Page 1

Tall Hood-type

LISTED

Dishwashers

Installation, Operation, Cleaning and Maintenance Manual

M1.5 Series

Models:

DH5000T, MDHHD

Hot water sanitizing machine w/fresh

water rinse and built-in stainless steel

electric booster

Options:

Ventless Heat Recovery

Issue Date: 2.24.16

Manual P/N 115744 rev. B

For machines beginning with S/N D150712934 and above

3765 Champion Boulevard

Winston-Salem, NC 27105

(336) 661-1556 Fax: (336) 661-1660

Toll-free: 1 (800) 858-4477

2674 N. Service Road, Jordan Station

Ontario, Canada L0R 1S0

(905) 562-4195 Fax: (905) 562-4618

Toll-free: 1( 800) 263-5798

Printed in the USA

Page 2

National Service Department

In Canada: In the USA:

Toll-free: (800) 263-5798 Toll-free: (800) 858-4477

Tel: (905) 562-4195 Tel: (336) 661-1556

Fax: (905) 562-4618 Fax: (336) 661-1660

email: service@moyerdiebellimited.com email: service@championindustries.com

ATTENTION

The model no., serial no., voltage, Hz

and phase are needed to identify your

machine and to answer questions.

The machine data plate

is located on the right front corner

of the lower panel

Please have this information ready

if you call for service assistance.

The USGBC and the CaGBC Member Logos are trademarks owned by the U.S. Green Building Council and The Canadian Green Building Council,

respectively, and are used by permission. The logos signify only that Champion Industries, and Moyer Diebel are USGBC and a CaGBC members;

USGBC and CaGBC do not review, certify nor endorse the products or services offered by its members.

COPYRIGHT © 2016 All rights reserved Printed in the USA

Page 3

Product Registration

Three ways to

REGISTER YOUR PRODUCT and

ACTIVATE YOUR WARRANTY.

4:34 PM 44%

The QR website is an excellent resource for operators

and service agents.

• Use your mobile device to scan the QR code located on the front panel

of your machine or enter our URL http://www.champdw.us/DH5000T.

• Visit our website at www.championindustries.com and register your

product there.

• Use the fax form on the next page and fax to 1-800 661-1660.

Page 4

PRODUCT REGISTRATION

Product Registration

BY FAX

COMPLETE THIS FORM AND FAX TO:

(336) 661-1660 in the USA

1-(800) 204-0109 in Canada

PRODUCT REGISTRATION CARD

Model

Date of Installation:

Company Name:

Serial #

Address:

Telephone #: ( ) --Contact:

Installation Company:

Address:

Telephone #:

Contact:

FAILURE TO REGISTER YOUR PRODUCT MAY VOID YOUR WARRANTY

(Street) Province Postal Code

IMPORTANT IMPORTANT

Page 5

Revision History

Revision History

We reserve the right to make changes to this manual without notice and without incurring any

liability by those changes. Equipment owners may request a revised manual, at no charge, by

calling 1 (800) 858-4477 in the USA or by calling 1 (800) 263-5798 in Canada.

Revision Revised Serial Number Revision

Date Pages Effectivity Description

12.7.15 All D151012934 Released first edition

2.4.16 3 D160113175 Revised splash shield instructions

11,12,13 D160113175 Revised signal instructions

3.1.16 D160113179 Removed direct vent instructions

i

Page 6

Limited Warranty

LIMITED WARRANTY

Champion Industries and Moyer Diebel (herein referred to as "The Companies"), 3765 Champion Blvd.,

Winston-Salem, North Carolina 27105, and 2674 N. Service Road, Jordan Station, Ontario, Canada, L0R 1S0,

warrants machines, and parts, as set out below.

Warranty of Machines: The Companies warrant all new machines of its manufacture bearing the name "Champion or

Moyer Diebel" and installed within the United States and Canada to be free from defects in material and workmanship for a

period of one (1) year after the date of installation or fifteen (15) months after the date of shipment by The Companies, whichever occurs first. [See below for special provisions relating to glasswashers.] Warranty registration must be submitted to The

Companies within ten (10) days after installation either online on the Champion Industries website (http://www.championindustries.com, or the Moyer Diebel website (http://www.moyerdiebel.com in the USA or http://www.championindustries.com/

canada in Canada or by the fax form provided at the front of this manual. The Companies will not assume any responsibility

for extra costs for installation in any area where there are jurisdictional problems with local trades or unions.

If a defect in workmanship or material is found to exist within the warranty period, The Companies, at their election, will either

repair or replace the defective part or accept return of the machine for full credit; provided; however, as to glasswashers, The

Companies' obligation with respect to labor associated with any repairs shall end (a) 120 days after shipment, or (b) 90 days

after installation, whichever occurs first. In the event that The Companies elect to repair, the labor and work to be performed in

connection with the warranty shall be done during regular working hours by a Champion or Moyer Diebel authorized service

technician. Defective parts become the property of The Companies. Use of replacement parts not authorized by The Companies will relieve The Companies of all furtherliability in connection with its warranty. In no event will The Companies' warranty

obligation exceed The Companies' charge for the machine. The following are not covered by The Companies' warranty:

a. Lighting of gas pilots or burners.

b. Cleaning of gas lines.

c. Replacement of fuses or resetting of overload breakers.

d. Adjustment of thermostats.

e. Adjustment of clutches.

f. Opening or closing of utility supply valves or switching of electrical supply current.

g. Cleaning of valves, strainers, screens, nozzles, or spray pipes.

h. Performance of regular maintenance and cleaning as outlined in the operator’s guide.

i. Damages resulting from water conditions, accidents, alterations, improper use, abuse,

tampering, improper installation, or failure to follow maintenance and operation procedures.

j. Wear on Pulper cutter blocks, pulse vanes, and auger brush.

Examples of the defects not covered by warranty include, but are not limited to: (1) Damage to the exterior or

interior finish as a result of the above, (2) Use with utility service other than that designated on the rating plate,

(3) Improper connection to utility service, (4) Inadequate or excessive water pressure, (5) Corrosion from

chemicals dispensed in excess of recommended concentrations, (6) Failure of electrical components due to

connection of chemical dispensing equipment installed by others, (7) Leaks or damage resulting from such

leaks caused by the installer, including those at machine table connections or by connection of chemical

dispensing equipment installed by others, (8) Failure to comply with local building codes, (9) Damage

caused by labor dispute.

Warranty of Parts: The Companies warrant all new machine parts produced or authorized by The Companies to be free

from defects in material and workmanship for a period of 90 days from date of invoice. If any defect in material and workmanship is found to exist within the warranty period The Companies will replace the defective part without charge.

DISCLAIMER OF WARRANTIES AND LIMITATIONS OF LIABILITY. THE COMPANIES' WARRANTY IS ONLY TO THE EXTENT

REFLECTED ABOVE. THE COMPANIES' MAKE NO OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING, BUT NOT

LIMITED, TO ANY WARRANTY OF MERCHANTABILITY, OR FITNESS OF PURPOSE. THE COMPANIES SHALL NOT BE LIABLE FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES. THE REMEDIES SET OUT ABOVE ARE THE EXCLUSIVE REMEDIES FOR ANY

DEFECTS FOUND TO EXIST IN THE COMPANIES' DISHWASHING MACHINES AND THE COMPANIES' PARTS, AND ALL OTHER

REMEDIES ARE EXCLUDED, INCLUDING ANY LIABILITY FOR INCIDENTALS OR CONSEQUENTIAL DAMAGES.

