Page 1

en-1

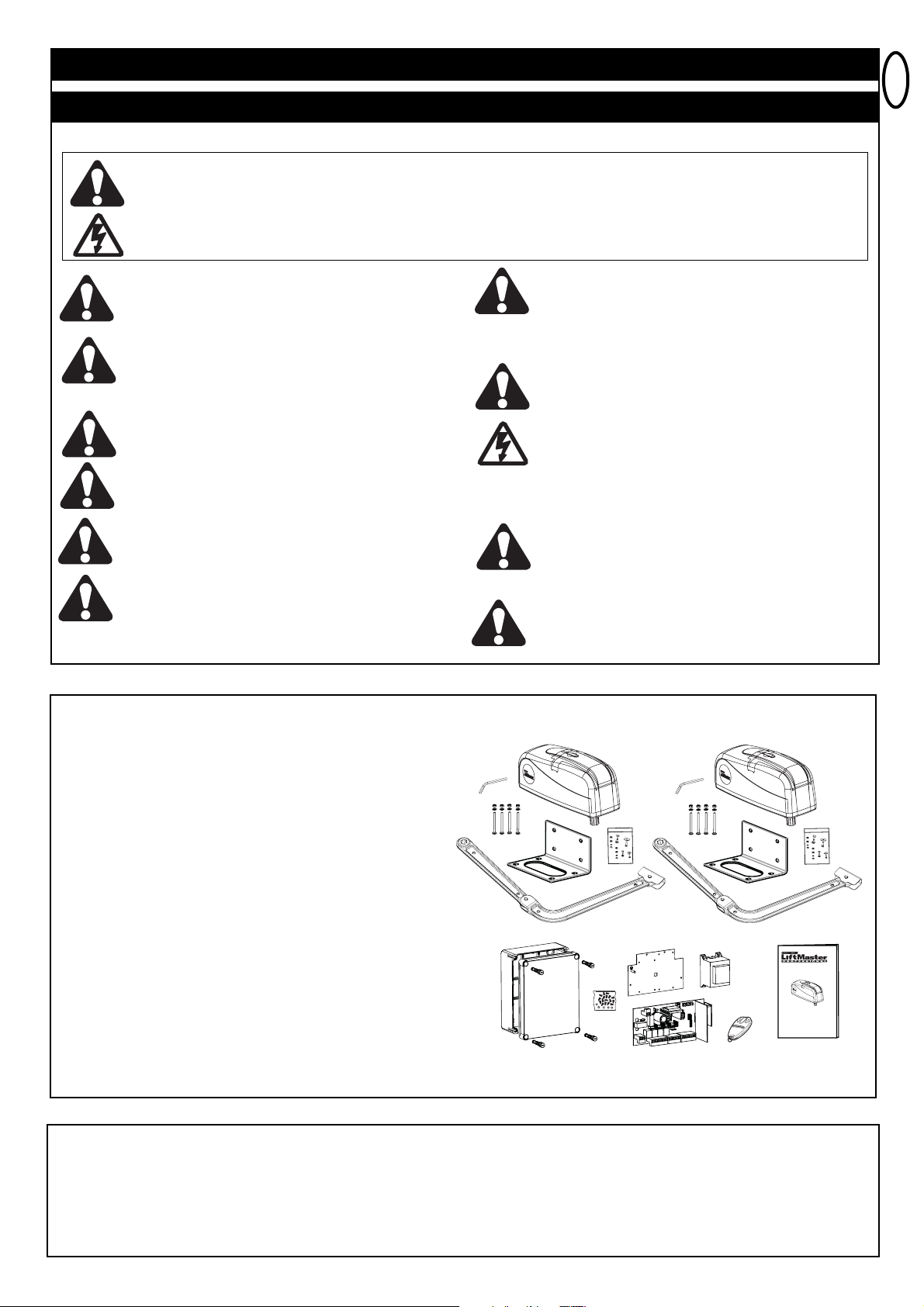

CARTON CONTENTS ART200K

Drive motors 2x

Release key 2x

Box for control 1x

Cover for box 1x

Hinges for box 4x

Control 1x

Transformer 1x

Baseplate For Transformer 1x

Remote control 1-2x*

Radio receiver 1

Radio module 1x

Hardwarebag For Box 1x

Pillar fittings 2x

Gate fittings 2x

Door arm 2x

Hardwarebag 1x

Instructions 1x

Flashing light 1x

Key switch 1x

Photocells 1x

* depending on model resp. available as optional accessory

INSTALLATION CHECKLIST - PREPARATIONS

Check the carton contents and read the instructions carefully. Make sure your gate equipment operates perfectly. The gate must run evenly and

smoothly and must not stick at any point. Remember that the ground level may be several centimeters higher in winter. The gate must be stable

and as free of backlash in order to prevent any unwanted movement. The easier the gate movement the less power is needed by the motor.

Write down any materials you still need and obtain them before starting to install. Heavy-duty plugs, bolts, gate stops, cables, distribution boxes,

tools, etc.

PLEASE START BY READING THESE IMPORTANT SAFETY RULES • SAVE THESE INSTRUCTIONS

This safety alert symbol means "Caution" - failure to comply with such an instruction involves risk of personal injury or

damage to property. Please read these warnings carefully.

This gate drive mechanism is designed and tested to offer appropriately safe service provided it is installed and operated in

strict accordance with the following safety rules.

Incorrect installation and/or failure to comply with the following instructions may result in serious personal injury or property

damage.

Installation and wiring must be in compliance with

your local building and electrical installation codes.

Power cables must only be connected to a properly

earthed supply.

Any entrapment possibility by the moving wing

between wing & walls must be secured with safety

edges or IR-sensors.

Disconnect electric power to the system before making

repairs or removing covers.

A disconnecting device must be provided in the

permanently-wired installation to guarantee all-pole

disconnection by means of a switch (at least 3mm

contact gap) or by a separate fuse.

When using tools and small parts to install or carry

out repair work on a gate exercise caution and do not

wear rings, watches or loose clothing.

Make sure that people who install, maintain or operate

the gate drive and/or the control board are qualified and

follow these instructions.

Keep these instructions in a safe place so that you can

refer to them quickly when you need to.

Please remove any locks fitted to the gate in order to

prevent damage to the gate.

Frequently examine the installation for imbalance and

signs of wear or damage to cables, hardware and

mountings. Do not use if repair or adjustment is

necessary. Gates which stick or jam must be repaired

immediately. Employ a qualified technician to repair the

gate, never attempt to repair it yourself.

