Page 1

Operation Manual

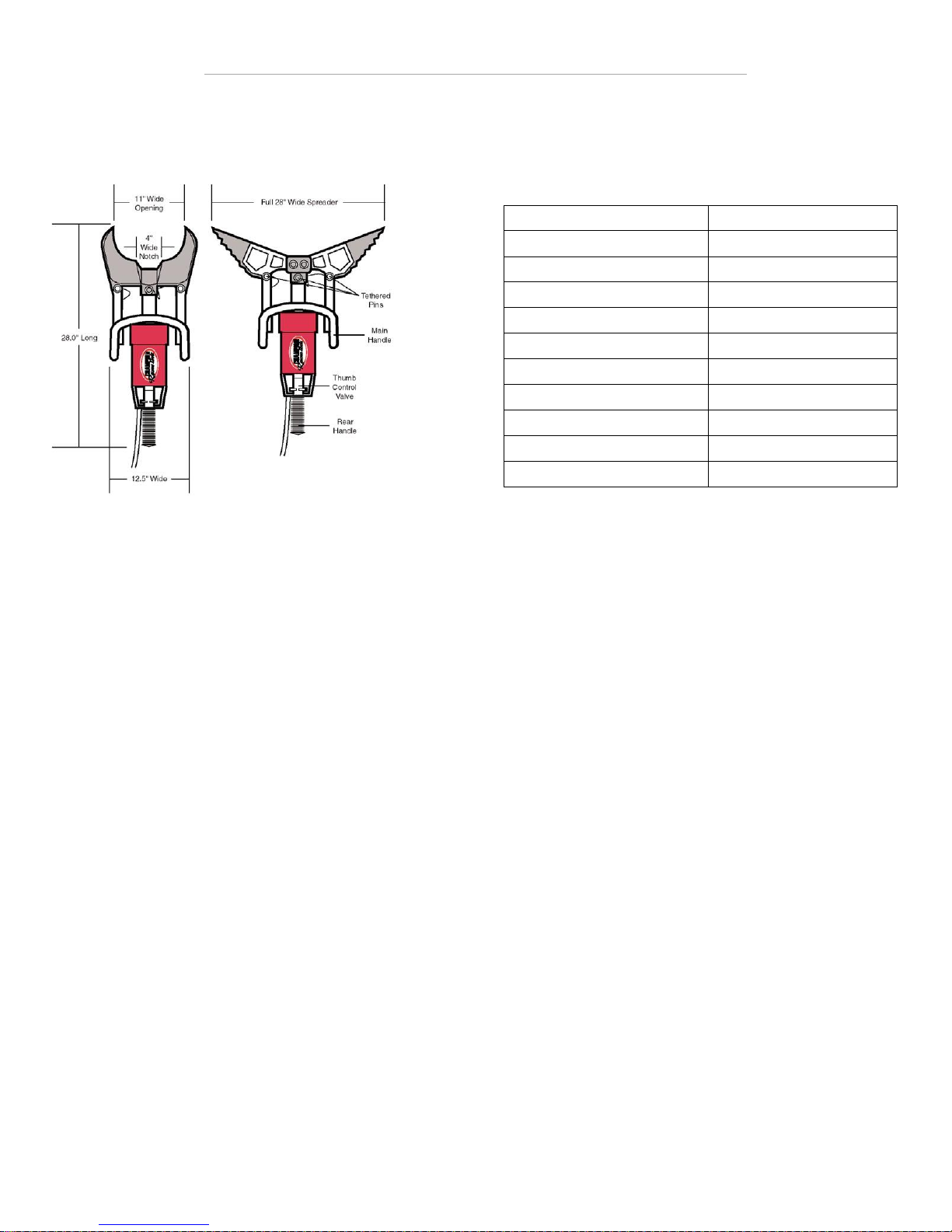

SUPER BEAST Multi-tool

SC-11M-10

Technical Specifications

General Safety/Operating Instructions

Attaching/Changing the Head

Using the SUPER BEAST as a Cutter

Using the SUPER BEAST as a Spreader

Maintenance Instructions

This is a detailed instruction guide specific to Champion Rescue Tools SUPER BEAST Multi-tool – please see

separate information provided for general hydraulic tool usage, warranty information, MSDS information, etc.