The Companies do not authorize any other person, including persons who deal in Champion or Moyer Diebel dishwashing

machines to change this warranty or create any other obligation in connection with Champion or Moyer Diebel dishwashing

machines.

ii

Page 7

Table of Contents

Table of Contents

Revision History ................................................................................................................ i

Limited Warranty ............................................................................................................. ii

Safety Symbols ................................................................................................................iv

Installation ......................................................................................... 1

Receiving and Placement ............................................................................ 1

Dish Table Connections .............................................................................. 2

Converting from Standard to Corner Operation ............................................. 3

Water Connection ..................................................................................... 5

Standard Hot Water Connection ...................................................... 5

Ventless Heat Recovery (VHR) Cold Water Connection ....................... 6

Drain Connection ...................................................................................... 7

Drain Water Tempering .................................................................. 8

Electrical Connections ................................................................................ 9

Ventilation Connection .............................................................................. 11

Chemical Connections .............................................................................. 12

Operation ......................................................................................... 14

Control Panel Description.......................................................................... 14

Cycle Option .......................................................................................... 14

Set-Up .................................................................................................... 16

Loading Wares ........................................................................................ 17

Wash Cycles ........................................................................................... 18

Rinse Sentry ............................................................................................ 20

Automatic Drain Cycle ............................................................................. 21

Cleaning ............................................................................................22

Wash and Rinse Spray Arms ..................................................................... 22

Wash Tank and Scrap Screens .................................................................. 23

Exterior .................................................................................................. 23

De-lime ................................................................................................... 24

Maintenance .......................................................................................25

Maintenance Schedules ............................................................................ 25

Troubleshooting Chart .............................................................................. 26

Temperature Display Error Codes ............................................................... 27

Timing Charts and Electrical Schematic ...................................................29

Timing Charts .......................................................................................... 29

Electrical Schematic ................................................................................. 31

iii

Page 8

Safety Symbols

Safety Symbols

The following symbols are used throughout this manual to alert the reader to important information.

WARNING:

Warnning statements indicate a condition or practice that can result in personal injury

or possible death.

CAUTION:

Caution statements indicate a condition or practice that can result in damage to the

machine or associated equipment.

DO NOT:

Do not statements indicate that a condition or practice will diminish the effective

operation of the machine.

OKAY:

Okay statements indicate that a condition or practice is correct and should be

followed.

NOTE:

Note statements highlight important information necessary for the operation of the

machine.

iv

Page 9

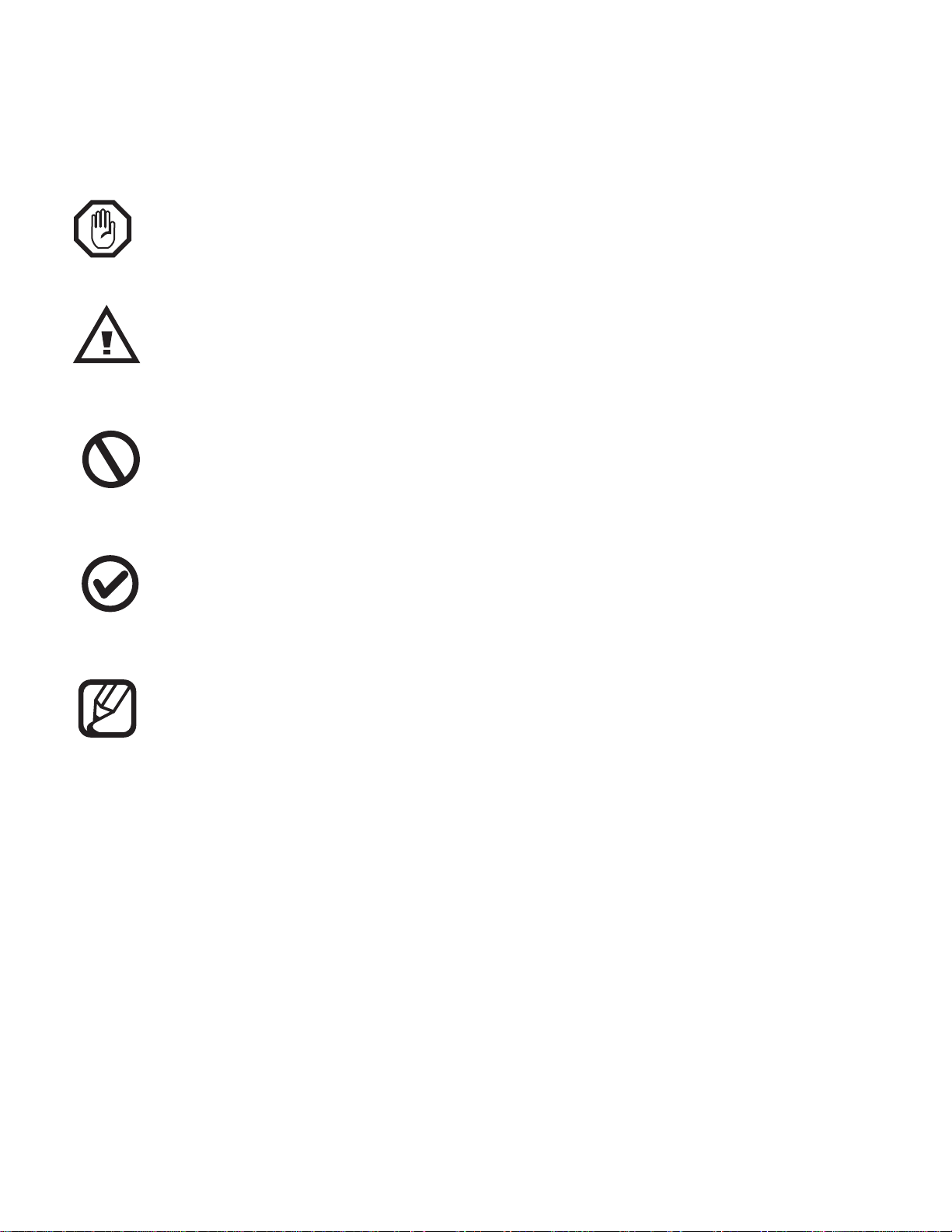

Receiving and Placement - Installation

34 "

9

/

16

Receiving

Inspect the outside of the shipping carton for signs of damage and report

any damage immediately to a supervisor.

Remove the carton, inspect the dishwasher, and check the inside of the

machine for accessories and installation parts.

Register your machine by fax or online as soon as possible.

CAUTION:

Be careful when lifting and moving the machine to avoid damage.

Placement

Compare the installation site utility connections with the dishwasher utility connections and

make sure they are the same.

For straight-through operation, provide 20" [508mm] clearance out from the front of the

machine and 20" [508mm] out from the left-side of the machine by 27" [686mm] clearance

above the floor for servicing.

For servicing a corner operation machine, provide 35" [889mm] clearance out from the

front of the machine under the right-hand tabling, 35" [889mm] out from the left-hand of the

machine under the left-hand tabling, and 35" [889mm] out from the front of the machine.

Provide 27" [686mm] clearance above the floor on all sides. The dishwasher has 4 adjustable

feet for leveling. Level the dishwasher front-to-back and side-to-side.

NOTE:

Dishwashers are shipped from the factory for straight-through operation but are field

convertible to corner operation.