Keep additional accessories away from children. Do not

allow children to play with pushbuttons or remote controls.

A gate can cause serious injuries as it closes.

After the installation a final test of the full function of

the system and the full function of the safety devices

must be done.

The full protection against potential squeeze or

entrapment must work direct when the drive arms are

installed.

This drive cannot be used with a gate incorporating a

wicket door unless the drive cannot be operated with

the wicket door open.

IMPORTANT FITTING AND OPERATING INSTRUCTIONS

WARNING / ATTENTION

Page 2

3x

en-2

BEFORE YOU BEGIN: The ART is suitable for use with wide pillars, up to about 30cm in width.Width of doorwing must comply with chart.

The maximum recommended opening angle of the gate is 105 degrees. Ensure that ample space is available next to the drive for the arms and

assembly. Gates exposed to a high wind load must be fixed with an electric lock for additional protection. Gate stops must be installed

There are many important factors when deciding on the correct motor. Assuming a well functioning gate, the initial force is the most difficult

moment. When the gate is moving it generally requires a considerably smaller amount of force.

Gate Size: Gate size is an important factor. Wind can slow down gate or distort it, leading to higher amount of required force.

Gate weight: Specification of gate weight represents only a rough parameter, which can vary according to actual demand. Operation is

important.

Influence of temperature: Low outdoor temperatures can impede or even prevent starting torque (ground deformation etc.). High outdoor

temperatures can lead to premature initiation of temperature protection (approx. 135°)

Attention: Motors are not designed to run continuously (continuous operation). The motor warms up and can reach a temperature at which it

shuts down until operating temperature is reached again. Outside temperature and gate represent important parameters for actual operating

duration.

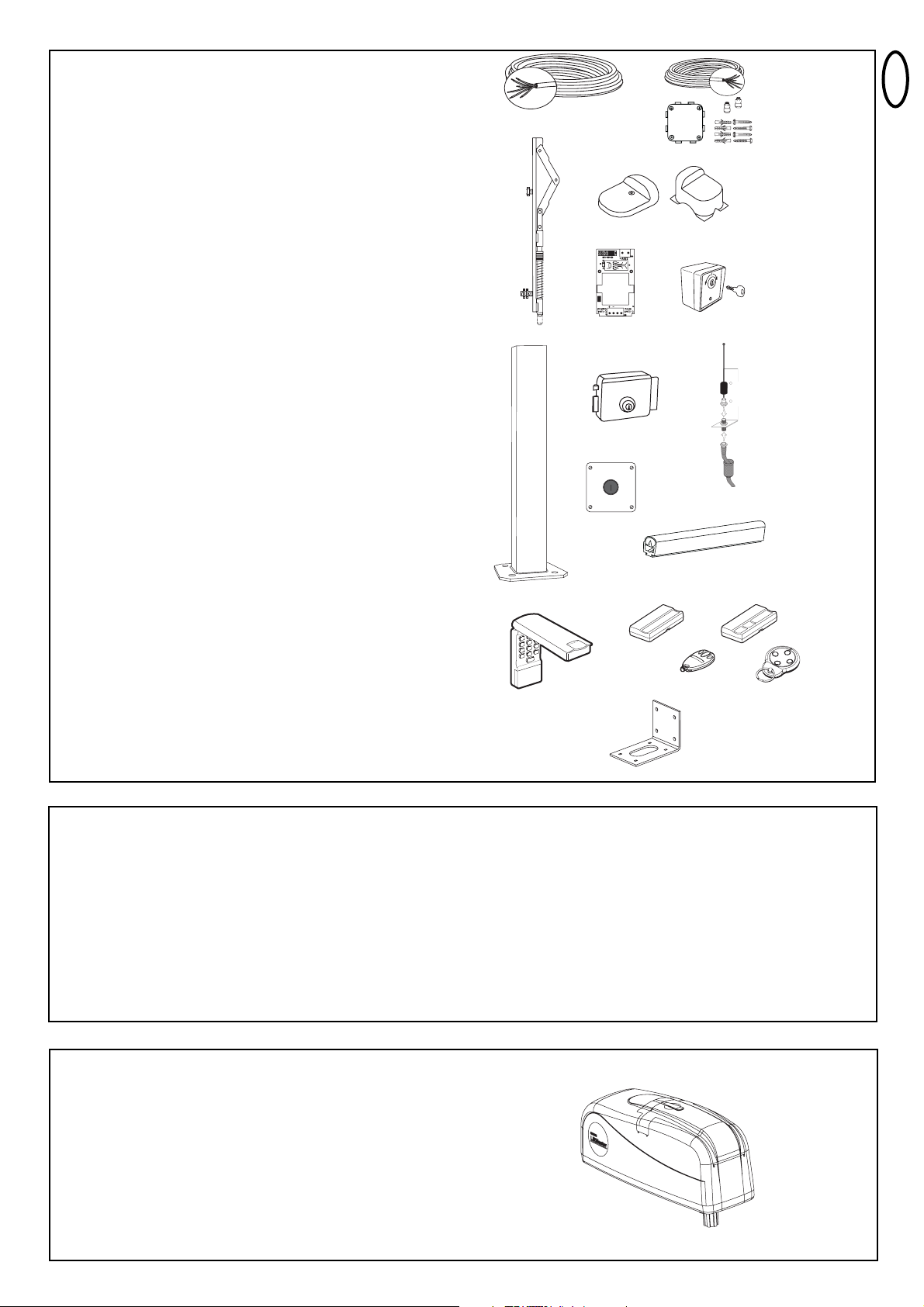

AVAILABLE INSTALLATION ACCESSORIES

1. 041ASWG-0482-50 50m roll of installation cable, 6-pole for

outdoor use, Laying possible without

cable duct with the identical wire colours

as motor

2. LA400-JB40E Kit for cable extension of one installation

unit. Consists of 12m of cable 6-pole with

identical colours, distribution box IP65,

cable screw joints and fastening material

3. E-lock 203285 (12Volts)

4. Transformer for E-lock 207399

5. Floor locking 203339 (in combination with E-lock)

6. Stops for wings 203315 (standard) and 203322

(high)

7. Safety edge 600046 2.5m set of safety edge

(profile & rail)

600053 20m of rubber profile (small)

600077 20m of mounting rail

600077-1 2m of mounting rail

600060 Assembly pack is required for

each safety edge

8. IR Sensor stand 600008 single, height 530mm

9. Emergency Stop switch 600084 plastic enclosure, IP65

10. Keyswitch 100034 2-Function, flush-mount

100041 2-Function, surface-mount

11. External Antenna ANT4X-1LM

12. Remote Controls 94330E 1-channel

94333E 3-channel

94334E 4-channel, mini

94335E 3-channel, mini

13. Wireless keypad 9747E

14. Base plate slim ART-6

TECHNICAL DATA:

Motor voltage 24V

Nominal power 10W

Max. power 40W

Current nom. 0,5A

Current max. 1,3A

Torque max. 200Nm

Opening time 90° ~16 sec.

