Page 1

R-SERIES

THIS MANUAL CONTAINS IMPORTANT SAFETY INFORMATION AND SHOULD ALWAYS

Air Compressors and Units

OPERATION & SERVICE MANUAL

Engine Drive Compressors & Units

BE AVAILABLE TO THOSE PERSONNEL OPERATING THIS UNIT. READ, UNDERSTAND

AND RETAIN ALL INSTRUCTIONS BEFORE OPERATING THIS EQUIPMENT TO PREVENT

INJURY OR EQUIPMENT DAMAGE.

CQF3474 v.00 Jan.2018

Page 2

MAINTAIN COMPRESSOR RELIABILITY AND PERFORMANCE WITH

GENUINE CHAMPION® COMPRESSOR

PARTS AND SUPPORT SERVICES

Champion® Compressor genuine parts, manufactured to design tolerances, are developed for

optimum dependability – specifically for Champion compressor systems. Design and material

innovations are the result of years of experience with hundreds of different compressor

applications. Reliability in materials and quality assurance are incorporated in our genuine

replacement parts.

Your authorized Champion Compressor distributor offers all the backup you’ll need. A

worldwide network of authorized distributors provides the finest product support in the air

compressor industry. Your authorized distributor can support your Champion air compressor

with these services:

1. Trained parts specialists to assist you in selecting the correct replacement parts.

2. A full line of factory tested CHAMPLUB™ compressor lubricants specifically formulated

for use in Champion compressors.

3. Repair and maintenance kits designed with the necessary parts to simplify servicing your

compressor.

Authorized distributor service technicians are factory trained and skilled in compressor

maintenance and repair. They are ready to respond and assist you by providing fast, expert

maintenance and repair services.

To Contact Champion or locate your local distributor:

Visit: www.championpneumatic.com

Or

Call: (888)436-5499

INSTRUCTIONS FOR ORDERING REPAIR PARTS

When ordering parts, specify Compressor MODEL, HORSEPOWER and SERIAL NUMBER

(see nameplate on unit). All orders for Parts should be placed with the nearest authorized

distributor.

Order by part number and description. Reference numbers are for your convenience only.

R-Series Engine 2 CQF3474 v.00

Operation & Service Jan.2018

Page 3

Table of Contents

Introduction ............................................................................................................................................ 4

Safety and Operation Precautions ........................................................................................................... 5

Explanation of Safety Instructions, Symbols, and Decals .......................................................................... 6

Safety and Operation Precautions ........................................................................................................... 6

Unit Hazard Decal List – See Page 8 ......................................................................................................... 7

Pump Hazard Decal List – See Page 9 ....................................................................................................... 7

Unit Hazard Decals .................................................................................................................................. 8

Pump Hazard Decals ................................................................................................................................ 9

Installation ............................................................................................................................................ 10

Air Receiver Installation ......................................................................................................................... 15

Operation .............................................................................................................................................. 16

Compressor Oil Specifications................................................................................................................ 18

Guide to Maintenance ........................................................................................................................... 20

Maintenance Checklist .......................................................................................................................... 26

Troubleshooting Chart ........................................................................................................................... 27

Maintenance Log ................................................................................................................................... 28

Notes .................................................................................................................................................... 31

R-Series Engine 3 CQF3474 v.00

Operation & Service Jan.2018

Page 4

Introduction

Champion R Series compressors are the result of advanced engineering and skilled manufacturing. To

be assured of receiving maximum service from this machine the owner must exercise care in its operation

and maintenance. This book is written to give the operator and maintenance department essential

information for day-to-day operation, maintenance and adjustment. Careful adherence to these

instructions will result in economical operation and minimum downtime.

Champion Five Year Warranty

"R" Series Compressors

CHAMPION warrants each new compressor pump manufactured by CHAMPION, mounted on a factory assembled unit, to

be free from defects in material and workmanship under normal use and service for a period of sixty (60) months from date

of installation or sixty-six (66) months from date of shipment by CHAMPION or CHAMPION distributor, whichever may

occur first. Applies to the compressor pump only, excluding head valves. Valves, controls and accessories are warranted

for the first year only. Compressor pumps purchased separately would carry a one year warranty.

This five year extended warranty will be prorated over the 5 years as follows:

First Year - 100% Allowance, Parts and Labor

Second Year - 90% Allowance, Parts and Labor

Third Year - 80% Allowance, Parts and Labor

Fourth Year - 70% Allowance, Parts and Labor

Fifth Year - 60% Allowance, Parts and Labor

Applies to CHAMPION logo, tank or base mounted complete compressors only.

Express Limited Warranty

CHAMPION warrants each new air compressor unit manufactured by CHAMPION to be free from defects in material and

workmanship under normal use and service for a period of twelve (12) months from date of installation or eighteen (18)

months from date of shipment by CHAMPION or CHAMPION distributor, whichever may occur first.

CHAMPION makes no warranty in respect to components and accessories furnished to CHAMPION by third parties, such as

ELECTRIC MOTORS, GASOLINE OR DIESEL ENGINES and CONTROLS, which are warranted only to the extent of the original

manufacturer's warranty to CHAMPION. To have warranty consideration, electric motors must be equipped with thermal

overload protection.

The extended five year warranty will apply to ASME air receivers provided they are installed on rubber vibro-isolator pads.

When a compressor pump, or component is changed or replaced during the warranty period, the new/replaced item is

warranted for only the remainder of the original warranty period.

Repair, replacement or refund in the manner and within the time provided shall constitute CHAMPION'S sole liability and

your exclusive remedy resulting from any nonconformity or defect. CHAMPION SHALL NOT IN ANY EVENT BE LIABLE FOR

ANY DAMAGES, WHETHER BASED ON CONTRACT, WARRANTY, NEGLIGENCE, STRICT LIABILITY OR OTHERWISE, INCLUDING

WITHOUT LIMITATION ANY CONSEQUENTIAL, INCIDENTAL OR SPECIAL DAMAGES, ARISING WITH RESPECT TO THE

EQUIPMENT OR ITS FAILURE TO OPERATE, EVEN IF CHAMPION HAS BEEN ADVISED OF THE POSSIBILITY THEREOF.

CHAMPION MAKES NO OTHER WARRANTY OR REPRESENTATION OF ANY KIND, EXCEPT THAT OF TITLE, AND ALL OTHER

WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WARRANTIES OR MERCHANTABILITY AND FITNESS FOR A PARTICULAR

PURPOSE, ARE HEREBY EXPRESSLY DISCLAIMED. NO SALESMAN OR OTHER REPRESENTATIVE OF CHAMPION HAS

AUTHORITY TO MAKE ANY WARRANTIES.

