Page 1

OPERATION/MAINTENANCE

MANUAL & PARTS LIST

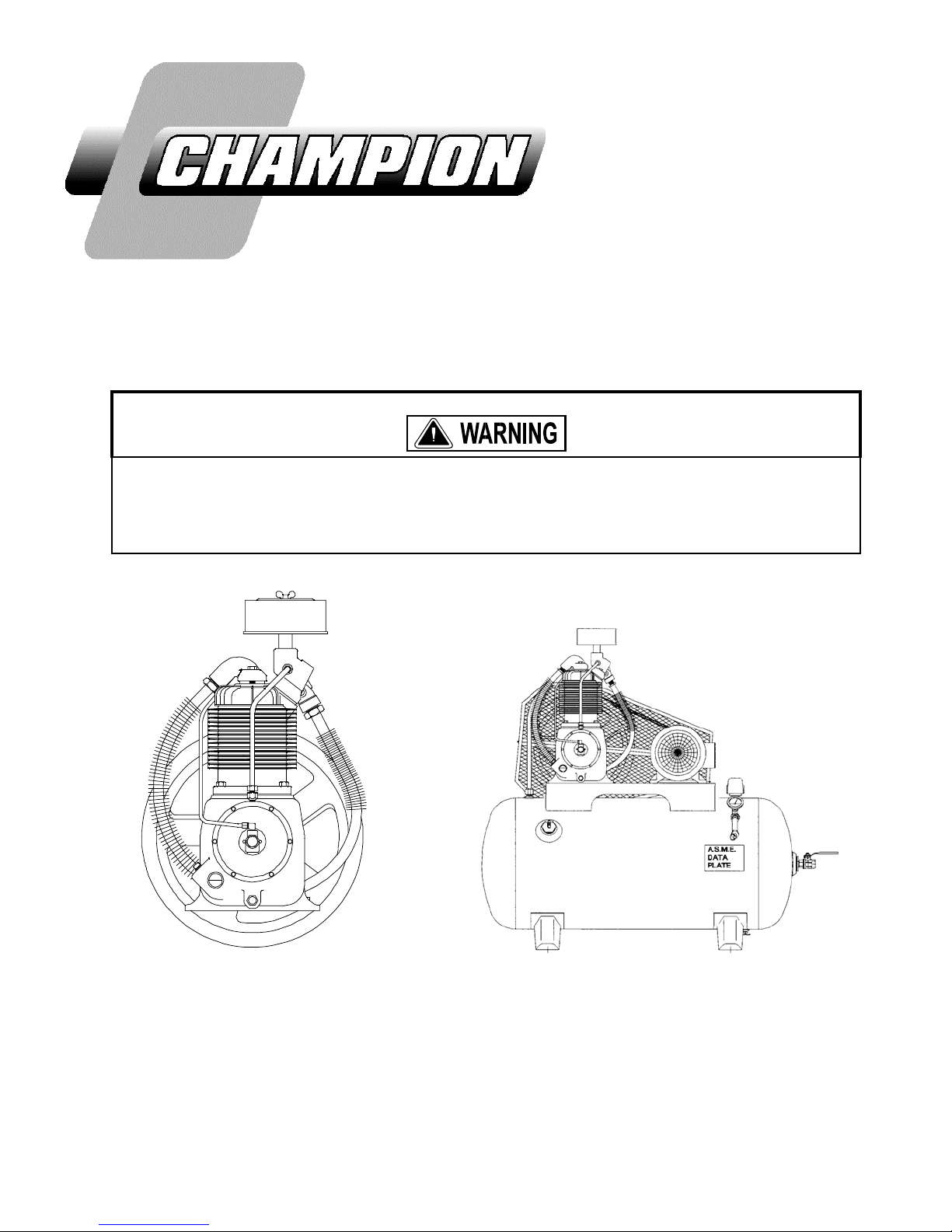

TWO STAGE/TWO CYLINDER AIR COMPRESSORS & UNITS

FEATURING THE R10 & R15 PUMPS

THIS MANUAL CONTAINS IMPORTANT SAFETY INFORMATION AND SHOULD

ALWAYS BE AVAILABLE TO THOSE PERSONNEL OPERATING THIS UNIT.

READ, UNDERSTAND AND RETAIN ALL INSTRUCTIONS BEFORE OPERATING THIS

EQUIPMENT TO PREVENT INJURY OR EQUIPMENT DAMAGE.

R15B HR3-6

Form No. F3231 REV 12/00

Page 2

TABLE OF CONTENTS

_______________________________________________________

Subject

Page

Safety And Operation Precautions ......................................................... 3

Explanation Of Safety Instructions Symbols And Decals....................... 4

Introduction .............................................................................................5

Warranty.................................................................................................. 5

Dimensions And Specifications ........................................................6 & 7

Installation ............................................................................................... 8

Preparation For Initial Start-Up And Operation....................................... 9

Maintenance............................................................................ 10,11 & 12

Compressor Oil Specifications.............................................................. 13

Trouble Shooting Guide.......................................................... 14,15 & 16

Parts List ............................................................. 16, 17, 18, 19 , 20 & 21

Constant Speed Head Unloader Kit .....................................................22

Operation And Adjustment Of Pilot Valves........................................... 23

Unit Hazard Decal & Tags ................................................... 24 , 25 & 26

Pump Hazard Decals & Tags ............................................................... 27

Record Of Maintenance Service............................................ 28, 29 & 30

2

Page 3

SAFETY AND OPERATION PRECAUTIONS

_______________________________________________________________________________________

Because an air compressor is a piece of machinery with moving and rotating parts, the same precautions should be

observed as with any piece of machinery of this type where carelessness in operation or maintenance is hazardous to

personnel. In addition to the many obvious safety rules that should be followed with this type of machinery, the additional

safety precautions as listed below must be observed:

1. Read all instructions completely before operating air compressor or unit.

2. For installation, follow all local electrical and safety codes, as well as the National Electrical Code (NEC) and the

Occupational Safety and Health Act (OSHA).

3. Electric motors must be securely and adequately grounded. This can be accomplished by wiring with a grounded,

metal-clad raceway system to the starter; by using a separate ground wire connected to the bare metal of the

motor frame; or other suitable means.

4. Protect the power cable from coming in contact with sharp objects. Do not kink power cable and never allow the

cable to come in contact with oil, grease, hot surfaces, or chemicals.

5. Make certain that the power source conforms to the requirements of your equipment.

6. Pull main electrical disconnect switch and disconnect any separate control lines, if used, before attempting to work

or perform maintenance on the air compressor or unit. "Lock out" or "Tag out" all power sources.

7. Do not attempt to remove any compressor parts without first relieving the entire system of pressure.

8. Do not attempt to service any part while machine is in an operational mode.

9. Do not operate the compressor at pressures in excess of its rating.

10. Do not operate compressor at speeds in excess of its rating.

11. Periodically check all safety devices for proper operation. Do not change pressure setting or restrict operation

in any way.

12. Be sure no tools, or rags or loose parts are left on the compressor or drive parts.

13. Do not use flammable solvents for cleaning the air inlet filter or element and other parts.

14. Exercise cleanliness during maintenance and when making repairs. Keep dirt away from parts by covering parts

and exposed openings with clean cloth or Kraft paper.

15. Do not operate the compressor without guards, shields and screens in place.

16. Do not install a shut-off valve in the discharge line, unless a pressure relief valve, of proper design and size, is

installed in the line between the compressor unit and shut-off valve.

17. Do not operate compressor in areas where there is a possibility of ingesting flammable or toxic fumes.

18. Be careful when touching the exterior of a recently run motor - it may be hot enough to be painful or cause injury.

With modern motors this condition is normal if operated at rated load - modern motors are built to operate at

higher temperatures.

