Page 1

Technical Manual

Gas Fired

Boiler

Model

CSS-130

Read all instructions carefully before starting the installation.

Save this manual for future reference

July, 1997

P. O. Box 4149

Winston-Salem, North Carolina 27115-4149

336/661-1556 Fax: 336/661-1660

CAUTION

Manual P/N 111995 REV. A

2674 N. Service Road

Jordan Station, Ontario, Canada LOR 1SO

905/562-4195 Fax: 905/562-4618

Champion Industries, Inc.

Page 2

Complete the information below so it will be available for quick reference.

Model Number CSS-130 Serial Number

Voltage and Phase 115/60/1

Champion Parts Distributor Phone

Champion Service Agency Phone

In the United States Call:

Champion Industries Service: 1-800-858-4477 Champion Service Fax: 1 (336) 661-1660

In Canada Call:

Champion Industries Service: 1-800-263-5798 Champion Service Fax: 1 (905) 562-4618

NOTE:When calling to order parts, be sure to have the model number, serial number,

voltage and phase of your machine.

COPYRIGHT © 1996, 1997 by Champion Industries, Inc.

Page 3

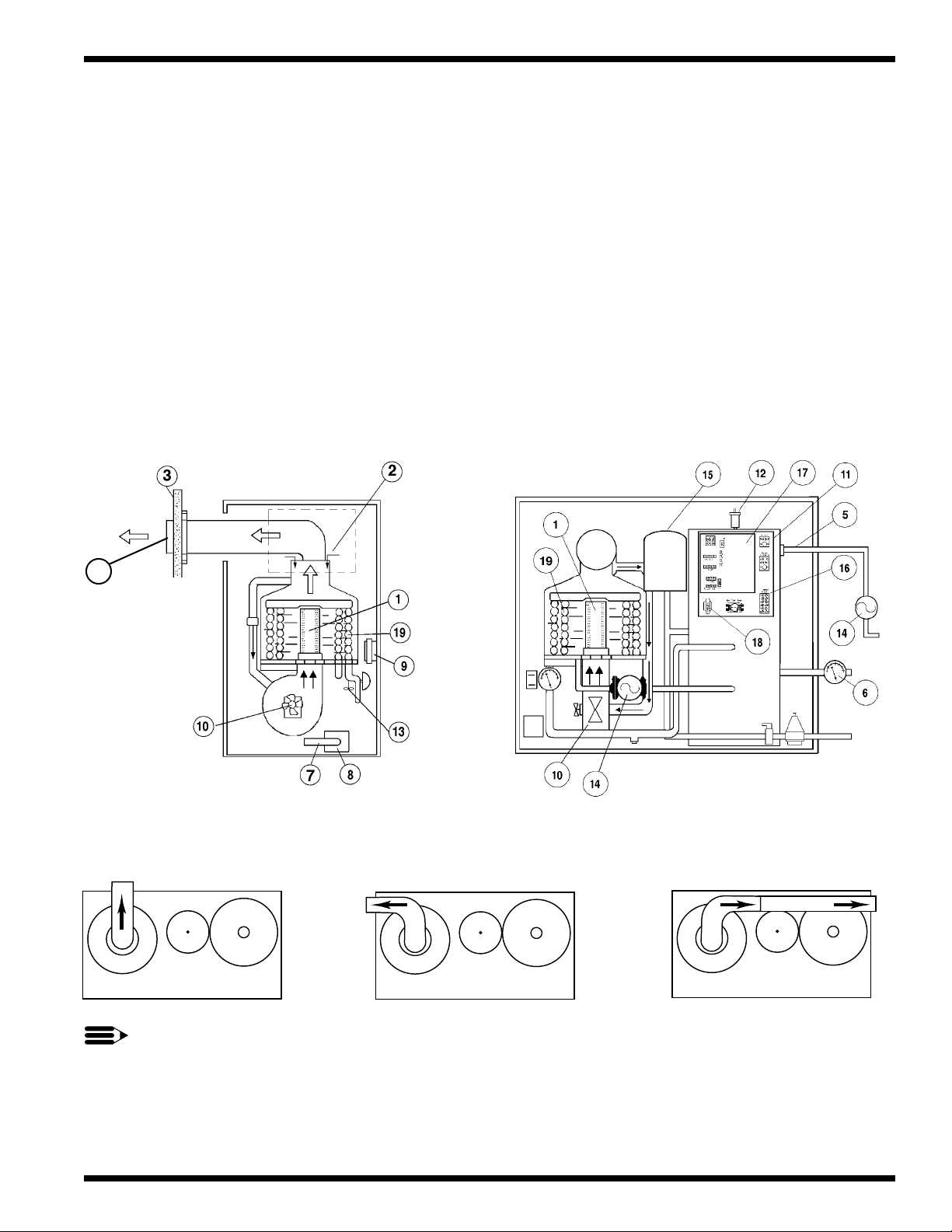

CSS-130 GAS FIRED BOILER COMPONENT LOCATOR

TO THE INST ALLER:

BEFORE YOU BEGIN

It is important for you to read all Installation and Operating sections of this manual before you begin

installation. This will avoid mistakes and confusion when installing and operating the unit.

1. Gas Burner

2. Air Intake

3. Outside Vent Wall

4. Exhaust Air

5. Dishwasher Water Supply

6. Water Return From Dishwasher

7. Gas Supply

8. Gas Valve

9. Stack Switch

10. Blower Motor and Housing

11. Control Cabinet

12. Tank Vent

13. Coil Air Bleed Off

14. Circulation Pump

15. Expansion Tank

16. Terminal Strip

17. Boiler Control

18. Transformer 24V

19. Copper Coil Heat Exchanger

4

Left Side View

Gas Flue (Rear of CSS-130)

Gas Flue (Left end of CSS-130)

Front View

Gas Flue (Right end of CSS-130)

NOTE:

The CSS-130 is available in (3) venting configurations: rear, left, or right direction.

Gas flue venting configurations are specified at the time of order.

Figure 1

Component Locator

i

Page 4

REVISIONS

Revision History

Revision Revised Serial Number Comments

Date Pages Effectivity

7/7/97 All — Reissue of manual and replacement parts lists

ii

Page 5

CONTENTS

CONTENTS

LIMITED WARRANTY ....................................................................................... 1

INTRODUCTION ................................................................................................. 2

Unpacking the Gas Fired Boiler ......................................................................................... 3

Installation Codes ............................................................................................................. 3

Locating the Gas Fired Boiler ............................................................................................ 3

Clearance to Combustibles ............................................................................................ 4

Air for Combustion and Ventilation ............................................................................... 5

INSTALLATION ................................................................................................... 6

VENT INSTALLATION .................................................................................................... 6

General........................................................................................................................... 6

Existing Boiler Removal ................................................................................................ 6

Common Venting ........................................................................................................... 7

Vertical V enting.............................................................................................................. 8

Chimney V enting............................................................................................................ 10

Horizontal Through-the-W all Venting ........................................................................... 14

Pipe Cutting and Joining Procedures......................................................................... 15

Locating the Vent Opening in the Outside Wall ........................................................ 16

Installing the Horizontal Venting and Termination.................................................... 17

GAS SUPPLY CONNECTIONS........................................................................................ 18

Gas Fuel Requirements .................................................................................................. 18

Gas Pressure Requirements............................................................................................ 18

Gas Piping Installation................................................................................................... 19

Pressure Testing the Gas Piping Installation .................................................................. 20

Field Conversion of Gas Orifice .................................................................................... 21

ELECTRICAL CONNECTIONS....................................................................................... 22

PLUMBING CONNECTIONS .......................................................................................... 24

Water and Drain Connections ........................................................................................ 24

INITIAL START-UP AND SERVICE................................................................... 25

Instructions for Setting Air Pressure in Expansion Tank.................................................... 26

Instructions for Manually Venting Air from Boiler Water System ..................................... 27

Gas Valve Operating Instructions .......................................................................................28

Check Test, and Start-up ..................................................................................................... 29

Sequence of Operation Explained ......................................................................................36

TROUBLESHOOTING FLOW CHARTS............................................................ 37

ELECTRICAL SCHEMATICS ............................................................................. 45

REPLACEMENT PAR TS LIST............................................................................ 48

iii

Page 6

CONTENTS

Figure 1 – Component Locator .................................................................................................. i

Figure 2 – Minimum Clearance to Combustibles (Top View) ................................................... 4

Figure 3 – Minimum Clearance to Combustibles (Front View) ................................................. 4

Figure 4 – Clearance Dimensions Chart .................................................................................... 4

Figure 5 – Vent Pipe Slope and Horizontal Support .................................................................. 8

Figure 6 – Vertical Through-the-Roof Vent Installation with Fire Stops ................................... 9

Figure 7 – Vertical Vent Configuration ...................................................................................... 9

Figure 8 – Type B-1 Vent Chimney Venting Detail .................................................................... 11

Figure 9 – Type B-1 Chimney Vent Connection without Elbows .............................................. 12

Figure 10 – T ype B-1 Chimney Vent Connection with Elbows ................................................... 12

Figure 11 – Horizontal Through-the W all Venting ....................................................................... 14

Figure 12 – Horizontal Vent (Exit Through Rear Wall) ............................................................... 16

Figure 13 – Horizontal T ermination Clearance............................................................................16

Figure 14 – Horizontal Vent T ermination (Window and Grade Level) ........................................ 17

Figure 15 – Horizontal Vent (Exit Through Side Wall)................................................................ 17

Figure 16 – Pipe Sizing Table ......................................................................................................19

Figure 17 – Gas Supply Piping (Drip Leg) .................................................................................. 19

Figure 18 – CSS-130 Manual Gas Shut-off Valve ....................................................................... 20

Figure 19 – CSS-130 Gas Connection Point (Side View) ............................................................ 20

Figure 20 – CSS-130 Gas Connection Point (T op View) ............................................................. 20

Figure 21 – Gas Orifice Union Location......................................................................................21

Figure 22 – Gas Orifice Union ..................................................................................................... 21

Figure 23 – LP Gas Orifice Kit P/N 111993................................................................................ 21

Figure 24 – Electrical Connections (Right side of CSS-130) ......................................................22

Figure 25 – Electrical Schematic Detail....................................................................................... 23

Figure 26 – CSS-130 Control Panel Power Connections (Inside right front side)....................... 23

Figure 27 – Plumbing Connections (Right side of CSS-130) ...................................................... 24

Figure 28 – Electrical Diagrams...................................................................................................46

Figure 29 – Parts Diagrams..........................................................................................................48

LIST OF FIGURES

iv

Page 7

WARRANTY

LIMITED WARRANTY

Champion Industries Inc. (herein referred to as Champion), P.O. Box 4149, Winston-Salem, North Carolina 27115,

and P.O. Box 301, 2674 North Service Road, Jordan Station, Ontario, Canada L0R 1S0 warrants machines, and parts,

as set out below.

