Installation/Operation with Service Replacement Parts

LISTED

Beginning with Serial No. J2089 and above

Eseries

High Temperature

Upright Conveyor Dishwasher

EUCCW-8 / EUCC-8

EUCCW-6 / EUCC-6

EUCCW-4 / EUCC-4

Models:

EUCCW

center section

29" wide conveyor with a 4', 6',or 8'

EUCC 24" wide conveyor with a 4', 6',or 8'

center section

www.championindustries.com

3765 Champion Boulevard,

Winston-Salem, NC 27105

336/661-1556 Fax: 336/661-1660

Toll-free: 800.858.4477

2674 N. Service Road, Jordan Station

Ontario, Canada L0R 1S0

905/562-4195 Fax: 905/562-4618

Toll-free: 800.263.5798

Issue Date: 2.28.17

Manual P/N 114254 rev. i

For machines beginning with S/N J2089 and above

Printed in USA

ATTENTION:

The dishwasher model no., serial no., volt-

age, Hz and phase are needed to identify

your machine and to answer questions.

Please have this information on-hand

if you call for service assistance.

For all models:

The data plate mounts to

one side of the top-mounted

control cabinet.

National Service Department

In Canada: In the USA:

Toll-free: 800/ 263-5798 Toll-free: 800/ 858-4477

Tel: 905/ 562-4195 Tel: 336/ 661-1556

Fax: 905/ 562-4618 Fax: 336/ 661-1660

email: service@moyerdiebellimited.com email: service@championindustries.com

COPYRIGHT © 2017 All rights reserved Printed in the USA

Two ways to

REGISTER YOUR PRODUCT and

ACTIVATE YOUR WARRANTY.

4:34 PM 44%

• Use your mobile or computer to go to our website at

www.championindustries.com and register your product there.

• Use the fax form on the next page.

PRODUCT REGISTRATION

BY FAX

COMPLETE THIS FORM AND FAX TO:

(336) 661-1660 in the USA

1-(800) 204-0109 in Canada

PRODUCT REGISTRATION CARD

Model

Date of Installation:

Company Name:

Serial #

Address:

Telephone #: ( ) --Contact:

Installation Company:

Address:

Telephone #:

Contact:

FAILURE TO REGISTER YOUR PRODUCT MAY VOID YOUR WARRANTY

(Street) Province Postal Code

IMPORTANT IMPORTANT

Revision History

Revision History

Revision Revised Serial Number Revision

Date Pages Effectivity Description

3.16.07 All J2089 Issue of First Edition

3.22.07 All J2089 Revised Parts Format

7.27.07 All J2089 Added 575VAC Parts

11.18.08 All J08102541 Added Digital Display

10.5.09 All ------- Changed P/N's for

Clutch

12.6.09 63-71 J09062644 Added Standpipe

Gasket

1.6.10 181,183 J09062644 Corrected P/N's

45, 46, 47

2.10.10 92,94,102 J09062644 Changed 1/4" plug

to 1/8" plug for rinse

injector

2.10.10 176-183 J10012728 Updated P/N's and

added new control

cabinet layout

8.10.10 114,116.120 J10012728 Changed 1" Steam

124, 128,130 to P/N 114800

8.25.10 104-105, J09062644 3/4" solenoid valve

108-109 changed to 1/2"

8.25.10 166-170 --------------- Added EUCC belts

8.25.10 204-208 J09062644 Added swing-out doors

5.2.11 194, 198 J08102541 Corrected Item 35 P/N

from 111980 to 114505

2.28.17 30-33 J11062899 Changed clutch to

anti-jam switch design

added VFD drive.

211-220 J11062899 Updated parts lists and

electrical schematics

i

Dear Owner:

Thank-you for choosing our dishwasher.

We appreciate your business.

This manual covers two models:

EUCCW Electrichightemperatureight-typeconveyordishwasherwithbuilt-in

EUCC electric booster in 40° F/22° C rise or an optional 70° F/39° C rise booster.

EUCCW Steamhightemperatureight-typeconveyordishwasherwithbuilt-in

EUCC steam booster in 40° F/22° C rise or an optional 70° F/39° C rise booster.

The installation, and initial start-up of your dishwasher must be performed by qualied

electricians, plumbers, and authorized service technicians trained in commercial

dishwashers.

Defects and repairs caused by unauthorized installers will not be covered by the

dishwasher warranty.

ii

Table of Contents

Table of Contents

E series Upright Conveyor Dishwashers

Revision History ___________________________________________________________________i

Limited Warranty _________________________________________________________________ iv

Operating Instructions ___________________________________________ 1

Construction

How to Operate your Dishwasher

Cleaning and Maintenance

Troubleshooting

Installation _____________________________________________________ 21

The plumbing and electrical connection diagram, (P&E).

Unpack and Place

Order of Assembly

Section Assembly

Water Connection

Drain Connection

Electrical Connection

Ventilation

Initial Start-up

Service Replacement Parts ______________________________________ 47

Electrical Schematics ______________________________________ 217

iii

Limited Warranty

LIMITED WARRANTY

Champion Industries Inc. (herein referred to as Champion), 3765 Champion Blvd, Winston-Salem, North Carolina

27105, and P.O. Box 301, 2674 N. Service Road, Jordan Station, Canada, L0R 1S0, warrants machines, and parts,

as set out below.

Warranty of Machines: Champion warrants all new machines of its manufacture bearing the name

"Champion" and installed within the United States and Canada to be free from defects in material and workman

shipforaperiodofone(1)yearafterthedateofinstallationorfteen(15)monthsafterthedateofshipmentby

Champion,whicheveroccursrst.[Seebelowforspecialprovisionsrelatingtoglasswashers.]Thewarranty

registration card must be returned to Champion within ten (10) days after installation. If warranty card is not

returned to Champion within such period, the warranty will expire after one year from the date of shipment.

Champion will not assume any responsibility for extra costs for installation in any area where there are

jurisdictional problems with local trades or unions.

If a defect in workmanship or material is found to exist within the warranty period, Champion, at its election,

will either repair or replace the defective machine or accept return of the machine for full credit; provided;

however, as to glasswashers, Champion's obligation with respect to labor associated with any repairs shall end

(a)120daysaftershipment,or(b)90daysafterinstallation,whicheveroccursrst.IntheeventthatChampion

elects to repair, the labor and work to be performed in connection with the warranty shall be done during regular

working hours by a Champion authorized service technician. Defective parts become the property of Champion.

Use of replacement parts not authorized by Champion will relieve Champion of all further liability in connection

with its warranty. In no event will Champion's warranty obligation exceed Champion's charge for the machine.

The following are not covered by Champion's warranty:

a. Lighting of gas pilots or burners.

b. Cleaning of gas lines.

c. Replacement of fuses or resetting of overload breakers.

d. Adjustment of thermostats.

e. Adjustment of clutches.

f. Opening or closing of utility supply valves or switching of electrical supply current.

g. Cleaning of valves, strainers, screens, nozzles, or spray pipes.

h. Performance of regular maintenance and cleaning as outlined in operator’s guide.

i. Damages resulting from water conditions, accidents, alterations, improper use, abuse,

tampering, improper installation, or failure to follow maintenance and operation procedures.

j. Wear on Pulper cutter blocks, pulse vanes, and auger brush.

Examples of the defects not covered by warranty include, but are not limited to: (1) Damage to the exterior or

interiornishasaresultoftheabove,(2)Usewithutilityserviceotherthanthatdesignatedontheratingplate,

(3) Improper connection to utility service, (4) Inadequate or excessive water pressure, (5) Corrosion from

chemicals dispensed in excess of recommended concentrations, (6) Failure of electrical components due to

connection of chemical dispensing equipment installed by others, (7) Leaks or damage resulting from such

leaks caused by the installer, including those at machine table connections or by connection of chemical

dispensing equipment installed by others, (8) Failure to comply with local building codes, (9) Damage

caused by labor dispute.

Warranty of Parts: Champion warrants all new machine parts produced or authorized by Champion to be free

from defects in material and workmanship for a period of 90 days from date of invoice. If any defect in

material and workmanship is found to exist within the warranty period Champion will replace the defective

part without charge.

DISCLAIMER OF WARRANTIES AND LIMITATIONS OF LIABILITY. CHAMPION'S WARRANTY IS ONLY TO THE EXTENT REFLECTED ABOVE. CHAMPION MAKES NO OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING,

BUT NOT LIMITED, TO ANY WARRANTY OF MERCHANTABILITY, OR FITNESS OF PURPOSE. CHAMPION SHALL

NOT BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES. THE REMEDIES SET OUT ABOVE ARE

THE EXCLUSIVE REMEDIES FOR ANY DEFECTS FOUND TO EXIST IN CHAMPION DISHWASHING MACHINES AND

CHAMPION PARTS, AND ALL OTHER REMEDIES ARE EXCLUDED, INCLUDING ANY LIABILITY FOR INCIDENTALS

OR CONSEQUENTIAL DAMAGES.