[878]

27"

LEVEL ADJUSTMENT

[686]

Door

Clearance

33¾"

[857]

71½"

[1816]

Fig. 1

1

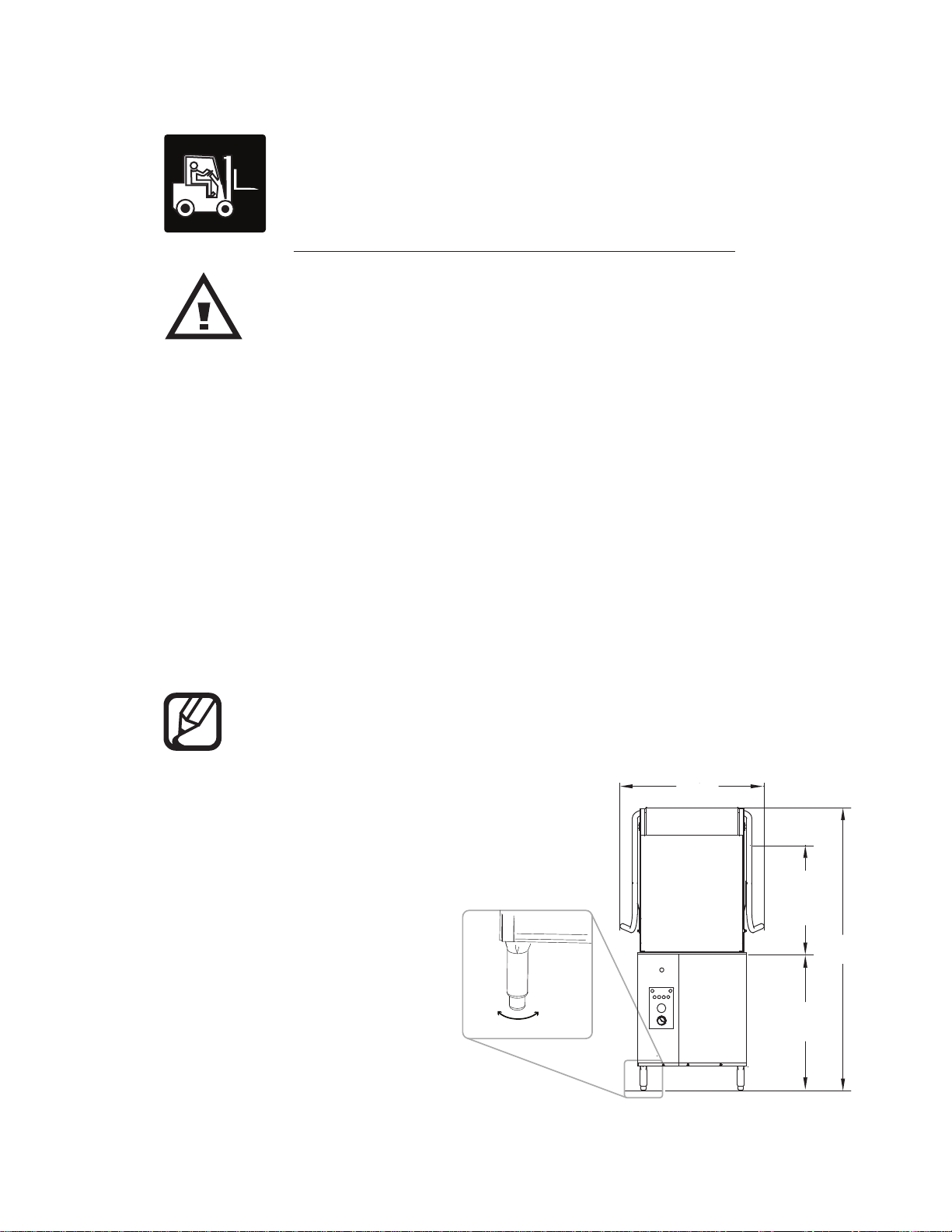

Page 10

Installation

1/2”

Dish Table Connections

CAUTION:

Dish tables should be secured to the dishwasher after it is permanently located.

Dish table Dish table

Fig. 2 - Standard straight-through operation.

Refer to Fig. 3 below.

1. Level the dishwasher and dish tables to the required height.

2. Lift up to remove the dishwasher track assembly and set aside.

3. Remove the dishwasher side panels (front and side panel for corner operation).

4. Fit the dish table flanges over the ends of the dishwasher tank and mark two hole locations.

5. Drill 1/4" holes through the table flange and the dishwasher tank.

6. Apply sealant between the table flanges and the wash tank.

7. Install stainless steel 1/4-20 fasteners to secure the tables to the tank.

8. Reinstall the panels and track assembly.

Dish table flange

Drill holes, apply sealant,

& fasten flange to wash tank

Side

panel

Inner wall of

wash tank

Fig. 3 - Dish table flange installation.

2

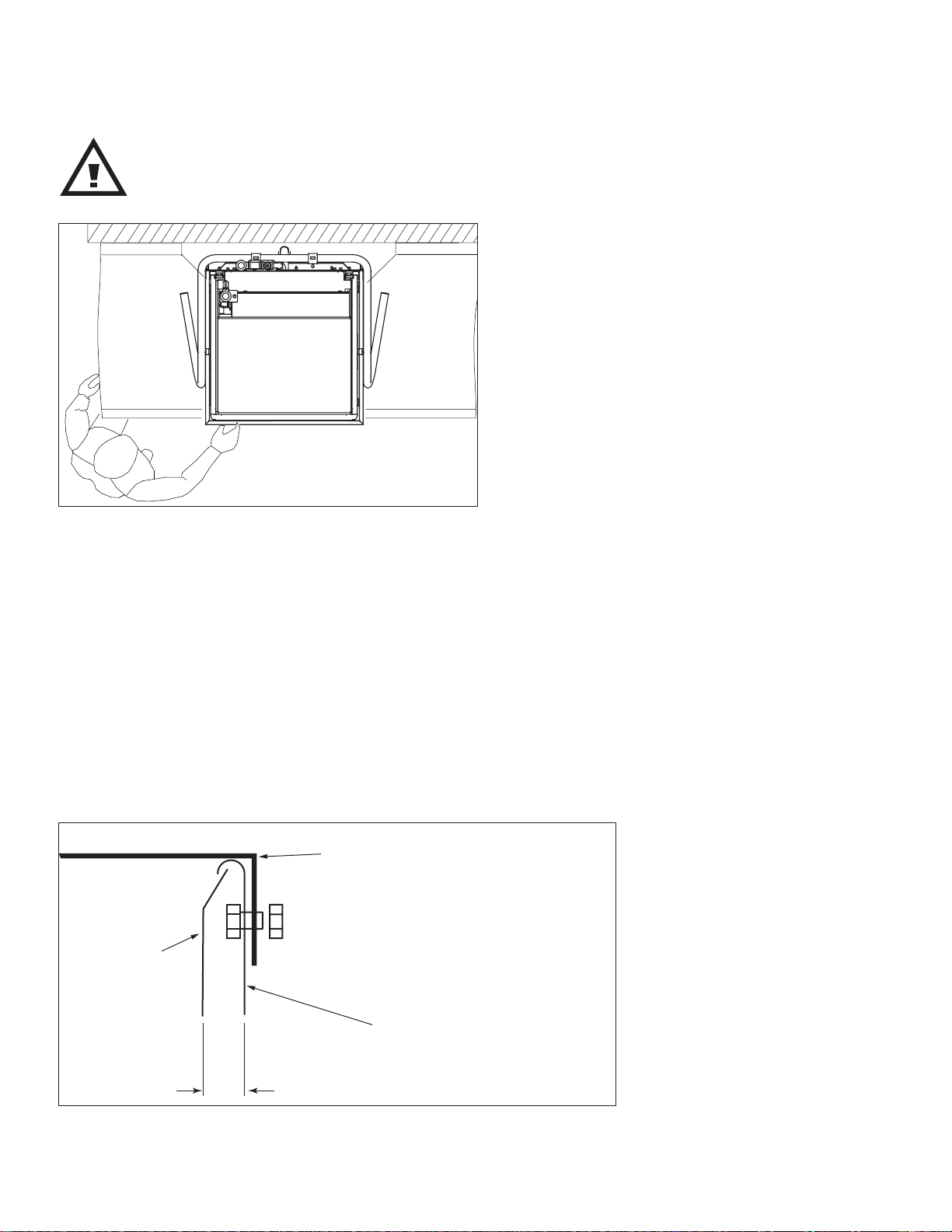

Page 11

Installation

Converting from Standard to Corner Operation

NOTE: An optional splash shield is available for corner operation but may not have

shipped with the machine unless it was specified at the time of order. Contact the

equipment dealer for instructions on how to order the splash shield.

