Page 1

OPERATOR'S MANUAL

MODEL #100592

6250W DUAL FUEL GENERATOR

US Patent # D710,802

Made in China - REV 20190515 Champion Power Equipment, Inc., Santa Fe Springs, CA USA

or visit championpowerequipment.com

SAVE THESE INSTRUCTIONS. This manual contains important safety precautions which should be read and understood before operating the product. Failure

to do so could result in serious injury. This manual should remain with the product.

Specifications, descriptions and illustrations in this manual are as accurate as known at the time of publication, but are subject to change without notice.

This product is rated in accordance with PGMA (Portable Generator Manufacturers’ Association) standard A NSI/PGMA G300 (Safety and Performance of

Portable Generators).

REGISTER YOUR PRODUCT ONLINE

at championpowerequipment.com

CARBON MONOXIDE AUTO-SHUTOFF

Page 2

100592 - 6250W DUAL FUEL GENERATOR

TABLE OF CONTENTS

TABLE OF CONTENTS

Introduction ................................................ 3

Safety Definitions

Important Safety Instructions

Fuel Safety ...................................................... 6

Safety Labels .................................................... 7

Safety Symbols .................................................. 8

Operation Symbols .............................................. 9

Quickstart Label Symbols......................................10

Controls and Features ...............................11

Generator .......................................................11

Control Panel ...................................................12

Intelligauge .....................................................13

Tools Needed ...................................................14

Assembly ...................................................15

Unpacking ......................................................15

Install the Wheel Kit ............................................15

Add Engine Oil ..................................................15

Add Fuel: Gasoline .............................................16

Add Fuel: Propane (LPG) .......................................17

Grounding ...................................................... 18

Operation ...................................................18

CO Shield™ - Carbon Monoxide (CO)

Detection and Auto-shutoff System ...........................18

Generator Location .............................................19

Surge Protection ...............................................20

Fuel Selector ...................................................20

Starting the Engine: Gasoline ..................................20

Starting the Engine: Propane (LPG) ...........................22

Connecting Electrical Loads ...................................23

Do Not Overload Generator ....................................23

GFCI .............................................................24

Stopping the Engine ............................................24

Moving the Generator ..........................................25

Operation at High Altitude .....................................25

....................................... 3

.................... 4

Maintenance ............................................. 26

Cleaning the Generator ........................................26

Changing the Engine Oil .......................................26

Cleaning and Adjusting the Spark Plug ........................26

Cleaning the Air Filter ..........................................27

Cleaning the Spark Arrestor ...................................27

Adjusting the Governor .........................................27

Maintenance Schedule .........................................27

Storage ..................................................... 28

Short Term Storage (up to 30 days) ...........................28

Mid Term Storage (up to 1 year) ...............................28

Long Term Storage (more than 1 year) ........................29

Removing from Storage ........................................29

Specifications ........................................... 30

Generator Specifications .......................................30

Engine Specifications ..........................................30

Oil Specifications ...............................................30

Fuel Specifications .............................................30

Temperat ure Specificati ons ....................................30

Parts Diagram ..................................................31

Parts List .......................................................32

Engine Parts Diagram ..........................................34

Engine Parts List ...............................................35

Wiring Diagram .................................................37

Troubleshooting ........................................ 38

2

Page 3

100592 - 6250W DUAL FUEL GENERATOR

INTRODUCTION

INTRODUCTION

Congratulations on your purchase of a Champion Power

Equipment (CPE) product. CPE designs, builds, and supports

all of our products to strict specifications and guidelines. With

proper product knowledge, safe use, and regular maintenance,

this product should bring years of satisfying service.

Every effort has been made to ensure the accuracy and

completeness of the information in this manual at the time

of publication, and we reserve the right to change, alter and/

or improve the product and this document at any time without

prior notice.

CPE highly values how our products are designed,

manufactured, operated, and serviced as well as providing

safety to the operator and those around the generator.

Therefore, it is IMPORTANT to review this product manual

and other product materials thoroughly and be fully aware

and knowledgeable of the assembly, operation, dangers

and maintenance of the product before use. Fully familiarize

yourself, and make sure others who plan on operating the

product fully familiarize themselves too, with the proper safety

and operation procedures before each use. Please always

exercise common sense and always err on the side of caution

when operating the product to ensure no accident, property

damage, or injury occurs. We want you to continue to use and

be satisfied with your CPE product for years to come.

When contacting CPE about parts and/or service, you will

need to supply the complete model and serial numbers of your

product. Transcribe the information found on your product’s

nameplate label to the table below

SAFETY DEFINITIONS

The purpose of safety symbols is to attract your attention to

possible dangers. The safety symbols, and their explanations,

deserve your careful attention and understanding. The safety

warnings do not by themselves eliminate any danger. The

instructions or warnings they give are not substitutes for proper

accident prevention measures.

! DANGER

DANGER indicates a hazardous situation which,if not

avoided, will result in death or serious injury.

! WARNING

WARNING indicates a hazardous situation which, if not

avoided, could result in death or serious injury.

! CAUTION

CAUTION indicates a hazardous situation which, if not

avoided, could result in minor or moderate injury.

"

NOTICE

NOTICE indicates information considered important, but

not hazard-related (e.g., messages relating to property

damage).

CPE TECHNICAL SUPPORT TEAM

1-877-338-0999

MODEL NUMBER

100592

SERIAL NUMBER

DATE OF PURCHASE

PURCHASE LOCATION

3

Page 4

100592 - 6250W DUAL FUEL GENERATOR

IMPORTANT SAFETY INSTRUCTIONS

IMPORTANT SAFETY INSTRUCTIONS

! WARNING

Cancer and Reproductive Harm – www.P65Warnings.ca.gov

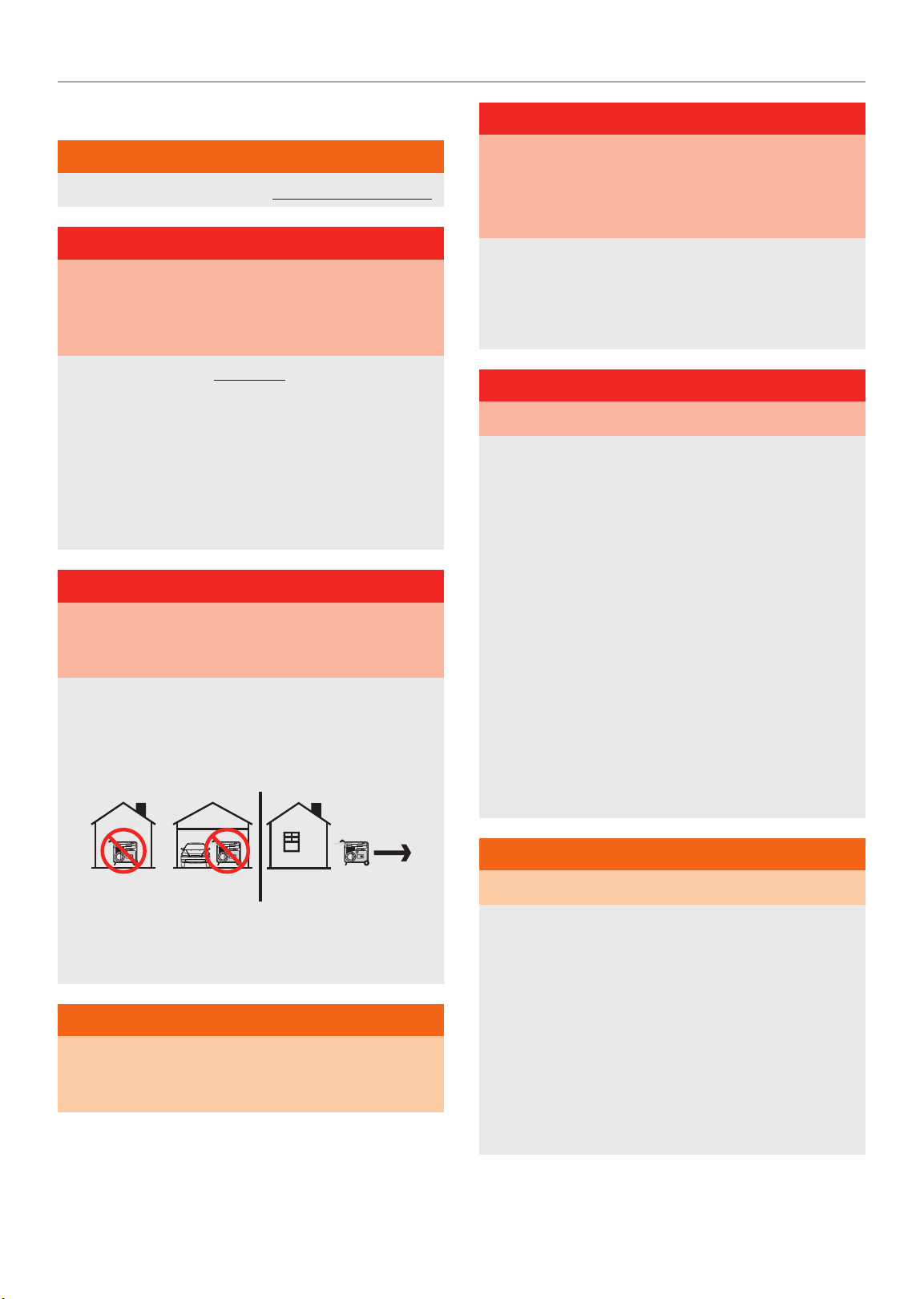

! DANGER

Generator exhaust contains carbon monoxide, a colorless,

odorless, poisonous gas. Breathing carbon monoxide will

cause nausea, dizziness, fainting or death. If you start to

feel dizzy or weak, get to fresh air immediately.

OPERATE GENERATOR OUTDOORS ONLY IN A WELL

VENTILATED AREA AND POINT EXHAUST AWAY.

DO NOT operate the generator inside any building, including

garages, basements, crawlspaces and sheds, enclosure or

compartment, including the generator compartment of a

recreational vehicle.

DO NOT allow exhaust fumes to enter a confined area

through windows, doors, vents or other openings.

! DANGER

Using a generator indoors CAN KILL YOU IN MINUTES.

Generator exhaust contains carbon monoxide. This is a

poison you cannot see or smell.

NEVER use inside a home or garage, EVEN IF doors and

windows are open.

ONLY use OUTSIDE and far away from windows, doors,

and vents.

! DANGER

Operate equipment with guards in place.

Rotating parts can entangle hands, feet, hair, clothing and/

or accessories. Traumatic amputation or severe laceration

can result.

Keep hands and feet away from rotating parts.

Tie up long hair and remove jewelry.

DO NOT wear loose-fitting clothing, dangling drawstrings or

items that could become caught.

! DANGER

Generator produces powerful voltage.

DO NOT touch bare wires or receptacles.

DO NOT use electrical cords that are worn, damaged or

frayed. Use only Champion electrical cords for proper

application.

DO NOT operate generator in wet weather.

DO NOT allow children or unqualified persons to operate or

service the generator.

Use a ground fault circuit interrupter (GFCI) in damp areas

and areas containing conductive material such as metal

decking.

Connection to your home’s electrical system requires a

listed 30A transfer switch installed by a licensed electrician

and approved by the local authority having jurisdiction. The

connection must isolate the generator from the utility power

and must comply with all applicable laws and electrical

codes.

Install battery-operated carbon monoxide alarms or plug-in

carbon monoxide alarms with battery back-up according to

the manufacturer’s instructions.

! WARNING

Although the generator contains a spark arrester, maintain

a minimum distance of 5 ft. (1.5 m) from dry vegetation to

prevent fires.

! WARNING

Do not use generator for medical and life support uses.

In case of emergency, call 911 immediately.

NEVER use this product to power life support devices or life

support appliances.

NEVER use this product to power medical devices or

medical appliances.