Champion does not authorize any other person, including persons who deal in Champion dishwashing machines

to change this warranty or create any other obligation in connection with Champion Dishwashing Machines.

iv

Operation

Operating Instructions

IMPORTANT

Please read the steps below before you operate your dishwasher.

1. Make sure the dishwasher was properly installed and tested prior to operation.

2. Read the operating instructions completely before you operate your dishwasher for

the rst time.

3. Keep these instructions available for quick reference.

4. Contact your supervisor immediately if you have questions about the dishwasher.

5. Contact your local authorized Champion service agency for technical support.

6. Our National Service Department provides 24 hour support 365 days a year with a

Toll-free number in the United States.

USA National Service

M-F • 8 AM - 5PM EST

Toll-free: 1 (800) 858-44772

In the USA, a factory technician will return your call after-hours and during holidays.

or

Canadian National Service

M-F • 8:30 AM - 4:30PM EST

Toll-free: 1 (800) 263-5798

1

Dishwasher Construction

Operating Instructions

Dishwasher Construction

1. The Upright Conveyor dishwasher, (also called the ight-type conveyor), is assembled

as a single unit from sections or modules.

2. This basic design is then customized to the customer's specications.

3. The information presented blow explains the basic construction of the upright conveyor

dishwasher. It does not cover custom-built innovations.

4. Study the diagrams on the next page, then continue reading below.

Dishwasher Sections:

Five sections make up the basic assembly. The sections are:

Load, Prewash, Wash, Rinse,

Final rinse, Unload

Dishwasher Views:

Plan View

Elevation

Side View

2

Operating Instructions

All Models

The diagrams below are an example, your machine may be different.

Operation

UNLOAD END "B"

RINSE

WASH/RINSE "C"

RINSE "C1" WASH "C1"

POWER

RINSE

DIRECTION OF

OPERATION

POWER

WASH

LOAD END "A"

PREWASHFINAL

3

Operation

Operating Instructions

DO NOT ip the dishwasher power switch "ON"

until you check the items below.

1. Check that the following utilities are connected:

to the dishwasher and ready for use:

Electrical service

Hot water supply

Drain

Ventilation

2. Check the chemical connections and chemical containers are

installed and ready for operation, (Consult your chemical supplier for instructions).

3. Check the interior of the dishwasher for foreign objects and remove.

4. Turn on the water supply to the dishwasher.

5. Turn on the main power switch at the building service disconnect switch.

4

1. Close all drains.

2. Makesureoats,

overows,drain

screens,andpump

screens are clean

and in place.

Operation

Operating Instructions

3. Alwaysslidethepump

screens up and lift out.

4. Check the

bottomtomakeabsolutely

sure they are clean.

Replace in reverse order

5

Operation

Operating Instructions

1. Place the curtains in

2. To install the curtains:

the dishwasher making

sure the short aps

face the load end

of the machine.

Locate the curtain

hooks in each section.

3. Place the curtain rod

in the rear hook, then

lift the opposite end of

the curtain rod and place

it in the front hook.

4. Place the 19" long

curtains at each end

of the dishwasher.

5. Place the 14" center

curtains in each section.

6. Place the 10" nal rinse

curtain between the nal rinse

and auxiliary rinse pipes.

6

7. Check the upper and lower

wash arm manifold o-rings

to make sure they are

in place and in good

condition.

8. Install the upper wash arm

assemblies.

Operation

Operating Instructions

9. Install the lower wash arm

assemblies.

10. Make sure all wash arm

assemblies are locked

in place.

11. The auxiliary rinse section

is equipped with an upper and

lower rinse arm.

Refer to the illustrations on the next page for a more detailed view of the spray arms.

7

Operation

LOCK

RELEASE

LOCKING

SLOT

LOCKING

SLOT

LOCKING

SLOT

LOCKING

SLOT

LOCK RELEASES

TO INSTALL UPPER SPRAY ARM:

TO REMOVE UPPER SPRAY ARM:

TAB PREVENTS

SPRAY ARM

FROM DROPPING

TAB

PREVENTS

SPRAY ARM

FROM

DROPPING

LOCKING

SLOT

LOCKING

SLOT

TO INSTALL UPPER SPRAY ARM:

Operating Instructions

8

12. There are 2 removable

auiliary rinse spray pipes

in the auxiliary rinse section.

13. Make sure the upper and

lower auxiliary rinse spray

pipe gaskets are in place.

Operation

Operating Instructions

14. Position the spray pipe

so the rinse nozzle points

toward 10 o'clock.

15. Push the rinse pipe

forward.

16. Turn the auxiliary rinse pipe

1/4 turn clockwise to

lock it in place.

Note:

The nal rinse pipes are permanently installed

and do not require assembly.

9

Operation

Operating Instructions

17. Install the scrap

screens.

18. Install the scrap baskets if applicable.

19. Make sure the screens

are fully seated to the

rear of the dishwasher

and interlocked into

the scrap basket.

10

20. Close all doors.

21. Lift the door up

slightly,then

push the door catch

back toward the

inside of the

dishwasher.

Operation

Operating Instructions

22. Slowly lower the door.

Thedoorcatchremainsdisengage

23. There are 2 half-size Econo-rinse doors.

The operator lifts the upper door which hooks

inplace.Next,heliftsthelowerdoorwhich

hooks in front of the upper door.

Tolowerthedoors,theoperatorreleasesthe

lower door hook and closes the door then

releases the upper door hook to close the

upper door.

11

Operation

Operating Instructions

24. Flip the dishwasher

power switch up.

25. The dishwasher

automatically lls

with water.

26. The tank heat comes

on as soon as the tanks are full.

27. Wait for 15-20 minutes to allow the wash and

rinse tanks to reach operating temperature.

R-L shown

The prewash tank is not heated so its temperature

may be lower than the wash tank. This is okay.

Thenalrinsetemperatureischeckedwhenthedishwasher

conveyor belt and wash pumps are running during normal operation.

12

28. Push the GREEN

START BUTTON

to start the

conveyor belt.

Operation

Operating Instructions

NOTE:

Pushing the green start

button:

1. Starts the conveyor belt.

29. Push the

RED STOP BUTTON

to stop the

conveyor belt.

Thewashpumpsstop.

Tank heaters continue to operate.

30. Push the

GREEN START BUTTON

to re-start the conveyor belt.

13

Operation

Operating Instructions

31. Your dishwasher

These stations work exactly as

Start-stop stations make it

is equipped with start-stop

stations. The load

station is standard equipment; the

unload station is an option.

the control cabinet start and stop

buttons.

possible for the person

loading the wares on the

conveyor belt to start and

stop the dishwasher as needed.

The person unloading the wares also has

the ability to start and stop the dishwasher

using the optional unload start-stop station

(if it is installed .)

32. Push the GREEN

START BUTTON to start the

conveyor belt.

33. Push the

RED STOP BUTTON

to stop the conveyor belt.

Load-end Start-Stop Station

14

Optional Unload-end

Start-Stop Station

34. An important safety feature

designed to stop the conveyor belt during operation is

the shut-off shelf.

This device is located at

the very end of the unload

section.

35. The shut-off shelf moves

backward when wares

contact it as the belt

moves forward.

Operation

Operating Instructions

36. The shut-off shelf stops

the conveyor belt.

It also turns the blower

dryer heat off (if equipped).

The wash pumps continue

to operate when the shut-off

moves backward to stop

the conveyor belt.

37. The unload person may

now remove the wares

from their end of the

dishwasher.

38. The conveyor belt begins

moving again when the

person moves the shut-off

shelf back to its original

position.

Shut-off shelf in the RUN position

Shut-off shelf in the STOP position

15

Operation

Operating Instructions

Daily Maintenance

1. Keep your dishwasher and the surrounding area clean.

After each meal period or every 2 hours of operation, whichever occurs rst

Turn POWER OFF

Drain the dishwasher

Remove and clean the curtains

Flush the inside of the machine from top to bottom and all hidden places

Remove and clean scrap screens and baskets ushing with fresh water

Clean drain screens and pump screens

and at the end of the day.

Wipe the exterior of the dishwasher with a soft cloth DO NOT HOSE WITH WATER

Leave doors open so the dishwasher may better dry overnight

2. Immediately report loose, broken or missing parts to your supervisor.

3. Check drains for ow restrictions.

4. Check the dishwasher for leaks.

5. Operate the dishwasher as explained in this manual.

Monthly Maintenance

1. Inspect pump hoses, door linkage, springs, and exterior of dishwasher for wear.

2. Inspect the wash arm bearings and O-rings.

3. Check the condition of scrap screens and dishracks for damage.

4. Check the toggle switches and indicator lights for damage.

5. Check the wash pump motor for loud bearings and leaking pump seal.

16

Annual Maintenance

Call your authorized service agent or local service representative and schedule

a complete inspection of your dishwasher by our trained professionals.