19. Inspect unit daily to observe and correct any unsafe operating conditions found.

20. Do not "play around" with compressed air, nor direct air stream at body, because this can cause injuries.

21. Compressed air from this machine absolutely must not be used for food processing or breathing air without

adequate downstream filters, purifiers and controls.

22. Always use an air pressure regulating device at the point of use, and do not use air pressure greater than marked

maximum pressure of attachment.

23. Check hoses for weak or worn condition before each use and make certain that all connections are secure.

24. Always wear safety glasses when using compressed air gun.

The user of any air compressor package manufactured by Champion – A Gardner Denver Co., is hereby warned that

failure to follow the preceding Safety and Operation Precautions can result in injuries or equipment damage. However,

Champion – A Gardner Denver Co., does not state as fact or does not mean to imply that the preceding list of Safety

and Operating Precautions is all inclusive, and further that the observance of this list will prevent all injuries or equipment

damage.

3

Page 4

EXPLANATION OF SAFETY INSTRUCTIONS SYMBOLS AND DECALS

DANGER

Indicates immediate hazards which will result in severe injury or death.

WARNING

Indicates hazards or unsafe practice which could result in severe injury or death.

CAUTION

Indicates hazards or unsafe practice which could result in damage to the Champion compressor

or minor injury.

OBSERVE, UNDERSTAND, AND RETAIN THE INFORMATION GIVEN IN THE SAFETY PRECAUTION DECALS

AS SHOWN IN THE PARTS LIST SECTION.

DANGER

This Oil-Less compressor must not be used for breathing air, unless proper downstream filtraton

and purification is added. To use for breathing air without proper downstream equipment will

cause serious injury whether air is supplied direct from the compressor source or to the breathing

tanks for later use. Any and all libilities for damage or loss due to injuries, death and/or property

damage including consequential damages stemming from the use of this compressor to supply

breathing air, without proper downstream filtration and purificaton, will be disclaimed by the

manufacturer.

WARNING

The use of this compressor as a booster pump and/or to compress a medium other than

atmospheric air is strictly non-approved and can result in equipment damage and/or injury. Nonapproved uses will also void the warranty.

CAUTION

This unit may be equipped with special options which may not be included in this manual. User

must read, understand and retain all information sent with special options.

4

Page 5

INTRODUCTION

____________________________________________________________________

Your new Champion Reciprocating Air Compressor is constructed to exacting standards of material and

workmanship.

The instructions in this manual have been prepared to ensure that the Champion air compressor will give

long and satisfactory service.

A copy of this manual must be given to the personnel responsible for installing and operating the Champion

air compressor or unit.

Although precautions have been taken to prevent damage to your compressor or unit by freight carrier, the

unit must be carefully examined and the carrier notified within 24 hours in the event of mishandling.

Champion Five Year Warranty

"R" Series Compressors

CHAMPION warrants each new compressor pump manufactured by CHAMPION, mounted on a factory assembled unit,

to be free from defects in material and workmanship under normal use and service for a period of sixty (60) months from

date of installation or sixty-six (66) months from date of shipment by CHAMPION or CHAMPION distributor, whichever

may occur first. Applies to the compressor pump only, excluding head valves. Valves, controls and accessories

are warranted for the first year only. Compressor pumps purchased separately would carry a one year warranty.

This five year extended warranty will be prorated over the 5 years as follows:

First Year - 100% Allowance, Parts and Labor

Second Year - 90% Allowance, Parts and Labor

Third Year - 80% Allowance, Parts and Labor

Fourth Year - 70% Allowance, Parts and Labor

Fifth Year - 60% Allowance, Parts and Labor

Applies to CHAMPION logo, tank or base mounted complete compressors only.

Express Limited Warranty

CHAMPION warrants each new air compressor unit manufactured by CHAMPION to be free from defects in material and

workmanship under normal use and service for a period of twelve (12) months from date of installation or eighteen (18)

months from date of shipment by CHAMPION or CHAMPION distributor, whichever may occur first.

CHAMPION makes no warranty in respect to components and accessories furnished to CHAMPION by third parties, such

as ELECTRIC MOTORS, GASOLINE ENGINES and CONTROLS, which are warranted only to the extent of the original

manufacturer's warranty to CHAMPION. To have warranty consideration, electric motors must be equipped with thermal

overload protection.

The extended five year warranty will apply to ASME air receivers provided they are installed on rubber vibro isolator pads.

When a compressor pump, or component is changed or replaced during the warranty period, the new/replaced item is

warranted for only the remainder of the original warranty period.

Repair, replacement or refund in the manner and within the time provided shall constitute CHAMPION'S sole liability and

your exclusive remedy resulting from any nonconformity or defect. CHAMPION SHALL NOT IN ANY EVENT BE LIABLE

FOR ANY DAMAGES, WHETHER BASED ON CONTRACT, WARRANTY, NEGLIGENCE, STRICT LIABILITY OR

OTHERWISE, INCLUDING WITHOUT LIMITATION ANY CONSEQUENTIAL, INCIDENTAL OR SPECIAL DAMAGES,

ARISING WITH RESPECT TO THE EQUIPMENT OR ITS FAILURE TO OPERATE, EVEN IF CHAMPION HAS BEEN

ADVISED OF THE POSSIBILITY THEREOF.

CHAMPION MAKES NO OTHER WARRANTY OR REPRESENTATION OF ANY KIND, EXCEPT THAT OF TITLE, AND

ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING WARRANTIES OR MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, ARE HEREBY EXPRESSLY DISCLAIMED. NO SALESMAN OR OTHER

REPRESENTATIVE OF CHAMPION HAS AUTHORITY TO MAKE ANY WARRANTIES.