Inform your electricity provider immediately if you or anyone

in your household depends on electrical equipment to live.

Inform your electrical provider immediately if a loss of power

would cause you or anyone in your household to experience

a medical emergency.

4

Page 5

100592 - 6250W DUAL FUEL GENERATOR

IMPORTANT SAFETY INSTRUCTIONS

! WARNING

Spark from removed spark plug wire can result in fire or

electrical shock.

When servicing the generator:

Disconnect the spark plug wire and place it where it cannot

contact the plug or any other metal object.

DO NOT check for spark with the plug removed.

Use only approved spark plug testers.

! WARNING

Running engines produce heat. Severe burns can occur on

contact. Combustible material can catch fire on contact.

DO NOT touch hot surfaces.

Avoid contact with hot exhaust gases.

Allow equipment to cool before touching.

Maintain at least 3 ft. (91.4 cm) of clearance on all sides to

ensure adequate cooling.

Maintain at least 5 ft. (1.5 m) of clearance from combustible

materials.

! CAUTION

Start the generator and allow the engine to stabilize before

connecting electrical loads.

Connect electrical equipment in the off position, and then

turn them on for operation.

Turn electrical equipment off and disconnect before

stopping the generator.

! CAUTION

Improper treatment or use of the generator can damage it,

shorten its life or void the warranty.

Use the generator only for intended uses.

Operate only on level surfaces.

DO NOT expose generator to excessive moisture, dust,

or dirt.

DO NOT allow any material to block the cooling slots.

If connected devices overheat, turn them off and disconnect

them from the generator.

DO NOT use the generator if:

– Electrical output is lost

! WARNING

Rapid retraction of the starter cord will pull hand and arm

towards the engine faster than you can let go. Unintentional

startup can result in entanglement, traumatic amputation or

laceration. Broken bones, fractures, bruises or sprains could

result.

When starting engine, pull the starter cord slowly until

resistance is felt and then pull rapidly to avoid kickback.

DO NOT start or stop the engine with electrical devices

plugged in and turned on.

! CAUTION

Exceeding the generator’s running capacity can damage the

generator and/or electrical devices connected to it.

DO NOT overload the generator.

DO NOT tamper with the governed speed.

DO NOT modify the generator in any way.

– Equipment sparks, smokes or emits flames

– Equipment vibrates excessively

! WARNING

Tamper ing with CO Shield™ could result in a hazardous

condition. Removing the CO Shield module will not allow the

generator to start.

5

Page 6

100592 - 6250W DUAL FUEL GENERATOR

IMPORTANT SAFETY INSTRUCTIONS

Fuel Safety

! DANGER

GASOLINE, GASOLINE VAPORS AND PROPANE (LPG) ARE

HIGHLY FLAMMABLE AND EXPLOSIVE.

Fire or explosion can cause severe burns or death.

Gasoline and gasoline vapors:

– Gasoline is highly flammable and explosive.

– Gasoline can cause a fire or explosion if ignited.

– Gasoline is a liquid fuel but it’s vapors can ignite.

– Gasoline is a skin irritant and needs to be cleaned up

immediately if spilled on skin or clothes.

– Gasoline has a distinctive odor, this will help detect potential

leaks quickly.

– In any petroleum gas fire, flames should not be extinguished

unless by doing so the fuel supply valve can be turned OFF.

This is because if a fire is extinguished and a supply of

fuel is not turned OFF, then an explosion hazard could be

created.

– Gasoline expands or contracts with ambient temperatures.

Never fill the gasoline tank to full capacity, as gasoline

needs room to expand if temperatures rise.

LPG:

– LPG is highly flammable and explosive.

– LPG is under pressure and can cause a fire or explosion if

ignited.

– LPG is heavier than air and can settle in low places while

dissipating.

– LPG has a distinctive odor added to help detect potential

leaks quickly.

– In any petroleum gas fire, flames should not be extinguished

unless the fuel supply valve is turned OFF. This is because if

a fire is extinguished and a supply of fuel is not turned OFF,

then an explosion hazard could be created.

– When exchanging LPG cylinders, be sure the cylinder valve

is of the same type.

– Always keep the LPG cylinder in an upright position.

– LPG will burn skin if it comes in contact with it. Keep any

and all LPG away from skin at all times.

When adding or removing gasoline:

DO NOT light or smoke cigarettes.

Turn the generator off and let it cool for at least two minutes

before removing the gasoline cap. Loosen the cap slowly to

relieve pressure in the tank.

Only fill or drain gasoline outdoors in a well-ventilated area.

DO NOT pump gasoline directly into the generator at the gas

station. Use an approved container to transfer the fuel to the

generator.

DO NOT overfill the gasoline tank.

Always keep gasoline away from sparks, open flames, pilot

lights, heat and other sources of ignition.

When starting the generator:

DO NOT attempt to start a damaged generator.

Make certain that the gasoline cap, air filter, spark plug, fuel

lines and exhaust system are properly in place.

Allow spilled gasoline to evaporate fully before attempting to

start the engine.

Make certain that the generator is resting firmly on level

ground.

When operating the generator:

DO NOT move or tip the generator during operation.

DO NOT tip the generator or allow fuel or oil to spill.

When transporting or servicing the generator:

Make certain that the fuel valve is in the OFF position and the

gasoline tank is empty.

For LPG compatible models, be sure that the LPG cylinder is

disconnected and stored securely away from the generator.

Disconnect the spark plug wire.

When storing the generator:

Store away from sparks, open flames, pilot lights, heat and

other sources of ignition.

Do not store generator, gasoline or LPG cylinders near furnaces,

water heaters, or any other appliances that produce heat or

have automatic ignitions.

! WARNING

Never use a gasoline container, gasoline tank, LPG

connector hose, LPG cylinder or any other fuel item that is

broken, cut, torn or damaged.

6

Page 7

100592 - 6250W DUAL FUEL GENERATOR

IMPORTANT SAFETY INSTRUCTIONS

7

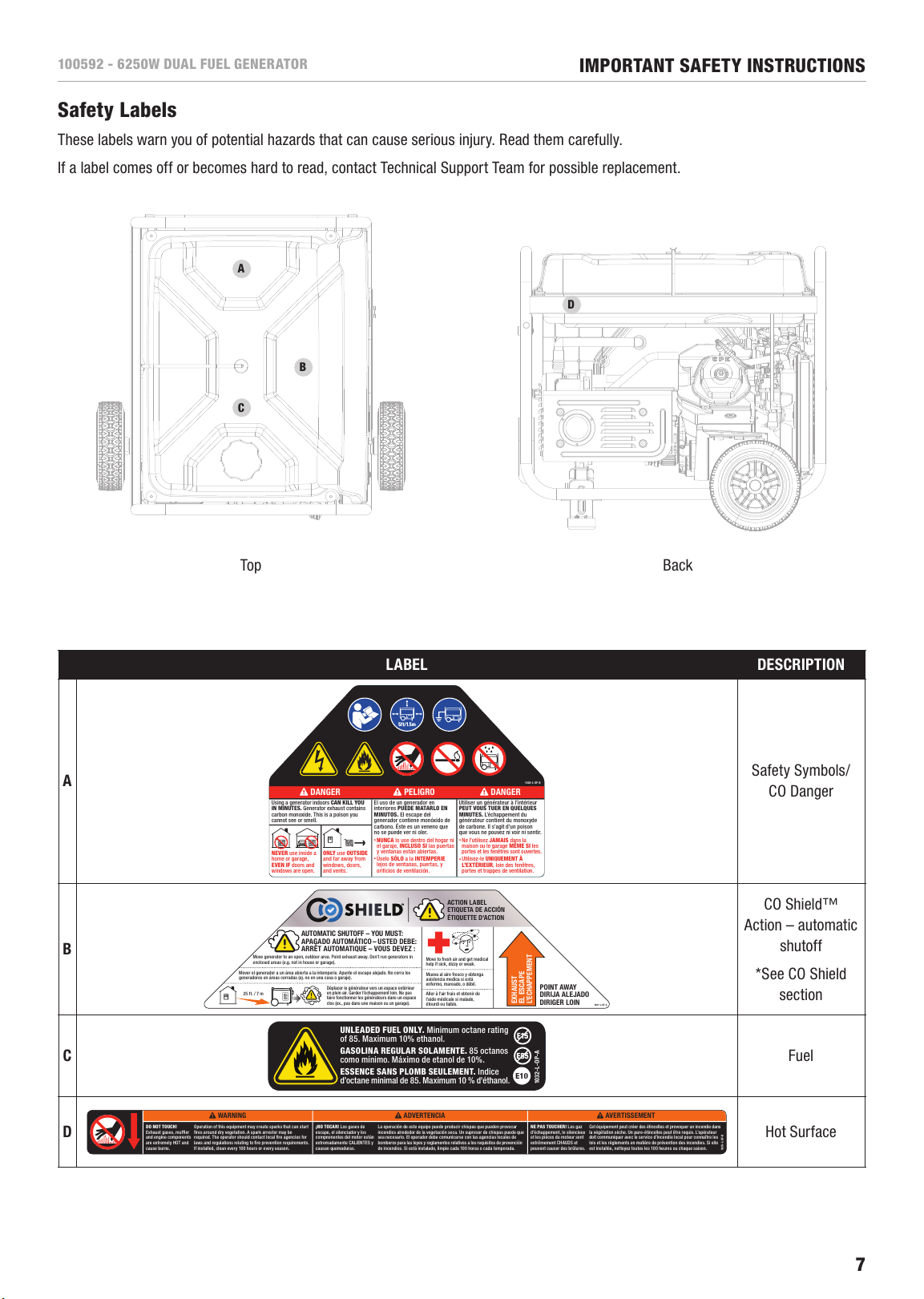

Top

A

C

B

Safety Labels

These labels warn you of potential hazards that can cause serious injury. Read them carefully.

If a label comes off or becomes hard to read, contact Technical Support Team for possible replacement.

Back

D

LABEL DESCRIPTION

A

! PELIGRO

El uso de un generador en

interiores PUEDE MATARLO EN

MINUTOS. El escape del

generador contiene monóxido de

carbono. Éste es un veneno que

no se puede ver ni oler.

•

NUNCA lo use dentro del hogar ni

el garaje, INCLUSO SI las puertas

y ventanas están abiertas .

•

Úselo SÓLO a la INTEMPERIE

lejos de ventanas, puertas, y

orificios de ventilación.

! DANGER

Utiliser un générateur à l’intérieur

PEUT VOUS TUER EN QUELQUES

MINUTES. L’échappement du

générateur contient du monoxyde

de carbone. Il s’agit d’un poison

que vous ne pouvez ni voir ni sentir.

•

Ne l’utilisez JAMAIS dans la

maison ou le garage MÊME SI les

portes et les fenêtres sont ouvertes.

•

Utilisez-le UNIQUEMENT À

L’EXTÉRIEUR, loin des fenêtres,

portes et trappes de ventilation.

ONLY use OUTSIDE

and far away from

windows, doors,

and vents.

NEVER use inside a

home or garage,

EVEN IF doors and

windows are open.

! DANGER

Using a generator indoors CAN KILL YOU

IN MINUTES. Generator exhaust contains

carbon monoxide. This is a poison you

cannot see or smell.

1028-L-SF-B

Safety Symbols/

CO Danger

B

1607-L-SF-A

25 ft. / 7 m

AUTOMATIC SHUTOFF – YOU MUST:

APAGADO AUTOMÁTICO– USTED DEBE:

ARRÊT AUTOMATIQUE– VOUS DEVEZ :

Move generator to an open, outdoor area. Point exhaust away. Don’t run generators in

enclosed areas (e.g. not in house or garage).

Mover el generador a un área abierta a la intemperie. Apunte el escape alejado. No corra los

generadores en áreas cerradas (ej. no en una casa o garaje).