Cycles/h ~ 20

Consecutive cycles max. 8

Operating temperature -20°C - +55°C

Degree of protection IP44

Weight 8kg

2

3

4

5

6

7

8

9

10

11

12

13

1

14

Page 3

en-3

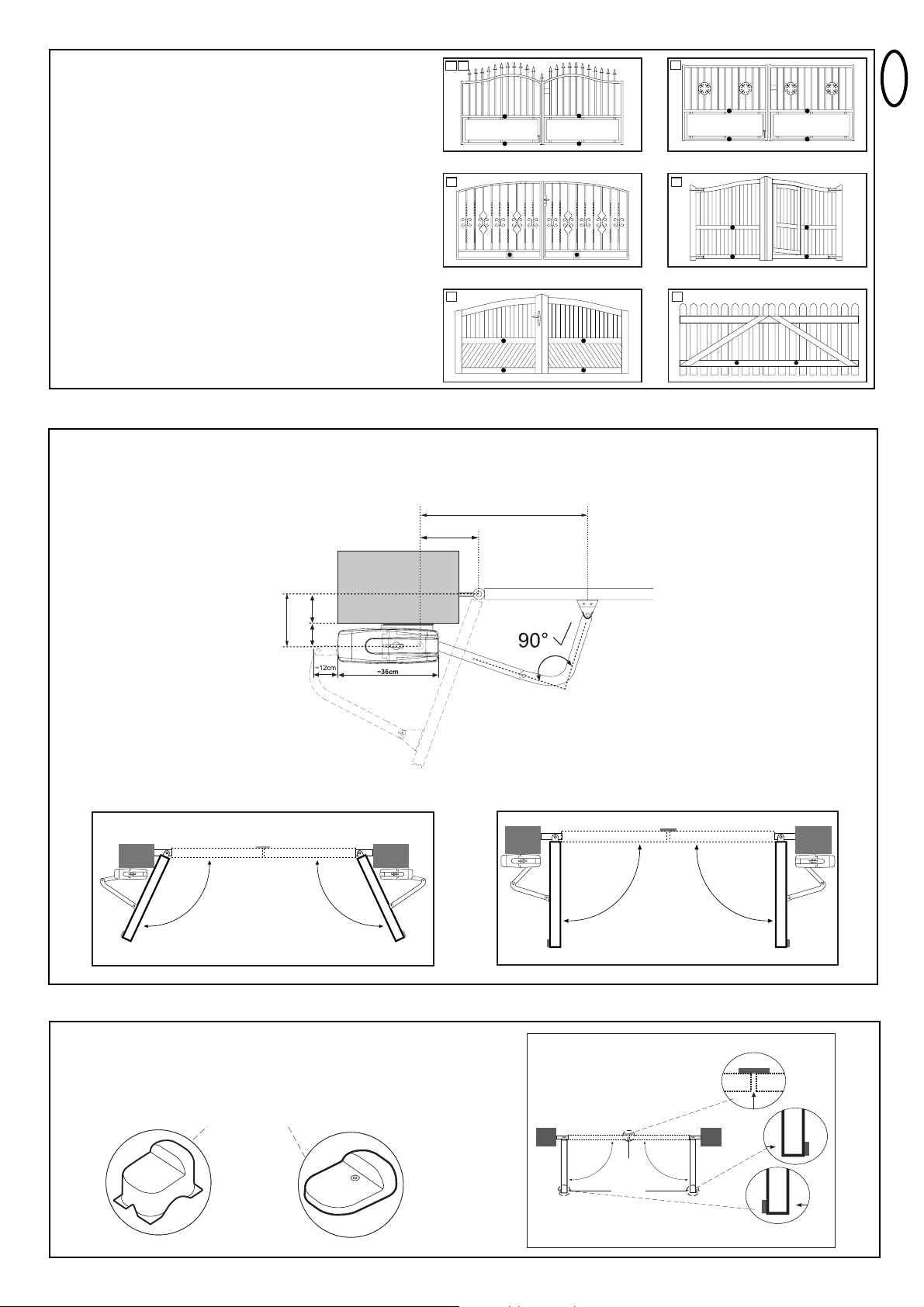

GATE TYPES

The location of the motor installation depends on the type of gate.

If the gate stop is on the floor the motor should also be installed as

low as possible in order for the gate not to be distorted. Only use

frame elements for fastening.With steel gates the fittings should be

fastened to the main frame. If you are not sure about the stability of

the frame in question then reinforce it.

With wooden gates the frame has to be drilled through

completelywhere the fittings are to be fastened. Attaching a plate

from the outside is recommended in order to prevent fastening from

becoming loose. Thin wooden gates must be reinforced additionally

as they do not withstand the strain otherwise.

GATE CONFIGURATION

The ART is suitable for use with wide pillars, up to about 30cm in width. The amount of room around the pier affects the opening angle and the

position of the arms.

2 A

B

C D

E F

GATE STOPS

A SWING GATE NEEDS A FIXED GATE STOP IN BOTH THE OPEN AND

CLOSE POSITIONS. Gate stops save wear and tear on the motor, gate and

fittings. Operating a gate without fixed limit stops results in poor performance. It is

often dangerous, leads to premature wear and voids your warranty!

90

0

90

0

Max gate width/weight

Max gate height

2,5m per wing / 150Kg

2,0m per wing / 200Kg

1,5m per wing / 250Kg

1,5m

Specifications calculated without windload

A=38,5cm

8,5cm

30cm

C

B=60-70cm

ca.