5

Page 6

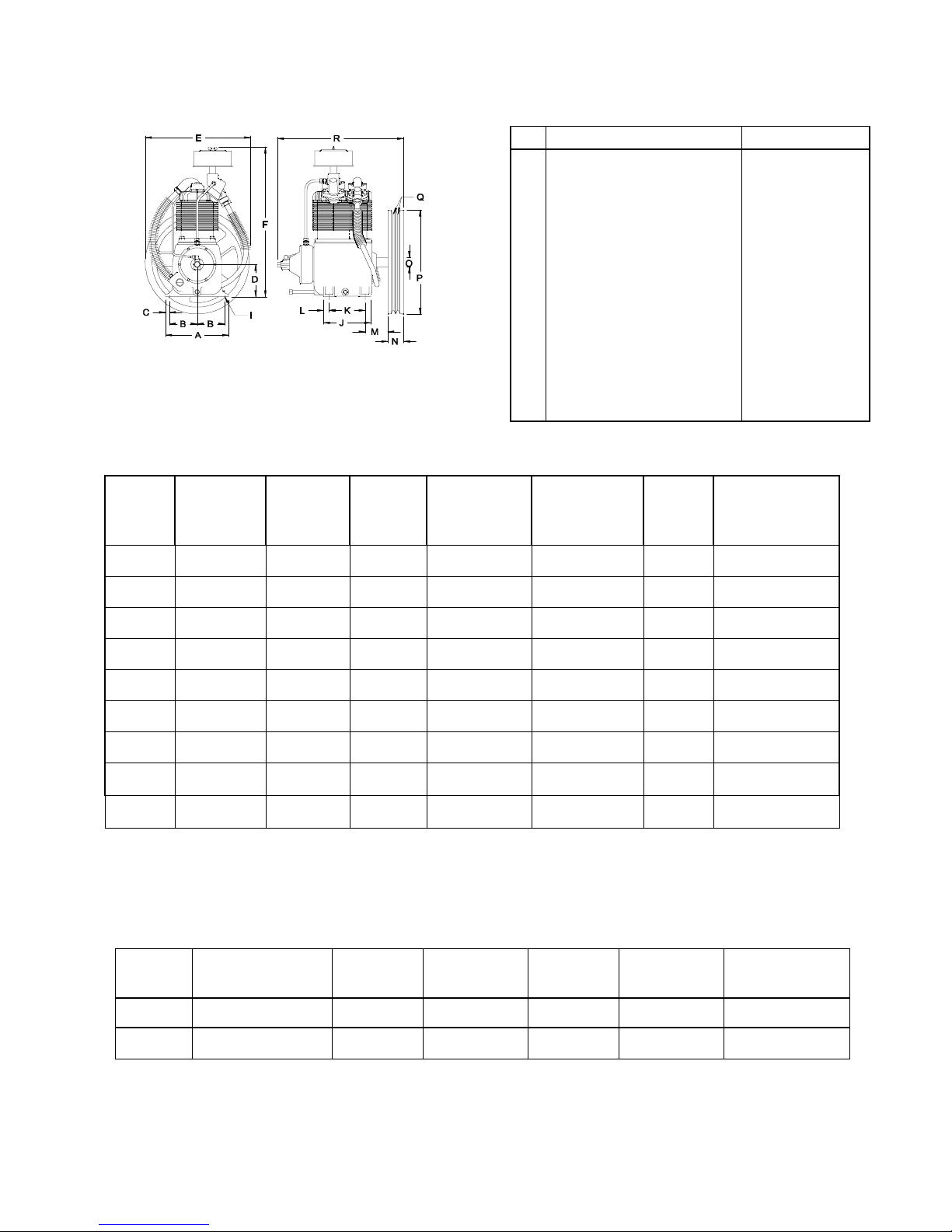

TWO STAGE AIR COMPRESSORS - MODELS R-10D & R-15B

PERFORMANCE

DIMENSIONS

ITEM R-10 & R-15

Base-Width

A

Bolt Down-Width

B

Bolt Down to Edge

C

Base to Crank Ctr

D

Overall Width

E

Overall Height

F

Bolt Down Hole Dia.

I

Base-Depth

J

Bolt Down Depth

K

Bolt Down to Edge

L

Bolt Hole to Wheel (Max.)

M

Flywheel Width

N

Crank Diameter

O

Flywheel Diameter

P

Flywheel Grooves

Q

Overall Depth

R

NOTE: H.P. Exhaust Opening 3/4" Tubing.

10

4-3/8

5/8

5½

18

23-1/4

15/32

7½

5-3/4

7/8

3-5/8

2½

1-5/16

16½

2VB

20

PUMP

OUTPUT

PRESS.

PSIG

MOTOR

H.P.

DISPL.

CFM

COOLING

AIR FLOW

CFM

HEAT

REJECTION

BTU/HR

PUMP

RPM

APPROX.

PULLEY O.D.

INCHES

R-10D 125 1-1/2 11.0 660 3360 570 5.55

R-10D 175 1-1/2 10.5 625 3360 542 5.25

R-10D 125 2 14.8 875 4480 760 7.35

R-10D 175 2 14.1 835 4480 725 7.0

R-15B 125 3 14.5 565 6700 490 4.75

R-15B 175 3 12.8 505 6700 440 4.31

R-15B 125 5 21.9 868 12,000 750 7.35

R-15B 175 5 20.7 820 12,000 710 7.00

R-15B 175 7-1/2 30.2 1195 16,800 1035 9.75

All data is based on 1725 RPM electric motors as a power source.

Flywheel Rotation; Clockwise When Min. RPM 400

Viewed From Front - Flywheel to Rear Max. RPM 1050

SPECIFICATIONS

BORE & STROKE

MODEL

R-10D 4-5/8 & 2-1/2 x 2 2 2 QT. 107 175 PSIG .01942*

R-15B 4-5/8 & 2-1/2 x 3 2 2 QT. 109 175 PSIG .02914

INCHES

* Clearance Volume Modified to Effective .014 Cu. Ft./Rev.

NO. CYLS.

OIL CAPY.

6

WT. (LBS)

MAX.

PRESS.

CU FT./REV.

Page 7

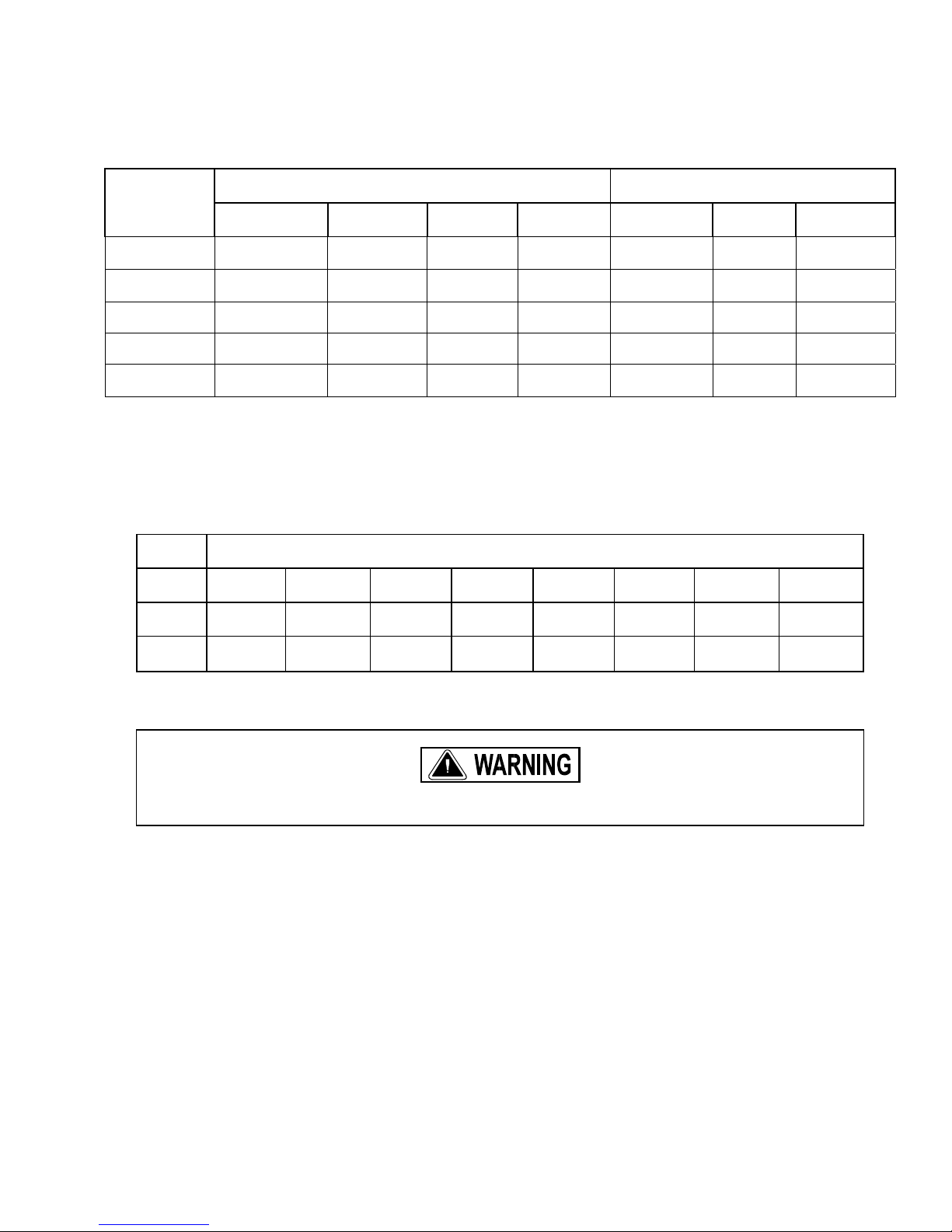

ELECTRIC WIRING (BASED ON 1999 NEC)

Wire Size (Rubber Covered) AWG NO.

