Page 1

Installation/Operation Manual with Service Re

Undercounter

High Temperature

Dishwasher

Model:

IUH 351

placement Parts

3765 Champion Boulevard

Winston-Salem, NC 27105

336/661-1992 Fax: 336/661-1660

Toll-free: 800/858-4477

IUH 351

Issue Date: 6.9.11

Manual P/N 0512961 rev. D

For machines beginning with S/N W09019166 and above

2674 North Service Road, Jordan Station

Ontario, Canada L0R 1S0

905/562-4195 Fax: 905/562-4618

Toll-free: 800/263-5798

Machine Serial No.

Printed in the USA

Page 2

For future reference, record your dishwasher information in the box below.

Model Number__________________________ Serial Number_______________________

Voltage________________Hertz_____________ Phase__________________

Service Agent __________________________________ Tel:______________________

Parts Distributor _________________________________ Tel:______________________

National Service Department

In the U.S.A.

Toll-free: 800/ 858-4477

Tel: 336/ 661-1992

Fax: 336/ 661-1660

Email: service@championindustries.com

ATTENTION:

The model no., serial no., voltage, Hz

and phase are needed to identify your

machine and to answer questions.

The machine data plate is located

on the lower front panel.

Please have this information ready

if you call for service assistance.

COPYRIGHT © 2011 All rights reserved Printed in the USA

Page 3

Revision History

Revision History

• The Revision History can contain part number changes, new instructions, or

information that was not available at print time.

• We reserve the right to make changes to these instructions without notice and without

incurring any liability by making the changes..

• Equipment owners may request a revised manual, at no charge, by calling

1 (800) 858-4477 in the USA.

Revision Revised Serial Number Revision

Date Pages Effectivity Description

8.31.09 All W09019168 Releasedrstedition

6.14.10 4 W09019168 Corrected drain type to gravity

1.21.11 15-37 W09019168 Reformatted parts list

5.5.11 30-31 W09019168 Changed Item 1 to 220VAC

6.9.11 34-35 W09019168 Changed door assembly to P/N 0713141

i

Page 4

Blank Page

This Page

Intentionally

Left Blank

ii

Page 5

Table of Contents

Table of Contents

Model IUH 351 Undercounter Dishwasher

Revision History .................................................................................................................i

Model Description

..............................................................................................................iv

Installation ..............................................................................................1

Receiving ....................................................................1

Electrical Connections ................................................2

Water Connections .....................................................4

Drain Connections ......................................................5

Initial Start-up ..........................................................................................6

Operation ...............................................................................................................7

Normal Wash Mode ....................................................7

Rinse Sentry Mode .....................................................8

Cleaning and Maintenance .......................................................................9

Cleaning ......................................................................9

Maintenance ...............................................................12

Troubleshooting ..........................................................13

Service Replacement Parts .......................................................................15

Electrical Schematic

Timer Chart

.............................................................................................39

.............................................................................................38

iii

Page 6

Model Description

Model Description

IUH 351

High temperature hot water sanitizing dishwasher with built-in 40°F/22°C rise booster heater.

208-240VAC/50/60/1

iv

Page 7

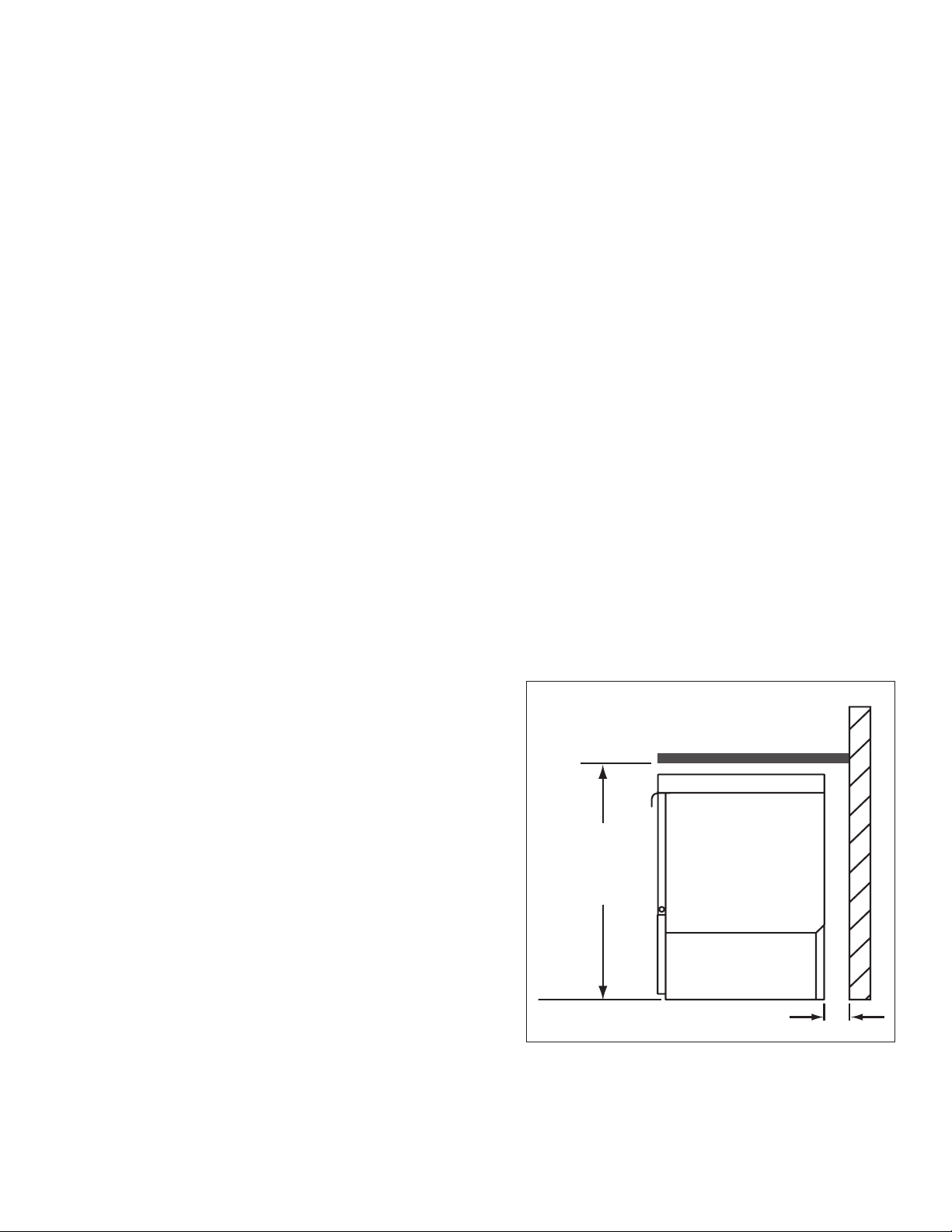

Installation

Counter-top

Wall

3" [8cm] Min.

34"

[86cm]

Min.

Floor

Receiving

NOTE:

The installation of your dishwasher must be performed by qualified service personnel.

Problems due to improper installation are not covered by the Warranty.

1. Inspect the outside of the dishwasher carton for signs of damage.

2. Remove the carton and inspect the dishwasher for damage.

3. Check for any accessories that may have shipped with your dishwasher.

4. Move the dishwasher near its permanent location.

CAUTION:

Be careful when lifting the to prevent damage.

NOTE:

The installation must comply with local health codes.

5. Check the utility connections are the same.

6. The dishwasher can be installed as a free-standing or under a built-in counter-top.

The typical counter-top height 34" [86cm].

7. Place the dishwasher in its permanent location.

8. The dishwasher has 4 adjustable feet for leveling.

9. Level the dishwasher front-to-back and

side-to-side.

1

Page 8

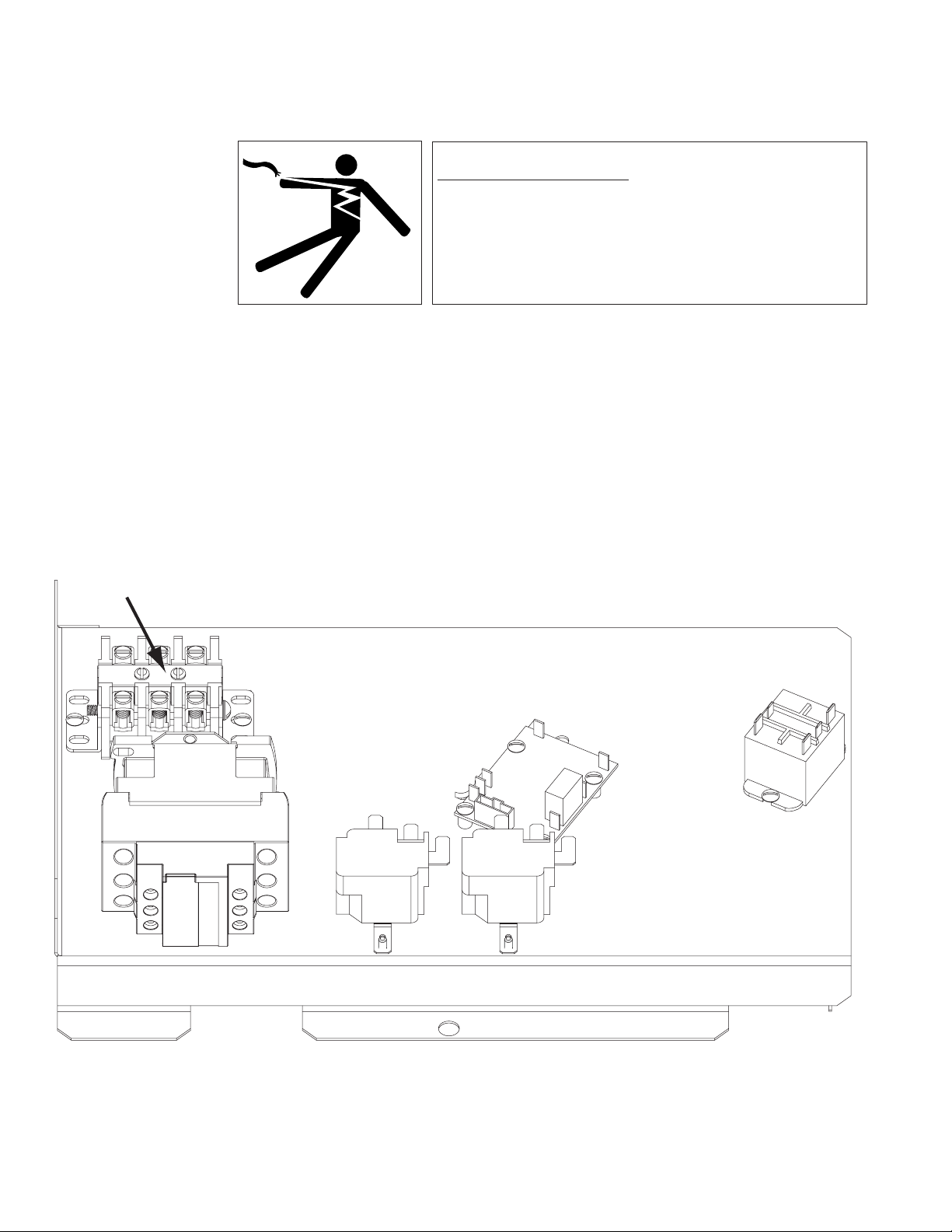

Installation

Main Terminal Block

Electrical Connections

WARNING:

Electrocution or serious injury may result when working on an

energized circuit.

Disconnect power at the main breaker or service disconnect

switch before working on the circuit.

Lock-out and tag the breaker to indicate that work is being

performed on the circuit.

ATTENTION

A qualified electrician must connect the main incoming power to the dishwasher in accordance

with all local codes and regulations .

VERIFY THE CORRECT VOLTAGE IS SUPPLIED TO THE MACHINE

THE CORRECT SUPPLY VOLTAGE IS/208-240VAC/50/60/1.

(See the diagram on next page.)

2

The Main Terminal Block (MTB) is located on the left-rear corner

of the electrical panel.

