Champion MARQUIS 3000 DD, MARQUIS 6500 DD, MARQUIS 4300 DD, MARQUIS 4800 DD, MARQUIS 5500 DD Owner's Manual

OWNER’S MANUAL

CHAMPION•MARQUIS

EVAPORATIVE COOLER

MODELS

3000 DD

4300 DD

4800 DD

5500 DD

6500 DD

CIRCLE THE MODEL OF YOUR

COOLER AND RECORD THE SERIAL

NUMBER BELOW.

ENCIERRE CON UN CIRCULO EL

MODELO DE SU ENFRIADOR Y ESCRIBE

EL NÚMERO DE SERIE ABAJO.

SERIAL #

NÚMERO DE SERIE

READ AND SAVE THESE INTRUCTIONS

VEA EL ESPAÑOL EN EL INTERIOR.

SAFETY RULES

1. Read instructions carefully.

2. Electrical hook up should be done by a qualified electrician, so that all electrical wiring will conform to your local

standards.

3. Always turn OFF POWER and UNPLUG motor and pump

inside the cooler before installing or performing any maintenance.

4. Your cooler will run on 120 volt A.C., 60 Hz (cycle) current

only.

5. Motor and pump have a grounded, molded plug and an

automatic thermal overload switch which will shut motor off

when it overheats. The motor will restart automatically when

it cools down.

WARNING: To reduce the risk of fire or electric shock,

do not use this fan with any “solid-state fan speed control

device.”

READ CAREFULLY ALL OF THIS

MANUAL BEFORE INSTALLING THE

UNIT

LEA CON CUIDADO TODO ESTE MANUAL

ANTES DE INSTALAR LA UNIDAD

EVAPORATIVE COOLING

Evaporative cooling is nature’s way of cooling. When air is

moved over a wet surface, water is evaporated and heat is

absorbed. When stepping out of a swimming pool with the

wind blowing, evaporative cooling makes you feel cool, even

though the air may be warm. The human body itself is cooled

primarily by the evaporation of perspiration.

This unit works on the same principle. Air is drawn across wet

filter pads where the air is cooled by evaporation and then

circulated throughout the building. It is this combination of

cooled air and the movement of air over the skin which makes

it feel cool.

Unlike refrigeration systems which recirculate the air, an

evaporative cooler continually brings in fresh air while

exhausting old air. You are completely replacing the air every

2 to 4 minutes by opening windows or doors or a combination

of both. The air is always fresh, not stale, laden with smoke

and odors as happens with refrigerated air conditioning.

110503 10-03

www.championcooler.com

OPERATION

To eliminate delivery of hot air when starting your cooler, first

turn the pump on for the first few minutes, then turn on the blower

motor.

These coolers may be used without water for ventilation purposes.

When outside air is cool (for example, at night) or when humidity

is high, the water pump can be turned off.

A cooler can also be installed with a thermostat and attic exhaust

dampers to provide completely automatic operation.

OPEN WINDOWS TO EXHAUST AIR

An often misunderstood concept of evaporative cooling is the

amount of air that should be exhausted. How much should you

open your windows? The fact is that most people do not open

their windows enough. The following two methods will help you

determine the amount to open your windows.

FIRST METHOD

Y ou should allow an opening of at least 2 square feet (288 square

inches) for each 1000 CFM rating of your unit. Example: At

3654 CFM, model 4800 DD requires 7.3 square feet (1052 square

inches) of opening (3654/1000 * 2 = 7.3). Multiply the number of

windows by window width in inches and divide this into the number

of square inches required for your size unit. This will give you

the height to open windows. In this example, four 36 inch wide

windows should be opened 7.3 inches each.

CAUTION: Make sure that the mounting surface is

strong enough to support the operating weight of the

cooler when in use. (For operating weight, see Specification Table.)

CAUTION: Never plug in cooler until installation is com-

plete and unit has been tested for rigidity .

