Page 1

LittleBrute

RB30

MAGNETIC DRILL PRESS

SAFETY GUIDELINES

USER GUIDELINES

PARTS & SCHEMATICS

Page 2

LittleBrute

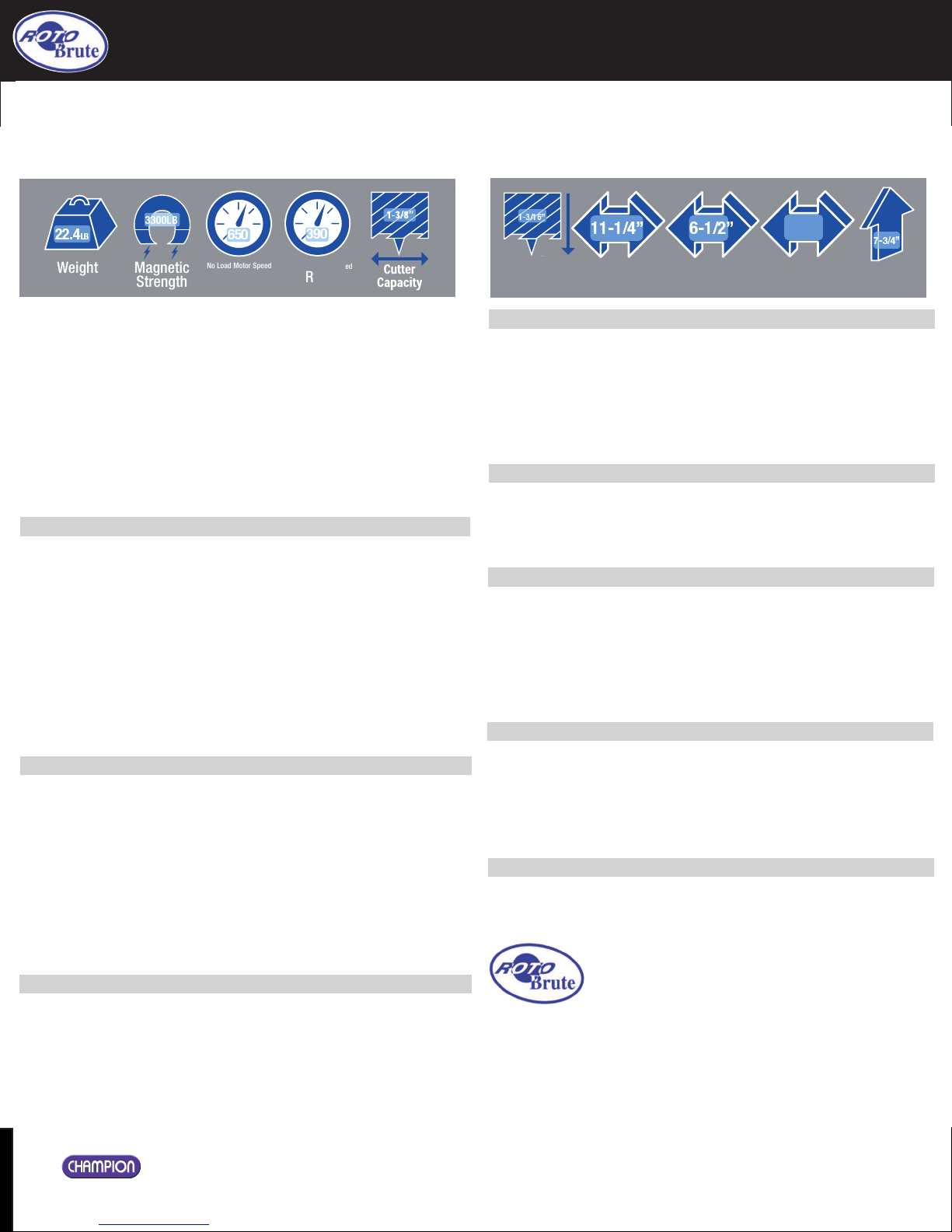

22.4LB

1-3/16Ó

11-1/4Ó

3300LB

390

7-3/4Ó

6-1/2Ó

650

4”

RB30

COMPONENTS & SAFETY

IMPORTANT

Please read these operating and safety instructions carefully and completely. For your own safety - before using this equipment check that the voltage

is correct and that all handles and parts are firmly secured. If you are uncertain about any aspect of using this equipment, contact your distributor.