when every second counts

trust a CHAMPION

Page 2

Champion Rescue Tools – SUPER BEAST Multi-tool Detailed Tool Instructions

Operating Pressure

10,500 psi

Weight (Cutter)

51.9 lbs

Weight (Spreader)

45.0 lbs

Length

28 – 34 inches

Width

12.5 inches

Height

8 inches

Blade Opening

10.75 inches

Max Cutting Force

500,000 lbs

Spreader Opening

28 inches

Max Spreading Force

140,000 lbs

Hydraulic Fluid Type

Specified by Customer

Introduction

Thank you for purchasing the SUPER BEAST Multi-tool –

the safest, most powerful and functional rescue tool in

the market. For General Operating and Safety

Instructions please refer to the “General Operating

Procedures” Booklet furnished with your tool.

General Safety and Operating Instructions

1. Always turn the power unit to the “off” position and

place the control valve in the “off” position for any

service or clearing work. You should also “dump”

the valve by pushing it all the way to one side and

then the other – this releases any stored energy and

eliminates tool creep.

2. Familiarize yourself with the tool(s) and control

valve, moving the control valve back and forth until

familiar with the valve action and operation. NEVER

put any part of your body between the moving parts

of this or any other tool!

3. The SUPER BEAST will cut a broad range of

materials. Inspect the cutter blades after each use

to make sure it is in good condition. Inspection of

the blades before each use is a MUST! If blades are

suspect in any way, pull the tool out of service

immediately and replace the blades. Remember

you are cutting with many thousands of pounds of

force.

4. Worn edges can be filed, but NEVER grind them

with a hand grinder. To file the blades simply lay a

file on the inside, or ground side, of the blade being

careful to NOT just file the edge. File at least 2 to 3

inches of the blade at a time so as to keep the blade

edge flat and do not roll it over. If rolled, the blade

will be ruined. If this happens, the blade will have

to be returned to the factory for repair or

replacement. Note: Do not file the blades regularly

as maintenance – only file if the blade is damaged.

5. If your spreader tips get worn or have dings and

dents you may also file those as needed.

6. The Hydraulic Cylinder on your new tool operates

under extreme pressure and is a sealed unit. Under

normal use, it does not require service. The factory

sealed cylinder must NEVER be taken apart. Doing

so will void your warranty and could potentially

result in severe injure or even death.

7. As long as the cylinder remains sealed and is not

tampered with, any defect or malfunctions are

covered by the Champion limited lifetime warranty

(to the original purchaser). See the “Champion

Rescue Tools Statement of Lifetime warranty” for

additional information.

8. The control valve must be kept clean. Blow off sand

and dirt with an air hose. Use WD-40- on the valve

spring. Valve does not need any maintenance.

9. Make sure the tethered pins or ball detents that

hold the head clevis and arms/blades in place stay

adjusted so the pins do not work loose.

10. As with all Champion Rescue Tools, the operating

speed can be slowed down or increased by moving

the trigger accordingly. If the trigger is opened

partial the movement will be slow; If the trigger is

opened all the way movement will be faster.

Always use proper safety gear and follow all safety

instruction as outlined in this manual

© Champion Rescue Tools

Page 3

Champion Rescue Tools – SUPER BEAST Multi-tool Detailed Tool Instructions

Step 1

Step 2

Step 3

Attaching (or Changing) the Head on the SUPER BEAST

1. Remember to always the wear the appropriate

safety equipment (PPE), including gloves, as

the blades have sharp protrusions and edges.

2. Note: The tethered pins holding the

blades/arms or clevis will not come out until

cylinder is extended a minimum of 1” or 25.4

mm.

3. Turn the power unit pump control valve to the

“OFF” position.

4. Cycle the valve trigger (control) on the tool left,

then right, or right then left.

