Champion W-DH Service Manual

Technical Manual

Hood Type

Dishwasher

Model:

W-DH

High Temperature with Built-in Booster

Machine Serial No.

March, 2003 Manual P/N 113365 Rev B

P.O. Box 4149 2674 N. Service Road

Winston-Salem, North Carolina 27115-414 Jordan Station, Ontario, Canada L0R 1S0

336/661-1556 Fax: 336/661-1660 905/562-4195 Fax: 905/562-4618

www.championindustries.com

Complete the information below so it will be available for quick reference.

Model Number Serial Number

Voltage and Phase

Champion Service Agency Phone

Champion Parts Source Phone

Champion Service:

Champion (USA)

Phone: 1 (336) 661-1556

1 (800) 858-4477

Fax: 1 (336) 661-1660

E-mail service@championindustries.com

We strongly recommend that you Fax or e-mail your orders.

NOTE: When calling to order parts, be sure to have the model number, serial number,

voltage and phase of your machine.

Machine Data Plate with

model & serial number

located on the front of the

lower panel.

COPYRIGHT © 2003 by Champion Industries, Inc.

REVISION RECORD

Revision History

Revision Revised Serial Number Comments

Date Pages Effectivity

09/01/01 — First issue of manual and replacement parts

06/10/02 3 Inserted electrical wiring diagrams.

3/28/03 16, 17 Inserted revised drawing and parts list.

i

TABLE OF CONTENTS

CONTENTS

Page

REVISION HISTORY .................................................................................................................... i

GENERAL....................................................................................................................................... 1

INSTALLATION ............................................................................................................................ 2

Unpacking........................................................................................................................... 2

Electrical Connections ........................................................................................................ 2

Plumbing Connections........................................................................................................ 4

Ventilation Connections ..................................................................................................... 4

Chemical Connections ........................................................................................................ 5

Completing Installation ...................................................................................................... 5

OPERATION................................................................................................................................... 6

MAINTENANCE ............................................................................................................................ 7

Daily Cleaning .................................................................................................................... 7

Maintenance........................................................................................................................ 7

TROUBLESHOOTING .................................................................................................................. 9

REPLACEMENT PARTS...............................................................................................................11

ELECTRICAL SCHEMATICS....................................................................................................... 23

LIST OF FIGURES

Figure 1— Front Panel..................................................................................................................... 2

Figure 2— Wiring Connection ........................................................................................................ 3

Figure 2— Wash Tank Assembly.................................................................................................... 12

Figure 3— Wash and Rinse Assemblies .......................................................................................... 14

Figure 4— Rinse Booster Assembly and Rinse System .................................................................. 16

Figure 5— Control Cabinet ............................................................................................................. 18

Figure 6— Control Panel ................................................................................................................. 20

iii

GENERAL SPECIFICATION

GENERAL SPECIFICATIONS

About this manual

All information, illustrations and specifications contained in this manual are based upon the

latest product information available at the time of publication. Champion constantly improves

its products and reserves the right to make changes at any time or to change specifications or

design without notice and without incurring any obligation.

Organization of Manual

This manual is divided into seven parts:

• General Specifications

• Installation

• Daily Operation

• Cleaning and Maintenance

• Troubleshooting

• Replacement Parts, contains parts diagrams and parts list.

• Electrical Schematics

NOTE:

Unless noted otherwise, dimensions, capacities, temperatures, etc., given in this manual

are U.S. Customary Measures and the Metric Equivalent of the U.S. Customary measures.

Model

The W-DH model is a high temperature (180F/82°C rinse) sanitizing model with booster.

Standard Equipment

• Automatic operation

• Built-in electric booster heater

• Field convertible to corner model

• Electric tank heat

• Extended wash/de-lime switch

• Low-water tank heat protection

• 1-hp drip-proof pump motor

• Splash-proof control console

• Door safety switch

• Common utility connections

• Detergent/chemical connection

provisions

• Balanced door lift system

• Stainless steel front and side panels

• Interchangeable upper and lower

spray arms

• International symbols on controls

1

INSTALLATION

INSTALLATION

Unpack the dishwasher

!

CAUTION:

Care should be taken when lifting the machine to prevent damage.