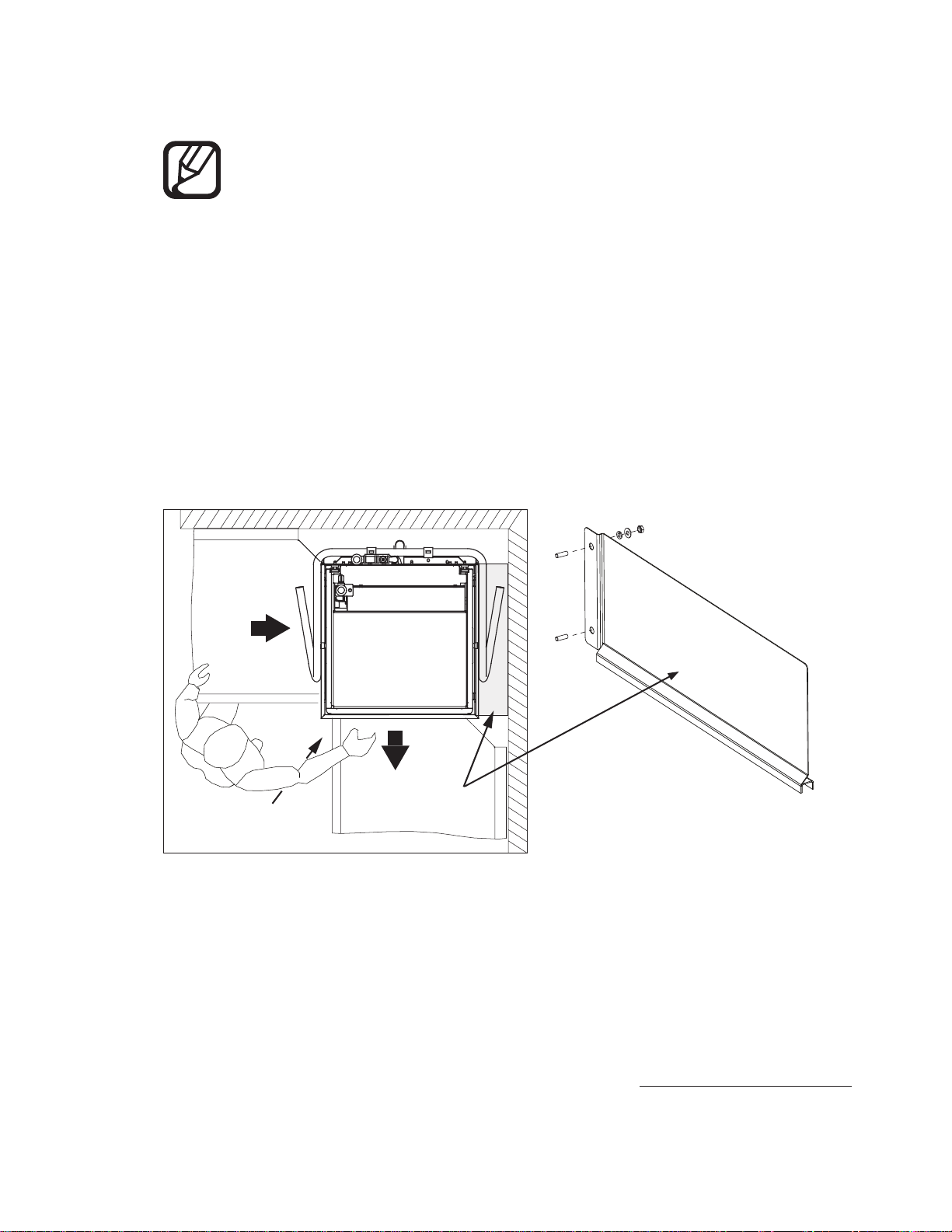

Refer to Fig. 4 and Fig. 5 below to convert the machine:

1. Place the dishwasher so that the control panel is easily accessible.

2. Install the optional splash shield before moving the machine against the wall. The splash shield

may have been installed at the factory or shipped separately. Locate the fasteners supplied at

the rear of the machine, remove and set aside. Place the channel on the bottom of the shield

over the edge of the tank. Reinstall the fasteners and make sure the hood opens smoothly.

3. Connect the utilities before placing the machine in its permanent location.

4. Follow the instructions on the previous page to install the dish tables.

Control

Panel

Fig. 4 - Corner configuration.

Splash

Shield

Fig. 5 -

The splash shield fits over the right-hand edge of

the wash tank and fastens to studs on the back

support .

Continued on the next page.

3

Page 12

Installation

Track Assembly

Guide

Converting from Standard to Corner Operation (continued)

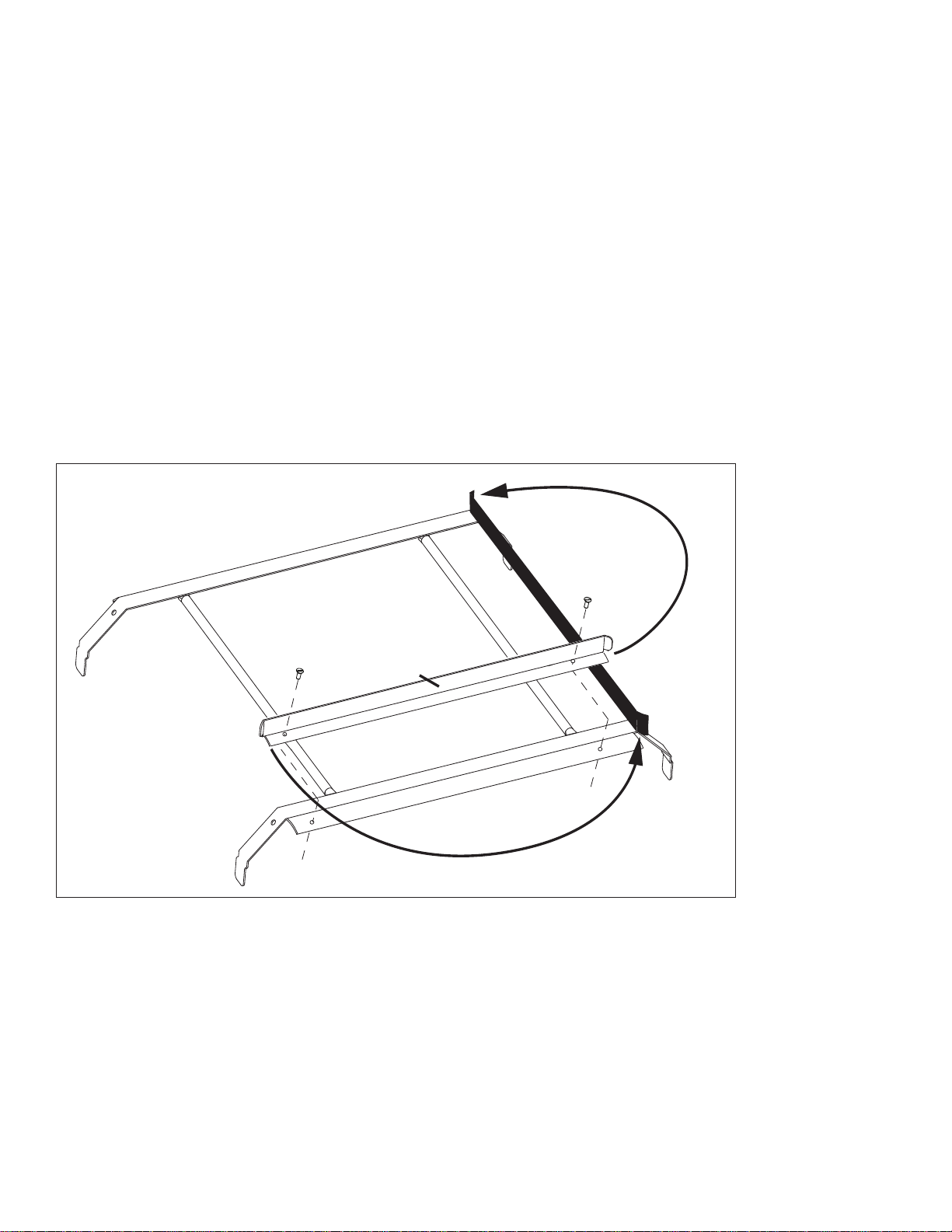

Follow the steps below to convert the track assembly for corner operation:

1. Pull the track assembly straight up and lift it out of the machine, then rotate the track

assembly 180° and reinstall it in the machine.

