Page 1

Indirect Cooler Module

Users Manual

Model

IM70

2 Stage Evaporative Cooling

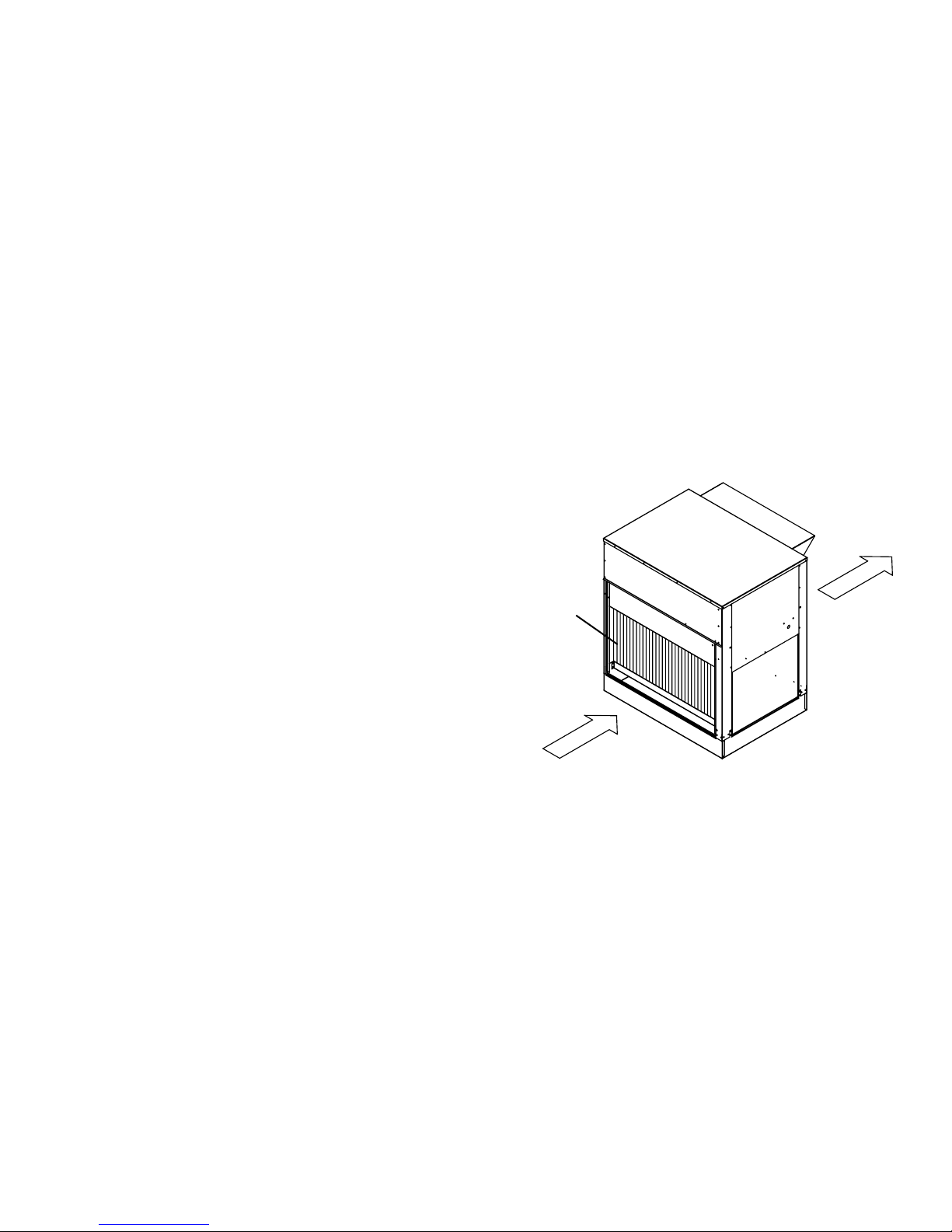

The IM70 indirect cooling module (ICM) is a pre-cooler used in 2-Stage or Indirect/Direct evaporative cooling. The ICM cools

the air without adding any additional moisture. It accomplishes this by circulating water downward through a heat exchanger,

while a fan draws air upward through the heat exchanger. This air and water are cooled by evaporation and in turn cool the

walls of the heat exchanger. The removed heat is exhausted

from the unit with the moist air. Hot, dry outside air is pulled

horizontally through the cooled walls of the heat exchanger by

the attached evaporative cooler. This air is cooled and since

it does not contact water, there is no moisture added.

The dry air cooled by the ICM is then cooled more by the direct

evaporative cooler. The dry bulb temperature of the air after

going past the ICM drops as does the wet bulb or saturation

temperature. This cooled dry air from the ICM is pulled through

wet evaporative media in the direct evaporative cooler which

cools the air and adds moisture. The temperature leaving the

evaporative cooler is lower than what is possible without the

ICM, often below the ambient wet bulb temperature.