NOTE:

The installation of your machine must meet all applicable health and safety codes.

1. Immediately after unpacking the machine, inspect for any shipping damage.

If damage is found, save the packing material and contact the carrier

immediately.

2. Remove the dishwasher from the skid. Move the machine to its

permanent location.

3. Machine must be placed on a sound self-draining floor.

4. Level the machine (if required) by placing a level on the top of the

machine and adjusting the feet. Level the machine from

front-back and side to side.

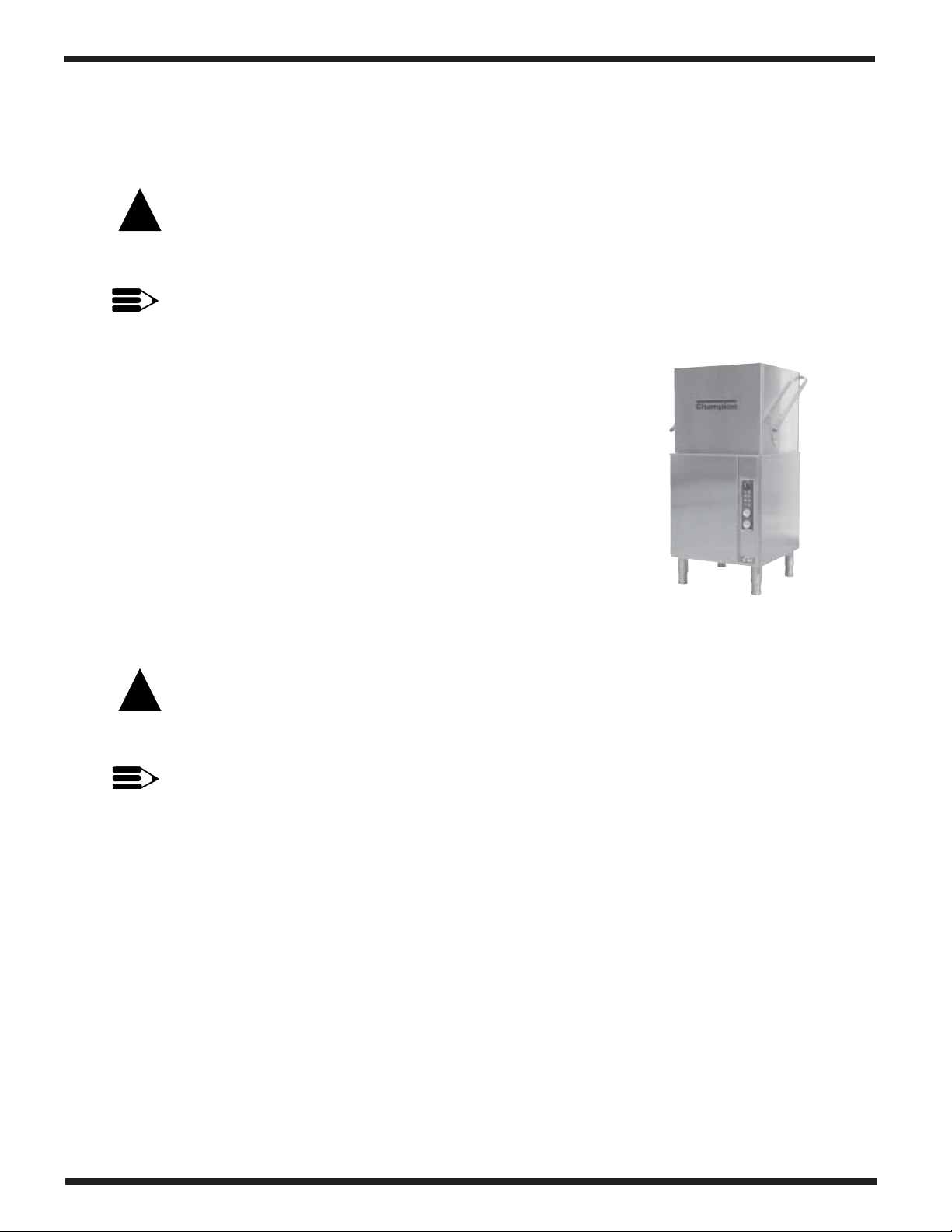

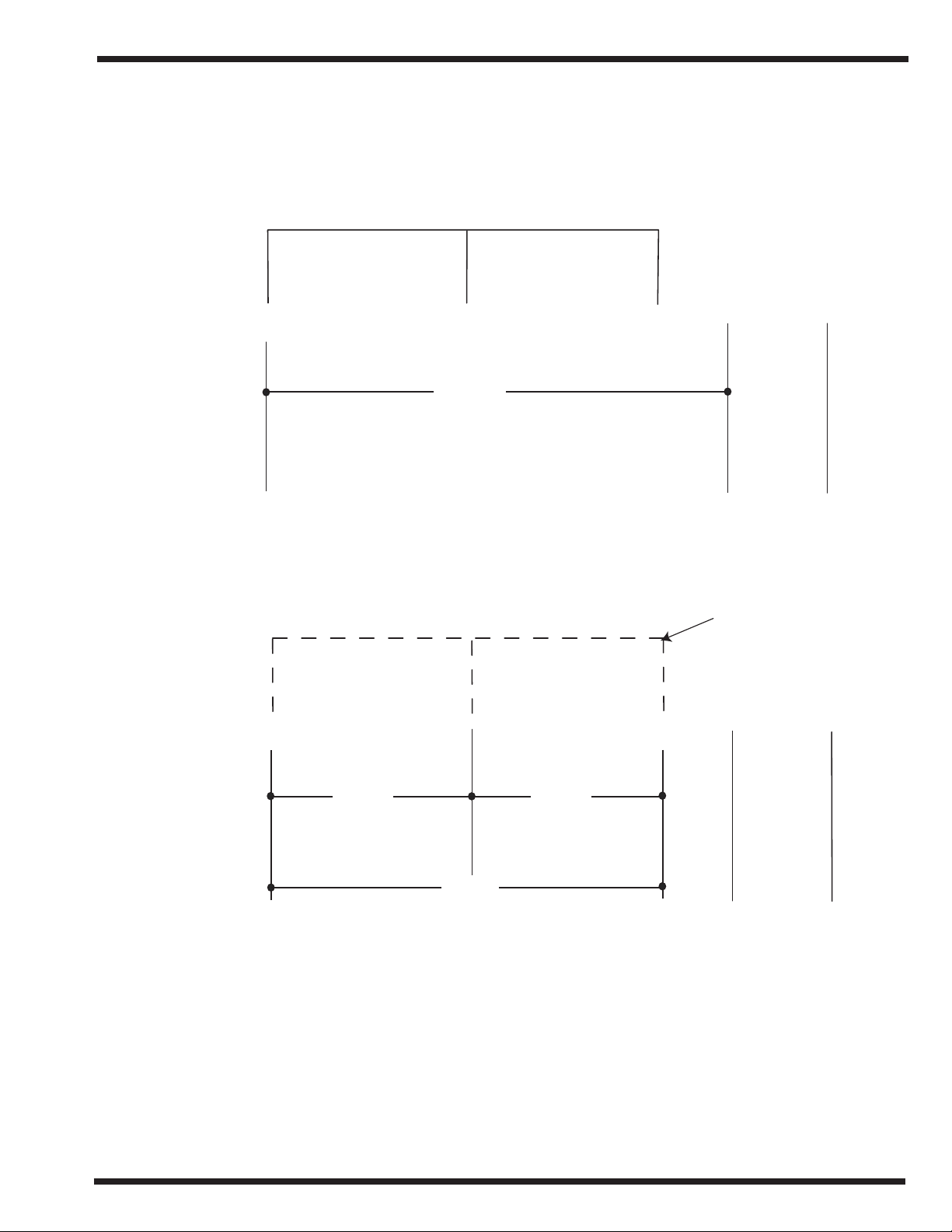

5. Refer to Fig 1. Remove (2) screws that hold the front panel.

Remove the front panel in preparation for service connections.

Figure 1

Remove Front Panel

Electrical Connections

WARNING:

!

Electrical grounding connections must comply with all applicable Electrical Codes.

WARNING:

When working on the dishwasher, disconnect the electric service and place a tag at the

disconnect switch to indicate work is being done on that circuit.