2. Note the guide attached to the track asssembly. Remove and save the fasteners holding the guide.

3. Position the guide on the right-hand side of the trach assembly and secure with the existing fasteners.

4. Slide a dish rack through the machine to ensure it moves freely.

5. The corner conversion is complete.

FIg. 6 - Move the rear dish rack guide to the right-hand side of the track assembly.

4

Page 13

Water Connection - Standard Model

Installation

HOT

WATER

Connect the plumbing in accordance with the specifications below.

MINIMUM ¾” NPT HOT WATER SUPPLY LINE.

CAUTION: To prevent damage to the dishwasher supply valves, the installing

plumber must thoroughly flush debris from the water supply line before connecting

it to the dishwasher. Damage caused by improper installation is not covered by the

limited warranty.

BOOSTER

RISE ºF

40º

RISE

70º

RISE

MINIMUM INCOMING

TEMPERATURE

140ºF / 60ºC

110ºF / 43ºC

WATER HARDNESS OF 3 GRAINS/US GAL - 0.83 IMP GAL - 5.3mg/L OR LESS. .

INSTALL A ¾” OR LARGER SHUT-OFF VALVE IN THE WATER SUPPLY LINE

AS CLOSE TO THE DISHWASHER AS POSSIBLE FOR SERVICING.

MINIMUM INCOMING

SUPPLY FLOWING PRESSURE

45 PSI / 310 kPa

45 PSI / 310 kPa

MINIMUM/MAXIMUM

OPERATING FLOWING PRESSURE

20/25 PSI / 138/172 kPa

20/25 PSI / 138/172 kPa

CONNECTION IS LOCATED AT REAR LEFT-SIDE OF MACHINE.

Fig. 7 - The incoming HOT water line is a 3/4" NPT connection.

Continued on the next page.

5

Page 14

Installation

Water Connection - Ventless Heat Recovery (VHR) Model

COLD

Connect the plumbing in accordance with the specifications below.

WATER

CAUTION: To prevent damage to the dishwasher supply valves, the installing

plumber must thoroughly flush debris from the water supply line before connecting

it to the dishwasher. Damage caused by improper installation is not covered by the

limited warranty.

BOOSTER

RISE ºF

40-70º

RISE

MINIMUM/MAXIMUM INCOMING

TEMPERATURE

55-75ºF / 13-24ºC

WATER HARDNESS OF 3 GRAINS/US GAL - 0.83 IMP GAL - 5.3mg/L OR LESS. .

INSTALL A ¾” OR LARGER SHUT-OFF VALVE IN THE WATER SUPPLY LINE

AS CLOSE TO THE DISHWASHER AS POSSIBLE FOR SERVICING.

MINIMUM ¾” NPT COLD WATER SUPPLY LINE.

MINIMUM INCOMING

SUPPLY FLOWING PRESSURE

45 PSI / 310 kPa

MINIMUM/MAXIMUM

OPERATING FLOWING PRESSURE

20/25 PSI / 138/172 kPa

NOTE: Local codes may require the installation of a backflow preventer and a pressure

relief tank in the cold water supply line. Consult the local authority for details.

The backflow preventer and pressure relief tank are not supplied by the factory.

Fig. 8 - The COLD water supply is a 3/4" NPT connection

located at the top left-side of the machine.

6

Page 15

Drain Connection - Standard and VHR Models

Connect the drain in accordance with the specifications below.

Installation

DRAIN

GRAVITY DRAIN - 2” OD SLIP-FIT HOSE CONNECTION.

CAUTION: The dishwasher drain connection must comply with all local plumbing,

health and safety codes. Damage caused by improper installation is not covered by

the limited warranty

AUTOMATIC ELECTRIC DRAIN VALVE.

MAXIMUM FLOW RATE: 15 US GPM / 12.5 IMP. GPM / 57 LPM.

NOTE: A Drain Water Tempering Kit Option is available to ensure the temperature of

the water entering the drain does not exceed 140ºF/60ºC ( see next page).

Automatic Electric

Drain Valve

Fig. 10 - The drain is a 2" OD slip-fit hose connection.

7

Page 16

Installation

Water Connection for Drain Water Tempering Valve

Standard and VHR Models

NOTE: The drain water tempering kit is designed to reduce the temperture of

water entering the building drain when the dishwasher is in the automatic drain cycle.

A field installation kit is available from the factory if needed.

Connect the plumbing in accordance with the specifications below.

COLD

WATER

MINIMUM 1/2” NPT COLD WATER SUPPLY LINE.

MAX OPERATING FLOWING PRESSURE IS 45 PSI / 310 kPa.

CONNECTION LOCATED AT REAR OF MACHINE.

CAUTION: To prevent damage to the dishwasher supply valves, the installing

plumber must thoroughly flush debris from the water supply line before connecting

it to the dishwasher. Damage caused by improper installation is not covered by the

limited warranty.

NOTE: A drain water tempering kit is available to install in the field if necessary.

Contact the local authority for information concerning local codes and regulations.

Fig. 9 - The drain water tempering connection is

a 1/2" NPT COLD water connection.

8

Page 17

Installation

Electrical Connection - Single Phase and Three Phase

Standard and VHR Models

The installation of the dishwasher must comply with all local electrical, plumbing,

health, and safety codes or in the absence of local codes, installed in accordance

with the applicable requirements in the National Electrical Code, NFPA 70,

Canadian Electrical Code (CEC), Part 1, CSA C22.1; and the Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations, NFPA 96.

WARNING:

Electrocution may occur when working on energized circuits.

Disconnect power at the main breaker or service disconnect switch,

then lock out and tag it to indicate that work is being performed

on the circuit.

Follow the instructions below and on the next page to connect the electrical power to the machine.

1. A conduit mounting bracket is located at the right rear corner of the machine base as shown

in Fig. 10 below. Position the machine near its permanent location and route the flexible

conduit to the machine making sure to leave a 6 foot / 2 meter service loop.

2. Remove the machine front panel and locate the main terminal block at the right front

corner of the machine. Refer to the Machine Electrical Connection plate mounted directly in

front of the terminal block for electrical specifications. See Fig. 11 below.

3. Route the supply wiring to the main terminal block. A cable clamp is provided to secure the

wiring to the base of the machine. Connection diagrams are located on the next page.

PLAN VIEW

Fig. 10

FRONT VIEW

Continued on the next page.

Machine Electrical Connection

Serial Number: DH5000TModel:

For supply connection, use copper conductors

in accordance with local electrical code, Rated Minimum 90° C (194° F)

Minimum

Supply Conductor Ampacity

Supply Overcurrent Protection Device

Maximum

Overcurrent Protection Device:

Time Delay Fuse or Inverse Time CKT Breaker

Voltage:

Hertz:

0

Phase:

AMPS:

-- AMPS

-- AMPS

3

--

Fig. 11

9

Page 18

Installation

Electrical Connection - Single Phase and Three Phase

Standard and VHR Models (continued)

Refer to the diagrams below for the main terminal block wiring and

three phase and single phase motor connections.

WARNING:

There may be more than one power source connected to the

machine. Make sure all power sources are disconnected, locked

and tagged out before working on the machine.

3 Phase Power Connection

208-240/480V/60/3

L1

L2

L3

Fig. 12

Three Phase Motor

HIGH Voltage Connection

W2 U2 V2

Y/G Y/G

U1 V1 W1

BLK BRN G R AY

L1 L2 L3

L1

LINE IN

L2

L3

GND

Three Phase Motor

LOW Voltage Connection

W2 U2 V2

U1 V1 W1

BLK BRN G R AY

L1

L2

L3

1 Phase Power Connection

208-240V/60/1

L1

L2

NOT

USED

L1

L2

USED

GND

NOT

Fig. 13

Single Phase Motor Wiring

with Run Capacitor

Motor

A

M

T

Thermal

Protector

WHT

BRN

BLK

W1

V1

U1

LINE IN

Cable

GRAY

BRN

BLK

Y/G

CAP

L1

L2

10

Fig. 14

NOTE: CHANGING MOTOR ROTATION -

An arrow on the rear motor housing indicates that the proper motor rotation is

clockwise when viewed from the rear. To change the rotation on three phase machines,

reverse L1 and L2 at the main terminal block.