Warranty of Machines: Champion warrants all new machines of its manufacture bearing the name

"Champion" and installed within the United States and Canada to be free from defects in material and workman

ship for a period of one (1) year after the date of installation or fifteen (15) months after the date of shipment by

Champion, whichever occurs first. [See below for special provisions relating to glasswashers.] The warranty

registration card must be returned to Champion within ten (10) days after installation. If warranty card is not

returned to Champion within such period, the warranty will expire after one year from the date of shipment.

Champion will not assume any responsibility for extra costs for installation in any area where there are

jurisdictional problems with local trades or unions.

If a defect in workmanship or material is found to exist within the warranty period, Champion, at its election,

will either repair or replace the defective machine or accept return of the machine for full credit; provided, how

ever, as to glasswashers, Champion's obligation with respect to labor associated with any repairs shall end

(a) 120 days after shipment, or (b) 90 days after installation, whichever occurs first. In the event that Champion

elects to repair, the labor and work to be performed in connection with the warranty shall be done during regular

working hours by a Champion authorized service technician. Defective parts become the property of Champion.

Use of replacement parts not authorized by Champion will relieve Champion of all further liability in connection

with its warranty. In no event will Champion's warranty obligation exceed Champion's charge for the machine.

The following are not covered by Champion's warranty:

a. Lighting of gas pilots or burners.

b. Cleaning of gas lines.

c. Replacement of fuses or resetting of overload breakers.

d. Adjustment of thermostats.

e. Adjustment of clutches.

f. Opening or closing of utility supply valves or switching of electrical supply current.

g. Cleaning of valves, strainers, screens, nozzles, or spray pipes.

h. Performance of regular maintenance and cleaning as outlined in operator’s guide.

i. Damages resulting from water conditions, accidents, alterations, improper use, abuse,

tampering, improper installation, or failure to follow maintenance and operation procedures.

j. Wear on Pulper cutter blocks, pulse vanes, and auger brush.

Examples of the defects not covered by warranty include, but are not limited to: (1) Damage to the exterior or

interior finish as a result of the above, (2) Use with utility service other than that designated on the rating plate,

(3) Improper connection to utility service, (4) Inadequate or excessive water pressure, (5) Corrosion from

chemicals dispensed in excess of recommended concentrations, (6) Failure of electrical components due to

connection of chemical dispensing equipment installed by others, (7) Leaks or damage resulting from such

leaks caused by the installer, including those at machine table connections or by connection of chemical

dispensing equipment installed by others, (8) Failure to comply with local building codes, (9) Damage caused by

labor dispute.

Warranty of Parts: Champion warrants all new machine parts produced or authorized by Champion to be free

from defects in material and workmanship for a period of 90 days from date of invoice. If any defect in

material and workmanship is found to exist within the warranty period Champion will replace the defective

part without charge.

DISCLAIMER OF WARRANTIES AND LIMITATIONS OF LIABILITY. CHAMPION'S WARRANTY

IS ONLY TO THE EXTENT REFLECTED ABOVE. CHAMPION MAKES NO OTHER WARRANTIES,

EXPRESS OR IMPLIED, INCLUDING, BUT NOT LIMITED, TO ANY WARRANTY OF

MERCHANTABILITY, OR FITNESS OF PURPOSE. CHAMPION SHALL NOT BE LIABLE FOR

INCIDENTAL OR CONSEQUENTIAL DAMAGES. THE REMEDIES SET OUT ABOVE ARE

THE EXCLUSIVE REMEDIES FOR ANY DEFECTS FOUND TO EXIST IN CHAMPION DISHWASHING

MACHINES AND CHAMPION PARTS, AND ALL OTHER REMEDIES ARE EXCLUDED,

INCLUDING ANY LIABILITY FOR INCIDENTALS OR CONSEQUENTIAL DAMAGES.

Champion does not authorize any other person, including persons who deal in Champion dishwashing

machines to change this warranty or create any other obligation in connection with Champion Dishwashing Machines.

1

Page 8

INTRODUCTION

INTRODUCTION

Welcome to Champion...

and thank you for allowing us to take care of your dishwashing needs.

This manual covers the Champion Single Source Gas Fired Boiler, Model CSS-130.

The CSS-130 operates in conjunction with the Champion door-type dishwasher model D-HB and

the rack conveyor dishwasher model 44-WS and 66-WS

The CSS-130 is a low pressure gas fired boiler capable of supplying hot water to the dishwasher

wash tank heating coil for wash tank heat and 180°F final rinse water for sanitizing.

Your gas fired boiler was completely assembled, inspected, and thoroughly tested at our factory

before it was shipped to your installation site.

This manual contains:

• Installation Instructions

• Operation Instructions

• Maintenance Instructions

• Service Instructions

• Replacement Parts Lists

• Electrical Schematics

All information, illustrations and specifications contained in this manual are based upon the

latest product information available at the time of publication. Champion constantly improves

its products and reserves the right to make changes at any time or to change specifications or

design without notice and without incurring any obligation.

For your protection, factory authorized parts should always be used for repairs.

Replacement parts may be ordered directly from your Champion authorized parts distributor

or authorized service agency. When ordering parts, please supply the model number, serial

number, voltage, and phase of your machine, the part number, part descriptions and quantity.

2

Page 9

INTRODUCTION

Unpacking the Gas Fired Boiler

CAUTION:

!

Care should be taken when lifting the machine to prevent damage.

1. Immediately after unpacking the machine, inspect for any shipping damage.

If damage is found, save the packing material and contact the carrier immediately.

2. Remove the gas fired boiler from the skid.

Move the boiler to its permanent location.

Installation Codes

The installation of this unit must conform to local codes or, in the absence of local code,

to the National Fuel Gas Code, ANSI Z223.1-Latest Edition. Where required by the authority

having jurisdiction, the installation also must conform to the Standards for Controls and Safety

Devices for Automatically Fired Boilers, ANSI/ASME CSD-1.

For Canada, the installation of this unit must conform to all Canadian local codes as applicable or,

in the absence of local codes, to the Canadian installation code, CAN/CGA-B149, and CSA C22.1

Canadian Electrical Code Part 1.

Locating the Gas Fired Boiler

Locate the gas fired boiler as near to the exhaust venting system as practical. Air openings on the front,

back and sides of the boiler housing should not be obstructed since they supply air to the combustion

chamber.

The location of the boiler should be chosen with regard to venting dimensions, convenient access to

piping, ventilation of operating components and accessibility for service and cleaning.

The boiler shall be installed such that the gas ignition system components are protected from water

(dripping, spraying, rain, etc.) during appliance operation and servicing procedures such as pump

replacement, burner cleaning and the like.

When the unit is located in an unconfined space of a building, air infiltration may be adequate to provide

air for combustion and ventilation. Where normal infiltration does not provide the necessary air , outside

air must be introduced.

In buildings of unusually tight construction, or when locating the unit in a confined space, additional air

must be provided. For confined spaces, two (2) permanent openings shall be provided:

One (1) opening within 12" of the ceiling and one (1) within 12" of the floor of the enclosing space.

Each opening shall be at least 1 square inch per 1,000 BTU/HR heater input of the total for all appliances

in the area, but not less than 100 square inches. These openings shall freely connect with areas having

adequate infiltration from outside.

The boiler should be placed beside the Champion dishwasher model that it serves so that all plumbing and

electrical connections between the boiler and the dishwasher can be made per Champion's specifications.

If installed in a finished area, provisions should be made for drainage of any accidental spillage or

leakage of water. The boiler pressure relief valve and back-flow preventor should be piped to a

drain to protect from the occasional discharge of water.

3

Page 10

INTRODUCTION

INTRODUCTION (CONT'D)

Locating the Gas Fired Boiler (Cont'd)

Clearance to Combustibles

The CSS-130 is certified by the American Gas Association, (AGA), and the Canadian Gas Association

(CGA), for installation on combustible flooring. The CSS-130 is rated for alcove installation.

NOTE:

DO NOT INSTALL THE GAS FIRED BOILER ON CARPETING.

Refer to Fig. 2-4 below for the minimum allowable clearances to combustible

and noncombustible materials.

BD

A

C

Dishwasher

Figure 2

Minimum Clearance

to Combustibles

CSS-130

T op View

A

(Horizontal Vent Arrangement Shown)

A

B

A

B

Dishwasher

(Horizontal Vent Arrangement Shown)

Figure 3

Minimum Clearance

to Combustibles

CSS-130

Front View

CLEARANCE TO COMBUSTIBLES

(Dimensions in Inches)

Location Item Minimum Clearance

A

B

C

D

Boiler to Top, Back, & Side Walls

Double wall Type B-1 Vent

Single Wall SST or

Galvanized Vent

Hot Water Pipes

Through Combustible Wall

1 inch

1 inch

6 inches

3 inches

2 inches

Figure 4

Clearance Dimensions Chart

(See Fig. 2-3 above)

4

Page 11

INTRODUCTION

Clearance to Combustibles (Cont'd)

The clearances listed in the Clearance Chart (See Fig. 4) are minimum clearances. Clearances for service

accessibility to the gas fired boiler must take preference over the fire protection clearances. The installer

should allow a minimum of 12" for servicing at the sides and back of the boiler if possible.

!

WARNING:

Provide a screen or other type of protective barrier around exposed vent pipe to reduce burn

hazards where inadvertent contact with hot vent surfaces by personnel can occur.

Air for Combustion and V entilation

General

An adequate supply of air for combustion and ventilation must be supplied in accordance with

Section 5.3 of the National Fuel and Gas Code, ANSI Z223.1-Latest Edition or applicable

provisions of the local building codes for gas utilization equipment installed in buildings that

require air for combustion, ventilation, and the dilution of flue gases from within the building.