Déplacer le générateur vers un espace extérieur

en plein air. Garder l’échappement loin. Ne pas

faire fonctionner les générateurs dans un espace

clos (ex., pas dans une maison ou un garage).

ACTION LABEL

ETIQUETA DE ACCIÓN

ÉTIQUETTE D'ACTION

EXHAUST

EL ESCAPE

L’E C H A P P E M E N T

POINT AWAY

DIRIJA ALEJADO

DIRIGER LOIN

Move to fresh air and get medical

help if sick, dizzy or weak.

Mueva al aire fresco y obtenga

asistencia medica si está

enfermo, mareado, o débil.

Aller à l'air frais et obtenir de

l'aide médicale si malade,

étourdi ou faible.

CO Shield™

Action – automatic

shutoff

*See CO Shield

section

C

UNLEA DED FUEL ONLY. Minimum oct ane rating

of 85. Ma ximum 10% ethanol.

GASOL INA REGU LAR SOLAMEN TE. 85 octanos

como mínimo . Máximo de etanol d e 10%.

ESSENC E SANS PLOMB SEULEMENT. Indice

d’octane minimal de 85. Maximum 10 % d'éthanol.

1032-L- OP-A

Fuel

D

! WARNING

DO NOT TOUCH!

Exhaust gases, muffler

and engine components

are extremely HOT and

cause burns.

Operation of this equipment may create sparks that can start

fires around dry vegetation. A spark arrestor may be

required. The operator should contact local fire agencies for

laws and regulations relating to fire prevention requirements.

If installed, clean every 100 hours or every season.

! ADVERTENCIA

¡NO TOCAR! Los gas es de

escape, el silenciador y los

compnonentes del motor están

extremadamente CALIENTES y

causan quemaduras.

La operación de este equipo puede producir chispas que pueden provocar

incendios alrededor de la vegetación seca. Un supresor de chispas puede que

sea necesario. El operador debe comunicarse con las agencias locales de

bomberos para las leyes y reglamentos relativos a los requisitos de prevención

de incendios. Si está instalado, limpie cada 100 horas o cada temporada.

! AVERTISSEMENT

NE PAS TOUCHER! Les gaz

d’échappement, le silencieux

et les pièces du moteur sont

extrêmement CHAU DS et

peuvent causer des brûlures.

Cet équipement peut créer des étincelles et provoquer un incendie dans

la végétation sèche. Un pare-étincelles peut être requis. L’opérateur

doit communiquer avec le service d’incendie local pour connaître les

lois et les règlements en matière de prévention des incendies. Si elle

est installée, nettoyez toutes les 100 heures ou chaque saison.

1035-L-SF- B

Hot Surface

Page 8

100592 - 6250W DUAL FUEL GENERATOR

IMPORTANT SAFETY INSTRUCTIONS

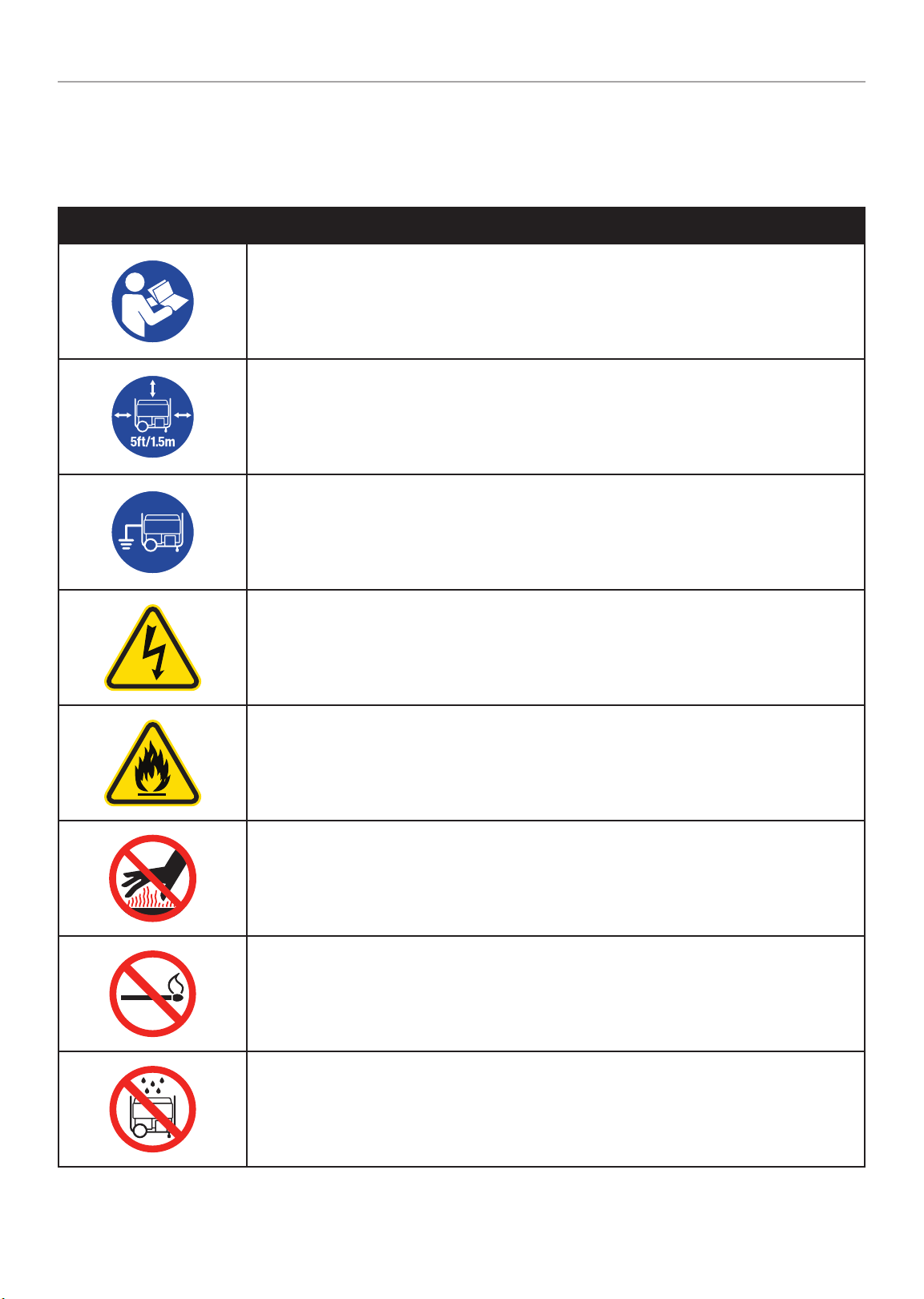

Safety Symbols

Some of the following symbols may be used on this product. Please study them and learn their meaning. Proper interpretation of

these symbols will allow you to more safely operate the product.

SYMBOL MEANING

Read Operator’s Manual. To reduce the risk of injury, user must read and understand operator’s

manual before using this product.

Clearance. Keep all objects at least 5 feet (1.5m) from generator. Heat from the muffler and exhaust

gas can ignite combustible objects.

Ground. Consult with local electrician to determine grounding requirements before operation.

Electric Shock. Failure to use in dry conditions and to observe safe practices can result in electric

shock. Improper connections to a building can allow current to backfeed into utility lines, creating an

electrocution hazard. A transfer switch must be used when connecting to a building.

Fire/Explosion. Fuel and its vapors are extremely flammable and explosive. Fire or explosion

can cause severe burns or death. Keep generator at least 5 feet (1.5m) from all objects to prevent

combustion.

Hot Surface. To reduce the risk of injury or damage, avoid contact with any hot surface.

Open Flame Alert. Fuel and its vapors are extremely flammable and explosive. Keep fuel away from

smoking, open flames, sparks, pilot lights, heat, and other ignition sources.

Wet Conditions Alert. Do not expose to rain or use in damp locations.

8

Page 9

100592 - 6250W DUAL FUEL GENERATOR

IMPORTANT SAFETY INSTRUCTIONS

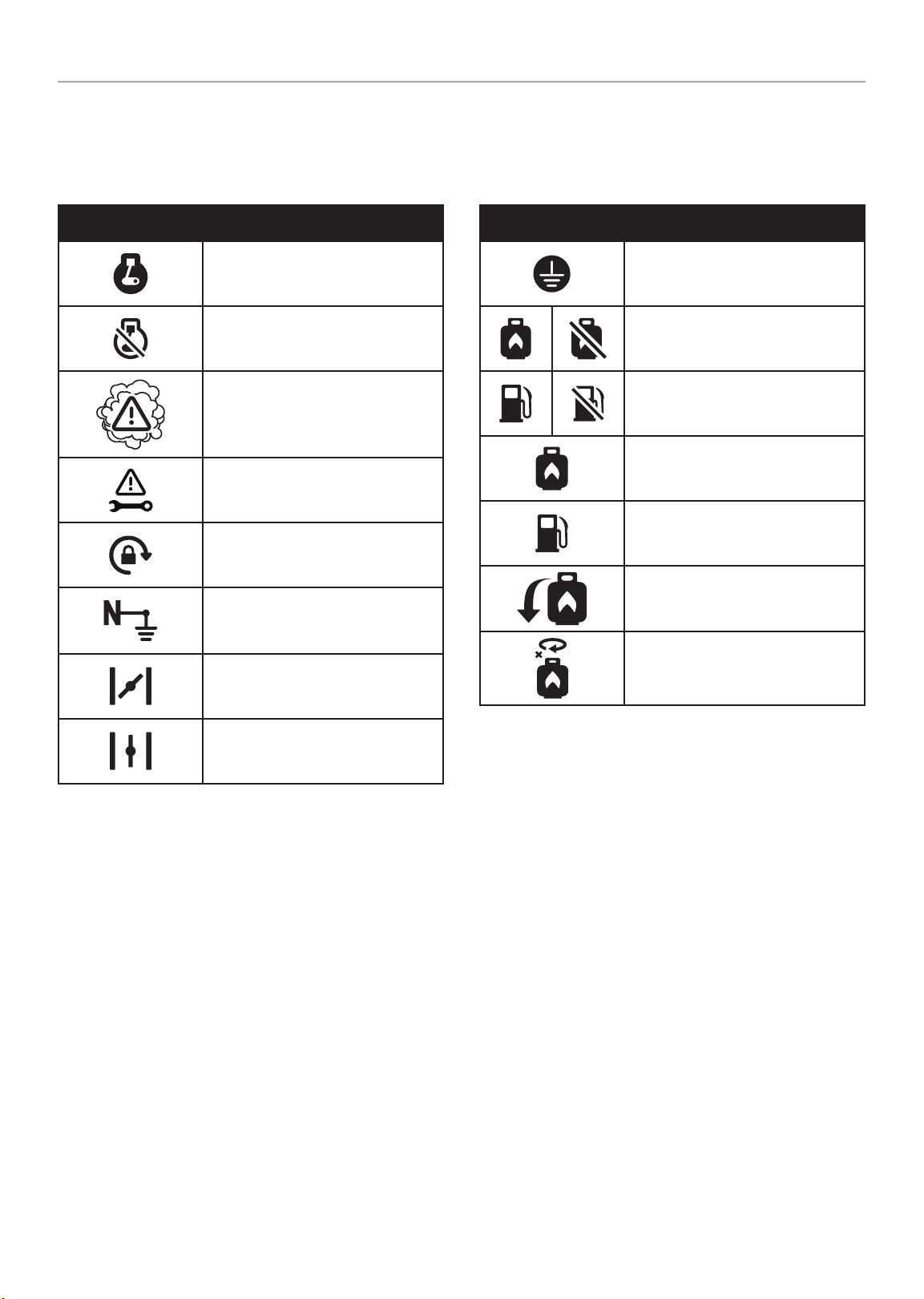

Operation Symbols

Some of the following symbols may be used on this product. Please study them and learn their meaning. Proper interpretation of

these symbols will allow you to more safely operate the product.