The IM70 can be mounted directly to Champion’s Ultracool 51

& 71 series evaporative cooler models for a complete 2-stage

evaporative cooling process.

Heat

Exchanger

Cool Dry

Air

Hot Dry

Air

Safety Rules

1. Read instructions carefully.

2. Electrical hook up should be done by a qualifi ed electrician, so that all electrical wiring will conform to your local stan-

dards.

3. Always Disconnect from Power Source before installing or performing any maintenance.

4. The IM70 will run on 120V A.C., single phase, 60 Hz (cycle) current only.

5. The pump and motor are equipped with an automatic thermal overload switch which will shut motor off when it overheats.

The motor may start unexpectedly after it cools down.

www.championcooler.com

5-07110521

Page 2

Installation

CAUTION: Make sure that the mounting surface is strong enough to sup-

port the operating weight of the cooler when in use. (For operating weight,

see Specifi cation Table.)

CAUTION: Never start cooler until installation is complete and unit has

been tested for rigidity.

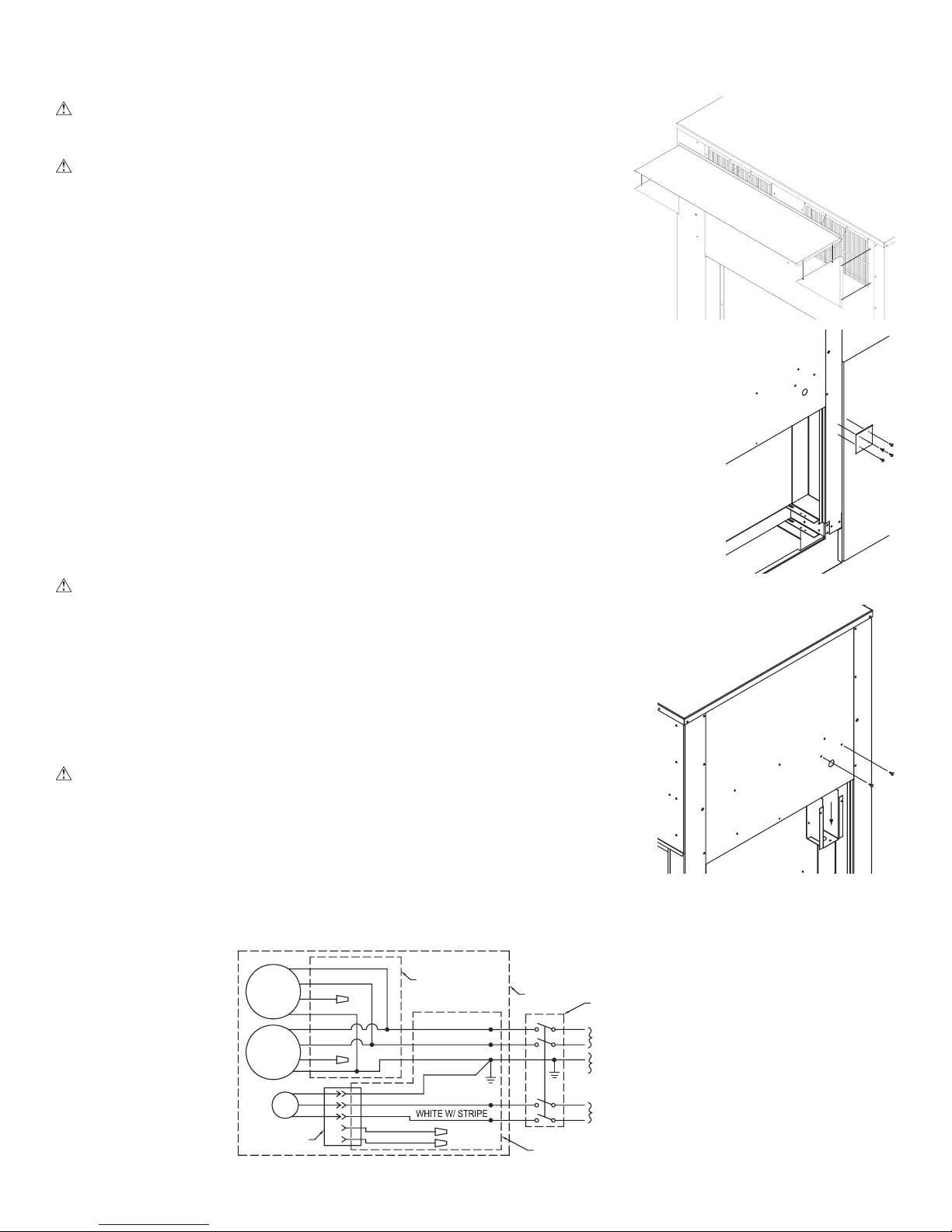

• Install rain guard. A 3 piece rain guard kit is included with the unit. Refer to

fi gure 1 for installation instructions. Place the fl ange of the top piece over the

side piece and screw together with the provided screws. Repeat for both left

and right sides. Slide the fl ange of the top section under the top pan. Screw the

sides of the rain guard into the holes in the exhaust panel.