R-Series Engine 4 CQF3474 v.00

Operation & Service Jan.2018

Page 5

Safety and Operation Precautions

Because an air compressor is a piece of machinery with moving and rotating parts, the same precautions should be

observed as with any piece of machinery of this type where carelessness in operation or maintenance is hazardous

to personnel. In addition to the many obvious safety rules that should be followed with this type of machinery, the

additional safety precautions as listed below must be observed:

1. Read all instructions completely before operating air compressor or unit.

2. For installation, follow all local safety codes, as well as the Occupational Safety and Health Act (OSHA).

3. Do not attempt to remove any compressor parts without first relieving the entire system of pressure.

4. Do not attempt to service any part while machine is in an operational mode.

5. Do not operate the compressor at pressures in excess of its rating.

6. Do not operate compressor at speeds in excess of its rating.

7. Periodically check all safety devices for proper operation. Do not change pressure setting or restrict operation

i

n any way.

8. Be sure no tools, rags or loose parts are left on the compressor or drive parts.

9. Do not use flammable solvents for cleaning the air inlet filter or element and other parts.

10. Exercise cleanliness during maintenance and when making repairs. Keep dirt away from parts by covering parts

and exposed openings with clean cloth or Kraft paper.

11. Do not operate the compressor without guards, shields and screens in place.

12. Do not install a shut-off valve in the discharge line, unless a pressure relief valve, of proper design and size, is

installed in the line between the compressor unit and shut-off valve.

13. Do not operate compressor in areas where there is a possibility of ingesting flammable or toxic fumes.

14. Be careful when touching the exterior of a recently run engine - it may be hot enough to be painful or cause

injury.

15. Inspect unit daily to observe and correct any unsafe operating conditions found.

16. Do not "play around" with compressed air or direct air stream at body. This can cause injuries.

17. Compressed air from this machine must not be used for food processing or breathing air without adequate

downstream filters, purifiers and controls.

18. Always use an air pressure regulating device at the point of use. Do not use air pressure greater than marked

maximum pressure of attachment.

19. Check hoses for weak or worn condition before each use and make certain that all connections are secure.

20. Always wear safety glasses when using a compressed air blow gun.

21. Engine drive unit precautions:

a. Understand the operation of all controls and learn how to stop the engine quickly in case of emergency.

Make sure the operator receives adequate instruction before operating the equipment.

b. Do not allow children to operate the engine. Keep children and pets away from the area of operation.

c. Your engine’s exhaust contains poisonous carbon monoxide. Do not run the engine without adequate

ventilation. Never run the engine indoors.

d. The engine and exhaust become very hot during operation. Keep the engine at least 3 feet away from

buildings and other equipment during operation. Keep flammable materials away. Do not plac

ng on the engine while it is running.

anythi

e

The user of any air compressor package manufactured by Champion – A Gardner Denver Co., is hereby warned that

failure to follow the preceding Safety and Operation Precautions can result in injuries or equipment damage.

However, Champion – A Gardner Denver Co., does not state as fact or does not mean to imply that the preceding

list of Safety and Operating Precautions is all inclusive, and further that the observance of this list will prevent all

injuries or equipment damage.

R-Series Engine 5 CQF3474 v.00

Operation & Service Jan.2018

Page 6

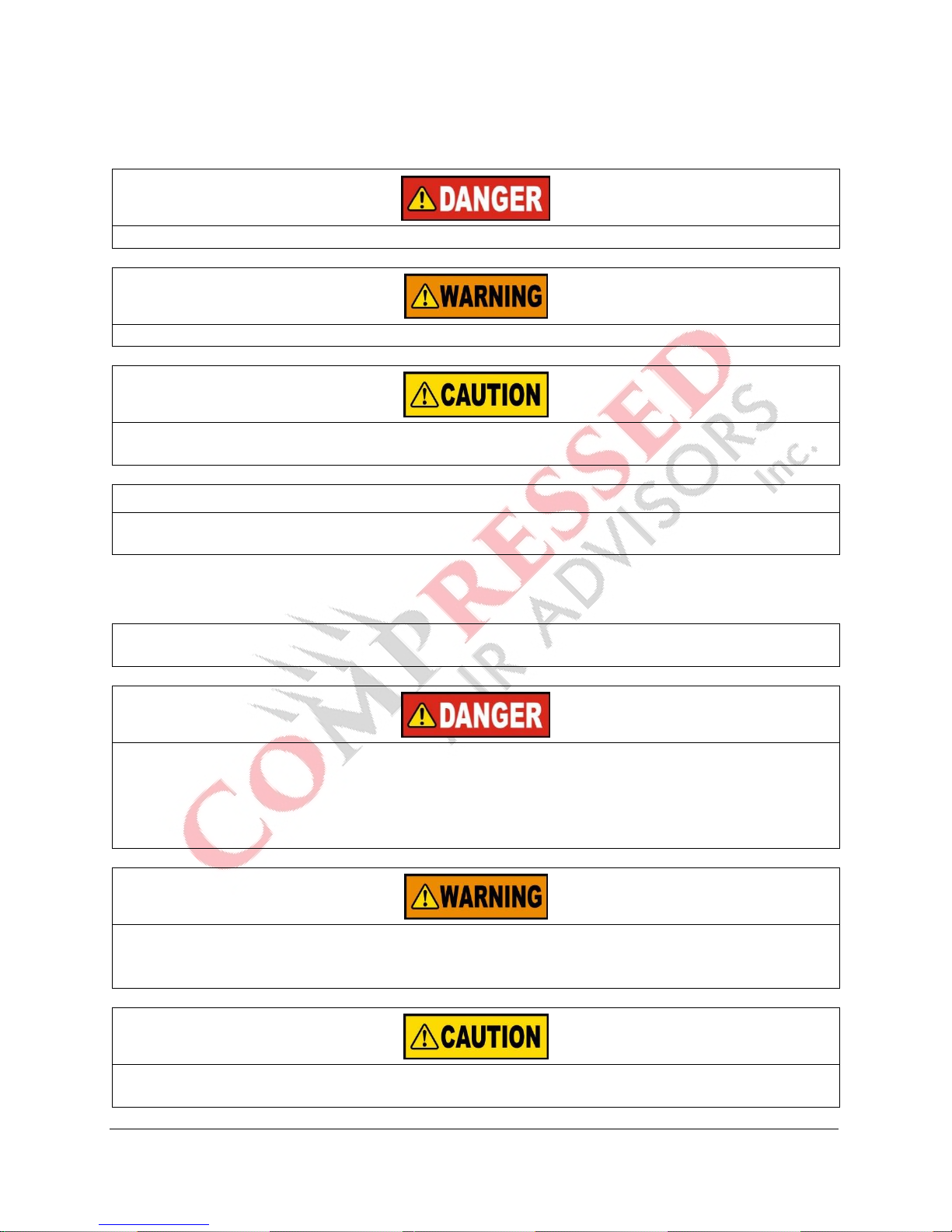

Explanation of Safety Instructions, Symbols, and Decals

Indicates immediate hazards which will result in severe injury or death.

Indicates hazards or unsafe practice which could result in

severe injury or death.