SYMBOL MEANING

ON

STOP or OFF

High CO Warning. Move generator to

an open, outdoor area. Move to fresh

air and get medical help if sick, dizzy

or weak.

System Fault. Electrical issue,

tampering, end of life.

Locking Receptacle

Neutral Bonded to Frame. Neutral

circuit IS electrically connected to the

frame/ground of the generator.

Choke

SYMBOL MEANING

Ground Terminal

Propane Valve ON/OFF

Fuel/Gasoline Valve ON/OFF

Propane Operation

Gasoline Operation

Propane Inlet

Propane Fuel Source. Turn off fuel

source when generator is not in use.

Run

9

Page 10

100592 - 6250W DUAL FUEL GENERATOR

1604-L-OP -A

!

10W-30

"

1 4

5 6 7 8 1 3

2A

2B

3A

2A

2B

3B

b

c

"

+

+

+

+

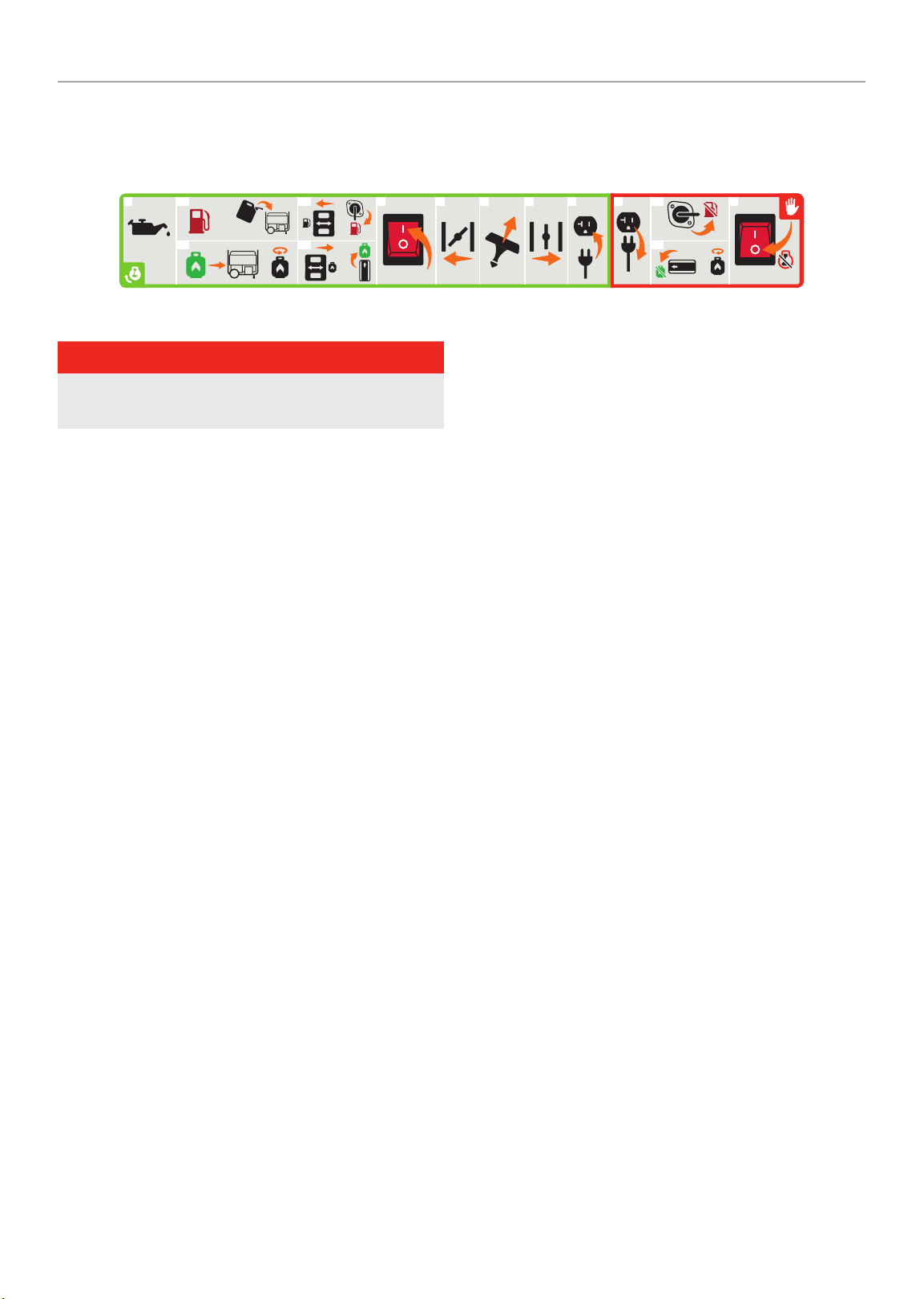

IMPORTANT SAFETY INSTRUCTIONS

Quickstart Label Symbols

Some of the following symbols may be used on this product. Please study them and learn their meaning. Proper interpretation of

these symbols will allow you to more safely operate the product.

Starting the Engine

! DANGER

Move generator outside and far away from windows,

doors and intake ventilation covers.

1. Check oil level.

Recommended oil is 10W-30.

2. Add fuel.

2a. If operating on gasoline, check gasoline level.

When adding gasoline, use a minimum octane rating of

85 and an ethanol content of 10% or less by volume.

2b. If operating on propane, connect propane tank.

Open valve on propane tank.

3. Fuel Selector

3a. Slide Fuel Selector to the left for gasoline operation.

Then turn the fuel valve to the “ON” position.

3b. Slide Fuel Selector to the right for LPG operation. Then

turn the fuel valve to the “ON” position.

4. Press engine switch to the “ON” position.

Stopping the Engine

1. Tur n of f a nd unplug a ll conn ected elec tric al loads .

2. Fuel Valve

2a. If operating on gasoline, turn the fuel valve to the

“OFF” position.

2b. If operating on LPG, turn the fuel valve to the “OFF”

position on the generator and on the tank.

3. Press the engine switch to the “OFF” position.

5. Move choke lever to “CHOKE” position.

6. Pull the recoil starter.

7. Move the choke lever to “RUN” position.

8. Plug in desired device.

10

Page 11

100592 - 6250W DUAL FUEL GENERATOR

CONTROLS AND FEATURES

11

CONTROLS AND FEATURES

Read this operator’s manual before operating your generator. Familiarize yourself with the location and function of the controls and

features. Save this manual for future reference.

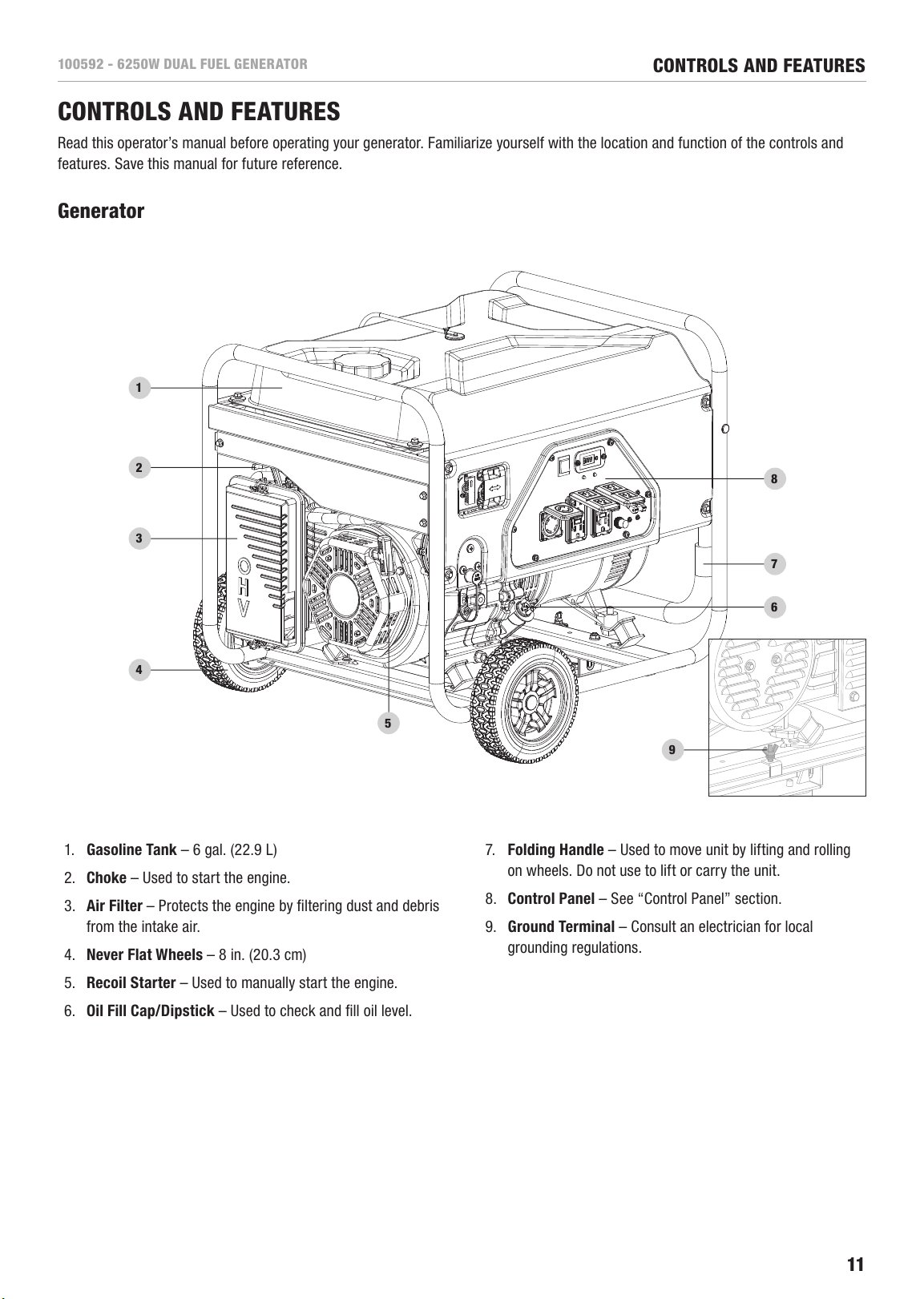

Generator

1. Gasoline Tank – 6 gal. (22.9 L)

2. Choke – Used to start the engine.

3. Air Filter – Protects the engine by filtering dust and debris

from the intake air.

4. Never Flat Wheels – 8 in. (20.3 cm)

5. Recoil Starter – Used to manually start the engine.

6. Oil Fill Cap/Dipstick – Used to check and fill oil level.

7. Folding Handle – Used to move unit by lifting and rolling

on wheels. Do not use to lift or carry the unit.

8. Control Panel – See “Control Panel” section.

9. Ground Terminal – Consult an electrician for local

grounding regulations.