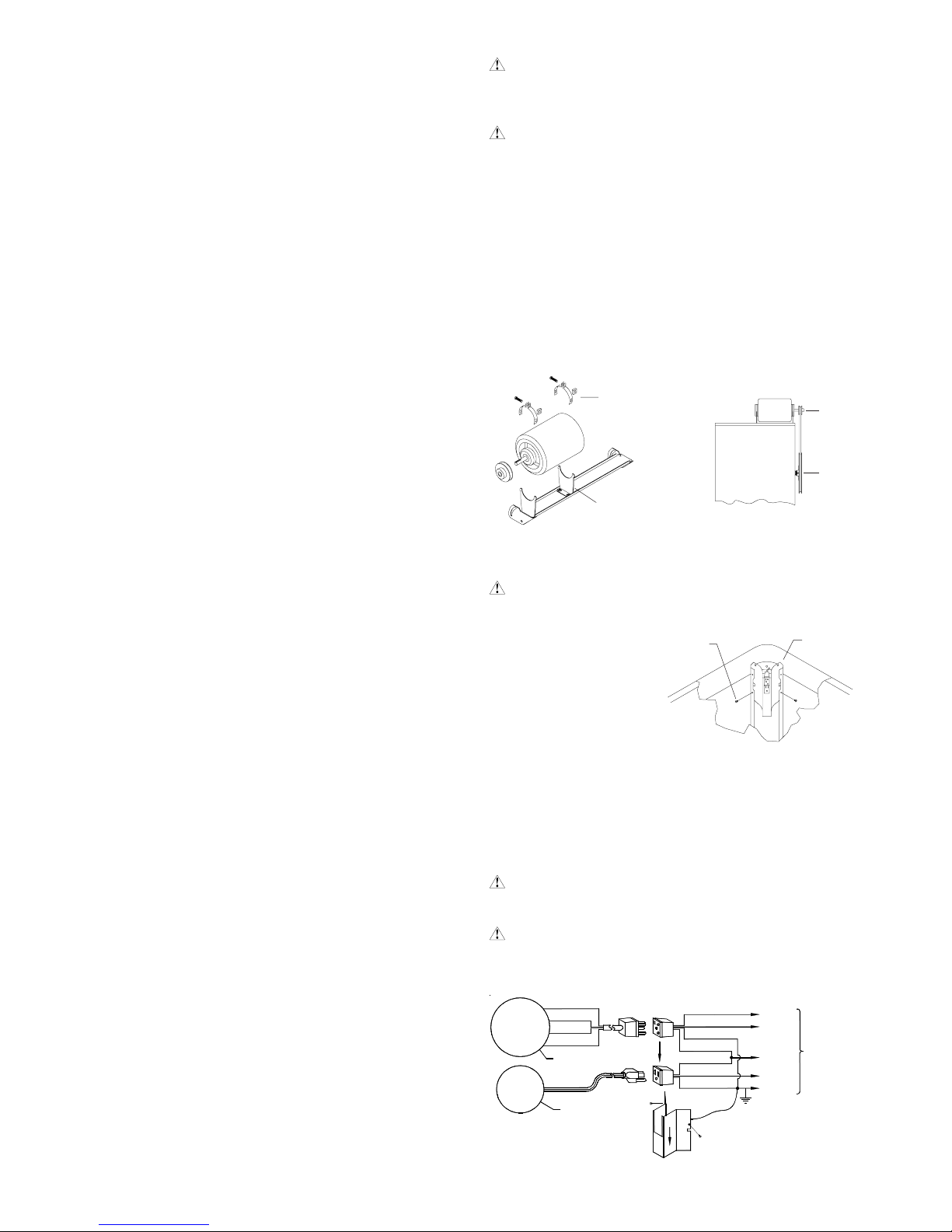

MOTOR INSTALLATION

• Install motor cord. Connect motor cord to motor using the

following color code: Black - Hi, Red - Low, White - Com.,

Green - Ground.

• Mount motor. Install blower motor in the motor mount yokes,

adjusting the yoke if necessary. Fasten with the provided mounting clips (see Fig. 1).

• Install pulley . Install the adjustable motor pulley so that it aligns

with the blower drive pulley (see Fig. 2) and tighten set screw.

MOTOR

FIG. 1

CLIPS

ADJUSTABLE

YOKE

BLOWER

HOUSING

FIG . 2

MOTOR

PULLEY

BLOWER

PULLEY

CHAMPION AIR BALANCING METHOD

1. T ake a piece of tissue paper and cut it lengthwise into 3 equal

strips.

2. Turn your cooler on high cool.

3. Open one window at least six inches wide in each room that

you want to cool.

4. T ake the piece of tissue paper and put it up against the screen

of the open window furthest from the cooler discharge opening. Let go of it. It will do one of three things.

IF It falls down.

THEN CLOSE all of the windows one inch and try step 4 again.

IF It plasters itself to the screen.

THEN OPEN all of the windows one inch and try step 4 again.