Page 19

Ventilation - Vent Fan Control for Standard Model Only

Standard model installations using an approved vent hood may require a vent

fan signal. This signal is supplied by the dishwasher control circuit. A qualified

installer must connect a signal circuit to the fuse holder and a common

neutral terminal provided. See Fig. 15.

Installation

CAUTION: To prevent damage to the dishwasher do not connect vent fan motor

to the Line Power 120VAC 1.0 Amp fused connection terminals. Damage to any

component caused by improper installation is not covered by the limited warranty.

The fused 120VAC Line Power is designed to operate an external vent fan contactor

only (supplied by others), and is limited to 1.0 AMP maximum load. The 120VAC

signal is available when the dishwasher power switch is turned ON.

SIGNAL

ONLY

COMMON

NEUTRAL

LINE

POWER

120VAC

1.0 A

MAX.

DETERGENT

120VAC

0.5 AMP

MAX.

RINSE AID

120VAC

0.5 AMP

MAX.

GROUND

120VAC

FACTORY

USE ONLY

GROUND

1.0A

0.5A 0.5A

Fig. 15

11

Page 20

Installation

Detergent Dispenser Connection - Standard and VHR Models

USE A NON-CHLORINATED COMMERCIAL GRADE DETERGENT.

DET

ONLY

SIGNAL

COMMON

NEUTRAL

WASH TANK CAPACITY: 9.5 US GAL / 7.9 IMP. GAL / 36 L

TWO 7/8” DIAMETER HOLES ON LOWER RIGHT SIDE OF TANK.

• TOP HOLE IS FOR DETERGENT INJECTION.

• BOTTOM HOLE IS FOR THE DETERGENT PROBE.

FUSED 120VAC 0.5 AMP MAX. LOAD DETERGENT SIGNAL CONNECTION

AT LOWER FRONT OF MACHINE BEHIND THE FRONT PANEL.

NOTE:

LINE

POWER

120VAC

1.0 A

MAX.

DETERGENT

120VAC

0.5 AMP

MAX.

RINSE AID

120VAC

0.5 AMP

MAX.

GROUND

GROUND

120VAC

FACTORY

USE ONLY

A fused 120VAC 1.0A

Line Power connection is

supplied for chemical

dispensing equipment

if needed.

1.0A

0.5A 0.5A

12

Fig. 16

THE DETERGENT SIGNAL IS ENABLED

THROUGHOUT THE WASH CYCLE.

INJECTION POINT

PROBE

Fig. 17

Page 21

Rinse-Aid Dispenser Connection - Standard Model

STD. RINSE / RACK: .85 US GAL / .7 IMP. GAL / 3.2 L

POT/PAN RINSE / RACK: 1.18 US GAL / .98 IMP. GAL / 4.5L

R /A

1/8” NPT PIPE PLUG AT THE REAR OF THE MACHINE

NEAR THE VACUUM BREAKER FOR RINSE AID INJECTION.

FUSED 120VAC 0.5 AMP MAX. LOAD RINSE AID SIGNAL CONNECTION

• TOP HOLE IS FOR DETERGENT INJECTION.

AT LOWER FRONT OF MACHINE BEHIND THE FRONT PANEL.

• BOTTOM HOLE IS FOR THE DETERGENT PROBE.

Installation

SIGNAL

ONLY

COMMON

NEUTRAL

LINE

POWER

120VAC

1.0 A

MAX.

1.0A

Fig. 18

DETERGENT

120VAC

0.5 AMP

MAX.

RINSE AID

120VAC

0.5 AMP

0.5A 0.5A

Fig. 19

MAX.

NOTE:

A fused 120VAC 1.0A

GROUND

GROUND

120VAC

FACTORY

USE ONLY

Line Power connection

is supplied for chemical

dispensing equipment

if needed.

13

Page 22

Operation

Operation - Control Panel Description

The control panel is located on the front left side of the lower panel. The controls include:

A - ON/OFF green power button. Turns power on and off and initiates a drain cycle

when the switch is placed in the OFF position.

B - CYCLE green indicator light. Illuminates during an automatic timed cycle.

The cycle light is off during the 10 minute automatic drain cycle.

C- CYCLE SELECTION buttons. Four blue push buttons provide 1 minute, and 1.5 minute total cycle

times for normally soiled wares and 4 minute and 6 minute total cycle times for pots, pans and

heavily soiled wares.

D- WASH digital temperature display. Indicates the wash tank water temperature with green LED's

when the wash water temperature is 150°F/66°C.

E- RINSE digital temperature display. Indicates the final rinse water temperature with green LED's

when the final rinse temperature is 180-195°F/ 82-91°C.

F- PRESSURE gauge. Indicates the final rinse water flowing pressure during the final rinse.

The proper pressure reading is 20-22 PSI during the final rinse.

NOTE: The wash cycle time cannot be changed while the dishwasher is washing.

Time Cycle Options

CYCLE OPTION TOTAL CYCLE TIME

Dishwasher Cycle Option 1 Approx. 1 minute

Wash 35 seconds

Rinse 10 seconds

Dwell 15 seconds

Dishwasher Cycle Option 1.5 Approx. 1-1/2 minutes

Wash 65 seconds

Rinse 10 seconds

Dwell 15 seconds

Pot/Pan Cycle Option 4 Approx. 4 minutes

Wash 3-1/2 minutes

Rinse 15 seconds

Dwell 10 seconds

Pot/Pan Cycle Option 6 Approx. 6 minutes

Wash 5-1/2 minutes

Rinse 15 seconds

Dwell 10 seconds

14

Page 23

Control Panel Description

A

CYCLE TIME

1 1.5 46

C

WASH RINSE

Operation

B

D

E

F

PRESSURE

Fig. 21

15

Page 24

Operation

Operation - Set-up

TURN WATER SUPPLY AND MAIN POWER ON.

1

INSTALL PUMP STRAINER AND SCRAP SCREENS (See Fig. 22).

2

INSTALL UPPER AND LOWER WASH AND RINSE SPRAY ARMS.

3

MAKE SURE THEY SPIN FREELY (See Fig. 23).

SCRAP SCREENS X 2

Fig. 22

PUMP STRAINER

WASH SPRAY ARM

16

RINSE SPRAY ARM

Fig. 23

Page 25

Operation - Loading Wares

REMOVE LARGE FOOD PARTICLES AND DEBRIS BEFORE LOADING WARES.

1

LOAD PLATES IN A PEG RACK, BOWLS AND GLASSES IN A FLAT-BOTTOM RACK.

LOAD SILVERWARE IN A SINGLE LAYER IN A FLAT-BOTTOM RACK.

2

LOAD POTS, PANS, AND UTENSILS UPSIDE DOWN IN A FLAT-BOTTOM RACK.

LOAD BAKE SHEETS AND TRAYS ON THE SHORT EDGE IN A BAKE SHEET RACK.

DO NOT OVERLOAD RACKS AND ONLY WASH ONE RACK AT A TIME.

3

NEVER WASH FOREIGN OBJECTS SUCH AS FLOOR MATS, MOPS, OR TOOLS.

4

Operation

CAUTION: Ferrous metals in the form of metal scrub pads must not be used to

clean wares or dishwasher surfaces. Avoid putting any type of ferrous metal

in the machine.

Fig. 24

17

Page 26

Operation

150°F

Operation - Wash Cycles

NOTE: The DH5000T operates as a dishwasher in cycles 1 and 1.5 and as a

pot/pan washer in cycles 4 and 5.