Schedule your annual maintenance when you can give the service

agent unrestricted access to the dishwasher for at least 2 to 3 hours.

Operation

Troubleshooting

17

Troubleshooting

Troubleshooting

On occasion your machine may not operate as expected.

Use the checklist below before you decide that a mechanical or electrical failure has occurred.

Checklist

1. Are the main disconnect switches, breakers, or motor overloads turned ON?

2. Are the main water and steam supplies turned ON?

3. Are the drain valves closed?

4. Are the spray pipes and rinse nozzles clean?

5. Are the spray pipes in the proper locations?

6. Are the pump intakes clean?

7. Are the scrap screens clean and in place?

8. Are the thermostats correctly adjusted?

9. Are the high limit temperature thermostats reset?

10. Are the doors fully closed?

11. Are the conveyor shut-off and drive assemblies in operating condition?

12. Are the chemical supplies adequately lled?

If a problem still exists after verifying the checklist, refer to the following

CONDITION CAUSE SOLUTION

Conveyor will not run Door not closed ................................... Make sure doors are fully closed

Door safety switch faulty .................... Contact your service agency

Start switch faulty ............................... Contact your service agency

Main switch OFF ................................ Check disconnect

Control panel power switch OFF ........ Flip switch ON

Conveyor shut-off shelf operated........ Move shelf toward tunnel of machine

Motor overload protector tripped ........ Reset overload in control cabinet

Green start button not pressed ............ Press green start button

18

Troubleshooting

Troubleshooting

CONDITION CAUSE SOLUTION

A single pump will not run Motor overload tripped ....................... Reset overload in control cabinet

Defective motor Contact your service agency

Low or no water Main water supply is turned off .......... Turn on house water supply

Drain valves are open.......................... Close all drain valves

Doors are not fully closed ................... Close doors

Faulty ll valve ................................... Contact your service agency

Stuck or defective oat switch............ Free oat /Contact service agency

Cross-ow piping misadjusted/

clogged ................................................ Adjust cross-ow setting/Clean piping

Clogged strainer at supply

connection ........................................... Clean strainer screen

PRV misadjusted or defective............. Readjust pressure setting or replace PRV

Continuous water lling Stuck or defective oat switch............ Free oat/Contact service agency

Fill valve will not close....................... Clean valve,repair or replace valve

Drain valves open................................ Close drain valves

Wash/Rinse tank Incoming water temp. Raise incoming temperatureis low

temperature low at machine low..................................... 140°F minimum for 40°F rise booster

110°F minimum for 70°F rise booster

180° F minimum without booster

Defective thermometer ........................ Check or replace

Defective thermostat ........................... Readjust setting or replace

Defective electric heater element ........ Check or replace

Low steam pressure or volume ........... Check steam supply pressure

Defective steam trap............................ Check or replace

Defective solenoid valve ..................... Check or replace

Prewash tank temperature Incoming cold water temperature Lower incoming water temperature

is too high (Optional Cold too high................................................ to maximum of 65°F

Water thermostat Only) Defective cold water thermostat ......... Check or replace

Insufcient pumped spray Clogged pump intake screen ............... Clean

pressure Clogged spray pipe.............................. Clean

Scrap screen full .................................. Must be kept clean and in place

Low water level in tank Check drain valves

Pump motor rotation incorrect ............ Reverse wires L1 and L2 in control cabinet

Defective pump seal ............................ Contact service agency

Insufcient nal rinse or Faulty pressure reducing valve

no nal rinse (PRV) .................................................. Clean or replace

Improper setting on PRV .................... Set Flow pressure to 20-22 PSI

Clogged rinse nozzle or pipe .............. Clean

Improper water line size...................... Installer must change to proper size

Clogged “Y” strainer........................... Clean or replace

19

Troubleshooting

Troubleshooting

CONDITION CAUSE SOLUTION

Low nal rinse temperature Low incoming water temperature ....... Raise incoming water temperature

140°F for 40°F rise booster

110°F for 70°FS rise booster

180°F without booster

Defective thermometer ........................ Check or replace

Defective thermostat ........................... Recalibrate or replace

High limit thermostat tripped .............. Reset or replace

Low steam pressure............................. Check steam supply pressure

Poor washing results Detergent dispenser not operating ...... Contact the chemical supplier

Detergent supplied not strong

enough ................................................. Contact the chemical supplier

Wash water temperature too low See Condition “Wash/Rinse tank

water temperature too low”

Spray pipes clogged ............................ Clean

Improperly scrapped dishes ................ Check scrapping procedures

Ware improperly loaded on

conveyor .............................................. Stagger ware on belt

Maintenance not performed

as required ........................................... See Maintenance Schedule

Electric elements/steam coils have ..... Clean and delime

lime build-up ....................................... Contact the chemical supplier

Poor drying results Excessive humidity in

warewashing area ................................ Check vent dampers and exhaust

Improperly stacked dishes

after washing ....................................... Check unloading procedures

Insufcient rinse-aid ........................... Contact chemical supplier

Final rinse temperature See Condition “Final Rinse temperature

too low ................................................ too low”

20

Installation

Installation Instructions

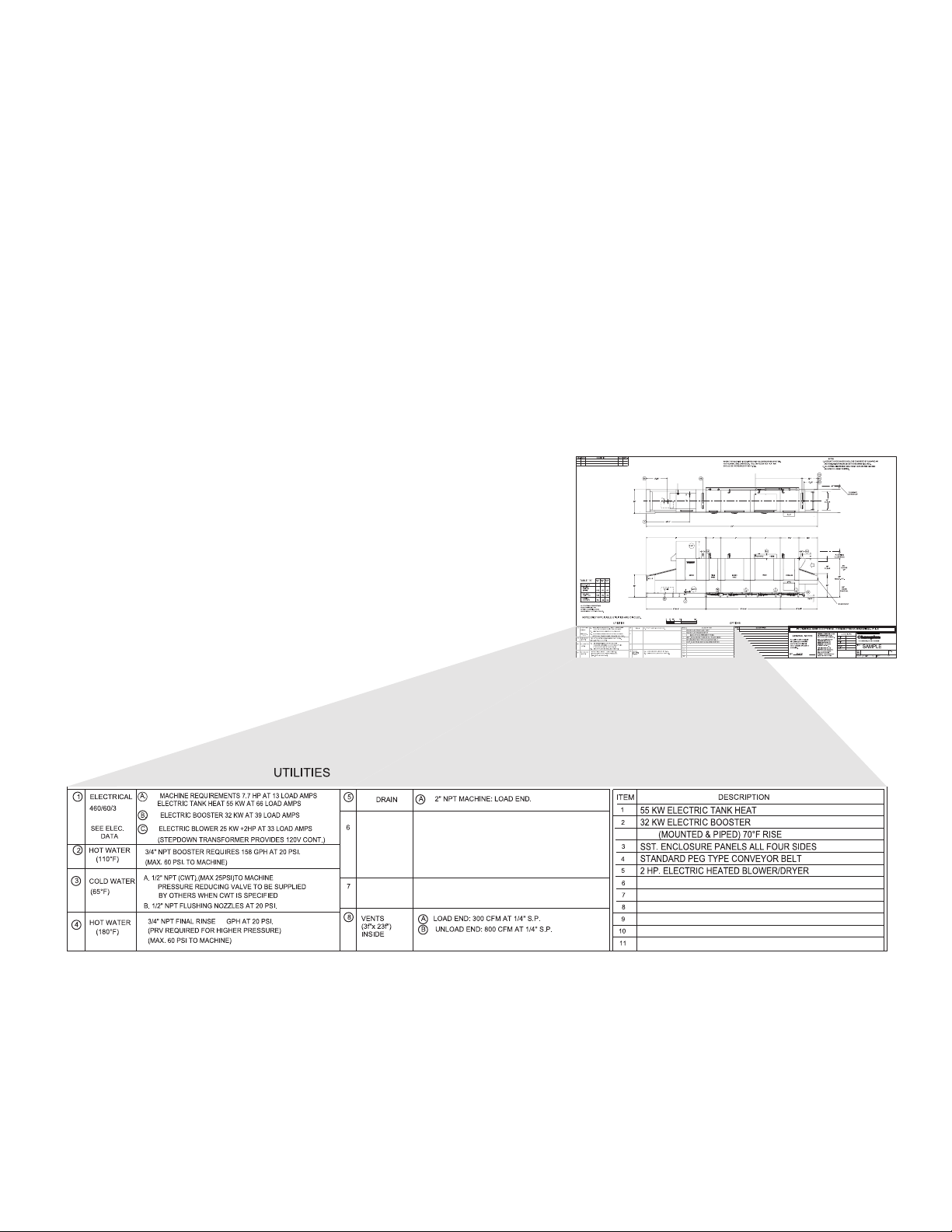

Plumbing and Electrical Diagram, (P & E)

1. The dishwasher P&E is a documented drawing that contains the critical data for the

proper construction and utility connections for the dishwasher.