Indicates hazards or unsafe practice which could result in damage to the Champion compressor or

Notice is used to notify people of installation, operation, or maintenance information which is

OBSERVE, UNDERSTAND, AND RETAIN THE INFORMATION GIVEN IN THE SAFETY PRECAUTION

This reciprocating compressor must not be used for breathing air. To

do so will cause serious injury

The use of this compressor as a booster pump and/or to compress a medium other than

This unit may be equipped with special options which may not be included in this manual. User

minor injury.

NOTICE

important but not hazard related.

Safety and Operation Precautions

DECALS AS SHOWN IN THE DECAL LIST SECTION.

whether air is supplied direct from the compressor source or to breathing tanks for later use. Any

and all liabilities for damage or loss due to injury, death and/or property damage including

consequential damages stemming from the use of this compressor to supply breathing air, will be

disclaimed by the manufacturer.

atmospheric air is strictly non-approved and can result in equipment damage and/or injury. Nonapproved uses will also void warranty.

must read, understand, and retain all information sent with special options.

R-Series Engine 6 CQF3474 v.00

Operation & Service Jan.2018

Page 7

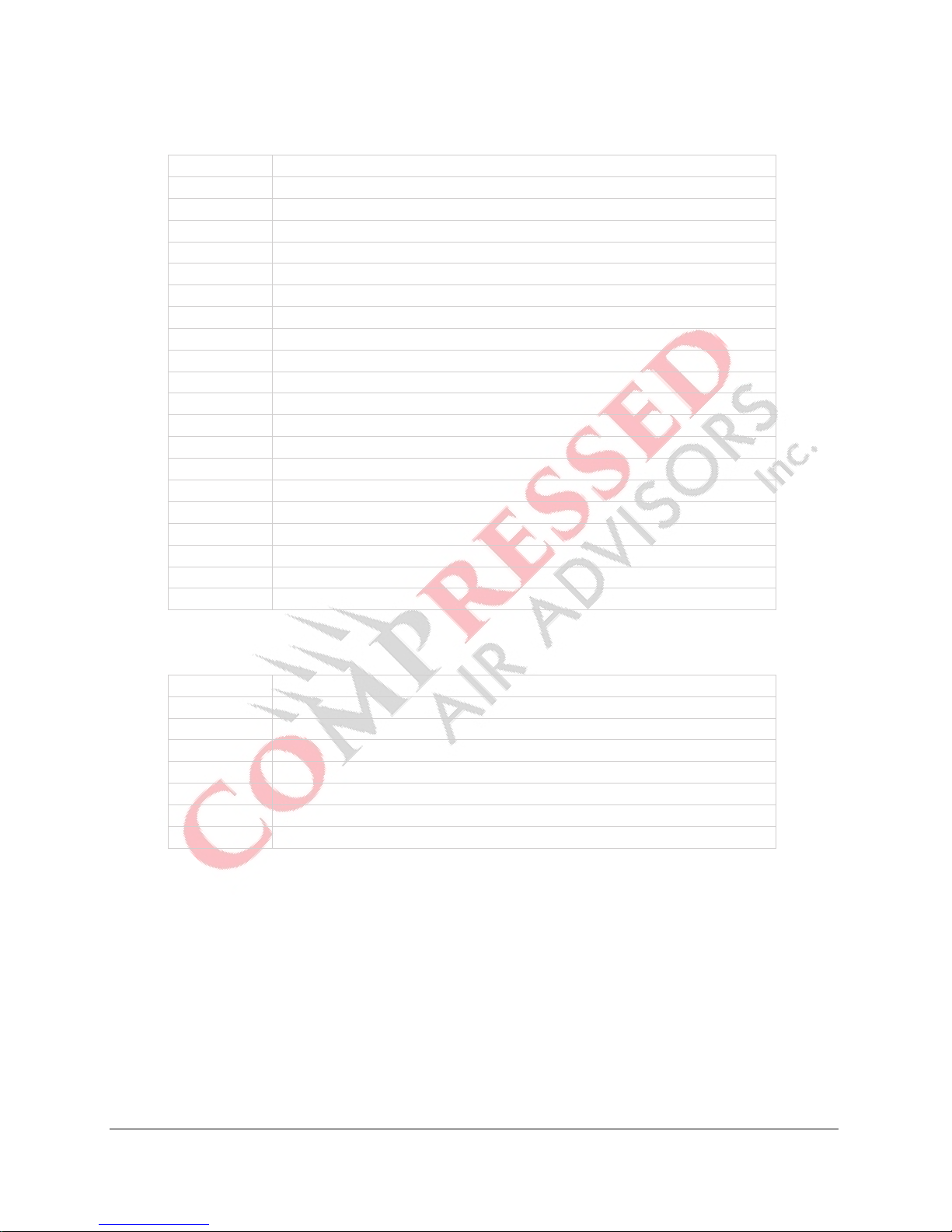

Unit Hazard Decal List – See Page 8

PART NO.