Page 9

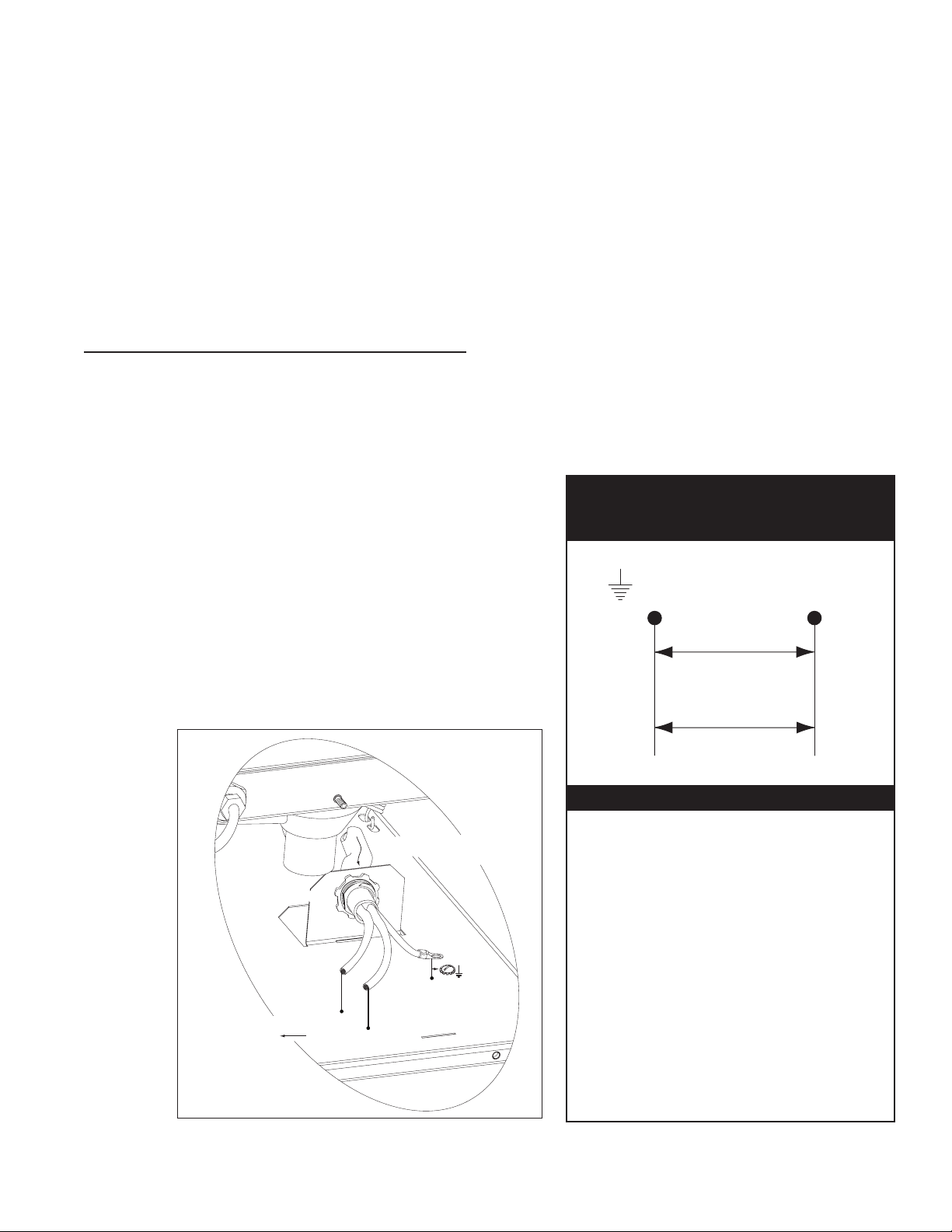

Installation

Electrical Connections

1. Refer to the connection diagram on the preceding page and the photo below:

2. Machines require a 2-wire plus ground supply which includes a current carrying neutral.

3. Power connections are made at the Main Terminal Block (MTB).

4. The MTB is located on the left-rear corner of the electrical panel behind the front access panel.

(See the illustration on the previous page.)

NOTE:

Provide a 3 foot service loop in the power cable at the back of the dishwasher for service.

To Connect Main Power to the Dishwasher:

1. Remove the lower front access panel of the dishwasher.

2. Locate the electrical mounting panel on the right-side of the machine.

Remove the retaining nut at the top of the panel that holds the panel in place.

3. Lower the panel and pull it forward to gain access the MTB.

4. Feed the power cable through the cable hole located

on the right side, as viewed from the front of the machine,

into the interior of the machine.

5. Make sure the cable passes through the cable mounting

bracket located near the front-center of the

base and secure the cable with a cable connector.

6. Connect the ground wire to the base of the dishwasher

with the ground screw provided next to the

cable mounting bracket.

SINGLE PHASE POWER CONNECTION

208-240VAC 50/60/1

GRD

L1 L2

7. Feed the remaining cable wires to the Main Terminal

Block and connect according to the connection

diagram to the right.

From Rear of Machine

Cable Bracket

GRD

L1

To Main Terminal Block

L2

208-240

VAC

HOW TO CONNECT POWER

1. Check the data plate on the front of the

dishwasher for the voltage of the machine.

2. Remove the lower-front access panel.

3. Lower the electrical component bracket.

4. Feed the power cable from the rear of the

dishwasher to the center of the machine

and through the cable bracket.

5. Connect the ground wire to the base of the

dishwasher using the ground screw located

near the bracket.

6. Feed the power leads to the terminal block.

7. Connect L1, L2 and ground.

8. Main Power connections are complete.

Route the supply cable through the cable bracket.

3

Page 10

Installation

Water Connections

NOTE

Plumbing connections must comply with local plumbing and sanitary codes.

IMPORTANT

Make sure that the flexible water supply and drain hoses are not kinked.

1. All models have a 6 ft. exible hot water ll hose with a 3/4" NPS connector.

2. A 1/2" or larger main incoming supply line should be installed to the dishwasher.

3. A 1/2" or larger shut-off valve should be installed in the water supply line as close to the

dishwasher as possible for service.

4. The pressure regulating valve, PRV, must be installed after the shut-off service valve if the

incoming ow pressure exceeds

20-22 psi.

5. The hot water supply must provide a minimum of 140°F/60°C, measured at the dishwasher for

the 40°F/ 22°C rise booster.

Drain Connections

1. The dishwasher has a 6 ft. exible hot water ll hose with a 3/4" NPS connector.

2. The machine is a gravity drain.

3. The maximum drain ow is 8 U.S. gpm /30 LPM.

4. Make sure the drain hose does not kink. Kinks will prevent the dishwasher from draining

completely causing water to ow out the front door.

4

Page 11

Blank Page

This Page

Intentionally

Left Blank

5

Page 12

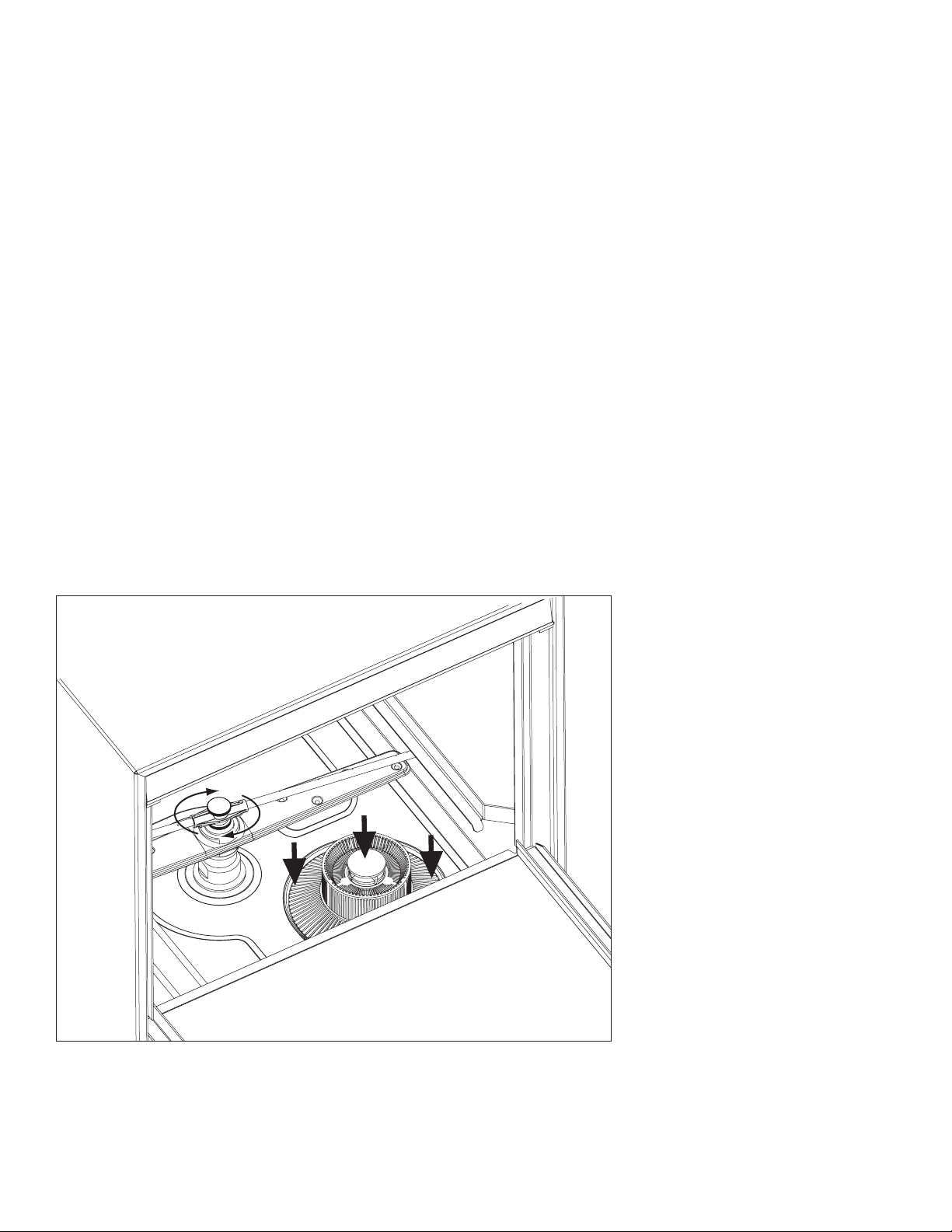

Initial Start-up

Check List

1. Remove any protective lm from dishwasher. Check the interior for foreign material.

2. Make sure that the dishwasher is permanently located.

3. Make sure that all utility connections are complete.

4. Make sure that the exible drain hose and the hot water ll hose are not kinked.

5. Make sure that the sump lter is in place.

6. Make sure that the overow tube is installed and rmly seated in the sump.

7. Make sure that the spray arms are in place and that they spin freely.

8. Fully close the dishwasher door.

9. Turn hot water supply on and check for leaks in the main water supply piping connected

to the dishwasher.

IMPORTANT

During the initial fill, adjust the PRV to ensure that the flowing pressure of the incoming water

is set to 20-22 PSI.

Install the scrap screen, overflow tube, and spray arms.

Make sure the spray arms turn freely.

6

Page 13

Operation

Normal Wash Mode

Follow the instructions below to operate the dishwasher in a Normal Wash Mode.

holds the dishwasher in a wash mode if the booster heater temperature is below 180ºF/82ºC.

1. Turn the main power on at the main circuit breaker.

2. Install the sump lter, overow tube and spray arms.

3. Make sure the exible drain hose and the exible ll hose are not kinked,

then turn the water supply on.

4. Close the dishwasher front door.

5. Push the dishwasher Power Switch to the ON position.The power switch will illuminate and the

machine will ll with water.

6. Wait 15-minutes for dishwasher to reach a minimum of 150ºF/66ºC.

At the beginning of the day, run 2 empty cycles before checking the final rinse

operating temperature. The first cycle will take longer than normal because the

7. Load soiled wares into the dish rack. Place plates, glasses, cups and bowls in a peg rack.

Place utensils in a single layer in a flat-bottom rack. Place pots and pans in a flat-bottom rack.

Do not overload the dish racks.

water temperature in the booster is low.

ATTENTION

A Rinse Sentry feature

8. Slide 1 dish rack into the wash compartment making sure that wares do not interfere with the

rotating spray arms. Do not wash more than 1 dish rack at a time.

9. Close the front door fully, then press and hold the START BUTTON for 1-second. The green

in-cycle light will illuminate and the wash cycle will begin. The wash cycle time runs for

approximately 1-1/2 minutes. (continued on next page)

10. Opening the door when the dishwasher is in-cycle will stop the dishwasher. The cycle will resume

automatically when the dishwasher door is closed fully.

7

Page 14

Operation

Normal Wash Mode

11. The nal rinse cycle begins at the end of the wash cycle and runs for approximately 15-seconds

12. At the end of the rinse cycle, the in-cycle light will go out. Open the door and remove the clean

rack of wares. Repeat steps 8-12 for additional dish racks.

13. Refer to the Cleaning Instructions, "After Each Meal Period or every 8 Hours of Operation", on

page 9 for the procedures to drain and clean the dishwasher.

Rinse Sentry Mode

The nal rinse water temperature must be a minimum of 180ºF/82ºC during the final rinse cycle to ensure

that all wares are sanitized. If for any reason, the hot water temperature in the booster tank cannot provide

this temperature, the dishwasher will enter a Rinse Sentry Mode of operation and extend the cycle time.

The Rinse Sentry changes the Normal Operation Mode as described below:

1. The Rinse Sentry constantly monitors the water temperature inside nal rinse booster.

2. If the temperature inside the booster heater falls below 180ºF/82ºC then the Rinse Sentry

will extend the wash cycle time until the booster heater water temperature reaches the proper

temperature.

3. The in-cycle light will remain illuminated during the Rinse Sentry Mode.

(continued)

4. An extraordinarily long wash cycle may indicate a low incoming water temperature or a

problem with the booster heater operation.

DO NOT REMOVE WARES UNTIL THE FINAL RINSE CYCLE HAS

SANITIZED THE WARES AND THE GREEN CYCLE LIGHT GOES OUT.

8

Page 15

Cleaning and Maintenance

Cleaning

After Each Meal Period or every 8 Hours of Operation.

1. Press the lighted power switch to the OFF position. The power switch light will go out.

2. Open the door and remove the overow tube.

3. Inspect and clean the overow tube rubber seal

4. Remove the sump lter carefully to keep the soil or waste particles from falling into the sump.

5. Clean the sump lter by rinsing with clean water.

Be sure to back-ush the lter.