2. The P&E was reviewed and approved by all authorized persons prior to shipment.

3. The sample diagram below illustrates the format and presentation of the data necessary

to connect the dishwasher.

21

Blank Page

This Page

Intentionally

Left Blank

22

(machine viewed from front)

Installation Instructions

1. The illustrations below are an example machine, your machine may be different.

Plan View

(machine viewed from above)

Installation

UNLOAD END "B"

RINSE

WASH/RINSE "C"

RINSE "C1" WASH "C1"

POWER

RINSE

DIRECTION OF

OPERATION

Elevation View

POWER

WASH

LOAD END "A"

PREWASHFINAL

23

Unpack and Place

Installation Instructions

Unpack and Place

Unpack and place

1. Upright conveyor dishwashers ship in

sections. Each section comes wrapped

in a protective covering and secured

toa wooden pallet. Labels note the

totalnumber of sections shipped, such

as 1 of 4.

Accessories

2. Check the shipment for damage

immediately upon receipt. Save all

packing materials and pallets, then

contact a supervisor, the equipment

dealer, and the factory to report the

damage.

3. Fasteners, curtains, panels and other

pieces are packing in cardboard boxes

and secured to the wash/rinse section of

the machine. Inventory these parts and

report shortages to a supervisor, then

store the parts in a secure location.

CAUTION:

Standard 36" doorways often measure

less than 35" in width.

Shipping pallets measure 48" wide.

24

Fasteners

4 Inspect the route that sections

must travel if the shipment was

not delivered to the dishwashing

room. Measure allpassageways

and doors before moving the

dishwasher.

IMPORTANT

Check the utilities early

Incorrect voltage, hot water supply,

or steam piping may delay the

completion of the installation

Unpack and Place

Installation Instructions

Unpack and Place

5. Piping on the rear wall of the

dishwasher may be removed to

allow the dishwasher to pass

through narrow openings if

necessary.

6. Compare the location of the site

utilities with the Plumbing and

Electrical Connection Diagram,

(P&E).

CAUTION

Use extreme care when lifting

a section off its pallet to prevent

damage to the dishwasher.

25

Order of Assembly

Installation Instructions

Order of Assembly

7. Next, compare the site utilities with the utility connections

on the dishwasher.

The utility locations and ratings of the must match

the dishwasher when it is re-assembled in its

permanent location.

Contact a supervisor immediately if a utility location

does not match the

dishwasher.

8. Checkoorstability.Flooringmustsupporttheweightofthe

dishwasher without bowing when weight is applied.

Tiledoorsmayfractureifloadsaredroppedonordrugacross

its surface.

9. Move the palleted sections near their permanent locations.

Remove protective coverings, shipping straps, brackets and

palletized accessories.

10. Inspect the underside of each section, (below the base) and

note the position of piping, valves, and other components that

may be in the way

11. Carefully lift each section off the pallet. Screw the adjustable

bullet-feet in as far as possible, then lower the section to the

nishedoor.

26

Order of Assembly

Installation Instructions

Order of Assembly

12. The illustration above shows the correct placement of the sections.

13. The recommended spacing between sections is 2 feet. Of course, the size of your dishroom

dictates the actual section spacing.

14. Study the illustration above. Note that each section name also contains a designated letter,

(A, B, C, E).

15. The illustrated dishwasher is a right-to-left, (R-L)congurationwhichindicatesthatsoiled

wares enter on the right and exit on the left. A left-to-right, (L-R), dishwasher is the reverse

of a R-L dishwasher.

16. The "E" or Eco-rinse section is an option and may not be a part of your installation.The

dashed lines between the "C" and "E" sections indicate that the "E" section usually ships

as part of "C" section.

17. The "C" section ships as a single assy in 4, 6, or 8 ft. lengths.

18. The Order of Assembly should start with the "C" section; however, it is okay to start with

the "B" section if the plumber is ready to make the hot water and steam connections.

27

Section Assembly

Installation Instructions

Section Assembly

19. Remove the shipping braces from

the sections.

20. Identify the location of piping

between the sections.

21. Check the height of each section

and determine which section is the

highestduetooorvariations.

22. Set the "C" section and adjust to its

minimum height.

23. Level the "C" section side to side

and front to back in several places

with a bubble level.

24. The remaining sections are leveled

in relation to "C" section.

Do not adjust the "C" section

too high.

25. Apply a 1/4" bead of FOOD

GRADE sealant to the foam

gaskets on each section.

APPROVED SEALANT WAS SUPPLIED IN

THE HARDWARE KIT.

DO NOT SUBSTITUTE ANOTHER

TYPE OF SEALANT.

26. Move the next section close to

the "C". Adjust the feet of this

section to align the 20 bolt holes

around the hood.

27. Slide the connecting hoses and

clamps on drain pipes and crossowpipes.Donottighten

at this time.

28

28. Level each section side to side

and front to back making sure

the section connecting bolt holes

align.

29. Make sure the sections are

adjusted to the same height.

30. Check the alignment of the

conveyor tracks inside the

machine and adjust tracks if

necessary. Tracks should align

if the sections are level.

31. Bolt all the HOOD sections

together with twenty (20), 5/1618 X 3/4" bolts, lockwashers and

nuts included in the hardware kit.

32. Tighten the hood bolts in a

cross-pattern to pull the sections

together.

Section Assembly

Installation Instructions

Section Assembly

33. Silicon sealant should squeeze

out of the section joints.

34. Apply a 1/2" bead of Foodgrade

sealant in the bottom of the clip.

35. Invert the clip and slide it over

the section joint

36. Bolt the clip securely in place.

29

Section Assembly

Installation Instructions

Conveyor Belt Installation

Beginning with S/N J11062899 and above

1. Remove the key from the conveyor drive

sprocket.

2. Start at the unload end of the machine

and pull the conveyor belt around the end

sprockets until approximately 1.5 feet/76.2

cm of belt rests on the upper track of the

dishwasher.

3. Pull a section of belt to the next section along

the upper track into the unload end.

4. Join the belt sections together by feeding a

conveyor rod through the links, spacers, and

rollers. Install a cotter pin on each end of the

rod to secure the assembly.

5. Use an assembled rod section on the belt as

a guide for the placement of the spacers, etc.,

continue this procedure until the conveyor belt

is assembled in a complete loop.

Connect the conveyor belt sections with

a rod, spacers, and washers included

in the hardware kit.

30

Remove the key from the conveyor drive sprocket.

Section Assembly

Roller seated

in sprocket

Steel links do not

rub sprocket

Conveyor Belt Installation

The take-up assemblies are located on either

side of the load end conveyor shaft as shown in (A).

Adjust the conveyor belt tension at the load end. Loosen

the adjusting bolt locknuts then turn the adjusting bolts CW

to tighten the belt.

Make sure the belt tension is even on both sides.

Check the slack of the lower portion of the belt. The lower

belt must not sag.

Continue to adjust belt tension as you manually remove

lower belt slack until the lower slack is minimized.

Check the belt tension by lifting the upper conveyor belt

at the load end of the dishwasher as shown in (B).

The proper belt tension is achieved when the top of the

conveyor belt rods are even with the top of the belt

access hole as shown in (C).

DO NOT OVERTIGHTEN THE BELT.

Belt Access Hole

A

Tighten the adjusting bolt locknuts on each take-up

assembly to hold the belt adjustment.

Check that the conveyor belt tracks evenly on all

of the conveyor drive sprockets during operation and

adjust the take-up assemblies as required

as shown in (D).

Proper tracking requires that the rollers seat evenly

in the conveyor belt drive sprockets. The metal links

on the conveyor belt must not rub the sides of the

belt sprockets as shown in (E).

B

C

E

D

31

Section Assemby

Installation Instructions

Conveyor Drive

Beginning with S/N J11062899 and above

There are two conveyor drive designs.

Therstisthestandarddrivecomprisedofa

gear box, drive belt motor and chain connected

to the conveyor drive shaft.

The second design is variable speed solid-state

electronic speed control, a variable speed motor

and a chain connected to the conveyor drive

shaft.

Variable Frequency Drive (VFD) Conveyor Drive Motor

The conveyor drive is equipped with anti-jam protection and a reversing switch if an object

becomes jammed in the conveyor. This anti-jam mechanism shuts the conveyor drive off to

prevent damage to the conveyor belt. The anti-jam switch is adjusted at the factory and should not

require adjustment.

Standard Single Speed Conveyor Drive

Anti-jam Swith Operation

The anti-jam switch assembly consists of a base mounting bracket, a limit switch with a mounting

bracket, and a spring loaded tensioner arm with a sprocket. A reverse jog switch button is always

used in conjunction with the anti-jam switch. The tensioner arm with the sprocket is positioned on

the drive side of the drive chain.