7-8 cm = 90°

max. 10 cm

=

90

o

90

o

105°

105°

Page 4

en-4

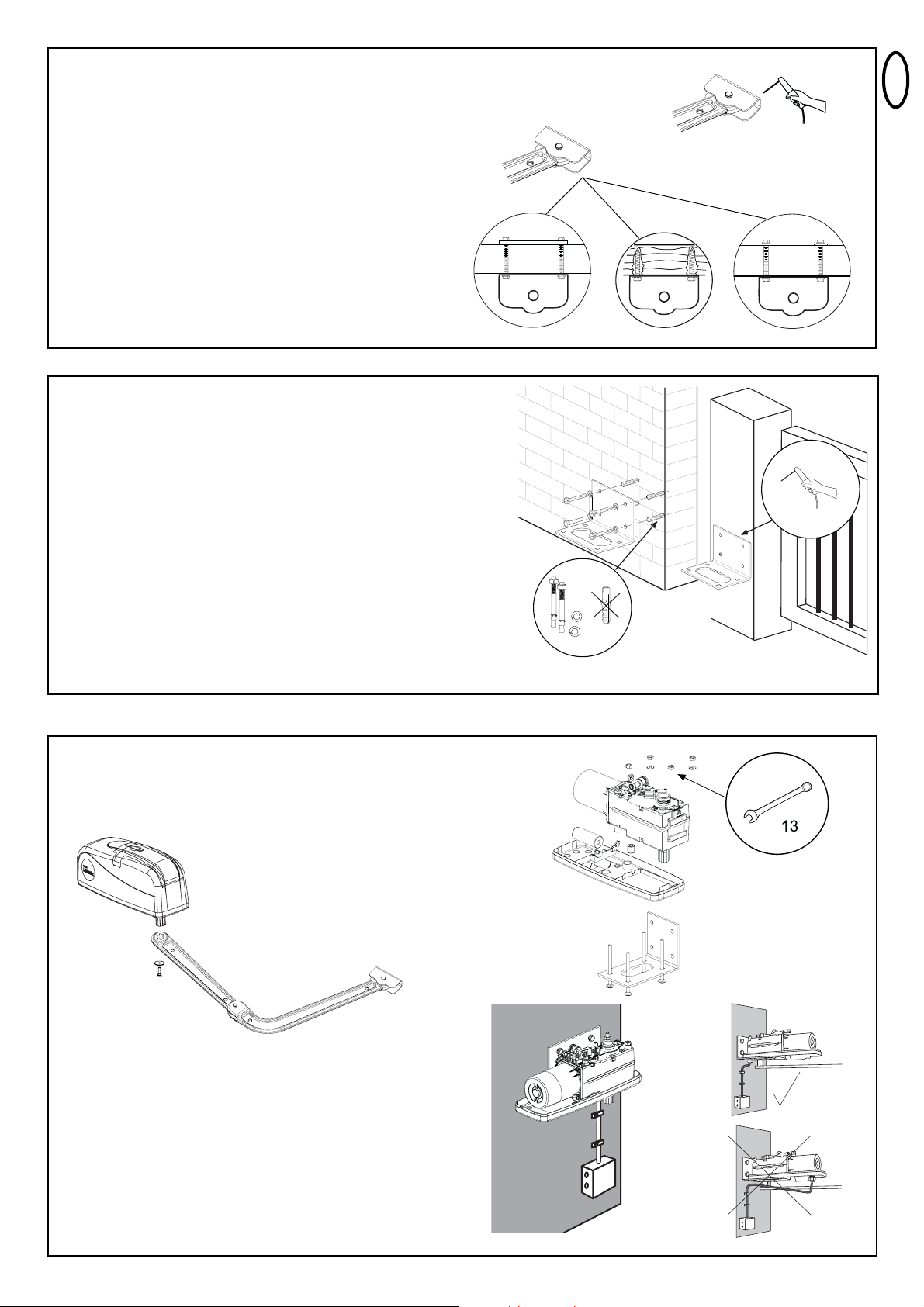

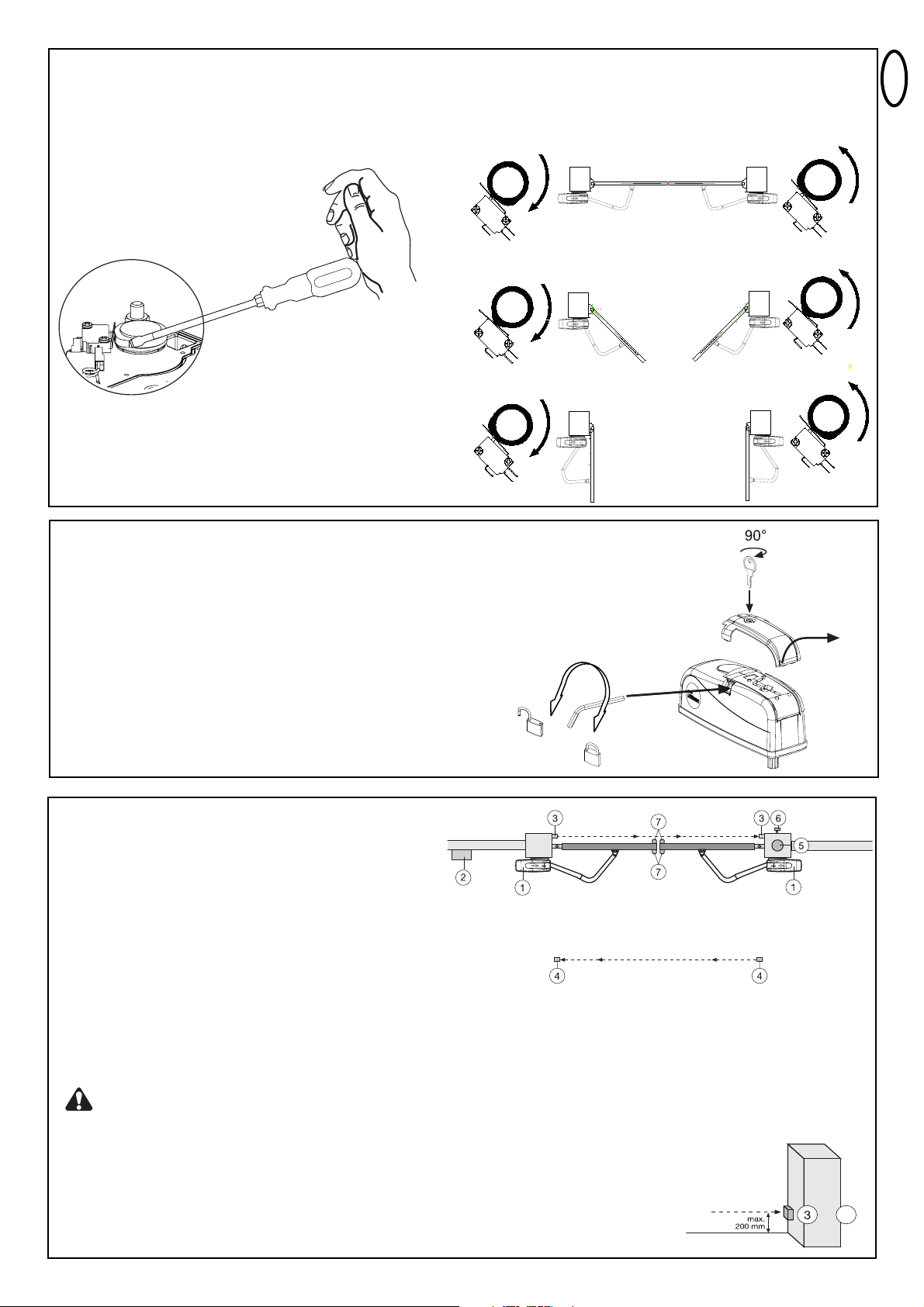

BASE PLATE

Select and mark the mounting height on the pier.

Finding the right mounting position. Mount the drive on the pier and

attach it to the gate. The drive exerts a great amount of force on the

pier. A steel pier will provide the most stability. Welding the supplied

hinge plate directly on to the pier will generally provide enough room

for mount. In the case of thick brick or concrete pillars, the hinge

plate should be welded onto a support plate, that is mounted in such

a way that the plugs cannot work loose. Adhesive shear connectors

are better than steel or plastic wedge anchors for this purpose. A

threaded rod is then mounted into the masonry with a stress free

adhesive seal. A watertight distribution unit should be mounted on

the pier next to the hinge plate. The feed cable for the wing gate

opener is led into this unit from underneath.

GATE FITTING

With steel gate the fastenings should either be welded on or drilled

through completely. If drilling then attach large washers or a plate to

the back of the frame.With wooden gates the gate frame has to be

drilled through completely where the fittings are to be fastened.

Attach reinforcement plate on the outside and inside of the gate in

order to prevent wood from giving and the connection to become

loose.

Thin wooden gates without metal frame must be reinforced

additionally, as they do not withstand the strain otherwise.

Before installing the gate fitting, check if you measured the right

position for it. Adjust if needed.

Attach gate fitting with a c-clamp or mark its designated position.

To compare, open the gate to designated OPEN position.

Now finally mont gate fitting.

Mount operator and run cable the right way

Once the base plate has been mounted, the drive can then be fitted.

The drives can be used left or right without requiring conversion. For

the purposes of fitting the drive, the lock screws need to be reinserted and tightened up.

Several openings for the cable have been pre-punched in the base

and need only be broken through, as required. The drive must be

standing on a solid surface for the purposes of breaking the holes

through to prevent the PVC base plate from breaking. A small, flat

screwdriver should be used for breaking the holes through. For this

purpose, tap on the screwdriver handle with the palm of the hand

from the inside. Repeat this as necessary at several points on the

pre-marked circle. The pre-punched area can then be easily

removed and the strain relief supplied as standard fitted in its place.

Page 5

en-5

RELEASE/ MANUAL GATE OPERATION

The release lock for the casing is located under the rubber waterproof

cover. Use the socket spanner supplied in the hardware bag to lift the

cover up. The release key located beneath the hood should be

inserted into the side openings and turned approx. 180 degrees until

it cannot turn any further. The drive has now been released. To reengage it, the key should be turned back to its original position.