1

3

2

4

5

6

8

7

9

Page 12

100592 - 6250W DUAL FUEL GENERATOR

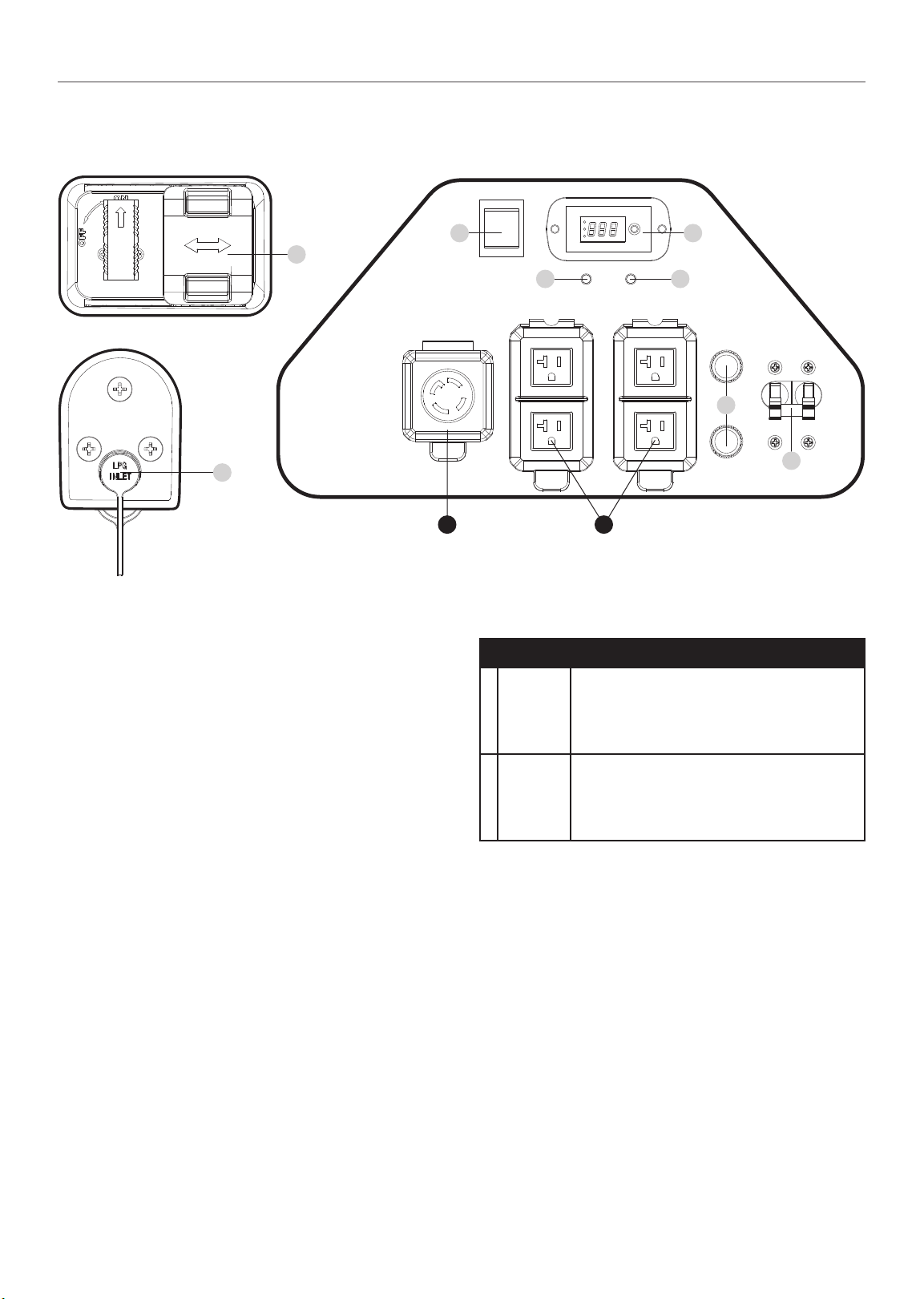

Control Panel

CONTROLS AND FEATURES

1

2

1. Fuel Selector – Used to select and turn on gasoline or

propane (LPG) fuel source.

2. LPG Inlet – Used to connect LPG fuel source to generator.

3. Engine Switch – Used to put in START mode or STOP the

generator. When operating by propane, this switch will NOT

stop the engine.

4. Intelligauge – Three mode digital meter for displaying

total run time, voltage and hertz.

5. CO Shield red shutoff LED

3

5

A

A

Y

B

C

B

RECEPTACLES

120/240V AC, 30A Locking (NEMA L14-30R)

May be used to supply electrical power for

operation of 120/240 Volt AC, 30 Amp, single

phase, 60 Hz electrical loads.

(4×) 120V AC, 20A GFCI (NEMA 5-20R)

May be used to supply electrical power for

operation of 120 Volt AC, 20 Amp, single

phase, 60 Hz electrical loads.

4

6

7

8

6. CO Shield yellow service LED

The CO Shield technology monitors for accumulation of

poisonous carbon monoxide (CO) gas produced by engine

exhaust when the generator is running. If CO Shield detects

elevated levels of CO gas, it automatically shuts off the engine.

* *See CO Shield section for more information

7. Circuit Breakers (Push Reset) – Protects the generator

against electrical overloads.

8. Circuit Breakers (Flip Reset) – Protects the generator

against electrical overloads.

12

Page 13

100592 - 6250W DUAL FUEL GENERATOR

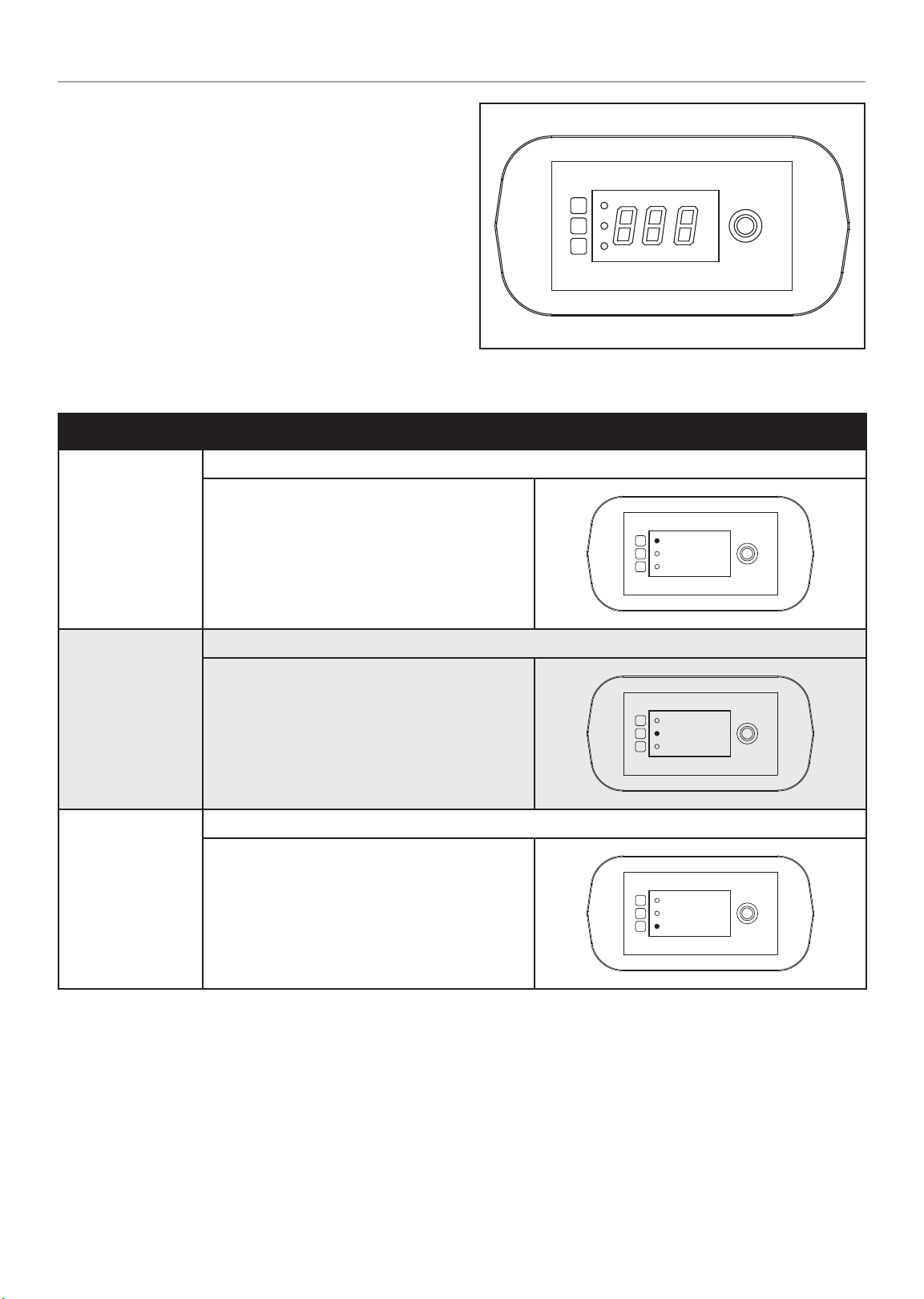

Intelligauge

Three mode digital meter for displaying voltage, hertz, and total

run time.

Push SELECT button on right side of gauge to display different

modes.

MODE DESCRIPTION

CONTROLS AND FEATURES

V

Hz

H

Output voltage of the generator.

Voltage (V)

Frequency (Hz)

Tot al Run Time(H)

Example: 120 volts

Example: 60.0 hertz

Example: 80 hours

V

Hz

120

H

Output frequency in hertz.

V

Hz

60.0

H

Tot al run time o f the generato r since first operatio n.

V

Hz

80.0

H

13

Page 14

100592 - 6250W DUAL FUEL GENERATOR

Parts Included

Accessories

Oil Funnel ..............................................................................1

3.3 ft. (1 m) LPG Hose with Regulator .................................... 1

Assembly Parts

Wheels

8 in. (20.3 cm) Never Flat Wheel (A) .................................. 2

Roll Pin (B)........................................................................2

Large R-clip (C) ................................................................2

Engine Vibration Mounts

Support Leg with Vibration Mounts (D) ..............................1

Flange Bolt (M8×16) (E) ....................................................2

Flange Lock Nut (M8) (F) ..................................................2

Tools Needed

– Pliers

CONTROLS AND FEATURES

A

B C

– Metric wrench or socket set

D

E F

14

Page 15

100592 - 6250W DUAL FUEL GENERATOR

ASSEMBLY

15

ASSEMBLY

Your generator requires some assembly. This unit ships from

our factory without oil. It must be properly serviced with fuel

and oil before operation.

If you have any questions regarding the assembly of your

generator, call our Technical Support Team at 1-877-338-0999.

Please have your serial number and model number available.

Unpacking

1. Set the shipping carton on a solid, flat surface.

2. Remove everything from the carton except the generator.

3. Carefully cut each corner of the box from top to bottom.

Fold each side flat on the ground to provide a surface area

to work with the generator.

Install the Wheel Kit

! CAUTION

The wheel kit is not intended for over-the-road use.

Install the Wheels

1. Slide the roll pin (A) through the wheel (B) from the outside.

2. Slide the roll pin through the mount point on the frame.

3. Secure with the R-clip (C).

4. Repeat to attach the second wheel.

A

B

C

Install the Support Leg

1. Attach the support leg (D) to the generator frame with

flange bolts (E) and flange lock nuts (F).

2. Slowly tip the generator back down so that it rests on the

wheels and support leg.

F

E

D

Add Engine Oil

! CAUTION

DO NOT attempt to crank or start the engine before it has

been properly filled with the recommended type and amount

of oil. Damage to the generator as a result of failing to follow

these instructions will void your warranty.

"

NOTICE

The generator rotor has a sealed, pre-lubricated ball bearing

that requires no additional lubrication for the life of the bearing.

"

NOTICE

The recommended oil type for typical use is 10W-30

automotive oil.

If running generator in extreme temperatures, refer to the

following chart for recommended oil type.

-20 0 20 40 60

Ambient temperature

Recommended Engine Oil Type

80 100 120

-28.9

°F

°C -17.8 -6.7 4.4 15.6 26.7 37.8 48.9

10W-30

5W-30 Synthetic

10W-405W-30

1. Place the generator on a flat, level surface.

2. Remove oil fill cap/dipstick to add oil.

Page 16

100592 - 6250W DUAL FUEL GENERATOR

ASSEMBLY

3. Using a funnel, add up to 37.2 fl. oz. (1.2 qt.) of oil

(not included) and replace oil fill cap/dipstick.

DO NOT OVERFILL.

4. Check engine oil level at every use and add as needed.

MAX

MIN

OIL DIP STICK

"

NOTICE

Synthetic oil may be used after the 5 hour initial break-in

period. Using synthetic oil does not increase the

recommended oil change interval. Full synthetic 5W-30

oil will aid in starting in cold ambient < 41º F (5º C)

temperatures.

