Page 1

Project

Item No.

Quantity

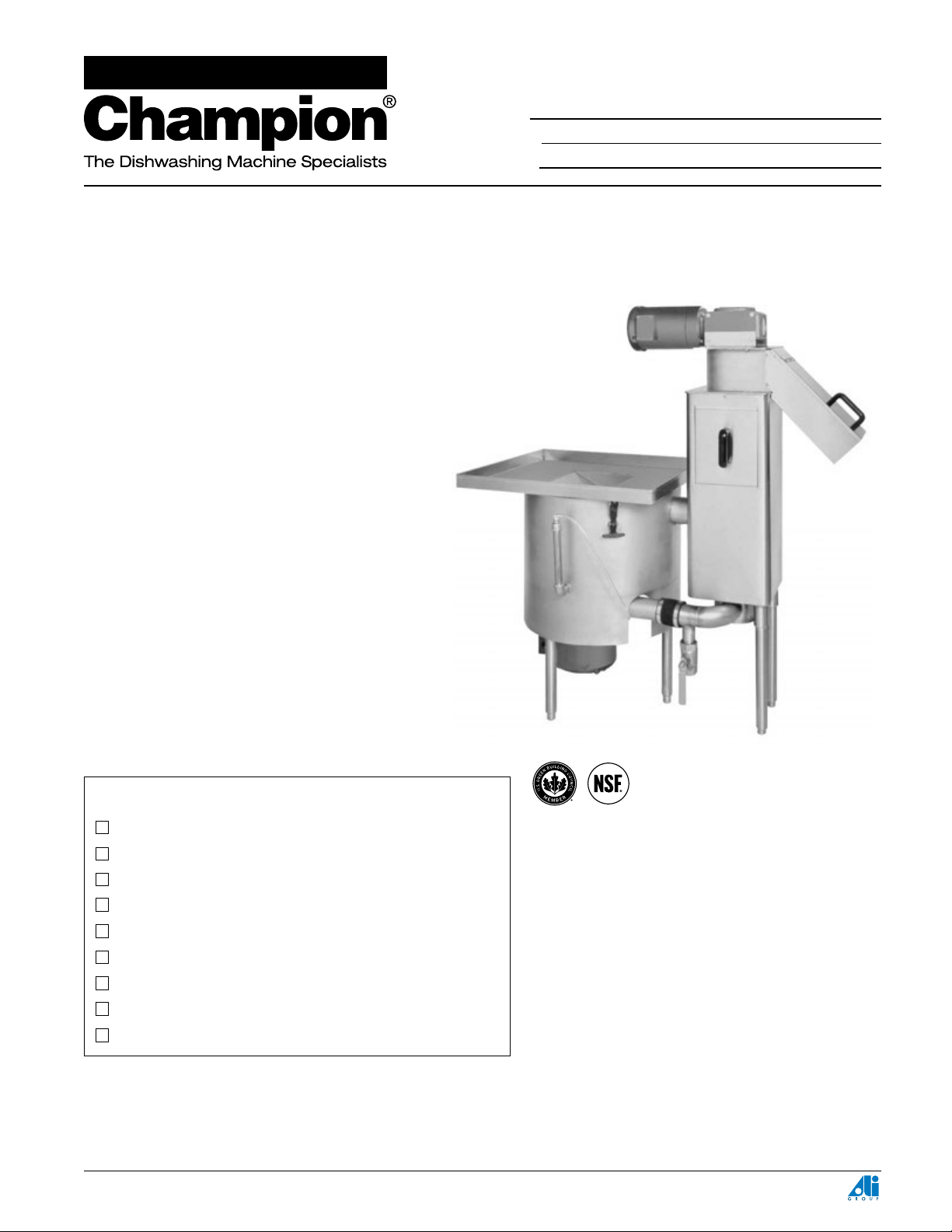

P730 PULPER

STANDARD FEATURES

• Flatware saver

• Flushing valve to pump-motor seal

• Flexible draw latches on feed tray assembly

• Remote mounted control box and

circuit breaker

• Removable, gasketless water extractor door

• Start/stop switch mounted on extractor

• Stainless steel tubular bulletfeet legs

• 1-1/2" total adjustment

• Total stainless steel construction

• Water level control

P730

7.5 Hp - 30” Pulper

Waste Handling System

OPTIONS & ACCESSORIES

Anti-vibration feet for quieter operation

Recirculating pump

Multiple trough configurations

Extractor flushing system

Spray Reel - 30ft. unmounted

Automatic shutdown timer

Deodorizer injector

Remote mounted start-stop station (unmounted)

Multiple trough configurations (9" & 12")

Champion Industries, Inc.

2674 N. Service Road

Jordan Station, Ontario, Canada L0R 1S0

Tel: 800/263-5798 Fax: 905/562-4618

(1M) 7/14 Printed in U.S.A.

CH062

SPECIFIER STATEMENT

Specified unit will be Champion model P730 Pulper

waste handling system.

Features 7.5 Hp grinding motor with 30" diameter

slurry chamber, flatware saver, four stationary blocks

with four cutting surfaces each, two tool steel rotating

shearing blades, large water extractor chamber with

removable gasketless door and external drain handle.

Constructed of Type 304 SST.

1 year parts and labor warranty.

Champion Industries, Inc.

