Page 1

Belt Drive Battery Backup

Garage Door Opener

Models

• HD920EV

• HD930EV

• LW5000EV

• WD962KEV

• WD962KPEV

• WD962MLEV

• 349544

FOR RESIDENTIAL USE ONLY

■ Please read this manual and the enclosed safety materials carefully!

■ Fasten the manual near the garage door after installation.

■ The door WILL NOT CLOSE unless the Protector System

■ Periodic checks of the garage door opener are required to ensure safe operation.

■ The model number label is located on the left side panel of your garage door

®

properly aligned.

opener.

■ This garage door opener is compatible with MyQ

accessories.

■ DO NOT enable the Timer-to-Close feature if you are installing the garage

door opener on a one-piece door. The Timer-to-Close is to be used ONLY with

sectional doors.

.

.

Write down the following information for

future reference:

Model Number:

Serial Number:

Date of Purchase:

is connected and

®

and Security✚ 2.0™

CONTENTS

Preparation . . . . . . . . . . . . . . . .1-4

Assembly . . . . . . . . . . . . . . . . .5-9

Installation . . . . . . . . . . . . . . 10-19

Install the Door Control. . . . . . 20-21

Install the Protector System

Power. . . . . . . . . . . . . . . . . . 26-28

Adjustments . . . . . . . . . . . . . 29-31

Battery Backup. . . . . . . . . . . . 32-33

Operation . . . . . . . . . . . . . . . . . 34

Features . . . . . . . . . . . . . . . . . . 35

Door Control . . . . . . . . . . . . . 36-38

Remote Control . . . . . . . . . . . 39-40

To Erase the Memory . . . . . . . . . 40

To Open the Door Manually . . . . . 40

Maintenance . . . . . . . . . . . . . . . 41

Troubleshooting. . . . . . . . . . . 42-43

Accessories. . . . . . . . . . . . . . . . 44

Warranty. . . . . . . . . . . . . . . . . . 45

Repair Parts . . . . . . . . . . . . . 46-47

www.chamberlain.com

The Chamberlain Group, Inc.

Elmhurst, Illinois 60126-1196

®

. . 22-25

845 Larch Avenue

Page 2

Torsion

Spring

Extension

Spring

OR

Preparation

Safety Symbol and Signal Word Review

Thisgarage door opener has been designed and tested to offer safe service provided it is installed,

operated, maintained and tested in strict accordance with the instructions and warnings contained in this

manual.

When you see these Safety Symbols and Signal Wordson the following pages,they will alert you to the

possibilityofserious injury or death if you do notcomply with the warnings that accompanythem.The

hazard may come fromsomething mechanicalor from electric shock.Read the warnings carefully.

Mechanical

Electrical

When you see this Signal Word on the following pages,it will alertyou to the possibility of damage to

your garage door and/or the garage door opener ifyou do notcomplywiththe cautionary statementsthat

accompanyit.Read them carefully.

Check the Door

To prevent possible SERIOUS INJURY or DEATH:

l

ALWAYS call a trained door systemstechnician ifgarage door binds,sticks, or isout of balance.

An unbalanced garage door may NOT reverse when required.

l

NEVER try to loosen, move or adjustgarage door,door springs,cables, pulleys, bracketsor their

hardware, ALL of which are under EXTREME tension.

l

Disable ALL locksand remove ALL ropesconnectedto garage door BEFORE installation and

operating garage door opener to avoid entanglement.

To prevent damage to garage door and opener:

l

ALWAYS disable locks BEFORE installing and operating the opener.

l

ONLY operate garage door opener at120 V,60 Hz to avoid malfunctionand damage.

Before you begin:

1. Disable locksand removeany ropesconnected tothe garage door.

2. Liftthe door halfwayup. Release the door. If balanced, it should stay

in place,supported entirely by itssprings.

3. Raise and lower the door to check for binding orsticking. Ifyour door

binds, sticks,or is outofbalance, call a trained door systems

technician.

4. Checkthe seal on the bottom of the door. Any gap between the floor

and thebottomof the door mustnot exceed 1/4 inch(6 mm).

Otherwise,the safetyreversal systemmaynot work properly.

5. The opener should be installed above the center ofthe door. Ifthere

is a torsion spring or center bearing plate in the way of the header

bracket,itmaybe installed within 4feet (1.2 m)to the left or right of

the door center.See page11.

1

Page 3

2

1

3/16

7/16

1/2

5/32

5/16

5/8

9/16

1/4

7/16

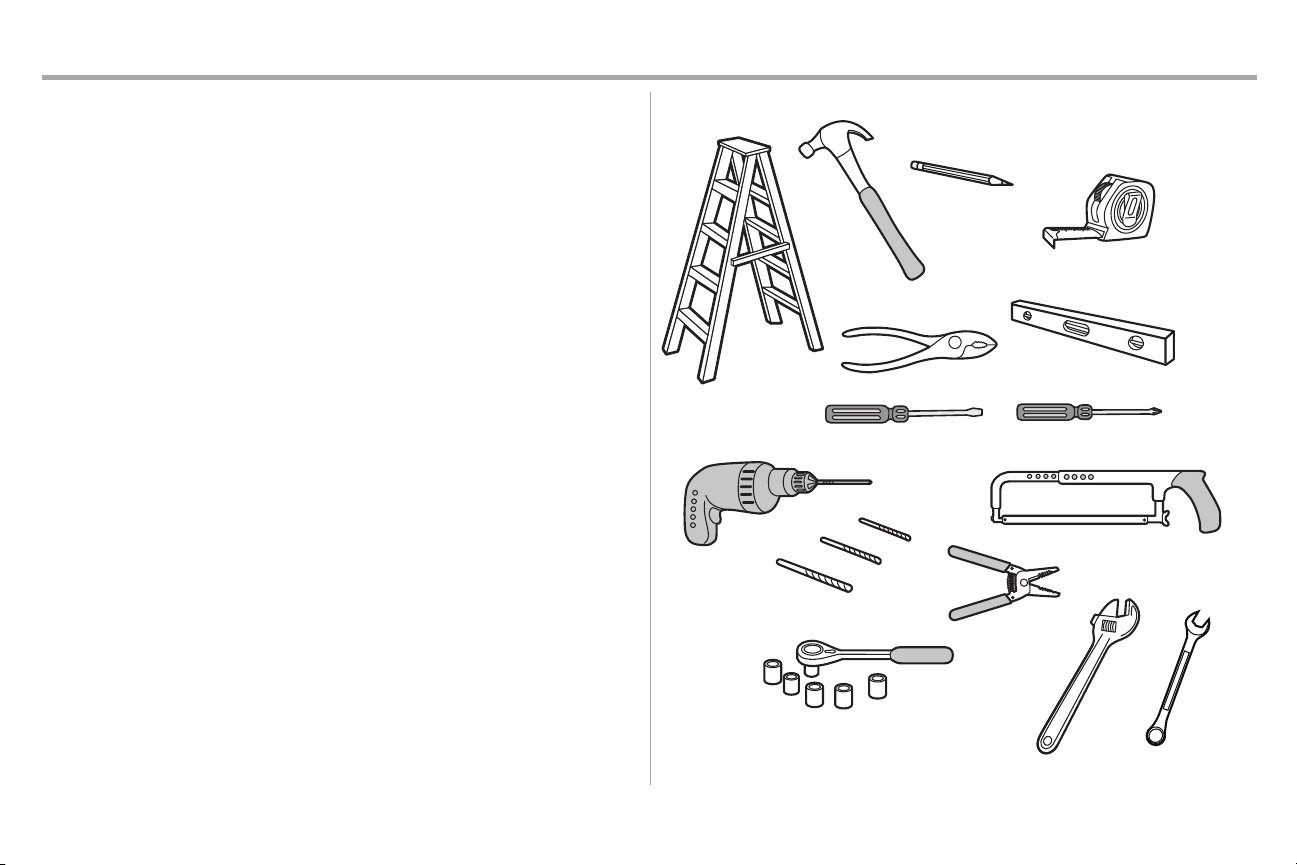

Preparation

Additional Items You May Need:

Survey your garage area to see ifyou will need any ofthe following items:

n

(2) 2X4 PIECES OF WOOD

Maybe usedto fastenthe header bracket to the structural supports.Also used toposition the

garage door opener during installation and for testing the safetyreversing sensors.

n

SUPPORT BRACKET AND FASTENING HARDWARE

Mustbe used ifyou have a finished ceiling in your garage.

n

EXTENSION BRACKETS (MODEL 041A5281-1) OR WOOD BLOCKS

Depending upon garage construction,extensionbracketsor wood blocksmay be needed to

install the safetyreversing sensor.

n

FASTENING HARDWARE

Alternate floor mounting of the safetyreversing sensor willrequire hardware not provided.

n

OUTSIDE QUICK RELEASE (MODEL 7702CB)

Required fora garage with NO access door.

n

DOOR REINFORCEMENT

Required ifyou have a lightweight steel, aluminum, fiberglass or glass panel door.

n

RAIL EXTENSION KIT

Required ifyour garage door is more than 7 feet (2.13 m) high.