• Mount unit to the evaporative cooler. For two stage evaporative cooling, at-

tach the IM70 to an Mastercool 51 or 71 unit (sold separately). Remove the perforated grill on

the Mastercool Attach weather stripping (not supplied) around the perimeter of the Mastercool.

Slide the IM70 next to the cooler making sure the units fi t snugly together. Using the provided

mounting brackets and self drilling screws, locate the bracket below the top of the inspection

panel on the IM70 (Fig. 2). Attach using the provided screws. Making sure that there is a

good fi t between the IM70 and the cooler, screw the self drillers into the cooler to lock it into

place. Repeat for opposite side. Install the perforated grill removed previously to the rear

of the IM70.

Note: If this unit is mounted to another unit besides an Mastercool 51 or 71 series unit, you

will need to purchase separately a 51 series perforated grill (part #222130-078).

Fig. 1

Electrical Installation

WARNING: Disconnect all electrical service that will be used for this unit before you

begin the installation.

• Remove junction box. The electrical junction box is located inside the unit above

the inspection panel door. Remove two screws and slide the junction box down to

gain access to wiring (Fig. 3).

• Hook up electrical. Electrical hook up should be done by a qualifi ed electrician,

so that all electrical wiring will conform to your local standards. This unit is suppled

with a 120V pump and fan motor. See fi gure 4 for the wiring diagram.

WARNING: Make sure the cooler cabinet is properly grounded to a suitable

ground connection for maximum safety.

Wiring Diagram

FAN

MOTOR

FAN

MOTOR

BLACK

WHITE

RED

GREEN

RED

INTERNAL

WIRING BOX

BLACK

WHITE

GREEN

GREEN

UNIT

CABINET

REQUIRED SERVICE

DISCONNECT IN SIGHT

OF UNIT

L1

120V - 60Hz - 1 PH

N

EQUIPMENT GROUND

Fig. 2

Fig. 3

PUMP

PUMP

RECEPTACLE

BROWN

ORANGE

BLUE

L1

120V - 60Hz - 1 PH

N

INSTALLATION WIRING BOX

Fig. 4

1105212

Page 3

Water Connection

• Install overfl ow assembly. Place drain nipple through the hole in the bottom pan, with the rubber

washer between the pan and the head of the drain nipple (Fig. 5). Screw on nut and draw up tight

against bottom of pan. Insert the overfl ow pipe in the nipple to retain water. The overfl ow pipe may

be removed to drain the pan when necessary . A garden hose may be screwed onto the drain nipple to

drain water away from your unit.

Overfl ow Pipe

Nipple

Rubber Washer

Bottom Pan

Nut

Fig. 5

• Connect water supply line. Find the closest supply of water. Run 1/4” tubing from the unit to the

water supply . You may use a saddle valve (Fig. 6) to connect 1/4” tubing to the cold water supply

or a Sillcock and water valve connected to an outside faucet (Fig. 7).

Place the nut and ferrule on the tubing and tighten the nut until water

tight. Insert the tubing into the fl oat hole of the corner post. Remove the

1/4” Tubing

Saddle

Valve

Faucet

Nut

Water Supply

Valve

Ferrule

perforated grill if installed to have access to the fl oat. Attach the tubing to

the fl oat using a nut and ferrule. Tighten until water tight. IMPORTANT:

Do not connect the water supply to any soft water applications. Soft

water will cause corrosion and decrease the life of the unit.

Fig. 6

Cold

Water

Pipe

Sillcock

Fig. 7

• Fill pan. Allow water to fi ll to approximately 3” in the bottom pan and

adjust the fl oat to maintain this water level. This can be accomplished by bending the fl oat rod.

Maintenance

WARNING: Before doing any maintenance be sure power is off. This is for your safety.

Spring Start-Up

• Clean heat exchanger. Clean the inlet face of the heat exchanger with a garden hose. Remove any obstruction and lightly

clean any scale buildup. To clean the top of the heat exchanger , remove the top pan. Remove the media brackets holding the

fi lters in place and remove the fi lters. Cover up the blower housings so no water comes into contact with the motors. Clean

with a hose, removing any obstruction and scale buildup.