1. A qualified electrician must compare the electrical power supply with the machine electrical specifications before connecting to the incoming service through a fused disconnect

switch.

2. Recommended electrical supply is three phase, permanently wired via wall switch

mounted adjacent to machine. Machine may also be installed on 25A single phase (15A

single phase with reduced rinse heating). Easy on site conversion of standard machine for

any of these requirements.

3. A knock out is provided at the lower right rear corner (as viewed from the front) for

electrical service connection. A fused disconnect switch or circuit breaker (supplied by

others) is required to protect the power supply circuit.

4. Remove (2) lower screws from the front panel of the machine to expose the electrical

controls.

5. Three phase or single phase incoming wire connections are made at the bottom of the

machine’s main terminal block. The main terminal block is located on the side of the front

right post of the dishwasher.

2

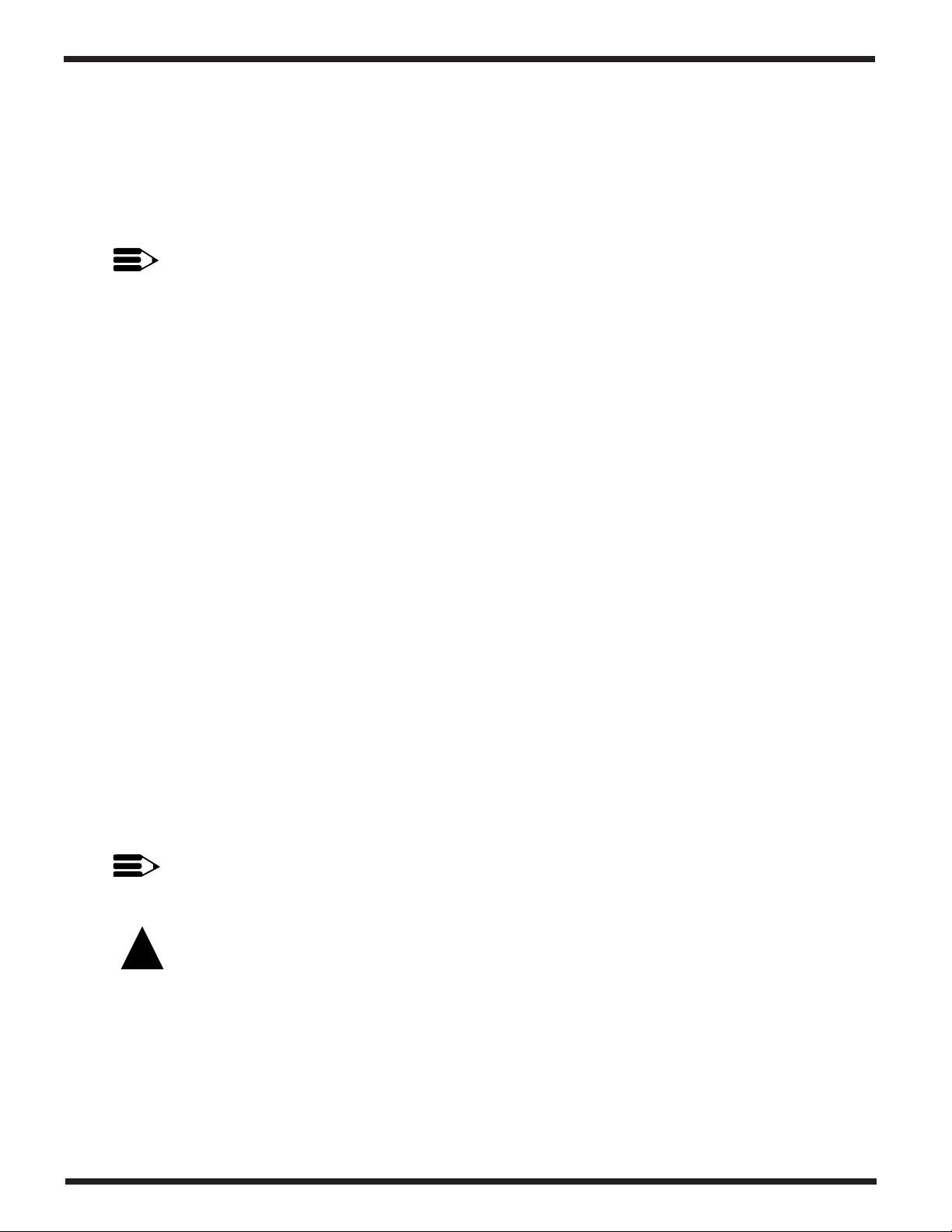

SINGLE PHASE CONNECTION

INSTALLATION

L1

Connect (1) Hot wire

to either L1, L2 or L3

THREE PHASE CONNECTION

L1

L2 L3

208/240V

L2 L3

N

Connect the second

Hot wire to "N"

terminal

NOTE: Remove Jumper

wires for 3 phase

applications.

N

Ground

Earth

Ground

Ground

208/240V

208/240V

Connect (3) Hot wires

to L1, L2 and L3

Figure 2

Wiring Connections

208/240V

Connect the

Neutral wire

to "N" terminal

{

Earth

Ground

3

INSTALLATION

INSTALLATION (CONT.)

Plumbing Connections

NOTE:

Plumbing connections must comply with all applicable sanitary and plumbing codes.

Water Connections

1. All W-DH dishwashers require a single, hot water supply.

2. The hot water connection to the dishwasher is 1/2” BSP male.

3. The connection is made from underneath the dishwasher.

4. The recommended minimum water temperature is 140F/60°C.

5. A manual shut-off valve for water (supplied by others) should be installed in the supply

line to allow for servicing of the machine. The shut-off valve should be the same size or

larger than the supply line.

6. Install a pressure reducing valve (PRV) in the water supply line if flow pressure exceeds

20-22 PSI/138-151.8kPa.

Drain Connections

1. The dishwasher is a gravity drain machine equipped with 1-1/2” O.D. hose connection

point.

2. The maximum drain flow rate is 15 gallons/min-56.8 liters/min.