3765 Champion Blvd., Winston-Salem, NC 27105

Tel: 336/661-1556 Fax: 336/661-1979

www.championindustries.com

Page 2

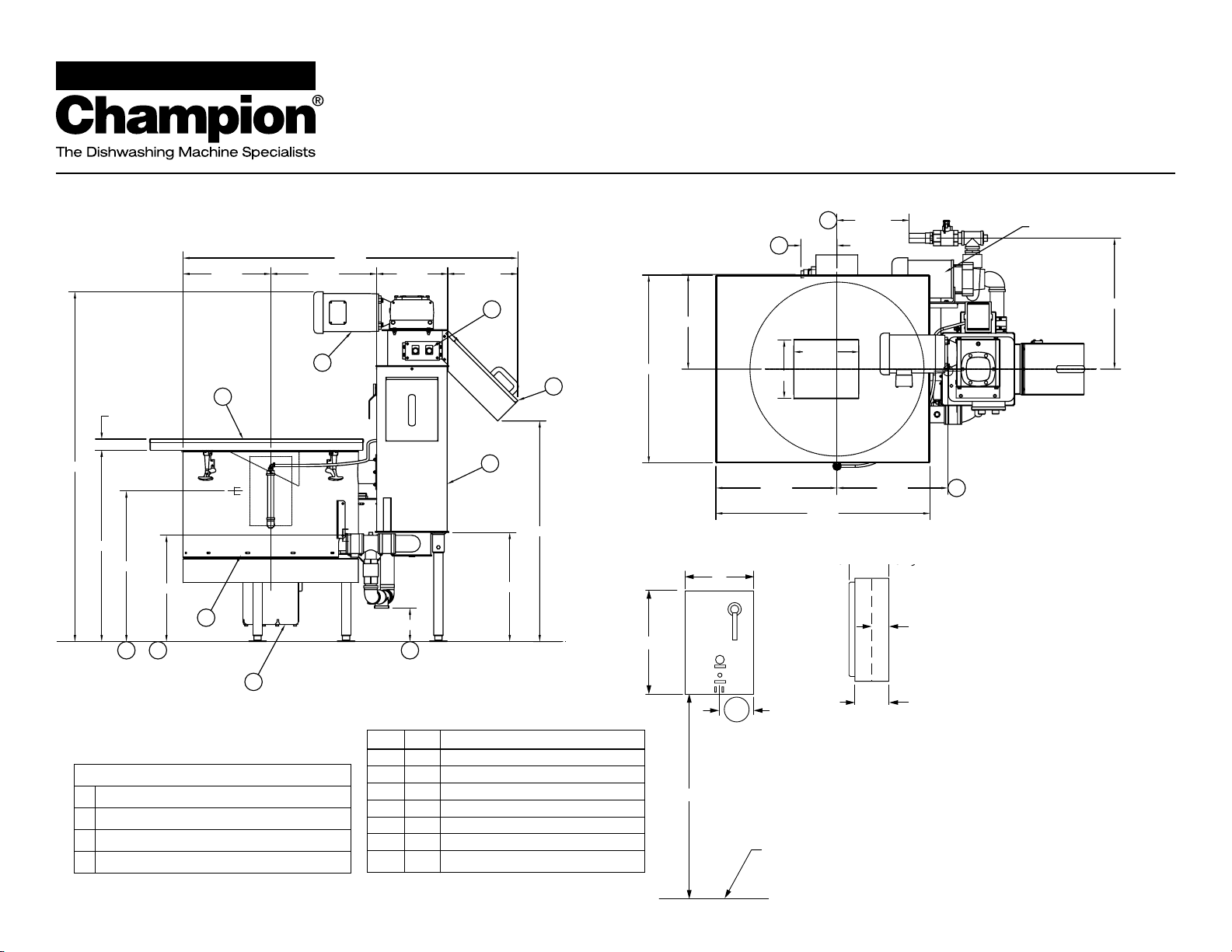

16-5/16"

20-7/8"

36-7/8"

32-3/8"

22-9/16"

10"

3

19-1/8"

11-3/16"

3HP

12-7/16"

6-1/4"

2HP

4

2

2HP Recirculating Pump

P730 PULPER

FLOORLINE

8"1

9"

16"

Control Cabinet

Front View

7-1/2 HP

3

2HP

P5-24 with Optional Recirculating Pump

Mounted on Front of Water Extractor

Front View

Top View

2HP

A

B

F

C

G

E

D

2

4

3

4

18-1/2"

39"

17"

33"

63"

2"

26"

5"

12-3/16"

12-1/8"

13-5/8"

16-3/4"

54-11/16"

17-1/2"

29"

14-1/2"

10"

6"

21-1/2"

15-1/2"

16"

Remote Mounted

Control Cabinet

Front View

7-1/2 HP

3

2HP

P5-24 with Optional Recirculating Pump

Mounted on Front of Water Extractor

Front View

A

B

F

C

G

E

D

2

4

18-1/2"

39"

17"

33"

63"

2"

26"

5"

12-3/16"

12-1/8"

13-5/8"

16-3/4"

54-11/16"

7.5 Hp - 30" Pulper

Waste Handling System

60-5/16"

Utilities