DESCRIPTION

P10157A

PRODUCT LIABILITY DECAL SHEET

- MASTER

1 Unit Pressure Setting

2 WARNING

– Tank Pressure

3 DANGER

– Breathing Air

4 DANGER

– Drain Tank Daily

5 WARNING

– Pressure/Safety Valve

6 NOT USED

7 DANGER

– Valve Maintenance

8 NOT USED

9 WARNING

– Hot Surfaces

10 WARNING

– Do Not Remove Fan Guard

11a

NOTICE

- Lubricant

11b

NOT USED

12 DECAL

– Synthetic or Food Grade Inserts

13 NOT USED

14 DECAL

– Pressure Setting: 140

-

175 PSIG

15 NOTICE

– Read and Retain Manuals

16 NOT USED

17 DECAL

– Rotation Direction

18 NOT USED

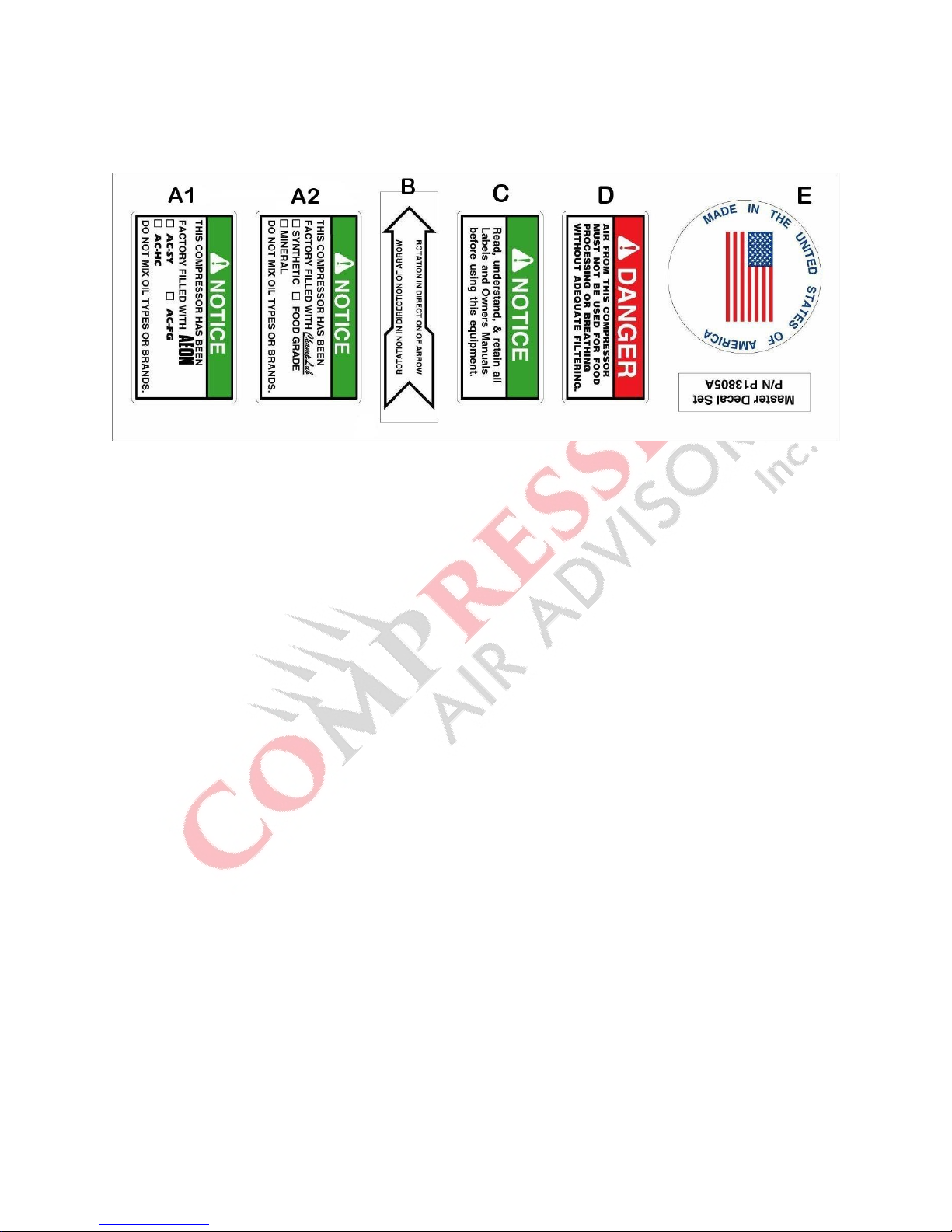

PART NO.

DESCRIPTION

P13805A

PUMP DECAL SHEET

– MASTER

A1 NOT USED

A2 NOTICE

- Lubricants

B DECAL

– Rotation

Direction

C NOTICE

– Read and Retain Manuals

D DANGER

– Breathing Air

E DECAL

– Made in the United States of America

Pump Hazard Decal List – See Page 9

R-Series Engine 7 CQF3474 v.00

Operation & Service Jan.2018

Page 8

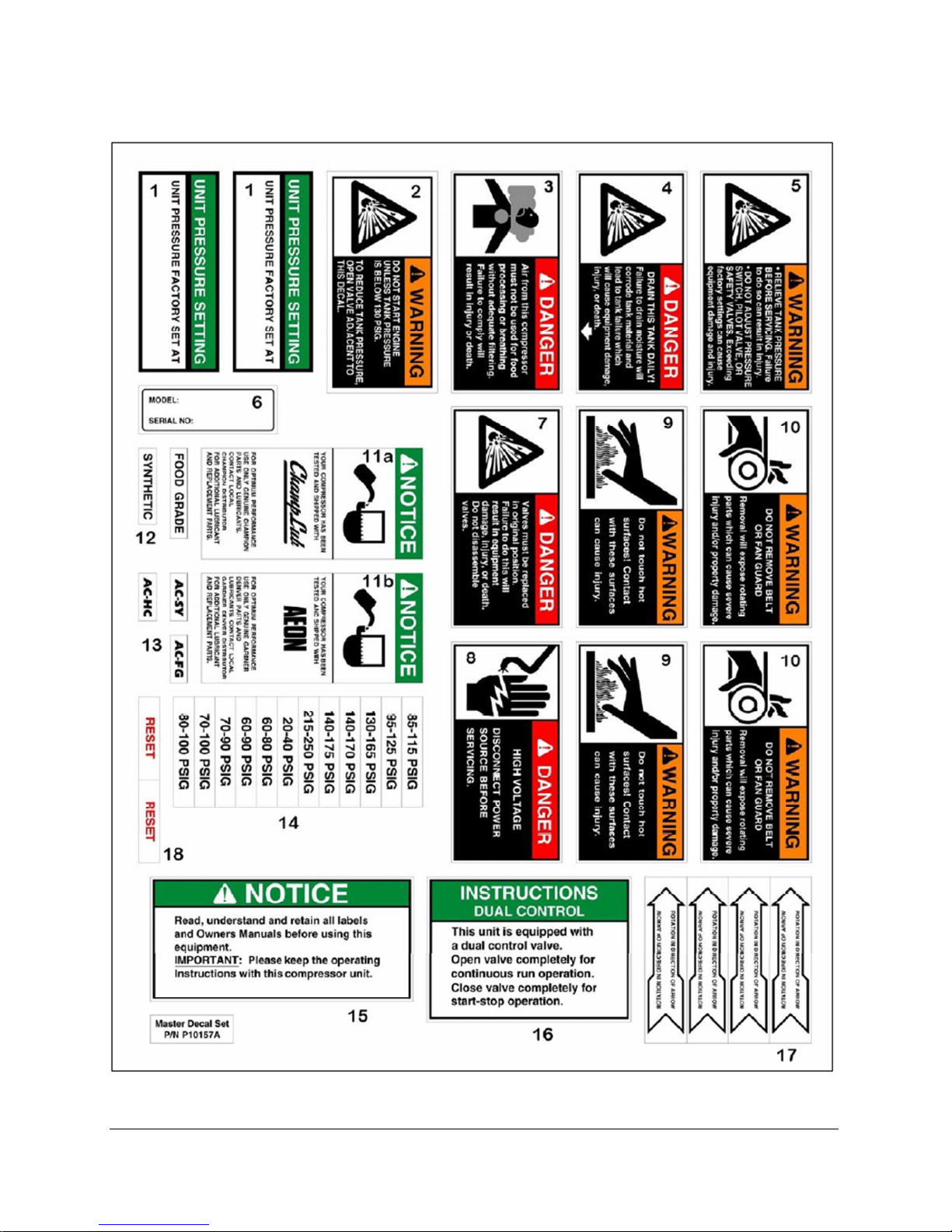

Unit Hazard Decals

R-Series Engine 8 CQF3474 v.00

Operation & Service Jan.2018

Page 9

Pump Hazard Decals

R-Series Engine 9 CQF3474 v.00

Operation & Service Jan.2018

Page 10

Installation

D

o not tighten the

anchor

screws/nuts down completely

– this will result in undesirable stress on

Do not operate unit if damaged during shipping, handling or use. Operating unit if damaged may

result in injury.