Tools Needed

2

Page 4

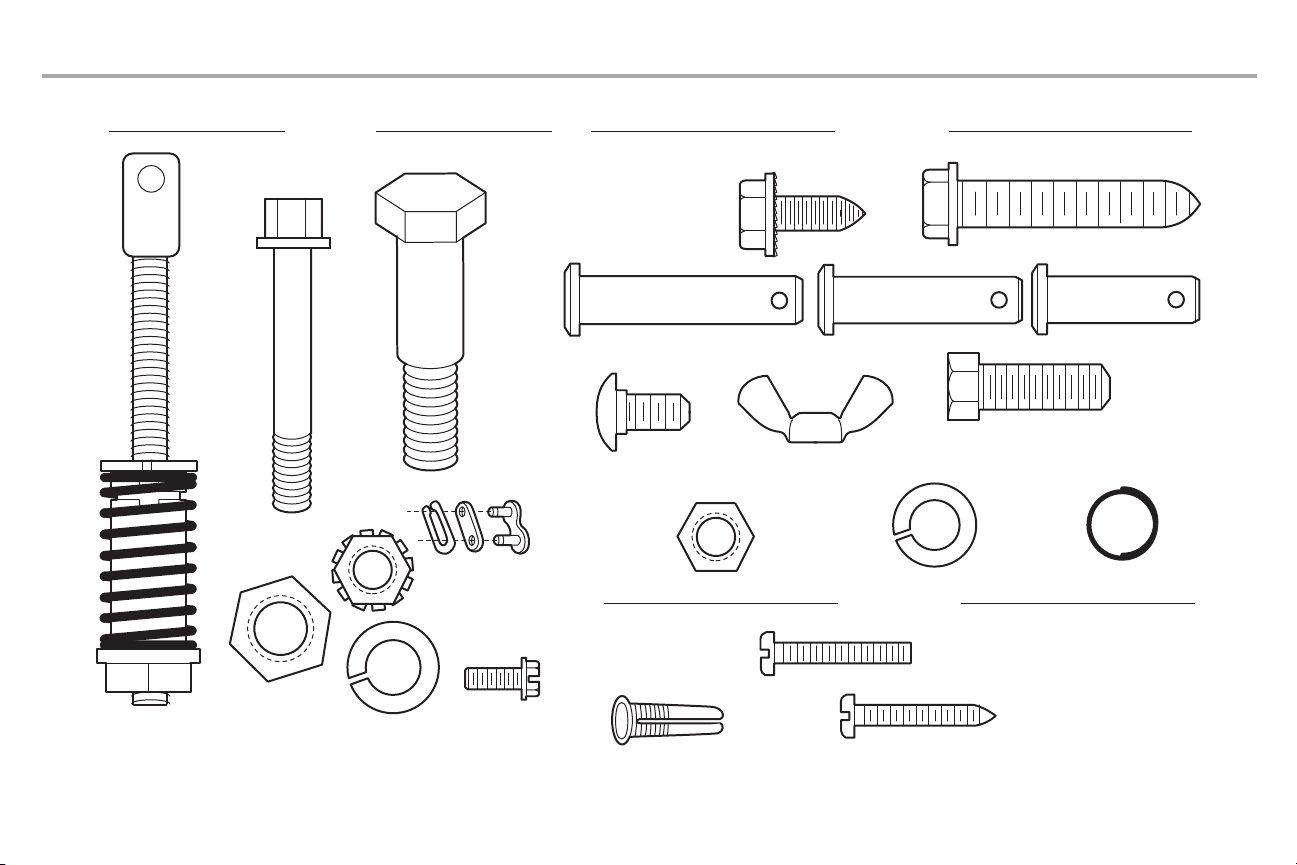

N

A

B

C

H

K

J

O

I

D

E

F

G

L

M

P

OR

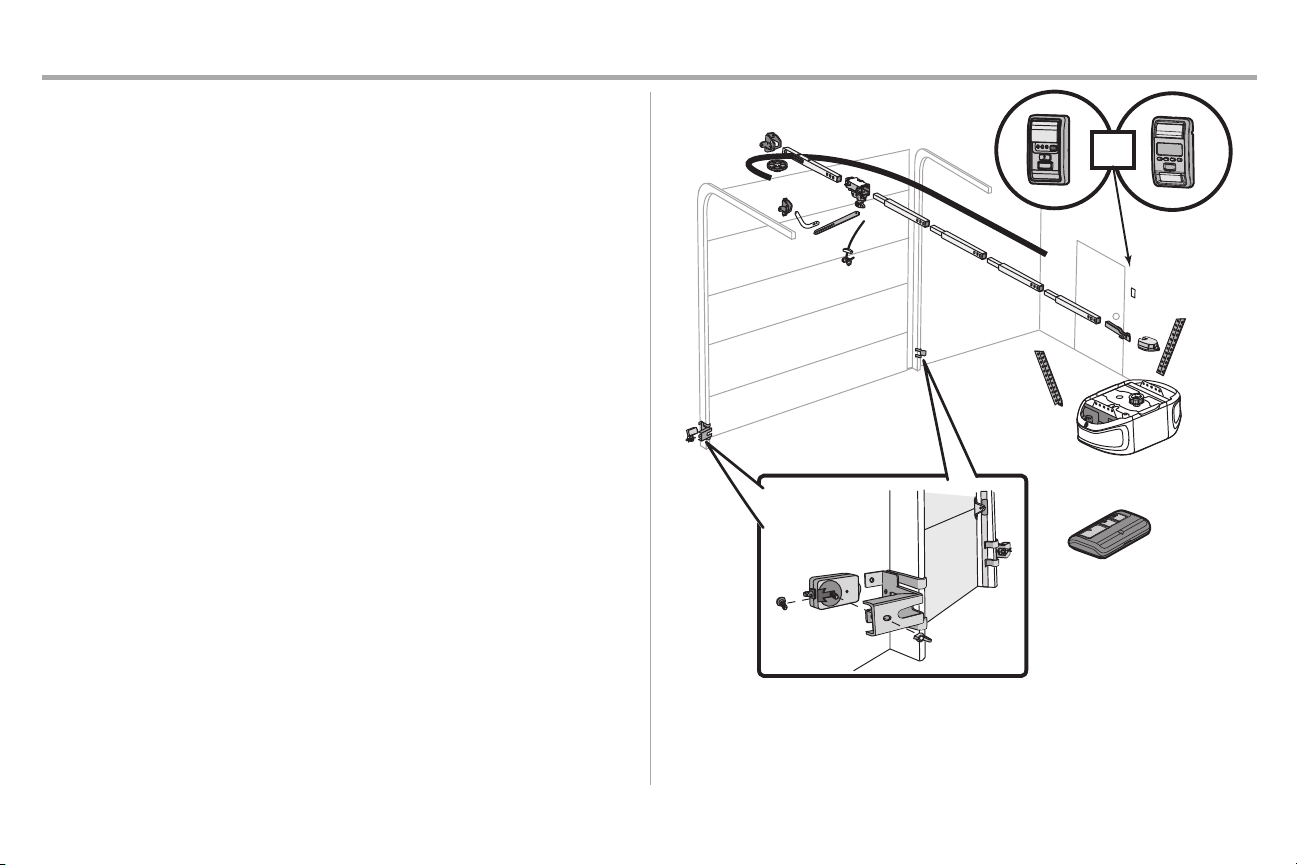

Preparation

Carton Inventory

Your garage door opener is packaged in one carton which contains the motor unit and all parts

illustrated below. Accessoriesvarydepending on thegarage door opener model purchased. Depending

on your model, other accessories may be included with your garage door opener. Instructions for these

accessories will be attached to the accessory and are notincluded in thismanual. Save thecarton and

packing material untilthe installation and adjustmentis complete.The images throughoutthismanual

are forreference only and your product may look different.

A. Header bracket

B. Pulley

C. Door bracket

D. Curved door arm

E. Straight door arm

(Packaged insidefrontrail section)

F. Trolley

NOTE: Be sure to assemble the trolley before sliding onto rail.

G. Emergency releaserope and handle

H. Rail(1 front and 4 centersections)

I. Hanging brackets(2)

(Packaged insidethe front rail section)

J. Garage door opener (motor unit)

K. Sprocketcover and screws

L. “U” bracket

M. Belt

N. Door control (Motion-Detecting Control Panel or SmartControl Panel®)

O. Remotecontrol

P. The ProtectorSystem

®

Safetyreversing sensors with 2 conductor white and white/blackwire attached:Sending Sensor

(1), Receiving Sensor(1), and SafetySensor Brackets(2)

NOT SHOWN

White and red/whitewire

Owner's manual

Hardware

3

Page 5

Clevis Pin 5/16"x1-1/2"

Ring Fastener (3)

Hex Bolt 5/16"-18x7/8" (4)

Lock Washer

5/16"-18 (5)

Nut

5/16"-18 (6)

Self-Threading Screw

1/4"-14x5/8" (2)

Clevis Pin 5/16"x1"

Clevis Pin 5/16"x1-1/4"

Carriage Bolt

1/4"-20x1/2" (2)

Wing Nut 1/4"-20 (2)

ASSEMBLY INSTALLATION

Screw 6ABx1" (2)

Drywall Anchors (2)

Screw 6-32x1" (2)

DOOR CONTROL

Insulated

Staples

(N

ot Shown)

Lag Screw 5/16"-9x1-5/8" (4)

Hex Screw

#8x3/8" (3)

(packed with the

sprocket cover)

Bolt

1/4"-20x1-3/4"

Lock Nut

1/4"-20

Bolt

Nut 3/8"

Lock Washer 3/8"

Master Link

Spring

Trolley Nut

Threaded

Shaft

with

Preparation

Hardware

4

Page 6

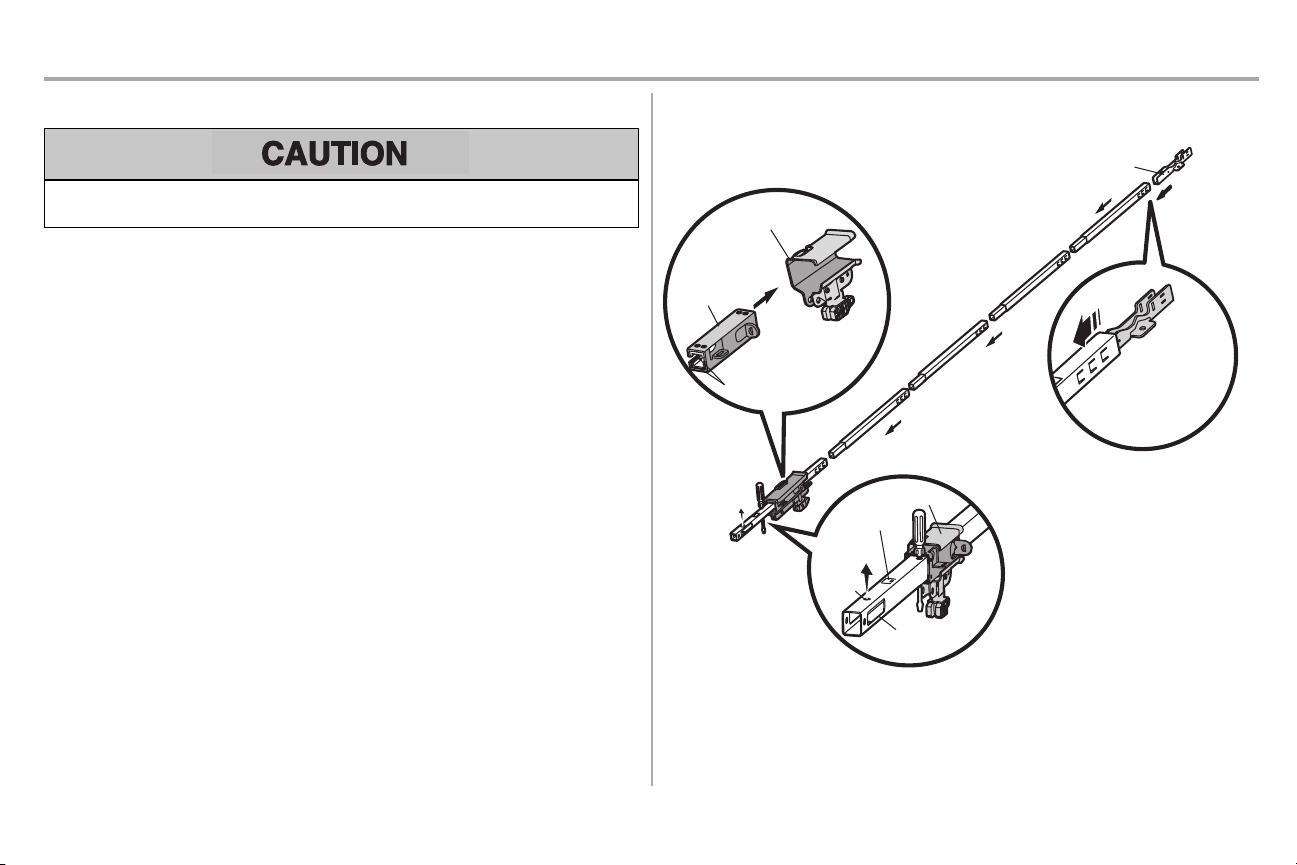

Assembly

To garage

door opener

(TO MOTOR UNIT)

Front Rail

Section

(TO DOOR)

“U” Bracket

Outer Trolley

Inner Trolley

Wear Pads

SLIDE TO STOPS

ON TOP AND

SIDES OF

“U” BRACKET

Rail

Tab

Trolley

Window

Cut-Out

Idler

Pulley

Hole

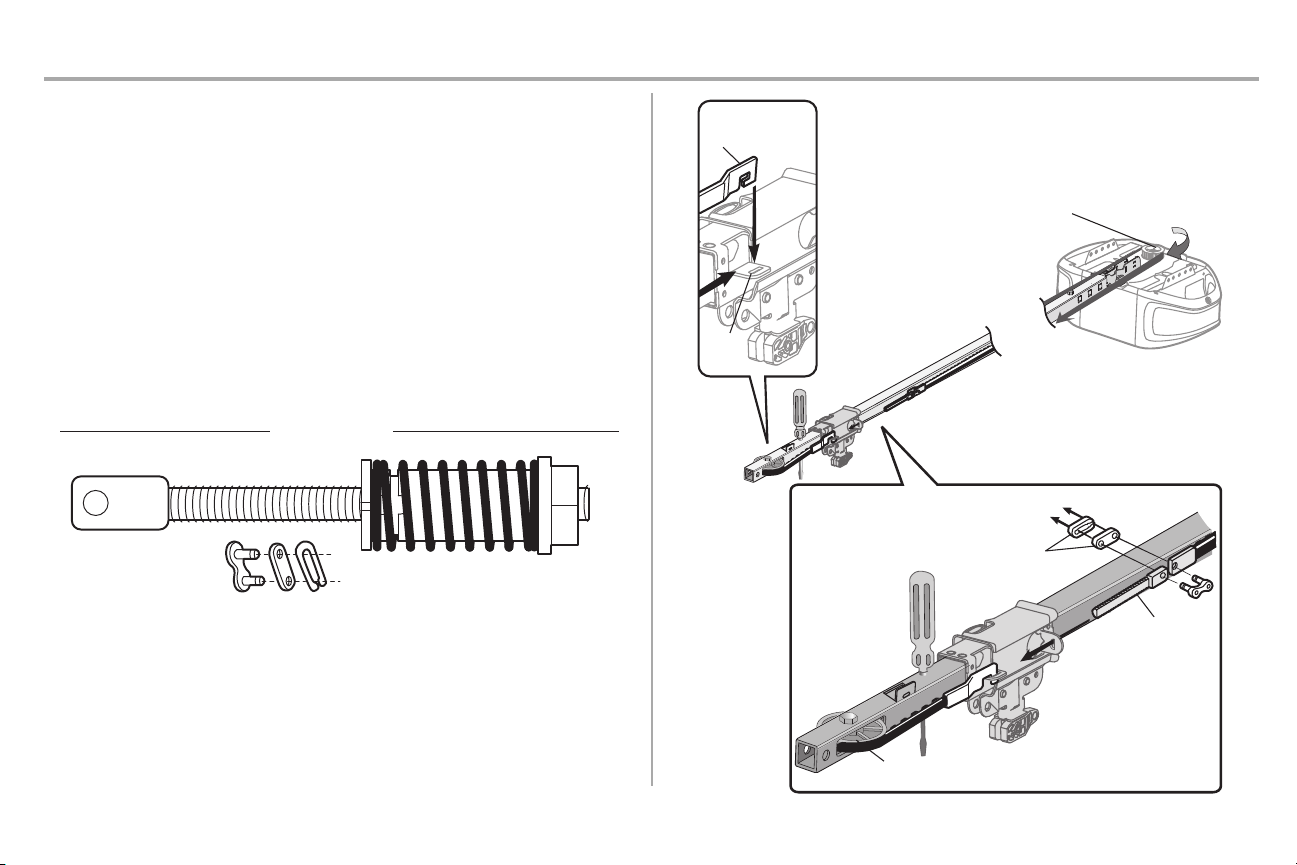

STEP 1 Assemble the rail and install the trolley

To prevent INJURY frompinching, keep handsand fingersaway from the jointswhile assembling the

rail.

To avoidinstallation difficulties, do not run the garage dooropener untilinstructed to do so.

The front rail has a cutout “window” at the door end. The front and back rail both have rail tabs. These

rail tabsMUST be on top of the rail when assembled.

1. Removethe straight door arm and hanging bracketpackaged inside the front rail and setaside

for Installation Step 5 and 9.NOTE: To prevent INJURY while unpacking the rail carefully remove

the straight door arm stored within the rail section.

2. Align the rail sections on a flat surface as shown and slide the tapered ends into the larger ones.

Tabs along the side will lockinto place.

3. Place the motorunit on packing material to protectthe cover,and rest the backend of therail on

top.For convenience, put a support under the front end of the rail.

4. As a temporarystop, insert a screwdriver intothe hole 10" (25 cm) from the front end of the rail,

as shown.

5. Checktobe sure there are 4 plastic wear pads inside theinner trolley.If they became loose

during shipping, check all packingmaterial.Snap thembackinto position asshown.

6. Slide the trolley assemblyalong the rail fromthe back end to the screwdriver.

7. Slide the rail onto the “U” bracket, until itreachesall thestopson the top and sides ofthe “U”

bracket.

