Champion PHX-250, PHX-320, PHX-700, PHX-700-AL, PHX-900 Installation Manual

...

Installation, Operation and Cleaning Manual

Phoenix Recycling Machine

Models:

PHX-250

PHX-320

PHX-700

PHX-700-AL

PHX-900

PHX-900-AL

PHX-2400-AL

PHX-2400-AL

PHX-250 Shown

3765 Champion Blvd.,

Winston-Salem, NC 27105

(336) 661-1556 Fax: (336) 661-1660

Toll-free: (800) 858-4477

Issue Date: 11.24.15

Manual P/N 115521 rev. A

2674 N. Service Road, Jordan Station

Ontario, Canada L0R 1S0

(905) 562-4195 Fax: (905) 562-4618

Toll-free: (800) 263-5798

Printed in the USA

Champion, an Ali Group Company

For future reference, record your service information in the box below.

Service Agent __________________________________ Tel:______________________

Parts Distributor _________________________________ Tel:______________________

National Service Department

In Canada: In the USA:

Toll-free: (800) 263-5798 Toll-free: (800) 858-4477

Tel: (905) 562-4195 Tel: (336) 661-1556

Fax: (905) 562-4618 Fax: (336) 661-1660

email: service@moyerdiebellimited.com email: service@championindustries.com

ATTENTION:

The model no., serial no., voltage, Hz

and phase are needed to identify your

machine and to answer questions.

The machine data plate is located on

the right side of the machine.

Please have this information ready

if you call for service assistance.

COPYRIGHT © 2015 All rights reserved Printed in the USA

Online Product Registration

REGISTER YOUR PRODUCT ONLINE

Make sure you are connected to the internet then enter an address below:

In the U.S.A.

http://www.championindustries.com/register

In Canada

http://www.championindustries.com/canada/register

Fax Product Registration

PRODUCT REGISTRATION

BY FA X

COMPLETE THIS FORM AND FAX TO:

(336) 661-1660 in the USA

1-(800) 204-0109 in Canada

PRODUCT REGISTRATION CARD

Model

Date of Installation:

Company Name:

Address:

Telephone #: ( ) ---

Contact:

Installation Company:

Address:

Serial #

(Street) Province Postal Code

Telephone #:

Contact:

FAILURE TO REGISTER YOUR PRODUCT MAY VOID YOUR WARRANTY

IMPORTANT IMPORTANT

1

2

1. Safety Instruction

Part 1: GUIDELINES FOR SAFE OPERATION

To ensure safe operation, please carefully read the following warnings and cautions prior to using

any of the organic waste dehydrating systems.

HIGH VOLTAGE! – DO NOT ATTEMPT ANY REPAIRS OR MAINTENANCE BEFORE

TURNING OFF THE MAIN POWER!

ALWAYS TURN THE MAIN POWER OFF AND LET THE MOTOR AND ALL MOVING

PARTS COOL DOWN AND COME TO A COMPLETE STANDSTILL PRIOR TO ATTEMPTING

ANY MAINTENANCE, ADJUSTMENT OR CLEANING OF THE MACHINE

EFORE STARTING THE OPERATION OF THE MACHINE, MAKE SURE THAT ALL

B

PERSONNEL ARE CLEAR OF ALL MOVING PARTS OF THE MACHINE

AMILIARIZE YOURSELF WITH THE LOCATION AND OPERATION OF ALL START / STOP

F

BUTTONS AND SAFETY SWITCHES OF THE MACHINE

DURI

NG PERIODIC MAINTENANCE, CHECK ALL SAFETY SWITCHES TO ENSURE

THAT THEY ARE WORKING PROPERLY

DO

NOT REMOVE OR ALTER GUARDS

NOT REMOVE OR ALTER SAFETY LABELS. IF SAFETY LABELS ARE DESTROYED,

DO

MISSING OR ILLEGIBLE, PLEASE CONTACT GREENSMITH ENVIRONMENTAL FOR

REPLACEMENTS

NOT OBSTRUCT ELECTRICAL SWITCHES OR PUSH BUTTONS

DO

K

EEP THE AREA OF OPERATION CLEAN AND DRY TO ENSURE THE SAFETY OF THOSE

WORKING IN THE AREA.

DO NOT USE SOLVENTS TO CLEAN THE UNIT. CLEANING SHOULD BE DONE WITH A

O NOT ATTEMPT TO ALTER OR “JUMP START” THE MACHINE IN ANY WAY

D

DAMP SPONGE OR TOWEL (WATER ONLY!!) ON A DAILY BASIS.