1. Permanently installed compressors must be located in a clean, well ventilated dry room so

compressor receives adequate supply of fresh, clean, cool, and dry air. It is recommended that a

compressor, used for painting, be located in a separate room from that area wherein body sanding

and painting is done. Abrasive particles or paint, found to have clogged the air intake filters and

intake valves, shall automatically void warranty.

2. Compressors should never be located so close to a wall or other obstruction that flow of air through

the fan-bladed flywheel, which cools the compressor, is impeded. Permanently mounted units

should be installed so that the belt guard is at least 12" from wall.

3. Place stationary compressors on firm level ground or flooring. Permanent installations are required

to be anchored to floor or truck bed. Bolt holes are provided in the air receiver or base feet. Use

shims to level the compressor unit. It is recommended that optional vibration isolator pads be

installed with the unit. Tanks anchored directly to a floor without vibration isolator pads will not be

warranted against cracking. Champion vibration isolator pads must be used for extended warranty

to apply to ASME air receivers. See “Air Receiver Installation” section.

the tank foot. This can cause abnormal vibration and possible cracking of the air receiver, resulting

in injury or equipment damage.

4. If installing base mounted unit, make certain the pressure limiting controls are properly installed

and operational. The unloading system requires a control air pressure line from the air receiver to

be connected to the pilot valve fitting on the pump.

5. A properly sized air check valve must be installed in the discharge piping, between the compressor

outlet and the inlet of any receiver tank(s) in the system.

6. Engine driven units installed indoors must have proper engine exhausting out of building. See Safety

& Precautions Item 21 (page 5).

R-Series Engine 10 CQF3474 v.00

Operation & Service Jan.2018

Page 11

Installation (continued)

CONNECT POSITIVE

CONNECT POSITIVE

. Battery and Wiring Recommendations

7

A. If engine is connected to a dedicated battery:

1) The battery should have a minimum capacity of 24 AH and at least 350 CCA rating.

he wire size must be a minimum of #4 AWG. If the positive cable is longer than 5 feet or

2) T

t

he negative cable is longer than 7.5 feet the wire size should be increased so that t

mum voltage drop from the battery to the unit connection does not exceed 0.5 volt

maxi

while cranking. The battery location should be selected to keep the connecting leads as

short

as possible.

3) Care should be taken when routing battery leads to insure that the leads are properly

support

4) T

conducting covers. See Figure 1 for Kohler (gas) connection. See Figure 2 for Honda (g

onnection.

c

ed and insulated.

he positive lead should be color coded RED and all connections should be enclosed by non-

he

s

as)

LEAD TO THIS TERMINAL

LEAD TO THIS TERMINAL

Figure 1

Figure 2

5) The negative lead should be connected directly to the engine using one of the four 3/8”

diameter mounting foot studs.

6) Electrical connections should be regularly inspected to insure that they are clean and tight.

R-Series Engine 11 CQF3474 v.00

Operation & Service Jan.2018

Page 12

Installation (continued)

B. HONDA GAS ENGINE ONLY: If engine is connected to the vehicle battery:

1

) The vehicle battery should have a minimum capacity of 24 AH and at least 350 CCA rating.

2) The wire size must be a minimum of #4 AWG. If the positive cable is longer than 5 feet or the

Negative cable is longer than 7.5 feet the wire size should be increased so that the maximum

voltage drop from the battery to the unit connection does not exceed 0.5 volts while cranking.

The battery location should be selected to keep the connecting leads as short as practical.

3) The Honda engine’s charging system should be disabled to prevent the damage from the

vehicles charging system. This is done by removing the rectifier diode that is located in the

key switch box.

a) Remove the Phillips head screw holding the black plastic cover on the back of the key

switch box See Figure 3.

R-Series Engine 12 CQF3474 v.00

Operation & Service Jan.2018

Figure 3

Page 13

Installation (continued)

b) Remove the black plastic cover from the back of the key switch box. Locate the black

rectangular rectifier diode. It is on the side closest to the engine. Gently pry back the

white plastic retainer clip on top of the diode closest to the key switch end and remove

the diode. See Figure 4

c) Replace the black plastic cover on the back of the key switch box. Insure rubber wire

grommet is installed correctly in the slot.

d) Tighten Phillips head screw.

4) Care should be taken when routing battery leads to insure that the leads are properly

supported and insulated.

5) The positive lead should be color coded RED and all connections should enclosed by nonconducting covers. See Figure 2

6) The negative lead should be connected directly to the Honda engine using one of the four

3/8” diameter mounting foot studs.

7) Electrical connections should be regularly inspected to insure that they are clean and tight.

RECTIFIER DIODE

Figure 4

R-Series Engine 13 CQF3474 v.00

Operation & Service Jan.2018

Page 14

Installation (continued)

●

Do not install in an area where ambient temperature is below 32

°

F or above 10

4°

F.

MODEL

25’ 50’ 100’ 200’ 300’ R15B

3/4” (1”) 3/4” (1”) 3/4” (1”) 1” (1-1/4”)

1” (1-

1/4”)

R30D

3/4” (1-1/4”)

1” (1-

1/4”)

1” (1-

1/4”)

1” (1-

1/2”)

1” (1-

1/2”)

Do not install isolating valves between compressor outlet and air receiver. This will cause excessive

pressure if valve is closed, and cause injury and equipment damage.

Always use an air pressure regulating device at the point of use. Failure to do so can result in injury

or equipment damage.

● Do not install unit in an area where air is dirty and/or chemical laden.

R LINE PIPING

AI

Connection to air system should be of the same size, or larger, than discharge pipe out of unit. The table

gives recommended minimum pipe sizes. A union connection to the unit and water drop leg is

recommended. Install a flexible connector between the discharge of the unit and the air piping. Piping

should be periodically inspected for leaks using a soap and water solution for detection on all pipe

joints. Air leaks waste energy and are expensive.

Minimum Pipe Sizes For Compressor Air Lines

(Based on clean Smooth Schedule 40 Pipe)

ues in ( ) are for duplex unit.

Val

Never use plastic pipe or improperly rated metal pipe. Improper piping material can burst and cause

injury or property damage.

R-Series Engine 14 CQF3474 v.00

Operation & Service Jan.2018

Page 15

Air Receiver Installation

D

o not tighten the

anchor

screws/nuts down completely

– this will result in undesirable stress on

TEN011442

-00

CUT-AWAY VIEW OF

bration isolator pads can be purchased from your local authorized distributor. Installation hardware

Vi

items (studs, screws, nuts, shims) are not provided. It is the compressor owner’s responsibility to

provide a suitable foundation and isolator installation.

the tank foot. This can cause abnormal vibration and possible cracking of the air receiver, resulting

in injury or equipment damage.