Do not strike the lter against solid objects.

6. Check the sump for foreign material and clean as required.

7. Replace sump lter and the overow tube.

8. Make sure that spray arms turn freely.

9. Close the door and turn the ON/OFF switch to ON and return to normal operation mode.

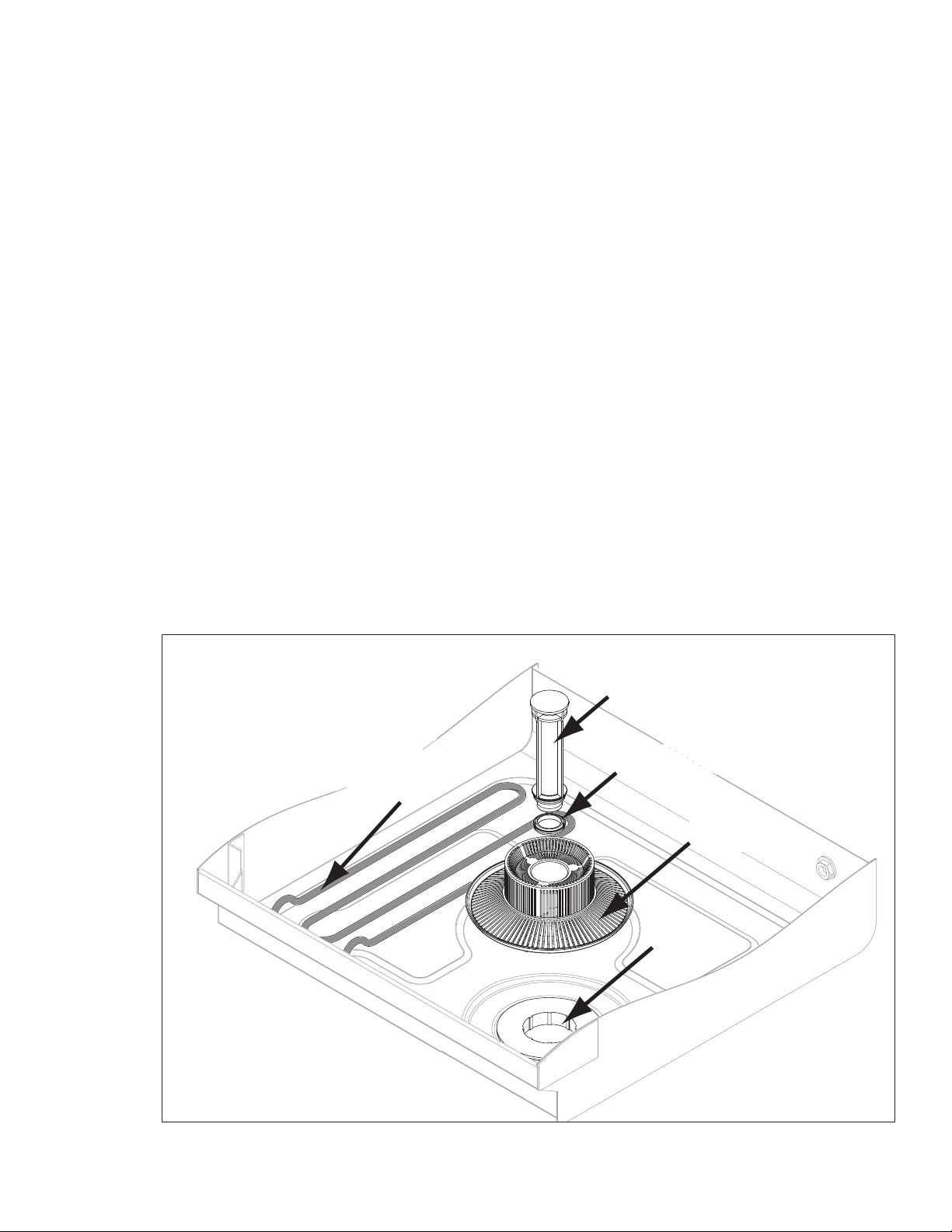

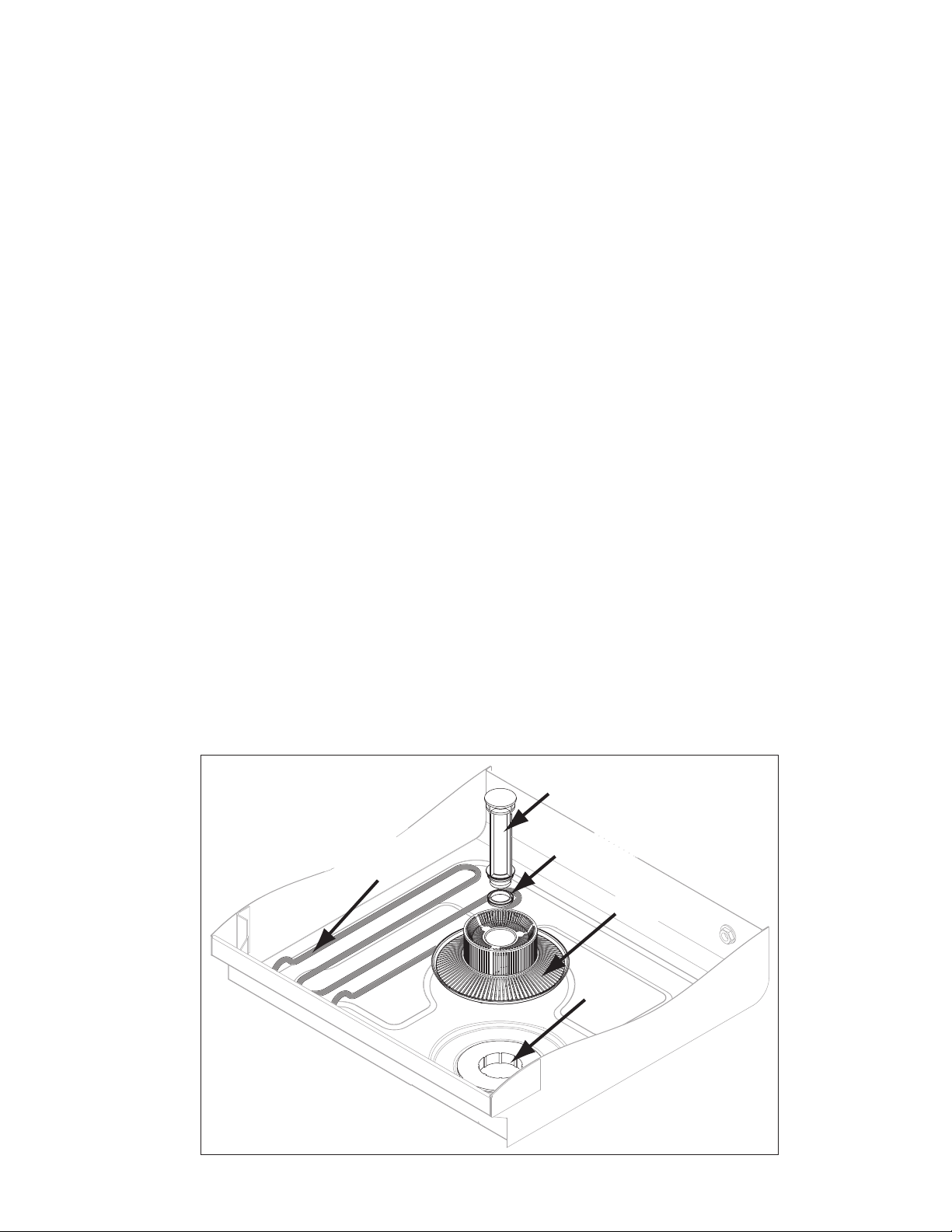

Heating

Element

Overflow

Tube

Overflow

Seal

Sump

Filter

Sump

9

Page 16

Cleaning and Maintenance

Cleaning

At the End of the Day

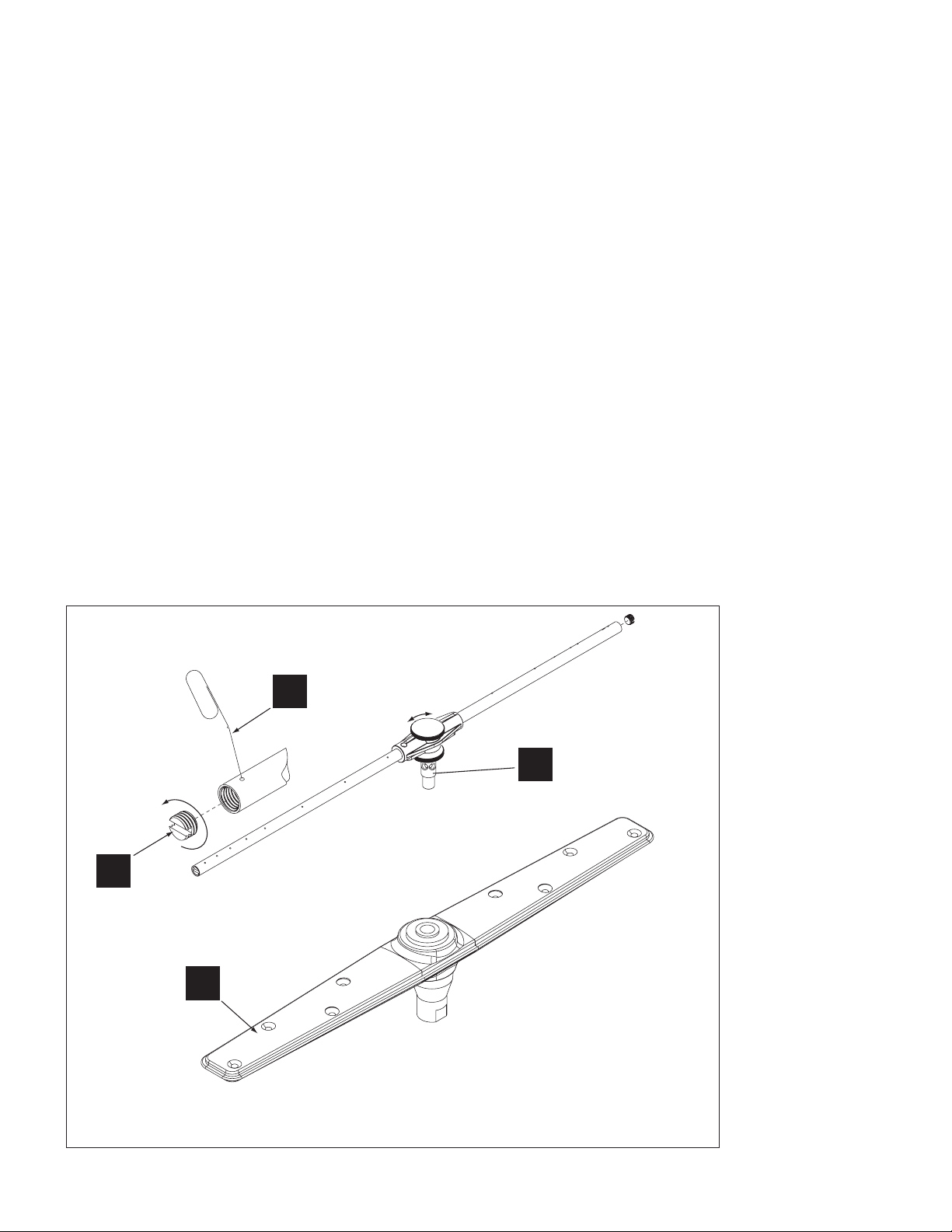

1. Remove the upper and lower rinse and wash spray arms. The spray arms are interchangeable.

2. Unscrew the rinse arm pin (A). Remove the rinse arm assemblies

3. Clean the nal rinse arm nozzles using a small paper clip (B).

4. Remove the rinse arm end plugs (C) if necessary, and ush the rinse arm with clean water.

5. Re-install the rinse arm end plugs if they were removed.

6. Remove the wash spray arms and ush with clean water.

7. DO NOT USE STEEL WOOL TO CLEAN THE INTERIOR OF THE MACHINE.

8. Contact the chemical supplier for de-liming if required (see next page).

9. Wipe the interior and exterior of the machine with a soft cloth and a mild detergent.

DO NOT HOSE THE EXTERIOR OF THE MACHINE WITH WATER.

10. Reassemble the dishwasher and leave the door open to allow overnight drying.

Paper Clip

End

Plug

C

Wash Spray arm

D

B

Rinse Arm Pin

A

10

Page 17

Cleaning and Maintenance

De-liming

Minerals accumulate on the interior surfaces of the dishwasher. The deposits have a white haze

and, in cases of heavy accumulation, may appear as a granular solid. The generic name for mineral

deposits is lime. The removal of lime deposits is called de-liming. Your dishwasher should be delimed regularly; how often will depend on the mineral content of your water.

Inspect your machine interior for lime deposits. If deliming is required, a de-liming agent should be

used for best results in accordance with the chemical supplier's instructions.

DANGER:

Death or serious injury may result when de-liming solution is mixed with sodium hypochlorite

(chlorine bleach) sanitizing agent. Mixing may cause hazardous gases to form.