3

2. Food Waste Consideration

3. Use of the Machine

It is rec ommende d that overs ized vegetables are chopped before they are put into the machine.

For optimal results, a pulper can be used to process food waste BEFORE being put into the Eco

Smart unit.

Do NOT insert large animal bones, which may impede the operation of the crankshaft & paddle

arms and cause malfunction.

The processing time may be prolonged if food waste contains excessive water.

The standard capacity of the machine is 2/3 height of the drum. Overloading food waste impedes

the progress of the crankshaft paddles and may cause a malfunction of the equipment.

It is recommended that food waste containing a lot of starch (rice, noodle, etc…) be mixed with

vegetables for an optimal processing time. Food waste containing starch should not exceed

30% of the food waste component since it may stick to the agitator if not diluted with additional

food types.

It is recommended that food waste fill at least 1/2 of the drum’s capacity in order to maximize

the effective utility of the machine.

Do NOT put OIL into the machine. Oil cannot be dried and leaves a greasy residue.

DO NOT open the input lid while operation. Also, DO NOT touch the inside of the drum, which

is extremely hot.

DO NOT disassemble the lid or seals of either the Input or the Output door. Altering these

components allows processing vapors to escape during the operation.

Low level noises are commonplace during operation. Should there be excessive noise, turn the

equipment off, allow cooling and removing any obstructions to the equipment’s operation.

After the cycle is complete, DO NOT discharge dried waste for 30 minutes or until the machine

has fully cooled down.

During discharge, it is recommended that some dried waste (approx. 1 inch) be left at the bottom

of the drum accelerate the drying process of the next cycle.

Regularly clean the outlet door.

As you load food waste into the drum, be careful to ensure that food waste does not enter the

blower.