(Ref. Drawing)

R-Series Engine 15 CQF3474 v.00

Operation & Service Jan.2018

ANCHORED

INSTALLATION

Page 16

Operation

“MANUAL UNLOAD”

“RUN”

This compressor has been inspected, thoroughly tested and approved at the factory. For this unit to

give long satisfactory service it must be installed and operated properly. This compressor has been

designed for an 80%/ON – 20%/OFF duty cycle.

Engine Drive units are equipped with a pilot valve and head unloaders to provide continuous run

capabilities. The pilot valve acts as an automatic air switch allowing air to flow from the receiver to the

head unloader mechanism, thus actuating it. The pilot valve senses receiver pressure. When the

receiver pressure reaches the cut-out pressure setting of the pilot valve, the pilot valve opens and air is

released to the unloader mechanism. The compressor stops compressing air and runs unloaded until

the cut-in pressure setting of the pilot valve has been reached. At this time air is released from the

unloader mechanism and the compressor starts compressing again.

INITIAL START UP

1. Inspect unit for any visible signs of damage that would have occurred in shipment or during

installation.

2. Check compressor oil level. Add oil as required. See “Compressor Oil Specifications” Section.

NOTE: Do not mix oil type, weights, or brands.

3. Check engine oil level. Add oil as required. Consult engine manual for oil specifications.

4. Close receiver discharge ball valve.

ip toggle lever on pilot valve to the “Manual Unload” position. See Figure 5.

5. Fl

POSITION

POSITION

R-Series Engine 16 CQF3474 v.00

Operation & Service Jan.2018

Figure 5

Page 17

Operation (continued)

6. Start engine. Allow engine to warm up.

7. Flip toggle lever on pilot valve to the “Run” position. See Figure 5.

8. With receiver ball valve closed, let the machine pump up to operating pressure.

9. Check for proper operation of the head unloaders.

a. When the air receiver pressure reaches the cut-in setting of the pilot valve, the head

unloaders will activate. The air compressor continues to run, but air compression is stopped.

b. Open the receiver ball valve slowly, allowing pressure in the receiver to drop.

c. When the air receiver pressure drops to the cut-out setting of the pilot valve, the head

unloaders will de-activate. Air compression will resume.

d. Repeat steps a. thru c. three times.

10. Check for proper operation of any options.

11. When the initial run period has shown no operating problems, shut unit down and recheck oil level.

Add oil if needed.

12. Open receiver ball valve. The air compressor unit is now ready for use.

DAILY STARTING

1. Check compressor and engine oil level.

2. Drain liquid from receiver.

3. Close receiver outlet valve.

4. Flip toggle lever on the pilot valve to the “Manual Unload” position. See Figure 5.

5. Start engine. Allow engine to warm up.

6. Flip toggle level on pilot valve to “Run” position. See Figure 5.

7. When unit reaches operation pressure, open receiver outlet valve.

R-Series Engine 17 CQF3474 v.00

Operation & Service Jan.2018

Page 18

Compressor Oil Specifications

ompressors are factory filled with CHAMPLUB hydrocarbon-based recip lubricant. This is an ISO 100

C

non-detergent industrial lubricant with rust and oxidation inhibitors specially formulated for

reciprocating compressors. It is recommended this compressor be maintained using this oil for ambient

temperatures above 32°F.

CHAMPLUB synthetic is a premium grade diester based synthetic lubricant providing excellent

performance in high temperature applications.

Do not mix oil types, weights or brands.

Emulsification of oil (white milky substance) indicates unsafe accumulation of moisture and may

be evidence compressor is oversized for application. Failure to promptly consult your local

distributor, or Champion Customer Service, can be grounds to deny warranty.

BREAK

CHANGING TO SYNTHETIC LUBRICANT

(Applies to diester based synthetic lubricant only)

If changing to synthetic lubricant, the following steps must be completed.

-IN PERIOD:

1. Compressor must run for a 100 hour break-in period using ChampLub ISO 100 lubricant.

2. During the first 100 hours of compressor operation, a careful and regular check of the oil level

should be made. Maintain oil level at the full line.

3. After 100 hours of operation, thoroughly drain existing oil from crankcase.

4. Add a full charge of CHAMPLUB ISO 100 lubricant.

1. Compressor must run for a 100 hour break-in period using CHAMPLUB ISO 100 lubricant.

2. After 100 hours of operation, thoroughly drain existing oil from crankcase.

3. Add a full charge of CHAMPLUB SYNTHETIC lubricant.

4. Run compressor for 200 hours.

5. Stop compressor and thoroughly drain the synthetic lubricant.

6. Add a full charge of CHAMPLUB SYNTHETIC lubricant.

7. Compressor is now ready to run for extended period before next lubricant change. Maintain oil

level at the full line.

R-Series Engine 18 CQF3474 v.00

Operation & Service Jan.2018

Page 19

Compressor Oil Specifications (continued)

DESCRIPTION

PART NUMBER

1 – Quart Case (12/case)

P09479A

1 – Gallon Case (4/case)

P08909A

5 – Gallon Pail

P08908A

55 –

Gallon Drum

P08907A

DESCRIPTION

PART NUMBER

1 – Quart Case (12/case)

P13179A

1 – Gallon Case (4/case)

P13180A

5 – Gallon Pail

P11506A

55 –

Gallon Drum

P13181A

CANTS

LUBRI

CHAMPLUB ISO 100

CHAMPLUB SYNTHETIC

R-Series Engine 19 CQF3474 v.00

Operation & Service Jan.2018

Page 20

Guide to Maintenance

For Service contact an authorized Champion distributor. To obtain reliable and satisfactory service, this

unit requires a consistent preventive maintenance schedule. Maintenance schedule pages are included

in the back of this manual to aid in keeping the proper records.

Before performing any maintenance function, be sure all air pressure in unit is relieved. Failure to

do this may result in injury or equipment damage.

Never add fuel to the fuel tank of a hot engine. Spilled fuel may ignite and cause injury or

equipment damage.

Do not exceed 15 PSIG nozzle pressure when cleaning element parts with compressed air. Do not

direct compressed air against human skin. Serious injury could result. Never wash elements in fuel

oil, gasoline or flammable solvent.

Never operate unit without belt guard in place. Removal will expose rotating parts which can cause

injury or equipment damage.

Valves must be reinstalled in original position. Valve gaskets should be replaced each time valves

are serviced.

NGINE: For service, refer to separate engine manual.

E

PRESSURE RELIEF VALVE: The pressure relief valve is an automatic pop valve. Each valve is properly

adjusted for the maximum pressure permitted by tank specifications and working pressure of the unit

on which it is installed. If it should pop, it will be necessary to drain all the air out of the tank in order to

reseat properly. Do not adjust.

TANK DRAIN VALVE: Drain valve is located at bottom of tank. Open drain valve daily to drain

condensation. Do not open drain valve if tank pressure exceeds 25 PSIG.