5. Place the tool on the ground or a stable surface

in a well lit area.

6. Pull the center pin by the knurled knob first.

Then remove the pins on each side of blade or

arm. Do not pull on the tethers.

7. Remove the head and place out of the work

area.

8. Make sure the head and socket are clean, with

no dirt, sand, or debris. Take the desired

head and slide over the center shaft.

9. Align center hole and insert large pin, pushing

pin all the way down.

10. Take the blades/arms and align the holes with

the link arms on the tool.

11. Insert pins as previously described.

12. Turn the “dump” valve at the power unit to

“on position”. Now the tool is ready for use.

© Champion Rescue Tools

Page 4

Champion Rescue Tools – SUPER BEAST Multi-tool Detailed Tool Instructions

Using the SUPER BEAST as a Cutter

1. Always inspect the tool prior to each use.

2. Turn the valve at the power unit to the “ON”

position

3. Be sure to follow proper general procedures (as well

as any department specific procedures) for

performing vehicle extrication – otherwise severe

injure or even death for occupants or tool operators

is possible.

4. Do a visual check before making a cut, as for every

action there is often an equal reactions. Check

twice and cut once.

5. Open the cutting blade to the distance required to

ensure you get the material to be cut into the notch

(bottom of the blades close to the blade bolt) and

6. Remember, the notch is where the tool makes its

Using the SUPER BEAST as a Spreader

1. The SUPER BEAST Spreader can be used to spread,

crush or lift. Keep in mind if you lift with this tool,

lift 1” crib 1”.

2. DO NOT use the aluminum portion of the arms for

spreading, lifting, or crushing as this may result in

damage to the arms and presents potential risk to

the operator.

3. Try and use as much spreading surface area to push,

crush, or lift on the tips so you have more contact

surface.

4. Always pick up the tool by the handles only.

5. To take the spreader off line or to change the head

6. When the tool is not in action rest the tool on a part

start your cut. If you are unable to get the material

all the way into the notch at least get it as deep as

possible. Don’t use the tip of the blades on solid or

extremely had materials. If the cut cannot be made

the first time, then reopen the blades and

reposition for another cut. Always use common

sense.

maximum power.

Champion offers a line of specialty blades designed

for specific extrication applications – contact the

Sales Department for more information.

back to the cutter head follow the head change

instructions provided in this manual.

of the vehicle or structure with a firm grip on the

handles while you are awaiting you next task.

Otherwise you can rest the tip of the tool on the

ground, in vertical position, holding the rear handle

while you are waiting. This will help reduce

operator fatigue.

Maintenance Instructions

1. Inspect both heads and the tool after every use for

wear and damage. Never use a damaged tool.

2. Remove any debris from the tool or heads.

3. Keep the tool clean and dry. Wipe with a clean

cloth if necessary. Use a mild detergent to clean the

tool and dry thoroughly.

4. Lubricate the valve spring with a light lubricant, such

as WD-40.

5. Lubricate the detents on the pins with a light

lubricant such as WD-40 or a light silicon lubricant.

Check adjustments on detents.

6. Ensure that all handles are tight. There are screws

on both rear and front handles, use blue lock-tight

to secure if necessary.

7. Inspect couplers to ensure that they operated

correctly and are free of dirt and debris. Blow out

with an air hose if needed.

8. Inspect hoses for cracks, cuts and bulges. DO NOT

operate tools with damaged hoses.

9. Inspect the spreader arms and cutting head for

wear or damage. DO NOT operate with damaged

arms or blades.

10. Keep tool free from rust and corrosion.

11. Replace handle if broken or damaged.

12. Replace Missing or damaged decals, if needed.

© Champion Rescue Tools

Page 5

Support

Should you require either technical, service, training, or any other type of support, please contact our Corporate

Offices at:

Champion Rescue Tools

814 Berry Court

Upland, California 91786 USA

Phone: (909) 982-1126 Fax: (9090 982-0050

Toll Free: (888) 396 -2426 www.championrescuetools.com

© Champion Rescue Tools

Loading...

Loading...