4

1. Food Waste Dehydrating Machine

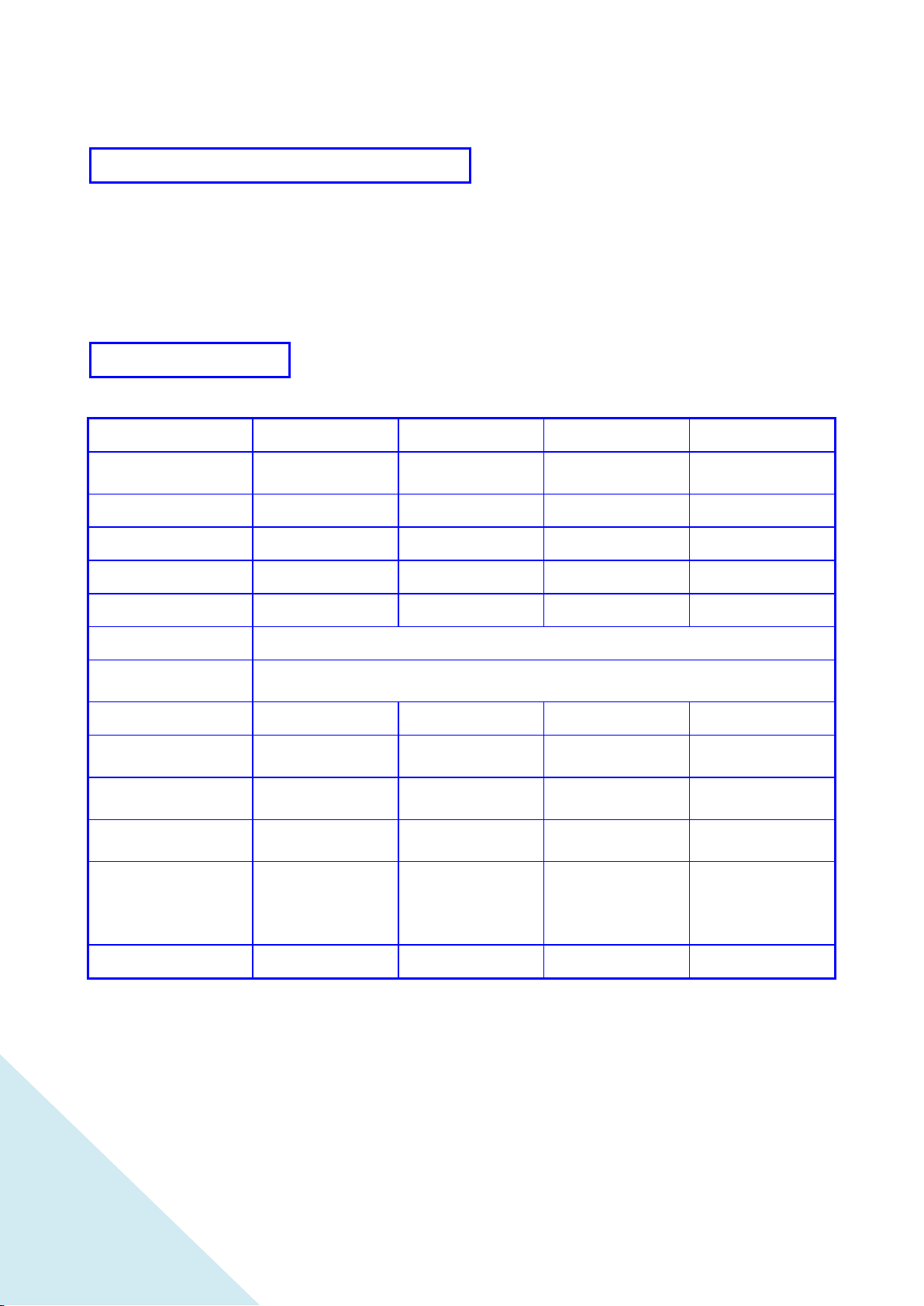

2. Specifications

Part 2: OVERVIEW OF THE DEHYDRATING SYSTEM·

Model

HGF-250ML

HGF-320ML

HGF-700ML

HGF-900ML

Cycle Times

Full Load (Note 1)

1 Cycle

12-16hrs

1 Cycle

14-19hrs

1 Cycle

15-19-hrs

1 Cycle

17-22hrs

Capacity (Note 2)

75kg/160lbs

150kg/320lbs

300kg/700lbs

400kg/900lbs

Width

1004mm

1204mm

1300mm

1500mm

Length

1104mm

1304mm

1500mm

1910mm

Height

1000mm

1200mm

1280mm

1600mm

Reduction Rate

80% - 90%

Electricity

(Note 4)

220V/380V/440V, 50/60Hz, 1Phase/3Phase

Total Watt

Power Usage

(Note 3)

3.2kw/hour

4.72kw/hour

6.86kw/hour

11.9kw/hour

Power Rated

(Note 3)

4.7kw/

8.47Amp

8.1kw/

10.9Amp

15.5kw/

15.52Amp

20.1kw/

27.61Amp

Max. Ampere

(Note 3)

Av. Amp

(Note 3)

Net Weight

400Kg

550Kg

800Kg

1,300Kg

The Food Waste Dehydrating Machine is an automated, on-site drying syst em that speeds up

the drying process and turns food waste into a rich soil amendment. The drying time will vary

depending upon type of input, but the entire cycle finishes within 24 hours. The machine is

constructed of durable stainless steel with an easily accessible control panel equipped with

locking mechanism.

4,680 Watt 8,066 Watt 15,402 Watt 20,052 Watt

12.30Amp 21.20Amp 40.42Amp 52.68Amp

(70%) during

Operation

8.6Amp 14.8Amp 28.29Amp 36.87Amp

*** NOTE:

1. Cycle times will vary from load to load depending on the moisture content of the food waste.

2. Weight capacity is subject to variations in organic waste content.

3. The calculation above is for 220V, and the calculation may differ depending on local electricity.

4. Ampere Calculation = Total Watt ÷ Voltage ÷ 1.73

5

3. Advantages of Drying Decomposition System

Within 24 hours per cycle.

All kinds of organic food waste can be processed: It does not require assortment of food

waste before putting it into the drum.

Using circulat ing air s ystem to smell free: Circulating air system prevents smell leaking and

pollutants while operation.

Automated operation system: Entire process is co mpletely carried out automaticall y by one

touch button.

Economical use: As the machine uses only electricity, it is very economical.

Compact size with superior performance: Compact size suits in to any surroundings while

giving out superior performances.

6

4. Components of the Machine

Emergency Stop LED Lamp

Control

Switch Caster

Discharge Door Electrical Panel

Power Connection

Cleaning Tap

Condensed Water

Discharge

7

5. Outlook of the Machine

Whole View 1

Whole View 2

Front

Side

Back

Impeller

Loading...

Loading...