R-Series Engine 20 CQF3474 v.00

Operation & Service Jan.2018

Page 21

Guide to Maintenance (continued)

1 3 2

4

ACTUATING TUBE

MOUNTING

SENSING TUBE

ILOT VALVE: The pilot valve actuates the head unloader mechanism to provide a means of stopping or

P

starting the compression of air by the compressor without stopping or starting the engine.

The pilot valve is pre-set from the factory, according to the order specification. Only a certified field

service technician should make adjustments to the pilot valve.

ILOT VALVE PRESSURE ADJUSTMENT

P

Proceed with the following instructions while compressor is running:

1. Loosen locknut (4) and back off several turns. Do not turn differential pressure adjustment nut

(3).

2. Check reading on the tank pressure gauge. Set the compressor maximum pressure by turning

threaded cap (1) clockwise to increase pressure or counter clockwise to decrease pressure.

3. After pressure is set, tighten locknut (4). Be careful not to move threaded cap (1).

PILOT VALVE DIFFERENTIAL PRESSURE ADJUSTMENT

Proceed with the following instructions while compressor is running:

1. Loosen locknut (2) and back off several turns.

2. Check reading on the tank pressure gauge. Set the pressure to 30 psig differential (unload at

170 psig, reload at 140 psig). Turn nut (3) clockwise to increase differential pressure

c

ounterclockwise to decrease differential pressure.

or

3. After pressure is set, tighten locknut (2). Be careful not to move nut (3).

THREAD

TO HEAD UNLOADERS

R-Series Engine 21 CQF3474 v.00

Operation & Service Jan.2018

FROM AIR RECEIVER

Page 22

Guide to Maintenance (continued)

COMPRESSOR VALVES: If compressor fails to pump air or seems slow in filling up tank, disconnect unit

from power source and remove valves and clean thoroughly, using compressed air and a soft wire

brush. After cleaning, exceptional care must be taken that all parts are replaced in exactly the same

position. All joints must be tight or the compressor will not function properly. When all valves are

replaced and connections are tight, close ball valve at tank outlet for final test. Valve gaskets should

be replaced each time valves are removed from pump.

CENTRIFUGAL UNLOADER AND UNLOADER PRESSURE RELEASE VALVE: The centrifugal unloader is

operated by two governor weights. It is totally enclosed and lubricated from the crankcase of the

compressor. When compressor starts, the governor weights automatically open, compressing the

main spring, allowing the unloader pressure release valve to close. When the compressor stops, the

main spring returns the governor weights to normal position, opening the unloader pressure release

valve and unloading the compressor. This prevents overloading the motor when starting. If air

continues to escape through the governor or unloader pressure release valve while operating, this is

an indication that the unloader pressure release valve is not closing tightly and may be held open by

a foreign substance which has lodged against the seat. In order to correct this, remove the governor

release valve cap, allowing access to unloader pressure release valve spring and ball. Clean

thoroughly and return parts in the same order in which they were removed. See Centrifugal

Unloader section in parts list for diagram. Loose drive belts can also cause unloader to leak by

preventing the compressor from reaching proper speed. (See “BELTS” page 23).

CHECK VALVE: The check valve closes when the compressor stops operating, preventing air from

flowing out of the tank through the pressure release valve. After the compressor stops operating, if

air continues to escape through the release valve, it is an indication that the check valve is leaking.

This can be corrected by removing check valve and cleaning disc and seat. If check valve is worn

badly, replace it.

Before removing check valve, be sure all air is drained out of tank and power is disconnected.

Failure to do so may result in injury or equipment damage.

THE INTERSTAGE PRESSURE RELIEF VALVE is provided to protect against interstage over pressure and is

factory set for maximum pressure of 75 PSIG. DO NOT RESET. If the pressure relief valve pops, it

indicates trouble. Shut down the unit immediately and determine and correct the malfunction.

Inspect the head valves. Serious damage can result if not corrected and can lead to complete

destruction of the unit. Tampering with the interstage pressure relief valve or plugging the opening

destroys the protection provided and voids all warranty.

COMPRESSOR LUBRICATION: Fill crankcase to proper level as indicated by oil sight gauge. Keep

crankcase filled as required by usage. It is recommended that only Champlub recip lubricant be

used. This is an ISO 100, non-detergent industrial oil with rust and oxidation inhibitors specially

formulated for reciprocating compressors. Do not mix oil types, weights, or brands.

R-Series Engine 22 CQF3474 v.00

Operation & Service Jan.2018

Page 23

Guide to Maintenance (continued)

ORQUE VALUES:

T

omponent Fastener Size & Thread Model Torque

C

Governor Housing 3/8-16 R15 400 Inch-lb.

Governor Housing 7/16-20 R30 550 Inch-lb.

Cylinder Flange 7/16-20 R15, R30 400 Inch-lb.

Governor Spindle Screw 7/16-20 R15, R30 470 Inch-lb.

Rod Bolt 5/16-18 R15, R30 230 Inch-lb.

Manifold Cap Screw 3/8-16 R15, R30 200 Inch-lb.

Flywheel Pinch Bolt 1/2-13 R15, R30 600 Inch-lb.

R-Series Engine 23 CQF3474 v.00

Operation & Service Jan.2018

Page 24

Guide to Maintenance (continued)

TEN011448

-00

ETTING BELT TENSION

S

1. Proper setting of the belt tension requires a belt tension checker (part number

EN011452).

T

2. Measure the belt span.

3. On the belt tension checker, position the o-ring on the span scale at the

belt span.

4. Position the o-ring on the deflection force scale to zero.

5. Place a straight edge across the outside diameters of the motor pulley

ompressor flywheel.

c

6. Place the tension checker squarely on one belt at the center of the belt span. Appl

force on the plunger, perpendicular to the belt span until the bottom of the larg

a

o

-ring is even with the bottom of the straight edge.

7. Remove the tension checker and read the force applied from the bottom of t

smal

l o-ring on the deflection force scale.

8. Compare the force you have applied with the values given in the table on page 25.

The force should be between the minimum (used belt) and maximum (new belt

shown.

. Make adjustments to the location of the motor to achieve proper tension.

9

measured

and

y

e

he

)

(Ref. Drawing)

R-Series Engine 24 CQF3474 v.00

Operation & Service Jan.2018

Page 25

Guide to Maintenance (continued)

MODEL

H.P. PSI RPM MOTOR

BELT

BELT

QTY

USED BELT

NEW BELT

LT DEFLECTION FORCE

BE

PULLEY

O.D.

R15 GAS 13, 14 175 1025 4.95 BX 71 2 3.6 5.2

R15 DIESEL 9.1, 9.3 175 870 4.35 BX 71 2 3.9 5.6

R30 GAS 20.5 175 765 4.35 B 80 2 5.0 7.1

R30 GAS 22.5 175 940 5.75 B 81 2 5.0 7.3

SECTION

NUMBER

OF

BELTS

DEFLECTION

FORCE

(lbs. min)

DEFLECTION

FORCE

(lbs. max)

1. The values given in the “BELT DEFLECTION FORCE” table are calculated for nominal

conditions and are provided for reference only. The required tension may vary due t

ication, manufacturing variances, component wear, etc. Drive belts must be kept tight

appl

enough to prevent slipping. If belts slip or squeak, they need to be tightened.