IF It stays on the screen lightly .

THEN PERFECT . You are done. Enjoy your cooler .

NOTES:

• When switching to low cool, you must rebalance your home.

Repeat step 4.

• Once you balance your home you can cool some areas more

than others by opening those windows more and closing the

others by the same amount. Repeat step 4 to make sure your

home is still air balanced.

INST ALLATION

NOTE: The pump and float are installed in the cabinet. The

belt, motor pulley, and motor cord are included in the cabinet,

the motor is shipped separately.

ELECTRICAL INST ALLA TION

WARNING: Disconnect all electrical service that will

be used for this unit before you begin the installation.

• Remove junction box.

The electrical junction

SCREWS

box is located in the upper inside corner of the

cooler cabinet. Remove

the two screws and slide

cover down for access to

plug wiring (Fig. 3).

• Hook up electrical. Electrical hook up should be done by a

qualified electrician, so that all electrical wiring will conform to

your local standards. See Fig. 4 for the wiring diagram.

IMPORTANT: When a single speed motor is used, do not use

the red lead on the receptacle and motor plug wiring. T ape of f

end of both of the red leads.

CAUTION: Pump receptacle is for grounded evapora-

tive cooler pump only. Do not plug anything else into

receptacle.

WARNING: Make sure the cooler cabinet is properly

grounded to a suitable ground connection for maximum

safety .

BLACK

HI

LO

GND.

COM.

RED

GREEN

WHITE

BLOWER MOTOR

PUMP MOTOR

BLACK

RED

GREEN

WHITE

WHITE

BLACK/BLUE

GREEN

HI

LO

COM

PUMP

GND

JUNCTION

BOX

FIG . 3

TO

SWITCH

2

FIG. 4

110503

WATER CONNECTION

• Install overflow assembly. Re-

move nut and place nipple through

the hole in the pan, with the rubber washer between the pan and

the head of the drain nipple (Fig.

5). Screw on nut and draw up tight

against bottom of pan. Insert overflow pipe in nipple to retain water.

Overflow pipe may be removed to

drain pan when necessary . A garden hose may be screwed on the

drain nipple to drain water away

from your unit.

• Connect water supply line.

Find the closest supply of water.

Use a saddle valve (Fig. 6) to

connect 1/4” tubing to the cold

water supply or use a Sillcock

and water valve connected to an

outside faucet (Fig. 7). Place the

nut and ferrule on the tubing and

tighten the nut until water tight.

IMPORTANT: Do not connect the

water supply to any soft water

applications. Soft water will

cause corrosion and decrease

the life of the cooler.

SILLCOCK

• Install float and attach water

line to float. The float may be

installed in either the corner

post or bracket (see Fig. 8).

Refer to figure 9 for installation

instructions. Insert the float (1)

thru the hole in the corner post

or bracket. Install the washer

(2) and nut (3). Tighten to

keep the float from turning.

Place the nut (5) and ferrule (4)

on the water supply line. Con-

FIG . 8

nect to float fitting and tighten

until water tight.

• Fill pan. Allow water to fill to

within 1” of top of pan and ad-

1

just float to maintain this water

level. This can be accomplished by bending the float

rod.

• Level water troughs. Operate pump until pads are satu-

rated. Check each trough to see if water is evenly dispersed in

the trough. If they are not, loosen adjustment bolts and level

trough. Retighten bolts. Check to see that all pads are saturated with water and that there are no dry spots or openings in

the pads.

• Adjust water amount. Y our cooler is equipped with a unique

water metering valve (Fig. 10). The amount of water delivered

to the pads may be decreased by pressing the plastic valve as the arrows

indicate. If water is splashing out of water troughs, you may need to decrease

the amount of water delivery. Check to

see that all pads are saturated with water and that there are no dry spots or

openings in the pads.