1 Electrical See Chart.

2 Optional Recirculation Pump

3 Drain 1-1/2" NPT.

4 Cold Water 1/2" NPT cold water connection.

P7-30 with Optional Recirculating Pump Mounted on

Rear of Water Extractor

57-3/4"

12-1/4" 12-1/16"18-1/4"15-1/8"

3HP

C

5-3/4"

3

Item Qty. Description

G 1 Start/Stop Station

A 1 Slurry Chamber 30" dia.

B 1 Motor – Main Drive 7.5 Hp

C 1 Water Extractor Drive Motor 3 Hp

D 1 Water Extractor

E 1 Discharge Chute

F 1 Scrapping Tray

1-15/16"

33"

25-15/16"

2

Front View

18-5/16"

4

F

A

B

7.5HP

G

D

18-13/16"

E

38-1/16"

32-3/8"

16-5/16"

20-7/8"

Remote Mounted

Control Cabinet

8"1

Front View

48"

FLOORLINE

6-1/4"

4

11-3/16"

10"

36-7/8"

12-7/16"

2

2HP Recirculating Pump

2HP

22-9/16"

3HP

19-1/8"

4"

3

Top View

Side View

8"

Warning: Plumbing and electrical connections

should be made by qualified personnel who will

observe all the applicable plumbing, sanitary and

safety codes and the National Electrical Codes.