Copper Conductor -- 75°C Temp Rating -- 30°C Ambient

MOTOR

3 PHASE 1 PHASE

HP

200/208V 230V 460V 575V 115V 208V 230V

1-1/2 14 14 14 14 10 14 14

2 14 14 14 14 8 12 12

3 14 14 14 14 8 10 10

5 10 (8) 12 (8) 14 (12) 14 - 8 (6) 8 (6)

7-1/2 8 (6) 10 (6) 14 (10) 14 (10) - - 6 (4)

Values in ( ) for Duplex Unit w/one incoming power line to both motors.

PIPE SIZES FOR COMPRESSED AIR LINES - R-10D & R-15B

(Based on Clean, Smooth Schedule 40 Pipe)

LENGTH OF PIPE LINES IN FEET

25 50 75 100 150 200 250 300

R-10D

3/4 3/4 3/4 3/4 3/4 3/4 3/4 3/4

R-15B

Values in ( ) for Duplex Unit.

Never use plastic pipe or improperly rated metal pipe. Improper piping materials can burst and

cause injury or property damage.

3/4 (1) 3/4 (1) 3/4(1) 3/4 (1) 1 (1-1/4) 1 (1-1/4) 1 (1-1/4) 1 (1-1/4)

7

Page 8

INSTALLATION

1. Permanently installed compressors must be located in a clean, well ventilated dry room so compressor receives

adequate supply of fresh, clean, cool and dry air. It is recommended that a compressor, used for painting, be located

in a separate room from that area wherein body sanding and painting is done. Abrasive particles or paint, found to

have clogged the air intake filters and intake valves, shall automatically void warranty.

2. Compressors should never be located so close to a wall or other obstruction that flow of air through the fan bladed

flywheel, which cools the compressor, is impeded. Permanently mounted units should have flywheel at least 12" from

wall.

3. Place stationary compressors on firm level ground or flooring. Permanent installa-tions require bolting to floor. Bolt

holes in tank or base feet are provided. Before bolting or lagging down, shim compressor level. Avoid putting a

stress on a tank foot by pulling it down to floor. This will only result in abnormal vibration, and possible cracking of

Air Receiver. It is recommended that optional vibro-isolator pads be installed on unit. Tanks bolted directly to a

concrete floor without padding will not be warranted against cracking. Champion vibro-isolators must be used for

extended warranty to apply to ASME air receivers.

4. If installing a bare pump or a base mounted unit, make certain the system has adequate pressure limiting controls.

Controls could be a pressure switch for start/stop operation or a pilot valve for continuous operation. If a pilot valve

is used, the compressor must be equipped with head unloaders. Control air must be piped from the air receiver to

the pilot valve.

DANGER

Do not install isolating valves betweencompressor outlet and air receiver. This will cause excessive

pressure if valve is closed, and cause injury and equipment damage.

WARNING

Always use an air pressure regulating device at the point of use. Failure to do so can result in injury or

equipment damage.

CAUTION

● Do not install in an area where ambient temperature is below 32 degrees F or above 100 degrees F.

● Do not install unit in an area where air is dirty and/or chemical laden.

● Unit is not to be installed outdoors.

ELECTRICAL POWER SUPPLY

It is essential that the power supply and the supply wiring are adequately sized and that the voltage correspond to

the unit specifications.

All wiring should be performed by a licensed electrician or electrical contractor. Wiring must meet applicable codes

for area of installation.

Recommended electrical wiring specifi-cations are listed in "Specifications" section.

If ordered with a mounted starter, compressor unit is pre-wired at factory. It is necessary only to bring lines

fromproperly sized disconnect switch to magnetic starter mounted on compressor, and attach to terminals as

indicated on schematic diagram located inside cover of control. Be sure that power circuit and voltage correspond

with the specifications

.

CAUTION

Wiring must be such that when viewing compressor from opposite shaft end, rotation of shaft is clockwise

as shown by arrow on guard. Wrong direction rotation for any length of time will result in damage to

compressor.

8

Page 9

INSTALLATION (CONT’D)

GROUNDING INSTRUCTIONS

This product should be connected to a grounded, metallic, permanent wiring system, or an equipment-

grounded terminal or lead on the product.

AIR LINE PIPING

Connection to air system should be of the same size, or larger, than discharge pipe out of unit. See

recommended piping sizes listed in "Specifications" section. A union connection to the unit and water drop leg

is recommended. Install a flexible connector between the discharge of the unit and the plant air piping. Plant air

piping should be periodically inspected for leaks using a soap and water solution for detection on all pipe joints.

Air leaks waste energy and are expensive.

PREPARATION FOR INITIAL START-UP AND OPERATION

1. Pull main disconnect switch to unit and tag out to assure that no power is coming into the unit. Connect

power leads to starter.

WARNING

Do not attempt to operate compressor on voltage other than that specified on order or on compressor

motor.

2. Check compressor oil level. Add oil as required. See section on "Oil Specifications".

3. Inspect unit for any visible signs of damage that would have occurred in shipment or during installation.

4. Activate main disconnect switch.

5. "Jog" motor and check for proper rotation by direction of arrow. If rotation is wrong, reverse input

connections on the magnetic starter.

6. Close receiver outlet hand valve and start unit.

7. With receiver hand valve closed, let machine pump up to operating pressure. At this stage the automatic

controls will take over. Check for proper cycling operation.

8. Check for proper operation of any options, e.g. LOSC or head unloaders with pilot valve. Refer to individual

option instruction sheet.

9. When the initial run period has shown no operating problems, shut unit down and recheck oil level.

10. Open receiver hand valve. The air compressor unit is now ready for use.

9

Page 10

GUIDE TO MAINTENANCE

To obtain reliable and satisfactory service, this unit requires a consistent preventive maintenance schedule.

Maintenance schedule pages are included in the back of this manual to aid in keeping the proper records.

WARNING

Before performing any maintenance function, switch main disconnect switch to "off" position to assure

no power is entering unit. "Lock Out" or "Tag Out" all sources of power. Be sure all air pressure in unit

is relieved. Failure to do this may result in injury or equipment damage.

DAILY MAINTENANCE

1. Check oil level of both compressor and engine if so equipped. Add quality lubricating oil as required. See

Section on "Oil Specifications".

2. Drain moisture from tank by opening tank drain valve located in bottom of tank. Do not open drain valve

if tank pressure exceeds 25 PSIG.

3. Turn off compressor at the end of each day's operation. Turn off power supply at wall switch.

WEEKLY MAINTENANCE

1. Clean dust and foreign matter from cylinder head, motor, fan blade, air lines, intercooler and tank.

2. Remove and clean intake air filters.

WARNING

Do not exceed 15 PSIG nozzle pressure when cleaning element parts with compressed air. Do not direct

compressed air against human skin. Serious injury could result. Never wash elements in fuel oil,

gasoline or flammable solvent.

3. Check V-belts for tightness. The V-belts must be tight enough to transmit the necessary power to the

compressor. Adjust the V-belts as follows:

Remove bolts and guard to access compressor drive.

Loosen mounting hardware which secures motor to base. Slide motor within slots of baseplate to desired

position.

Apply pressure with finger to one belt at midpoint span. Tension is correct if top of belt aligns with bottom

of adjacent belt. Make further adjustments if necessary.

Check the alignment of pulleys. Adjust if necessary.

Tighten mounting hardware to secure motor on base.

Re-install guard and secure with bolts.

WARNING

Never operate unit without belt guard in place. Removal will expose rotating parts which can cause

injury or equipment damage.

10

Page 11

EVERY 90 DAYS OR 500 HOURS MAINTENANCE

1. Change crankcase oil. Use type and grade oil as specified in the section on "Compressor Oil

Specifications".

2. Check entire system for air leakage around fittings, connections, and gaskets, using soap solution and

brush.

3. Tighten nuts and capscrews as required.

4. Check and clean compressor valves, replace springs, discs and seats when worn or damaged.

CAUTION

Valves must be reinstalled in original position. Valve gaskets should be replaced each time valves are

serviced.