LEASE KEEP THESE INSTRUCTIONS

P

Weight

Magnetic

Strength

INCLUDED WITH EVERY RB30

Carrying case, cutting fluid, wrench M8, hex key M2.5, hex key M4 and safety chain

Ear and eye protection MUST be worn during operation of this equipment. Do NOT

touch the cutter while it is in motion. Always follow the Personal Protection

Equipment (PPE) recommendations while operating this tool.

This machine is designed specifically for drilling holes in steel using annular cutters.

We recommend Champion RotoBrute annular cutters. Please consult your Champion

authorized distributor for a complete range of sizes.

DO NOT modify and / or use your RotoBrute magnetic drill press for any application

other than for which it is intended.

No Load Motor Speed

RPM

Full Load Motor Speed

RPM

SAFETY

Be sure to read and follow these important safety instructions:

When using your RB30 LittleBrute, be sure to follow these important safety precautions:

1. Before operating the machine, check supply voltage and general conditions, i.e. cable/cord

damage. A machine with damaged cable must be returned or repaired prior to use.

2. Always use the safety chain in all drilling applications.

4. Since cutting tools can shatter, eye and head protection should be worn at all times.

5. After use, clean machine and cutters and keep in the case provided.

6. Store when not in use, in a dry environment.

7. Always provide a method of catching slug, where the ejected slug may cause injury (slug

ejects at end of cut).

8. Should the cutter jam in the work-piece, stop the machine immediately. Isolate the

machine at the main supply. Loosen the cutter. Do not attempt to free cutter by starting and

stopping the motor.

Electrical Safety

1. Grounded tools must be plugged into an outlet properly installed and grounded in

accordance with all codes and ordinances. Never remove the grounding prong or modify the

plug in any way.

2. Do not use any adapter plugs. Check with a qualified electrician if you are in doubt as to

whether the outlet is properly grounded. If the tools should electrically malfunction or breakdown, grounding provides a low resistance path to carry electricity away from the user.

3. Never use the cord to carry the tools or pull the plug from an outlet. Replace damaged

cords immediately.

4. When operating a power tool outside, use an outdoor extension cord marked “W-A” or

“W”. These cords are rated for outdoor use and reduce the risk of electric shock. Minimal

gauge external cord should be 12/3.

5. Use the RB30 with 110 A/C voltage only. Not for use with generators, welders or any DC

power source. Do not use on any surface where welding is taking place.

Personal Safety

Stay alert, watch what you are doing and use common sense when operating a power tool.

Do not use tool while tired or under the influence of drugs, alcohol, or medication.

Do not wear loose clothing or jewelry. Avoid accidental starting. Be sure switch is off before

plugging in. Carrying tools with your finger on the switch or plugging in tools that have the

switch on, invite accidents.

Remove adjusting keys before turning the tool on.

Do not overreach. Keep proper footing and balance at all times.

Safety equipment (eye protection, dust mask, nonskid safety shoes, hard hat, hearing

protection, non-skid shoes) should always be worn.

Depth

of Cut

Length

of Machine

Machine

Width

Magnet

Width

Height

of Machine

Tool Use and Care

Use clamps or other practical ways to secure and support the work-piece to a stable

platform.

Do not force tool.

Disconnect the plug from the power source before making any adjustments, changing

accessories, or storing the tool.

Store idle tools out of reach of children and other untrained persons.

Maintain tools with care. Keep cutting tools sharp and clean.

Check for misalignment or binding of moving parts, breakage of parts and any other condition that may affect the tool’s operation. If damaged, have the tool serviced before using.

Service

Tool service must be performed only by qualified personnel.

When servicing a tool, use only original replacement parts.

Use of unauthorized parts will void the warranty.

Use of unauthorized parts or failure to follow maintenance instructions may create a risk of

electric shock or injury.

Magnetic Drill Safety

The drill’s magnetic adhesion depends on the thickness of the work-piece. 7/16” is the

minimum recommended thickness for safe operation. Keep the magnet clean of metal

chips and other dirt and debris. These will seriously reduce the magnetic adhesion. The

drill must be operated on its own electrical outlet. Always use the supplied safety chain.

An electrical overload can result in loss of adhesion.

CAUTION: The slug ejects at end of cut and is very hot.

WARNING: Do not attempt to drill a work-piece, which is thicker than the maximum cutting

depth of the cutter being used. Never exceed 1-3/8” cutter diameter.

Maintenance and Troubleshooting

Keep the drill press and the cord clean. In case of electrical or mechanical malfunction,

immediately switch off the tool and disconnect the plug. Excessive sparking generally

indicates the presence of dirt in the motor or worn out carbon brushes. Periodically check

brushes for wear and replace when they reach 1/4”.