2. Belt cross-section can be found printed on the outside surface of the belt.

If belts are too tight, overload will be put on motor and motor bearings.

o

R-Series Engine 25 CQF3474 v.00

Operation & Service Jan.2018

Page 26

Maintenance Checklist

Check oil level of compressor. Add Champlub recip lubricant as required. See “Compressor Oil

Drain moisture from tank by opening tank drain valve located in bottom of tank. Do not open

Clean dust and foreign matter from cylinder head,

motor, fan blade

s

, air lines, intercooler

, and

If necessary, l

oosen

engine mounting plate fasteners

.

Use belt adjustment bolt at end of base

Check the alignment of pulleys.

The compressor flywheel and

engine

sheave

should be aligned

Check entire system for air leakage around fittings, connections, and gaskets, using soap

Check and clean compressor valves

. R

eplace

valves

when worn or damaged.

Replace valve

DAILY MAINTENANCE

1

Specifications” Section. NOTE: Do not mix oil type, weight, or brands.

2 Check oil level of engine. Consult engine manual for manufacturer’s recommended oil.

3

drain valve if tank pressure exceeds 25 PSIG.

WEEKLY MAINTENANCE

1

tank.

2 Remove and clean intake air filters.

3 Check V-belts for proper alignment and tightness:

a Remove belt guard bracket and open top half of belt guard to access compressor drive.

b See “Setting Belt Tension” Section for details on how to check and set proper tension.

c

plate to adjust belt tension.

d

within ±1/2° with notched belts and ±2° with wrapped belts. Adjust if necessary.

e Tighten engine mounting plate fasteners to secure engine on base.

f Close top half of belt guard and re-install belt guard bracket

EVERY 90 DAYS OR 500 HOURS MAINTENANCE

1 Change compressor crankcase oil and oil filter. Use only Champlub recip lubricant.

2

solution and brush.

3 Tighten nuts and capscrews as required. See “Torque Values” section.

4

gaskets after each inspection.

5 Pull ring on all pressure relief valves to assure free movement.

R-Series Engine 26 CQF3474 v.00

Operation & Service Jan.2018

Page 27

Troubleshooting Chart

Symptom

Possible Cause(s)

Corrective Action

Tank pressure builds up slowly.

1.Air leaks.

1.

Tighten fittings.

Tank

pressure builds up quickly.

1.Excessive water in tank.

1.Drain tank.

Discharge pressure relief valve

1.

Wrong pressure switch setting.

1.

Adjust to correct setting.

before servicing.

Compressor will not unload

1.Wrong pilot valve setting.

1.

Adjust to correct setting

.

Excessive belt wear.

1.Pulley out of alignment.

1.

Realign motor pulley.

Compressor runs hot.

1.Improper flywheel rotation

1.

Check for correct rotation.

Interstage pressure relief

valve

1.

Defective compressor valves.

1.

Install new valves.

Excessive oil consumption.

1.Dirty air filter.

1.

Clean or replace.

Air escapes from centrifugal

1.

Centrifugal unloader release valve

1.

Clean or replace valve

Air escapes from

centrifugal

1.

Check valve stuck in open position.

1.Replace check valve.

Always shut off unit and relieve all pressure from air tank before performing any maintenance.

Failure to do so may result in equipment damage or injury.

Never operate unit without belt guard in place.

Troubleshooting Chart

Engine will not start.

pops off while compressor is

running.

1. No fuel in fuel tank.

2. High tank pressure.

3. Refer to separate engine manual for

other causes.

2. Dirty air filter.

3. Defective compressor valves

2. Defective ASME relief valve.

2. Defective pilot valve.

3. Lack of air to pilot valve.

2. Belts too tight or too loose.

2. Defective compressor valves.

3. Dirty air filter.

4. Dirty cylinder and/or intercooler.

1. Add fuel

2. Reduce tank pressure to 130 PSIG or

less.

2. Clean or replace.

3. Install new valves.

2. Replace valve.

Warning – Relieve tank pressure

2. Replace pilot valve.

3. Check piping from tank to pilot valv

for leaks

2. Adjust belt tension.

(Counter clockwise when viewed from

drive side.)

2. Install new valve assembly.

3. Clean or replace.

4. Clean cylinder fins and/or intercooler.

e

pops off.

unloader when unit is running

unloader when unit is stopped.

R-Series Engine 27 CQF3474 v.00

Operation & Service Jan.2018

2. Improper valve installation.

2. Wrong oil viscosity.

3. Oil leaks.

4. Worn piston rings.

5. Scored cylinder

dirty or detective.

2. Verify proper valve placement.

2. Refill with proper viscosity oil.

3. Tighten bolts. Replace gaskets.

4. Replace rings.

5. Replace cylinder.

Warning – Relieve tank pressure

before servicing.

Page 28

Maintenance Log

WEEKLY

MONTHLY

EVERY 3 MONTHS

DAILY

● CHECK OIL LEVEL

● DRAIN MOISTURE FROM TANK

● CLEAN FILTER

● CLEAN COMPRESSOR

● INSPECT AIR SYSTEM

● CHANGE OIL

● INSPECT VALVE ASSEMBLIES

● TIGHTEN ALL FASTENERS

● TEST PRESSURE RELIEF VALVE

R-Series Engine 28 CQF3474 v.00

Operation & Service Jan.2018

Page 29

Maintenance Log

WEEKLY

MONTHLY

EVERY 3 MONTHS

DAILY

● CHECK OIL LEVEL

● DRAIN MOISTURE FROM TANK

● CLEAN FILTER

● CLEAN COMPRESSOR

● INSPECT AIR SYSTEM

● CHANGE OIL

● INSPECT VALVE ASSEMBLIES

● TIGHTEN ALL FASTENERS

● TEST PRESSURE RELIEF VALVE

R-Series Engine 29 CQF3474 v.00

Operation & Service Jan.2018

Page 30

Maintenance Log

WEEKLY

MONTHLY

EVERY 3 MONTHS

DAILY

● CHECK OIL LEVEL

● DRAIN MOISTURE FROM TANK

● CLEAN FILTER

● CLEAN COMPRESSOR

● INSPECT AIR SYSTEM

● CHANGE OIL

● INSPECT VALVE ASSEMBLIES

● TIGHTEN ALL FASTENERS

● TEST PRESSURE RELIEF VALVE

R-Series Engine 30 CQF3474 v.00

Operation & Service Jan.2018

Page 31

Notes

R-Series Engine 31 CQF3474 v.00

Operation & Service Jan.2018

Page 32

*CQF3474VER00*

*CQF3474VER00*

Fo

r additional information, contact your local representative or visit:

www.championpneumatic.com/contactus.aspx

©2018 Gardner Denver, Inc. Printed in U.S.A.

Loading...

Loading...