110503

OVERFLOW PIPE

NIPPLE

RUBBER WASHER

BOTTOM PAN

NUT

FIG. 5

1/4” TUBING

FIG. 6

FAUCET

FIG . 7

CORNER

POST

FLOAT

FIG . 9

SADDLE

VALVE

WATER

SUPPLY VALVE

BRACKET

3

2

INCREASE

DECREASE

FIG . 10

COLD

WATER

PIPE

FERRULE

4

5

NUT

6

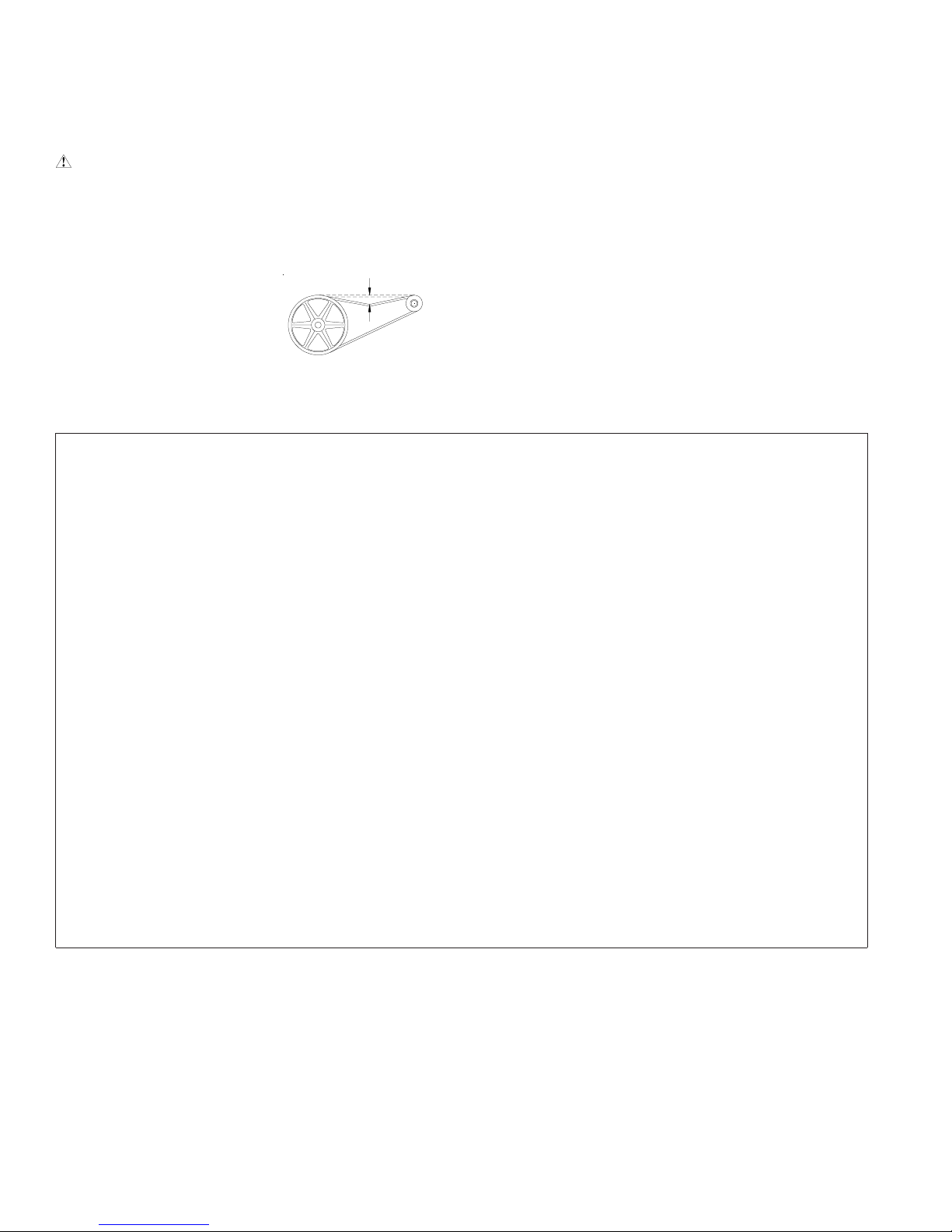

AMPERAGE DRAW AND BEL T TENSION

This unit is equipped with an adjustable motor drive sheave for

adjusting the blower wheel speed to the proper loading on different duct systems. It is important that the motor drive pulley is

adjusted to correct size to assure maximum air delivery without

damage to the motor. Be sure to follow these instructions carefully.

• Adjust drive pulley. After the unit is completely installed, adjust the drive pulley to the least diameter and adjust belt tension.

See the maintenance section for adjusting belt tension.

• Start cooler. Install all pad frames, start pump, and allow to

operate until pads are wet.

• Check amperage. With pads wet and unit started, check am-

perage draw with an amperage meter.

• Adjust pulley if necessary. If amperage draw is less than

motor rating, turn off electrical power and remove pad frame.