5

Page 7

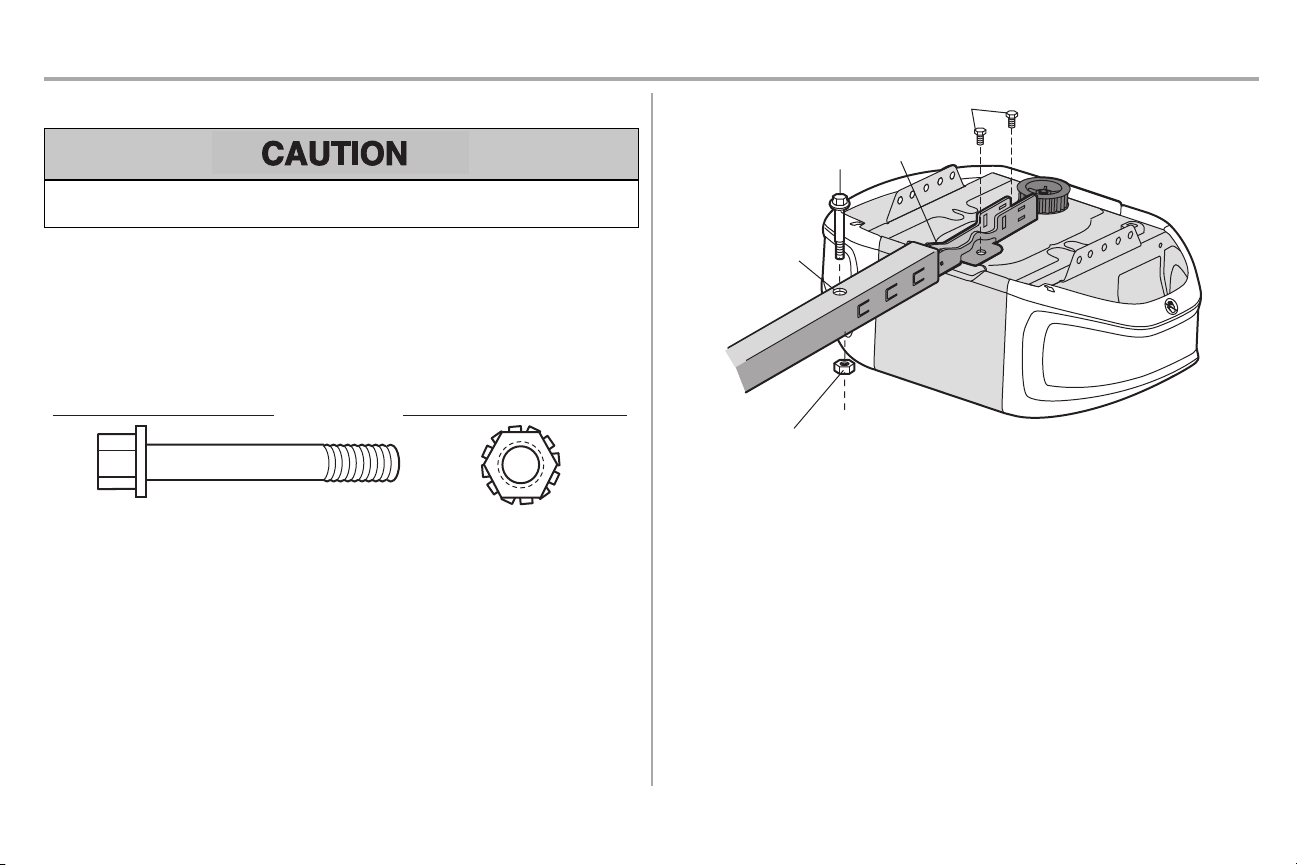

Assembly

HARDWARE

Bolt 1/4"-20x1-3/4"

Lock Nut 1/4"-20

“U” Bracket

Cover Protection

Bolt Hole

Bolt

1/4"-20x1-3/4"

Lock Nut 1/4"-20

Bolts (Mounted in the

garage door opener)

STEP 2 Fasten the rail to the motor unit

To avoid SERIOUSdamage to garage door opener, use ONLY those bolts/fastenersmounted in the

top of the opener.

1. Inserta 1/4"-20x1-3/4" boltinto the cover protection bolthole on the back end of the rail as

shown.Tighten securely with a 1/4"-20 lock nut. DO NOT overtighten.

2. Removethe bolts from the topof the motor unit.

3. Usethe carton to supportthe front end of the rail.

4. Place the “U” bracket,flatside down onto themotor unit and align the bracket holes with the bolt

holes.

5. Fasten the“U” bracket with the previouslyremovedbolts;DO NOT use anypower tools.The use

of power toolsmaypermanently damage the garage door opener.

6

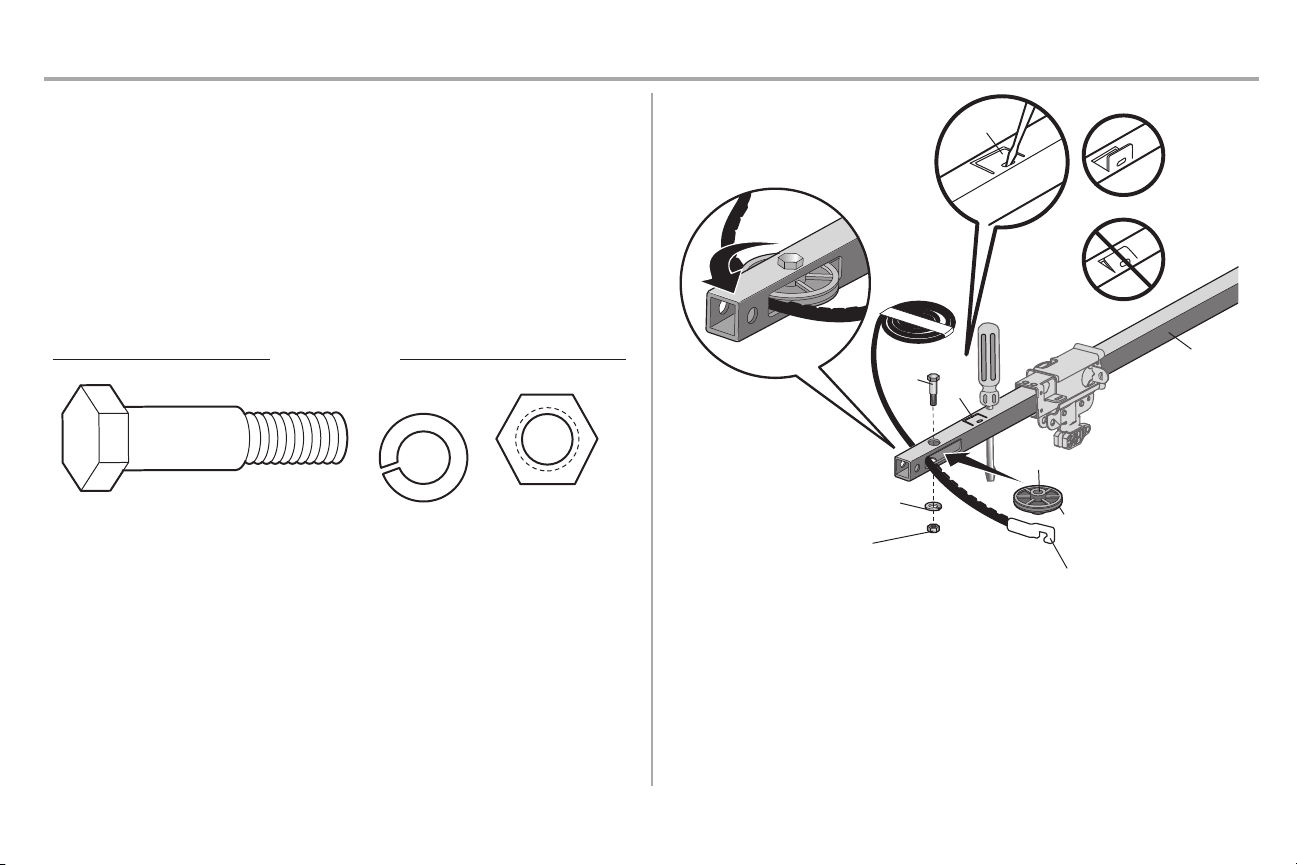

Page 8

Assembly

HARDWARE

Bolt

Nut 3/8"

Lock Washer 3/8"

Rail

Trolley Connector

Bolt

Lock Washer 3/8"

Nut 3/8"

Rail

Tab

CORRECT

INCORRECT

Rail Tab

Idler Pulley

Grease Inside Pulley

STEP 3 Install the idler pulley

1. Lay the beltbeside the rail, as shown. Grasp the end with thehooked trolleyconnector and pass

approximately 12" (30 cm) of beltthrough the window.Keep the ribbed side toward the rail,and

allow it to hang untilAssemblyStep 4.

2. Removethe tape fromtheidler pulley.The inside centershould be pre-greased.Ifdry,regrease

to ensure proper operation.

3. Place the idler pulleyinto the windowas shown.

4. Inserttheidler bolt from the top through the rail and pulley. Tighten with a 3/8" lock washer and

nut underneath the rail until the lockwasheris compressed.

5. Rotatethe pulley tobe sure itspins freely.

6. Locate the rail tab. The railtab is between theidler bolt and the trolley in the front rail section.Use

a flathead screwdriver and lift the rail tab until thetab is vertical (90º).

7

Page 9

Assembly

HARDWARE

Master

Link

Threaded Shaft with Spring Trolley Nut

Sprocket

Figure 3

Front Rail

Section

(TO DOOR)

Idler

Pulley

Threaded Shaft

Master

Link

Figure 2

Trolley Connector

Figure 1

Retaining

Slot

STEP 4 Install the belt

1. Pull thebelt around the idler pulleyand toward thetrolley.The ribbed side must contactthe

pulley.

2. Hook the trolley connector into the retaining slot on the trolley asshown(Figure 1).

3. Withthe trolley againstthescrewdriver,dispensethe remainder of the beltalong therail

lengthtowardthe motor unitand around the sprocket (Figure 2). The sprocket teeth mustengage

the belt.

4. Checktomake sure the belt is not twisted.Connectthetrolley threaded shaftwith the master link

(Figure 3).

l

Push pinsofmaster link bar through holesin end of belt and trolley threaded shaft.

l

Push master link capover pins and pastpin notches.

l

Slide clip-on spring over cap and onto pin notches until bothpins are securelylocked in

place.

5. Removethe spring trolleynut from the threaded shaft.

6. Insertthetrolley threaded shaftthrough the hole in the trolley.

8

Page 10

Assembly

Nut Ring

BEFORE

1"

(2.5

cm)

Nut Ring

AFTER

1-1/4"

(3.18 cm)

Nut Ring Slot

Spring Trolley

Hex Screw #8x3/8"

(Packed with the

sprocket cover)

HARDWARE

Hex Screw #8x3/8"

Sprocket Cover

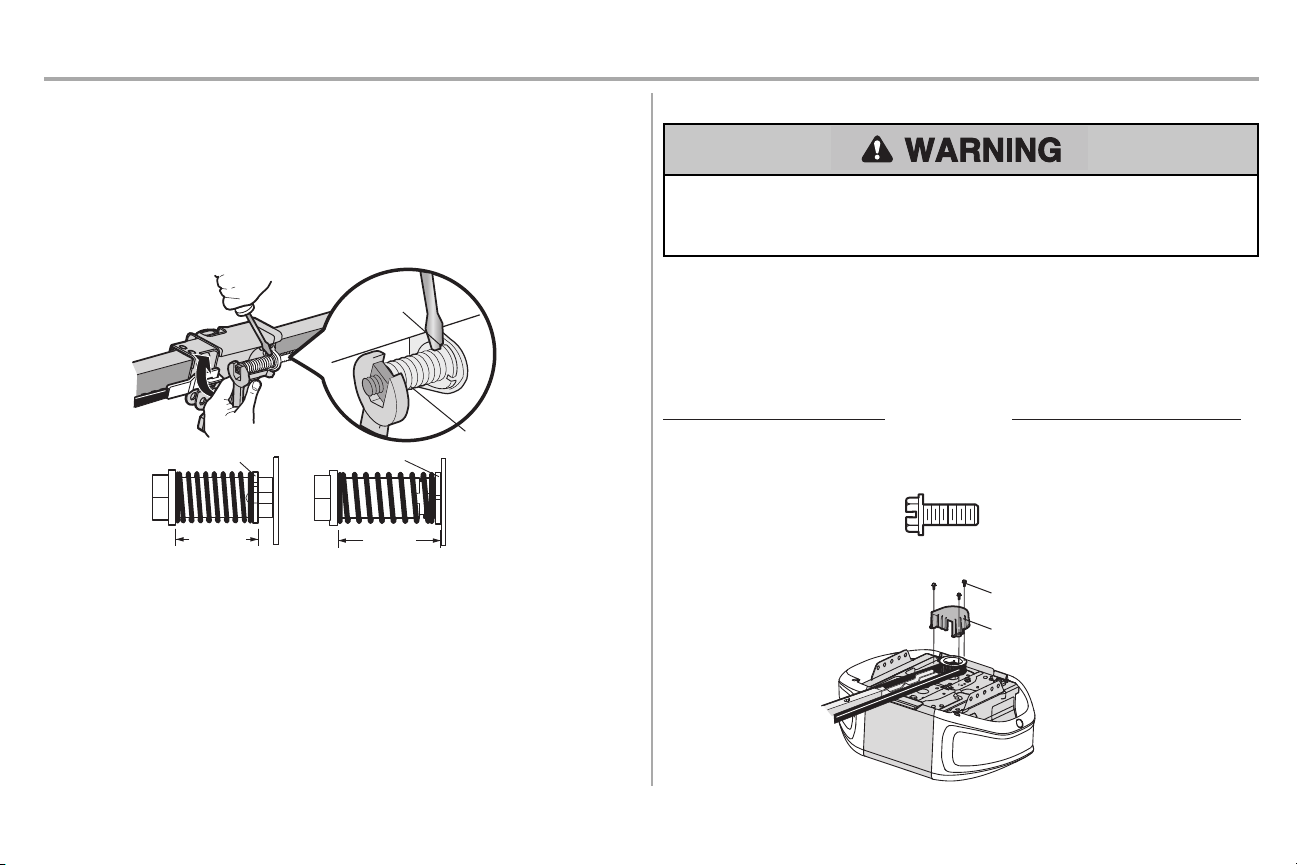

STEP 5 Tighten the belt

1. By hand,thread the spring trolley nut on the threaded shaftuntil it is finger tightagainst the

trolley.Do not use any tools.Remove thescrewdriver.

2. Inserta flathead screwdriver tip into one ofthe nut ring slotsand brace it firmlyagainst the trolley.

3. Tighten the spring trolley nut with an adjustable wrenchor a 7/16" open end wrench about a

quarter turn until the spring releases and snaps the nutring againstthe trolley.Thissetsthe

spring to optimumbelt tension.