Tak e car e when u nla tc hin g the d rive f or ma nual o per atio n. The

door leaf can move in an uncontrolled way, especially if it is

defective and not properly balanced.

Before initial operation check if operator does not come in contact

with the gate in the fully OPEN position.

SWITCHES, CAMS AND RIGHT ADJUSTMENT

There is a small switch operated by a cam under the operator’s

cover. The cam rotates simultaneously to the operator and pushes

the switch temporarily. The cam can be adjusted (rotated). (Tight)

Deinstallation is not required.

Use pliers or a big screwdriver to adjust (see picture).

RIGHT ADJUSTMENT

Gate closed: switch free

Gate at approx. 45°: switch fully pushed (cam operates

switch)

Gate open: switch free

4

+

TYPICAL CONFIGURATION OF A UNIT:

1. Motor

2. Control board

3. Photocell (active for closing), max. height 200 mm

First photocell.

4. photocell (active for opening and closing), max. height 200 mm

Second photocell (optional).

5. Flashing light (optional)

Important visual information on the movement of the gate.

6. Key-operated switch or wireless keypad (optional)

Is mounted on the outside. The gate is opened by key or by

entering a number.

7. Contact strip (optional)

Safeguards the gate on being touched. Contact strips can be

mounted on the gate or on the pillars. If required, contact strips

must be mounted at a height of up to 2.5m.

The control board complies with the latest EU

guidelines. One of these guidelines specifies that the

closing forces at the gate edge must not exceed 400 N (40 kg) for

the last 500 mm before the door is CLOSED. Above 500 mm, the

maximum force at the gate edge must not exceed 1400 N (140

kg). If this cannot be ensured, a contact strip must be mounted on

the gate at a height up to 2.5 m or on the pillar on the opposite

side (EN12453).

Note: The listed accessories on page 2 are especially suited for the professional

installation of a gate system.

Page 6

en-6

INSTALLATION OF CONTROL BOX

The control consists of several components which are fitted together

and are screwed into the box. Precision is important.

Complete the electrical installation (wiring, supply etc.) before turning

your attention to this point.

Find the following parts in the control box:

- Remote control 1-2x*

- Exterior installation box 1

- Cover for box 1

- Control 1

- Transformer 1

- Baseplate for transformer 1

- Radio receiver 1

- Radio module 1

- Cable bushing large 1

- Cable bushing small 1

- Flat washer 5

- Screws 3,5x 9,5 mm 17

* depending on model resp. available as optional accessory

PREPARING THE CONTROL BOX

Open the 4 pre-cut holes at the bottom of the casing with a

screwdriver or a similar device.

Attach large cable bushing on the left then the rest as shown in

picture.

Humidity and water destroy the control. All openings and cable

bushings must be sealed against water (waterproof). The control box

with the motor control is to be mounted with the cable bushings

facing down.

RECOMMENDED PROCEDURE:

A. Fasten control box of casing to wall, after previously measuring

required distances and establishing correct position of drill-holes.

