Champion RotoBrute Smart Brute SB35 Operator's Manual

2

www.championcuttingtool.com

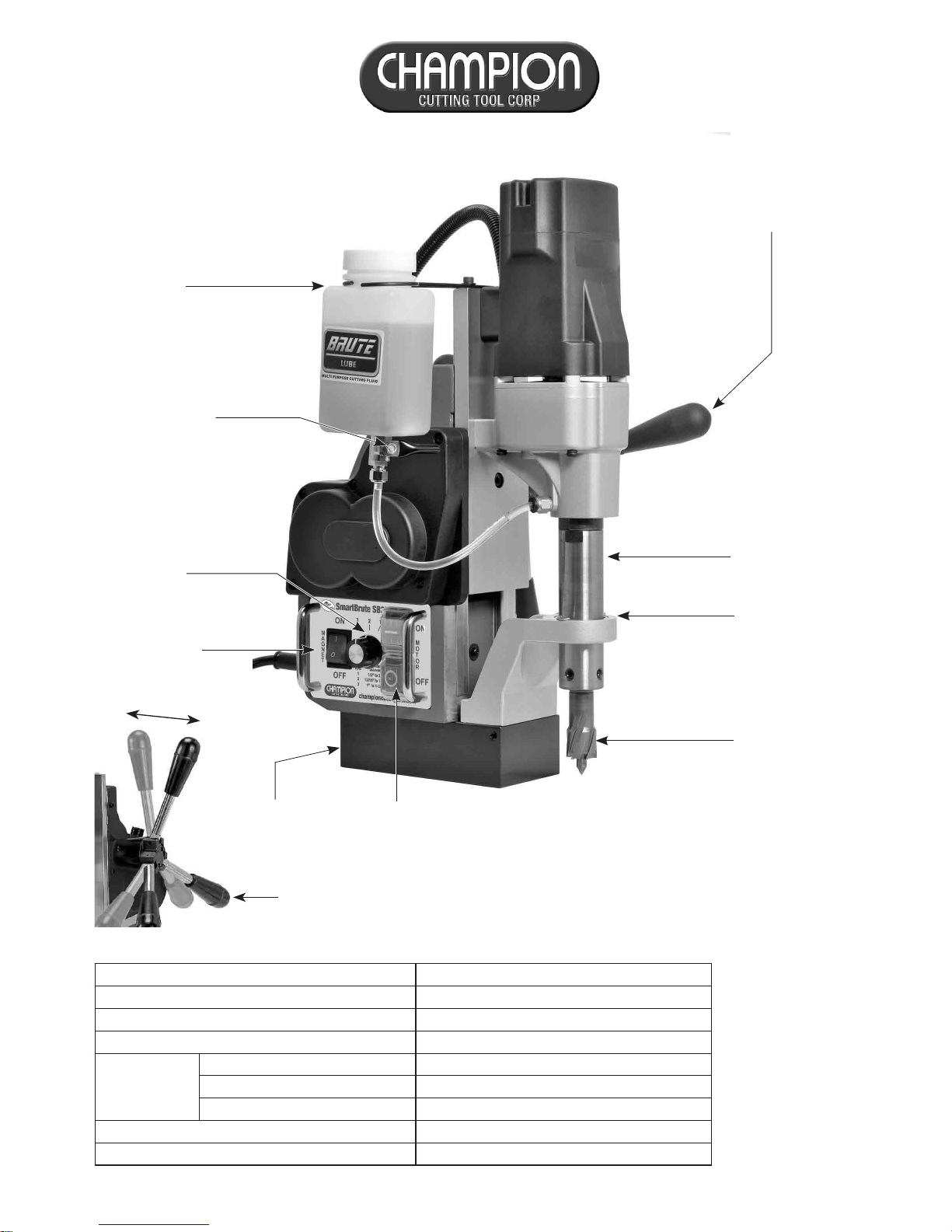

Dual purpose lever

Crank handle

Arbor

Arbor support

bracket

Annular cutter

(Not included)

Pilot pin

(Not included)

Coolant tank

Motor switch

Magnet switch

Coolant feed tap

Magnet base

3 position feed

rate selector

STANDARD ACCESSORIES

* WRENCH M8

* HEX. KEY M2.5

* HEX. KEY M4

* CHIP GUARD KIT

* COOLANT TANK KIT

* SAFETY CHAIN

MODEL SB35

POWER INPUT 1100 W

VOLTAGE 110 / 120

NO / FULL LOAD min

-1

550 / 330

CAPACITY

DIA. X DEPTH OF CUT ( HAND FEED)

1-3/8” x 2”

DIA. X DEPTH OF CUT ( AUTO FEED)

1-3/16” x 1-3/4

DIA. X DEPTH OF TWIST DRILL ( HAND FEED ONLY)

1/2” x 4-3/8”

MAGNETIC ADHESION 3370 lbs

NET WEIGHT 36 lbs

3

www.championcuttingtool.com

WARNING: Cancer & reproductive harm - See P65Warnings.ca.gov for more info.