For all other service and maintenance, please contact a Champion® authorized service

center.

Safety Chain

The safety chain must always be used.

Loop the chain through the slot above the magnet and around the workpiece. Push on the

spring buckle and thread the loose end of the strap through the loop and pull tight. Push on

the spring buckle to release chain.

2

Page 3

RB30

LittleBrute

OPERATING INSTRUCTIONS

Mounting Annular Cutters

1. Place a pilot pin in the cutter at the shank end. Insert the cutter into the special

arbor.

2. Whenever mounting or removing cutters, always unplug the machine.

3. Lower the arbor.

4. Push up on the quick-release collar. Insert the cutter with pilot pin and turn until

the flat meets the locking pin. When the flat meets the locking pin, the collar will

snap down. Double check to ensure that it is fully locked.

6. Position the machine on a clean, dry, ferrous surface at least 7/16” thick. Switch

on the magnet.

7. Apply BruteLube wax at all times to annular cutters

to enhance the quality of cut and prolong the cutting

tool life.

8. Switch on the drill. Always proceed with caution at

the start of drilling operations.

When using RotoBrute annular cutters apply pressure

gradually at first until a depth of 1/8” is reached.

Normal cutting pressure can then be applied.

9. On completion of cut, withdraw the cutter from hole,

switch off the drill, then the magnet. Ensure the

magnet base is clear of chips. Locate the next hole

using the above procedures.

10. To remove the cutter, lower the arbor, push up on the quick-release collar and

remove the cutter.

General Operation

WARNING: Always ensure that the magnet is adhered properly to the workpiece

before beginning drilling.

NOTE: If mounting to a curved surface beam, mount the machine parallel to the

curve in the work piece.

WARNING: Avoid operating at more than 90 degrees from horizontal. When drilling at

such an angle take precautions to prevent cutting

coolant from entering the motor.

BruteLube Wax should be used.

1. First fit tool into arbor and line up with

intended center of cut. Then switch magnet on.

2. Press green motor on button to start motor.

Use the crank handle to feed to work. Always use

very light pressure when beginning the cut and

just as the tool is breaking through.

Reversing of Changing the Position of the Handle

The handle is quick-release and adjustable to suit

different operating conditions.

If it is required to mount the handle on the

opposite side or to change its position, push the

Release Button in the center of the handle-hub

and remove. Press the Button and mount on the

opposite side or in the desired position.

L.E.D Work Light

The RB30 is equipped with the L.E.D WORK

LIGHT which is always on whenever the machine

is plugged in. This is useful when working in low

light conditions.

Carbon Brushes

The carbon brushes are a normal wear part and must

be replaced when they reach their wear limit.

Caution: Always replace the brushes as a pair.

To replace:

1. Remove the 4 screws and remove the motor tail

cover.

2. Using pliers rotate the brush spring out of the way

and slide the old carbon brush out of the brush holder.

3. Unscrew the screw to remove the brush lead. The

old carbon brush may now be lifted away.

4. To install a new brush, undertake the reverse of the

removal detailed above.

5. Replace the motor tail cover.

The brush design stops the machine before the

carbon brushes are finished and protects the motor.

In the event of the machine coming to a stop without

obvious reason - then check the brushes immediately.

The crank handle offers tremendous leverage. Therefore do not use too much force.

Allow the cutting tool to determine the pace. With experience, the operator will be

able to determine the best pace to feed to the work. There should be some degree

of audible slowing of the motor but not bogging in the cut. Correct cutting speed

with a properly sharp annular cutter will produce long unbroken chips, which

produce a “bird’s” nest shaped bundle of chips around the cut.

NOTE: Always ensure that the cutting tool is sharp. A dull cutter typically will have

finer and/or choppy shavings.

WARNING: ALWAYS clear chips when there is too much build-up. Excessive chip

build-up could result in a jammed cutter or other hazardous situation.

WARNING: The slug ejects at end of cut and is very hot. Always provide a method of

catching the slug, where the ejected slug may cause injury to people below.

CAUTION: Take extreme caution if attempting to cut half-circles or to stitch drill (drill

overlapping holes) with a tungsten carbide cutter. This may destroy the cutter.