When a jam occurs, the drive chain tightens, causing it to straighten changing the position of the

sprocket attached to the tensioner arm. When the sprocket position changes, the tensioner arm

rotates away from the button on the anti-jam switch causing it to open.

When the switch opens, all power to drive motor is disconnected stopping the forward motion of

the conveyor. The drive will not work in the forward direction as long as the anti-jam switch is

in the open position.

32

Section Assemby

Reverse Jog Switch Operation

The Single Speed Reverse Jog operates under the following conditions:

a) When the power is on and the anti-jam switch is open due to a conveyor jam.

b) When the power is on and the conveyor was stopped via the "STOP". The "START" switch

must be pressed to restart the forward motion of the conveyor.

c) If the reverse jog switch is pressed while the conveyor is moving forward, the forward motion

will stop as long as the switch is pressed. Releasing the switch will restart the belt forward

motion.

d) If the conveyor is stopped by the shut-off shelf, the "STOP" must be pressed before the reverse

switch will work.

The VFD Reverse Jog operates under the

following conditions:

a) When the VFD is powered on regardless if the

machine power is off.

b) If the button is pressed when the conveyor

is moving forward, the conveyor will run

in reverse as long as the button is pressed;

releasing the button returns the forward motion

of the belt.

c) When the anti-jam switch is open and the

reverse button is pressed, the conveyor

will run in reverse as long as the button is

pressed. Releasing the button stops the

conveyor. The START button must be

pressed to restart the conveyor.

d) The reverse button will work if the belt was

stopped by the shut-off shelf.

Reverse Jog Switch

Anti-Jam Switch Adjustments

The anti-jam switch has three adjustments.

Refer to the letters in the photo at right:

A. The base mounting bracket has horizontal

slots for positioning the tensioner arm sprocket

against the drive chain. This is a factory setting

and should not require changing.

B. The limit switch bracket has vertical slots to

adjust the switch up and down. Raising the

switch reduces the switch reaction time,

lowering it increases the reaction time.

C. The tensioner arm spring sets the amount

of force required to operate the jam switch. The

tighter the spring the more load it takes to

operate the switch and stop the conveyor.

C

A

B

Anti-jam Switch

33

Section Assemby

Installation Instructions

Section Assembly

21. The Installation Supervisor must

inspect the position, level and

proper connection of the piping

connections.

22. Steam supply and condensate

unions must be tight.

23. Drain piping must be checked.

24. Cross-owhosesmustbe

inspected and clamps tightened.

25. Flushing nozzle piping on the

load end must be inspected.

34

26. Checkandtightenthellpiping

compressionttings.

27. Make sure solenoid coils are positioned

correctly on the valve assemblies.

28. Vent stacks must be placed on the hood

with vent handles facing the front

of the dishwasher.

Section Assemby

Installation Instructions

Section Assembly

29. Panels must be rechecked for missing

parts, and the location numbers checked

with the numbers located on the

dishwasher.

30. Tanks must be checked for debris and

metal tailings must be vacuumed out of

the machine.

31. Curtains must be installed. Install

thecurtains. Long curtains hang in hooks

on each end of the machine. Short

curtains hang in hooks on the inside of

the machine.

32. Scrap screens, scrap baskets must be

checked and installed in the dishwasher.

35

Section Assemby

Installation Instructions

Optional Blower Dryer Assembly

1. The blower dryer comes in electric or

steam.

2. It ships on a separate pallet.

The vent cowl and mounting hardware

are included in the

accessories box and hardware

kit.

3. Lift the blower dryer off the pallet

with a forklift and place on the

end of the unload section.

If a forklift is not available, then

four (4) men are needed to lift

and install the unit manually.

4. Bolt the blower dryer in place using the

5/16-18X3/4"bolts,atwashers,and

lock washers from the hardware kit.

5. Fasten the vent cowl on the discharge

end of the blower dryer using the 1/4-

20plainnuts,atwashers,andlock

washers from the hardware kit.

REFER TO THE BLOWER-

DRYER SERVICE MANUAL

P/N 114316

SHIPPED WITH THE

BLOWER-DRYER

ASSEMBLY

FOR COMPLETE

INSTALLATION

INSTRUCTIONS.

6. Connecttheex-titeconduit

to the junction box located at

the rear of the dishwasher.

7. Match wire numbers in the junction box

and connect with wire nuts.

8. Close the junction box.

9. Install the cowl to the end of the

blower dryer.

36

Connect the dishwasher internal electric wiring

1. Wires,ex-tite,andsomecomponentswere

disconnected and pulled back to

each section, then junction boxes were

closed.

2. Openalljunctionboxes,identifytheex-tite

conduit connections, (A)

roll-out wire bundles, (B), and match

wire numbers attached on wires, (C).

3. Connecttheex-titeconduittotheir

associated junction boxes.

Section Assemby

Installation Instructions

Section Assembly

4. Connect matching wires using the

supplied wire nut connectors, (D)

included in the hardware kit.

5. Connect #2 and any white wires

together. All of these wires are

neutral returns.

6. Close all junction boxes.

37

Section Assemby

Installation Instructions

Section Assembly - Seal Joint Sections

1. Section joints must be sealed

with foodgrade silicon sealant.

2. Mask the joint edges with

a quick-release masking tape.

3. Apply a 1/8" bead of Foodgrade

silicon sealant. Apply moderate

pressure on the gun to ensure the

sealantllsthejoint.

4. Wait 45-seconds for the sealant

tormslightly.Thenwipethejoint

with a damp cloth.

Do not wait longer than 1 minute for

thesealanttorm.Thesealant

will not wipe correctly.

5. If the sealant dries longer than

1 minute, DO NOT try to wipe

the joint. Allow the sealant 30

minutes to dry, then cut the

sealant out of the joint and

begin again.

6. Wait 10-seconds after wiping the

joint, then remove the masking

tape.

7. Continue sealing the joints.

38

DO NOT SEAL more than

one joint at a time. The sealant

will dry faster than you can

work the joint.

8. Study the photos on the right. The top

photo shows a correctly sealed joint.

9. The stainless steel must be wiped with

Isopropyl alcohol to remove dust, oil

lm,andothercontaminants.

Section Assemby

Installation Instructions

Section Assembly - Seal Joint Sections

10. Notethatthejointislledpresenting

an even transition between sections.

11. The sealant is applied past the top

radius of the joint presenting a uniform

ll.

12.. Study the lower sealed joint. This

joint did not have enough sealant

applied and therefore presents a

crevasse where soils may be

trapped.

13. Practice this procedure on a

hidden joint if you experience

problems with the procedure.

39

Supply Connections

MACHINE ELECTRICAL CONNECTION

Installation Instructions

Supply Connections - Main Incoming Power

The Main incoming power to the dishwasher

is made at the top of machine in the control

cabinet.

The electrician must connect the power supply

in accordance with the data stamped on the

Machine Electrical Connection Plate.

This data is the ultimate authority and is not

superseded by any other data supplied in

print, or conveyed verbally.

WARNING:

Electrical and grounding connections

must comply with the National Electrical

Code and/or Local Electrical Codes.

WARNING:

When working on the dishwasher,

disconnect the electric service and

place a tag at the disconnect switch

to indicate work is being done on that

circuit.

Note:

Aqualiedelectricianmustcomparethe

electrical power supply with the machine

electricalspecicationsstamped

on the MACHINE ELECTRICAL

CONNECTION PLATE located inside

the control cabinet before connecting

to the incoming service at a fused

disconnect switch.

40

IMPORTANT

Main utility supply connections must

be performed by licenced tradesmen who abide

by local building, health and sanitation codes or

national codes in the absence of local codes.

THE MAIN INCOMING HOT WATER AND STEAM

SUPPLY CONNECTIONS ARE MADE

IN THE LOWER PART OF "D" SECTION

Supply Connections

Installation Instructions

Supply Connections - Water and Steam

ATTENTION INSTALLERS AND SUPERVISORS

REFER TO THE PLUMBING & ELECTRICAL

CONNECTION DIAGRAM FOR THE LOCATION

AND SIZE OF ALL UTILITIES.

BUILDING VENTILATION CONNECTIONS

ARE MADE AT THE TOP OF THE "A" AND "D"

SECTIONS.

BUILDING VENTS MUST ALIGN WITH THE

DISHWASHER CENTER-LINE AND MATCH THE

SIZE OF THE DISHWASHER VENT DUCTS.

Hot water connection

Steam and condensate connection

Drain Connection

41

Supply Connections

SIGNAL ONLY

VENT FAN

COMMON

COMMON

120V

DETERGENT

120V

RINSE AID

120V

Installation Instructions

Supply Connections - Chemical Dispensers

Chemical dispensing systems are supplied by others.

A connection point for detergent, and rinse-aid signals is provided in the

in the top-mounted control cabinet.