De-liming solution and other acids must never be mixed with chlorine, iodine, bromine, or fluorine.

CAUTION:

Skin contact with de-liming solutions can cause severe irritation and possible chemical burns.

Always wear protective clothing and googles when handling chemicals.

ATTENTION:

Contact your chemical supplier for specific safety procedures and instructions for the use of

the de-liming solution supplied for the dishwasher.

De-liming solution or other chemicals are not supplied by the dishwasher manufacturer.

Overflow

Tube

Heating

Element

Overflow

Seal

Sump

Filter

Sump

11

Page 18

Cleaning and Maintenance

Maintenance

Follow the maintenance schedules below to keep the dishwasher operating most efficiently.

Daily Maintenance

1. Check all of the wash arm and rinse arm spray jets and clean as necessary.

2. Make sure that the water supply is on and that the drain is not clogged.

3. Make sure that dish racks are in good condition.

4. Follow the cleaning procedures given above.

Weekly Maintenance

1. Perform Steps 1-4 in the Daily Maintenance.

2. Inspect water lines for leaks.

3. Check for water leaks underneath the dishwasher.

4. Make sure the exible water ll and drain hoses are not kinked.

5. Make sure that the dishwasher is level.

6. Clean accumulated lime deposits from the wash tank heating element.

7. Inspect the scrap screen and replace it if damaged.

8. Check the spray arms and replace or repair if damaged.

12

Page 19

Troubleshooting

Troubleshooting

Follow the troubleshooting guide below in the event that your dishwasher does not operate as

expected. Perform the basic checks below before calling an authorized service agent:

1. Make sure that the main water supply is turned on.

2. Make sure that the main power is turned on.

3. Make sure that the exible water ll and drain hoses are not kinked.

Condition Cause Solution

Dishwasher will not run.

Low or no water.

Poor wash results.

Dishwasher stays in

wash cycle.

Door not closed.

Main power OFF.

Dishwasher OFF.

Main water supply off.

PRV setting incorrect

Solenoid strainer clogged.

Solenoid valve defective.

Detergent not added to tank

Wares incorrectly loaded.

in dishrack.

Clogged sump filter.

Clogged spray arms.

Thermostat defective.

Detergent motor defective.

Water temperature low.

Rinse Sentry extends wash

mode to allow final rinse

water booster temperature

to reach 180˚F/82˚C.

Close door completely.

Check breaker on panel.

Turn dishwasher ON.

Open supply valve.

Adjust the PRV setting

Clean strainer.

Contact Service Agent.

Add detergent.

Reposition wares or

reduce amount of wares.

Clean sump filter.

Clean spray arms.

Contact Service Agent.

Contact Service Agent

Contact Service Agent

Contact Service Agent

because booster

thermostat is defective.

13

Page 20

Blank Page

This Page

Intentionally

Left Blank

14

Page 21

Service Replacement Parts

Service Replacement Parts

Illustrations Page

Wash Pump/Motor Assembly ................................................................................................................................. 16

Booster Assembly ................................................................................................................................................... 18

Electrical Panel and Timer Assembly ..................................................................................................................... 20

Control Panel Assembly ......................................................................................................................................... 22

Wash and Rinse Spray Arm Assemblies ................................................................................................................ 24

Lower Hose Assembly ............................................................................................................................................ 26

Wash Tank Heater and Drain Assemblies .............................................................................................................. 28

Fill Solenoid Valve Assembly .................................................................................................................................. 30

Panel Assembly ...................................................................................................................................................... 32

Door Assembly ....................................................................................................................................................... 34

Dish racks, Line Strainer, Pressure Regulating Valve (PRV) ................................................................................ 36

Electrical Schematic ............................................................................................................................................... 38

Timer Chart ............................................................................................................................................................. 39

15

Page 22

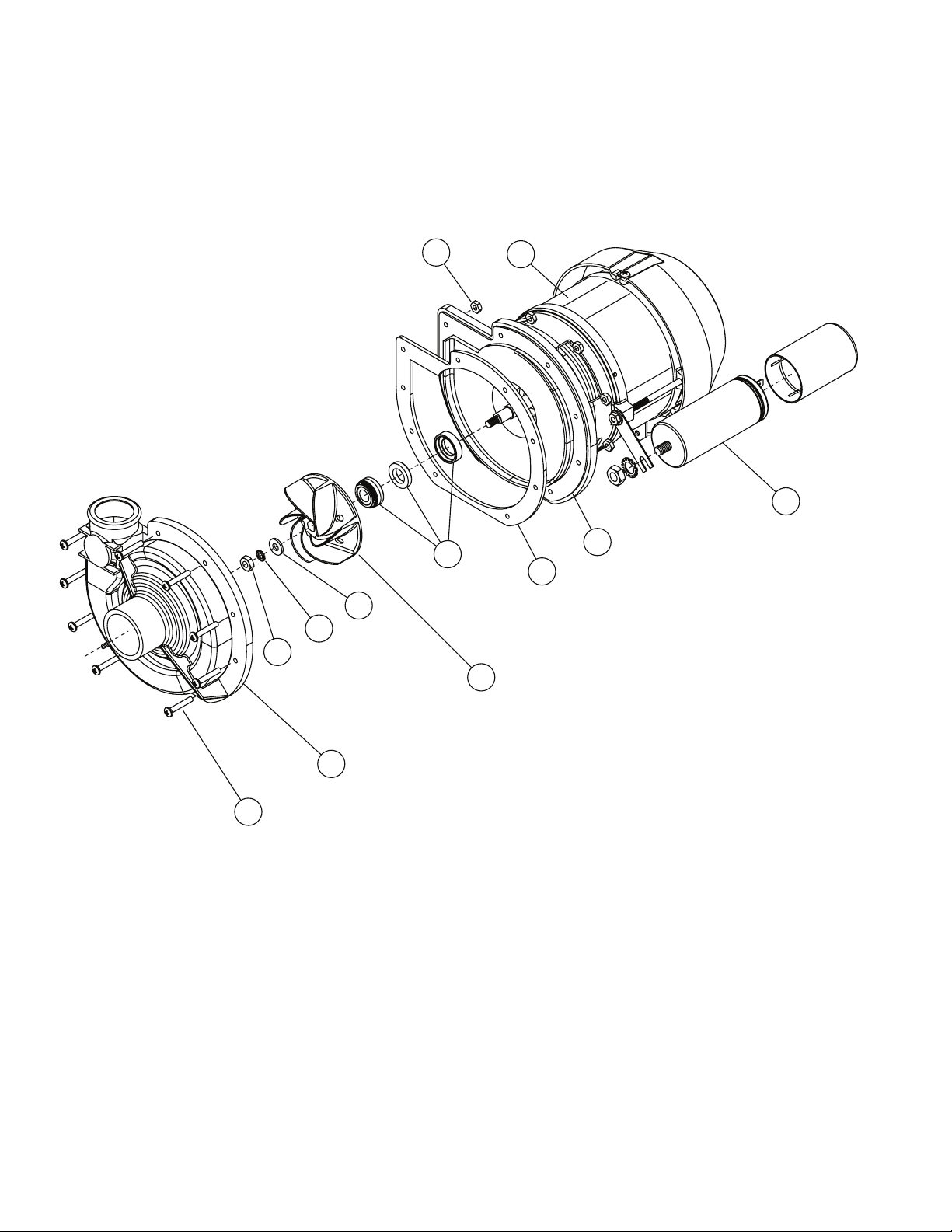

Wash Pump/Motor Assembly

10

7

5

4

3

11

12

9

8

6

16

2

1

Page 23

Wash Pump/Motor Assembly

Item Part Description Qty.

No. No.

1 0512340 SCREW, M4, PHIL, PAN HD. 9

2 0512341 IMPELLER HOUSING COVER 1

3 114144 NUT, M6 (left-hand thread) 1

4 0501501 WASHER, LOCK, 1/4" 1

5 0501478 WASHER, PLAIN, 17/64" 1

6 0512345 IMPELLER 1

7 114139 SEAL 1

8 110285 GASKET, PUMP

9 114137 BACKPLATE, PUMP 1

10 107337 NUT, M4 9

1 1 0512101-1 PUMP/MOTOR ASSEMBLY COMPLETE 1

220VAC 50/60/1

12 H29043 CAPACITOR 16μF 1

17

Page 24

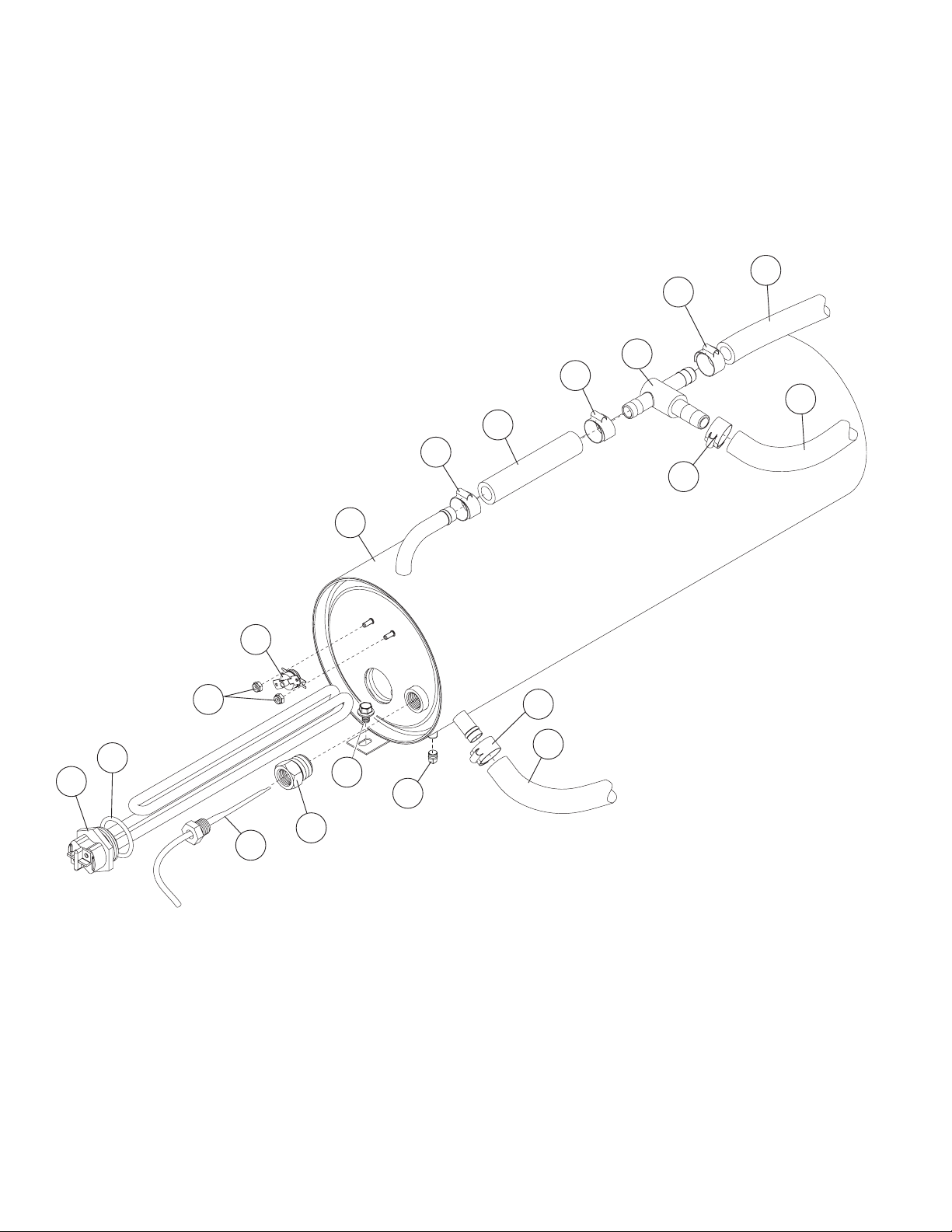

Booster Assembly

10

9

11

9

10

10

9

9

8

7

12

2

1

3

4

5

13

9

6

18

Page 25

Booster Assembly

Item Part Description Qty.

No. No.