For Canada, the installation of this unit must conform to all Canadian local codes as applicable or,

in the absence of local codes, to the Canadian installation code, CAN/CGA-B149.

Install the equipment in a location where the ventilation facilitates the satisfactory combustion of

gas, proper venting and maintenance of ambient temperature at safe limits under normal conditions

of use.

Equipment should be located so as not to interfere with proper air circulation.

When normal infiltration does not provide the necessary air, outside air must be introduced.

In addition to air needed for combustion, process air must be provided as required for:

cooling of equipment or material, controlling the dew point, heating, drying, oxidation or dilution, safety

exhaust, odor control, and air for compressors.

In addition to air needed for combustion, ventilation air must also be supplied, including all air required

for comfort and proper working conditions for personnel.

Unconfined Space

An unconfined space (such as an open basement) must have a minimum volume of 50 cubic feet per

1,000 BTU/HR input of the total of all appliances in the area. Adjoining rooms may be counted as one

area only if there are no doors between the rooms.

Air Contaminants

Compounds bearing contaminants such as chloride, fluoride, iodide, and bromide, when present in certain

concentrations in the air supplied for combustion to the boiler, can result in an accelerated and severe

corrosion condition in the heat exchanger and/or the venting systems. Avoid storing or using chemicals

containing these compounds in the vicinity of the boiler if at all possible.

!

CAUTION:

Combustion air must not be contaminated by corrosive chemical fumes which can damage

the heat exchanger in the boiler.

5

Page 12

INSTALLATION

INSTALLATION

!

WARNING:

Read all of the instructions included with your machine before

attempting any installation. Faulty vent installation can cause

improper operation of the gas fired boiler..

Vent Installation

General

The CSS-130 gas fired boiler is approved as a Category I Boiler when the following vent

installations are used:

1. Common vent installation

2. Vertical through-the-roof vent installation

3. Masonry chimney vent installation using Type B-1 Double-wall vent.

The CSS-130 is approved as a Category III Boiler when a horizontal through-the-wall vent

installation is used. This installation is a positive pressure venting system and requires that

all connections be sealed with an approved high temperature sealant.

Refer to the specific venting installation section for detailed instructions.

Vent installation must be in compliance with Part 7 "Venting of Equipment", of the

National Fuel Gas Code; ANSI Z223.1-Latest Edition, (In Canada, to the Canadian installation code, CAN/CGA-B149), local codes, or ordinances, these instructions, and good

trade practices.

Existing Boiler Removal

When an existing boiler is removed from a venting system serving other appliances, the

venting system is likely to be too large to properly vent the remaining attached appliances.

Perform the following steps individually with each appliance that remains connected to the

common vent system placed in operation with the other appliances remaining connected to

the common venting system but not in operation.

If improper venting is observed during any of the following tests, the common venting system

must be corrected.

1. Seal any unused openings in the common venting system.

2. Visually inspect the vent system for proper size and horizontal pitch and determine that

there is no blockage or restriction, leakage, corrosion, and other deficiencies which could

cause an unsafe condition.

3. As far as practical, close all building doors and windows plus all doors between the space

which the appliances remain connected to the common vent system are located and the

other spaces of the building.

6

Page 13

INSTALLATION

Existing Boiler Removal (Cont'd)

4. Turn on clothes dryers and any appliance NOT connected to the common vent system.

Turn on any exhaust fans, such as range hoods and bathroom exhausts so they will operate

at maximum speed. DO NOT operate a summer exhaust fan. Close fireplace dampers.

5. Follow the lighting instructions of the appliance being tested and place the appliance in

operation. Adjust the thermostat so the appliance operates continuously.

6. After five minutes of main burner operation, test for air spillage at the draft hood relief

opening. Use the flame of a match or candle, or the smoke from a cigarette, cigar, or pipe.

7. Repeat steps for each appliance connected to the common vent system.

After it has been determined that each appliance remaining connected to the common vent

system properly vents when tested as outlined above, return all doors, windows, exhaust fans,

fireplace dampers, and any other gas burning appliance to their previous conditions of use.

If necessary the common vent should be re-sized to approach the minimum size as

determined by using the appropriate tables in Appendix G in the National Fuel Gas Code,

ANSI Z223.1-Latest Edition.

For Canada, the installation of this unit must conform to all Canadian local codes as applicable or,

in the absence of local codes, to the Canadian installation code, CAN/CGA-B149.

The boiler should not be connected to a chimney flue serving a separate appliance that is designed

to burn solid fuel.

No portion of the venting system can extend into, or pass through any circulating air duct or plenum.

All vent pipe passing through floors, walls, and ceilings must be installed with the listed clearance to

combustible materials and be fire stopped according to local codes.

Common V enting

Vent connectors serving Category I appliances shall not be connected to any portion of the mechanical

draft systems operating under positive pressure such as Category III or Category IV venting systems.

When two or more vent connectors enter a common gas vent, chimney flue, or a single-wall metal pipe,

the smaller of the connectors shall enter at the highest level consistent with the available headroom or

clearance to combustible material.

Vent connectors shall be firmly attached to draft hood outlets or flue collars by sheet metal screws or

other approved means, except vent connectors of listed Type B-1 vent material (which shall be assembled

in accordance with the vent manufacturer's instructions). Fasten joints between sections of single-wall

connector piping with sheet metal screws or other approved means.

7

Page 14

INSTALLATION

INSTALLA TION (CONT'D)

Vent Installation

Common V enting (Cont'd)

Horizontal portions of the venting system must be supported at least every 5 feet with metal

straps to prevent sagging. All horizontal sections of the vent connection must slope upwards

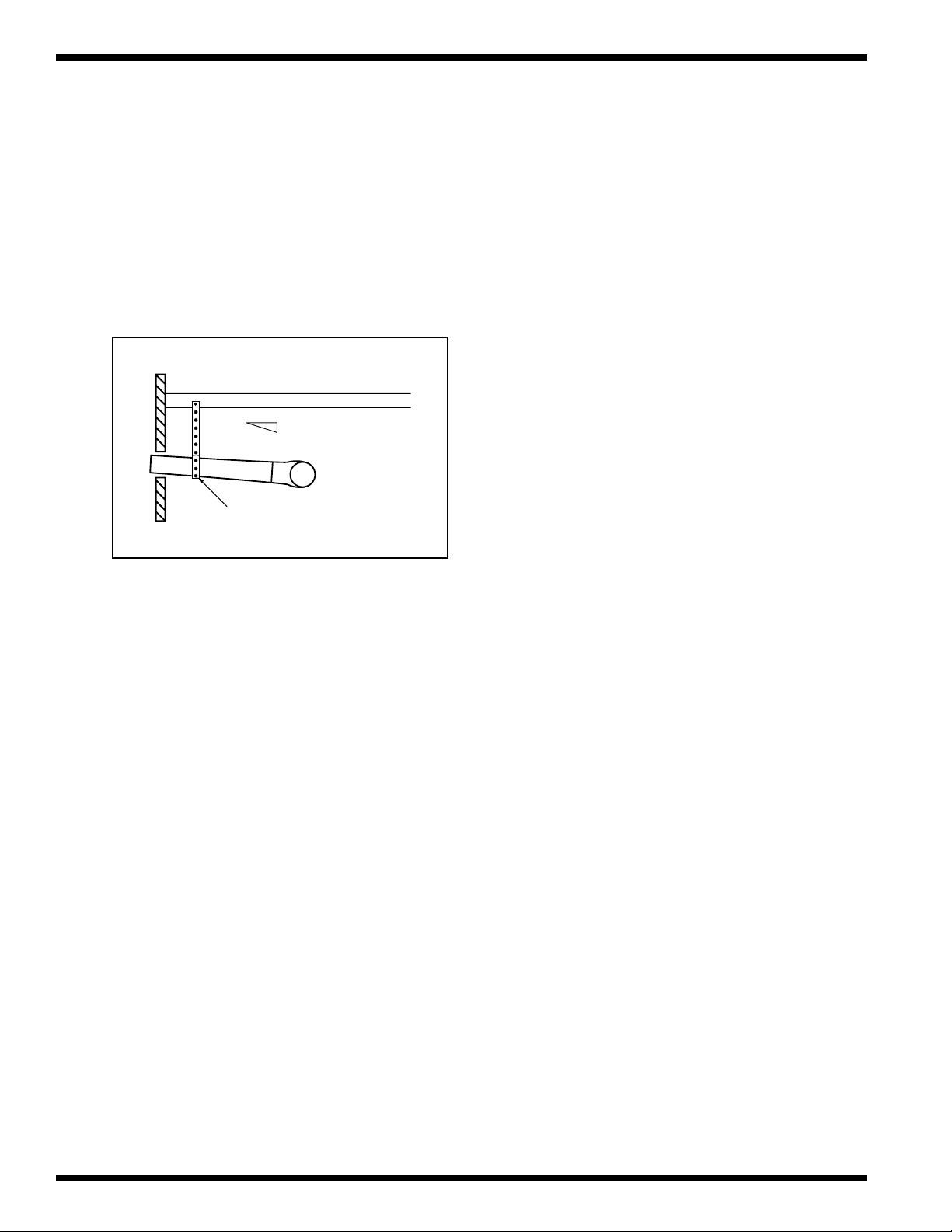

1/4 inch per foot from the boiler to the vent termination (See Figure 5 below).

Upward slope =

1/4" minimum per foot

Vent Connector

Support horizontal sections

every 5 feet with metal straps

Figure 5

Vent Pipe Slope

and

Horizontal Support

The vent connector should be routed to the vent using the shortest route possible.

The entire length of a vent connector shall be readily accessible for inspection, cleaning,

and replacement.

V ertical V enting

The CSS-130 is certified for use with up to 50 equivalent feet of 3" diameter pipe

for vertical vent installations. A 90° elbow equals 5 equivalent feet of pipe.

Vent pipe and fittings must be securely supported horizontal sections require supports

every 5 feet. Fire stops can support up to ten feet of vertical run.

Galvanized or stainless steel vent pipe may be used for vertical runs.

Stainless steel vent pipe must be used for horizontal runs.