5. Pull ring on all pressure relief valves to assure proper operation.

GENERAL MAINTENANCE NOTES

PRESSURE RELIEF VALVE: The pressure relief valve is an automatic pop valve. Each valve is properly

adjusted for the maximum pressure permitted by tank specifications and working pressure of the unit on

which it is installed. If it should pop, it will be necessary to drain all the air out of the tank in order to reseat

properly. Do not readjust.

TANK DRAIN VALVE: Drain valve is located at bottom of tank. Open drain valve daily to drain condensation.

Do not open drain valve if tank pressure exceeds 25 PSIG. The automatic tank drain equipped

compressor requires draining manually once a week.

PRESSURE SWITCH: The pressure switch is automatic and will start compressor at low pressure and stop

when the maximum pressure is reached. It is adjusted to start and stop compressor at the proper pressure

for the unit on which it is installed. Do not readjust.

BELTS: Drive belts must be kept tight enough to prevent slipping. If belts slip or squeak, see V-belt

maintenance in preceding section.

CAUTION

If belts are too tight, overload will be put on motor and motor bearings.

COMPRESSOR VALVES: If compressor fails to pump air or seems slow in filling up tank, disconnect unit from

power source and remove valves and clean thoroughly, using compressed air and a soft wire brush. After

cleaning exceptional care must be taken that all parts are replaced in exactly the same position and all

joints must be tight or the compressor will not function properly. When all valves are replaced and

connections tight, close hand valve at tank outlet for final test. Valve gaskets should be replaced each time

valves are removed from pump.

11

Page 12

GENERAL MAINTENANCE NOTES (CONT'D)

CENTRIFUGAL UNLOADER AND UNLOADER PRESSURE RELEASE VALVE:

The centrifugal unloader Is operated by two governor weights. It is totally enclosed and lubricated from

the crankcase of the compressor. When compressor starts, the governor weights automatically open

compressing the main spring, allowing the unloader pressure release valve to close. When the compressor

stops, the main spring returns the governor weights to normal position opening the unloader pressure

release valve and unloading the compressor. This prevents overloading the motor when starting. If air

continues to escape through the governor or unloader pressure release valve while operating, this is an

indication that the unloader pressure release valve is not closing tightly and may be held open by foreign

substance which has lodged on the seat. In order to correct this, remove the governor release valve cap,

giving access to unloader pressure release valve spring and ball. Clean thoroughly and return parts in the

same order in which they were removed. Loose drive belts can also cause unloader to leak by preventing

the compressor from reaching proper speed. (See "BELTS" above.)

CHECK VALVE:

The check valve closes when the compressor stops operating, preventing air from flowing out of the tank

through the pressure release valve. After the compressor stops operating, if air continues to escape

through the release valve, it is an indication that the check valve is leaking. This can be corrected by

removing check valve and cleaning disc and seat. If check valve is worn badly, replace same.

WARNING

Before removing check valve be sure all air pressure in unit is relieved and power is disconnected. Failure

to do so may result in injury or equipment damage.

THE INTERSTAGE PRESSURE RELIEF VALVE is provided to protect against interstage over pressure and is

factory set for maximum pressure of 75 PSIG.

DO NOT RESET

If the pressure relief valve pops, it indicates trouble. Shut down the unit immediately and determine and

correct the malfunction. Inspect the head valves. Serious damage can result if not corrected and can lead

to

complete destruction of the unit. Tampering with the interstage pressure relief valve, or plugging the

opening destroys the protection provided and voids all warranty.

LUBRICATION OF COMPRESSOR:

Fill crankcase to proper level as indicated by oil sight gauge. Keep crankcase filled as required by usage.

12

Page 13

COMPRESSOR OIL SPECIFICATIONS

1. AIR COMPRESSOR

Compressors shipped on units are factory filled with ISO 100 reciprocating compressor oil. Compressors

shipped as basic (pump only) do not have any oil in the crankcase. Be sure to add oil to these pumps prior

to start-up.

It is recommended that this compressor be maintained using the ISO 100 recip oil for ambient

temperatures above 32 degrees F. This is a 30 weight, non-detergent industrial oil with rust and oxidation

inhibitors specially formulated for reciprocating compressors. Contact your distributor for information and

purchase of this oil. For temperatures below 32 degrees F, use an ISO 68 compressor oil. A separate

list of acceptable oils can be obtained from the distributor's Service Department.

NOTES:

1. Do not mix oil types, weights, or brands. Consult factory for the use of synthetic lubricants.

2. For the first 100 hours of compressor operation, a careful and regular check of the oil level should

be made. Maintain oil level at the full line.

2. ELECTRIC MOTORS

Electric motors are equipped with sealed-for-life bearings and require no additional lubrication.

13

Page 14

TROUBLE SHOOTING CHART FOR COMPRESSOR

Always disconnect unit from power supply and relieve all pressure from air tank before

performing any maintenance. Failure to do so may result in equipment damage or injury.

ALock Out" or "Tag Out" all power sources.

WARNING

Never operate unit without belt guard in place.

Never use gasoline or flammable solvent on or around compressor unit. Explosion may

result.

SERVICE PROBLEM

A Motor will not Start

B Motor is Noisy or Overheats

C Motor Stops

D Compressor Runs Hot

E Compressor Pumps Too Slowly

F Compressor Won't Shut Off

G Noisy Check Valve

H Excessive Belt Wear

I Abnormal Pressure Fluctuation

J Air Escapes From Unloader Muffler When Running

K Air Escapes From Unloader Muffler When Stopped

L Interstage Pressure Relief Valve Pops Off Continuously

M Compressor Cycles (runs) too Often

N Starter Kicks Out

POSSIBLE CAUSE OF PROBLEM

1 Main Switch and Fuses Open 1

2 Magnetic Starter Heater Coils Open 2

3 Magnetic Starter Tripped 3

4 Points in Pressure Switch Defective 4

5 Diaphragm in Pressure Switch Bad 5

6 Low Voltage 6

7 Motor Lubrication Inadequate 7

8 Excess Water in Air Receiver 8

9 Dirty Aftercooler; Cylinder and Intercooler 9

10 "V" Belts Improperly Tensioned 10

11 Improper Flywheel Rotation 11

12 Compressor Pump Valves Defective 12

13 Pipe Line Leaks 13

14 Misadjustment of Pilot Valve - This is for

optional parts.

15 Pilot Valve Leaks - This is for optional parts. 15

NMLKJIHGF EDCB A

14

16 Centrifugal Unloader Valve is Leaking 16

17 Check Valve is Leaking 17

18 Check Valve is Worn 18

19 Check Valve or Line to Tank is Plugged 19

20 Misaligned Belts 20

21 Dirty Intake Filter 21

22 Low Crankcase Oil Level 22

FOR EXPLANATION SEE NEXT PAGE

NMLKJIHGF EDCB A

14

Page 15

EXPLANATION OF TROUBLE SHOOTING GUIDE

1/2. Check all fuses and switches on lines to motor to be sure it is receiving power. Check for loose or

faulty wires.

3. A magnetic starter embodies a reset button which may be used to place the motor back in service

after some unusual power conditions.

4/5. A pressure switch uses a diaphragm to open and close a set of points. Points may become pitted

or dirty through use. Clean by "touching up" with sandpaper or replace. See instructions in pressure

switch cover.

WARNING

Disconnect unit from power source before checking pressure switch.

6. Low voltage is prime cause of motor trouble. Ask you power company to test for low voltage.

7. Most electric motors are of the sealed bearing type. Check motor manufacturer's recommendation.

8. Water in the form of vapor is compressed along with incoming air and condenses in tank. Tank must

be drained daily so that full storage capacity of tank may be used. To drain, relieve tank pressure,

open valve at bottom of horizontal or vertical tank. If compressor is equipped with automatic tank

drain, drain manually once a week.