WARNING! Read and understand all instruction before operating any drilling system. Failure to

follow all instructions listed below may result in electrical shock, damage to drilling system and even

personal injury.

GENERAL SAFETY INSTRUCTIONS

Work area

1. Keep work area clean and well lit. Cluttered or dark areas invite accidents.

2. Do not operate power tools in explosive atmosphere, such as in the presence of flammable liquids,

gases or extreme dust. Power tools create sparks that may ignite gases as well as flammable

liquids.

3. Keep children and bystanders away while operating a power tool. Distractions can cause you to lose

control.

Electrical Safety

1. Grounded tools must be plugged into an outlet properly installed and grounded in accordance

with all codes and ordinances. Never remove the ground prong or modify the plug in any way. Do

not use any adaptor plugs. Check with a qualified electrician if you are in doubt as to whether the

outlet is properly grounded. If tools should electrically malfunction or break down, grounding provides

a low resistance path to carry electricity away from the user.

2. Do not abuse the cord. Never use the cord for carrying, pulling or unplugging the power tool. Keep

cord away from heat, oil, sharp edges or moving parts. Damaged or entangled cords increase the risk

of electric shock.

3. Don’t expose power tools to rain or wet conditions. Water entering a power tool will increase the risk

of electric shock. When operating a power tool outside, use an outdoor extension cord marked .

W-A. or. W. These cords are rated for outdoor use and reduce the risk of electric shock.

Personal Safety

1.

Stay alert, watch what you are doing and use common sense when operating a power tool. Do not

use tool while tired or under the influence of drugs, alcohol, or medication. A moment of

inattention while operating power tools may result in serious personal injury.

2.

Dress properly. Do not wear loose clothing or jewelry. Contain long hair. Keep your hair, clothing,

and gloves away from moving parts. Loose clothes, jewelry, or long hair can be caught in moving

parts.

3.

Avoid accidental starting. Be sure switch is off before plugging in. Carrying tools with your finger on

the switch or plugging in tools that have the switch on invites accidents.

4.

Remove adjusting keys or switches before turning the tool on. A wrench or a key that is left attached

4

www.championcuttingtool.com

to a rotating part of the tool may result in personal injury.

5.

Do not overreach. Keep proper footing and balance at all times. Proper footing and balance enables

better control of the tool in unexpected situations.

6.

Use safety equipment. Always wear eye protection. Dust mask, non-skid safety shoes, hardhat, or

hearing protection must be used for appropriate conditions.

Tool use and care

1. Use clamps or other practical way to secure and support the work piece to a stable platform.

Holding the work by hand or against your body is unstable and may lead to loss of control.

2. Do not force tool. Use the correct tool for your application. The correct tool will do the job better and

safer at the rate for which it is designed.

3. Do not use tool if switch does not turn it on or off. Any tool that cannot be controlled with the switch

is dangerous and must be repaired.

4. Disconnect the plug from the power source before making any adjustments, changing accessories,

or storing the tool. Such preventive safety measures reduce the risk of starting the tool accidentally.

5. Store idle power tools out of the reach of children and do not allow persons unfamiliar with

the power tool or these instructions to operate the power tool. Power tools are dangerous in the

hands of untrained users.

6. Maintain tools with care. Keep cutting tools sharp and clean. Properly maintained tools, with sharp

cutting edges are less likely to bind and are easier to control.

7. Check for misalignment or binding of moving parts, breakage of parts, and any other condition

that may affect the tools operation. If damaged, have the tool serviced before using. Poorly

maintained tools cause many accidents.

8. Use only accessories that are recommended by the manufacturer for your model. Accessories that

may be suitable for one tool may become hazardous when used on another tool.

Service

Only qualified repair personnel must perform tool service. Service or maintenance performed by

unqualified personnel could result in a risk of injury.

When servicing tool, use only identical replacement parts. Follow instructions in the maintenance

section of this manual. Use of unauthorized parts or failure to follow Maintenance Instructions may create a

risk of electric shock or injury.