Note: Water Hammer Arrestor (meeting ASSE-1010

standard or equivalent) to be supplied (by others) in

common water supply line at service connection.

Page 3

10"

19-1/8"

16-5/16"

32-3/8"

19-11/16"

2HP

12-7/16"

2

11-3/16"

3HP

22-9/16"

2HP Recirculating Pump

20-7/8"

36-7/8"

6-1/4"

4

3

P730 PULPER

F

1-15/16"

60-5/16"

33"

25-15/16"

23-3/4"

7.5HP

A

4

2

B

Minimum

Supply Ckt.

Elec. Specs Rated Amps

Conductor

Ampacity

208/60/3 40 50 50

230/60/3 36 50 50

460/60/3 18 25 25

57-3/4"

18-1/4"15 1/8"

3HP

C

2HP

Maximum

Overcurrent

Protective

Device

P7-30 with Optional Recirculating Pump Mounted on

12-1/4" 12-1/16"

5-3/4"

3

P7-30 w/2 Hp Recirculating PumpP7-30 w/out Recirculating Pump

Elec. Specs Rated Amps

208/60/3 45 60 60

230/60/3 42 60 60

460/60/3 21 30 30

Front of Water Extractor

G

D

38-1/16"

18-13/16"

Front View

E

Minimum

Supply Ckt.

Conductor

Ampacity

16-5/16"

32-3/8"

Maximum

Overcurrent

Protective

Device

7.5 Hp - 30" Pulper

Waste Handling System

Volume crated: 99 cu. ft.

Shipping weight crated: 1000 lbs.

Dimensions shown in inches

3

Top View

19-11/16"

22-9/16"

20-7/8"

4

10"

36-7/8"

6-1/4"

11-3/16"

19-1/8"

3HP

2HP

12-7/16"

2

2HP Recirculating Pump

SPECIFICATIONS

Capacities Input

Waste (approx. lbs. per hr.) 1000

Initial Fill Volume 24 U.S. Gal.

Motor horsepower

Pulper 7.5

Water Extractor 3

Slurry Chamber

Tank (in. dia.) 30

Cutting Disk (in. dia.) 12

Connections

Fresh water (in.) 1/2

Drain (in.) 1-1/2

Due to an ongoing value analysis program at Champion, specifications contained in this catalog are subject to change without notice.

Champion Industries, Inc., 3765 Champion Blvd., Winston-Salem, NC 27105 •336/661-1556 • Fax: 336/661-1979 • www.championindustries.com

Page 4

Front View

Front View

P730

7.5 Hp - 30" Pulper

Waste Handling System

Sample Trough Configurations and Feed Methods

For additional trough configurations and feed methods, contact Factory

Trough Feed

Trough Feed #1

30-1/4"

#1

Trough Feed

Trough Feed #2

#2

Trough Feed

Trough Feed #4

#4

Trough Feed

Trough Feed #5

#5

Feed Tray with Hood Under Table Feed Tray

Feed Tray w/Hood

Top View

3HP

Under Table Feed Tray

26-1/4"

Trough Feed

Trough Feed #6

3HP

Trough Feed

Trough Feed #3

#3

#6

Top ViewTop View

Top View

12"

33"

13-1/8"

26-1/4"

7.5 HP

3HP

18-1/2"

33"

32-1/8"

47-1/4"

30-1/4"

3"

12"

7.5 HP

15-1/8"

3HP

18-1/2"

Front View Front View

Due to an ongoing value analysis program at Champion, specifications contained in this catalog are subject to change without notice.

Champion Industries, Inc., 3765 Champion Blvd., Winston-Salem, NC 27105 • 336/661-1556 • Fax: 336/661-1979 • www.championindustries.com

‘USGBC’ and related logo is a trademark owned by the U.S. Green Building Council and is used by permission.

Loading...

Loading...