®

Saf-T Vent

and is approved for use in the United States and Canada.

manufactured by Heat Fab, Inc., is constructed from AL294C stainless steel

8

Page 15

INSTALLATION

V ertical Venting (Cont'd)

Maintain six inches (6") air space to combustible around the pipe for single wall metal vent.

Maintain one inch (1") air space to combustible around pipe for Type B-1 vent.

Whenever possible , the vent should be continued straight up through the roof. If it is necessary to

make an offset in the attic, the horizontal run should slope upwards minimum of 1/4 inch per foot

and be supported by metal straps.

Vent pipe passing through floors, ceilings, or framed walls must be fire stopped at floors and ceilings.

The fire stop must close-in the area between the outside of the vent and the opening in the structure.

Fire stops and supports can be purchased from Plexco Inc., or Hart and Cooley Inc.

When the vent passes through the roof, a flashing and storm collar must be used. Seal the storm

collar to the pipe using a high temperature sealant. Terminations must be used in all installations

above the roof to ensure the proper performance of the boiler and to prevent the entrance of debris.

Type B-1 gas vents shall terminate above the roof surface with a U.L. listed cap or roof assembly.

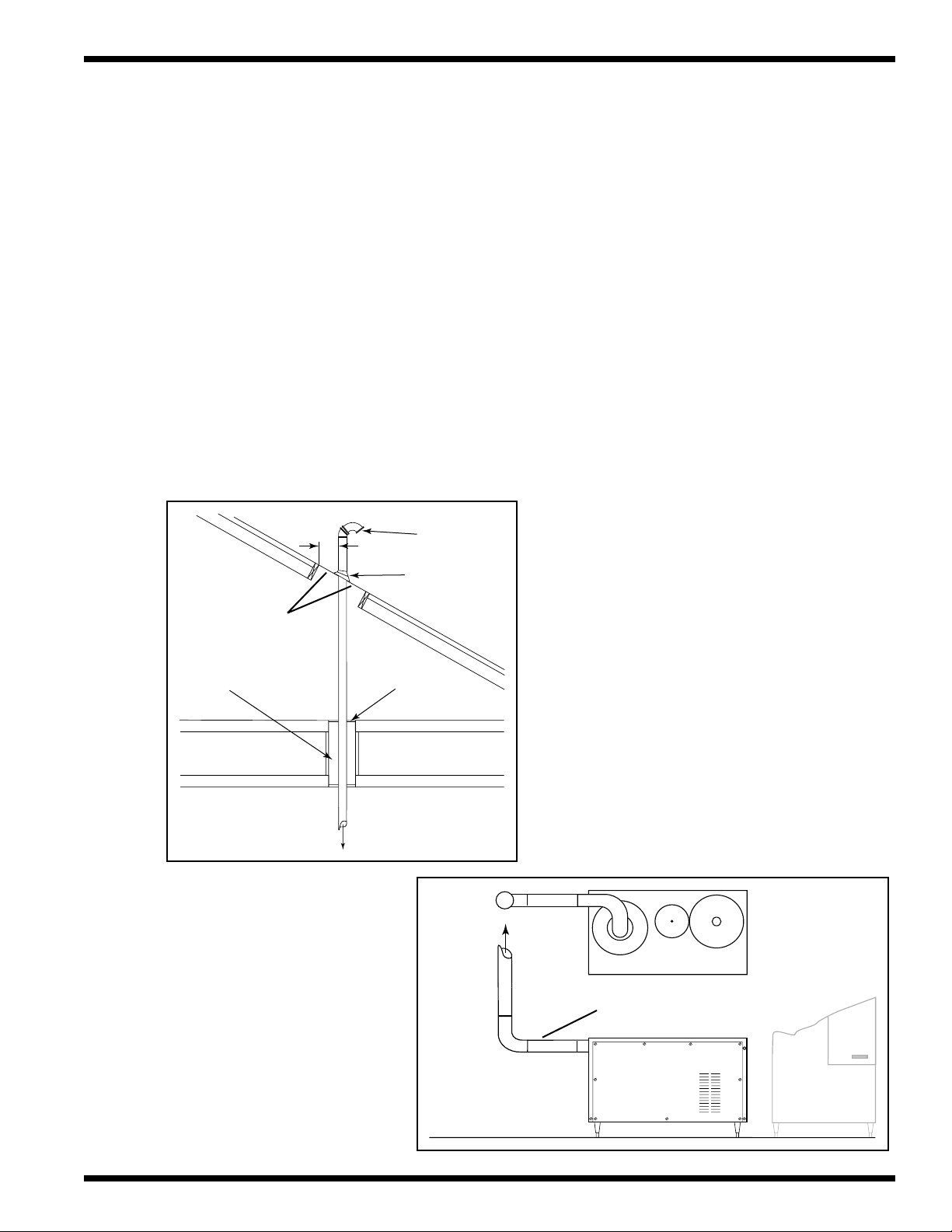

Maintain

minimum

air space

Termination

Storm collar

and flashing

Fire stopChase

To CSS-130

Vent

To roof

Figure 6

Vertical Through-the -Roof

Vent Installation with Fire Stops

CSS-130

T op View

Figure 7

CSS-130

Vertical Vent Configuration

Slope up = 1/4" min. per foot

CSS-130

Front View

Dishwasher

9

Page 16

INSTALLATION

Vent Installation (Cont'd)

Chimney V enting

The CSS-130 is certified as a Category I Boiler and approved for venting in a masonry

chimney with Type B-1 Double-walled vent connector.

The following requirements must be met to use this type of vent installation:

1. The chimney must be internal lined or internal B vent type.

2. An external or unlined chimney may serve as a chase for the use of high temperature

plastic pipe alternative venting provided that no other equipment is vented into the

chimney . The chimney may have an approved liner installed into the flue.

3. Two (2) or more vent connectors, from either power or natural draft units, may enter a

common gas vent provided that they conform to the provisions and tables of the

National Fuel Gas Code, ANSI Z223.1/NFPA 54- Latest Edition, or applicable provisions

of local building code. For Canada, the installation of this unit must conform to all

Canadian local codes as applicable or,in the absence of local codes, to the Canadian

installation code, CAN/CGA-B149.

4. None of the vent connectors may be connected to equipment with a positive vent

pressure.

5. The unit must be located as close to the chimney as possible to provide the

shortest vent connector.

Installation

Refer to Fig. 8 on page 11, and note the dimensions (H, L, D, and A).

These dimensions are taken in to consideration when determining the vent and

vent connector requirements. Follow the procedure below to size the venting.

Determine the height of the chimney or Type B-1 vent and the length of the lateral run.

Select the proper vent connector diameter from Table 11-2, Table 11-2a or Table 11-3

shown on pages 12-13. These tables were derived from Tables 11-2 and Table 11-3 of the

National Fuel Gas Code, ANSI Z223.1/NFPA 54-Latest Edition.

Install and adaptor at the flue outlet of the boiler to step up to the diameter of the vent

connector. Install elbows for the vent connector if required. All elbows should be the full

size of the vent connector.

Caution:

!

Do Not install a three inch (3") elbow between the flue outlet on the

boiler and the adaptor.

Install the vent connector between the elbows, if used, and the chimney.

Slope the vent connector upwards toward the chimney 1/4" minimum per foot of lateral run.

Secure all joints in accordance with the vent manufacturer's instructions for

Type B-1 vent material.

10

Page 17

INSTALLATION

Chimney V enting

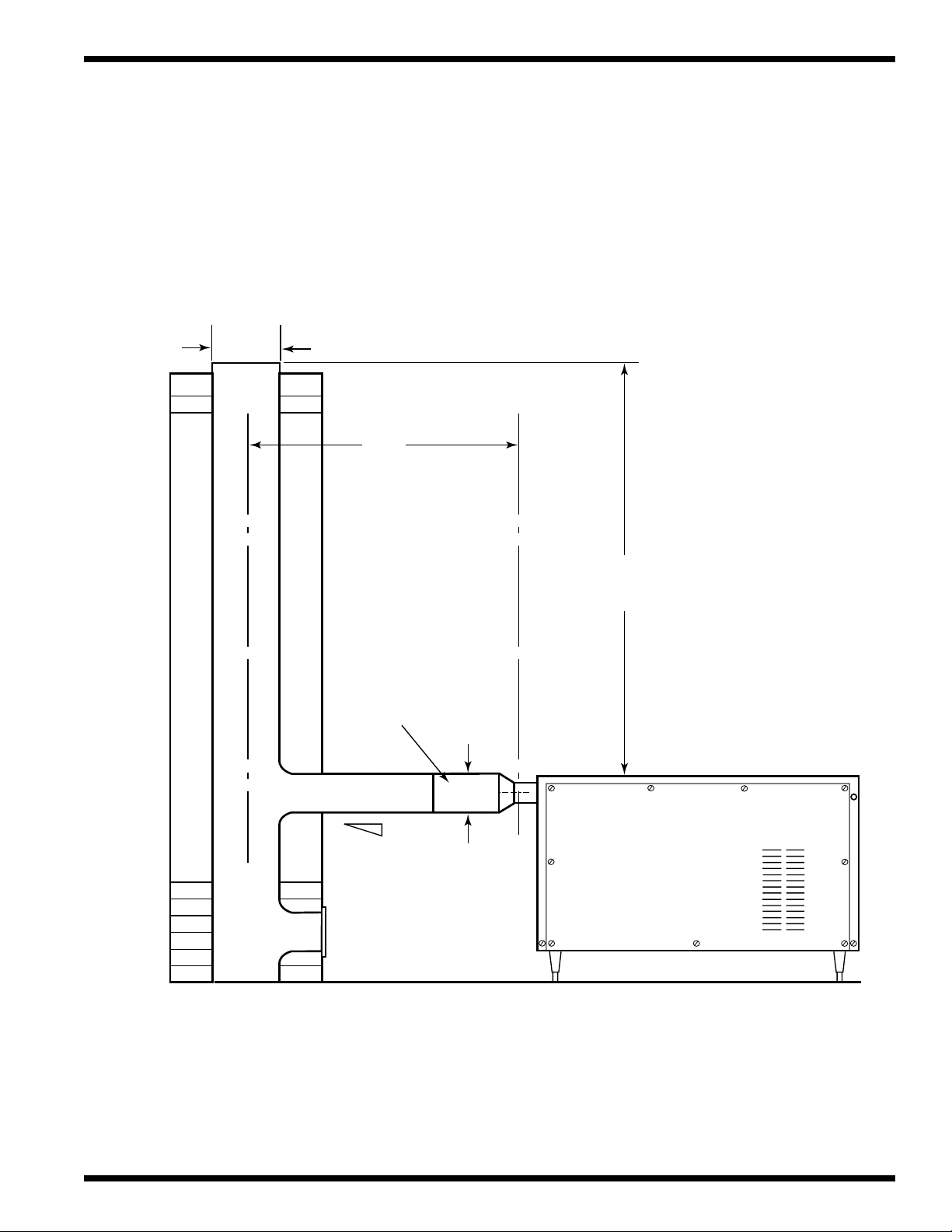

Figure X below shows the dimensions that must be taken into consideration when sizing the vent and the

vent connector.