• Clean or change fi lters. There is a 3 piece fi lter set located under the heat exchanger. Remove the inspection panel to ac-

cess these fi lters. Remove the fi lters and clean out the openings with a garden hose. Clean off the face any scale or other

obstruction to the passages. Slight scraping may be required to remove hardened scale. There are also mist eliminating

fi lters above the water distribution system. Remove the top pan to gain access to these mist eliminating fi lters. The media

brackets will need to be removed before removing the mist eliminating fi lters. If cleaning the mist eliminating fi lters while in the

unit, make sure to cover the fan blower housings so that water does not come in contact with the motors. The fi lters should

be replaced after 5 years or when necessary.

• Clean pump. Periodic cleaning of the pump will prolong the life and effi ciency

of the pump. For your safety, make certain the unit is disconnected from the

power source before servicing pump. Remove the pump from the pump mount.

Refer to fi gure 8 for disassembling the pump. DO NOT open the sealed portion

of the unit or remove housing screws. Remove the intake screen. Remove

the volute mounting screws. Lightly clean any corrosion or debris which may

clog the impeller. Use a brush and penetrating oil and lightly scrape to remove

encrusted material. Turn the impeller by hand to make sure it turns freely.

After cleaning, reinstall in reverse order. Do not forget to replace the water

delivery tube onto the pump outlet.

• Clean bottom pan of any debris.

Winter Shut-Down

• Drain water. Always drain all of the water out of the unit and water supply line when not in use for prolonged periods, and

particularly at the end of the season. Keep the water line disconnected from both the unit and water supply so that it does not

freeze.

• Unplug pump. When cooler is not used for extended periods unplug the pump from inside cooler.

• Cover unit. To protect the life of the fi nish, a cover for the unit is suggested in extended periods of non use.

110521 3

Impeller

Volute

Intake Screen

Fig 8

Page 4

Replacement Parts List

When ordering parts, please be sure to furnish the following information on all orders. Failure to do so may delay your

order.

1. Cooler model number

2. Cooler serial number

3. Description and part number

4. Date of purchase

No. Description IM70

1. Top Pan ......................................................................................................................222150-001

2. Bottom Pan .................................................................................................................322150-002

3. C-Channel Bracket (2) ................................................................................................216150-001

4. Inlet Panel ..................................................................................................................222150-006

5. Grill Insert Panel .........................................................................................................222150-013

6. Left Side Panel ...........................................................................................................222150-005

7. Right Side Panel .........................................................................................................222150-010

8. Inspection Panel .........................................................................................................222150-016

9. Outlet Panel ................................................................................................................220150-001

10. Corner Post, Outlet .....................................................................................................222150-003

11. Corner Post, Inlet .......................................................................................................222150-004

12. Side Filler Panel .........................................................................................................222150-009

13. Outlet Support Bracket ...............................................................................................220150-003

14. Inlet Support Bracket ..................................................................................................220150-004

15. Media Bracket (4) .......................................................................................................222150-007

16. Media Filler Panel .......................................................................................................222150-015

17. Water Distributor Support Bracket ..............................................................................222150-008

18. Pump Mounting Bracket .............................................................................................220150-002

19. Pump ..........................................................................................................................110437

20. Float Mounting Bracket ..............................................................................................222150-014

21. Float Valve ..................................................................................................................FL-C

22. Squaring Bracket ........................................................................................................220150-005

23. Heat Exchanger ..........................................................................................................110140

24. Filter Pad ...................................................................................................................310105-101

25. Mist Eliminator Filter Pad ...........................................................................................310105-201

26. Blower Housing (2) .....................................................................................................324102-005

27. Blower Wheel, Left (2) ................................................................................................110747

28. Blower Wheel, Right (2) .............................................................................................110748

29. Blower Motor (2) .........................................................................................................110441-C

30. Fan Motor Junction Box .............................................................................................281004-002

31. Receptacle, Pump ......................................................................................................110361

32. Electrical Junction Box ...............................................................................................322009-004

33. Rain Guard Kit ............................................................................................................322150-011

34. Water Delivery Tube ...................................................................................................310717

35. Water Distributor Assembly ........................................................................................3D-29

36. Nozzles (8) .................................................................................................................110141

37. Over Flow Assembly ...................................................................................................3OA-2

38. Connecting Bracket (2) ...............................................................................................220150-006

NOTE: Standard hardware items may be purchased from your local hardware store.

1105214

Page 5

Parts Drawing

Model Voltage Total Fan Motor

Amperage

IM70 1 15 V *8 Amps 1.5 Amps 17 Gal. 240 377

* Motor amperage is for 2 motors.

110521 5

Specifi cations

Pump

Amperage

Approx. Reservoir

Weight (Lbs.)

Capacity

Shipping Operating

Page 6

CHAMPION COOLER LP

5800 Murray St.

Little Rock, AR 72209

(800) 643-8341

www.championcooler.com

1105216

Loading...

Loading...