Add Fuel: Gasoline

Use clean, fresh, regular unleaded gasoline with a minimum

octane rating of 85 and an ethanol content of 10% or less by

volume. ybc

DO NOT mix oil with gasoline.

1. Remove the gasoline cap.

2. Slowly add gasoline to the tank. Tank is full when gasoline

reaches red circle on screen. DO NOT OVERFILL. Gasoline

can expand after filling. A minimum of ¼ in. (6.4 mm) of

space left in the tank is required for gasoline expansion,

although more than ¼ in. (6.4 mm) is recommended.

Gasoline can be forced out of the tank as a result of

expansion if overfilled, and can affect the stable running

condition of the generator.

"

NOTICE

Once oil has been added, a visual check should show oil

about 1-2 threads from running out of the fill hole.

When using the dipstick to check oil level, DO NOT screw in

the dipstick while checking.

"

NOTICE

Check oil level often during the break-in period. Refer to the

Maintenance section for recommended service intervals.

! CAUTION

This engine is equipped with a low oil shut-off and will stop

when the oil level in the crankcase falls below the threshold

level.

"

NOTICE

The first 5 hours of run time are the break-in period for the

unit. During the break in period stay at or below 50% of the

running watt rating and vary the load occasionally to allow

stator windings to heat and cool. Adjusting the load will also

cause engine speed to vary slightly and help seat piston

rings. After the 5 hour break-in period, change the oil.

3. Screw on the gasoline cap and wipe away any spilled fuel.

! CAUTION

Use unleaded gasoline with a minimum octane rating of 85

and an ethanol content of 10% or less by volume.

DO NOT light cigarettes or smoke when filling the tank.

DO NOT mix oil and gasoline.

DO NOT overfill the tank. Fill tank to approximately ¼ in.

(6.4 mm) below the top of the tank to allow for gasoline

expansion.

DO NOT pump gasoline directly into the generator at the

pump. Use an approved container to transfer the gasoline to

the generator.

DO NOT fill tank indoors.

DO NOT fill tank when the engine is running or hot.

16

Page 17

100592 - 6250W DUAL FUEL GENERATOR

ASSEMBLY

! WARNING

Pouring gasoline too fast through the fuel screen may result

in gasoline splashing over the generator and operator while

filling.

"

NOTICE

The generator engine works well with 10% or less ethanol

blend gasoline. When using ethanol-gasoline blends there

are some issues worth noting:

– Ethanol-gasoline blends can absorb more water than

gasoline alone.

– These blends can eventually separate, leaving water or

a watery goo in the tank, fuel valve and carburetor. The

compromised gasoline can be drawn into the carburetor

and cause damage to the engine and/or potential

hazards.

– If a fuel stabilizer is used, confirm that it is formulated to

work with ethanol-gasoline blends.

– Any damages or hazards caused by using improper

gasoline, improperly stored gasoline, and/or

improperly formulated stabilizers, are not covered by

manufacturer’s warranty.

It is advisable to always shut off the gasoline supply and

run the engine to starvation after each use. See Storage

instructions for extended non-use.

3. Remove the safety plug or cap from the cylinder valve.

4. Attach the other end of the hose to the LPG connector on

the cylinder and hand tighten.

5. Check all connections for leaks by wetting the fittings with

a solution of soap and water. Bubbles which appear or

bubbles which grow indicate that a leak exists. If a leak

exists at a fitting then turn off the valve on the cylinder

and tighten the fitting. Turn the valve back on and recheck

the fitting with the soap and water solution. If the leak

continues or if the leak is not at a fitting then do not use

the generator and contact customer service.

"

NOTICE

– The LPG hose included with this unit connects to 20, 30,

and 40 pound LPG cylinders.

– Verify the requalification date on the cylinder has not

expired.

Add Fuel: Propane (LPG)

Connecting an LPG cylinder

1. Make sure the LPG valve on the generator is in the “OFF”

position.

2. Attach the LPG hose (included) to the LPG inlet on the

generator and tighten with a 19 mm or adjustable wrench

to torque specified on hose label.

Important: DO NOT use thread seal tape or any other type

of sealant to seal LPG hose connection.

– All new cylinders must be purged of air and moisture

prior to filling. Used cylinders that have not been plugged

or kept closed must also be purged.

– The purging process should be done by an LPG supplier

(cylinders from an exchange supplier should have been

purged and filled properly already).

– Always position the cylinder so the connection between

the cylinder valve and generator inlet won’t cause sharp

bends or kinks in the LPG hose.

! CAUTION

Do not allow children to tamper or play with the LPG cylinder

or hose connections.

17

Page 18

100592 - 6250W DUAL FUEL GENERATOR

1607-L-SF-A

25 ft. / 7 m

AUTOMATIC SHUTOFF – YOU MUST:

APAGADO AUTOMÁTICO– USTED DEBE:

ARRÊT AUTOMATIQUE– VOUS DEVEZ :

Move generator to an open, outdoor area. Point exhaust away. Don’t run generators in

enclosed areas (e.g. not in house or garage).

Mover el generador a un área abierta a la intemperie. Apunte el escape alejado. No corra los

generadores en áreas cerradas (ej. no en una casa o garaje).

Déplacer le générateur vers un espace extérieur

en plein air. Garder l’échappement loin. Ne pas

faire fonctionner les générateurs dans un espace

clos (ex., pas dans une maison ou un garage).

ACTION LABEL

ETIQUETA DE ACCIÓN

ÉTIQUETTE D'ACTION

EXHAUST

EL ESCAPE

L’E C H A P P E M E N T

POINT AWAY

DIRIJA ALEJADO

DIRIGER LOIN

Move to fresh air and get medical

help if sick, dizzy or weak.

Mueva al aire fresco y obtenga

asistencia medica si está

enfermo, mareado, o débil.

Aller à l'air frais et obtenir de

l'aide médicale si malade,

étourdi ou faible.

OPERATION

! CAUTION

Use approved LPG cylinders equipped with an OPD

(overfilling prevention device) valve. Always keep the

cylinder in a vertical position with the valve on top and

installed at ground level on a flat surface. Cylinders must

not be installed near any heat source and should not be

exposed to sun, rain, and dust. When transporting and

storing, turn off the cylinder valve and generator LPG valve,

and disconnect the cylinder. Plug the outlet, usually by a

plastic protective cap, if one is available. Keep cylinders

away from heat and ventilated when in a vehicle.

! WARNING

If there is a strong smell of LPG: Close valve on the cylinder.

Check all connections for leaks by wetting the fittings

with a solution of soap and water. Bubbles which appear

or bubbles which grow indicate that a leak exists. Do not

smoke or light a cigarette, or check for leaks using a match,

open flame source or lighter. Contact a qualified technician

to inspect and repair an LPG system if a leak is found,

before using the generator.

Neutral Bonded to Frame*

– Neutral circuit IS electrically connected to the frame/ground

of the generator.

– The generator system ground connects lower frame

cross-member below the alternator. The system ground is

connected to the AC neutral wire.

* See your Specifications section for specified type of grounding.

OPERATION

CO Shield™ - Carbon Monoxide (CO)

Detection and Auto-shutoff System

The CO Shield™ technology monitors the accumulation of

poisonous CO gas produced by engine exhaust when the

generator is running. If CO Shield detects elevated levels of

CO gas, it automatically shuts off the engine. Generators are

intended to be used outdoors, far away from occupied buildings

and exhaust pointed away from people and buildings.

Grounding

Your generator must be properly connected to an appropriate

ground to help prevent electric shock.

! WARNING

Failure to properly ground the generator can result in

electric shock.

A ground terminal connected to the frame of the generator has

been provided (see Controls and Features for terminal location).

For remote grounding, connect of a length of heavy gauge

(12 AWG minimum) copper wire between the generator ground

terminal and a copper rod driven into the ground. We strongly

recommend that you consult with a qualified electrician to

ensure compliance with local electrical codes.

Neutral Floating*

– Neutral circuit IS NOT electrically connected to the frame/

ground of the generator.

– The generator (stator winding) is isolated from the frame

and from the AC receptacle ground pin.

– Electrical devices that require a grounded receptacle pin

connection will not function if the receptacle ground pin is

not functional.

25 ft. / 7 m

If misused and operated in a location that results in the

accumulation of CO inside an enclosed or partially enclosed

space, for example a house, garage or a garage with the

door partially open, CO Shield will automatically shut off the

generator and then illuminate a red LED. Read the action label

for what steps to take. CO Shield is not a substitute for an

indoor carbon monoxide alarm.

When you approach the generator to investigate a shut off, a

blinking red LED light in the CO Shield area provides notification

that the generator shut off due to an accumulating CO hazard.

The red LED light will blink for at least five (5) minutes after a

shutoff event.

18

Page 19

100592 - 6250W DUAL FUEL GENERATOR

OPERATION

AUTOMATIC SHUTOFF SERVICE

AUTOMATIC SHUTOFF

Red LED

Move the generator to an open, outdoor area and point the

exhaust away from people and buildings. Once relocated to

a safe area, the generator can be restarted, and the proper

electrical connections made. Introduce fresh air and ventilate

the location where the generator shut off.

When starting, the red and yellow LED will blink eight (8) times

simultaneously to indicate the LED is working.

"

NOTICE

This blinking does not indicate CO Shield is working, as

CO Shield is working at all times the generator is running.

Also, the LED will not blink (8) times if the generator was

restarted within 1 minute after it was manually shut off.

This does not occur if generator shut off from a high CO

event.

If CO Shield system experiences a fault and no longer provides

protection, the generator is shutoff automatically and the

yellow LED light will blink for at least five (5) minutes to notify

you of the fault.

carbon monoxide has been detected. You must take action

to move and direct the equipment to better dissipate carbon

monoxide far away from people or buildings.

! WARNING

Tamper ing with CO Shield™ could result in a hazardous

condition. Removing the CO Shield module will not allow the

generator to start.

Generator Location

NEVER operate the generator inside any building, including

garages, basements, crawlspaces and sheds, enclosure or

compartment, including the generator compartment of a

recreational vehicle. Please consult your local authority. In

some areas, generators must be registered with the local

utility. Generators used at construction sites may be subject

to additional rules and regulations. Generators should be on

a flat, level surface at all times. (Even while not in operation)

Generators must have at least 5 ft. (1.5 m) of clearance from

all combustible material. In addition to clearance from all

combustible material, generators must also have at least 3 ft.

(91.4 cm) of clearance on all sides to allow for adequate cooling,

maintenance and servicing. Generators should never be started

or operated in the back of a SUV, camper, trailer, in the bed of

a truck (regular, flat or otherwise), under staircases/stairwells,

next to walls or buildings, or in any other location that will not

allow for adequate cooling of the generator and/or the muffler.

DO NOT contain generators during operation. Allow generators

to properly cool before transport or storage.

AUTOMATIC SHUTOFF SERVICE

SERVICE

Yellow LED

Call our Technical Support Team at 1-877-338-0999 for repair.

The generator can be restarted, but will continue to shutoff.

CO Shield will detect the accumulation of carbon monoxide

from other fuel burning sources such as engine powered tools,

or propane heaters used in the area of operation. If another

generator is used and the exhaust is pointed at a CO Shield

equipped generator, the CO Shield may initiate a shutoff due

to rising carbon monoxide levels. This is not a fault. Hazardous

Place the generator in a well-ventilated area. DO NOT place the

generator near vents or intakes where exhaust fumes could

be drawn into occupied or confined spaces. Carefully consider

wind and air currents when positioning generator.

Failure to follow proper safety precautions may void

manufacturer’s warranty.

19

Page 20

100592 - 6250W DUAL FUEL GENERATOR

! WARNING

Do not operate or store the generator in rain, snow, or wet

weather.