H = Height of the chimney or Type B vent

L = Total lateral length of the vent connector

D = Required diameter of vent connector (Refer to Tables on pages X-X).

A = Minimum/maximum size limits of internal area of the chimney

A

L

Adapter

D

Slope up =

1/4" min. per foot

Figure 8

T ype B-1 Vent Chimney Venting Detail

(Vent Connection without Elbows Shown)

(Lateral slopes up 1/4" min. per foot)

H

CSS-130

Refer to V ent Tables 11-2, 11-2a, and 11-3 on the next page

for vent and vent connector diameter sizes.

11

Page 18

INSTALLATION

Vent Installation (Cont'd)

Chimney V enting (Cont'd)

Refer to Table 11-2, 11-2a or 11-3 and select the

vent and vent connector diameter that meets

the requirements for your installation.

For example:

For Type B venting into a masonry chimney, refer to

Table 11-3. If dimension (H) equals 30 feet, and the

total (L) equals 10 feet, then the required vent diameter

would be 8 inches (8") as denoted by the dot (

•) in

the 8" Diameter Pipe column of the Table.

Table 11-3

Type B-1 Chimney Venting

For CSS-130 Gas Fired Boiler

Rated 130,000 BTU/HR

Fan Assist

Total

Height

(ft)

(H)

10 2

15

20

30

50

Type B-1 Double Connector Diameter to be used

with chimney areas within the size limits at bottom

Total

Lateral

(ft)

Total (L)

2

5

10

2

5

10

2

5

10

2

5

7" Diameter

Pipe

(D)

8" Diameter

Pipe

(D)

A

L

H

Slope up =

1/4" min.

per foot

D

CSS-130

Adapter

Figure 9

Type B-1 Chimney

Vent Connection without Elbows

(Lateral slopes up 1/4" min. per foot)

A

L

D

H

Slope up =

1/4" min.

per foot

Minimum Internal

Area of Chimney

(Square Inches)

(A)

Maximum Internal

Area of Chimney

(Square Inches)

(A)

Capacity of Masonry Chimney Flue with

Type B-1 Double Wall Flue Connector

Serving a Single Category I Appliance

6350

352269

12

CSS-130

Adapter

Figure 10

Type B-1 Chimney

Vent Connection with Elbows

(Laterals slope up 1/4" min. per foot)

Page 19

INSTALLATION

Chimney V enting

Refer to Figs. 9-10 on the preceding page to determine the dimensions for your installation.

Use the appropriate Table for your installation to determine the correct diameter of vent

and vent connector.

H = Height of the chimney or Type B vent

L = Total lateral length of the vent connector

D = Required diameter of vent connector

A = Minimum/maximum size limits of internal area of the chimney

Table 11-2

with Single Wall Metal Connectors Serving a Single

Type B-1 Double-Wall Venting

Category I Appliance

For CSS-130 Gas Fired Boiler

Rated 130,000 BTU/HR

Table 11-2a

Type B-1 Double-Wall Venting

Derated for Sizing Flexible Metal Flueliners

For CSS-130 Gas Fired Boiler

Rated 130,000 BTU/HR

Fan Assist

Vent and Connector Diameter

Total

Height

(ft)

(H)

6

8

10

15

20

30

Total

Lateral

(ft)

Total (L)

0

2

4

6

0

2

5

8

0

2

5

0

2

5

10

0

2

5

10

0

2

5

10

15

4" Diameter

Pipe

(D)

5" Diameter

Pipe

(D)

6" Diameter

Pipe

(D)

Total

Height

(ft)

(H)

6

8

10

15

20

30

Total

Lateral

(ft)

Total (L)

0

2

4

6

0

2

5

8

0

2

5

0

2

5

10

0

2

5

10

0

2

5

10

15

Fan Assist

Vent and Connector Diameter

4" Diameter

Pipe

(D)

5" Diameter

Pipe

(D)

6" Diameter

Pipe

(D)

13

Page 20

INSTALLATION

INSTALLA TION (CONT'D)

Vent Installation (Cont'd)

Horizontal Through-the-Wall V enting

The CSS-130 is approved as a Category III Boiler when a horizontal through-the-wall vent

installation is used. This installation is a positive pressure venting system and requires that

all connections be sealed with an approved high temperature sealant such as Dow Corning

Silastic 736 RTV high temperature adhesive/sealant or UltraVent

Hart and Cooley Inc.

The CSS-130 is certified for use with up to 50 equivalent feet of 3" diameter stainless steel

pipe for horizontal vent installations. A 90° elbow equals 5 equivalent feet of pipe.

NOTE:

STAINLESS STEEL VENT PIPE MUST BE USED FOR HORIZONTAL RUNS.

™

sealant from

Saf-T Vent

steel and is approved for use in the United States and Canada.

Vent installation must be in compliance with Part 7 "Venting of Equipment", of the

National Fuel Gas Code; ANSI Z223.1-Latest Edition, local codes, or ordinances,

these instructions, and good trade practices.

For Canada, the installation of this unit must conform to all Canadian local codes as applicable or, in the absence of local codes, to the Canadian installation code, CAN/CGA-B149.

Vent pipe and fittings must be securely supported. Horizontal runs must be supported at

five foot intervals and at each point where an elbow is used.

To prevent condensate collection at any one point in the horizontal vent run, slope the

vent pipe down 1/4" min. per foot of horizontal run (See Fig. 11 below).

®

manufactured by Heat Fab, Inc., is constructed from AL294C stainless

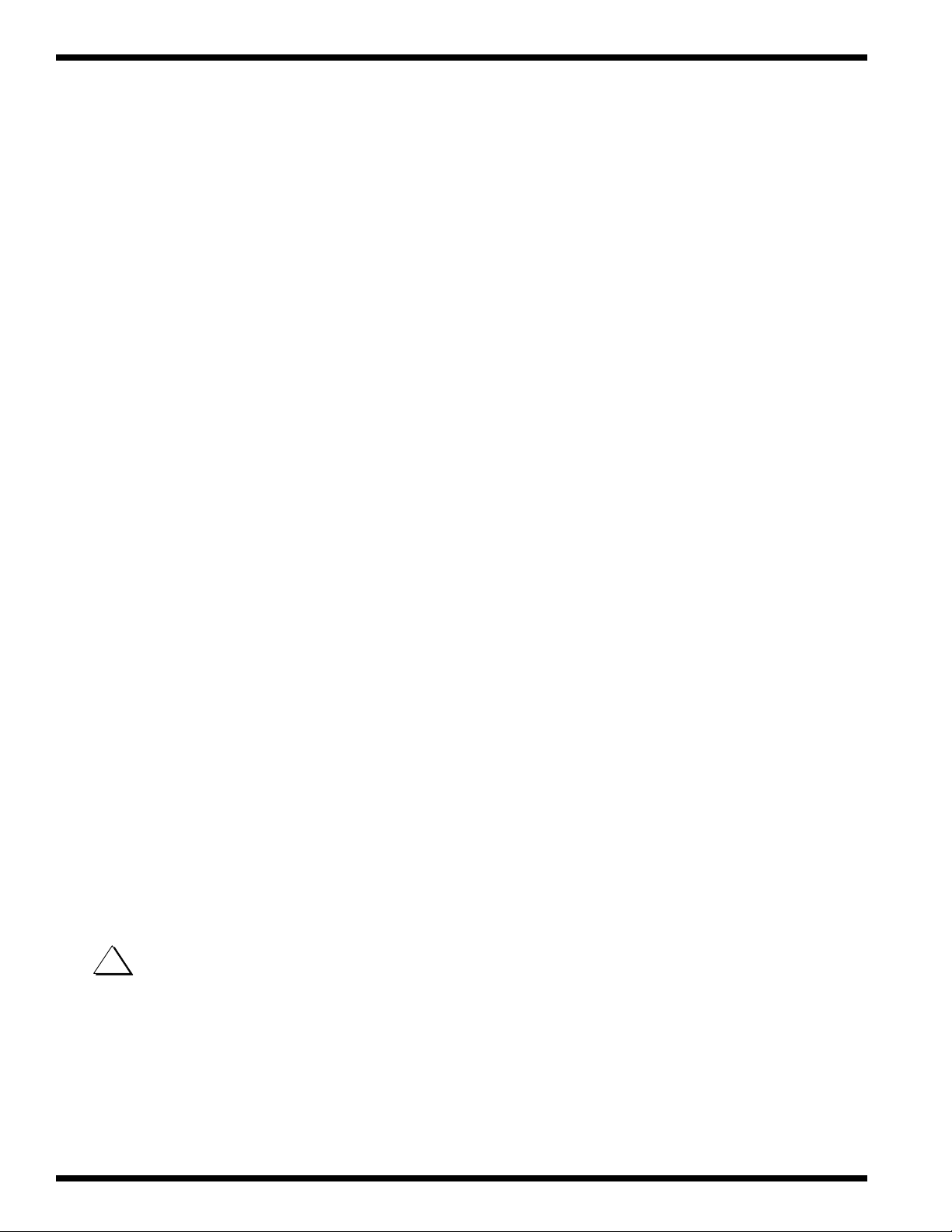

Support every 5 feet

Boiler

Slope down =

Wall

1/4" min. per foot

14

CSS-130

Figure 11

Horizontal Through-the-wall Venting

( Slope down 1/4" min. per foot)

Page 21

Horizontal Through-the-Wall V enting (Cont'd)

Pipe Cutting and Joining Procedure

1. Using a sharp 24 teeth per inch hacksaw, hand cut pipe to length as square as possible.

Caution:

!