(Hardware not included)

B. Fasten baseplate for transformer in casing. (Screws 3.5 x 9.5mm)

C. Fasten transformer on to baseplate; do this using 4 screws

( Screws 3.5 x 9.5mm). On the right hand side of transformer

there is sufficient space for a second transformer( Screws 3.5 x

9.5mm), which can control locking of a 12Volts E Lock.

(accessories).

Attach short earthing cable (yellow/green) to the plate using a

screw and a washer.

D. Attach logic board underneath baseplate; do this using 5 screws

and fasten in the box at the marked positions. Before that pull all

plug ins from their sockets. A small bag contains jumpers for the

control. These might be needed later on individual settings in the

controls’ programming. (refer to JUMPERS)

Put the 4 large closure screws of the box through cover of the

box. Fasten 2 of them (left or right) approx 2cm into the box. After

that the cover may be opened to the side.

Close box on a trial basis turning the screws all the way in. If the

lid does not close completely, then the box is not fitted to the wall

evenly and is therefore distorted. This must be corrected. It is very

important for the box to be waterproof once closed.

A

B

C

D

X 5

Page 7

en-7

TECHNICAL DATA OF MOTOR CONTROL:

Voltage 230VAC

Transformer 230/24VAC minimum60VA

Output motor 24VDC max.

Supply accessories 24VDC - 100mA

Operating temperature -20°C - +55°C

Degree of protection IP54

30VDC

MOTOR

MASTER

+

-

MOTOR

SECOND

24V/150mA

BRN GRN WHT YEL

MASTER

BRN GRN WHT YEL

SECOND

COM

PHOTO

1 2

COM

STOP/*

8.2

Ω

DIAGNOSTIC

LEARN

PHO1

PHO2

STOP/8.2K

JP2

JP1

OPEN / PED

1/2 MOTOR

STOP/8.2K

P1 P2 P3

LN

250V/2A

250V/2A

TRANSFORMER

230VAC

INPUT

24VAC

RADIO

801719

/ LAMP

Ω

8.2

+

+

-

RED

RED

BLUE

BLUE

230VAC

+

+

+

Ω

+

PE

PE

WIRING OF CONTROL / SUMMARY

a) start with still dead 230Volts supply cable on the left side of the box.

b) Attach cable eye to ground wire. Then connect ground wire to base

plate with washer and nut (exactly as shown in picture detail).

Connect all other cables to control.

Attention:Check repeatedly that cable colours are connected correctly

to motor. Otherwise motor might be damaged or will not operate

properly. Pay special attention when using distribution boxes.

We recommend the following accessories: LA400-JB40E Kit for

cable extension of one installation unit. Consists of 12m of

cable 6-pole with identical colours, distribution box IP65,cable screw

joints and fastening material

Page 8

en-8

DESCRIPTION OF PUSH BUTTONS

P1 button to program “simple” mode

P2 button to program “individual” mode

P3 button to program “Timer to close”

Description of LED’s (light-emitting diode)

Description Colour Function

STOP/8.2KOhms green monitors emergency switch

or safety edge

ON: blocks control board

OFF: OK

“Key symbol” red key switch

ON: key switch is operating

OFF: key switch is not

operating

PHO2 red Photocells 2

ON: OK (active)

OFF: no photocell fitted

PHO1 red Photocells 1

ON: OK (active)

OFF: no photocell fitted

LEARN yellow learn mode indication

ON: learn mode active

OFF: learn mode inactive

DIAGNOSTIC red diagnosis mode

Refer to FAQ’s

DESCRIPTION FUNCTION

L Connector L 230V supply

N Connector N 230V supply

Battery Connector for a battery kit +/-

475E + 041ADBL-0115

Motor MASTER motor 1 (master opens first)

Motor SECOND motor 2 (Second opens second)

24V/150mA Flashing light (accessory)

MASTER Motor1

BRN brown cable

GRN green cable

WHT white cable

YEL yellow cable

SECOND Motor2

BRN brown cable

GRN green cable

WHT white cable

YEL yellow cable

“Key symbol” key switch

COM negative pole

PHOTO1 Photocells 1

PHOTO2 Photocells 2

COM negative pole

STOP 8.2KOhms connector for emergency switch or

safety edge with 8.2KOhms

RADIO connection for 801719 radio receiver

E-lock symbol connection for E-lock control board

INPUT 24VAC 24V power input from transformer.

Can be connected with any polarity.

Transformer 230VAC 230V supply to transformer. Can be

connected with any polarity.

250V/2A Fuse 250V/2A (2x included)

Only modify settings when control bord

is disconnected. Otherwise modifications will

not be accepted!!!

Page 9

en-9

COM

PHOTO

1 2

COM

STOP/*

8.2

Ω

KEY SWITCH (OPTIONAL)

The system can be operated by key switch. It is possible to operate

only 1 wing or two wings. This depends on how the JUMPERS are

used (connectors: key symbol and COM)

COM

PHOTO

1 2

COM

STOP/*

8.2

Ω

COM

PHOTO

1 2

COM

STOP/*

8.2

Ω

Ω

8.2

Ω

8.2

+

+

+

+

+

E-LOCK (OPTIONAL)

The control board allows the use of a 12V E-lock. (instructions

included with E-lock).

A support board must be connected for the E-lock on the main

board.

Attach support board next to the transformer on to the baseplate

using screws.

Open its casing and make all necessary electrical wiring.

Plug support board in to where the E-lock symbol is depicted.

P1 P2 P3

PHOTOCELLS (OPTIONAL)

The photocells are for safeguarding the gate and must be used. The

fitting location depends on the gate’s design. EN12453 specifies that a

pair of photocells must be installed at a height of 200 mm and activated

to “Close”. The photocells consist of a transmitter and a receiver and

must be opposite each other. The photocell is mounted on the wall

using small screws and wall plugs. To enable the “Automatic Closing”

function, the Chamberlain failsafe photocell must be installed. The

Chamberlain failsafe system (2-cable system) has small LEDs (light)

that can be seen from the outside on both sides to indicate the status

of the photocell.

Diagnosis at the Chamberlain failsafe photocell

LED constant = OK

LED flashes = photocell disables control board

LED off = no current, incorrect connection or polarity

Diagnosis on the control board

LED off = OK no photocell connected

LED on constantly = OK

LED flashes = photocell disables control board

Connection between 1 & COM will give:

ignored when gate is opening, when closing if beam is blocked gate

stops then reopens (does not matter when beam is unblocked).

Connection between 2 & COM will give:

when gate is opening block beam gate stops when you un-block beam

gate caries on opening.

When gate is closing block beam gate stops un-block beam gate

reopens.