1 0512847 HEATER, BOOSTER 4kW, 208V, 40°F RISE 1

(Does not include gasket)

2 0512928 GASKET, BOOSTER HEATER 1

3 0512108 THERMOSTAT, CONTROL 195°F 1

4 0512185 BOLT, HEX FLANGE, 1/4-20 X 3/8" SST 1

5 0508817 PLUG, 1/8" SST 1

6 0512926 HOSE, BOOSTER FILL 1

7 110562 THERMOSTAT, HI-LIMIT FIXED SNAP 240°F 1

8 0712835 TANK, BOOSTER WELDMENT 1

9 0503679 CLAMP, GEAR-TYPE, 7/16" SST 5

10 107417 HOSE, 1/2" ID A/R

11 0512968 TEE 1

12 108954 NUT, GRIP 6-32 W/NYLON INSERT 2

13 0512920 FITTING, BOOSTER THERMOSTAT 1

19

Page 26

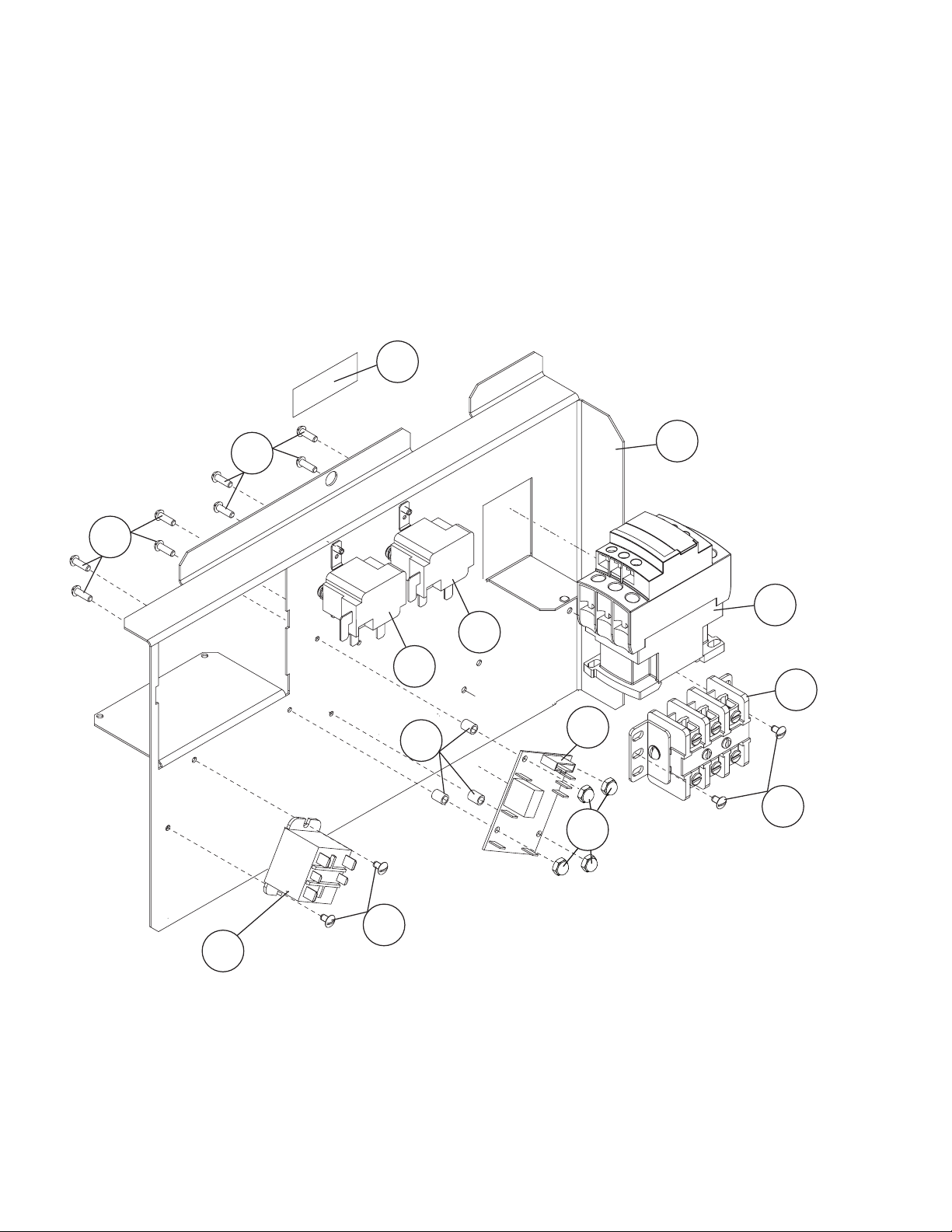

Electrical Panel and Timer Assembly

13

11

12

4

5

2

3

6

8

9

7

14

20

7

10

Page 27

Electrical Panel and Timer Assembly

Item Part Description Qty.

No. No.

1 0507323 THERMOSTAT, WASH T ANK 1

3 0512108 THERMOSTAT, BOOSTER 195°F 1

4 0312909 PANEL, CONTROL 1

5 C120444 CONTACTOR, 25/40A, 3P, 220V COIL 1

6 0504951 BLOCK, TERMINAL 1

7 0503745 SCREW, RH 8-32 X 3/16" SLOTTED SST 4

8 0512969 TIMER 1

9 CM0082006 STAND-OFF, CIRCUIT BD. NYLON 4

10 0509428-1 RELAY, 15 AMP 1

11 0503620 SCREW, RH, 4-40 X 3/16" SLOTTED SST 4

12 0501450 SCREW, NIBS RH 6-32 X 3/16" PHIL. SST 4

13 0512934 LABEL, WASH-RINSE TEMPERA TURE 1

14 CM0082007 CAP, STAND-OFF, NYLON 4

21

Page 28

Control Panel Assembly

12

13

9

8

7

6

4

3

10

2

11

12

1

13

22

Page 29

Control Panel Assembly

Item Part Description Qty.

No. No.

1 0312959 PANEL, FACIA, IUH 351 1

2 0512958 LABEL, FACIA, IUH-351 1

3 0513075 SWITCH, ROCKER DPDT 250V NEON IUH 351 1

4 0512216 CONTACT, MOMENTARY, N.O. 2

5 0512217 HOUSING, SWITCH 2

6 0512218 BUTTON, SWITCH (GREEN) 1

7 0512232 LIGHT, INDICATOR LED, 2VDC (GREEN) 1

8 H160121 HOSE, 4.1 ft / 125cm 1

9 H450134 CLIP, HOSE 2

10 109835 SCREW, #8 1/2" PAN PHIL. T/A SELF-TAPPING 1

11 H31171 SWITCH, PRESSURE 1

12 0501408 SCREW, TRUSS SLOT., 8-32 X 1/4" SST 2

13 0512320 GASKET, STEAM 2

23

Page 30

Wash and Rinse Spray Arm Assemblies

14

15

1

2

3

4

5

6

7

22

22

21

20

22

23

20

19

24

21

22

8

11

10

16

12

12

9

17

13

18

19

24

6

8

24

Page 31

Wash and Rinse Spray Arm Assemblies

Item Part Description Qty.

No. No.

1 0501478 WASHER, 17/64 id X 9/16" OD SST 4

2 107967 NUT, HEX 1/40-20 NYLON INSERT SST 4

3 H35509 HUB, UPPER WASH ARM 1

4 107873 WASHER, PACKING 1

5 110215 SCREW, RETAINING 1

6 0502571 CLAMP, HOSE GEAR 1-1/2" SST 2

7 0512120 HOSE, UPPER WASH ARM 1

8* 0712749 BEARING ASSEMBLY 2

9 0512133 O-RING, 2-1/8" OD X 1-3/4" ID X 3/16" 1

10 0512066 HUB, LOWER WASH ARM 1

11 0512918 MANIFOLD, LOWER FWR 1

12 H420548 WASH ARM ASSEMBL Y (Includes Item 8) 2

13 0512133 O-RING, 2-1/8" OD X 1-3/4" ID X 3/16" 1

14 0501481 WASHER, NYLITE 4

15 100738 BOLT, 1/4-20 X 1" SST 4

16 0512124 SHAFT, LOWER 1

17 0512239 O-RING 1

18 0312840 HUB, RINSE ARM, MOLDED 2

19 0501408 SCREW, TRUSS SLOTTED 8-32 X 1/4" SST 4

20 0512841 ARM, RIGHT-HAND RINSE (7 JETS) 2

21 0512842 ARM, LEFT-HAND RINSE (8 JETS) 2

22 0512843 CAP, RINSE ARM, 5/16-24 4

23 H36275 SPINDLE, RINSE ARM 2

24 H34998 SPACER, NUT 2

--- 0712834 RINSE ARM ASSEMBL Y (Includes Items 18-24) 2

* Note:

The bearing assembly, P/N 0712749 includes 2 bearings, 1 locknut, and 1 wash arm hub.

The bearings, locknut and hub are not available as separate service replacement parts.

25

Page 32

Lower Hose Assembly

From Final Rinse Tee

To upper washarm hub

1

5

2

8

4

3

7

7

6

8

9

10

26

14

13

1

11

12

8

Page 33

Lower Hose Assembly

Item Part Description Qty.

No. No.

1 0502563 CLAMP, HOSE GEAR-TYPE 1" SST 2

2 107417 HOSE, RUBBER 1/2" id X .84" OD A/R

3 0503679 CLAMP, HOSE GEAR-TYPE 1

4 0512120 HOSE, UPPER WASH 1

5 0512119 HOSE, DISCHARGE, WASH PUMP 1

6 0502571 CLAMP, HOSE GEAR-TYPE1-1/2" SST 2

7 0512322 CLAMP, HOSE GEAR-TYPE 1-13/16" -2/34" MAX SST 2

8 0512885 HOSE, SUCTION, WASH PUMP 1

9 0312144 BRACKET, WASH PUMP 1

10 0502668 HOSE, DRAIN PUMP SUCTION 1

11 0512925 HOSE, FILL 1/2" X 7' C/W FNPS 1

12 0512936 WASHER, SILICON 5/8" ID X 7/8" OD 1

13 0512926 HOSE BOOSTER FILL 1/2" X 1' 1

14 0502572 CLAMP, HOSE GEAR-TYPE 5/16" 1

27

Page 34

Wash Tank Heater and Drain Assembly

1

21

25

24

22

23

2

20

19

3

4

5

6

7

8

2

9

18

3

3

4

10

4

28

11

10

12

13

14

15

17

16

Page 35

Wash Tank Heater and Drain Assembly

Item Part Description Qty.

No. No.

1 0512930 GASKET, DOOR 1

2 0512846 HEATER, WASH TANK, 2KW, 240VAC 1

3 100003 WASHER, SPLIT LOCK 1/4" SST 4

4 0501539 NUT, HEX 1/4-20 SST 4

5 0501836 O-RING 2

6 0508873 ADAPTER, THERMOSTAT 1

7 0512920 BUSHING, THERMOSTAT 1

8 0507323 THERMOSTAT, WASH T ANK 1

9 201029 NUT, LOCK 1/2" NICKLE-PLATED 2

10 108954 NUT, GRIP 6-32 W/NYLON INSERT 4

11 113604 THERMOSTAT, FIXED, SNAP 212°F 1

12 0501437 SCREW, 4-40 X 1/2" SST 2

13 0501379 SWITCH, DOOR 15 AMP 1

14 0309228 BRACKET, SWITCH 1

15 0312605 PLATE, SWITCH NUT 1

16 D500605 ELBOW, PUMP SUCTION 1

17 D80208 GASKET, PUMP SUCTION 1

18 D540088 FLANGE, PUMP SUCTION 1

19 H250110 TRAP. AIR 1

20 H25263 GASKET, FLAT 1

21 H25239 O-RING 1

22 H25011 COVER, AIR TRAP 1

23 0512845 FILTER, SUMP 1

24 0512789 SEAL, OVERFLOW TUBE 1

25 0512844 TUBE, OVERFLOW 1

29

Page 36

FillSolenoidValveAssembly

1

2

3

4

30

Page 37

FillSolenoidValveAssembly

Item Part Description Qty.

No. No.

1 0512853-1 VALVE, WATER INLET 220VAC/60/1 1

(Includes Item 2)

2 0512860 KIT, REPAIR SOLENOID VALVE A/R

3 0512185 BOLT, HEX FLANGE 1/4-20 X 3/8" SST 2

4 0312893 BRACKET, VALVE 1

31

Page 38

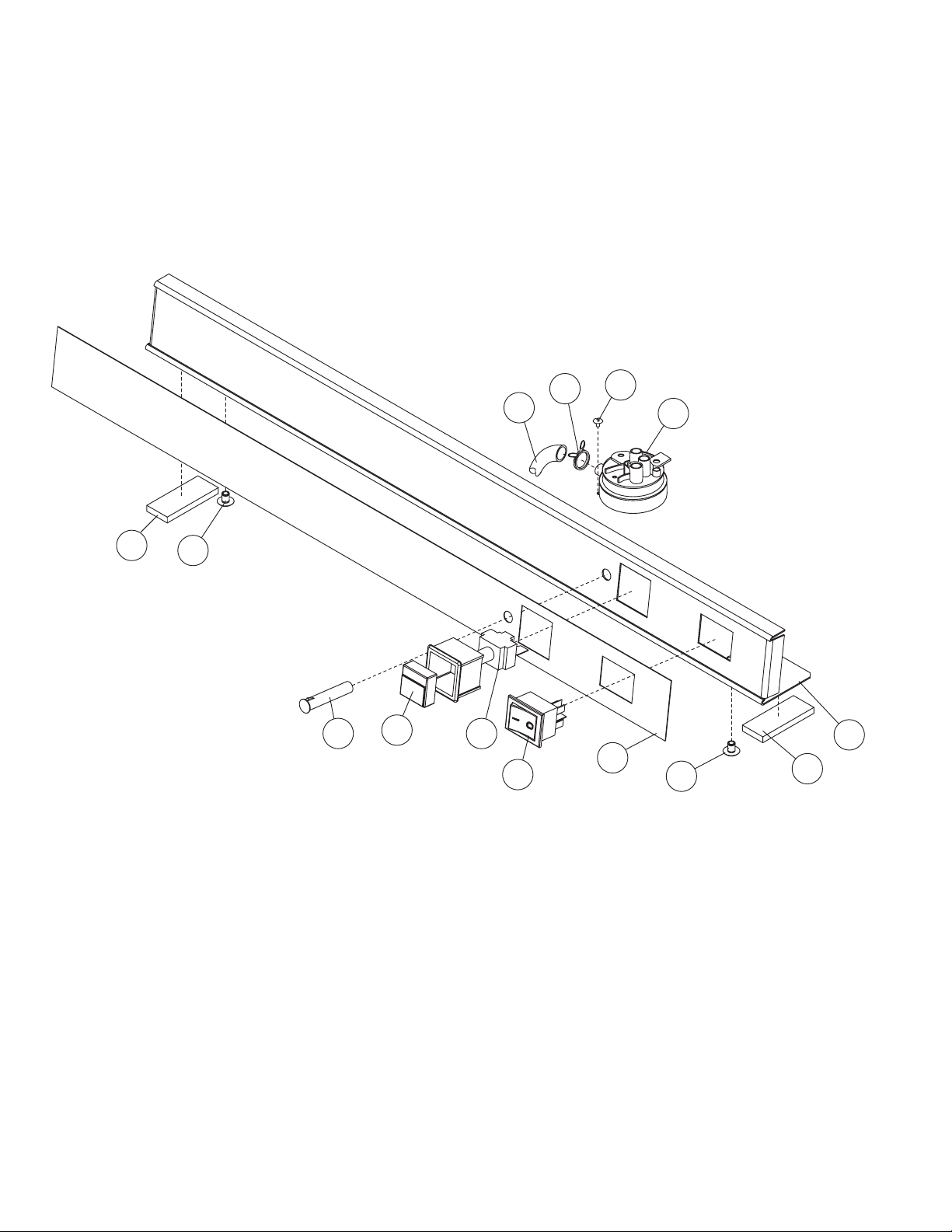

Panel Assembly

1

6

6

4

2

5

4

4

3

5

32

Page 39

Panel Assembly

Item Part Description Qty.