WARNING

Do not open drain valve if tank pressure exceeds 25 PSIG.

9. The fins on the cylinder and tubing should be free of dirt which acts as an insulation. This is easily

done by periodically blowing them clean or through the use of a wire brush.

9. "V” belts must be tight enough to transmit the necessary power to the compressor. If too tight they

will overload the motor. If, by pushing down on one belt, its top lines up with the bottom of the belt

next to it, the tension is correct. Should it be necessary to change the tension, slide the engine or

motor in slots provided in tank baseplate to desired position.

WARNING

Disconnect unit from power source before checking or adjusting belts. Always reinstall belt guard

after adjusting belts.

11. The fan blade flywheel must rotate in the direction shown by the arrows.

12. Compressor valves may become fouled by carbon or other foreign matter. To service, remove

manifold and extract valve. Remove screw in center of valve and clean all parts. Seat and disc may

be lapped in on fine sandpaper if badly carboned. If a smooth finish cannot be obtained, replace with

new parts. Reassemble and install, taking caution that all parts are returned to their original position

with screw head up.

13. All air lines from compressor to tank and from tank to air operated devices should be tight. A soap

solution will show bubbles when put on a leaky joint. At 175 PSIG a 1/32" hole will allow almost 3

cubic feet per minute of air to escape.

14. Pilot Valve adjustment is found on page 23.

15. Check pilot valve for loose connections.

16. The centrifugal unloader valve may become fouled by foreign matter. To clean, unscrew hex cap on

end of unloader, remove spring and ball, to remove ball, you may need to "rock" flywheel. Clean or

replace if necessary.

15

Page 16

EXPLANATION OF TROUBLE SHOOTING GUIDE (CONT'D.)

17/18. Before servicing check valve, be sure pressure in tank is ZERO. Replace check valve.

19. Badly worn compressors which are pumping oil may deposit carbon within after-cooler tube and check

valve, restricting flow of air and possibly plugging these parts completely. These parts should be

cleaned or replaced.

WARNING

Disconnect unit from power source and relieve tank pressure before servicing these components.

20. Motor pulley and flywheel must be in line to prevent wear on sides of belts. If misaligned, disconnect

unit from power source and move pulley in or out by loosening set screw on key and tapping pulley

in appropriate direction.

WARNING

Disconnect power source before adjusting pulley.

21. Intake filter should be cleaned periodically to allow unrestricted flow of entering air. To service filter,

remove wing nut, metal cover and filter element. Element may be blown clean with an air nozzle if

moderately dusty. Heavily fouled elements should be replaced. Never clean element with fuel oil,

gasoline or flammable solvent.

22. Cool running and long life can be assured by careful attention to crankcase oil. Check frequently and

change as indicated on compressor data sheet.

_____________________________________________________________________________

PARTS LIST

MAJOR COMPRESSOR UNIT COMPONENTS

Parts common to all models except base mounted :

7) Pressure Switch - M1227

8) Pressure Relief Valve - M2843

9) Pressure Gauge - M519C

10) Drain Valve - M2684

11) Check Valve - P05822A

12) Tank Drain - Z1542 - Horizontal Tank

- Z1541 - Vertical Tank

13) Belt Guard - Z-307

(All units except those equipped with air-cooled

aftercoolers)

Additional parts for Duplex Unit (Not Shown)

• Alternator Class 47, 208V, 3 Phase; P10043A

230V, 3 Phase; P05814A

460V, 3 Phase; P05815A

• Magnetic Starter (2), Specify Voltage & Phase

16

Page 17

PARTS LIST CONT'D

HORIZONTAL TANK MODEL ILLUSTRATED (See Preceding Page)

12 34 5

Model

Number Pump

HR1-3

HR1-6

HR1-8

HR2-3

HR2-6

HR2-8

HR3-6

HR3-8

HR3-12

HR5-6

HR5-8

HR5-12

HR5D-12

VR1-6

VR1-8

VR2-6

VR2-8

R-10D

R-10D

R-10D

R-10D

R-10D

R-10D

R-15B

R-15B

R-15B

R-15B

R-15B

R-15B

R-15B (2)

R-10D

R-10D

R-10D

R-10D

Elec.

Motor Air Tank

12 HP

12 HP

12 HP

2 HP

2 HP

2 HP

3 HP

3 HP

3 HP

5 HP

5 HP

5 HP

5 HP (2)

1-1/2HP

1-1/2HP

2 HP

2 HP

P04390D

P01136D

P01164D

P04390D

P01136D

P01164D

P01136D

P01164D

P01596D

P01136D

P01164D

P01596D

P02080D

P01161D

P01217D

P01161D

P01217D

Motor Pulley

(Not Shown)

Hand

Valve 1 Phase 3 Phase V-Belts

M3590

M3590

M3590

M3590

M3590

M3590

M3590

M3590

M2686

M3590

M3590

M2686

M2686

M3590

M3590

M3590

M3590

P09315B

P09315B

P09315B

M7009D

M7009D

M7009D

M4309D

M4309D

M4309D

M7009D

M7009D

M7009D

M7009D

P09315B

P09315B

M7009D

M7009D

P09315B

P09315B

P09315B

P11703A Pulley

P09423A Bushing

P11703A Pulley

P09423A Bushing

P11703A Pulley

P09423A Bushing

M4309D

M4309D

M4309D

M7009D

M7009D

M7009D

M7009D

P09315B

P09315B

P11703A Pulley

P09423A Bushing

P11703A Pulley

P09423A Bushing

6

4L-650

4L-650

4L-650

4L-680

4L-680

4L-680

5L-650

5L-650

5L-650

5L-680

5L-680

5L-680

5L-680 (4)

4L-650

4L-650

4L-680

4L-680

VR3-6

VR3-8

VR3-12

VR5-6

VR5-8

VR5-12

BR-1

BR-2

BR-3

BR-5

HR7F-8

HR7F-12

HR7DF-25

VR7F-8

VR7F-12

BRF-7

R-15B

R-15B

R-15B

R-15B

R-15B

R-15B

R-10D

R-10D

R-15B

R-15B

R-15B

R-15B

R-15B(2)

R-15B

R-15B

R-15B

* "BR" units are not supplied with tanks. Baseplate P09195C is common to all models.

3 HP

3 HP

3 HP

5 HP

5 HP

5 HP

12 HP

2 HP

3 HP

5 HP

7-1/2 HP

7-1/2 HP

7-1/2 HP (2)

7-1/2 HP

7-1/2 HP

7-1/2 HP

P01161D

P01217D

P02212D

P01161D

P01217D

P02212D

*

*

*

*

PO1164D

P01596D

P05763D

P01217D

P02212D

*

M3590

M3590

M2686

M3590

M3590

M2686

*

*

*

*

M3590

M2686

M2686

M3590

M2686

*

M4309D

M4309D

M4309D

M7009D

M7009D

M7009D

P09315B

M7009D

M4309D

M7009D

P07981A - Pulley

P05607A - Bushing

P07981A - Pulley

P05607A - Bushing

P07981A - Pulley

P05607A - Bushing

P07981A - Pulley

P05607A - Bushing

P07981A - Pulley

P05607A - Bushing

P07981A - Pulley

P05607A - Bushing

M4309D

M4309D

M4309D

M7009D

M7009D

M7009D

P09315B

P11703A Pulley

P09423A Bushing

M4309D

M7009D

P07981A - Pulley

P05607A - Bushing

P07981A - Pulley

P05607A - Bushing

P07981A - Pulley

P05607A - Bushing

P07981A - Pulley

P05607A - Bushing

P07981A - Pulley

P05607A - Bushing

P07981A - Pulley

P05607A - Bushing

5L-650

5L-650

5L-680

5L-680

5L-680

4L-650

5L-680

5L-650

5L-680

5L-680

B68

B68

B68 (4)

B68

B68

B68

17

Page 18

R-10D AND R-15B

FLYWHEEL, CYLINDER, CRANKCASE & UNLOADER ASSEMBLY

ITEM PART NO. NAME REQ. ITEM PART NO. NAME REQ.