SAFETY EDGE (OPTIONAL)

A safety edge working according to the 8.2 kilo ohm principle can be

connected to the control board, i.e. a 8.2 kilo ohm test resistor is

attached to the end of the safety edge. It ensures that the electric

circuit is monitored permanently. The control board is supplied with

an 8.2 kilo ohm resistor installed. Several safety edges are

connected in series.

Cable cross-section: 0.5 mm2or more.

Page 10

en-10

RADIO

There are two small cartons. One of the cartons contains the receiver,

which stores remote control codes. The other one contains the radio

module, which receives the radio signal.

1. connect the smaller radio module with the receiver

Make sure all pins are properly engaged

2. connect the receiver with the control board

Antenna: The receiver includes a short antenna. It should

not come in contact with any cable and should not be rolled

up. It is possible to install an external antenna which

enlarges the operating distance of the remote control

(optional accessory).

PROGRAM / DELETE REMOTE CONTROLS

The receiver has two channels CH1 and CH2. Using the different

channels enables the opening of one wing resp. both wings. For

example, if CH1 receives the code from the remote control only one

wing will open. Choosing a different button on the remote control in

combination with CH2 will cause both wings to open.

In order to store a code press a previously selected button on the

remote control while simultaneously pressing the learn-buttons CH1

or CH2 of the receiver. Repeat for all remote controls.

A maximum of 12 remote controls can be programmed to each

channel.

Note: Make sure not to pogramm the same remote button to CH1

and CH2, otherwise the gate may work improperly. Redo

programming if required.

DELETE

Press learn-buttons (CH1 or CH2) for approx. 10 seconds until LED

goes out. All codes programmed to this channel are deleted.

1 / 2 Motor

1 or 2 motors are connected to the control board.

FREE: both motors connected

LINKED: only one motor connected

STOP / 8.2 KOhms

Defines if connector STOP / 8.2 KOhms is used for an emergency

stop switch or for a safety edge. The emergency stop switch stops

any movement of the system immediately. The safety edge causes

the wings to reverse for one second.

FREE: Factory setting is for 8.2 KOhms. In this case safety edge

must be installed or a 8.2 KOhms resistor must be

connected.

LINKED: used for emergency stop switch, in this case the pre-

installed resistor has to be removed from terminals and

replaced by a suitable switch or terminals have to be

bridged.

Open / Ped

Defines if key switch operates only one wing (Master) or both wings

FREE: only one wing (Master)

LINKED: both wings

JUMPERS

JP2

JP1

OPEN / PED

1/2 MOTOR

STOP/8.2K

Ω

30VDC

MOTOR

MASTER

+

-

MOTOR

SECOND

24V/150mA

BR

/ LAMP

+

-

RED

BLUE

FLASHING LAMP (OPTIONAL)

A flashing lamp can be connected to the control board. It warns

when the gate is being moved. The flashing light should be fitted as

high as possible and in good clear view. The control board emits a

constant signal that the lamp converts to a flashing signal.

Cable cross-section: 0.5 mm2or more.

Voltage: 24 V DC

Page 11

en-11

INITIAL OPERATION

BASIC SETTING

Proceed step by step. If you are not sure, start again at the beginning. Take sufficient time to make these settings.

1. Are all components required for operation connected? Motors, photocells, safety contact strip, stop switch.

2. Make sure that nobody is present in the range of the gates.

3. Check/Adjustment/Correction of cams on both motors

Gate closed: switch free

Gate at approx. 45°: switch fully pushed (cam operates switch)

Gate open: switch free

(for adjustment refer to mechanical installation)

PROGRAMMING TRAVEL DISTANCES “ADVANCED”

NOTE: In this mode P1 must be pressed 9 times. With every time the button is pressed a position (time) is stored. (This allows

programming of SOFT-STOP (slow travel) in order to adjust to application. Long or short phases of SOFT-STOP are possible.

1. Both wings must be closed.

2. Press P1 and P2 for approx.5-6 seconds until wing / motor 1 starts opening.Release buttons!!!

3. Press P1 again. SOFT-STOP for wing / motor 1 in OPEN direction starts at this point.

4. Press P1 again when OPEN position is reached.Now wing / motor 2 starts automatically to open.

5. Press P1 again. SOFT-STOP for wing / motor 2 in OPEN direction begins at this point.

6. Press P1 again when OPEN position is reached. Now wing / motor 2 starts closing automatically.

7. Press P1 again. SOFT-STOP for wing / motor 2 in CLOSE direction begins at this point.

8. Press P1 again when CLOSE position is reached. Now wing / motor 1 starts automatically to close.

9. Press P1 again. SOFT-STOP for wing / motor 1 in CLOSE direction begins at this point.

10. Press P1 again when CLOSE position is reached.

Done!

BASIC SETTING:

1. Press buttons P1, P2 and P3 simultaneously for approx. 2-3 seconds until yellow LED flashes.

2. Monitor the gate. Press and hold P1 for 1-2 seconds. The wing with motor 1 opens. If motor 1 closes, it is wired incorrectly and

the red and blue wires of the motor cable must be inverted. (Caution: Disconnect Power!)

Repeat steps 1 and 2. Leave gate/s in partially open position.

NOTE: General operation – if you release the button, the gate will immediately stop. By pressing the button again the gate will

move in the opposite direction until you release the button, and so on.

3. Press and hold P2 for 1-2 seconds. The wing with motor 2 must open. (Do not open gate completely, only short distances.)

If motor 2 closes, it is wired incorrectly and the red and blue wires of the motor cable must be inverted.

(Caution: Disconnect Power!)

Repeat steps 1 and 2. Leave gate/s in partially open position.

NOTE: The control board is active for this manual setting mode for approx. 20 seconds. If necessary, start again by pressing P1,

P2 and P3 simultaneously.

Now check the following:

1. If both operators connected open both wings completely.

2. Both wings must open completely. Do not open the wings too far! A gate stop in OPEN position is required.

Caution: Gate must not come in contact with operator (i.e. when operator has been released for manual operation)

Wait until learn-LED goes out (20 seconds after a button was pressed).

PROGRAMMING TRAVEL DISTANCES “SIMPLE I”

NOTE: only with stops in OPEN and CLOSE position

1. Wings must be closed

2. Press P1 until wing / motor 1 starts opening (learn-LED flashes resp. glows)

Automatic programming starts (slow travel)

Wing 1 moves to the stop in OPEN position

Wing 2 moves to the stop in OPEN position

Then wing 2 moves to the stop in CLOSE position.