5

Page 4

RB30

LittleBrute

ELECTRICAL DIAGRAM

3

Page 5

RB30

LittleBrute

MINIBRUTE

RB30 SCHEMATIC

4

Page 6

RB30

LittleBrute

KEY TO RB30 SCHEMATIC

No. List/Size Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

RB3001

RB3002

RB3003

B3004

R

RB3005

RB3006

RB3007

RB3008

RB3009

RB3010

RB3011

RB3012

RB3013

RB3014

RB3015

RB3016

RB3017

RB3018

RB3019

RB3020

RB3021

RB3022

RB3023

RB3024

RB3025

RB3026

RB3027

RB3028

RB3029

RB3030

RB3031

INTERNAL CIRCLIP R19

ARBOR WASHER

COOLANT SEAL

SPRING

LOCK PIN

SET SCREW M3

LOCK PIN SPRING

BALL STOP

SPINDLE

RING

COLLAR PIN

QUICK-RELEASE COLLAR

SPRING

SPRING SEAT RING

EXTERNAL CIRCLIP S-35

INTERNAL CIRCLIP R-47

BEARING 6005ZZ

SPINDLE GUIDE

EXTERNAL CIRCLIP S-25 (3)

GEAR CASE

BUSHING 18X23X4

QUILL GEAR

BUSHING 30X36X12

BALL BEARING 608ZZ (3)

BEVEL GEAR M1X46T

PARALLEL KEY M4X4X8

INTERMEDIATE GEAR M1.25X9T

SCREW M5X25 (2)

SCREW M5X30 (2)

GEAR COVER

SCREW M5X25 (4)

No. List/Size Description

32

3

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

62

3

RB3032

RB3033

RB3034

RB3035

RB3036

RB3037

RB3038

RB3039

RB3040

RB3041

RB3042

RB3043

RB3044

RB3045

RB3046

RB3047

RB3048

RB3049

RB3050

RB3051

RB3052

RB3053

RB3054

RB3055

RB3056

RB3057

RB3058

RB3059

RB3060

RB3061

RB3062

BEARING 60012RS

ARMATURE 110V M1X6T

CREW M5X60 (2)

S

STATOR

MOTOR HOUSING

CARBON BRUSH 7X11 (2)

BRUSH HOLDER (2)

NUT M4 (2)

BRUSH SPRING (2)

SCREW M4X10 (2)

SCREW M4X12 (4)

MOTOR TAIL COVER

SCREW M4X25 (2)

CRANK SPINDLE

CRANK BUSHING 28X32X12 (2)

THRUST WASHER 25.5X40X2 (2)

BALL SEAT

CHECK BALL 05

CRANK HUB

SPRING .6X4.1X5.3X4TX8.5L

PLUNGER

PLUNGER GUIDE 4.1X10X4.5

BUTTON

CRANK LEVER

GRIP

SOCKET CAP SCREW M6X30 (2)

SPRING WASHER M6 (3)

LED LAMP

FLAT HEAD SCREW M4X6

MAGNET BASE 164X80X48

SCREW M4X14 (2)

No. List/Size Description

63

RB3063

4

6

RB3064

65

B3065

R

66

RB3066

67

RB3067

68

RB3068

69

RB3069

70

RB3070

71

RB3071

72

RB3072

73

RB3073

74

RB3074

75

RB3075

76

RB3076

77

RB3077

78

RB3078

79

RB3079

80

RB3080

81

RB3081

82

RB3082

83

RB3083

84

RB3084

85

RB3085

86

RB3086

All parts are 1 Piece unless

otherwise stated in brackets

CABLE CLIP

ORD ARMOR

C

POWER SUPPLY CABLE - 110v

MOTOR NVR SWITCH 110V

MAGNET SWITCH

SCREW M4x8 (8)

SWITCH BRACKET

MOUNTING PLATE

OVERLOAD UNIT - 110V

SCREW M4X8

SOCKET CAP SCREW M6X16

SCREW M4X16

SUN WASHER M4

WASHER 30X38.5 (2)

SEAL

STRAP (inc. 78-1, 78-2 & 78-3)

SCREW M5x8

SCREW M5X10

FLAT WASHER M10.1X14X1

SAFETY CHAIN

WIRE LEAD-BLACK 18CM (2)

WIRE LEAD-YELLOW 18CM (2)

O-RING 12X20X4

E-CLIP E3

OTHER MODELS AVAILABLE FROM CHAMPION

RB32 MINIBRUTE RB45 MIGHTIBRUTE RB65 MEGABRUTE AC35

P.O.Box 368, Rockville Centre, NY 11571-0368

Tel: 516-536-8200 Fax: 516-536-8186

www.championcuttingtool.com

Loading...

Loading...