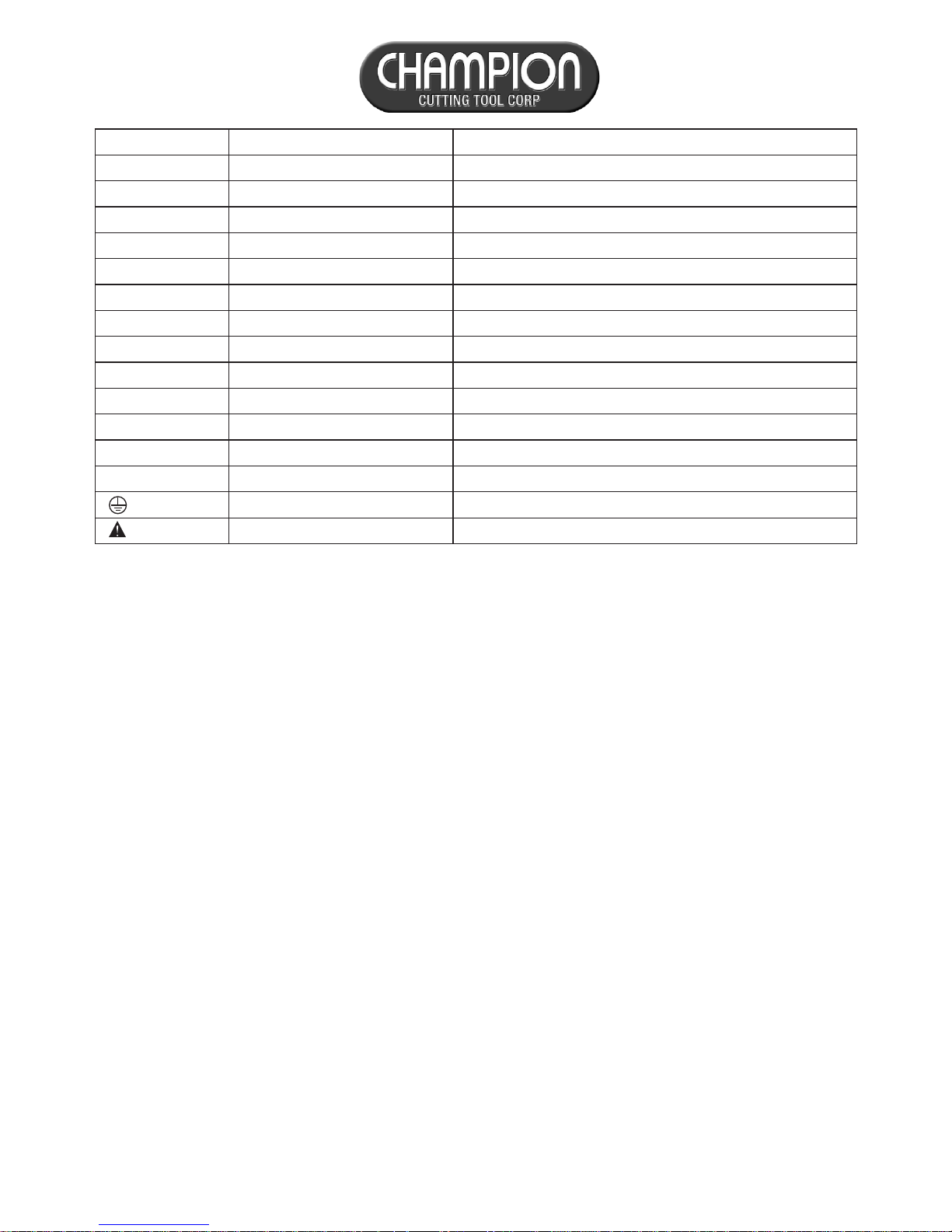

Symbols used in this manual

IMPORTANT: Some of the following symbols may be used on your tool. Please study them and learn their

meaning. Proper interpretation of these symbols will allow you to operate the tool better and safer.

5

www.championcuttingtool.com

Terminology used in the manual

1. Warning: This term means that there is a risk of physical harm or death to the operator or people

nearby.

2. Caution: This term means that there is a risk of damage to the machine, cutting tool or other

equipment.

3. Note: These terms offer useful information relating to the operation of the machine or its

maintenance.

SPECIFIC SAFETY RULES AND REGULATIONS

1. Always use safety chain. Magnet can release.

2. The magnet’s adhesion depends on the thickness of the work piece. Always ensure that the work

piece is a minimum of 7/16” thick.

3. Metal chips and other debris will seriously hamper magnetic adhesion. Always ensure that the

magnet is clean and free of rust and scale.

4. Other units used on the same receptacle will cause uneven voltage that could lead to the magnet

releasing. Always use the tool alone on the receptacle.

5. It is hazardous to use the drill upside-down. Do not exceed 90 degrees from horizontal.

6. Avoid the magnet releasing. Ensure that the magnet has properly adhered to the work piece before

beginning drilling.

7. Avoid operating annular cutters without coolant fluid. Always check coolant level before operating.

8. Do not operate with dull or damaged cutting tools. This may overload the motor.

9. Protect the motor. Never allow cutting fluid, water, or other contaminants to enter the motor.

Symbol Name Designation/Explanation

V Volt Voltage (potential)

A Amperes Current

Hz Hertz Frequency (cycles per second)

W Watt Power

kg Kilograms Weight

min Minutes Time

s Seconds Time

Ø Diameter Size of drill bits

n

0

No load speed Rotational speed, at no load

min

-1

Revolutions per minute Revolutions, strokes, surface speed per minute.

0 Off position Zero speed, zero torque…

1, 2, 3, … Selector settings Feed Rate: Lower number means higher feed rate.

~ Alternating current Type or a characteristic or current

Class I construction With electrical earth

Warning symbol Alerts user to warning messages

Loading...

Loading...