No. No.

1 0312905 WRAP, OUTER PANEL 1

2 0503718 FOOT , ADJUSTING 4

3 0312960 PANEL, FRONT IUH 351 1

4 100007 SCREW TRUSS SLOT SS 10-32X3/8 4

5 0503718 ADJUSTING, FOOT 4

6 0512761 CLAMP, DOUBLE CONDUIT 3

33

Page 40

Door Assembly

1

2

3

2

4

5

3

34

Page 41

Door Assembly

Item Part Description Qty.

No. No.

1 0713141 DOOR WELDED ASSY 1

2 0312892 ARM, DOOR SPRING 2

3 0512854 SPRING, DOOR 2

4 0312908 ACTUATOR, DOOR SWITCH 1

5 0503745 SCREW, 8-32 X 3/16" PHIL. SST 2

35

Page 42

DishRacks,LineStrainer,PRV

1

2

4

3

36

Page 43

DishRacks,LineStrainer,PRV

Item Part Description Qty.

No. No.

1 101273 DISH RACK, FLAT-BOTTOM AR

2 101285 DISH RACK, PEG AR

3 104421 STRAINER, LINE 1/2" BRONZE (OPTIONAL) 1

4 108265 VALVE, PRESSURE REGULATING (PRV) (OPTIONAL) 1

37

Page 44

Electrical Schematic

38

Page 45

Timing Chart

39

Page 46

Español

Manual de Español

40

Page 47

Instalación Y Operación, Manual de Servicio y Partes de Reemplazo

Lavadora de Platos

Bajo Barra

De Alta Temperatura

Modelo:

IUH 351

3765 Champion Boulevard

Winston-Salem, NC 27105

336/661-1992 Fax: 336/661-1660

Toll-free: 800/858-4477

IUH 351

Fecha Expedición: 6.9.11

Manual P/N 0512961 rev. D

para máquinas que empiezan con S/N W09019166 y arriba

2674 North Service Road, Jordan Station

Ontario, Canada L0R 1S0

905/562-4195 Fax: 905/562-4618

Toll-free: 800/263-5798

Maquina Número de Serie.

Impreso en los EE. UU.

Page 48

Para futuras referencias, escribir la infomaciόn de su lavadora de platos in el cuadro abajo.

Numero de Modelo__________________________ Numero de Serial_______________________

Voltaje________________Frecuencia_____________ Fase__________________

Servicio __________________________________ Tel:______________________

Distribuidor _________________________________ Tel:______________________

Departmento de Servicio Nacional en los EE.UU.

Toll-free: 800/ 858-4477

Tel: 336/ 661-1992

Fax: 336/ 661-1660

Email: service@championindustries.com

ATENCIÓN:

Nú.de modelo, Nú de serial, voltaje, Hz

y fase se necesitan para identicar su

máquina y para responder sus preguntas.

La placa de datos de la máquina se

encuentra en el panel frontal inferior.

Por favor tenga esta información lista

al momento de llamar al servicio de

asistencia.

COPYRIGHT © 2011 Todo derecho Reservado Impreso en los EE. UU.

Page 49

Historial de Revisiones

Historial de Revisions

Fecha de Revisiόn Effectividad de Descripciόn

Revisiόn de Páginas numero de serie de la Revisiones

8.31.09 Todas W09019166 PrimeroEdiciόn

6.14.10 4 W09019166 La máquina tiene un drenaje de gravedad

1.21.11 15-37 W09019166 Para formatear la lista de partes

5.5. 11 30-31 W09019166 Cambie artículo 1 a 220VAC

6.9.11 34-35 W09019166 Cambie ensamble de la Puerta a P/N 0713141

i

Page 50

Página en Blanco

Esta Página

Intencionalmente se ha

Dejado en Blanco

ii

Page 51

Indice de Contenidos

Indice de Contenidos

Model IUH 351 Lavaplatos Bajo Barra

Historial de Revisiones .......................................................................................................i

DescripciόndeModelo .......................................................................................................iv

Instalaciόn ..............................................................................................1

Recibir .........................................................................1

Conexiones Eléctricas ................................................2

Conexiones de agua ...................................................4

Conexiones de desagüe .............................................5

Arranque Inicial .......................................................................................6

Montaje ........................................................8

Funcionamiento ....................................................................................................7

Modo de Lavado Normal ............................................7

Modo de Enjuague Centinela .....................................8

Limpieza Y Mantenimiento ........................................................................9

Limpieza .....................................................................9

Mantenimiento ............................................................12

Localizaciόn Y Soluciόn De Problemas ......................13

Servicio, Partes De Reemplazo .................................................................15

Esquemas Eléctricos

Grácas para Medidor de Tiempos

............................................................................................38

............................................................39

iii

Page 52

DescripciόndeModelo

Descripciόn de Modelo

351HT E

El lavaplatos esterilizador de alta temperatura con agua caliente, está construido con

temperatura de calefacción de refuerzo integrado 40°F/22°C aumento.

208-240VAC/50/60/1.

iv

Page 53

Instalación

Barra

Pared

3" [8cm] Min.

34"

[86cm]

Min.

Piso

Recibir

ATENCIÓN:

La instalación de su lavaplatos debe realizarse por una persona de servicio calificado.

Problemas debido a la instalación incorrecta de su equipo no serán cubiertos por la garantía.

1. Inspeccionar el exterior de la caja de cartón de su lavaplatos por si tiene muestras de daño.

2. Quitar la caja de cartón e inspeccionar el lavaplatos por daños.

3. Buscar todos los accesorios que pueden haber sido enviadas con su lavaplatos.

4. Mueva el lavaplatos cerca de la ubicación permanente.

PRECAUCIÓN:

Tenga cuidado al levantarla para evitar daños.

ATENCIÓN:

La instalación debe cumplir con códigos de salud local.

5. Compruebe que las conexiones de utilidad sean los mismos.

6. El lavaplatos puede instalarse como un lavaplatos independiente o en virtud de uno bajo barra.

La altura típica de uno bajo barra es 34" [86cm].

7. Coloque el lavaplatos en su ubicación permanente.

8. El lavaplatos tiene 4 pies ajustables de nivelación.

9. Nivelar el lavaplatos alfrente y atrás, y lado a lado.

1

Page 54

Instalación

Conexiones Eléctricas

ADVERTENCIA:

Electrocución o lesiones serias pueden resultar cuando

se trabaja con un circuito de energía. Desconecte la energía

en el interruptor principal o de servicio de interruptores y

desconéctelo antes de trabajar en el circuito. Mirar y marcar

el interruptor para indicar que esta trabajando con

ese circuito.

ATENCIÓN

Un electricista calificado debe ser quien conecte la entrada de energía del lavaplatos de

acuerdo con las regulaciones de conformidad con todos los códigos reglamentarios locales.

VERIFICAR EL VOLTAJE CORRECTO QUE SE ESTA SUMINISTRANDO A LA MAQUINA

EL SUMINISTRO DE VOLTAGE CORRECTO ES 208 - 240 VCA/50/60/1.

(Vea el diagrama en la página siguiente.)

El Bloque Principal, Terminal Eléctrico

El bloque principal, terminal eléctrico (MTB) se encuentra en la esquina trasera izquierda del panel eléctrico.

2

Page 55

Instalación

Conexiones Eléctricas

1. Consulte el diagrama de conexión en la página anterior y en la foto debajo:

2. Máquinas requieren 2 abastecimientos, uno de tierra y uno que incluye un cable de transporte de

corriente neutral.

3. Las conexiones de energía se realizan en el bloque principal del terminal (MTB).

4. El MTB se encuentra en la esquina trasera izquierda del panel eléctrico detrás del panel frontal de

acceso. (Consulte la ilustración en la página anterior).

ATENCIÓN:

Proporcionar 3 pies de cable de energía eléctrica enrollado en la parte trasera del lavaplatos para el servicio.

Conexión de suministro principal al lavaplatos.

1. Quitar el panel delantero de acceso al lavaplatos.

2. Busque el panel de montaje eléctrico en el lado derecho

de la máquina. Quite la tuerca de retención en la parte

superior del panel que mantiene el panel en su lugar.

3. Disminuir el panel y tire hacia adelante para acceder al

bloque principal del terminal (MTB).

4. Colocar el cable de energía eléctrico a través del agujero

de cable, localizado en el lado derecho, tal como se

puede ver en la parte frontal de la maquina, en el interior

del lavaplatos.

5. Asegúrese de que el cable pase a través del soporte

situado en el montaje cerca de la parte frontal-centro de

la base y asegurar el cable con un conectador de cable.

6. Conecte el cable de tierra a la base del lavaplatos, con el

tornillo de tierra junto al cable de soporte de montaje.

7. Los cables de energía eléctrica que sobren, deben ser

colocados con el terminal principal y conectar según el

diagrama de conexión a la derecha.

Fase Sencilla de Conexión Eléctrica

208-240VAC 50/60/1

GRD

L1 L2

208-240

VAC

Desde la Parte Posterior

de la Máquina

Soporte de Cable

Bloque Terminal

Eléctrico Principal

Dirija el cable de suministro a través del soporte de cable.

L1

GRD

L2

Como Conectar la Electricida

1. Compruebe la placa de datos en la parte

delantera del lavaplatos para los voltios de la

máquina.

2. Quitar la parte inferior del panel de acceso

frontal.

3. Disminuir el soporte de componentes

eléctricos.

4. Suministrar el cable eléctrico de la parte

posterior del lavaplatos en el centro de la

máquina y a través del soporte del cable

5. Conecte el cable de tierra a la base de

la lavadora de platos utilizando el tornillo

de tierra situado cerca del soporte.

6. Suministrar la luz que conduce al bloque

de terminal.

7. Conecte L1, L2 en el piso.

8. Conexiones de suministro principal

están completas.

3

Page 56

Instalación

Conexiόn de Agua

ATENCIÓN

Conexiones de plomería deben cumplir con plomería local y cόdigos sanitarios.

IMPORTANTE

Asegúrese de que el suministro de agua y tubos flexibles de drenaje no estén torcidos.

1. Todos los modelos cuentan con una manguera de agua caliente de 6 pies, y con un

conectador de NPS 3/4".

2. Un 1/2" o una mas grande línea principal de suministro entrante debe ser instalado en el

lavaplatos.

3. Un 1/2" o una más grande válvula de cierre debe ser instalado en la línea de suministro de

agua lo mas cerca posible para poder darle un buen servicio al lavaplatos.

4. La válvula reguladora de presión, PRV, debe instalarse después que la válvula de cierre de

servicio este apagada, Si la entrante es bajo la presión que no sea superior a 20-22 psi.

5. El suministro de agua caliente debe proporcionar un mínimo de 140°F/60°C,

Medir en el lavaplatos para el calentador de agua de 40°F / de 22°C.

Conexiόn de Desagüe

1. El lavaplatos tiene una manga de desagüe de gravedad.

2. El ujo máximo de desagüe es 8 (E.U.) galones por minuto/30 litros por minuto.

3. Asegúrese de que la manga de desagüe no tiene retorcedura. Las retorceduras

prevendrán el agua de desaguar completamente, y el lavaplatos se derramará

fuera la puerta principal.