42

Supply Connections

Installation Instructions

Initial Start-up

Perform the following checks and adjustments before placing the machine into service.

• Check the interior of the machine and remove any foreign material.

• Check the exterior of the machine — make sure that the conveyor belt is free of tape

and foreign material.

Bafes –

Tankbafesredirecttheowofwaterfromthesprayarmsystemsbackintothetanks.

Thispreventswaterlossandkeepsthewash,rinse,andnalrinsewaterintheproper

tank.Checkthebafes—makesurethattheyareinstalledandpositionedcorrectly.

Close the tank drain valves along the lower front of the machine.

Open the water supply valves. Check for leaks and take corrective action as required.

Open the steam supply valves (if applicable). Check for leaks and take corrective

action if required.

Turn the main power on at the breaker panel or fused disconnect switch.

Machine main power

Electric booster main power (if applicable)

Flip the Power Switch on the frontof the Control Cabinet to the "ON" position.

The Red power on light will illuminate.

Themachinewillbegintollwithwater.

Allowthemachinetocompletelyllwithwater.

The water will shut off automatically.

Check for leaks and take corrective action if required.

Monitor the tank thermometers for the proper temperature reading.

Allowsufcienttimeforthetankheattoreachoperatingtemperature.

Move the conveyor shut-off shelf located at the end of the unload section toward the

machine. This resets the automatic conveyor stop system.

When an object on the conveyor contacts the shut-off shelf, the conveyor stops.

Press the GREEN start button on the front of the control cabinet.

43

Initial Start-up

Installation Instructions

Initial Start-up

Check the direction of rotation of the conveyor belt by observing the direction

arrow decal on the large conveyor drive sprocket. The sprocket is located on

the side of the unload section.

If rotation direction is incorrect, reverse wires L1 and L2 on the disconnect

switch side of the main electrical connection terminal block located inside the

control cabinet.

Each temperature gauge is marked with its proper operating range.

Check the Energy Sentinel (idle pump shut-off) by placing a tray or dish on

the moving conveyor belt.

The pumps will start as the object enters the tunnel of the machine.

Theoptionalecono-rinsepumpstartswiththenalrinse.

Check pump motor rotation, CW when viewed from the rear of motor.

44

Initial Start -up

Checkthenalrinsetemperatureastheobjectentersthenalrinsearea.

The Final rinse temperature must be 180-195°F.

Adjust the temperature of the incoming water supply if necessary.

Adjust the booster thermostat setting if necessary.

ChecktheFinalrinsewaterpressureastheobjectentersthenalrinsearea.

Thenalrinsepressuremustbe20-22PSI.

Adjust the Pressure Reducing Valve setting if necessary.

Checkthatthepumpsandnalrinseshut-offbeforetheobjectreachesthe

conveyor shut-off shelf.

Check that the conveyor belt stops when the object pushes the conveyor shut-off

shelf.

Move the shut-off shelf toward the tunnel of the machine. The conveyor belt will

start moving again.

Push the RED stop button. The conveyor belt will stop moving.

Flip the power switch on the control cabinet to OFF. The red power light will go out.

Openallthedrainvalvesandcheckthatthehousedrainscanhandletheow.

Removeanyprotectivelmfromthestainlesssteelandinstallthesidepanelsand

chain guard.

Check the curtains for correct placement in the machine.

BesuretheshortapsoftheLongCurtainsfacetheloadendofthemachine.

Check the spray pipes.

Be sure the spray pipe gasket is installed on the end of spray pipe before

installing.

Spray pipes are installed by inserting the pipe into the coupler and turning 1/4 turn

clockwise.

Check the scrap screens.

Install any scrap basket covers.

Check that the conveyor shut-off shelf is pushed toward the machine tunnel.

Close the drain valves, located under the base of each tank.

When the drain handle is horizontal, the valve is open.

When the valve handle is vertical, the valve is closed

Check the detergent and rinse aid supplies (supplied by others).

45

Blank Page

This Page

Intentionally

Left Blank

46

Service Replacement Parts

Illustration Page

Pump/Motor Assembly................................................................................................................................................................ 48

3HP, C3/C4 Pump Installation .................................................................................................................................................... 50

1HP, B-30 Prewash Right-Left Pump Installation ....................................................................................................................... 52

1HP, B-30 Prewash Left-Right Pump Installation ....................................................................................................................... 54

3HP, B-30 Prewash Left-Right Pump Installation ....................................................................................................................... 56

3HP, B-30 Prewash Right-Left Pump Installation ....................................................................................................................... 58

Auxiliary Rinse Right-Left Pump Installation............................................................................................................................... 60

C8 Wash/Rinse Wash System Installation ................................................................................................................................. 62

1HP 30" Prewash Right-Left Wash System Installation ............................................................................................................. 64

1HP 30" Prewash Left-Right Wash System Installation ............................................................................................................. 66

C4 Single Tank Wash System Installation .................................................................................................................................. 68

C6 Wash/Rinse Wash System Installation ................................................................................................................................. 70

C4 Wash without Scrap Basket Electric Tank Heat Installation .................................................................................................. 72

C4 Rinse without Scrap Basket Electric Tank Heat Installation .................................................................................................. 74

C4 Wash with Scrap Basket Electric Tank Heat Installation ....................................................................................................... 76

C4 Rinse with Scrap Basket Electric Tank Heat Installation ....................................................................................................... 78

Auxiliary Rinse Tank Heat Installation ........................................................................................................................................ 80

Electric Booster Element Congurations .................................................................................................................................... 82-87

Electric Booster Installation ........................................................................................................................................................ 88

Float Switches ............................................................................................................................................................................ 90

Final Rinse Installation EUCC8/EUCCW8.................................................................................................................................. 92

Final Rinse Installation C4/C6 EUCC/EUCCW .......................................................................................................................... 94

Auxiliary Rinse Installation EUCC/EUCCW ................................................................................................................................ 96

Cold Water Fill Piping Sub-assembly ......................................................................................................................................... 100

Electric Booster Fill Piping (Prior to S/N J10012728) ................................................................................................................. 102

Electric Booster Fill Piping (Beginning with S/N J10012728 and above) ................................................................................... 104

Fill Piping - No Booster (Prior to S/N J10012728) ...................................................................................................................... 106

Fill Piping - No Booster (Beginning with S/N J10012728 and above) ........................................................................................ 108

#120-1 Steam Booster Installation RL ........................................................................................................................................ 110

#120-1 Steam Booster Assembly RL 40-70°F ............................................................................................................................ 112

#120-1 Steam Booster Installation LR ........................................................................................................................................ 116

#120-1 Steam Booster Assembly LR 40-70°F ............................................................................................................................ 118

Steam Coil Heat Installation C4 Wash, Rinse 15-30 PSI ........................................................................................................... 122

Steam Coil Heat Installation C3 Wash, Rinse 15-30 PSI ........................................................................................................... 124

Steam Coil Heat Installation Auxiliary, 15-30 PSI ....................................................................................................................... 128

Steam Injector Heat Installation C4/C8, 15-30 PSI .................................................................................................................... 132

Steam Injector Heat Installation Auxiliary Rinse RL ................................................................................................................... 136

Drain Installation B-30 Prewash RL ............................................................................................................................................ 138

Drain Installation B-30 Prewash LR............................................................................................................................................ 140

Drain Installation C4 Wash, Rinse .............................................................................................................................................. 142

Drain Installation Auxiliary LR ..................................................................................................................................................... 144

Drain Installation D5 Unload ....................................................................................................................................................... 146

Drain Installation B4 Prewash RL ............................................................................................................................................... 148

Drain Installation B4 Prewash LR ............................................................................................................................................... 150

Drain Installation C3 Wash, Rinse .............................................................................................................................................. 152

Electric Eyes, Start-Stop Station, Flushing Nozzles ................................................................................................................... 154

Idle Shaft Assembly .................................................................................................................................................................... 156

Drive Assembly, Prior to S/N J11062899 ................................................................................................................................... 158

EUCCW Peg Belt and Peg Belt with Upper Rod Conveyor Belts............................................................................................... 160

EUCCW Flat and Insulated Conveyor Belts ............................................................................................................................... 162

EUCCW Stainless Steel Conveyor Belt...................................................................................................................................... 164

EUCC Peg Belt and Peg Belt with Upper Rod Conveyor Belts .................................................................................................. 166

EUCC Flat and Insulated Tray Belts ........................................................................................................................................... 168

EUCC Stainless Steel Conveyor Belt ......................................................................................................................................... 170

Vent Cowl Installation ................................................................................................................................................................. 172

Curtain Locations.....................................................................................................................................................................174-185

Tank Bafes EUCC/EUCCW

Control Cabinet (From S/N J2098 up to J08102541) ................................................................................................................. 188

Control Cabinet (From S/N J08012541 up to J10012728) ......................................................................................................... 192