STEP 6 Install the sprocket cover

To avoid possible SERIOUS INJURY to finger from moving garage door opener:

l

ALWAYS keep hand clear of sprocket while operating opener.

l

Securely attach sprocketcoverBEFORE operating.

1. Position the sprocket cover over the sprocketasshown and fasten to the mounting plate with

8x3/8"hex screwsprovided.

You have now finishedassembling your garage door opener. Please read the followingwarnings

beforeproceedingtothe installationsection.

9

Page 11

Installation

IMPORTANT INSTALLATION INSTRUCTIONS

To reduce the risk of SEVERE INJURY or DEATH:

1. READ AND FOLLOW ALL INSTALLATIONWARNINGS AND INSTRUCTIONS.

2. Install garage door opener ONLY on properly balanced and lubricatedgarage door. An

improperly balanced door mayNOT reverse when required and could result in SEVERE

INJURY or DEATH.

3. ALL repairs to cables, spring assembliesand other hardware MUST be made bya trained door

systemstechnician BEFORE installing opener.

4. Disable ALL locksand remove ALL ropesconnected to garage door BEFORE installing opener

to avoid entanglement.

5. Install garage door opener 7 feet(2.13 m) or more abovefloor.

6. Mount the emergencyrelease within reach,butatleast 6 feet (1.83m) above the floor and

avoiding contact with vehicles to avoid accidentalrelease.

7. NEVER connect garage door opener to power source until instructedto do so.

8. NEVER wear watches,rings or loose clothing while installing or servicing opener.Theycould be

caught in garage door or opener mechanisms.

9. Install wall-mounted garage door control:

l

within sight of the garage door.

l

out of reachof children atminimum height of5 feet (1.5m).

l

away from ALL moving parts of the door.

10. Placeentrapment warning label on wall nextto garage door control.

11. Placemanual release/safetyreversetestlabel in plain viewon inside of garage door.

12. Upon completion ofinstallation,testsafetyreversal system.Door MUST reverse on contactwith a

1-1/2" (3.8 cm) high object (or a 2x4 laid flat) on the floor.

13. To avoid SERIOUS PERSONAL INJURYor DEATH from electrocution, disconnect ALL electric

power BEFOREperforming ANY service or maintenance.

14. DO NOT enable the Timer-to-Close functionality if operating either one-piece or swinging

garage doors. To be enabled ONLY when operating a sectional door.

10

Page 12

Installation

Header Wall

Vertical Centerline of Garage Door

2x4

Structural

Supports

Level

(Optional)

Unfinished

Ceiling

2x4

OPTIONAL CEILING MOUNT

FOR HEADER BRACKET

Sectional door with curved track

Header Wall

Track

2" (5 cm)

Highest

Point of

Travel

Door

One-piece door with horizontal track

Header Wall

Track

2" (5 cm)

Highest

Point of

Travel

Door

One-piece door without track:

jamb hardware

Header Wall

8" (20 cm)

Highest

Point of

Travel

Door

Jamb

Hardware

One-piece door without track:

pivot hardware

Header Wall

8" (20 cm)

Highest

Point of

Travel

Door

Pivot

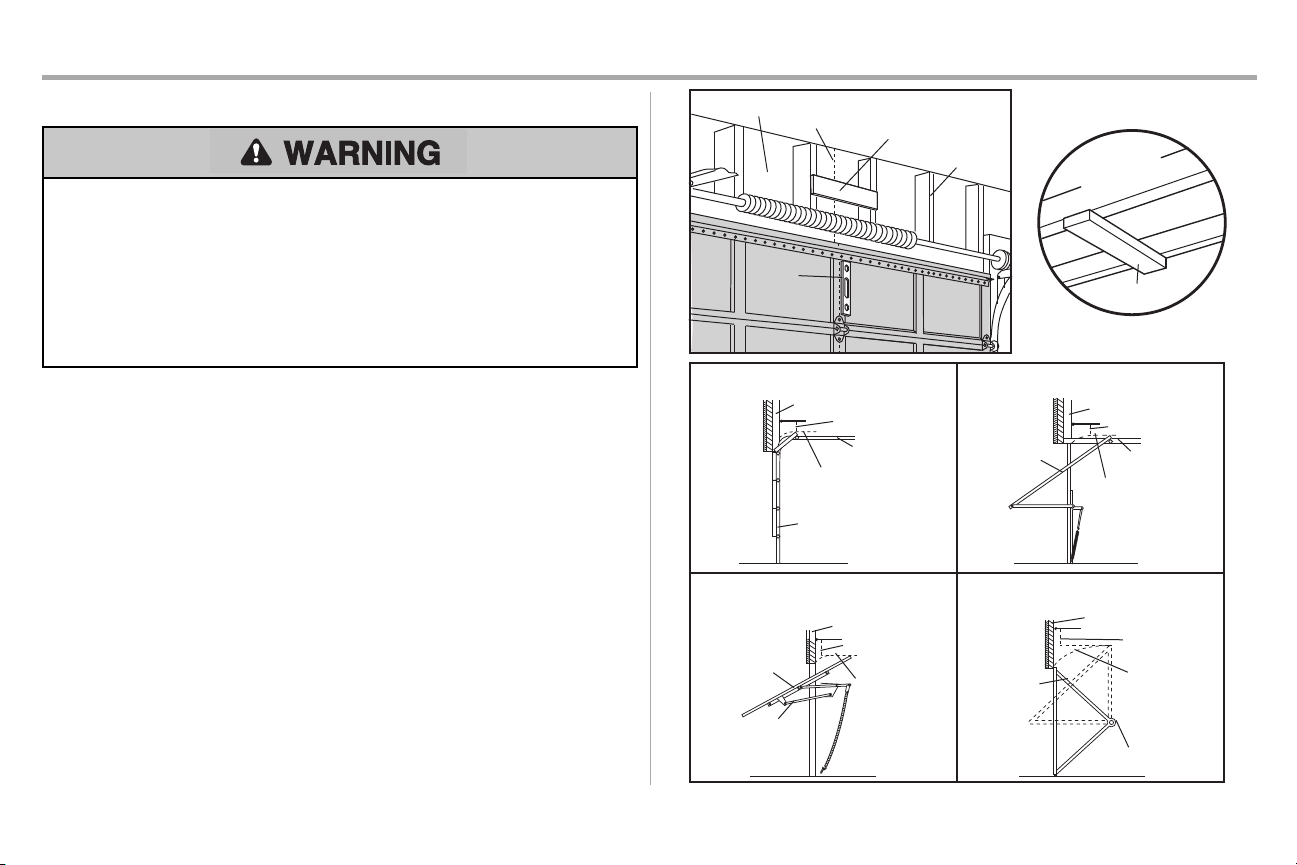

STEP 1 Determine the header bracket location

To prevent possible SERIOUS INJURY or DEATH:

l

Header bracket MUST be RIGIDLY fastened to structural support on header wall or ceiling,

otherwise garage door mightNOTreverse when required. DO NOTinstall header bracketover

drywall.

l

Concreteanchors MUST be used if mounting header bracketor 2x4 intomasonry.

l

NEVER try to loosen, move or adjustgarage door,springs,cables,pulleys,brackets,or their

hardware, ALL of which are under EXTREME tension.

l

ALWAYS call a trained door systemstechnician ifgarage door binds,sticks, or isout of balance.

An unbalanced garage door might NOT reverse when required.

Installation procedures vary according togarage door types.Follow the instructionswhich apply to your

door.

1. Close the door and markthe inside vertical centerline of the garage door.

2. Extend the line onto the header wall above thedoor.You can fasten the header bracketwithin 4

feet(1.22 m) ofthe left or right of the door center onlyifa torsion spring or centerbearing plate is

in the way;or you can attach it to the ceiling (seepage 12) when clearance is minimal.(Itmaybe

mounted on the wall upside down ifnecessary, to gain approximately 1/2" (1 cm).Ifyou need to

install the header bracket on a 2x4 (on wall or ceiling), uselag screws (not provided) to securely

fasten the2x4 to structural supports as shown here and on page 12.

3. Open your door to the highestpoint of travel as shown.Draw an intersecting horizontal line on

the header wall 2"(5 cm) abovethe high point :

l

2" (5 cm)above the high pointfor sectional door and one-piece door with track.

l

8" (20 cm) above the high point for one-piece door withouttrack.

Thisheight will provide travel clearancefor the top edge ofthe door. NOTE: Ifthe total number of inches

exceeds the heightavailable in your garage, use the maximum heightpossible, or refer to page12 for

ceiling installation.

11

Page 13

Installation

HARDWARE

Lag Screw 5/16"-9x1-5/8"

UP

Wall Mount

Optional Mounting

Holes

Vertical

Centerline of

Garage Door

(Header Wall)

Header

Bracket

2x4 Structural

Support

Door Spring

(Garage Door)

Highest Point

of Garage

Door Travel

Horizontal

Line

Lag Screw

5/16"-9x1-5/8"

UP

(Header Wall)

Ceiling Mounting

Holes

(Finished Ceiling)

Vertical

Centerline

of

Garage Door

Header

Bracket

6" (15 cm)

Maximum

Door Spring

(Garage Door)

Lag Screw

5/16"-9x1-5/8"

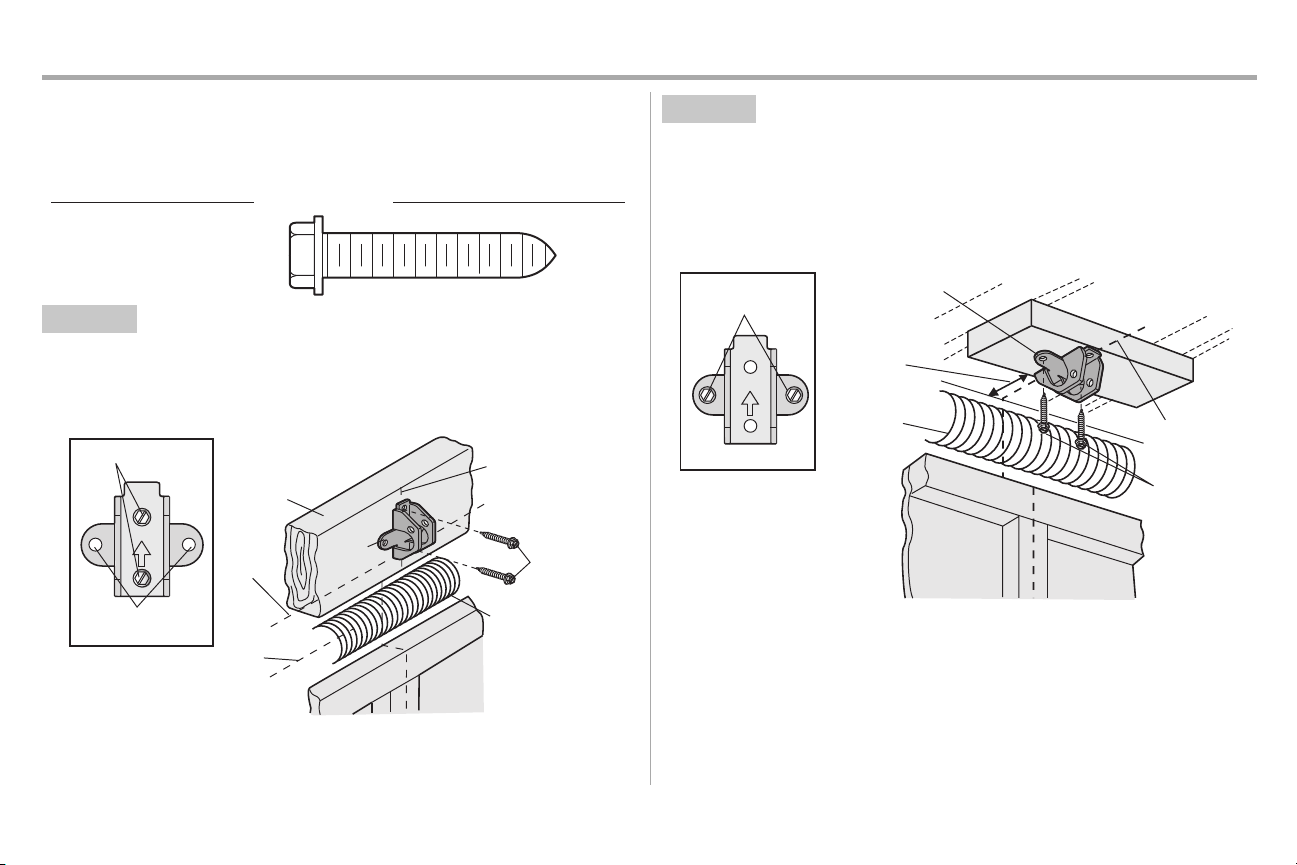

STEP 2 Install the header bracket

You can attachthe header bracketeither to thewall above the garage door, or to the ceiling.Followthe

instructions which will workbestfor your particular requirements.Donot install the header bracket over

drywall. If installing into masonry, use concrete anchors (not provided).

OPTION A WALL INSTALLATION

1. Center the bracket on the verticalcenterline with the bottomedge of thebracketon the horizontal

line asshown (with the arrowpointing toward the ceiling).

2. Mark the vertical set of bracket holes. Drill 3/16"pilot holesand fasten the bracket securely to a

structural supportwith thehardware provided.

OPTION B CEILING INSTALLATION

1. Extend the vertical centerline onto the ceiling as shown.

2. Center the bracket on the verticalmark,no more than 6" (15cm) from the wall.Makesure the

arrow is pointing away from the wall.The bracket can be mounted flush againsttheceiling when

clearance is minimal.

3. Mark the side holes.Drill 3/16" pilotholes and fastenbracketsecurelytoa structural support with

the hardwareprovided.