3. Drain height for the dishwasher must not exceed 11” (280mm) above the floor level.

4. The drain connection is made to the dishwasher from behind the machine or through an

access hole in the base of the machine.

Ventilation

NOTE:

Ventilation must comply with local sanitary and plumbing codes.

CAUTION:

!

Exhaust air should not be vented into a wall, ceiling, or concealed space of a building.

Condensation can cause damage.

4

INSTALLATION (CONT.)

Chemical Connections

NOTE:

Consult a qualified chemical supplier for your chemical needs.

1. A chemical signal terminal block is supplied for chemical dispensing equipment.

2. The terminal block is located below the control panel fuse block.

3. The detergent signal is limited to a maximum load of 1 Amp. Signal voltage is 115VAC.

4. The Rinse aid signal is limited to a maximum load of 1 Amp. Signal voltage is 115VAC.

5. The feeder units must have separate neutrals for detergent and rinse aid connections.

INSTALLATION

6. A 1/2” detergent injection point is provided at the rear and left side of the dishwasher.

7. Detergent may be added manually, put in three tablespoons of powdered domestic detergent into the wash tank after the machine has been filled, then add another tablespoon full

after every fourth or fifth cycle. This is not recommended except in a temporary situation,

ex: dispensing equipment is down, out of chemical and awaiting supplier, etc.

8. Rinse aid injectors can be purchased separately. There is a 1/4” NPT rinse aid injection

point provided in the final rinse manifold. Use a liquid rinse aid. Contact your local

chemical supplier about product type for factors such as water hardness etc.

Peristaltic Detergent Pump

To prime the peristaltic pump:

1. Insert pump inlet hose into the detergent container.

2. Close machine door and switch machine on.

3. Allow wash tank to fill up then press detergent pump prime switch to prime inlet and

outlet hose.

4. Stop priming when detergent reaches machine.

Machine will not fill unless READY light is on and door is shut. Turn power off before

opening door as machine will cycle again when door is closed. Pump operates during the wash

cycle and is set to run for approximately 10 seconds. Use yellow adjusting tool, supplied with

the instructions, to adjust cam 6 to vary this time. Increase cam gap (away from 0 mark) to

increase pumping time.

5

Loading...

Loading...