1

4

1

1

1

2

2

1

1

1

1

1

1

1

6

1

1

1

1

1

1

10

11

12

13

14

15

16

17

18

1

2

3

4

5

6

7

8

9

P12237D

M2345

NR29A

NR7A

U8

M738

M465

M1820

M2326

RE714

M459

M492

M461

Z130

SE1430

SE1430A

SE1430B

SE1430C

Cylinder

Screw, Hex Head Cap

Gasket, Cylinder

Flange

Flywheel

Key

Screw, Hex Head Cap

Nut, Hex

Crankcase

Pipe Plug

Gauge, Oil Level

Pipe Plug (Oil Fill)

Pipe, Oil Drain

Cap, Oil Drain

Gasket Set, Gov.

Housing

Gasket, Gov. Housing

(.030" Thick)

Gasket, Gov. Housing

(.005" Thick)

Gasket, Gov. Housing

(.010" Thick)

Gasket, Gov. Housing

(.015" Thick)

1

6

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

NR80A

M2343

SE1489

NR104

SE583B

SE582

SE 592A

M466

M2345

M912A

SE590

SE587

RE10100A

Z4593

M3473

Z12414A

SE586B

P07841A

SE591

NR101

Z764

Gov. Housing

Screw, Hex Head Cap

Gasket, Gov Housing Cover

Plate, Gov Baffle

Spindle, Gov. Wt.

Gov. Wt.

Pin. Gov. Wt.

Washer, Spring Lock

Screw, Hex Head Cap

Washer, Flat

Spring, Gov. Main

Sleeve, Spring

Cover, Gov. Housing

MUFFLER ASSY, UNLOADER

Screw, Hex Head Machine

RELEASE VALVE ASSY. KIT

Plunger, Release Valve

Ball Release Valve

Spring, Release Valve

Body, Release Valve

GASKET SET, COMPLETE PUMP

18

Page 19

R-10D AND R-15B

CRANKSHAFT, PISTONS, CONNECTING ROD ASS'YS.

ITEM PART

NO.

1

2

3

4

5

6

7

R105

R155

ZNR16

OSN4

Z750

Z752

NSS

M1583

R1024

R1524

NAME REQ ITEM PART

Crankshaft (R-10D only)

Crankshaft (R-15B only)

ASSY; Main Bearing

Oil Seal

KIT, CONNECTING ROD ASSY.

(Items 5,6,7 & 8)

R-15B, Low Pressure & High Pressure

R-10D, Low Pressure

KIT, CONNECTING ROD ASSY.

(Items 5,6,7 & 8)

R-10D, High Pressure (side only)

Connecting Rod

Bolt, Connecting Rod

Dipper, Oil (R-10D only)

Dipper, Oil (R-15B only)

NOTE: NSS= Not Sold Separately

NAME REQ

NO.

1

1

2

1

2

1

1

4

2

2

8

9

10

11

12

13

14

R1037

ZR154

ZP2709C

R1021

R10102

Z797

Z798

Z9100

Z9101

Z799

Bearing, Piston Pin

Piston, Low Pressure w/Pin

Piston, High Pressure w/Pin

Pin, Piston

Ring, Piston Pin Retaining

RING SET, HIGH PRESSURE PISTON

RING SET, LOW PRESSURE PISTON

KIT, HIGH PRESSURE PISTON ASSY.

(Items 10, 11, 12 & 13)

KIT, LOW PRESSURE PISTON ASSY.

(Items 9, 11, 12 & 14)

KIT, COMPLETE RING SET

(Items 13 & 14)

2

1

1

2

4

1

1

1

1

1

19

Page 20

R-10D AND R15B

VALVES & FILTER, MANIFOLD ASS'YS.

ITEM PART NO. NAME REQ. ITEM PART NO. NAME REQ.

1

1

1

1

1

1

1

1

1

8

3

3

1

1

1

1

1

1

1

1

10

11

12

13

14

15

16

17

18

19

20

21

22

1

2

3

4

5

6

7

8

9

P04544A

RE1471A

RE1470

RE1458

M2098

P04134A

M3220

P04135A

M2099

RE1059

RE1061

M2097

P04135A

M3220

P09191A

P09172B

RE1062

RE760

M2101

P09170A

M3220

P04137A

Screw, Hex Head Machine

Seat, Intake Valve

Disc, Valve

Spring, Valve

Cage, Intake Valve

Gasket, Valve

Screw, Hex Head Machine

Gasket, Valve

Cage, Exhaust Valve

Spring, Exhaust Valve

Disc, Valve

Seat, Exhaust Valve

Gasket, Valve

Screw, Hex Head Machine

Gasket, Valve

Seat, Intake Valve

Disc, Valve

Spring, Valve

Cage, Intake Valve

Gasket, Valve

Screw, Hex Head Machine

Gasket, Valve

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

M2100

RE760

RE1062

RE757A

P04136

RE102E

P12303B

P09669C

P12302B

P05005A

SE542

SE541

P04999A

P05050A

P03592A

P09704A

Z812

Z813

Z5117

Z115

Z5155

Z5156

Cage, Exhaust Valve

Spring, Valve

Disc, Valve

Seat, Exhaust Valve

Gasket, Valve

Manifold, LP Exhaust

Manifold, HP Exhaust

Manifold, LP Intake

Manifold, HP Intake

Screw, Hex Head Cap (All Manifolds)

Ferrule

Nut, compression

Intake Filter

Filter Element

Interstage Pressure Relief Valve

Pressure Relief Valve

VALVE ASSY, LP INTAKE*

VALVE ASSY, LP EXHAUST

VALVE ASSY, HP INTAKE*

VALVE ASSY, HP EXHAUST

COMPLETE VALVE SET w/GASKETS*

COMPLETE VALVE GASKET SET

* See page 18, Unloader Kit, for intake valves for head unloader pumps. Use Z6795 - Complete Valve Set for Head Unloader Pumps.

20

Page 21

R10D AND R-15B

INTERCOOLER & TUBING

ITEM PART NO. NAME REQ.

1

2

3

4

5

6

7

M2863

ZSB250A

M2864

ZUB375

M2864

M2868

Z9140

Compression Fitting

Tube, Unloading w/Fittings

Compression Fitting

Breather Tube w/Fittings

Compression Fitting

Compression Fitting

Intercooler w/Fittings

1

1

1

1

1

1

1

21

Page 22

CONSTANT SPEED HEAD UNLOADER KIT Z9144

For Air Compressor Pump Models R-10D and R-15B

NOTE: This is optional equipment and may not be included on your unit.

The purpose of constant speed unloading is to provide a means of stopping or starting the compression of air by the compressor

without stopping or starting the electric motor or gasoline engine after each cycle.

To accomplish this, an air pilot valve is used to replace the pressure switch used for stop-start operation. The pilot valve senses

storage tank pressure, and when the pressure is raised to a predetermined setting, this air is released to an intake valve hold-open

mechanism. The compressor stops compressing air and runs free until the pilot valve senses that the pressure in the tank has

dropped to the predetermined setting. At this time the air is released from the intake valve hold-open mechanism, and the

compressor starts compressing air again.

The parts called out below replace or are substituted for those found in the regular parts list.

Z9144 - CAPTURED UNLOADER VALVE

R-10D, R-15B

TYPICAL MINIFOLD ASSEMBLY

FOR HEAD UNLOADERS

REF. NO. TOTAL

REQ'D

1

2

3

4

5

6

7

8

9

1

1

1

1

1

1

1

1

1

1

REF. NO. TOTAL

REQ

-

1

2

3

4

5

6

7

8

9

10

11

REF.

NO.