Control Cabinet (Beginning with S/N J10012728 and above) .................................................................................................... 196

Standard 30" Door Assembly ..................................................................................................................................................... 200

Split Door Assembly ................................................................................................................................................................... 202

Swing-out Door Assembly - B-30 R-L/E2 L-R............................................................................................................................. 204

Swing-out Door Assembly - E2 R-L/ B-30 L-R............................................................................................................................ 206

Swing-out Door Assembly - C4................................................................................................................................................... 208

Scrap Screens ............................................................................................................................................................................ 210

Conveyor Shut-off Shelf ....................................................................................................................................... 211

Drive Assembly, Beginning with S/N J11062899 and above ................................................................................ 212

L-R Anti-jam and Tensioner Assembly .................................................................................................................. 213

R-L Anti-jam and Tensioner Assembly .................................................................................................................. 214

Reverse Jog Switch Assembly ............................................................................................................................. 215

Hot Water Coil for C3, EUCCW ............................................................................................................................ 216

...................................................................................................................................................... 186

47

Pump/Motor Assembly

48

Pump/Motor Assembly

1 100735 HEX HEAD,1/4-20 X 5/8 SST1

2 100736 HEX HEAD,1/4-20 X 3/4 SST10

3 100754 SCREW,FLAT HEAD,10-32 X 1/2 SST3

4 102500 PLUG,1/4"NPT SQ.HEAD,BRASS3

5 102504 PLUG,1/2"NPT SQ.HEAD,BRASS1

6 106407 WASHER,LOCK,3/8 SPLIT,SST4

7 106482 WASHER,LOCK,1/4 SPLIT,SST11

8 107690 HEX PLAIN JAM NUT,3/8-16 SST4

9 109654 SLINGER, JET PUMP1

10 110247 HEX PLAIN JAM NUT,7/16-14 SST1

11 110248WASHER,FLAT,.440x.750x.043 SST1

12 110270WASHER,LOCK,CSK EXTERNAL TOOTH,#10 3

13 110424MOTOR,3HP 3PH, MV JET PUMP 1

14 110734 STUD,3/8-16 X 1 3/8 LG.SST,PUMP4

15 111111 SEAL ASSY,CI PUMP1

16 111941 GASKET,PUMP VOLUTE,.0085 THICK1

17 111942 GASKET,PUMP VOLUTE,.015 THICK1

18 111943 GASKET,PUMP VOLUTE,.032 THICK1

19 112338 GASKET,PUMP SUCTION FLANGE1

20 113120 IMPELLER,3HP SST,MACHINED B4 /C3 / C4 EUCCW 1

--- 113119 IMPELLER,3HP SST,MACHINED C3 EUCC 1

--- --- IMPELLER,3HP SST,MACHINED B4 / C4 EUCC 1

21 113634 VOLUTE,JET PUMP,SST1

22 113635 FLANGE,JET PUMP,SST1

23 113636 SUCTION FLANGE 1

24 204460 BACKING PLATE,NG JET PUMP1

113263 MOTOR, 3HP, 575V/60/3

49

1

2

3

4

6

7

8

9

10

11

12

13

1

3

4

4

4

7

5

3HP, B4/C3/C4 Pump Installation

50

3HP, C3/C4 Pump Installation

1 100154 HEX PLAIN NUT,5/16-18 SST10

2 100739 HEX HEAD,5/16-18 X 3/4 SST2

3 100740 HEX HEAD,5/16-18 X 1 SS T8

4 102376 WASHER,FLAT,5/16 x 3/4 x.06 SST16

5 104203 CLAMP,HOSE,M52,71/95,SST GEAR TYPE2

6 104640 GASKET,PUMP SUCTION RACK/CC/UC1

7 106013 WASHER,LOCK,5/16 SPLIT,SST10

8110372 HOSE,PUMP SUCTION,UC1

9 313300 FLANGE WELD,PUMP SUCTION,UC1

10 319742 HOOD WELDMENT,PUMP SUCTION,UC 1

11 319743 PLATE,PUMP SUCTION HOOD 1

12 320918 SUPPORT,PUMP MOTOR,C3 NUCCW1

13 405923 PUMP ASSY,3HP MV 3PH, UC B4 / C3 / C4 EUCCW 1

405922 PUM

415920 PUMP ASSY, 3HP, 575/60/3 LH, UC B4/C3 EUCCW

415921 PUMP ASSY, 3HP, 575/60/3 RH, UC B4/C4 EUCC

P ASSY,3HP MV 3PH, UC C3 EUCC 1

---

---

--- PUMP ASSY,3HP MV 3PH, UC B4 / C4 EUCC 1

51

1HP, B-30 Prewash Right-Left Pump Installation 53 1HP, B-30 Prewash Right-Left Pump Installation

16

14

3

4

15

4

3

4

USED ON MACHINES

WITH LOAD FLUSHING

SYSTEM

11

10

8

6

5

5

9

4

7

1

1

7

1

7

4

52

12

13

3

1 100154 HEX PLAIN NUT,5/16-18 SST12

2 100739 HEX HEAD,5/16-18 X 3/4 SST4

3 100740 HEX HEAD,5/16-18 X 1 SS

T

8

4 102376 WASHER,FLAT,5/16x3/4x.06 SST20

5 104203 CLAMP,HOSE,SST GEAR TYPE2

6 104640 GASKET,PUMP SUCTION RACK/CC/UC1

7 106013 WASHER,LOCK,5/16 SPLIT,SST12

8 109926 FITTING,COMPRESSION,5/8OD X 1/2"MNPT,ELL,BRASS1

9110372 HOSE,PUMP SUCTION,UC1

10 205192 TUBE,1/2"COPPER X 3.00"LG 1

11 313300 FLANGE WELD,PUMP SUCTION,UC1

12 319742 HOOD WELDMENT,PUMP SUCTION,UC1

13 319743 PLATE,PUMP SUCTION HOOD1

14 322150 SUPPORT,PUMP MOTOR,B2 NUCCW1

15 329618 BRACKET,PUMP SUPPORT,B-30 W/A3 1

16 405919-120 PUMP ASSY,1HP MV 3PH 1

415917 PUMP ASSY, 1HP, 575/60/3, UC

1

2

3

4

6

7

9

11

12

13

14

15

16

1

1

3

4

4

4

5

7

7

8

10

USED ON MACHINES

WITH LOAD FLUSHING SYSTEM

5

1HP, B-30 Prewash Left-Right Pump Installation 55 1HP, B-30 Prewash Left-Right Pump Installation

54

1 100154 HEX PLAIN NUT,5/16-18 SST12

2 100739 HEX HEAD,5/16-18 X 3/4 SST4

3 100740 HEX HEAD,5/16-18 X 1 SST8

4 102376 WASHER,FLAT,5/16x3/4x.06 SST20

5 104203 CLAMP,HOSE,M52,71/95,SST GEAR TYPE2

6 104640 GASKET,PUMP SUCTION RACK/CC/UC1

7 106013 WASHER,LOCK,5/16 SPLIT,SST 12

8 109926 FITTING,COMPRESSION,5/8OD X 1/2"MNPT,ELL,BRASS1

9110372 HOSE,PUMP SUCTION,UC1

10 205192 TUBE,1/2"COPPER X 3.00"LG 1

11 313300 FLANGE WELD,PUMP SUCTION,UC1

12 319742 HOOD WELDMENT,PUMP SUCTION,UC1

13 319743 PLATE,PUMP SUCTION HOOD1

14 322150 SUPPORT,PUMP MOTOR,B2 NUCCW1

15 329618 BRACKET,PUMP SUPPORT,B-30 W/A3 1

16 405919 PUMP ASSY,1HP MV 3PH, UC 1

415917 PUMP ASSY, 1HP, 575/60/3

1

2

3

4

6

7

9

11

12

13

14

15

16

1

1

3

4

4

4

4

7

7

8

10

USED ON MACHINES

WITH LOAD FLUSHING SYSTEM

5

5

3HP, B-30 Prewash Left-Right Pump Installation 57 3HP, B-30 Prewash Left-Right Pump Installation