Then wing 1 moves to the stop in CLOSE position.

When the learn-LED goes out the programming has finished.

Page 12

en-12

NOTE: If one wing reaches a stop and button P1 is not pressed, then the motor moves towards the stop and stores this position

automatically.

COMPLETION OF INSTALLATION / PROGRAMMING

Once the travel distances are programmed, the remote controls can be programmed as well.

(Refer to PROGRAMM / DELETE REMOTE CONTROLS).

1. Operate the gate with a remote control or with a connected switch and monitor the direction. Close the gate again WITHOUT

any interuptions.

2. If all adjustments are done, check operation of photocells, switch, flashing light, remotes, accessories, etc.

3. Advise people using the gate with regard to gate operation, safety functions and how to release the gate in order to operate it

manually.

TIMER TO CLOSE

NOTE: Only possible with connected photocells (1 + COM). Time frames from 2 seconds up to 120 seconds are possible.

Activate:

1. Press and hold P2 until yellow LED starts flashing

2. Now count the time you wish to program

3. Press P2 again. Done!

Deactivate:

1. Press and hold P2 until yellow LED starts flashing.

2. Press P3. Yellow LED goes out. Done!

TORQUE OF MOTOR

Thrust of the motor is set automatically while programming

the travel distance. Thrust can only be modified by

programming the travel distance again. If gate movement is

impeded by weather or changes to the installation (rust or

inappropriate lubrication) it may have to be repaired.

The control board complies with the latest EU

guidelines. One of these guidelines specifies that the

closing forces at the gate edge must not exceed 400 N (40 kg) for

the last 500 mm before the door is CLOSED. Above 500 mm, the

maximum force at the gate edge must not exceed 1400 N (140 kg). If

this cannot be ensured, a contact strip must be mounted on the gate

at a height up to 2.5 m or on the pillar on the opposite side

(EN12453).

Page 13

en-13

Indication Description Remedy

1x blinking Motor 1 has insufficient connection to control board Green or white cable not wired or badly connected Check

terminals precisely. Consider wire lengths

2x blinking Motor 2 has insufficient connection to control board Refer to 1x blinking

3x blinking Limits for motor 2 have not been accepted A: Open gate wide enough when programming the travel. Make

A: After or during first travel: operator did not open sure cam passes all 3 states (switch free, pushed, free)

open wide enough to meet not meet passpoint B: Check terminals precisely. Consider wire lengths

(cam did not operate switch)

B: Motorcables have insufficient connection to contol board

Yellow or white cable not wired or badly connected

4x blinking Limits for motor 1 have not been accepted Refer to 3x blinking

5x blinking Travel has not been programmed Repeat programming travel

The process of programming has been interrupted

6x blinking Force to operate the gate is too high

A: Gate is out of order A: Repair gate

B: Gate is rough-running B: Check if gate can be easily moved

C: Gate stopped through windload C: Do not operate gate by windstorm

D: Reprogram travel to achieve sufficient level of fo

7x blinking Photocells 1 block installation

A: Object blocks photocells A: Remove object

B: Alignment of the lenses is incorrect B: Check alignment

C: Power supply to photocells is insufficient C: Check cable widths and contacts

8x blinking Photocells 2 block installation Refer to 7x blinking

9x blinking Emergency stop switch blocks installation A: Check wiring

B: Check basic setting of control board (Jumpers)

10xblinking Safety edge blocks installation

A: Object obstructs safety edge A: Remove object

B: Defective safety edge B: Check wiring. Check resistor 8.2KOhms

C: Power too low or broken wire in supply C: Check basic setting of control board (Jumpers)

11xblinking Power supply to control board is too low

A: Defective supply 230V or malfunctioning contact A: Check electric contact

B: Broken wire in supply cable (copper cable) B: Check by electrician

C: The battery (accessory) to operate the gate whilst C: Allow battery to charge 24 hours

power failure is dead.

12xblinking EEPROM Fault

Power up failed Replace contol board

INDICATION OF THE DIAGNOSIS LED

Page 14

en-14

The gate opener doesn’t respond at all; no LED is

on.

Possibly power failure.

1. Check conductor and zero conductor.

2. Check house fusing.

Immediately after the gate has started moving, it

stops and reverses.

Obstacle in area of gate.

Check area of gate for objects

If there is no obstacle, make another initial

operation to ensure the force will be learned

again.

The gate opener does not open the gate fully. 1. Are the post dimensions A+B correct?

2. Has the travel of the controller been set

correctly?

1. Check A+B dimensions.

2. Reprogram if required

Gate can only be opened

1.photocell blocks 1.Function and connection must be

checked

“Timer to close” doesn’t work.

1. Only works if the 2-cable photocell

770E(ML) or 771E(ML) has been

installed.

The control board does not work any more using

the transmitter, only with the switch and even then

only as long as a button is pressed and kept

pressed.

A safety photocell, a contact strip or the stop

disables the control board

Only one photocell was connected for OPEN

At least one photocell must be

connected and activated for CLOSED

or OPEN.

The gate opener doesn’t respond at all, although

the controller has been connected (LEDs are on).

1. Remote control has not been programmed.

2. LEDs indicate a fault.

3. Photocell connected incorrectly.

4. Motor terminal possibly not connected

properly.

1. Programming remote control.

2. Find and rectify fault(s) (see description of

LEDs).

3. Check photocell connection / programming.

4. Check terminals and connections.

Control board does not work with transmitter 1.transmitter not programmed

2.An photocell blocks

1.Program transmitter

2.Check photocells

The control board is not running No travel has been learned Learn travel.

See Initial operation

The wings do not open completely. 1.Insufficient force in the event of high

wind loads (entire gates)

2.Gate sluggish/heavy

1.Reset force ( increase )

2.Improve ease of movement

3.Program control board again

The remote control’s range is too short.

The installation of an external aerial is recommended as the controller with the short cable

aerial is located either behind the post or near ground level in most cases. The optimum

location of the aerial is as high as possible in all cases. An appropriate aerial with installation

kit can be obtained from Chamberlain as an accessory with the product ref. no. ANT4X-1LM.

The gate must follow a slope.

Not recommended! Change gate! The gate can move in an uncontrolled (dangerous) manner if

the gate opener has been released. A stronger force is needed in the upwards direction of the

slope and then, in the opposite direction, the gate opener’s force is too strong.

The gate post is so thick that I am unable to

comply with the requisite A+B dimensions.

Reduce post thickness or shift gate location.

FAQs

Loading...

Loading...