Do not use a power saw as it may cause damage to the pipe.

2. Clean pipe mating surfaces of all dirt, grease, and moisture.

INSTALLATION

3. Use Dow Corning Silastic 736 RTV high temperature adhesive/sealant, UltraVent

sealant from Hart and Cooley , Inc., or other approved adhesive/sealant.

Caution:

!

Do not use solvent cements or other adhesives to join vent piping.

4. Insert one section of pipe into another. Use a felt marker or soft lead pencil to mark the

pipe at the full insertion depth.

5. Separate the pipe sections and apply a generous bead of adhesive material around the end

of the pipe within the marked area.

6. Using a twisting motion to spread the adhesive completely between the sections of pipe.

7. When the two sections of pipe have bottomed out, inspect the joint for a complete seal.

Additional sealant may be required for a complete seal. It takes 24 hours of curing time

to develop full joint strength.

Caution:

!

Do not drill holes through pipe or fittings.

Do not use sheet metal screws or rivets.

™

15

Page 22

INSTALLATION

INSTALLA TION (CONT'D)

Vent Installation

Horizontal Through-the-W all Venting

(Cont'd)

Locating the V ent Opening in the Outside Wall

It is essential to follow the National Fuel Gas Code, ANSI. Z223.1-Latest Edition and these

instructions for proper venting and condensate disposal.

For Canada, the installation of this unit must conform to all Canadian local codes as applicable or, in the absence of local codes, to the Canadian installation code, CAN/CGA-B149.

1. The vent termination must be located at least 12" inches above grade or the normally

expected snow accumulation level. (Snow level may be higher on walls exposed to

prevailing winds.)

2. If adjacent to public walkways, the vent termination must be located 7 feet above grade.

3. Do not locate termination close to shrubbery.

4. The termination must be located at least 10 feet from any forced air inlet into the

building and at least 4 feet horizontal and in no case above or below any other building

opening, gas meter, electrical meter, service regulator, reliefs, or other equipment.

5. Do not locate termination near an alcove, over a window well, or closer than 5 feet to the

corner of joining parts of the building structure.

6. Do not locate under any kind of deck or patio.

7. If possible, the wall through which the vent will pass should not be exposed to prevailing

winds.

8. Select a point of wall penetration where the minimum 1/4" minimum per foot

downward slope can be maintained.

Slope down

away

from Boiler =

1/4" min. per foot

Front View

16

Rear Wall

T op V iew

CSS-130

Figure 12

Horizontal Vent

(Exit Through Rear Wall)

4 feet

Horizontal Vent

12 " min.

Grade

Figure 13

Horizontal T ermination Clearance

(Window and Grade Level)

Termination

Page 23

INSTALLATION

Horizontal Through-the-Wall V enting

Installing the Horizontal V enting and Termination

1. Cut a hole in a wall of the building at least 7" in diameter.

2. The hole must be located to maintain a downward slope of 1/4" minimum per foot

of horizontal run from the boiler.

3. Install an approved thimble, one sleeve each to the inside and outside walls of the building.

4. Install the horizontal run from the boiler to the wall.

5. Install the last section of vent pipe so that it extends through both wall plates and terminates

1-1/4" beyond the outside wall thimble. (See Fig. X below)

6. Install a 3 inch (3") coupling to the end of the last section and seal with high temperature

adhesive/sealant.

7. Seal all joints between the mounting plates and thimble with high temperature adhesive/sealant.

8. Install a 90° elbow to a 6-3/4" piece of 3 inch vent pipe.

9. Install a debris screen in the 90° elbow.

10. Install the assembly to the 3 inch coupling described in step 6 sealing all joints and making sure that

the discharge end of the elbow is pointing straight down.

11. After installation, the distance between the outside wall thimble and the closest edge of the

termination elbow must not be less than six inches. (See Fig. 14).

Figure 14

Horizontal Vent T ermination

Side

Wall

Vent extends 1-1/4"

90° elbow points

Debris screen

12" (min.) above

highest snow fall

Slope down

away

from Boiler =

1/4" min. per foot

down

Wall thimble

3"

6"

Seal with

adhesive

5-3/4"

hole

Wall

T op V iew

Figure 15

Horizontal Vent

(Exit Through Side Wall)

CSS-130

Front View

17

Page 24

INSTALLATION

INSTALLA TION (CONT'D)

Gas Supply Connections

NOTE:

Gas connections must be in compliance with Part 3 "Gas Piping Installation",

of the National Fuel Gas Code; ANSI Z223.1-Latest Edition, local codes, or

ordinances, these instructions, and good trade practices.

For Canada, the installation of this unit must conform to all Canadian local

codes as applicable or, in the absence of local codes, to the Canadian

installation code, CAN/CGA-B149.

!

WARNING:

Gasoline, or other flammable materials and liquids (adhesives,

solvents, etc.) and the vapors that they produce, are extremely dangerous.

DO NOT handle, use or stor e gasoline or other flammable liquids anywhere

near or in the vicinity of the gas boiler.

!

WARNING:

Inspect the vent system for proper installation BEFORE making

gas supply connections.

Failure to install proper venting as described in the venting installation

instructions of this manual (See pages 6-17) can result in unsafe operation

of the CSS-130, gas fired boiler. T o avoid the risk of fire, explosion, or

asphyxiation from carbon monoxide, never operate the CSS-130, gas fired

boiler unless it is properly vented and an adequate air supply for proper

operation is available.

Gas Fuel Requirements

The CSS-130 is designed and certified for use with Natural Gas or LP Gas.

!

CAUTION:

Check the gas fuel specified on the CSS-130 rating plate before making any

gas connection. The rating plate is located on the lower left side of the unit.

If the rating plate and the gas supply do not agree, refer to page 21,

"Field Conversion of Gas Orifice".

Gas Pressure Requirements

1. Inlet gas supply pressure must be at least 4" W.C. and no greater than 14" W.C.

for Natural and LP gas installations.

18

2. For LP Gas Only, the CSS-130 operates best with a supply pressure of 9-10" W.C.

If no other appliances are being supplied by the LP gas supply, set the low pressure

regulator to 9-10" W.C.

3. A maxitrol RV48 regulator or equivalent is recommended for regulating the

inlet gas pressure.

Page 25

INSTALLATION

Gas Supply Connections (Cont'd)

Gas Piping Installation

1. Supply piping must be sized correctly to minimize pressure drop between the meter or regulator

and the CSS-130. Refer to Fig. 16 below for pipe capacity ratings and size the pipe for your

installation to meet or exceed the 130,000 BTU/HR rating of the CSS-130.

2. Run gas supply line in accordance

with all applicable codes.

3. If the CSS-130 is installed above

the gas supply, run piping up to a

point above the vent center line

and back down to the unit.

This prevents water from entering

the gas supply line should a water

leak develop in the boiler section of

the unit.

Length of

Pipe

(Straight Length)

10 ft.

20 ft.

30 ft.

40 ft.

50 ft.

Capacity of Pipe in MBTU/HR

(.6 Specific Gravity of Gas)

1/2"

132

92

73

63

3/4"

278

190

152

130

115

1"

520

350

285

245

215

1-1/4"

1,050

730

590

500

440

4. All threaded joints in the gas piping

should be coated with piping

compound. The compound must be

resistant to the action of liquefied

petroleum gases, (LP gas), even if

your unit uses natural gas.

5. Pipe unions used in the gas line

must be the ground-joint type.

6. Install a manual shut-off valve in

accordance with state and local

requirements if required.

The CSS-130 is equipped with a

manual shut-off valve.

7. A one-eighth inch (1/8') plugged tap,

accessible for test gauge connection

must be installed immediately upstream

of the CSS-130 gas supply connection.

8. Install a trap and drip leg in the last

vertical run before entering the CSS-130.

75 ft.

100 ft.

150 ft.

Add equivalent

ft. listed at right

for each ➞➞➞

Tee or Bend

(Capacity of Pipe in MBTU/HR)

Based on .6 Specific Gravity of Gas

93

79

64

1.3 ft.

1.7 ft.

Figure 16

Pipe Sizing T able

175

150

120

2.2 ft.

360

305

250

2.7 ft.

9. Support all piping with straps or hangers.

Figure 17

Gas Supply Piping

(Drip Leg)

19

Page 26

INSTALLATION

INSTALLA TION (CONT'D)

Gas Supply Connections

Gas Piping Installation (Cont'd)

Refer to Figs. 18, 19, and 20

9. Connect the gas supply piping to the CSS-130 at the lower left

side of the unit.

10. Gas connection point is 1/2" NPT. (See A, Fig. 18)

11. The unit comes equipped with a 1/2" manual shut-off valve.

12. All threaded joints in the gas piping should be coated with piping

compound. The compound must be resistant to the action of liquefied

petroleum gases, (LP gas), even if your unit uses natural gas.

A

Pressure Testing the Gas Piping Installation

1. The CSS-130 and its manual gas shut-off valve must be disconnected

from the gas supply piping system during any pressure testing of the

system at test pressures in excess of 1/2 psig.

2. The CSS-130 must be isolated from the gas supply piping system by

closing its individual manual gas shut-off valve during any pressure testing

of the gas supply system at test pressures equal to or less than 1/2 psig.

Figure 19

Gas Connection Point

(Side View)

Figure 18

CSS-130

Manual Gas Shut-off Valve

20

Figure 20

Gas Connection Point

(T op View)

Page 27

Gas Supply Connections

Field Conversion of Gas Orifice

The CSS-130 requires a gas orifice specifically

designed for either Natural or LP gas. If the

gas fuel supply at the installation site does not match

the gas type marked on the machine data plate located

on the front panel of the gas fired boiler, you will

have to change the gas orifice.

!

WARNING:

When working on any electrical circuit,

disconnect the power at the main service

disconnect switch or breaker and place a

tag at the disconnect switch to indicate that

work is being performed on the circuit.

WARNING:

!

Close the CSS-130 manual gas shut-off

valve located on the left side of the unit

before you remove the gas orifice union.