56

1 100154 HEX PLAIN NUT,5/16-18 SST 12

2 100739

HEX HEAD,5/16-18 X 3/4 SST 4

3 100740

HEX HEAD,5/16-18 X 1 SST

8

4 102376 WASHER,FLAT,5/16x3/4x.06 SST 20

5 104203 CLAMP,HOSE,M52,71/95,SST GEAR TYPE 2

6 104640 GASKET,PUMP SUCTION RACK/CC/UC 1

7 106013 WASHER,LOCK,5/16 SPLIT,SST 12

8 109926 FITTING,COMPRESSION,5/8OD X 1/2"MNPT,ELL,BRASS 1

9110372 HOSE,PUMP SUCTION,UC 1

10 205192 TUBE,1/2"COPPER X 3.00"LG 1

11 313300 FLANGE WELD,PUMP SUCTION,UC 1

12 319742 HOOD WELDMENT,PUMP SUCTION,UC 1

13 319743 PLATE,PUMP SUCTION HOOD 1

14 322150 SUPPORT,PUMP MOTOR,B2 NUCCW 1

15 329618 BRACKET,PUMP SUPPORT,B-30 W/A3 1

16 405923 PUMP ASSY,3HP MV 3PH, UC 1

415920 PUMP ASSY, 3HP, 575/60/3 LH, UC B4/C3 EUCCW

415921 PUMP ASSY, 3HP, 575/60/3 RH, UC B4/C3 EUCC

1

3

4

6

7

9

11

12

13

14

15

16

1

1

3

3

4

4

4

4

7

7

8

10

USED ON MACHINES

WITH LOAD FLUSHING

SYSTEM

5

5

3HP, B-30 Prewash Right-Left Pump Installation 59 3HP, B-30 Prewash Right-Left Pump Installation

58

1 100154 HEX PLAIN NUT,5/16-18 SST12

2 100739 HEX HEAD,5/16-18 X 3/4 SST4

3 100740 HEX HEAD,5/16-18 X 1 SST8

4 102376 WASHER,FLAT,5/16x3/4x.06 SST20

5 104203 CLAMP,HOSE,M52,71/95,SST GEAR TYPE2

6 104640 GASKET,PUMP SUCTION RACK/CC/UC1

7 106013 WASHER,LOCK,5/16 SPLIT,SST 12

8 109926 FITTING,COMPRESSION,5/8OD X 1/2"MNPT,ELL,BRASS1

9110372 HOSE,PUMP SUCTION,UC1

10 205192 TUBE,1/2"COPPER X 3.00"LG 1

11 313300 FLANGE WELD,PUMP SUCTION,UC1

12 319742 HOOD WELDMENT,PUMP SUCTION,UC1

13 319743 PLATE,PUMP SUCTION HOOD1

14 322150 SUPPORT,PUMP MOTOR,B2 NUCCW1

15 329618 BRACKET,PUMP SUPPORT,B-30 W/A3 1

16 405923-120 PUMP ASSY,3HP MV 3PH, UC 1

405920 PUMP ASSY, 3HP, 575/60/3 LH, UC B4/C3 EUCCW

405921 PUMP ASSY, 3HP, 575/60/3 RH, UC B4/C3 EUCCW

R-L SHOWN

1

2

3

4

5

6

7

9

10

11

8

8

12

13

14

15

16

17

18

6

9

Auxiliary Rinse Right-Left Pump Installation

60

Auxiliary Rinse Right-Left Pump Installation

1 100023 STREET ELBOW,3/4"NPT X 90,SST1

2 100051 NIPPLE,3/4"NPT X CLOSE,SST1

3 100154 HEX PLAIN NUT,5/16-18 SST4

4 100739 HEX HEAD,5/16-18 X 3/4 SST4

5 100740 HEX HEAD,5/16-18 X 1 SST4

6 102376 WASHER,FLAT,5/16x3/4x.06 SST8

7 102554 UNION,3/4"NPT, SST1

8 105993 CLAMP,HOSE,M20,19/44,SST GEAR TYPE4

9 106013 WASHER,LOCK,5/16 SPLIT,SST 8

10 108345 GASKET,HEATER/STANDPIPE1

11 114020 HOSE, 1 1/8"ID x 2 3/4" x 3/16" WALL 1

12 114199 PUMP ASSY AUXILIARY1

13 206643 HOSE,1.250 ID X 2.500 LG.EPDM 1

14 322832 HOOD WELDMENT,PUMP SUCTION,E21

15 329791 BASE DECK WELD,PUMP,E2 1

--- 0509303 KIT, PUMP BODY

KIT, SEAL AND GASKET

IMPELLER

1

--- 0510222 1

---

---

180413 1

16 329796 TUBE WELDMENT,E2 PUMP DISCHARGE EUCCW 1

330750 TUBE WELDMENT,E2 PUMP DISCHARGE EUCC 1

17 329797 FLANGE WELD,E2 PUMP SUCTION1

18 329798 PLATE,PUMP SUCTION HOOD,E2 1

111744 MOTOR, AUXILIARY, 1/4 HP, 575/60/3

452611 PUMP ASSY, AUXILIARY, 1/4 HP, 575/60/3

61

FRONT LOWER

CONVEYOR TRACK

MANIFOLD

TRACK SUPPORTS

(WELDED IN HOOD)

SUPPORT ANGLES

(WELDED IN HOOD)

1

2

4

5

6

7

8

10

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

12

14

1

3

3

5

6

11

11

5

9

27

27

C8 Wash/Rinse Wash System Installation

62

C8 Wash/Rinse Wash System Installation

1 100734 HEX HEAD,1/4-20 X 1/2 SST14

2 100755 SCREW,FLAT HEAD,1/4-20 X 1/2 SST4

3 104414 O-RING,1 X 1 1/4 X 1/8 9

4 106014 HEX ACORN PLAIN NUT,1/4-20 SST4

5 106026 WASHER,FLAT,1/4x5/8x.06 SST15

6 106482 WASHER,LOCK,1/4 SPLIT,SST14

7 108875 COTTER PIN,3/32 X 1/2 UNEVEN 1

8110858 HOSE CLAMP,HIGH PRESSURE,02561

9 111780 HOSE CLAMP,HIGH PRESSURE,02382

10 111964 HOSE CLAMP,HIGH PRESSURE,02751

11 112240 PLUG, DEBOSSED SPRAYPIPE9

12 113911 LOCKNUT,2 1/2" , NPSL, SST2

13 113984 HOSE, DISCHARGE MOLDED E1

14 114096 O-RING,2.225x.210 DIA. 2

15 202146 HOSE,1.875 ID X 5.375 LG.EPDM 1

16 206552 ROD, LATCH PIVOT,5 HOLE MANIFOLD1

17 329659 MANIFOLD WELDMENT,5 HOLE,UPPER EUCCW 1

18 329662 MANIFOLD WELDMENT,4 HOLE,LOWER EUCCW 1

19 329669 TRACK WELDMENT, LH LOWER, MANIFOLD EUCCW 1

20 329670 TRACK WELDMENT, RH LOWER, MANIFOLD EUCCW 1

21 329672 TRACK WELDMENT, LH UPPER, MANIFOLD EUCCW 1

22 329673 TRACK WELDMENT, RH UPPER, MANIFOLD EUCCW 1

--- 330632 MANIFOLD WELDMENT,5 HOLE,UPPER EUCC 1

--- 330633 MANIFOLD WELDMENT,4 HOLE,LOWER EUCC 1

--- 330644 TRACK WELDMENT, LH LOWER, MANIFOLD EUCC 1

--- 330645 TRACK WELDMENT, RH LOWER, MANIFOLD EUCC 1

--- 330641 TRACK WELDMENT, LH UPPER, MANIFOLD EUCC 1

--- 330642 TRACK WELDMENT, RH UPPER, MANIFOLD EUCC 1

23 329674 BRACKET, LOWER MANIFOLD LATCH2

24 329704 LATCH DEVP, UPPER MANIFOLD,5 HOLE1

25 330680 STANDPIPE WELDMENT, C4 1

26 330838 TUBE, PUMP DISCHARGE, WELDMENT EUCCW1

27 114692 2

--- 330639 TUBE, PUM

GASKET, STANDPIPE

P DISCHARGE, WELDMENT EUCC1

63

1

2

3

4

5

6

7

8

10

11

12

13

14

15

16

17

29

18

19

20

21

22

23

24

25

26

27

SUPPORT ANGLES

(WELDED IN HOOD)

MANIFOLD

TRACK SUPPORTS

(WELDED IN HOOD)

FRONT LOWER

CONVEYOR TRACK

1

5

6

12

13

15

5

3

11

9

30

30

1HP 30" Prewash Right-Left Wash System Installation

64

1HP 30" Prewash Right-Left Wash System Installation

1 100734 HEX HEAD,1/4-20 X 1/2 SST14

2

100755 SCREW,FLAT HEAD,1/4-20 X 1/2 SST4

3

104414 O-RING,1 X 1 1/4 X 1/8 5

4

106014 HEX ACORN PLAIN NUT,1/4-20 SST4

5

106026 WASHER,FLAT,1/4x5/8x.06 SST15

6

106482 WASHER,LOCK,1/4 SPLIT,SST14

7

108875 COTTER PIN,3/32 X 1/2 UNEVEN 1

8

110858 HOSE CLAMP,HIGH PRESSURE,02561

9

111780 HOSE CLAMP,HIGH PRESSURE,02382

10

111964 HOSE CLAMP,HIGH PRESSURE,02751

11

112240 PLUG, DEBOSSED SPRAYPIPE5

12

113911 LOCKNUT,2 1/2" , NPSL, SST2

13