1

1

1

1

1

1

1

1

1

1

1

1

TOTAL

REQ'D

PART NO. LOW PRESSURE

Z6312

P09670C

P02306B

P09923A

P02547A

Z4877

P09085A

P09084A

P09086A

P09083A

LP Intake Manifold Group (includes 1,2,3,4)

LP Intake Manifold

Cylinder

Unloader Piston

O-Ring

LP Valve Assembly

(includes 6,7,8,9)

Unloader Finger

Unloader Spring

Locknut

Guide Stem

PART NO. HIGH PRESSURE

Z9143 HP

Z9143

P12304B

P02306B

P09923A

P02547A

Z6308

P09297A

P01882A

P09086A

P09296A

P00746A

P09171A

HP Intake Manifold Goup

(Includes items 1,2,3,4,10)

HP Intake Manifold

Cylinder

Unloader Piston

O-Ring

HP Valve Assembly

(includes 6,7,8,9)

Unloader Finger

Unloader Spring

Locknut

Guide System

Cylinder Gasket

Valve Gasket

(not included)

PART NO. HIGH & LOW PRESSURE

12

13

14

15

16

17

18

19

20

1

1

1

1

1

1

1

1

1

M2879

Z9172

M2868

P12323A

M2853

M2881

M3465

M807

M2868

Compression Fitting

Manifold Tube

Compression Fitting

Actuating Tube

Pilot Valve

Compression Fitting

Screw, Hex Head Cap

Mounting bracket

Compression Fitting

22

Page 23

OPERATION AND ADJUSTMENT OF PILOT VALVES

B980-B

(Ref. Drawing)

PILOT VALVES

ASSEMBLY

PART NO.

M2855

M2854

M2853

PRESSURE RANGE,

PSIG

75 - 95

90-120

140 - 170

The Pilot Valve is designed to act as an automatic "on" and "off" air switch. When in the "on" position it allows air to flow

from the tank through the valve to some device such as a compressor suction unloader, thus actuating it. In the "off"

position this valve stops the flow of air through the valve and releases the pressure in the line to the device.

The Pilot Valve works as follows: Tank air pressure acts on the bottom of the valve. When pressure is great enough

to overcome spring force holding valve down on lower seat, it lifts off seat and allows air to flow around valve and out

through side opening in Pilot Valve. When valve lifts off lower seat it moves up and seats on upper seat where it is held

by tank pressure. When pressure in tank and on valve drops, spring forces valve back down on lower seat. Air in line

to device being actuated can then escape through upper seat and out vent hole. The pressure at which the Pilot Valve

is "on" or "off" is controlled by the spring which has been installed at the factory. A small adjustment can be made in

the field by changing the spring force by compressing the spring more or less with the adjusting screw provided on the

Pilot Valve.

COMPRESSOR PILOT VALVEPRESSURE ADJUSTMENT

Proceed with the following instructions while compressor is running:

1. Loosen locknut (4) and back off several turns. Do not turn differential adjuster (3).

2. Check reading on the tank pressure gauge. Set the compressor maximum pressure at 170 psig. Turn threaded

cap clockwise to increase pressure or counterclockwise to decrease pressure.

3. After pressure is set, tighten locknut (4). Be careful not to move the threaded cap (1).

COMPRESSOR PILOT VALVE DIFFERENTIAL PRESSURE ADJUSTMENT

Proceed with the following instructions while compressor is running:

1. Loosen locknut (2) and back off several turns.

2. Check reading on the tank pressure gauge. Set the pressure to 30 psig differential (unload at 170 psig, reload

at 140 psig). Turn nut (3) clockwise to increase differential pressure or counter-clockwise to decrease differential

pressure.

3. After pressure is set, tighten locknut (2). Be careful not to move nut (3).

23

Page 24

UNIT HAZARD DECAL LISTING

ITEM DESCRIPTION PART NO.

A

B

C

D

E

F

G

H

I

J

K

L

M

N

O

P

Q

R

S

T

Retain Labels

DANGER - Breathing Air

DANGER - Drain Tank Daily

DANGER - Valve Maintenance

DANGER - High Voltage

DANGER - Auto Start

WARNING - Pressure/Safety Valve

WARNING - Rotating Parts

WARNING - Hot Surfaces

WARNING - Tank Pressure

CAUTION - Clean Filters

Unit Location

Rotation Direction

Pressure Setting: Master

Pressure Setting: 140-175 psig

Maintenance Instructions

*Dual Control Valve

*Low Oil Safety Control

*Automatic Tank Drain

Service Information

P09879A

P09376B

P09430B

P09750B

P04934A

P09384B

P09752B

P09373B

P09758A

P04983A

M1736

P04518A

M422

P09388A

P04988A

P09755B

P05381A

P02134A

M653

P04995A

U

V

W

1

2

3

4

5

6

*For Optional Parts

UNIT HAZARD TAG LISTING

IMPORTANT - Electrical Specs

DANGER - Valve Instructions

WARNING - Read Owners Guide

PUMP HAZARD DECAL & TAG LISTING

DECAL - Retain Labels

DECAL - DANGER- Adequate Filtering

DECAL - Rotation Direction

DECAL - Service Filter

TAG - DANGER - Valve Instructions

TAG - WARNING - Read Owners Guide

P05257A

P09852A

P04996A

PO9879A

PO8586A

M442

M1736

PO9852A

PO4996A

24

Page 25

A

B

C

UNIT HAZARD DECALS & TAGS

G

D

E

H

I

J

F

25

Page 26

K

L

M

N

S

T

U

O

P

Q

140-175 PSIG

V

R

W

26

Page 27

PUMP HAZARD DECALS & TAGS

1

2

3

4

5

6

27

Page 28

RECORD OF MAINTENANCE SERVICE

DAILY

● CHECK OIL LEVEL

● DRAIN MOISTURE FROM TANK

WEEKLY

● CLEAN FILTER

● CLEAN COMPRESSOR

● CHECK V-BELTS

MONTHLY

● INSPECT AIR SYSTEM

EVERY 3 MONTHS

● CHANGE OIL

● INSPECT VALVE ASSEMBLIES

● TIGHTEN ALL FASTENERS

● TEST PRESSURE RELIEF VALVE

28

Page 29

RECORD OF MAINTENANCE SERVICE

DAILY

● CHECK OIL LEVEL

● DRAIN MOISTURE FROM TANK

WEEKLY

● CLEAN FILTER

● CLEAN COMPRESSOR

● CHECK V-BELTS

MONTHLY

● INSPECT AIR SYSTEM

EVERY 3 MONTHS

● CHANGE OIL

● INSPECT VALVE ASSEMBLIES

● TIGHTEN ALL FASTENERS

● TEST PRESSURE RELIEF VALVE

29

Page 30

RECORD OF MAINTENANCE SERVICE

DAILY

● CHECK OIL LEVEL

● DRAIN MOISTURE FROM TANK

WEEKLY

● CLEAN FILTER

● CLEAN COMPRESSOR

● CHECK V-BELTS

MONTHLY

● INSPECT AIR SYSTEM

EVERY 3 MONTHS

● CHANGE OIL

● INSPECT VALVE ASSEMBLIES

● TIGHTEN ALL FASTENERS

● TEST PRESSURE RELIEF VALVE

30

Page 31

Page 32

FOR PARTS: REFER TO PARTS DEPOT LIST

ACCOMPANYING THIS MANUAL.

www.championpneumatic.com

Champion

1301 North Euclid Avenue

Princeton, Illinois 61356 USA

Phone (815) 875-3321

Fax (815) 872-0421

Copyright 8 2000 Gardner Denver, Inc.

Printed in U.S.A.

E-mail: champion@championpneumatic.com

Plants in Princeton, IL, and Manteca, CA

Due to Champion=s continuing product development program,

specifications and materials are subject to change without notice or obligation

31

Loading...

Loading...