Unplug motor inside cooler, this will protect you from someone

turning on unit while you are working inside. This should be

done for your safety. Adjust pulley to a larger diameter and

readjust belt tension, plug motor in, install pad frame, and retest amperage

draw. Repeat this process until correct amperage draw is attained.

Increasing motor pulley diameter in-

DECREASE

AMPERAGE

creases amperage draw. Decreasing

motor pulley diameter decreases amperage draw (see Fig. 1 1).

FIG . 1 1

CAUTION: Do not operate cooler with larger amper-

age draw than specified on motor plate.

NOTE: No attempt should be made to completely install this unit

without the aid of an electrician or someone familiar with testing

amperage draw. Failure to comply with these instructions may

void your warranty.

MAINTENANCE

WARNING: Before doing any maintenance be sure

power is off. At the time you remove a pad frame be sure

to unplug motor and pump. This is for your safety .

SPRING ST ART -UP

• Clean pump. Cleaning the

pump is necessary once a

year at start-up. For your

safety, turn unit of f and unplug

motor and pump. Remove the

pump from the mount slot. Remove the base of the pump as

shown in Fig. 12. Clean the

pump and turn the impeller to

ensure free operation. Remove the pump spout and check for any blockage. After

cleaning, reinstall the base onto the pump. Reattach the pump

to the mount in the cooler using the plastic retainer to ensure

that the pump will not overturn. Do not forget to replace the

spout and water delivery tube onto the pump outlet. The pump

has an automatic reset thermal protection.

DEPRESS HERE

TO REMOVE

FIG . 12

3

• Oil bearings. The blower bearings and cooler motor in this

unit should be oiled with a few drops of non-detergent 20/30

weight oil once each year. The motor does not need oil if it has

no oil lines for oiling. Motors that have no lines are lifetime

oiled at the factory and require no further oiling for the life of

the unit.

CAUTION: Do not over oil. Over oiling can cause motor

burn out, due to excessive oil getting into motor winding.

• Change Pads. The pads should be replaced once or twice a

season, depending upon the length of the season. At the beginning and at mid season a clean pad is more absorbent and

efficient and will deliver substantially more

cool air.

• Check belt tension. A 3 lb. force

should deflect the belt 3/4 inches

(see Fig. 13). Readjust belt if

needed.

• Check bleed-off valve to be sure it is not clogged.

3 LB.

3/4 INCHES

FIG . 13

WINTER SHUT DOWN

• Drain water . Always drain all of the water out of the cooler

and water supply line when not in use for prolonged periods,

and particularly at the end of the season. Keep the water line

disconnected from both the unit and water supply so that it

does not freeze.

• Unplug motor and pump. When cooler is not used for extended periods, unplug the motor and pump from inside cooler.

• Cover unit. To protect the life of the finish, a cover for the

unit is suggested in extended periods of non use.

By following the operating, ins tallation, and maintenance suggestions as outlined, you can get many years of efficient and

satisfactory service from your cooler. In the event additional

information is desir ed, your de aler will be more than glad to as sist you in ev ery possible w a y.

LIMITED WARRANTY

This warranty is extended to the original purchaser of an evaporative cooler installed and used under normal conditions. It

does not cover damages incurred through accident, neglect, or abuse by the owner. We do not authorize any person or

representative to assume for us any other or different liability in connection with this product.

T erms And Conditions Of The Warranty

For Eight Years from date of installation, we will replace the original base assembly if water leakage should occur due to rust

out.

For One Y ear from date of installation, we will replace any original component provided by Champion Cooler which fails due to any

defect in material or factory workmanship only.

Exclusions From The Warranty

We are not responsible for replacement of cooler pads. These are disposable components and should be replaced periodically. We are not responsible for any incidental or consequential damage resulting from any malfunction.

We are not responsible for any damage received from the use of water softeners, chemicals, descale material, plastic wrap,

or if a motor of a higher horsepower than what is shown on the serial plate is used in the unit.

We are not responsible for the cost of service calls to diagnose cause of trouble, or labor charge to repair and/or replace parts.

How T o Obtain Service Under This Warranty

Contact the Dealer where you purchased the evaporative cooler. If for any reason you are not satisfied with the response from the

dealer, contact the Customer Service Department: Champion Cooler , 5800 Murray S treet, Little Rock, Arkansas 72209. 1-800643-8341. E-mail: info@championcooler.com.

This limited warranty applies to original purchaser only.

4

110503

Loading...

Loading...