INSTALLATION

Figure 21

Gas Orifice Union Location

Refer to Figs. 21, 22, and 23

1. The gas orifice union is located behind the gas

burner recirculation pump near the center of the

CSS-130.

2. The gas orifice is screwed into the union.

(See Fig. 22, Orifice Detail)

3. To convert the gas orifice, remove the orifice

union and unscrew the gas orifice.

4. Install the correct orifice for your gas supply.

5. An LP gas conversion kit, P/N 111993, is

available from Champion. This kit contains

a label marked "Propane Gas". Be sure to

apply this sticker to the data plate on the front

panel of the CSS-130 adjacent to the data plate.

4. Reassemble the gas union. All threaded joints in

the gas piping should be coated with piping

compound.

5. Turn the gas supply on. Test for gas leaks.

Check the CSS-130 for proper operation.

Orifice Detail

Figure 22

Gas Orifice Union

Figure 23

LP Gas Orifice Kit

P/N 111993

21

Page 28

INSTALLATION

INSTALLA TION (CONT'D)

Electrical Connections

Refer to Figs. 24-26.

1. The CSS-130 requires a single (120 v, 60 Hz, 15 amp) electrical power source.

2. Electrical fittings with conduit run through the interior of the boiler is provided to

connect the incoming power supply. Conduit to interconnect the CSS-130 to the

dishwasher is provided.

3. All electrical connections are made in the CSS-130 control cabinet which is located on

the right side front of the unit (See Fig. 25).

Wiring connections should be made as shown in the electrical schematic (See Fig. 26).

4. Control wiring for an optional dishwasher ventilation fan contactor or starter may be run

through the same conduit into the terminal strip located in the boiler control cabinet.

(Optional fans must be approved by local authority.)

5. A fused disconnect switch or circuit breaker (supplied by others) is required to protect

the power supply circuit.

NOTE:

All electrical and grounding connections must be made in accordance with

the requirements of the authority

having jurisdiction or, in the absence of

such requirements, with the National

Electrical Code, ANSI/NFPA 70.

Installation should also conform with

CSA C22.1 Canadian Electrical Code

Part I.

Incoming Power

CSS-130 to Dishwasher

Interconnect Conduit

WARNING:

!

When working on any electrical

circuit, disconnect the power at

the main service disconnect

switch or breaker and place a

tag at the disconnect switch to

indicate that work is being

performed on the circuit.

Figure 24

Electrical Connections

(Right side of CSS-130)

22

Page 29

C

C

Electrical Connections (Cont'd)

INSTALLATION

6. The schematic detail, Fig. 25 shows

the incoming power connected at

the power contactor. The contactor

is located inside the CSS-130

control cabinet.

7. The incoming power must be connected

to the power contactor as shown. Any

other connection point will prevent the

CSS-130 from operating properly.

8. The complete wiring schematic for the

CSS-130 can be found on page 44.

Figure 25

Electrical Schematic

Detail

1

B12

ER

TOR

10

INAL

K

B19

B17

32

10

2

32

33

B2

B17

CONTROL CABINET

COOLING FAN

B1

B2

L1

N

GROUND

TO DISH MACHINE

10

CONTROL CABINET

2

CIRCUIT BREAKER

LOAD SIDE

LOCATED IN

HC1

DISHMACHINE

CONTROL CABINET

33

EXHAUST FAN SIGNAL

TO TURN ON EXHAUST

FAN WHEN BOOSTER IS

VENTED INTO DISHMACHINE VENT HOOD

120V INPUT POWER

10

CONNECTION POINT

2

RACK MACHINE

CONTROL CABINET

4

CONNECTION POINT

2

D-H1 DOOR MACHINE

CONTROL CABINET

A701339/D

Connect Incoming Power

120V/60Hz/1PH

at Power Contactor

Conduit Connecting

CSS-130 to Dishwasher

Figure 26

CSS-130 Control Panel Power Connections

(Inside right front side)

23

Page 30

INSTALLATION

INSTALLA TION (CONT'D)

Plumbing Connections

WARNING:

!

Plumbing connections must comply with local sanitary and plumbing codes.

Water and Drain Connections

Refer to Fig. 27.

1. The CSS-130 requires a single 3/4" NPT hot water connection.

• Minimum incoming water supply temperature should be 140°F/60°C.

• Minimum and maximum incoming water supply pressure should be 23 PSI/159 kPa.

2. The CSS-130 is equipped with a 3/4" pressure reducing valve, PRV on the incoming

water supply line.

3. The CSS-130 is equipped with a pressure relief valve, (30 PSI/207 Kpa, 130 lbs/hr

minimum capacity) on the CSS-130 water outlet.

CAUTION:

!

The boiler pressure relief valve and back-flow preventer should be piped

separately to a floor drain to remove any water discharge from the

gas-fired boiler.

4. The CSS-130 is equipped with the piping required to interconnect it to the dishwasher.

Figure 27

Plumbing Connections

To final rinse

valve

Pressure

Relief Valve

(Pipe to Drain)

From wash tank

heater coil

(Right side of CSS-130)

24

To wash tank

heater coil

Back-Flow

Preventer

(Pipe to Drain)

To dishwasher fill

solenoid valve

Water Supply

Connection

3/4" NPT

Page 31

INITIAL START -UP AND SERVICE

INITIAL ST ART-UP

AND

SER VICE

25

Page 32

ATTENTION INST ALLER

INSTRUCTIONS FOR SETTING AIR

PRESSURE IN EXP ANSION TANK

NOTE:

Expansion tank air pressure should be set to 20 PSI for proper operation.

Note:

The best time to check the air pressure in the expansion tank is sometime before the water

and electric service are connected to the boiler.

For boiler assembly BEFORE it is filled with water

1. Make sure Dishwasher’s main power switch is

OFF.

2. Mare sure main water supply valve is OFF.

3. Check the expansion tank pressure with an

air guage.

4. Depress valve stem to allow air to escape.

5. Check pressure and repeat the above until the

tank pressure reading is 20 PSI.

6. If too much air is released, use a tire chuck and

add air until the pressure gauge reads 20 PSI.

7. Acceptable pressure range is 19-20 PSI.

For boiler assembly AFTER it is filled with water

1. Make sure Dishwasher’s main power switch is

OFF.

2. Mare sure main water supply valve is OFF.

3. Slightly open drain valve located at the bottom of

the storage tank to bleed off some water until the

dishwasher Final Rinse Gauge reads 0 PSI.

4. Close the storage tank drain valve.

5. Check the expansion tank pressure with an

air guage.

6. Check pressure and repeat the above until the

tank pressure reading is 20 PSI.

7. If too much air is released, use a tire chuck and

add air until the pressure gauge reads 20 PSI.

8. Acceptable pressur range is 19-20 PSI.

26

9. Open water supply valve.

Page 33

ATTENTION INST ALLER

INSTRUCTIONS FOR MANUALLY VENTING AIR

FROM BOILER W ATER SYSTEM

CAUTION:

Failure to follow instructions will result in permanent damage to the recirculating pumps.

NOTE: Plumbing and Electrical service connections must

be completed BEFORE performing the

following procedures.

1. Make sure Dishwasher’s main power switch is OFF.

2. Mare sure main water supply valve is OFF.

3. Check high vent knurled cap on boiler holding tank.

—If closed, turn knurled cap A CCW one

complete turn.

4. Open petcock

tank heater coil piping.

5. Remove silver air bleed plug C in center of

recirculating pump. Pump is located on right front

corner.

6. Remove silver air bleed plug

burner recirculating pump.

7. Open air bleed petcock

burner assy.

8. Turn main water supply ON

—Water fills the gas boiler and dishwasher tank

heater coil.

—Air or a mixture of air and water, then water

only should be observed coming from

petcock/vents.

on outlet side of dishwasher

B

in center of

D

on lower left front of

E

9. Observe air bleed petcock

—Make sure a steady stream of water comes from

petcock

10. When boiler holding tank is full, turn dishwasher

main power switch ON.

—Dishwasher fills automatically.

—Boiler may begin ignition cycle.

—One or both boiler recirculating pumps run.

11. Observe vent ports. Make sure a steady stream of

water comes from all ports.

12. Close petcock and reinstall recirculating

pump plugs in the following order.

—Install the plug

—Install the plug

—Close dishmachine’s petcock B located

on outlet side of wash tank heater coil.

13. Check the amp draw on the boiler recirculating pumps. The correct reading should

be between 1.2A to 1.7A.

14. If reading is less than 1.2A, repeat Steps 3-12

and recheck recirculating pump amps.

then close the petcock.

E

on burner recirculating pump.

D

on return recirculating pump.

C

.

E

E

A

C

D

B

27

Page 34

FOR YOUR SAFETY READ BEFORE OPERATING

WARNING:

If you not follow these instructions exactly, a fire

or explosion may result causing property damage,

personal injury or loss of life.

This appliance does not have a pilot.

A.

It is equipped with an ignition device

which automatically lights the burner.

DO NOT try to light the burner by hand.

BEFORE OPERATING

B.

the appliance area for gas. Be sure

to smell next to the floor because

some gas is heavier than air and will

settle on the floor.

smell all around

WHAT TO DO IF YOU SMELL GAS

* Do not try to light any appliance.

* Do not touch any electric switch;

do not use any phone in your

building.

* Immediately call your gas supplier

from a neighbor's phone. Follow

the gas supplier's instructions.

* If you cannot reach your gas

supplier, call the fire department.

C.

Use only your hand to push or turn

the gas control knob. Never use tools.

If the knob will not push in or turn by

hand, do not try to repair it, call

qualified service technician. Force or

attempted repair may result in a fire

or explosion.

D.

Do not use this appliance if any part

has been under water. Immediately call

qualified service technician to inspect

the appliance and to replace any part

of the control system and any gas

control which has been under water.

OPERATING INSTRUCTIONS

1.

STOP!

above on this label.

2.

Make sure system has been properly

filled with water and bled of air.

Turn off all electric power to the

3.

appliance.

This appliance is equipped with an

4.

ignition device which automatically

lights the burner. Do not try to light

the burner by hand.

Read the safety information

5.

Turn manual gas valve located on left

side of unit to "ON" position.

6.

Push in gas control knob slightly and

turn clockwise to "OFF". Do not force.

Wait five (5) minutes to clear out any

7.

gas. Then smell for gas, including near

the floor. If you smell gas, STOP!