CLOSE THE DOOR. PUSH THE POWER SWITCH ON.

THE POWER SWITCH WILL ILLUMINATE.

1

THE MACHINE WILL FILL WITH WATER AUTOMATICALLY.

CYCLE TIME

1

WAIT APPROXIMATELY 15 MINUTES UNTIL THE WASH TANK

2

DIGITAL DISPLAY INDICATES 150°F/66°C.

15

MINUTES

1.5 4 6

Fig. 25

150

18

WASH

Fig. 26

Page 27

Operation - Wash Cycles (continued)

PRESS A BLUE TIME CYCLE BUTTON. THE BUTTON ILLUMINATES.

3

CLOSE THE DOOR. THE GREEN CYCLE LIGHT ILLUMINATES AND THE WASH

4

CYCLE BEGINS. THE WASH CYCLE IS FOLLOWED BY THE FINAL RINSE.

CYCLE TIME

Operation

1

1.5 4 6

Fig. 27

IF THE DOOR IS OPENED DURING A CYCLE, THE

WASH TIMER WILL RESET AND THE DISHWASHER

WILL RESTART THE CYCLE FROM THE BEGINNING.

19

Page 28

Operation

E

20 PSI

Operation - Wash Cycles (continued)

MONITOR THE FINAL RINSE TEMPERATURE AND PRESSURE DURING THE FINAL RINSE.

7

THE PRESSURE MUST BE A MINIMUM OF 20 PSI AND THE TEMPERATURE MUST BE A

MINIMUM OF 180°F/82°C.

30

20

10

180

PRESSURE

FINAL RINS

180°F

Fig. 28

40

PSI

50

60

0

THE GREEN CYCLE LIGHT WILL GO OUT WHEN THE FINAL RINSE IS COMPLETE. THE

BLUE TIME SELECT BUTTON REMAINS ILLUMINATED.

8

OPEN THE DOOR AND REMOVE THE CLEAN RACK OF WARES. THE MACHINE WILL

REPEAT THE TIME CYCLE UNTIL ANOTHER TIME IS SELECTED.

CAUTION: Wares and dishwasher surfaces are hot during operation.

Be careful when opening the door and loading or unloading dish racks.

Rinse Sentry Feature

The DH5000T is equipped with the rinse sentry feature that continuously monitors the temperature

inside the booster heater to assist in maintaining a final rinse temperature of 180°F/82°C. In the

event that the temperature is below 180°F, Rinse Sentry will add a maximum of 5 minutes to the

selected wash cycle time.

NOTE: Repeated rinse sentry operation may indicate low incoming water

temperature. Check the incoming water temperature if required.

20

Page 29

Operation - Automatic Drain Cycle

The DH5000T is equiped with an automatic electrically operated drain valve.

TO DRAIN THE DISHWASHER:

1

OPEN THE DISHWASHER AND REMOVE ALL WARES FROM INSIDE THE MACHINE.

PUSH THE POWER SWITCH OFF. THE POWER LIGHT WILL GO OUT.

2

NOTE: THE GREEN CYCLE LIGHT IS OFF DURING THE DRAIN CYCLE.

THE DRAIN VALVE WILL OPEN, THE MACHINE WILL DRAIN FOR 10 MINUTES, THE DRAIN

3

VALVE WILL CLOSE AND THE MACHINE WILL POWER OFF.

PUSHING THE POWER SWITCH ON AND IMMEDIATELY OFF WILL START ANOTHER 10

4

MINUTE DRAIN CYCLE AND POWER OFF.

Operation

CYCLE

CYCLE TIME

1

1.5 4 6

Fig. 29

21

Page 30

Cleaning

Cleaning

WARNING:

Dishwasher surfaces can be hot and cleaning chemicals can be caustic to the

skin and eyes. Wear protective clothing and eye protection when handling

chemicals and cleaning the machine.

CLEAN THE MACHINE AT THE END OF EACH MEAL PERIOD OR AFTER EVERY

2 HOURS OF CONTINUOUS OPERATION AND AT THE END OF THE DAY.

To clean the dishwasher:

1. Push the power button OFF, the light will go out, the electric drain valve will open and the

machine will drain. The drain valve will remain open for 10 minutes. Pushing the power

button on and immediately off will open the drain valve for another 10 minutes.

2. Open the door and flush the interior with fresh water.

3. Remove the upper and lower wash and rinse spray arms and flush with clean water.

4. Check the rinse spray arm nozzles. If necessary, remove the end plugs and clean the nozzles

with a small paper clip to remove lime or other debris. Flush the arms clean and replace the

end plugs. See Fig. 30 below.

Rinse Arm Spindle

Paper Clip

End

Plug

Wash Spray arm

22

Fig. 30

Page 31

Cleaning

Cleaning (continued)

5. Remove the scrap screens and pump strainer making sure that debris does not fall out of the

screens and into the wash tank. Flush and backflush the screens in a sink.

Do not strike the screens against hard surfaces.

6. Clean the round drain screen in the bottom of the wash tank. Clean the float switch.

See Fig. 31 below.

SCRAP SCREENS X 2

PUMP STRAINER

DRAIN SCREEN

Fig. 31

7. Rinse and drain the machine. Wipe the interior with a soft cloth. Reinstall the scrap screens

and spray arms making sure the spray arms spin freely.

8. Wipe the exterior clean with a soft cloth and mild detergent.

DO NOT FLUSH THE EXTERIOR OF THE MACHINE WITH WATER.

9. Leave the door open to dry the interior of the machine.

23

Page 32

Cleaning

Cleaning - Deliming

Minerals accumulate on the interior surfaces of the dishwasher. The deposits have a white haze

and, in cases of heavy accumulation, may appear as a granular solid. The generic name for

mineral deposits is lime. The removal of lime deposits is called deliming. The dishwasher should be

delimed regularly.

WARNING:

Death or serious injury may result when deliming solution is mixed with

sodium hypochlorite (chlorine bleach) sanitizing agent. Mixing may cause

hazardous gases to form. Deliming solution and other acids must never be

mixed with chlorine, iodine, bromine, or fluorine.

WARNING:

Deliming solutions can cause severe irritation and possible chemical burns.

Always wear protective clothing and goggles when handling chemicals.

NOTE: Contact a qualified chemical supplier for deliming chemicals and

instructions to delime the dishwasher. Follow all of the chemical supplier's

directions making sure to always wear eye protection, rubber gloves and

rubber aprons when handling chemicals and deliming the machine.

24

Page 33

Maintenance

Daily Maintenance

1. Check all of the wash arm and rinse arm spray jets and clean as necessary.

2. Make sure the water supply is on and the drain is not clogged.

3. Check the temperature displays to ensure they are operating.

4. Make sure the dish racks are in good condition.

5. Check the chemical containers and refill as required.

6. Follow the cleaning procedures on pgs. 22-24.

Weekly Maintenance

1. Perform Steps 1-5 in the Daily Maintenance.

2. Inspect water lines for leaks.

Maintenance

3. Check for water leaks underneath the dishwasher.

4. Make sure the floor drain and/or piping handles the drain water discharge.

5. Make sure the dishwasher is level.

6. Clean accumulated lime deposits from the wash tank heating element.

7. Inspect the scrap screen and replace if damaged.

8. Check the spray arms and replace or repair if damaged.

Yearly Maintenance

Contact your authorized service agent for a preventive maintenance inspection.

Lubrication

There are no lubrication points nor schedules for this dishwasher.

NOTE: Consult the chemical supplier for dispensing system maintenance.

25

Page 34

Maintenance

Troubleshooting

Condition Cause Solution

Dishwasher will not run. Hood not closed.

Main power OFF.

Dishwasher OFF.

Low or no water. Main water supply is off.

PRV setting incorrect.

Line strainer clogged.

Solenoid valve defective.

Chemicals won’t feed into

dishwasher.

Poor wash results. Wares incorrectly loaded in

Chemical supply low.

Pick-up tube clogged.

Supply tubing damaged.