12

Page 14

Installation

HARDWARE

Clevis Pin 5/16"x1-1/2"

Ring Fastener

Clevis Pin

5/16"x1-1/2"

Ring Fastener

One-piece

door without

tracks

All other door types

Connected Disconnected

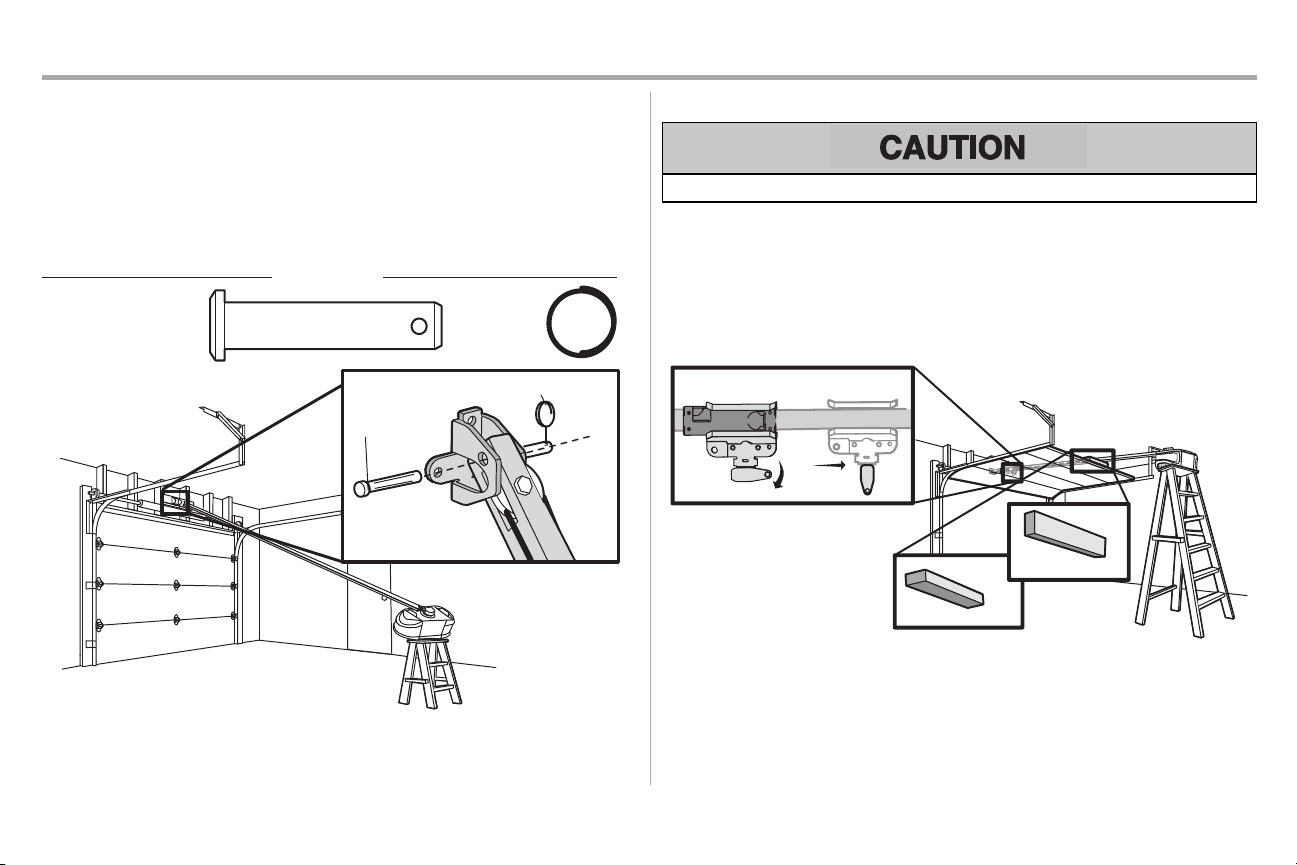

STEP 3 Attach the rail to the header bracket

1. Position the opener on the garage floor below the header bracket.Usepacking material asa

protective base.

NOTE: If the door spring isin the way, you will need help. Have someone hold the opener

securely on a temporary support to allow the rail to clear the spring.

2. Position the rail bracket against the header bracket.

3. Align the bracketholes and join witha clevis pin asshown.

4. Inserta ring fastener tosecure.

STEP 4 Position the garage door opener

To prevent damage to garage door, restgarage door opener rail on 2x4placed on top section of door.

1. Removethe packing material and liftthe garage door opener onto a ladder.

2. Fully open the door and place a 2x4(laid flat) under the rail.For one-piece doors without tracks,

lay the 2x4on it's side.

NOTE: A 2x4 is ideal for setting the distance between the rail and the door.Ifthe ladder isnot tall

enough you will need help at this point. If the door hits the trolley when it is raised, pull the trolley release

arm down to disconnectthe inner and outer trolley. Slide the outer trolley toward the garage door

opener. The trolley can remain disconnected until instructed.

13

Page 15

Installation

Finished

Ceiling

Unfinished

Ceiling

HARDWARE

Hex Bolt 5/16"- 18x7/8"

Nut 5/16"-18

Lock Washer

5/16"-18

Lag Screw 5/16"-9x1-5/8"

Finished

Ceiling

(not provided)

(not provided)

Lag Screw

5/16"9x1-5/8"

Lag Screw

5/16"9x1-5/8"

1

2

3

(not

provided)

Hex Bolt

5/16"- 18x7/8"

Nut 5/16"-18

Lock Washer

5/16"-18

4

5

6

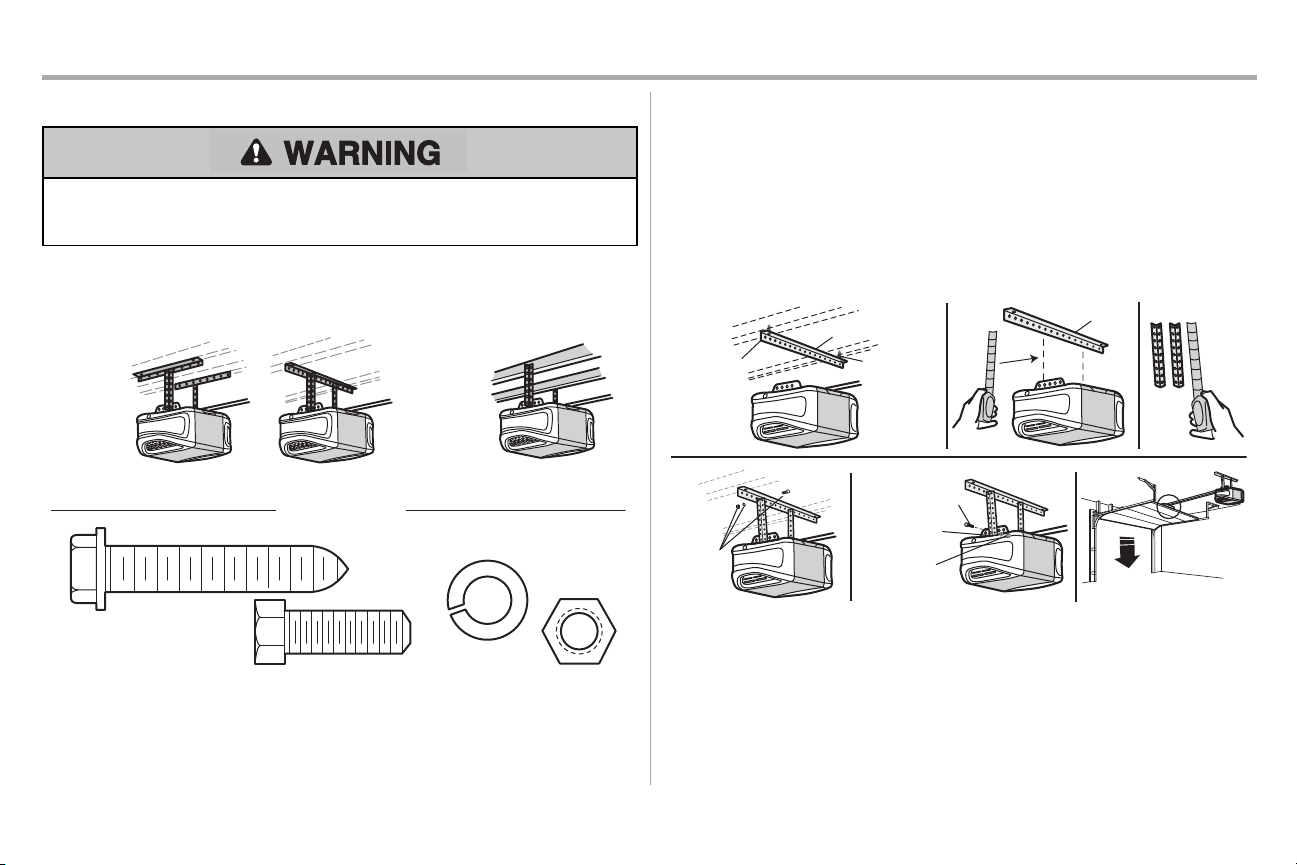

STEP 5 Hang the garage door opener

To avoid possible SERIOUS INJURY from a falling garage door opener, fasten it SECURELY to

structural supportsofthegarage. Concrete anchorsMUSTbe used ifinstalling ANY brackets into

masonry.

Hanging thegarage door opener willvary depending on your garage.Below are three example

installations.Your installation may be different.For ALL installationsthe garage door opener MUSTbe

connected to structural supports.Theinstructionsillustrateone ofthe examples below.

1. On finished ceilings,use the lag screwstoattach a support bracket (not provided) to the structural

supportsbefore installing the garage door opener.

2. Make sure the garage door opener is aligned with the header bracket. Measure thedistance

fromeach side ofthe garage door opener to the supportbracket.

3. Cutboth pieces ofthehanging bracketto required lengths.

4. Attach theend ofeach hanging bracket to the supportbracketwithappropriate hardware (not

provided).

5. Attach thegarage door opener tothe hanging bracketswith thehex bolts, lock washers,and

nuts.

6. Removethe 2x4 and manually close thedoor. If the door hits the rail,raise the header bracket.

14

Page 16

Installation

or

or

STEP 6 Install the light bulbs

To prevent possible OVERHEATING of theend panel or light socket:

l

UseONLY A19 incandescent (100W maximum) or compactfluorescent (26Wmaximum) light

bulbs.

l

DO NOT use incandescentbulbs larger than 100W.

l

DO NOT use compact fluorescentlight bulbslarger than 26W (100W) equivalent.

l

DO NOT use halogen bulbs.

l

DO NOT use shortneckor specialty light bulbs.

1. Pull on the top sidesof the lightlens and rotate the lightlens down.

2. Insertan A19 incandescent (100W maximum) or compactfluorescent (26W, 100Wequivalent)

light bulb into the light socket.

3. Rotatethe lens up to close.

NOTE: Do not use halogen, short neck, or specialty light bulbs as these may overheatthe end panel or

light socket.Do not use LEDbulbs as they may reduce the range or performance of your remote controls.

STEP 7 Attach the emergency release rope and handle

To prevent possible SERIOUS INJURY or DEATH from a falling garage door:

l

Ifpossible,use emergency releasehandle to disengage trolley ONLY when garage door is

CLOSED. Weak or broken springs or unbalanced door could result in an open door falling

rapidly and/or unexpectedly.

l

NEVER use emergencyrelease handle unlessgarage doorwayisclear of personsand

obstructions.

l

NEVER use handle to pull door open or closed. If rope knotbecomesuntied, you could fall.

1. Insertone end of the emergencyrelease rope through the handle. Make sure that “NOTICE” is

right side up. Tie a knotat least 1 inch(2.5 cm) from the end of the emergency release rope.

2. Inserttheother end of the emergencyrelease rope through the hole in the trolleyrelease arm.

Mount the emergencyrelease within reach,butatleast 6 feet (1.83m) above floor,avoiding

contactwith vehicles to preventaccidental release and secure with a knot.

NOTE: Ifit is necessaryto cut the emergency release rope, seal the cut end with a match or lighter to

prevent unraveling.Ensure the emergency release rope and handle are above the top of all vehicles to

avoid entanglement.

15

Page 17

Installation

Self-Threading Screw

1/4"-14x5/8"

HARDWARE

FIGURE 1

FIGURE 3

FIGURE 4

FIGURE 2

Vertical

Reinforcement

Vertical Centerline

of Garage Door

UP

Door Bracket

Vertical Reinforcement

Vertical Centerline

of Garage Door

Hardware

(not provided)

Door Bracket

UP

Vertical

Centerline

of Garage

Door

UP

Vertical Centerline of

Garage Door

Hardware

(not provided)

UP

Inside Edge of Door or

Reinforcement Board

Self-Threading Screw

1/4"-14x5/8"

Self-Threading

Screw

1/4"-14x5/8"

STEP 8 Install the door bracket

Fiberglass,aluminum or lightweight steel garage doors WILL REQUIRE reinforcement BEFORE

installation of door bracket.Contact the garage door manufacturer or installing dealer for opener

reinforcementinstructions or reinforcement kit.Failure to reinforce the top section as required

according to the door manufacturer may void the door warranty.

A horizontaland vertical reinforcement is needed for

lightweight garage doors (fiberglass, aluminum, steel,

doors with glasspanel, etc.) (notprovided). A horizontal

reinforcementbrace should be long enough to be

secured to two or three vertical supports. A vertical

reinforcementbrace should cover the heightof the top

panel. Contact the garage door manufacturer or installing

dealer for opener reinforcement instructions or

reinforcementkit.

NOTE: Many door reinforcement kitsprovide for directattachmentof the clevis pin and door arm. In this

case you will not need the door bracket;proceed to the nextstep.

OPTION A SECTIONAL DOORS

1. Center the door bracket on thepreviously marked vertical centerline used for the header bracket

2. Position the top edge ofthe bracket 2"-4" (5-10 cm) belowthe top edge of the door, OR directly

3. Mark,drill holesand install asfollows, depending on your door’sconstruction:

installation.NotecorrectUP placement,as stamped inside thebracket.

below anystructural support acrossthe top of the door.