4

Page 57

Página en Blanco

Esta Página

Intencionalmente se ha

Dejado en Blanco

5

Page 58

Arranque Inicial

Lista de Vericaciόn

1. Quitar cualquier protector del lavaplatos. Revise el interior por cualquier material extraño.

2. Asegúrese el lavaplatos esté permanentemente en su sitio.

3. Asegúrese todas las conexiones de servicios públicos están completos.

4. Asegúrese el conducto de drenaje extendido y la manguera de agua caliente no estén enredadas.

5. Asegúrese el filtro de el sifón este en su lugar.

6. Asegúrese el tubo de desagüe está instalado y bien puesto firmemente en el sifón.

7. Asegúrese los brazos rociadores están en su lugar y que giren libremente.

8. Totalmente cerrar la puerta del lavaplatos.

9. Gire el suministro de agua caliente y comprobar si hay fugas en el suministro de agua principal

conectados a la tubería del lavaplatos.

IMPORTANTE

Durante el relleno inicial, ajuste la PRV para garantizar que la presión que fluye

el agua entrante este establecida en 20-22 psi.

Instale el filtro del sifón, tubo de desbordamiento, y los brazos de rociado.

Asegúrese de que los brazos de rociado giren libremente.

6

Page 59

Operación

Modo de Lavar Normal

Siga las siguientes instrucciones para hacer funcionar el lavaplatos en un modo normal. Una

característica de enjuague Centinela mantiene el lavaplatos lavando si el calentador de agua esta

por debajo de 180ºF/82ºC.

1. Gire el interruptor principal que esta en el circuito principal.

2. Instalar el filtro del sifón, sobre el tubo de desagüe y los brazos rociadores.

3. Asegúrese de que la manguera de drenaje flexible y la manguera extensible del agua no

estén torcidas o enredadas, y encienda el abastecimiento de agua.

4. Cierre la puerta de entrada del lavaplatos.

5. Presione el interruptor de encendido de lavaplatos a la posición ON. El interruptor de

encendido se iluminará, la máquina empezará a llenarse con agua.

6. Espere 15 minutos para que el lavaplatos llegue a un mínimo de150ºF/66ºC.

7. Colocar platos sucios en el estante para platos. Coloque platos, vasos, tazas, y platos hondos

en una canasta de soporte. Coloque utensilios en una sola capa y acostados al fondo de

una canasta. Coloque ollas y sartenes en una canasta plana en el fondo de la misma. No

sobrecargue las canastas de platos.

8. Deslice 1 estante para platos en el compartimiento de lavado, asegurándose de que los

platos no toquen o interfieran con los brazos de rociado en rotación. No lavar mas de una

canasta a le vez.

9. Cerrar la puerta delantera plenamente, a continuación, presione y sostenga el interruptor de

encendido (Start) por un segundo. Se encenderá la luz en el ciclo de color verde y se iniciará

el ciclo de lavado. El ciclo de lavado tendrá un tiempo de duración aproximadamente 1-1/2

minutos.

10. Al abrir la puerta cuando el lavaplatos esta encendido la maquina automáticamente se

apagara. El ciclo se reanudará automáticamente cuando la puerta del lavaplatos se cierra

completamente.

11. El ciclo de enjuague comienza al final del ciclo de lavado y tiene una duración

aproximadamente 15 segundos.

12. Al final del ciclo de enjuague, la luz del ciclo se apagará, Abra la puerta y sacar la bandeja de

los platos limpios. Repita los pasos del 8-12 para canastas de platos adicionales.

13. Consulte las instrucciones de limpieza, "Después de cada periodo de comida o cada 8 horas

de funcionamiento", en la página 9 para los procedimientos drenaje y limpieza del lavaplatos.

7

Page 60

Operación

Modo de Enjuague Centinela

La temperatura del agua de enjuague final debe ser de un mínimo de 180ºF/82ºC durante el ciclo de

enjuague final para garantizar que todos los productos sean desinfectados. Si por cualquier motivo,

la temperatura del agua caliente en el tanque de calentador de agua no puede proporcionar esta

temperatura, el lavaplatos entra en el ciclo en modo de centinela y se extiende el tiempo de operación.

El enjuague centinela cambia el modo de operación normal, tal como se describe a continuación:

1. El centinela enjuague supervisa constantemente la temperatura del agua dentro del calentador de

agua en el enjuague final.

2. Si la temperatura dentro del calentador de agua cae por debajo de los 180ºF/82ºC entonces el

enjuague centinela ampliará el ciclo de lavado de tiempo hasta que la temperatura del agua del

calentador alcance la temperatura adecuada.

3. La luz permanecerá encendida durante el modo de enjuague de centinela.

4. Un ciclo de lavado extraordinariamente largo puede indicar una baja temperatura del agua entrante o

un problema con el funcionamiento del calentador de agua.

NO QUITE LOS PLATOS HASTA QUE EL CICLO DE ENJUAGUE FINAL HAYA

DESINFECTADO Y LA LUZ VERDE DEL CICLO FINAL SE HAYA APAGADO.

8

Page 61

La Limpieza Y Mantenimiento

Limpieza

Después de cada periodo de comida o cada 8 horas de funcionamiento

1. Presione el interruptor de encendido en la posición OFF. El interruptor de luz de encendido se

apagara.

2. Abra la puerta y retire el tubo de desagüe.

3. Quite el ltro del sifón con cuidado para mantener las partículas o residuos de comida, para que no

caigan dentro del sifón.

4. Limpie el ltro del sifón y enjágüelo con agua limpia.

Asegúrese de lavar el ltro por ambos lados.

No golpear el ltro contra objetos sólidos.

5. Revise el sifón por si quedo algún material extraño o comida y límpielo según sea necesario.

6. Reemplazar el ltro del sifón y el tubo de desagüe.

7. Asegúrese de que los brazos de rociado giren libremente.

8. Cerrar la puerta y prender el interruptor de encendido ON/OFF (PRENDER/APAGAR) a ON y

volver al modo de funcionamiento normal.

Resistencia de

Calefacción

Tubo de Desagüe

Sello para el Tubo

de Desagüe

Filtro Del

Sifón

Sifón

9

Page 62

La Limpieza Y Mantenimiento

Limpieza

Al final del día

1. Retire los brazos rociadores inferior y superior de enjuague y de lavado, Los brazos de rociado son

intercambiables.

2. Afloje el pin del brazo de enjuague (A). Quitar los brazos de enjuague ensamblables.

3. Limpiar las boquillas de brazo de enjuague final con un pequeño clip de papel (B).

4. Quite los tapones de los brazo de enjuague final (C) si es necesario, y lavar el brazo

de enjuague con agua limpia.

5. Vuelva a instalar los tapones de enjuague final del brazo si se quitan.

6. Quitar los brazos rociadores de lavado y lavarlos con agua limpia.

7. NO UTILICE ESPONJA DE ACERO PARA LIMPIAR EL INTERIOR DE LA MÁQUINA.

8. Póngase en contacto con el proveedor de productos químico para de-calcificar si es necesario

(consulte la página siguiente).

9. Limpiar dentro y fuera de la máquina con un paño suave y un detergente suave.

NO LAVE POR FUERA DE LA MÁQUINA CON UNA MANGUERA Y AGUA.

10. Volver a ensamblar el lavaplatos y dejar la puerta abierta para permitir que se seque durante la noche.

Clip de Papel

B

Clavija para el

Brazo de Enjuague

A

Tapón

Final

C

Brazo Rociador

de Lavado

D

10

Page 63

La Limpieza Y Mantenimiento

Para Descalcificar

Minerales se acumulan en las superficies interiores del lavaplatos. Los depósitos tienen una niebla

blanca y, en los casos de acumulación pesada, pueden aparecer como gránulos sólidos.

El nombre genérico para depósitos minerales es CAL. La eliminación de los depósitos de CAL se

denomina de - calcificar. Su lavaplatos debe ser de – calcificar regularmente; y con qué frecuencia

dependerá de el contenido de su agua mineral.

Inspeccionar el interior de máquina para depósitos de cal. Si se requiere de - calcificar, un químico

para de – calcificar debe utilizarse para obtener mejores resultados de conformidad con las

instrucciones del proveedor de productos químicos.

Peligro:

Pueden ocasionar la muerte o lesiones graves cuando de - calcificar solución se mezcla con

hipoclorito de sodio (blanqueador de cloro) un químico de limpieza. Mezclarlos puede causar gases

peligrosos. La solución de decalcificando y otros ácidos nunca deben ser mezclada con yodo, cloro,

bromo o flúor.

Precaución:

Contacto con la piel de las soluciones de cal puede causar irritación severa y posibles quemaduras

químicas. Siempre use ropa protectora y gafas al manipular los productos químicos.

Atención:

Comuníquese con su proveedor de sustancias químicas para los procedimientos específicos de

seguridad y las instrucciones para el uso de la solución de-calcificar, suministrados para el

lavaplatos. La solución para Decalcificar, o otros químicos no se pueden conseguir con la fabrica

de lavaplatos.

Tubo de Desagüe

Resistencia de

Calefacción

Sello para el Tubo

de Desagüe

Filtro Del

Sifón

Sifón

11

Page 64

La Limpieza Y Mantenimiento

Mantenimiento

Follow the maintenance schedules below to keep the dishwasher operating most efficiently.

Siga los planos de mantenimiento mencionados abajo para mantener el lavaplatos en un funcionamiento

más eficiente.

Mantenimiento diario

1. Mirar todos los Brazos de lavado y enjuague y los inyectores de roseo, limpiarlos si es necesario.

2. Asegúrese de que el suministro de agua estén encendidos y que el desagüe no esté obstruido.

3. Asegúrese de que las canastas de platos estén en buenas condiciones.

4. Siga los procedimientos de limpieza dados anteriormente.

Mantenimiento Semanal

1. Realicé los pasos 1-4 en el mantenimiento diario.

2. Inspeccionar las mangueras de agua por si hay una fuga.

3. Asegurase que no haya fugas de agua por debajo del lavaplatos.

4. Asegúrese de que la manguera de agua y de desagüe extensible no estén torcidas.

5. Asegúrese de que el lavaplatos esta en nivel.

6. Limpiar los depósitos de cal acumulados en la resistencia del tanque de lavado.

7. Inspeccione los filtros de desperdicios y reemplazarlos si están dañados.

8. Mirar los brazos de rociado y reemplazar o reparar si están dañados.

12

Page 65

Localizaciόn y Soluciόn de Problemas

Localizaciόn y Soluciόn de Problemas

Siga la guía de solución de problemas más adelante en caso de que su lavaplatos no funcione

como se espera. Chequear los controles básicos a continuación antes de llamar a un agente de

servicio técnico autorizado.

1. Asegúrese el suministro principal de agua está activado

2. Asegúrese el interruptor principal está encendido.

3. Asegúrese la manguera de agua y de desagüe extensible no estén torcidas

CONDICIÓN CAUSA SOLUCIÓN

El lavaplatos no se pone

en marcha

No hay agua o hay poco

agua

Resultados muy bajos

de lavado.

La puerta no cierra.

Interruptor principal

encendido apagado.

Lavaplatos apagado.

.

Suministro principal de

agua está apagado.

PRV configuración

incorrecta.

Solenoide filtro obstruido.

Solenoide de la válvula

defectuosa..

El tanque no tiene

detergente.

Platos incorrectamente

puestos en la conasta de

platos.

Filtro del sifón obstruido.

Brazos de rociado

obstruidos.

Termostato defectuoso.

Cerrar la puerta.

Verifica que el interruptor

de luz principal este

encendido.

Prender el lavaplatos.

Abra la válvula de

suministro.

Adjustar la configuración

PRV.

Limpiar el filtro.

Póngase en contacto con

el agente de servicio.

Añadir detergente.

Organizar los platos o

reducir la cantidad de

platos.

Limpiar el filtro de sifón.

Limpiar loas brazos de

rociado.

Póngase en contacto con

el agente de servicio.

Lavaplatos debe estar en

el ciclo de lavado.

Motor de detergente

defectuoso.

La temperatura del agua de

lavado es demasiado baja.

Enjuague centinela

ampliará el tiempo hasta

que la temperatura del

agua del calentador alcance

la temperatura adecuada

180˚F/82˚C.

Póngase en contacto con

el agente de servicio.

Póngase en contacto con

el agente de servicio.

Póngase en contacto con

el agente de servicio.

porque el motor del

termostato esta

defectuoso.

13

Page 66

Página En Blanco

Esta Página

Intencionalmente se ha

Dejado en Blanco

14

Page 67

Repuestos de Servicio

Respuestos de Servicio

Illustaciones Página

Motor/Bomba Para Lavar ....................................................................................................................................... 16

Calentador Eléctrico ............................................................................................................................................... 18

Panel Eléctrico y Temporizador .............................................................................................................................. 20

Panel de Control ..................................................................................................................................................... 22

Montaje de los Brazos Rociadores para Lavar y Enjugar ...................................................................................... 24

Montaje de los Mangueras de abajo ...................................................................................................................... 26

Calefacciόn para el Tanque de Lavado y Montaje del Sifόn ................................................................................... 28

Montaje de la Válvula Solenoide para Rellenar...................................................................................................... 30

Montaje del Panel ................................................................................................................................................... 32

Montaje de la puerta ............................................................................................................................................... 34

Bandeja de Platos, Filtro de Linea y Reguladora de Presiόn ................................................................................ 36

Esquema Eléctrico.................................................................................................................................................. 38

Temporizador Gráco ............................................................................................................................................. 39

15

Page 68

Motor/Bomba Para Lavar

10

7

5

4

3

11

12

9

8

6

16

2

1

Page 69

Motor/Bomba Para Lavar

Item Partes Descripción Cantidad.