Supply tubing kinked.

dishrack.

Clogged screens.

Clogged spray arms.

Chemical injectors not feeding.

Thermostat defective.

Close Hood completely.

Check breaker on panel.

Turn dishwasher ON.

Open supply valve.

Set to 20-22 PSI flowing.

Contact Service Agent.

Contact Service Agent.

Refill chemical container.

Contact Chemical Supplier.

Contact Chemical Supplier.

Straighten tubing.

Reposition wares or reduce

amount of wares.

Clean screens.

Clean spray arms.

Contact Chemical Supplier.

Contact Service Agent.

Detergent Dispenser defective.

Water temperature low.

Dishwasher stays in wash

cycle.

Dishwasher will not drain. Drain screen clogged.

Condensate Removal

Option Model Steam not

being vented.

Rinse Sentr

mode to allow final rinse water

booster temperature to reach

180°F/82°C.

Drain valve defective.

Building drain clogged.

Incoming cold water temp. is

above 75°F/24°C.

Incoming water pressure is

below 45 PSI flowing presuure

at the dishwasher.

Condensate coil or fan

defective.

y extends wash

Contact Chemical Supplier.

Contact Service Agent.

Contact Ser

cycle runs for longer than 6

minutes.

Clean drain screen.

Contact Service Agent.

Contact Building Maintenance.

Check incoming water

temperature.

Check incoming water pressure.

Contact Service Agent.

vice Agent is wash

26

Page 35

Troubleshooting - Display Error Codes

Indicates the wash thermistor is defective.

Indicates the final rinse thermistor is defective.

Maintenance

Indicates the booster thermistor is defective.

27

Page 36

Blank Page

This Page

Intentionally

Left Blank

28

Page 37

B

114470-9

TIME CYCLE - Tall Hood-type Series - MODE "B"

DRAWING REPRESENTS ONLY THE STRUCTURE OF TIME CYCLES.

FOR MODES OF OPERATION SEE DWG# 114470 SHEETS 10-16

NORMAL CYCLE EXTENDED CYCLE

60 SECONDS TOTAL CYCLE

90 SECONDS TOTAL CYCLE

Time Cycle Chart

WASH

DWELL

RINSE

SANITARY DWELL

0

35

35

45

45

45

60

6010020 4030 50 70 9080 100

10080 90705030 4020010 60

6010020 4030 50 70 9080 100

60

10080 90705030 4020010 60

35 SECONDS

0 SECONDS

10 SECONDS

15 SECONDS

WASH

DWELL

RINSE

SANITARY DWELL

0

64

65

64

6010020 4030 50 70 9080 100

65

80

6010020 4030 50 70 9080 100

9080

10080 90705030 4020010 60

80

10080 90705030 4020010 60

90

64 SECONDS

0 SECONDS

15 SECONDS

10 SECONDS

CYCLE# 1:

60 SECONDS CYCLE CONSISTING OF:

35 SECOND WASH,

0 SECOND DWELL,

10 SECOND RINSE,

15 SECOND SANITARY DWELL.

CYCLE# 2:

90 SECONDS CYCLE CONSISTING OF:

64 SECONDS WASH,

1 SECONDS DWELL,

15 SECONDS RINSE,

10 SECONDS SANITARY DWELL.

CUSTOMER TO SUPPLY RATED VOLTAGE/PHASE/H z,

AS SPECIFIED PER ORDER,TO DISCONNECT SWITCH.

ALL POWER SUPPLIED TO EACH CONNECTION POINT

MUST COMPLY WITH ALL LOCAL ELEC TRIC CODES.

J.MCALLISTER

DATE SHEET

2MAR12

SCALEDR.BY

1

OF

DESCRIPTIONREV.

A

CHANGED RINSE AND DWELL CYCLE TIMES

B

1

CHANGED RINSE AND DWELL CYCLE TIMES

DATE

13AUG12

19SEP12

BY

JAM

JAM

REV. DESCRIPTION

DATE

BY

TIME CYCLES

Tall Hood-type

The Dishwashing Machine Specialists

REV.

B

2929

Page 38

Time Cycle Chart

B

114470-17

Tall Hood-type Series - MODE C - TIME CYCLES 3 AND 4

CYCLE 3

SANITARY DWELL

WASH

DWELL

RINSE

0 10 20

0 10 20

DRAWING REPRESENTS ONLY THE STRUCTURE OF TIME CYCLES 3 AND 4.

FOR CYCLES 1 AND 2 SEE DWG# 114470 SHEET 9

30

40 6050 70 80 90

30

40

3010020 40 50 60 8070 90

6050 70 80 90

100

110 130120 150140 160

100

110 130120 150140 160

110 120 130 150140 160 200170 180 190 220210 230

100

214

215

214

200180170 190 220210 230

215

170 180 190 220210 230

200

230

250240 260 290280 300

240

270

270250240240 260 290280 300

270250240 260

JUMPER SETTINGS:

JB1 = OPEN

JB2 = CLOSED

JB3 = OPEN

330310 320 340300280 290260240 250 270230210 220190180170 200160140 1501301201109080706050402010030 100

320310 330

290280 300 340320310 330

NOTES:

TRIGGERING EVENT:

CYCLE SWITCH IN POSITION 1, 2, 3 OR

4

"CYCLE SWITCH" STATE IS IGNORED

DURING CYCLE, IT IS READ AT BEGINNING

AT THE CYCLE AND PROPER CYCLE TIME

STRUCTURE APPLIED.

INPUTS

SOLID LINE INDICATES SWITCH

CLOSURE

340

OUTPUT

SOLID LINE INDICATES 120VAC

COMING OUT OF THE OUTPUT

TERMINAL

340320310 330

INITIAL STATE:

POWER ON

DOORS OPEN

TANK FULL

CYCLE 4

SANITARY DWELL

WASH

DWELL

RINSE

CYCLE 3

0 10 20

01020

010 20

4 MINUTE CYCLE (240 SECONDS TOTAL)

CONSISTING OF: 214 SECOND WASH,

1 SECOND DWELL,

15 SECOND RINSE,

AND 10 SECOND DWELL.

40 6050 70 80 90

30

40 6050

30

40 6050

30

30010 20 40 6050 70 80 90

70 80 90

70 80 90

100

110 130120 150140 160

110 130120

100

100

110 130120

100

110 130120 150140 160 200180170 190 220210 230

150140 160

150140 160

CYCLE 4

180170 190 220210 230

180170 190

180170 190

6 MINUTE CYCLE (360 SECONDS TOTAL)

200

200

200

CONSISTING OF: 334 SECOND WASH,

1 SECOND DWELL,

15 SECOND RINSE,

AND 10 SECOND DWELL.

220210 230

220210 230

250240 260 290280 300

250240 260

250240 260

270

270

270

270250240 260 290280 300 340320310 330

290280 300

280 300

290

334

320310 330

334

320310 330

310 330

335

335

340

340

340320

350

360350

360350

360350

360

360350

WASH TIMES:

1 MINUTE =

∞

90 SECONDS = 0 Ω

4 MINUTE = 4.7K Ω

6 MINUTE = 15K Ω

CUSTOMER TO SUPPLY RATED VOLTAGE/PHASE/H z,

AS SPECIFIED PER ORDER,TO DISCONNECT SWITCH.

ALL POWER SUPPLIED TO EACH CONNECTION POINT

MUST COMPLY WITH ALL LOCAL ELEC TRIC CODES.

J.MCALLISTER

DATE SHEET

7MAR12

SCALEDR.BY

30

DESCRIPTIONREV.

A

CHANGED RINSE AND DWELL CYCLE TIMES

1

OF

1

DATE

19SEP12

BY

JAM

REV. DESCRIPTION

DATE

BY

TIME CYCLES

Tall Hood-type

The Dishwashing Machine Specialists

REV.

A

Page 39

Tall Hood-type PLC Electrical Schematic

31

Page 40

Blank Page

This Page

Intentionally

Left Blank

32

Loading...

Loading...