Metal or light weight doors usinga vertical angleiron brace between the door panel support and

the doorbracket:

l

Drill 3/16" fastening holes.Secure the door bracket using thetwo1/4"-14x5/8"selfthreading

screws. (Figure 1)

l

Alternately,use two 5/16"-18x2" bolts, lockwashers and nuts (not provided). (Figure 2)

Metal,insulated or light weight factory reinforced doors:

l

Drill 3/16" fastening holes.Secure the door bracket using theself-threading screws.(Figure 3)

Wood Doors:

l

Usetop and bottomor side toside door bracketholes. Drill 5/16" holes through the door and

secure bracket with 5/16"-18x2" carriage bolts,lockwashersand nuts(notprovided). (Figure 4)

NOTE: The 1/4"-14x5/8" self-threading screws are not intended for use on wood doors.

16

Page 18

Installation

For a door with no exposed

framing, or for the optional

installation, use lag screws

5/16"x1-1/2" (not provided)

to fasten the door bracket.

Vertical

Centerline

of Garage

Door

Optional

Placement

of Door

Bracket

Door Bracket

Header Bracket

Header Wall

2x4 Support

(Finished Ceiling)

Door

Brack

et

Top of Door

(Inside Garage)

Top Edge of

Door

Optional

Placement

Optional

Placement

Top Edge

of Door

Top of Door

(Inside Garage)

Door

Bracket

Hardware

(not provided)

Hardware

(not provided)

Metal Door

Wood Door

Self-Threading

Screw 1/4"-14x5/8"

STEP 8 Install the door bracket (continued)

OPTION B ONE-PIECE DOORS

1. Center the door bracket on thetop of the door, in line with the header bracketasshown.

2. Mark either the leftand right,or the top and bottom holes.

Metal Doors:

l

Drill 3/16" pilotholes and fastenthe bracket with the self-threading screws provided.

Wood Doors:

l

Drill 5/16" holes and use 5/16"-18x2" carriage bolts,lockwashersand nuts(notprovided) or

5/16"x1-1/2"lag screws (not provided) depending on your installation needs.

NOTE: The door bracket may be installed on the top edge of the door if required for your installation.

(Refer to the dotted line optional placement drawing.)

17

Page 19

Installation

HARDWARE

Hex Bolt 5/16"-18x7/8"

Nut 5/16"-18

Lock Washer 5/16" -18

Clevis Pin 5/16"x1" Clevis Pin 5/16"x1-1/4"

Ring

Fastener

Straight

Door Arm

Curved

Door

Arm

(Groove

facing

out)

CORRECT

Straight

Door

Arm

Curved

Door

Arm

INCORRECT

Lock Washer

5/16" -18

Nut

5/16"-18

Hex Bolt 5/16"-18x7/8"

Clevis Pin 5/16"x1-1/4"

Ring Fastener

Clevis Pin

5/16"x1"

STEP 9 Connect the door arm to the trolley

Installation willvaryaccording to thegarage door type. Follow the instructions which applytoyour door.

OPTION A SECTIONAL DOORS

IMPORTANT: The groove on the straight door arm MUST face away from the curved door arm.

1. Close the door.Disconnect the trolley bypulling the emergency releasehandle.

2. Attach thestraightdoor armto the outer trolleyusing the clevis pin.Secure with the ring fastener.

3. Attach thecurved door arm to the door bracket using the clevispin. Secure withthe ring fastener.

4. Bring arm sectionstogether.Find two pairs ofholes that line up and join sections. Select holesas

far apart aspossible to increase door armrigidity and attach using the bolts, nuts,and lock

washers.

5. Pull theemergency release handle towardthe garage door opener until the trolleyrelease arm

is horizontal. The trolleywill re-engage automaticallywhen the garage door opener is activated.

NOTE: Ifthe holes in the curved door arm and the straight door arm do not align,reverse the straight

door arm,selecttwo holes(as far apartas possible) and attach using bolts , nuts, and lockwashers. Ifthe

straight door arm is hanging down too far, you may cut 6 inches (15 cm) from the solid end.

18

Page 20

Installation

HARDWARE

Hex Bolt 5/16"-18x7/8"

Nut 5/16"-18

Lock Washer 5/16" -18

Clevis Pin 5/16"x1" Clevis Pin 5/16"x1-1/4"

Ring

Fastener

One-Piece Door without Track

One-Piece Door with Track

Straight

Door Arm

Curved

Door

Arm

(Groove

facing out)

CORRECT

INCORRECT

Straight

Door

Arm

Curved

Door

Arm

Ring

Fastener

Ring Fastener

Nut 5/16"-18

Nut 5/16"-18

Ring

Fastener

Ring Fastener

Lock Washer 5/16" -18

Lock Washer 5/16" -18

Clevis Pin 5/16"x1-1/4"

Clevis Pin

5/16"x1-1/4"

Hex Bolt 5/16"-18x7/8"

Hex Bolt 5/16"-18x7/8"

Clevis Pin

5/16"x1"

Clevis Pin

5/16"x1"

STEP 9 Connect the door arm to the trolley (continued)

OPTION B ONE-PIECE DOORS

IMPORTANT: The groove on the straight door arm MUST face away from the curved door arm.

1. Close the door.Disconnect the trolley bypulling the emergency releasehandle.

2. Fasten thestraightdoor arm and the curved door arm together tothe longestpossible length

3. Attach thestraightdoor armto the door bracket using the clevispin.Secure with the ring fastener.

4. Attach thecurved door arm to the trolleyusing the clevispin.Secure with the ring fastener.

5. Pull theemergency release handle towardthe garage door opener until the trolleyrelease arm

(with a 2 or 3 hole overlap) usingthe bolts, nuts,and lock washers.

is horizontal.

19

Page 21

Installation

HARDWARE

Screw

6ABx1" (2)

Drywall

Anchors (2)

Screw

6-32x1" (2)

7/16" (11 mm)

Wall

1

2 3

DRYWALL

GANG BOX

6ABx1"

6-32x1"

Drywall Anchor

4-5

6

6-32x1"

GANG BOX

8

DRYWALL

6ABx1"

Drywall Anchor

7

STEP 10 Install the door control

To prevent possible SERIOUS INJURY or DEATH from electrocution:

l

Be sure power is NOTconnectedBEFORE installing door control.

l

ConnectONLY to 12 VOLTlow voltage wires.

To prevent possible SERIOUS INJURY or DEATH from a closinggarage door:

l

Install door control within sightofgarage door, out ofreach of children at a minimumheight of 5

feet(1.5 m), and away from ALL moving parts of door.

l

NEVER permit children to operateor playwith door control push buttonsor remote control

transmitters.

l

Activate door ONLY when it can be seen clearly,isproperly adjusted, and there are no

obstructions to door travel.

l

ALWAYS keep garage door in sight untilcompletelyclosed. NEVER permitanyone to crosspath

of closing garage door.

INTRODUCTION

Compatible with MyQ®enabled accessories, see page 44.Your garage door opener is compatible with

up to 2 MyQ®door controls. NOTE: Older Chamberlain door controlsand third party products are not

compatible.

Install thedoor controlwithin sight of the door at a minimum heightof5 feet (1.5 m)where small children

cannot reach, and away from the moving partsof the door.For gang box installations it is notnecessary

to drill holes or install the drywall anchors.Use the existing holes in thegang box.

NOTE: Your product may look different than the illustrations.

1. Strip 7/16 inch (11 mm)of insulation from one end of the wire and separatethe wires.

2. Connectone wire to each ofthe two screwson the backofthe door control.The wires can be

connected to either screw. Ifyour garage is pre-wired for the door control chooseany two wires to

connect,notewhich wires are used so the correctwiresare connected to the garage door

opener in a later step.

3. Mark the location ofthe bottommounting hole and drill a 5/32 inch (4 mm) hole.

4. Install thebottomscrew, allowing 1/8 inch (3 mm) to protrude fromthe wall.

5. Position the bottom hole of the door control over the screwand slide down intoplace.

6. Liftthe push bar up and mark thetop hole.

7. Removethe door control from the wall and drill a 5/32 inch (4 mm) hole for the top screw.

8. Position the bottom hole of the door control over the screwand slide down intoplace.Attachthe

top screw.

20

Page 22

Installation

HARDWARE

Ins

ulated

Staple

(Not Shown)

RED

WHITE

WHITE

GREY

7/16" (11 mm)

2

3

1

Staple

STEP 11 Wire the door control to the garage door opener

1. Run the white and red/white wire fromthe door control to the garage door opener.Attach the

wire to the wall and ceiling with the staple (not applicable for gang box or pre-wired installations).

Do not piercethe wire with the staple as this may cause a shortor an open circuit.

2. Strip 7/16 inch (11 mm)of insulation from the end ofthewire near the garage door opener.

3. Connectthe wire tothe red and white terminals on the garage door opener.Ifyour garage isprewired make sure you use thesame wires that are connectedto the door control. To insert or

release wires fromthe terminal, push in the tab with screwdriver tip.

STEP 12 Attach the warning labels

1. Attach theentrapment warning label on the wall near thedoor controlwithtacks or staples.

2. Attach themanual release/safetyreverse testlabel in a visible location on theinside of the

garage door.

21

Page 23

Installation

Safety Reversing Sensor

6" (15 cm)

max. above floor

Invisible Light Beam

Protection Area

Facing the door from inside the garage

HARDWARE

Carriage Bolt

1/4"-20x1/2"

Wing Nut

1/4"-20

No more

than 6 inches

(15 cm)

Carriage Bolt

1/4"-20x1/2"

Wing Nut

1/4"-20

1

2

3

STEP 13 Install the Protector System

®

Be sure power is NOTconnectedto the garage door opener BEFORE installing the safetyreversing

sensor.

To prevent SERIOUS INJURY or DEATH from closing garage door:

l

Correctlyconnectand align the safetyreversing sensor. This required safetydeviceMUSTNOT

be disabled.

l

Install thesafety reversing sensor sobeam is NOHIGHERthan 6" (15 cm) above garage floor.

IMPORTANTINFORMATION ABOUTTHE SAFETY REVERSING SENSORS

The safety reversing sensors must be connected andalignedcorrectly before the garage door

openerwill move in the down direction.

The sending sensor (with an amber LED)transmits an invisible light beamto the receiving sensor(with a

green LED).Ifan obstruction breaks the light beam while the door is closing, the door will stop and

reverse to the fullopen position,and the garage door opener lightswill flash10 times.

NOTE: For energyefficiency the garage door opener will enter sleep mode when the door is fully

closed. The sleep mode shuts the garage door opener down until activated. The sleep mode is

sequenced with the garage door opener lightbulb; as the light bulb turns off the sensor LEDswill turn off

and whenever the garage door opener lights turn on the sensor LEDswill light. The garage door opener

will not go into the sleep mode until the garage door opener has completed 5 cycles upon power up.

When installing thesafety reversing sensorscheckthe following:

l

Sensors are installed inside the garage,one on either side of the door.

l

Sensors are facing each otherwiththe lenses aligned and the receiving sensorlens doesnot

receive direct sunlight.

l

Sensors are no more than 6 inches (15 cm)above the floor and the light beamis unobstructed.

The safetyreversing sensors can be attached to the door track,thewall,or the floor.The sensors should

be no more than 6 inches (15 cm) above thefloor. Ifthe door trackwillnot support the sensorbracketa

wall installation is recommended.Chooseone ofthe following installations.

OPTION A DOOR TRACK INSTALLATION

1. Slide the curved arms of the sensor bracketaround the edge of the door track.Snap into place

so that the sensor bracketisflushagainst the track.

2. Slide the carriage bolt into the sloton each sensor.

3. Insertthebolt through the hole in the sensorbracketand attach with the wing nut. The lenseson

both sensors should point toward eachother. Make sure the lens is notobstructed by the sensor

bracket.

22

Page 24

Installation

(Not provided)

No more than

6 inches (15 cm)

1

2

Inside

G

arage

Wall

(Not provided)

Lens

Carriage Bolt

1/4"-20x1/2"

Wing Nut

1/4"-20

3

4

I

nsid

e

G

arage

Wa

l

l

(Not provided)

1 2

Carriage Bolt

1/4"-20x1/2"

Wing Nut

1/4"-20

3

4

STEP 13 Install the Protector System®(continued)

OPTION B WALL INSTALLATION

Ifadditional clearanceis needed an extension bracket(notprovided) or wood blockscanbe used.Make

sure each brackethas the same amountofclearance so they willalign correctly.

1. Position the sensor bracketagainstthe wall with the curved arms facing the door.Make sure

there is enough clearancefor the beamto be unobstructed. Mark holes.

2. Drill 3/16 inch pilot holesfor each sensor bracketand attach the sensor brackets to the wall using

lag screws(not provided).

3. Slide the carriage bolt into the sloton each sensor.

4. Insertthebolt through the hole in the sensorbracketand attach with the wing nut. The lenseson

both sensors should point toward eachother. Make sure the lens is notobstructed by the sensor

bracket.

OPTION C FLOOR INSTALLATION

Usean extension bracket(not provided) or wood block to raise the sensor bracket if needed.

1. Carefullymeasure the positionof both sensor brackets so they will be the samedistancefromthe

wall and unobstructed.

2. Attach thesensor bracketstothe floor using concrete anchors (notprovided).

3. Slide the carriage bolt into the sloton each sensor.

4. Insertthebolt through the hole in the sensorbracketand attach with the wing nut. The lenseson

both sensors should point toward eachother. Make sure the lens is notobstructed by the sensor

bracket.

23

Page 25

Installation

HARDWARE

Ins

ulated

Staple

(Not Shown)

Staple

7/16" (11 mm)

WHITE

WHITE

GREY

RED

1

2

3

STEP 14 Wire the Safety Reversing Sensors

Ifyour garage alreadyhas wires installed for the safetyreversing sensors,proceed to page25.

OPTION A INSTALLATION WITHOUT PRE-WIRING

1. Run the wirefrom both sensors to the garage door opener. Attach the wire tothe wall and ceiling

withthe staples.

2. Strip 7/16 inch (11 mm)of insulation from eachsetof wires.Separate thewires.Twistthe white

wires together. Twistthe white/black wires together.

3. Insertthewhite wires into the whiteterminal on the garage door opener. Insert the white/black

wires into the grey terminal on the garage door opener. Toinsert or removethe wires from the

terminal,push in the tab with a screwdrivertip.

