trap should cock the throwing arm and at the same time drop one target onto the

throwing arm as it is cocking.

9. Activate the Foot Pedal Switch and the WheelyBird Trap will release the throwing arm

(launching the target), re-cock the throwing arm and deliver another target to the throwing

arm.

WARNING: IF THERE IS A TARGET ON THE THROWING ARM, SAFE RELEASING THE

THROWING ARM WILL THROW THE TARGET. DO NOT STAND IN FRONT OF THE TRAP.

10. When reloading the trap, first move the ON/OFF/SAFE RELEASE switch on the trap to the

“SAFE RELEASE” position momentarily to uncock the throwing arm. Allow the switch to

return to the „OFF‟ position. The trap magazine can then be safely reloaded with targets

from the rear of the trap.

12

Page 15

V. Adjustments

Limit Switch

Front Cover

1. Throwing Arm Limit Switch

WARNING: BEFORE MAKING ANY ADJUSTMENTS, MAKE SURE THE

THROWING ARM IS IN THE UNCOCKED POSITION, THE ON/OFF/SAFE

RELEASE SWITCH IS IN THE “OFF” POSITION, AND THE BATTERY IS

DISCONNECTED FROM THE TRAP.

The machine is set at the factory. Only make adjustments to the limit

switch if a target doesn‟t drop onto the throwing arm as the throwing arm is

cocking, or the throwing arm continuously fires. TEST MACHINE FIRST

WITHOUT ANY TARGETS.

1. The limit switch controls the stop position of the throwing arm during the traps

cocking cycle. The limit switch is located under the trap near the front. The

front cover can be removed to gain easier access to the switch. Replace cover

after adjusting switch.

13

Page 16

2. Adjustments to the limit switch are made by loosening the two mounting

Pivot switch this

direction to stop arm

closer to edge of top

plate

Pivot switch this

direction to stop arm

further from edge of

top plate

2.5” – 4.5“

Slide plate

lines up with

top plate

Loosen these

2 screws

screws and moving the switch slightly. Pivot the switch slightly towards the

center of the trap for the arm to stop further away from the edge of the main

body. Pivot the switch slightly towards the front of the trap for the arm to stop

closer to the edge of the main body. Re-tighten the mounting screws after

adjusting the switch. Adjust switch so that a target drops onto the throwing

arm as the arm is cocking. With the on/off/safe release switch set to "on", the

tip of the arm should stop within 2.5” to 4.5” from the edge of the top plate of

the trap. The opening in the sliding plate should line up with the opening in the

top plate and allow a target to drop..

Caution: Adjusting the arm to stop at a point too far away from the spring‟s

over-center point can result in a delayed release or improper loading and

targets breaking.

WARNING: ADJUSTING THE ARM TO STOP AT A POINT TOO CLOSE

TO THE SPRING‟S OVER-CENTER POINT CAN RESULT IN THE ARM

CONTINUOUSLY FIRING OR FIRING UNEXPECTEDLY AND CAUSING

POTENTIAL INJURY FROM BEING STRUCK BY THE ARM.

14

Page 17

2. Elevation Adjustment

Loosen Bolts

and Adjust

Elevation

WARNING: BEFORE MAKING ANY ADJUSTMENTS, MAKE SURE THE

THROWING ARM IS IN THE UNCOCKED POSITION, THE ON/OFF/SAFE

RELEASE SWITCH IS IN THE “OFF” POSITION, AND THE BATTERY IS

DISCONNECTED FROM THE TRAP.

1. To adjust the elevation, slightly loosen the four bolts (two on each side of the

trap).

2. Change the elevation by grasping the trap main body and pivoting the trap to

the desired position.

3. Re-tighten the four bolts to secure the trap in the new position.

15

Page 18

3. Distance Adjustment

S5

S4

S2

21/4" to 23/4" Bolt

Exposed

WARNING: BEFORE MAKING ANY ADJUSTMENTS, MAKE SURE THE

THROWING ARM IS IN THE UNCOCKED

RELEASE SWITCH IS IN THE “OFF” POSITION, AND THE BATTERY IS

DISCONNECTED FROM THE TRAP.

THIS TRAP IS CAPABLE OF THROWING TARGETS A MAXIMUM DISTANCE

OF OVER 65 YARDS. USE ONLY IN AREAS WHERE THERE IS NO RISK OF

CAUSING DAMAGE, OR HITTING A PERSON WITH A TARGET.

Adjustment to throwing distance is made by adjusting the mainspring tension.

1. With S4 (10mm Flange Nut) fully tightened and S2 (Mainspring Bolt) tight, the

mainspring is under standard tension. The trap

should be suitable for most users.

2. If reduced throwing distance is desired, mainspring tension can be adjusted to reduce the

throwing distance approximately 10 yards. First loosen S5 (10mm Hex Nut) and then S4

can be loosened up to a 1/2" on S2. DO NOT EXCEED THIS AMOUNT.

POSITION, THE ON/OFF/SAFE

will throw targets a distance which

3. After adjusting the spring to the desired tension, tighten S5 against S4 to lock the setting in

place. There should be a minimum of 2

1

/4" of S2 left exposed.