Using a generator or electrical appliance in wet conditions,

such as rain or snow, or near a pool or sprinkler system,

or when your hands are wet, could result in electrocution.

OPERATION

! WARNING

During operation the muffler and exhaust fumes will

become hot. If adequate cooling and breathing space are

not supplied, or if the generator is blocked or enclosed,

temperatures can become extremely heated and may lead

to fire.

Surge Protection

Electronic devices, including computers and many

programmable appliances use components that are designed

to operate within a narrow voltage range and may be affected

by momentary voltage fluctuations. While there is no way to

prevent voltage fluctuations, you can take steps to protect

sensitive electronic equipment.

– Install UL1449, CSA-listed, plug-in surge suppressors on the

outlets feeding your sensitive equipment.

Surge suppressors come in single- or multi-outlet styles.

They’re designed to protect against virtually all shortduration voltage fluctuations.

Fuel Selector

The fuel selector on the front panel of the generator is designed

specifically to choose between the fuel source desired, Gasoline

or Propane (LPG).

To select a fuel source simply slide the selector to either the

right or left, and this will uncover the fuel valve of the fuel

selected.

Once a fuel source has been selected, the user must turn the

fuel valve to the vertical position to open the fuel valve.

To turn a fuel valve to the “OFF” position the valve must be in

the horizontal position.

"

NOTICE

The fuel selector is specifically designed not to slide to

either side while a specific fuel has been selected and the

fuel valve is in the “ON” position. Only when the fuel valves

are in the “OFF” position can the cover slide side to side.

"

NOTICE

The fuel selector is locked into place once a “click” sound

is made. Only then can a fuel valve be turned to the vertical

position.

Starting the Engine: Gasoline

1. Make certain the generator is on a flat, level surface.

2. Disconnect all connected electrical loads from the

generator. Never start or stop the generator with electrical

devices plugged in or turned on.

3. Make sure the fuel selector is set to gasoline operation.

4. Tur n t he gasoline fuel va lve to the “ON” position.

For PROPANE, move selector to the right.

For GASOLINE, move selector to the left.

20

Page 21

100592 - 6250W DUAL FUEL GENERATOR

OPERATION

21

5. Push the engine switch to the “ON” position.

6. Move the choke to the “CHOKE” position.

7. For restarting a warm engine, move the choke to 75% of

the “CHOKE” position.

8. Pull the starter cord slowly until resistance is felt and then

pull rapidly.

9. Do not over-choke. As soon as engine starts, move the

choke to the “RUN” position over a 2-5 second duration.

"

NOTICE

Keep choke in “CHOKE” position for only 1 pull of the recoil

starter. After first pull, move choke to “RUN” position for

up to 3 pulls of the recoil starter. Too much choke leads to

spark plug fouling/engine flooding due to lack of incoming

air. This will cause the engine not to start.

"

NOTICE

For gasoline restarts with hot engine in hot ambient

temperature > 86°F (30°C), keep choke in 75% of the

“CHOKE” position for only 1 pull of the recoil starter. After

first pull, move choke to “RUN” position for up to 3 pulls

of the recoil starter. Too much choke leads to spark plug

fouling/engine flooding due to lack of incoming air. This will

cause the engine not to start.

"

NOTICE

For gas starting in cold ambient temperature < 59°F

(15°C), the choke must be in 100% of the “CHOKE” position

for recoil start procedures. Do not over-choke. As soon as

engine starts, gradually move the choke lever to the “RUN”

position over a 2-5 second duration.

"

NOTICE

If the engine starts but does not run make certain that the

generator is on a flat, level surface. The engine is equipped

with a low oil sensor that will prevent the engine from

running when the oil level falls below a critical threshold.

Page 22

100592 - 6250W DUAL FUEL GENERATOR

OPERATION

22

Starting the Engine: Propane (LPG)

1. Make certain the generator is on a flat, level surface.

2. Disconnect all electrical loads from the generator. Never

start or stop the generator with electrical devices plugged

in or turned on.

3. Make sure the fuel selector is set to LPG operation.

4. Fully open the fuel valve on the LPG cylinder.

5. Tur n the LPG f uel valve to t he “ON”posit ion .

6. Push the engine switch to the “ON” position.

7. Move the choke to the “CHOKE” position. (For restarting a

warm engine, move the choke the same position.)

8. PULL-TO-PRIME: Pull the starter cord slowly until

resistance is felt and then pull rapidly. Pull with 100%

“CHOKE” 1-3 times until you feel a few combustion pulses

that indicates that the engine momentarily started.

9. Move the choke to the “RUN” position.

10. Pull the starter cord slowly until resistance is felt and then

pull rapidly.

11. If engine fails to start in 1-pull with choke in the “RUN”,

then move choke to the “CHOKE” position and repeat the

PULL-TO-PRIME step.

12. Do not over-choke. As soon as engine starts, move the

choke to the “RUN” position over a 2-5 second duration.

"

NOTICE

For LPG starting in cold ambient temperature < 59°F

(15°C), move the choke lever to “CHOKE” for recoil start.

To PULL-TO -PRIME for recoil start, pull wi th choke in the

“CHOKE” position 1-3 times until you feel a few combustion

pulses that indicates that the engine momentarily started.

"

NOTICE

If the engine starts but does not run make certain that the

generator is on a flat, level surface. The engine is equipped

with a low oil sensor that will prevent the engine from

running when the oil level falls below a critical threshold.

Page 23

100592 - 6250W DUAL FUEL GENERATOR

"

NOTICE

OPERATION

! WARNING

Accumulation of frost on LPG cylinder and regulators is

common during operation and normally is not an indication

of a problem. As LPG vaporizes and travels from the cylinder

to the generator engine it expands. The amount of frost

that forms can be affected by the size of the cylinder, the

amount of LPG being used, the humidity of the air and other

operating conditions.

In unusual situations this frost may eventually restrict

the flow of LPG to the generator resulting in deteriorating

performance. For example, if the cylinder temperature is

reduced to a very low level then the rate at which the LPG

vaporizes is also reduced and may not provide sufficient

flow to the engine. This is not an indication of a problem

with the generator but only a problem with the flow of LPG

from the cylinder. If generator performance seems to be

deteriorating at the same time that ice formation is observed

on tank valve, hose or regulator then some actions may be

taken to eliminate this symptom.

In these rare situations it can be helpful to reduce or

eliminate the cold fuel system effects by doing one of the

following:

– Exchanging fuel cylinders to allow the first cylinder to

warm up, repeating as necessary.

Always remember to plug your appliances directly into the

generator and do not plug the generator power cord into any

electrical outlet or connect to the circuit breaker panel in

your home.

Connecting a generator to your home’s electric utility

company’s power lines, or to another power source, called

‘backfeeding’ is a dangerous practice that is illegal in many

localities.

In addition, this action if done incorrectly, could damage

your generator, appliances and could cause serious injury or

death to you or a utility worker attempting to restore power

to the neighborhood who may unexpectedly encounter high

voltage on the utility line and suffer a fatal shock. Further,

whether injuries occur or not, you may be subject to fines or

the utility company may disconnect your home should this

practice be found in your home.

If the generator will be connected to a building electrical

system, you are responsible for ensuring your generator’s

electricity does not backfeed into the electric utility power

lines. These connections must isolate the generator power

from the utility power – Consult your local utility company or

a qualified electrician to properly install this connection.

– Placing the cylinder at the end of the generator near

the handle, where engine fan air flows out from the

generator. This air is slightly heated by flowing over the

engine. The cylinder should not be placed in the path of

the muffler outlet.

– The cylinder can be temporarily warmed by pouring

warm water over the top of the cylinder.

Connecting Electrical Loads

Let the engine stabilize and warm up for a few minutes after

starting.

Plug in and turn on the desired 120 or 240 (if applicable) Volt AC

single phase, 60 Hz electrical loads.

– DO NOT connect 3-phase loads to the generator.

– DO NOT overload the generator.

Do Not Overload Generator

Capacity

Follow these simple steps to calculate the running and starting

watts necessary for your purposes:

1. Select the electrical devices you plan on running at the

same time.

2. Total the running watts of these items. This is the amount

of power you need to keep your items running.

3. Identify the highest starting wattage of all devices

identified in step 1. Add this number to the number

calculated in step 2. Starting wattage is the surge of power

needed to start some electric driven equipment. Following

the steps listed under “Power Management” will guarantee

that only one device will be starting at a time.

Power Management

Use the following formula to convert voltage and amperage to

watts:

Volts × Amps = Watts

To prolong the life of your generator and attached devices,

follow these steps to add electrical load:

1. Start the generator with no electrical load attached.

2. Allow the engine to run for several minutes to get up to

temperature.

23

Page 24

100592 - 6250W DUAL FUEL GENERATOR

OPERATION

24

3. Plug in and turn on the first item. It is best to attach the

item with the largest load first.

4. Allow the engine to stabilize.

5. Plug in and turn on the next item.

6. Allow the engine to stabilize.

7. Repeat steps 5-6 for each additional item.

"

NOTICE

Never exceed the specified capacity when adding loads to

the generator.

GFCI

Your generator is equipped with ground fault circuit interrupter

(GFCI) receptacles. In the event of a ground fault, a GFCI trips

automatically to stop the flow of electricity and prevent serious

injury. The green indicator light (A) on the receptacle will also

turn off. Press the “RESET” (B) button located on the front of

the receptacle to restore flow of electricity. The indicator light

will also turn back on. GFCI does not protect against circuit

overloads.

To ensure proper operation of the GFCI duplex, perform this test

monthly:

1. With the generator running, plug a lamp into the GFCI

receptacle. Turn the lamp on.

2. Press the “TEST” (C) button located on the front of the

receptacle to trip the device. This should immediately

stop the flow of electricity and shut off the lamp. If the

electricity is not stopped, do not use this receptacle until it

has been serviced or replaced.

3. Press the “RESET” button located on the front of the

receptacle to restore the flow of electricity. If the indicator

light does not come back on or if the GFCI cannot be reset

then it must be replaced.

B

C

A

"

NOTICE

In any electrical application, some current will flow through

the protective ground conductor to the ground, this is called

leakage current. It takes 4 mA (0.004 A) and higher of

leakage current from the hot wire to the ground to cause a

GFCI to trip. On circuits protected by GFCI’s, leakage current

can cause unnecessary and intermittent tripping.

Some stationary motors, such as a bathroom vent fan,

fluorescent lighting fixtures or some refrigerators, may

produce enough leakage to cause nuisance tripping. To avoid

nuisance tripping, a GFCI should not supply:

– Fluorescent or other types of electric-discharge lighting

fixtures.

– Permanently installed electric motors, like air

conditioners, furnaces or refrigerators.

Stopping the Engine

1. Turn off and unplug all connected electrical loads. Never

start or stop the generator with electrical devices plugged

in or turned on.

2. Let the generator run at no-load for several minutes to

stabilize internal temperatures of the engine and generator.

3. If operating by gasoline, turn the fuel valve to the “OFF”

position.

3a. If operating by propane (LPG), fully close the

propane (LPG) cylinder valve.

4. If operating by propane (LPG), turn the fuel valve to the

“OFF” position.

Page 25

100592 - 6250W DUAL FUEL GENERATOR

OPERATION

25

5. Press the engine switch to the “OFF” position.

Important: Always ensure that the fuel valve and the engine

switch are in the “OFF” position when the generator is not in

use.

"

NOTICE

If the engine will not be used for a period of two (2) weeks or

longer, please see the Storage section for proper engine and

fuel storage.

Moving the Generator

– NEVER lift or carry the generator using the folding handle.

– ALWAYS place the generator on its wheels in the upright

position.

– ALWAYS turn the generator off and ensure the fuel valve is

closed.

– ALWAYS make sure engine and muffler are cooled down

before the generator can be handled safely (typically 15-30

minutes).

1. Begin by raising the folding handle, found on opposite side

of wheels.

2. Using the handle, tilt the end of the generator slightly off

the ground until balanced on the wheels.