Follow "B" in the saftey information

above on this label. If you do not

smell gas, go to the next step.

Turn the gas control knob

8.

counter clockwise to "ON".

Close the access door on the left side

9.

cover panel.

Turn on all electric power to the

10.

appliance.

If the appliance will not operate,follow

11.

the instructions to "Turn Off Gas

Appliance" and call your service

technician or gas supplier.

TO TURN OFF GAS TO APPLIANCE

Turn off all electric power to the

1.

appliance if service is to be performed.

Turn manual gas valve located on left

2.

side of unit to "OFF" position.

28

Push in gas control knob slightly and

3.

turn clockwise to "OFF". Do Not Force.

Page 35

INITIAL START -UP AND SERVICE

CHECK, TEST & ST ART - UP

FILLING SYSTEM

1. Open all supply and return valves.

2. Fill heating system to minimum operating pressure -20 psig.

3. Open bleed pet cock and bleed air from heater coil until a

good dream of water comes out.

4. Purge all lines by opening vents, or with flushing valves.

5. Close gas valve.

6. Turn on 120 volt power, and listen for unit circulator to

start. Unit will cycle off on lockout.

7. Open all vents again to discharge any additional air and

close off after air is eliminated.

8. System is now ready for operation.

INITIAL FIRING

1. Be sure that system has been filled properly (see above)

and does not leak.

2. Open gas cock(s). Open manual gas shut-off valve by

turning to "on" position.

3. Turn on main dishwasher power switch, and set thermostat

to call for heat. In approximately 2 seconds, blower will

come on.

NOTE: Burner may not ignite on first attempt because of air

in gas lines. In this case, blower will stop after 5 minutes.

Should this happen, turn off main switch. Wait 5 minutes and

turn on main switch again.

4. If burner fails to ignite after three attempts, refer to Troubleshooting Section 2, Service Manual or call service for

troubleshooting.

WARNING: Should any pronounced odor of gas be

detected, or if the gas burner does not appear to be

functionlng in a normal manner, close main shut-off

valve, do NOT shut off switch, and contact your

heating contractor, gas company, or factory

representative.

5. You MUST check flame monitoring control (ignition

system safety shut-off device).

a. Close gas cock with burner operating.

b. In 3 seconds, FLAME indicator light will go out and

blower will continue to run on post purge cycle. Two

additional attempts to light will follow including pre-purge,

igniter on, valve/flame on and post purge. (Ignition will not

occur-gas off).

c. Open gas cock. Switch dishwasher power switch “OFF”

and then "ON" again. Burner should start after about

45 secs. It is recommended that the unit be checked with

a standard CO

into exhaust pipe through outside vent terminal. Readings

should be:

- 8% to 8.5% (nat. gas) 9% to 9.8% (LP gas)

CO

2

0

- 7% to 6%

2

or 0 2 tester. Insert tester probe at least 6"

2

6. Check burner input (other equipment off)

a. Measure the time, in seconds, it takes to use one

cubic foot of gas.

b. Divide the number of seconds into 3,600.

c. Multiply the result by the heating value of the gas to

obtain BTU/HR input.

Example: If it takes 36 seconds to use one cubic foot of gas

and the heating value of the gas is 1,000 BTU/CU FT,

(approximate natural gas value).

INPUT = 3,600/36 x 1,000 = 100,000 BTU/HR

Input Ranges

127,400 BTU/HR to 132,600 BTU/HR

Because of the altitude and other minor variations, it is

possible the input will not fall within this range and the gas

orifice must be replaced. See chart in an orifice kit.

LIGHTING AND

SHUTDOWN INSTRUCTIONS

A. LIGHTING

1. Ensure that heater is filled with water, air is bled from

boiler coil and water pressure is at a minimum of 12 psi.

2. Open manual gas valve.

3. Open gas cock on gas valve.

4. Turn “ON” dishwasher power.

5. After 45 seconds, ignition will occur (if there is a call for

heat).

B. SHUTDOWN

1. Turn “OFF” disconnect switch to boiler and dishwasher.

2. Close manual gas valve.

3. Close gas cock on gas valve.

MAINTENANCE

OWNER CARE AND MAINTENANCE

1. Inspect venting system - Annually remove screws on

vent terminal and remove terminal. Inspect interior with

flash light. Reassemble and reseal exhaust vent air

system.

2. General Housekeeping - Keep boiler area clear and free

from combustible materials, gasoline and other flammable

vapors and liquids.

Keep boiler cabinet louvers clear for proper cooling of

internal components.

Do not obstruct boiler room ventilation screens or grills.

SERVICE MAINTENANCE

Cleaning heat exchanger to be done by qualified service

person.

CAUTION: Label all wires prior to disconnection when

servicing controls. Wiring errors can cause improper and

dangerous operation.

Verify proper operation after servicing.

29

Page 36

INITIAL START -UP AND SERVICE

This Page

Intentionally

Left Blank

30

Page 37

INITIAL START -UP AND SERVICE

ADJUSTING BURNER / INPUT

The CSS-130 burner system is a pre-mixed, forced combustion

system. Outside air is drawn through the air orifice (located in

the air induction system) and mixed with the gas drawn in

downstream of the air orifice. The gas is metered through an

orifice located in the gas orifice union. All the air required for

complete combustion comes into the unit in this manner.

Adjusting the input is limited to changing the gas orifice to

achieve the proper input. The air orifice cannot be altered and

the gas valve pressure setting cannot be changed.

Before changing the gas orifice to correct input, service

representatives should make the following checks:

1. The pressure on the inlet side of the gas valve is

between 4" and 14" water column.

2. The pressure on the outlet side (manifold) of the gas

valve and “T” above air orifice is between -0.05"

and -0.35" water column with the unit operating.

To increase the input, install larger diameter gas orifice.

Each size will change the input approximately 5 C. F. H.

Once the correct input has been achieved, the burner should

be checked with an oxygen (0

analyzer.

The unit should be in operation 5 minutes before adjusting

input or taking C0

or 02 readings. This time will allow for

2

preheating of the intake air.

Insert the probe of the 0

through the vent terminal. If C0

readings should be between 8.0 and 8.5 for natural gas and

9.0 and 9.8% for propane. If 02 is being measured, the

readings should be between 7 and 6.

Measuring C0

*

2

When operating on natural gas, readings below 8.0 generally

indicate a lean mixture (not enough gas). Readings above

9.25 generally indicate a rich mixture (too much gas). Inputs

should be increased or decreased to correct lean or rich

mixtures.

NOTE: If the mixture is very rich (not enough air for

complete combustion), it is possible to get low readings on a

C0

analyzer. This situation does not occur often but it can be

2

detected if reading continues to go lower as the input is

increased. If this condition is suspected, a CO test should be

taken at the vent outlet. Inputs must be reduced to correct high

CO reading and to bring C0

*The following numbers apply to natural gas only. The range

of operation for LP is 9.0 to 9.8 % CO2.

Measuring 0

2

Readings above 7% indicate a lean mixture (not enough gas).

Readings below 6% indicate a rich mixture. Input should be

increased or decreased to correct lean or rich mixtures.

) or carbon dioxide (C02) gas

2

or C02 tester at least 6" into the vent

2

is being measured, the

2

readings to proper levels.

2

CLEANING COMBUSTION CHAMBER COIL

1. Turn off electric and gas supplies and remove the jacket

2. Remove the vent assembly and top cover.

3. Remove the top half of the combustion chamber by

removing the 3 screws and nuts that clamp the top half to

the bottom half. Remove the clamp on the air orifice hose

and the two clear plastic lines connected to the “T” on the

air induction elbow.

4. Remove the top insulator cap by spreading the retainer.

5. Remove the igniter.

6. Clean the finned tubing with a wire brush and vacuum all

loose material from the combustion chamber.

7. Replace all parts in the reverse order in which they were

removed.

8. Restart the unit as indicated by the lighting instruction

label.

UNIT PUMP

The unit pump operates whenever there is a call for heat or

hot water.

It is a wetted-rotor type pump and should always be filled with

water when it is operating so that it will cool properly.

If a pump change is required for any reason, close gas valve

and drain water from the unit. Turn off the main disconnect

switch and unplug the pump wires, remove the pump motor.

The pump housing need not be removed. The replacement

pump motor should be installed in the reverse order from

which the old pump motor was removed. After filling the

system be sure to bleed the coil at coil bleed petcock.

NOTE: If the pump motor is not defective the pump cartridge

alone may be changed.

GAS VALVE

The gas valve is a solenoid operated, negative pressure

regulated valve. The outlet pressure is regulated at -0.2”w.c.

It is designed to operate with supply pressures

of 4-14” w.c. Within that range of supply pressures, the

regulated discharge pressure may vary from -0.05” to

-0.35” inches w.c. The regulator is not adjustable and the

effect of this variation in discharge pressure is not significant.

Because of the fixed regulator setting, gas flow must be

adjusted by changing the gas orifice.

To remove the gas valve, shut off 120 volt power and the

master gas cock in gas line, loosen the nut on the gas orifice

union and remove the orifice union plus piping to the gas valve.

Disconnect the wires from the gas valve. The valve may now

be unscrewed from the inlet piping. After the valve has been

removed, replace with a new valve in the reverse order in which

the old valve was removed. Do not over tighten the fittings into

the valve body as this may cause damage to the valve.

NOTE: When fueled by LP gas, the CSS-130 performs best

with 9-10” w.c. supply pressure. If no other appliances are

being supplied by the LP supply set the low pressure regulator

to 9-10” w.c.

31

Page 38

INITIAL START -UP AND SERVICE

SAFETY LIMIT SWITCH

The Safety Limit Switch has a fixed set point at 240°F. It will

reset automatically.

To replace the switch, shut off the 120 volt power and close

gas valve, drain water from the heater and remove the nut

which holds the safety limit bulb in the heater discharge fitting.

Remove the bulb from the fitting and remove the 2 screws which

hold the switch assembly to the electrical control box. Disconnect the 2 wires from the quick connects at switch and remove

the safety limit assembly. To replace, perform the same

operations in reverse. Push the sensing bulb as far into the

fitting as possible before tightening sealing nut. No more than

1/2" of sensing bulb should be visible after installation. Fill the