16

Page 19

VI. Troubleshooting

I. THE MOTOR WILL NOT START

1. The “ON-OFF-SAFE RELEASE” switch on the trap is in the “OFF” position.

2. Circuit breaker on rear of trap is tripped - determine cause before resetting.

3. Battery is inadequately charged - recharge battery.

4. Electrical connections are loose or damaged.

5. The motor is hooked up incorrectly – check battery wires for correct polarity.

6. The motor is burned out.

7. The throwing arm is blocked from rotating.

8. The "ON-OFF-SAFE RELEASE" switch is broken.

9. The relay is burned out.

II. THE MOTOR RUNS, BUT DOES NOT COCK THROWING ARM

1. Battery is inadequately charged - recharge battery.

2. Drive chain broken.

III. THE TRAP COCKS, BUT DOES NOT FIRE

1. The “ON-OFF-SAFE RELEASE” switch is in the “OFF” position.

2. Electrical connections are loose or damaged.

3. The foot pedal switch is damaged.

IV. THE THROWING ARM STOPS, BUT A TARGET DOESN’T DROP

1. The throwing arm limit switch is damaged or out of adjustment.

2. Adjust limit switch so arm stops closer to the edge of the top plate.

3. Test with a different brand or shipment of targets.

V. THE THROWING ARM DOES NOT STOP AND CONTINUES FIRING

1. The throwing arm limit switch is damaged or out of adjustment.

2. Adjust limit switch so arm stops farther away from the edge of the top plate.

3. Foot pedal switch stuck.

4. Foot pedal switch cord wires are shorted together.

5. The relay is burned out.

VI. EXCESSIVE TRAP NOISE OR VIBRATION

1. Check all bolts to make sure they are tight.

2. The mainspring is too loose causing “spring slap”. Check to make sure flange nut is

backed off no more than 1/2" from fully tight position.

17

Page 20

VII. Maintenance

Preventive Maintenance Action

Frequency

Remove dust, dirt, and target debris with soft brush

Before every use

Check mounting bolts to insure they remain tight

Every month or 8,000 cycles

Every month or 8,000 cycles

Disconnect Battery

After Every use

WARNING: BEFORE PERFORMING ANY MAINTENANCE ON THE TRAP

MAKE SURE THAT THE THROWING ARM IS IN THE UNCOCKED POSITION,

THE ON/OFF/SAFE RELEASE SWITCH ON THE TRAP IS IN THE “OFF”

POSITION AND THE BATTERY HAS BEEN DISCONNECTED.

Lubricate moving parts with a good quality lubricating oil

such as HOPPE’S® Black Gun Grease

VIII. Replacement Parts

PART NUMBER DESCRIPTION

60R188 S1 - Mainspring ( see page 6 )

40226 Flight Rail ( see page 3 )

These and other replacement parts are available by calling Champion Customer Service

Department at (800) 379-1732.

18

Page 21

Wa rr anty C a rd (Please fill out completely & return with a copy of the receipt)

Owner’s Name: _______________________________________________________

Owner’s Signature:_________________________________

Address:

City: _______________________________

___________________________________Ph #: ___________________

State: _______ Zip: ______________

____________________

Date of Purchase: ________________

Business Where Trap Was purchased:_________________

___________________

WARRANTY CERTIFICATE

Your new WHEELYBIRDTM AUTO-FEED TRAP is warranted to be free from defects in material or

workmanship for a period of six (6) months from the date of purchase. This warranty is extended only

to the original consumer purchaser. Should you believe that your trap is defect

you should contact the CHAMPION Customer Service Department via phone at 800-379-1732.

In the event a warranty repair is required, all parts will be provided at no charge. THIS WARRANTY DOES

NOT COVER DEFECTS OR DAMAGE RESULTING FROM: CARELESSNESS, MISUSE, IMPROPER

INSTALLATION, MODIFICATION, OR NORMAL WEAR AND TEAR.

IN ORDER FOR THIS WARRANTY TO BE IN EFFECT, YOU MUST FILL OUT THIS

WARRANTY CARD AND RETURN IT WITHIN 30 DAYS OF PURCHASE. THE ATTACHED

WARRANTY CARD MUST BE FILLED OUT COMPLETELY AND SIGNED BY THE OWNER IN

ORDER TO BE VALID. WARRANTY SERVICES CANNOT BE PROVIDED WITHOUT MEETING

THE ABOVE REQUIREMENT. Retain this warranty certificate for future reference. THE IMPLIED

WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE

LIMITED TO THE DURATION OF THIS LIMITED WARRANTY.

CHAMPION IS NOT LIABLE FOR DAMAGES IN EXCESS OF THE PURCHASE PRICE

OF THE PRODUCT AND UNDER NO CIRCUMSTANCES SHALL CHAMPION BE LIABLE

FOR CONSEQUENTIAL OR INCIDENTAL DAMAGES. HOWEVER, SOME STATES DO NOT

ALLOW LIMITATIONS ON INCIDENTAL, OR CONSEQUENTIAL DAMAGES, SO THE ABOVE

LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

The above warranty provides the sole and exclusive warranty available to the customer in the

event of a

TRAP. This warranty gives you specific legal rights, and you may also have other rights which vary

from State to State.

defect in material or workmanship in the CHAMPION WHEELYBIRDTM AUTO-FEED

-

ive in material or workmanship,

19

Page 22

CONTACT INFORMATION

20

Champion Traps and Targets

1 Vista Way

Anoka, MN 55303

(800) 379-1732

championtarget.com

Email: tech.expert@vistaoutdoor.com

MADE IN CHINAPRINTED IN CHINA

CT879 7111

Loading...

Loading...