3. While maintaining balance, roll the generator to the desired

location.

– NEVER tilt sideways while moving the generator.

– Failure to follow these instructions could result in personal

injury or damage to the generator.

Operation at High Altitude

The density of air at high altitudes is lower than at sea level.

Engine power is reduced as the air mass and air-fuel ratio

decrease. Engine power and generator output will be reduced

approximately 3½% for every 1000 ft. of elevation above sea

level. At high altitudes increased exhaust emissions can also

result due to the increased enrichment of the air fuel ratio.

Other high altitude issues can include hard starting, increased

fuel consumption and spark plug fouling.

To alleviate high altitude issues other than the natural power

loss, CPE can provide a high altitude carburetor main jet.

The alternative main jet and installation instructions can be

obtained by contacting our Technical Support Team. Installation

instructions are also available in the Technical Bulletin area of

the CPE website.

The part number and recommended minimum altitude for the

application of the high altitude carburetor main jet is listed in

the following table.

In order to select the correct high altitude main jet it is

necessary to identify the carburetor model. For this purpose,

a code is stamped on the side of the carburetor. Select the

correct high altitude jet part number corresponding to the

carburetor code found on your particular carburetor.

Carb. Code High Alt. Jet Part Number Min. Altitude

P27-7-H 46.131017.20.01.H

5,000 ft.

(1,524 m)

P27-7-Y 46.131017.20.01.Y

P27-7-Z 46.131017.20.01.Z

Page 26

100592 - 6250W DUAL FUEL GENERATOR

MAINTENANCE

26

! WARNING

Operation using the alternative main jet at elevations lower

than the recommended minimum altitude can damage the

engine. For operation at lower elevations, the originally

supplied standard main jet must be used. Operating the

engine with the wrong engine configuration at a given

altitude may increase its emissions and decrease fuel

efficiency and performance.

MAINTENANCE

Make certain that the generator is kept clean and stored

properly. Only operate the unit on a flat, level surface in a clean,

dry operating environment. DO NOT expose the unit to extreme

conditions, excessive dust, dirt, moisture or corrosive vapors.

! WARNING

Never operate a damaged or defective generator.

! WARNING

Improper maintenance will void your warranty.

"

NOTICE

For Emission control devices and systems, read and

understand your responsibilities for service as stated in the

Emission Control Warranty Statement of this manual.

The owner/operator is responsible for all periodic maintenance.

Complete all scheduled maintenance in a timely manner.

Correct any issue before operating the generator.

For service or parts assistance, contact our

Technic al Support Te am at 1-877-338-0999.

Cleaning the Generator

! CAUTION

DO NOT spray generator directly with water.

Water can enter the generator through the cooling slots and

damage the generator windings. It can also contaminate the

fuel system.

1. Use a damp cloth to clean exterior surfaces of the

generator.

2. Use a soft bristle brush to remove dirt and oil.

3. Use an air compressor (25 PSI) to clear dirt and debris

from the generator.

4. Inspect all air vents and cooling slots to ensure that they

are clean and unobstructed.

To prevent accidental starting, remove and ground the spark

plug wire before performing any service.

Changing the Engine Oil

Change oil when the engine is warm. Refer to the oil

specification to select the proper grade for your operating

environment.

1. Remove the oil drain plug with a 15 mm socket

(not included) and extension.

2. Allow the oil to drain completely into an appropriate

container.

3. Replace the oil drain plug.

4. Remove the oil fill cap/dipstick to add oil.

5. Add oil according to “Add Engine Oil” in Assembly

section. DO NOT OVERFILL. Oil not included for routine

maintenance.

6. Dispose of used oil at an approved waste management

facility.

"

NOTICE

Once oil has been added, a visual check should show oil

about 1-2 threads from running out of the fill hole. If using

the dipstick to check oil level, DO NOT screw in the dipstick

while checking.

Cleaning and Adjusting the Spark Plug

1. Remove the spark plug cable from the spark plug.

2. Use a spark plug socket tool (not included), or a

13/16 in. (21 mm) socket (not included) to remove the plug.

3. Inspect the electrode on the plug. It must be clean and not

worn to produce the spark required for ignition.

4. Make certain the spark plug gap is

0.028-0.031 in. (0.7-0.8 mm).

Page 27

100592 - 6250W DUAL FUEL GENERATOR

MAINTENANCE

! CAUTION

SPARK PLUG GAP

5. Refer to the spark plug types in Specifications when

replacing the plug.

6. Firmly re-install the plug.

7. Attach the spark plug cable to the spark plug.

Cleaning the Air Filter

1. Remove the snap-on cover holding the air filter to the

assembly.

2. Remove the foam element.

3. Wash in liquid detergent and water. Squeeze thoroughly dry

in a clean cloth.

4. Saturate in clean engine oil.

5. Squeeze in a clean, absorbent cloth to remove all excess

oil.

6. Place the filter in the assembly.

7. Reattach the air filter cover and snap in place.

Cleaning the Spark Arrestor

1. Allow the engine to cool completely before servicing the

spark arrestor.

2. Remove the two or three screws (varies by model) holding

the cover plate which retains the spark arrestor to the

muffler.

3. Remove the spark arrestor screen.

Failure to clean the spark arrestor will result in degraded

engine performance.

"

NOTICE

Federal and local laws and administrative requirements

indicate when and where spark arrestors are required.

When ordered, spark arrestors are required for operation

of this generator in National Forest lands. In California,

this generator must not be used on any forest-covered

land, brush-covered land, or grass-covered land unless the

engine is equipped with a spark arrestor.

Adjusting the Governor

! WARNING

Tamper ing with the fac tor y set governor will void your

warranty.

The air-fuel mixture is not adjustable. Tampering with

the governor can damage your generator and your

electrical devices and will void your warranty. Contact our

Technical Support Team at 1-877-338-0999 for all other

service and/or adjustment needs.

Maintenance Schedule

Follow the service intervals indicated in the following

maintenance schedule.

Service your generator more frequently when operating in

adverse conditions.

Contact our Technical Support Team at 1-877-338-0999

to locate the nearest CPE certified service dealer for your

generator or engine maintenance needs.

4. Carefully remove the carbon deposits from the spark

arrestor screen with a wire brush.

Type 1 Type 2

* See your model’s parts list for specified type of spark arrestor.

5. Replace the spark arrestor if it is damaged.

6. Position the spark arrestor on the muffler and attach with

the screws removed in step 2.

EVERY 8 HOURS OR PRIOR TO EACH USE

# Check oil level

# Clean around air intake and muffler

# Check propane (LPG) hose for leaks

FIRST 5 HOURS (BREAK IN)

# Change oil

EVERY 50 HOURS OR ANNUALLY

# Clean air filter

# Change oil if operating under heavy load or in hot

environments

27

Page 28

100592 - 6250W DUAL FUEL GENERATOR

STORAGE

28

EVERY 100 HOURS OR ANNUALLY

# Change oil

# Clean/adjust spark plug

# Clean spark arrestor

# Clean fuel valve filter*

EVERY 250 HOURS

# Clean combustion chamber*

# Check/adjust valve clearance*

EVERY 3 YEARS

# Replace fuel line*

# Replace LPG hose

* To be performed by kn owledgea bl e, ex pe rienced o wners or CPE cer ti fie d

service centers.

STORAGE

! DANGER

Gasoline, gasoline vapors and propane (LPG) are highly

flammable and extremely explosive.

Fire or explosion can cause severe burns or death. Only

fill or drain fuel outdoors in a well-ventilated area. DO NOT

pump gasoline directly into the generator. Use an approved

container to transfer the fuel to the generator. Never use a

gasoline container, gasoline tank, LPG connector hose, LPG

cylinder or any other fuel item that is damaged or appears

damaged. DO NOT overfill the gasoline tank. Always keep

fuel away from sparks, open flames, pilot lights, heat and

other sources of ignition. DO NOT light or smoke cigarettes.

"

NOTICE

If no gasoline has been added to the generator, the gasoline

tank and carburetor drainage steps may be skipped.

Short Term Storage (up to 30 days)

Gasoline may gum up and clog the carburetor if the generator is

not run or carburetor drained within 4 weeks.

1. Be sure all appliances are disconnected from the generator.

2. Start the generator as instructed in “Starting the Engine:

Gasoline” section.

3. Turn the fuel val ve to t he “OFF” p osi tio n.

4. Let the engine run until fuel starvation has stopped the

engine. This usually takes a few minutes.

5. Move the engine switch to the “OFF” position.

Mid Term Storage (up to 1 year)

Gasoline in the gasoline tank has a maximum shelf life of up to

1 year with the addition of properly formulated fuel stabilizers

and if stored in a cool, dry place. Gasoline in the carburetor,

however, may gum up and clog the carburetor if it isn’t used or

drained within 2-4 weeks.

1. Be sure all appliances are disconnected from the generator.

2. Add a properly formulated fuel stabilizer to the gasoline

tank.

3. Set the fuel selector switch for operation on gasoline.

4. Start and run the generator for 10 minutes so the treated

gasoline cycles through the fuel system and carburetor.

5. Option 1: Drain Gasoline from Carburetor

5a. Turn ignition switch to the “OFF” position and allow

generator to cool completely before continuing.

5b. Set the fuel selector switch for operation on LPG

and be sure any LPG fuel source is turned off and

disconnected from the generator.

5c. Use the drain bolt on the carburetor to empty any

excess gasoline from the carburetor into an appropriate

container. Use a funnel (and appropriate hose if

necessary) under the carburetor drain bolt to avoid

spillage.

5d. When gasoline stops flowing from the carburetor,

replace and tighten the carburetor drain bolt and

be sure to properly dispose of the drained gasoline

according to local regulations or guidelines.

6. Option 2: Run Dry

6a. With the generator running, turn the fuel valve to the

“OFF” position and allow the generator to run until the

engine stops from complete fuel starvation. This may

take a few minutes.

6b. Turn engine switch to the “OFF” position and allow

generator to cool completely before continuing.

7. Remove the spark plug cap and spark plug and pour about

a tablespoon of oil into the cylinder.

Page 29

100592 - 6250W DUAL FUEL GENERATOR

STORAGE

8. Pull the recoil slowly to crank the engine to distribute the

oil and lubricate the cylinder.

9. Install the spark plug and spark plug cap.

10. Clean the generator according to Cleaning the Generator.

11. Store the generator in a cool, dry place out of direct

sunlight.

Long Term Storage (more than 1 year)

For storage over 1 year, the gasoline tank and carburetor must

be completely drained of gasoline.

1. Follow steps 1-4 according to Mid Term Storage.

1a. Turn engine switch to the “OFF” position and allow

generator to cool completely before continuing.

2. Use the drain bolt on the carburetor to empty any excess

gasoline from the gasoline tank and carburetor into an

appropriate container. Use a funnel (and appropriate hose if

necessary) under the carburetor drain bolt to avoid spillage.

3. When gasoline stops flowing from the carburetor, replace

and tighten the carburetor drain bolt and be sure to

properly dispose of the drained gasoline according to local

regulations or guidelines.

6. Check and clear air filter of any obstructions such as bugs

or cobwebs. If necessary, clean air filter according to

Cleaning the Air Filter.

7. Start the generator according to Starting the Engine.

! DANGER

Generator exhaust contains odorless and colorless carbon

monoxide gas.

To avoid accidental or unintended ignition of your generator

during periods of storage, the following precautions should

be followed:

– When storing the generator make sure the engine switch

and fuel valve are set to the “OFF” position.

4. Set the fuel selector switch for operation on LPG and be

sure any LPG fuel source is turned off and disconnected

from the generator.

5. Follow steps 7-11 according to Mid Term Storage.

Removing from Storage

If the generator has been improperly stored for a long period

of time with gasoline in the gasoline tank and/or carburetor, all

fuel must be drained and the carburetor must be thoroughly