24

Page 26

Installation

Safety reversing

sensor wires

Pre-installed

wires

White

White/Black

Yellow (for example)

Purple (for example)

Not Provided

Pre-installed wires

Safety reversing

sensor wires

7/16" (11 mm)

Yellow

Purple

1

3

4

7/16"

(11 mm)

2

WHITE

WHITE

RED

GREY

Purple

(for

example)

Yellow

(for example)

To insert or remove the wires from

the terminal, push in the tab with a

screwdriver tip.

5

STEP 14 Wire the Safety Reversing Sensors (continued)

OPTION B PRE-WIRED INSTALLATION

1. Cutthe end of the safetyreversing sensor wire, making sure there isenough wire to reachthe

pre-installed wiresfromthe wall.

2. Separate the safetyreversing sensorwires and strip 7/16 inch (11 mm) of insulation fromeach

end. Choose two of thepre-installed wiresand strip 7/16 inch (11 mm)of insulation fromeach

end. Make sure thatyou choose the samecolor pre-installed wiresfor each sensor.

3. Connectthe pre-installed wiresto the sensor wires with wire nutsmaking sure thecolors

correspond for each sensor. For example, the whitewire would connecttothe yellow wire and

the white/blackwire would connectto thepurple wire.

4. At the garage door opener,strip 7/16inch (11 mm) of insulation fromeach end of the wires

previously chosen for the safety reversing sensors. Twistthe like-colored wires together.

5. Insertthewires connected to the whitesafety sensor wires to thewhite terminal on the garage

door opener. Insert the wires that are connected to the white/black safetysensor wirestothe grey

terminal on the garage door opener.

25

Page 27

Installation

Ground Tab

Green Ground

Screw

Ground Wire

Black

Wire

White Wire

PERMANENT WIRING

Wire Nuts

STEP 15 Connect power

To prevent possible SERIOUS INJURY or DEATH from electrocution or fire:

l

Be sure power is NOTconnectedto the opener,and disconnectpower to circuit BEFORE

removing cover to establish permanent wiring connection.

l

Garage door installation and wiring MUSTbe in compliance with ALL local electricaland building

codes.

l

NEVER use an extension cord, 2-wire adapter, or change plug in ANY way to make it fit outlet. Be

sure the opener isgrounded.

To avoidinstallation difficulties, do not run the openerat this time.

To reduce the risk of electric shock,your garage door opener has a grounding type plug with a third

grounding pin. This plug will onlyfitintoa grounding type outlet. Ifthe plug doesn’t fit into the outletyou

have, contacta qualified electricianto install the proper outlet.

THERE ARE TWO OPTIONS FOR CONNECTING POWER:

OPTION A TYPICAL WIRING

1. Plug in the garage door opener into a grounded outlet.

2. DO NOT run garage door opener atthistime.

OPTION B PERMANENT WIRING (Models manufactured before October 2012)

If permanent wiring is required by your localcode,refer to the followingprocedure. To make a

permanent connection throughthe 7/8 inch hole in the topof the motor unit (accordingto local

code):

1. Be sure power is NOTconnectedto the opener,and disconnectpower to circuit.

2. Removethe garage door opener cover and setaside.

3. Removethe attached green ground terminal.

4. Cutblack and whitewiresand strip away1/2inch (1 cm)of insulation, 3 inch (7.5 cm) before

spade terminals.

5. Removethe power cord from opener.

6. Install a conduit or flexcable adapter to the 7/8 inchhole.

7. Run wires through conduit,cutto proper length and strip insulation.

8. Attach with wire nutsprovided. Attach the ground wire tothe green ground screw.The opener

must be grounded.

9. Properly secure wire under plastictiesso that wire doesnot come in contact with moving parts.

10. Reinstall the cover. DO NOTrun garage door opener at this time.

Refer to page 27 for models manufactured after October 2012.

26

Page 28

Installation

Ground Tab

Green

Ground

Screw

Ground

Wire

White Wire

Black

Wire

Black

Wire

OPTION B PERMANENT WIRING (Models manufactured after October 2012)

If permanent wiring is required by your localcode,refer to the followingprocedure. To make a

permanent connection throughthe 7/8 inch hole in the topof the motor unit (accordingto local

code):

1. Removethe motor unitcover screws and setthecover aside.

2. Removethe attached 3-prong cord.

3. Connectthe black (line) wire to thescrewon the brassterminal;the white (neutral) wire to the

screwon the silver terminal; and the ground wire tothe green ground screw.The opener must

be grounded.

4. Reinstallthe cover.

27

Page 29

Installation

Green LED

Amber LED

If the receiving sensor is in direct sunlight,

switch it with sending sensor so it is on the

opposite side of the door.

(invisible light beam)

SENDING SENSOR RECEIVING SENSOR

RED

WHITE

WHITE

GREY

3

2

1

1

2

STEP 16 Aligning the safety reversing sensors

The door willnotclose if the sensors have not been installed and aligned correctly.

When the light beam isobstructed or misaligned while the door isclosing,thedoor will reverse and the

garage door opener lightswill flash ten times.Ifthedoor isalready open,it will notclose.

1. Checktomake sure the LEDsin both sensorsare glowing steadily.TheLEDs in both sensorswill

glow steadily if they are aligned and wired correctly.

The sensors can be aligned by loosening the wing nuts,aligning the sensors,and tightening thewing

nuts.

IFTHE AMBER LED ON THE SENDING SENSOR IS NOT GLOWING:

1. Make sure there is power tothe garage door opener.

2. Make sure the sensorwire is notshorted/broken.

3. Make sure the sensorhas been wired correctly: white wires to white terminaland white/black

wires to grey terminal.

IFTHE GREEN LED ON THE RECEIVING SENSOR IS NOTGLOWING:

1. Make sure the sensorwire is notshorted/broken.

2. Make sure the sensorsare aligned.

STEP 17 Ensure the door control is wired correctly

Ifthe door control has been installed and wired correctly,a message will displayon the Smart Control

Panel screen or the command LED on the Motion-Detecting Control Panel will blink.

28

Page 30

Adjustments

UP (Open)

DOWN (Close)

CORRECT

INCORRECT

UP Button

Adjustment Button

DOWN Button

PROGRAMMING BUTTONS

Introduction

Withouta properly installed safetyreversal system,persons(particularly small children) could be

SERIOUSLY INJURED or KILLED by a closing garage door.

l

Incorrectadjustment of garage door travel limitswill interfere with proper operation of safety

reversal system.

l

AfterANY adjustmentsare made, thesafety reversal systemMUST be tested. Door MUSTreverse

on contact with 1-1/2" (3.8 cm) high object (or 2x4 laid flat) on floor.

To prevent damage to vehicles,be sure fullyopen door providesadequate clearance.

Your garage door opener is designed with electronic controls to make setup and adjustmentseasy.The

adjustmentsallowyou to program where thedoor will stop in theopen (UP) and close(DOWN) position.

The electronic controls sense the amount of force required to open and close the door.The force is

adjusted automaticallywhen you program the travel.

NOTE: Ifanything interferes with the door’s upward travel it will stop. Ifanything interferes with the door’s

downward travel, it will reverse.

One-Piece Doors Only

When setting the UPtravel for a one-piece door ensure thatthe door does not slantbackwards when

fullyopen (UP).Ifthedoor isslanted backwardsthiswill cause unnecessarybucking and/or jerking when

the door is opening or closing.

Programming Buttons

The programmingbuttonsare located on the leftside panel ofthe garage door opener and are used to

program thetravel.While programming,theUP and DOWNbuttonscan be used to move the door as

needed.

To watcha short instructional video on howtoprogram thetravel on your

new garage door opener use your smartphone to read the QR Code:

29

Page 31

Adjustments

UP Button

Adjustment Button

DOWN Button

PROGRAMMING BUTTONS

1 2

3

4 5

6 7

STEP 1 Program the Travel

Withouta properly installed safetyreversal system,persons(particularly small children) could be

SERIOUSLY INJURED or KILLED by a closing garage door.

l

Incorrectadjustment of garage door travel limitswill interfere with proper operation of safety

reversal system.

l

AfterANY adjustmentsare made, thesafety reversal systemMUST be tested. Door MUSTreverse

on contact with 1-1/2" (3.8 cm) high object (or 2x4 laid flat) on floor.

While programming,the UP and DOWNbuttonscan be used to move the door asneeded.

1. Press and hold the AdjustmentButtonuntil the UP Button begins toflashand/or a beep isheard.

2. Press and hold the UP Button until the door isin the desired UP position.

3. Once the door is in the desired UP position pressand releasethe Adjustment Button.The

garage door opener lightswill flash twiceand the DOWNButtonwill begin to flash.IMPORTANT

NOTE: For one-piece door installations refer to page 29.

4. Press and hold the DOWNbuttonuntil the door is in the desired DOWNposition.

5. Once the door is in the desired DOWNposition press and release the AdjustmentButton.The

garage door opener lightswill flash twiceand the UP Button will begin to flash.

6. Press and release the UP Button.When the door travels to the programmed UP position,the

DOWNButton will begin to flash.

7. Press and release the DOWNButton. The door will travelto the programmed DOWN position.

Programming iscomplete.

* Ifthe garage door opener lightsare flashing 5 times during the steps for Program the Travel, the

programming has timed out. Ifthe garage door opener lightsare flashing 10 times during the steps for

Program theTravel,the safetyreversing sensorsare misaligned or obstructed (refer to page 28). When

the sensors are aligned and unobstructed, cycle thedoor through a completeup and down cycle using

the remote control or the UP and DOWN buttons.Programming is complete. Ifyou are unable to operate

the door up and down, repeatthe steps for Programming the Travel.

30

Page 32

Adjustments

1 2

1

2

STEP 2 Test the Safety Reversal System

STEP 3 Test the Protector System

®

Withouta properly installed safetyreversal system,persons(particularly small children) could be

SERIOUSLY INJURED or KILLED by a closing garage door.

l

Safetyreversal system MUSTbe tested every month.

l

AfterANY adjustmentsare made, thesafety reversal systemMUST be tested. Door MUSTreverse

on contact with 1-1/2" (3.8 cm) high object (or 2x4 laid flat) on thefloor.

1. Withthe door fully open, placea 1-1/2inch (3.8 cm) board (or a 2x4laid flat) on the floor,

centered under the garage door.

2. Operate thedoor in the downdirection. The door MUSTreverse on striking theobstruction.

Ifthe door stops and does notreverse on theobstruction, the down travel needstobe increased(refer to

AdjustmentStep 1). Repeatthetest. When thedoor reverseson the 1-1/2" (3.8 cm) board (or 2x4 laid

flat),removethe obstruction and run the opener through 3 or 4 completetravel cycles to test adjustment.

Ifthe garage door opener continuesto fail the safetyreversal test,call a trained door systemstechnician.

Withouta properly installed safetyreversing sensor, persons (particularly small children) could be

SERIOUSLY INJURED or KILLED by a closing garage door.

1. Open the door. Placethe garage door opener carton in thepath of the door.

2. Press the remote control push button to close thedoor. The door will not move more than an inch

(2.5 cm),and thegarage door opener lightswill flash 10 times.

The garage door opener will not close froma remote control ifthe LED in either safety reversing sensor

is off(alerting you to the fact that the sensor ismisaligned or obstructed). If the garage door opener

closesthe door when the safetyreversing sensor isobstructed (and the sensors are no more than 6

inches [15 cm] above the floor), call for a trained door systems technician.

31

Page 33

Battery Backup

Battery

Status LED

1 2

3

STEP 1 Install the Battery

To reduce the risk of FIREor INJURY topersons:

l

Disconnect ALL electricand battery powerBEFORE performing ANY service or maintenance.

l

UseONLY Chamberlain part # 41A6357-1 for replacementbattery.

l

DO NOT dispose ofbatteryin fire. Battery may explode. Check with local codesfor disposal

instructions.

ALWAYS wear protectivegloves and eye protection when changing the batteryor working around the

batterycompartment.

1. Unplug the garage door opener.

2. Open the light lenson the right side panel of the garage door opener. Use a Phillips head

screwdriver toremove the batterycoveron the garage door opener.

3. Partially insert the battery into thebatterycompartment with the terminals facing out.

4. Connectred (+) and black(-) wires from thegarage door opener tothe corresponding terminals

on the battery.

5. Replace the battery cover.

6. Plug in the garage door opener.

7. Waitfor the green Battery Status LED to start flashing before proceeding to testthe battery.

STEP 2 Test the Battery

1. Unplug the garage door opener. The battery statusLED will wither glow solid orange indicating

opener is operating on batterypower or will flash indicating lowbatterypower.NOTE: Make sure

the garage door opener is unplugged.

2. Open and close thedoor using the remote control or door control.The garage door opener may

run slower ifthe battery is not fully charged.The battery will take 24 hours to fullycharge.

3. Plug in the garage door opener.Verifythe battery statusLEDis flashing green,indicating the

batteryischarging.

32

Page 34

Battery Backup

Battery Status LED

Charge the Battery

The battery charges when the garage door opener is plugged into a 110Vac electrical outletthat has

power and requires24 hoursto fully charge. A fullycharged battery supplies 12Vdc to the garage door

opener for one to two days of normal operation during an electrical power outage. After the electrical

power hasbeen restored, the batterywillrecharge within 24 hours.The batterywill lastapproximately 1

to 2 yearswith normal usage. Instructions for replacement are provided with the battery. To obtain

maximumbattery life and preventdamage, disconnectthe battery when the garage door opener is

unplugged for an extended period of time, such as a summeror winter home.

NOTE: When the garage door opener is in battery backup mode the garage door opener lights,Timerto-Close,and Remote Close features are unavailable.

Battery status LED

NOTE: The Battery Status LED is most visible with the garage door opener lightoff. Battery does not

have to be fully charged to operate the garage door opener.

GREEN LED:

All systemsare normal.

l

A solid green LED light indicatesthe batteryisfullycharged.

l

A flashing green LED indicates the battery is being charged.

ORANGE LED:

The garage door opener has lost power and is in battery backup mode.

l

A solid orange LED with beep,sounding approximately every 2 seconds,indicatesthe garage door

opener is operating on batterypower.

l

A flashing orange LED with beep, sounding every 30 seconds,indicatesthe batteryis low.