No. No.

1 0512340 TORNILLO, M4, PHIL, PAN HD. 9

2 0512341 TAPA PARA EL PROPULSOR 1

3 114144 TUERCA, M6 (roscas izquierdas) 1

4 0501501 ARANDELA DE CIERRE, 1/4" 1

5 0501478 ARANDELA, 17/64" 1

6 0512345 PROPULSOR 1

7 114139 SELLO 1

8 110285 EMPAQUE, BOMBA

9 114137 PLACA, BOMBA 1

10 107337 TUERCA, M4 9

11 0512101-1 BOMBA / DE MONTAJE DE MOTOR COMPLETO 1

220VAC 50/60/1

12 H29043 CAPACITOR 16μF 1

17

Page 70

Calentador Eléctrico

10

9

11

9

10

10

9

9

8

7

12

2

1

3

4

5

13

9

6

18

Page 71

Calentador Eléctrico

Item Partes Descripción Cantidad.

No. No.

1 0512847 RESISTENCIA, CALENTADOR 4KW, 208V, 40°F 1

(No Incluye la Empaque)

2 0512928 EMPAQUE, CALENTADOR 1

3 0512108 CONTROL, TERMOSTATO 195°F 1

4 0512185 PERNO, TUERCA EXAGONAL, 1/4-20 X 3/8" SS 1

5 0508817 TAPÓN, 1/8" SST 1

6 0512926 MANGUERA, PARA LLENAR EL CALENTADOR 1

7 110562 TERMOSTATO, ALTO – LÍMITE, FIJO 240°F 1

8 0712835 TANQUE, CALENTADOR 1

9 0503679 ABRAZADERA, 7/16" SST 5

10 107417 MANGUERA, 1/2" ID A/R

11 0512968 TE 1

12 108954 TUERCA, AGARRADERA DE NYLON 6-32" 2

13 0512920 UNION, TERMOSTATO DE CALENTADOR 1

19

Page 72

Panel Eléctrico y Temporizador

13

11

12

4

5

2

3

6

8

9

7

14

20

7

10

Page 73

Panel Eléctrico y Temporizador

Item Partes Descripción Cantidad.

No. No.

1 0507323 TERMOSTATO, TANQUE DE LAVADO 1

3 0512108 TERMOSTATO, CALENTADOR 195°F 1

4 0312909 PANEL, CONTROL 1

5 C120444 CONTACTOR, 25/40A, 3P, 220V BOBINA 1

6 0504951 BLOQUE, TERMINAL 1

7 0503745 TORNILLO, RH 8-32 X 3/16" RANURA SST 4

8 0512969 TEMPORIZADOR, TARJETA DE CIRCUITO 1

9 CM0082006 SEPARADOR, TARJETA DE CIRCUITO. NYLON 4

10 0509428-1 INTERRUPTOR DE RELEVO, 15 AMP 1

11 0503620 TORNILLO, RH, 4-40 X 3/16" RANURA SST 4

12 0501450 TORNILLO, NIBS RH 6-32 X 3/16" ESTRELLA. SST 4

13 0512934 ETIQUETA, LAVADO – ENJUAGUE, TEMPERATURA 1

14 CM0082007 TAPA, SEPARADOR, TARJETA DE CIRCUITO. NYLON 4

21

Page 74

Ensamble, Panel de Control

12

13

9

8

7

6

4

3

10

2

11

12

1

13

22

Page 75

Ensamble, Panel de Control

Item Partes Descripción Cantidad.

No. No.

1 0312959 PANEL, FRONTAL, IUH 351 1

2 0512958 ETIQUETA, FRONTAL, IUH 351 1

3 0513075 INTERRUPTOR DPDT 250V NEON IUH 351 1

4 0512216 CAJA, INTERRUPTORES 2

5 0512217 CAJA, INTERRUPTORES 2

6 0512218 BOTÓN, INTERRUPTOR (VERDE) 1

7 0512232 LUZ, INDICADOR LED, 2VDC (VERDE) 1

8 H160121 MANGUERA, 4.1 ft / 125cm 1

9 H450134 CLIP, MANGUERA 2

10 109835 TORNILLO, #8 1/2" ESTRELLA .T/A AUTORROSCANTE 1

11 H31171 INTERRUPTOR, DE PRESIÓN 1

12 0501408 TORNILLO, RANURA DE ARMADURA, 8-32 X 1/4" SST 2

13 0512320 EMPAQUE, VAPOR 2

23

Page 76

Montaje de los Brazos Rocíadores para Lavar y Enjuagar

14

15

1

2

3

4

5

6

7

22

22

21

20

22

23

20

19

24

21

22

8

11

10

16

12

12

9

17

13

18

19

24

6

8

24

Page 77

Montaje de los Brazos Rocíadores para Lavar y Enjuagar

Item Partes Descripción Cantidad.

No. No.

1 0501478 ARANDELA, 17/64 id X 9/16" OD SST 4

2 107967 TUERCA, EXAGONAL 1/40-20 INSERTADO, NYLON SST 4

3 H35509 CUBO DE BRAZO DE LAVADO, ARRIBA 1

4 107873 ARANDELA, EMPAQUE 1

5 110215 TORNILLO, RETENEDOR 1

6 0502571 CLAMP, HOSE GEAR 1-1/2" SST 2

7 0512120 ABRAZADERA, MANGUERA 1-1/2" SST 1

8* 0712749 BALINERAS DE ENSAMBLE 2

9 0512133 O-ANILLO, 2-1/8" OD X 1-3/4" ID X 3/16" 1

10 0512066 CUBO DE LA BRAZO DE LAVADO, ABAJO 1

11 0512918 COLECTOR, ABAJO FWR 1

12 H420548 ENSABLE, BRAZO DE LAVADO (Incluye Item 8 ) 2

13 0512133 O-ANILLO, 2-1/8" OD X 1-3/4" ID X 3/16" 1

14 0501481 ARANDELA, NYLON 4

15 100738 TORNILLO, 1/4-20 X 1" SST 4

16 0512124 EJE, INFERIOR 1

17 0512239 O - ANILLO 1

18 0312840 CUBO, BRAZO DE ENJUAGUE, MOLDEADO 2

19 0501408 TORNILLO, RANURA DE ARMADURA 8-32 X 1/4" SST 4

20 0512841 BRAZO, MANO – DERECHA DE ROCIADO (7 CHORROS) 2

21 0512842 BRAZO, MANO - IZQUIERDA DE ROCIADO (8 CHORROS) 2

22 0512843 TAPA, BRAZO DE ENJUAGUE, 5/16-24 4

23 H36275 HUSO, BRAZO DE ROCIADO 2

24 H34998 ESPACIADOR, TUERCA 2

--- 0712834 ENSAMBLADOR, BRAZOS DE ENJUAGUE (Incluye 18-24) 2

* Nota:

Ensamble de balinera, P/N 0712749 incluye 2 balineras, 1 contratuerca y 1 cubo de brazo de

lavado. Las balineras, la contratuerca y cubo no están disponibles como piezas de repuesto de

servicio independiente.

25

Page 78

Montaje de las Mangueras de abajo

Desde la te final de enjuague

1

Hasta Brazo superior de lavado

2

8

4

3

7

8

7

5

6

9

14

13

10

1

11

12

8

26

Page 79

Montaje de las Mangueras de abajo

Item Partes Descripción Cantidad.

No. No.

1 0502563 ABRAZADERA, MANGUERA SST 2

2 107417 MANGUERA, CAUCHO 1/2" ID X .84" OD A/R

3 0503679 ABRAZADERA, MANGUERA 1

4 0512120 MANGUERA, LAVADO SUPERIOR 1

5 0512119 MANGUERA, FLUJO, BOMBA DE LAVADO 1

6 0502571 ABRAZADERA, MANGUERA 1-1/2" SST 2

7 0512322 ABRAZADERA, MANGUERA 1-13/16" -2/34" MAX SST 2

8 0512885 MANGUERA, SUCCION, BOMBA DE LAVADO 1

9 0312144 SOPORTE, BOMBA DE LAVADO 1

10 0502668 MANGUERA, SUCCION DE LA BOMBA DE DESAGUE 1

11 0512925 MANGUERA, RELLENO 1/2" X 7' C/W FNPS 1

12 0512936 ARANDELA, SILICONA 5/8" ID X 7/8" OD 1

13 0512926 MANGUERA CALENTADOR RELLENO 1/2" X 1' 1

14 0502572 ABRAZADERA, MANGUERA 5/16" 1

27

Page 80

Calefacción para el Tanque de Lavado y Montaje de la Sifón

1

21

25

24

22

23

2

20

19

3

4

5

6

7

8

2

9

18

3

3

4

10

4

28

11

10

12

13

14

15

17

16

Page 81

Calefacción para el Tanque de Lavado y Montaje de la Sifón

Item Partes Descripción Cantidad.

No. No.

1 0512930 PUERTA, EMPAQUE 1

2 0512846 RESISTENCIA, TANQUE DE LAVADO, 2KW, 240VAC 1

3 100003 ARANDELA, RAJA DE CIERRE 1/4" SST 4

4 0501539 TUERCA, EXAGONAL 1/4-20 SST 4

5 0501836 O - ANILLO 2

6 0508873 UNION, TERMOSTATO 1

7 0512920 UNION, TERMOSTATO 1

8 0507323 TERMOSTATO, TANQUE DE LAVADO 1

9 201029 TUERCA DE CIERRE 1/2 2

10 108954 TORNILLO, AGARRAR 6-32, INSERTADOS DE NYLON 4

11 113604 TERMOSTATO, LÍMITE – ALTO, FIJO 212°F 1

12 0501437 TORNILLO, 4-40 X 1/2" SST 2

13 0501379 INTERUPTOR, PUERTA 15 AMP 1

14 0309228 SOPORTE, INTERRUPTOR 1

15 0312605 PLAT O, INTERRUPTOR TUERCA 1

16 D500605 CODO, SUCCIÓN DE LA BOMBA 1

17 D80208 EMPAQUETADURA, CODO, SUCCIÓN DE LA BOMBA 1

18 D540088 FLANGE, SUCCIÓN DE LA BOMBA 1

19 H250110 TRAMP A. AIRE 1

20 H25263 EMPAQUE, PLANO 1

21 H25239 O - ANILLO 1

22 H25011 COVERTURA, TRAMP A DE AIRE 1

23 0512845 FILTRO, SIFON 1

24 0512789 TUBO, DESAGÜE-EXCESO DE FLUJO 1

25 0512844 SELLO, TUBO DE DESAGÜE-EXCESO DE FLUJO 1

29

Page 82

Montaje de Válvula Solenoide para Rellenar

1

2

3

4

30

Page 83

Montaje de Válvula Solenoide para Rellenar

Item Partes Descripción Cantidad.

No. No.

1 0512853-1 VALVULA, AGUA ENTRANTE 220VAC/60/1 1

(Incluye Item 2)

2 0512860 CAJA DE REPARACION, VALVULA SOLENOIDE A/R

3 0512185 TORNILLO, RANURA EXAGONAL 1/4-20 X 3/8" SST 2

4 0312893 SOPORTE, VALVULA 1

31

Page 84

Panel de Ensamble

1

6

6

4

2

5

4

3

5

4

32

Page 85

Panel de Ensamble

Item Partes Descripción Cantidad.

No. No.

1 0312905 EMBOLTURA, PANEL EXTERIOR 1

2 0503718 PIE, AJUSTAMIENTO 4

3 0312960 PANEL, FRONTAL 351HT E 1

4 100007 TORNILLO RANURA DE PALA SS 10-32X3/8 4

5 0503718 PIES, AJUSTEBLES 4

6 0512761 TORNILLO, RANURA DE PALA 10-32-3/8" SST 3

33

Page 86

Ensamble De la Puerta

1

2

3

2

4

5

3

34

Page 87

Ensamble De la Puerta

Item Partes Descripción Cantidad.

No. No.

1 0713141 PUERTA, ENSAMBLE 1

2 0312892 BRAZO, RESORTE DE PUERTA 2

3 0512854 RESORTE, PUERTA 2

4 0312908 ACTUADOR, INTERRUPTOR DE PUERTA 1

5 0503745 TORNILLO, 8-32 X 3/16" ESTRELLA. SST 2

35

Page 88

BandejadePlatos,FiltrodeLineayReguladoradePresiόn

1

2

4

3

36

Page 89

BandejadePlatos,FiltrodeLineayReguladoradePresiόn

Item Partes Descripción Cantidad.

No. No.

1 101273 CANASTA DE PLATOS, DE FONDO PLANO AR

2 101285 CANASTA DE PLATOS, DE SOPORTE AR

3 104421 FILTRO, LINEA 1/2" BRONZE (OPCIONAL) 1

4 108265 VALVULA, PRESION REGULATORIA (PRV) (OPCIONAL) 1

37

Page 90

Esquemas Eléctricos -Modelo IUH 351

38

Page 91

ModeloIUH351-GrácoTemporizador

Item Partes Descripción Cantidad.

No. No.

39

Page 92

Página En Blanco

Esta Página

Intencionalmente se ha

Dejado en Blanco

40

Loading...

Loading...