RED LED:

The garage door opener's12V battery needstobe replaced.

l

A solid red LEDwithbeep, sounding every 30 seconds,indicatesthe 12V batterywill no longer hold

a charge and needs to be replaced. Please call for replacementbatteryto allow your systemto

operate during a power outage.

33

Page 35

Operation

IMPORTANT SAFETY INSTRUCTIONS

To reduce the risk of SEVERE INJURY or DEATH:

1. READ AND FOLLOW ALL WARNINGSAND INSTRUCTIONS.

2. ALWAYS keep remote controls out ofreach of children.NEVER permit children to operate

or playwithgarage door control push buttons or remotecontrols.

3. ONLY activate garage door when it can be seen clearly,itis properly adjusted,and there

are no obstructionstodoor travel.

4. ALWAYS keep garage door in sight and away from people and objectsuntil completely

closed.NO ONE SHOULDCROSS THEPATHOF THE MOVING DOOR.

5. NO ONE SHOULDGO UNDER A STOPPED,PARTIALLY OPENED DOOR.

6. Ifpossible,use emergency releasehandle to disengage trolley ONLY when garage door is

CLOSED. Use caution when using this releasewiththe door open. Weak or broken

springs or unbalanced door could result in an open door falling rapidlyand/or unexpectedly

and increasing the risk of SEVERE INJURY or DEATH.

7. NEVER use emergencyrelease handle unlessgarage doorwayisclear of personsand

obstructions.

8. NEVER use handle to pull garage door open or closed. If rope knotbecomesuntied, you

could fall.

9. AfterANY adjustmentsare made, thesafety reversal systemMUST be tested.

10. Safety reversal system MUST be tested everymonth.Garage door MUST reverse on contactwith

1-1/2" (3.8 cm) high object (or a 2x4 laid flat) on the floor. Failure to adjust the garage door

opener properly increasesthe riskof SEVEREINJURY or DEATH.

11.

ALWAYS KEEP GARAGE DOOR PROPERLY BALANCED(seepage 1).An improperly

balanced door may NOT reversewhen required and could resultin SEVEREINJURYor

DEATH.

12. ALL repairs tocables,spring assemblies and other hardware,ALL ofwhich are under

EXTREME tension, MUSTbe made by a trained door systemstechnician.

13. ALWAYS disconnectelectricpower to garage door opener BEFORE making ANY repairsor

removing covers.

14. This operatorsystemis equipped with an unattended operation feature. The door could move

unexpectedly.NOONE SHOULD CROSS THEPATHOF THE MOVING DOOR.

15. DO NOT enable the Timer-to-Close functionality if operating either one-piece or swinging

garage doors. To be enabled ONLY when operating a sectional door.

16. SAVE THESE INSTRUCTIONS.

34

Page 36

Operation

Features

Your garage door opener is equipped with features to provide you with greater control over your garage

door operation.

®

MyQ

MyQ®technology uses a 900MHzsignal to providetwo-waycommunication between thegarage door

opener and MyQ®enabled accessories. Your garage door opener iscompatiblewithup to 8 MyQ

accessories. For Smartphone App controlof your garage door opener and other MyQ®accessories,

Chamberlain's MyQ®InternetGateway(model CIGBU) is required.

TIMER-TO-CLOSE (TTC)

The Timer-to-Close feature automatically closesthe door aftera specified time period that can be

adjusted using the door control.DO NOT enable TTCifoperating a one-piecedoor. TTC is to be used

ONLY with sectional doors.Factory default is set to off. The garage door opener will beep and the lights

will flash before closing the door.The TTCfeature will deactivateif the garage door encounters an

obstruction twice;or the safety reversing sensors are incorrectlyinstalled.The garage door will reverse

open and WILL NOT close until the obstructionsare clear or the safety reversing sensors are correctly

installed.When the obstruction has been cleared or the safety reversing sensors havebeen aligned, the

door will close when thegarage door opener isactivated. TTCWILL NOTworkifthe garage door opener

is operating by battery power or if the safetyreversing sensors are misaligned. This feature is NOT

intended tobe the primary method of closing the door. A keyless entry shouldbe installed in the event

of an accidental lock out when usingthis feature.

REMOTE CONTROLS AND DOOR CONTROLS (MyQ®)

Your garage door opener hasalready been programmed atthe factorytooperate with your remote

control,whichchanges with each use,randomly accessingover 100 billion new codes. Compatible with

MyQ®enabled accessories, see page 44.

NOTE: Older Chamberlain remote controls, door controls,and third partyproductsare notcompatible.

MyQ®Accessories MEMORY CAPACITY

RemoteControls Up to 8

Door Controls Up to 2 MyQ®door controls

KeylessEntries Up to 1

®

THE PROTECTOR SYSTEM®(SAFETY REVERSING SENSORS)

When properly connected and aligned, thesafety reversing sensorswilldetectan obstruction in the path

of the infrared beam. If an obstruction breaksthe infrared beamwhile the door is closing, the door will

stopand reverseto full open position, and the opener lights will flash 10 times.Ifthe door isfullyopen,

and thesafety reversing sensorsare not installed, or are misaligned,the door will not close froma

remote control. However,you can close the door ifyouhold the button on the door control or keyless

entry until the door is fullyclosed. The safety reversing sensors do not effectthe opening cycle.

ENERGY CONSERVATION

For energyefficiency the garage door opener will enter sleep mode when the door is fully closed. The

sleep mode shutsthegarage door opener down until activated. The sleep mode issequenced with the

garage door opener light bulb; as thelight bulb turns off the sensor LEDswillturn off and whenever the

garage door opener lightsturn on the sensor LEDs will light.The garage door opener will not go into the

sleep mode until the garage door opener has completed 5 cyclesupon powerup.

LIGHTS

The garage door opener light bulbswill turn on when the opener isinitially plugged in; poweris restored

afterinterruption, or when the garage door opener is activated.The lights will turn offautomatically after

4-1/2 minutes. An incandescentA19 lightbulb (100 wattmaximum) or for maximum energy efficiencya

26W (100Wequivalent) compact fluorescentlight (CFL) bulb may be used.NOTE: Do not use halogen,

short neck,or specialty light bulbsas these may overheat the end panel or light socket.Do not use LED

bulbs as theymayreduce the range or performance of your remote controls.

Light Feature

The garage door opener is equipped with an added feature;thelights will turn on when someone enters

through the open garage door and the safetyreversing sensor infrared beam is broken.For added

control over the light bulbson your garage door opener, see page 36 and 37.

BATTERY BACKUP

The battery backup systemallowsaccess in and outofyour garage,even when the power isout.When

the garage door opener is operating on batterypower, the garage door opener will run slower,the light

will not function, the BatteryStatusLED will glowsolid orange,and a beep will sound approximately

every 2 seconds.

35

Page 37

Operation

ON (TTC)

OFF (TTC)

Command LED

Motion Sensor

Switch

LIGHT

Button

HOLD OPEN

Button(TTC)

Motion

Sensor

Push Bar

1, 5, and

10 Minute

TTC LED

LEARN Button

LOCK Button

Using your Garage Door Opener

The garage door opener can be activated through a wall-mounteddoor control,remotecontrol,wireless

keylessentryor MyQ®accessory.

When the door is closedand thegarage door opener isactivated the door will open. If the door senses

an obstruction or isinterrupted while opening the door will stop. When the door isin any position other

than closed and the garage door opener is activatedthe door will close. Ifthe garage door opener

sensesan obstruction while closing, the door will reverse. If the obstruction interrupts the sensor beam

the garage door opener lights will blink10 times.However, you can close the door if you hold the button

on the door control or keylessentryuntil the door is fully closed. The safety reversing sensors do not

affect the opening cycle.

The safetyreversing sensor must be connected and aligned correctly before the garage door opener will

move in thedown direction.

Using the Motion Detecting Control Panel

SYNCHRONIZE THE DOOR CONTROL

To synchronize the door control to the garage door opener, press the push bar until the garage door

opener activates (it may take up to 3 presses). Testthe door control by pressing thepush bar,each press

of the pushbar will activate the garage door opener.

MOTION DETECTING CONTROL PANEL FEATURES

PUSH BAR

Press the push bar to open or close the door.

LIGHTS

Light Button

Press the LIGHT button to turnthe garage door opener lights on or off.When the lightsare turned on

theywill stayon untilthe LIGHTbutton is pressed again,or untilthe garage door opener is activated.

Once the garage door opener is activated the lightswill turn offafter the specified period oftime (the

factory setting is 4-1/2 minutes). The LIGHT button will not control the lightswhen the door is in motion.

To changethe amount of time the garage door openerlights willstay on:

Press and hold the LOCK button (approximately10 seconds) until thegarage door opener lightsflash.

The time interval isindicated by the number times the garage door opener flashes:

l

1 flash is 1-1/2 minutes

l

2 flashes is 2-1/2minutes

l

3 flashes is 3-1/2minutes

l

4 flashes is 4-1/2minutes

To cyclethrough the timeintervalsrepeat the step above.

Light Feature

The lights will turn on when someone enters through the open garage door and the safety reversing

sensor infrared beam is broken.

l

Deactivate: Pressand hold the LIGHT button (approximately 10 seconds) until the garage door

opener lights turn on, then offagain.

l

Activate: Start with the garage door opener lightson.Pressand hold the LIGHTbutton

(approximately 10 seconds) until the garage door opener lights turn off, then on again.

Ifthe command LED is continuouslyblinking, the LOCK feature needs tobe deactivated.

36

Page 38

Operation

ON (TTC)

OFF (TTC)

Command LED

Motion Sensor

Switch

LIGHT

Button

HOLD OPEN

Button(TTC)

Motion

Sensor

Push Bar

1, 5, and

10 Minute

TTC LED

LEARN Button

LOCK Button

Push Bar

LIGHT Button

Motion Sensor

Navigation Buttons

Screen

Motion Detecting Control Panel (continued)

LOCK

The LOCK feature is designed to prevent activation of the garage door opener from remote controls

while still allowing activation fromthedoor controland keyless entry.Thisfeature is useful for added

peace of mind when the home is empty (i.e. vacation).

l

Activate: Pressand hold the LOCK buttonfor 2 seconds. The command LED will flash as long

as the lockfeature isactivated and your handheld remotecontrol will not operate your door at

thistime.

l

Deactivate: Pressand hold the LOCKbutton again for 2 seconds. The command LED will stop

flashing and normal operation will resume.

TIMER-TO-CLOSE

DO NOT enable TTC if operating a one-piece door. The TTC can be turned on or offand the time

interval can be adjusted to 1,5, and 10 minute intervals. Once theTTChasbeen setand the door is

open, the selected close intervalwill blink and begin to count downto close the door.

l

Activate: Pressand hold the ON button untilone ofthe TTCLEDslight up. Then press the ON

button again to cyclethrough the timeinterval options (the corresponding TTC LED will light for

each time interval). The garage door opener lightbulbs will blinkas confirmation.

l

Deactivate: Pressand hold the OFF button until all TTCLEDs turn off and a beep is heard from

the motor unit.

l

Temporarily hold door open (suspendTTC): Press and release the HOLD OPEN button.Press

the HOLD OPENbutton again to resume normalTTCoperation.

PROGRAM

Any compatible remote controls, wireless keylessentry,or MyQ®accessories can be programmedto the

garage door opener bypressing the Learn button.

Using the Smart Control Panel

SYNCHRONIZE THE DOOR CONTROL

To synchronize the door control to the garage door opener, press the push bar until the garage door

opener activates (it may take up to 3 presses). Testthe door control by pressing thepush bar,each press

of the pushbar will activate the garage door opener.

SMART CONTROL PANEL FEATURES

PUSH BAR

Press the push bar to open or close the door.

LIGHTS

Light Button

Press the LIGHT button to turnthe garage door opener lights on or off.When the lightsare turned on

theywill stayon untilthe LIGHTbutton is pressed again,or untilthe garage door opener is activated.

Once the garage door opener is activated the lightswill turn offafter the specified period oftime (the

factory setting is 4-1/2 minutes). The LIGHT button will not control the lightswhen the door is in motion.

The durationof the lighttiming can be adjusted by accessing the menu using the navigation buttons.

Motion Sensor

The motion sensor will automaticallyturn on thegarage door opener lightswhen motion is detected. The

lights will come on for the setperiod of time, then shutoff. The factorysetting ison and set at 4-1/2

minutes.

37

Page 39

Operation

Figure 2 Figure 3

Figure 1

Figure 4

Figure 5

Navigation Buttons

Screen

Use the navigation buttons to make selections and program features.

The screen will display the time, temperature, and

current battery charge (if applicable) until the menu

button is pressed, and then it will display the menu

options. If there is a problem with the garage door

opener the screen will display the Diagnostic Code.

Set the time, choose 12 or 24 hour clock and show/hide clock.

Set the Timer-to-Close feature off/on and set the time interval

before door closes.

Enable/disable lock.

Add remote controls, MyQ® devices, an extra remote button

to control your garage door opener lights, or a keyless entry.

Display the temperature in Fahrenheit or Celsius and

show/hide the temperature.

Select a language.

Set duration for garage door opener light to stay on after

operation, selectable range of 1-1/2 to 4-1/2 minutes. Turn the

Motion sensor off/on, and turn the entry light feature off/on.

Adjust the contrast of the screen.

Using the Smart Control Panel (continued)

Light Feature

The lights will turn on when someone enters through the open garage door and the safety reversing

sensor infrared beam is broken.Ifusingthe garage door opener light as a work light, turn the light on

using the light button on the wall control or the light will turn offifyou are beyond the range ofthesensor.

LOCK

The LOCK feature is designed to prevent activation of the garage door opener from remote controls

while still allowing activation fromthedoor controland keyless entry.Thisfeature is useful for added

peace of mind when the home is empty (i.e. vacation).

When the Lockfeature is on, your remote controls have been disabled and a message will displayon the

door control(Figure 1).

TIMER-TO-CLOSE (TTC)

DO NOT enable TTC if operating a one-piece door. TTCcan be settoautomatically close your garage