Page 1

ADDENDUM TO

GARAGE DOOR OPENER

OWNER’S MANUAL

Supplemental Instructions

Installing and Testing The Door Opener On a Swinging or Sliding Door

Failure to install, operate, maintain and test your door

opener in strict accordance with these instructions may

result in DEATH or SERIOUS PERSONAL INJURY

from entrapment.

• Carefully follow all installation and safety instructions.

• Save these instructions.

WARNING

WARNING

Page 2

2

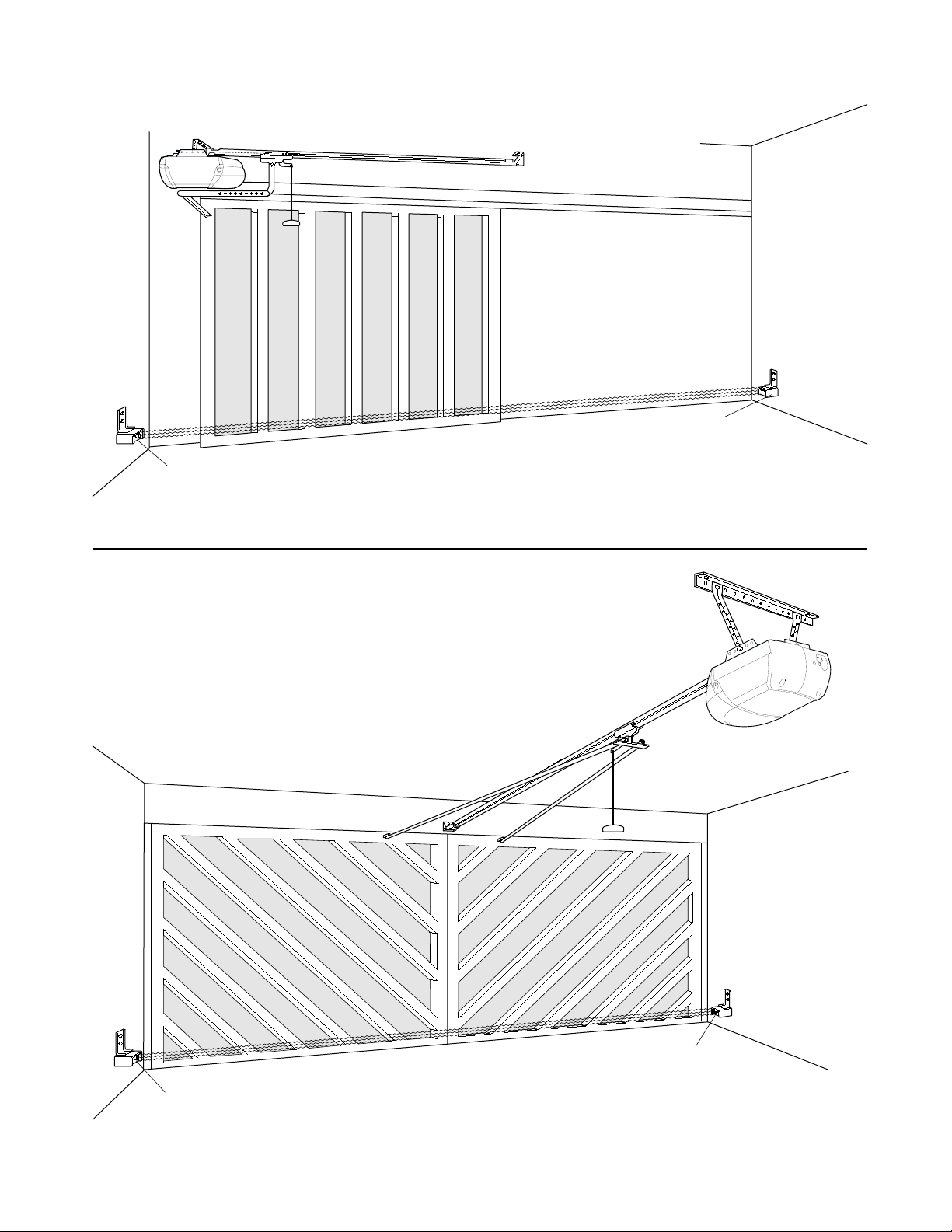

VIEW OF COMPLETED OPENER INSTALLATION ON A SLIDING DOOR

VIEW OF COMPLETED OPENER

INSTALLATION ON A SWINGING DOOR

Sensor Beam 6" max. above floor

Safety

Reversing

Sensor

Safety

Reversing Sensor

Header Wall

Safety

Reversing

Sensor

Sensor Beam 6" max. above floor

Safety

Reversing

Sensor

Page 3

3

In order to ensure the proper operation of your safety

reverse feature, replace the assembly instructions in

your Owner’s Manual with the following assembly steps.

WARNING

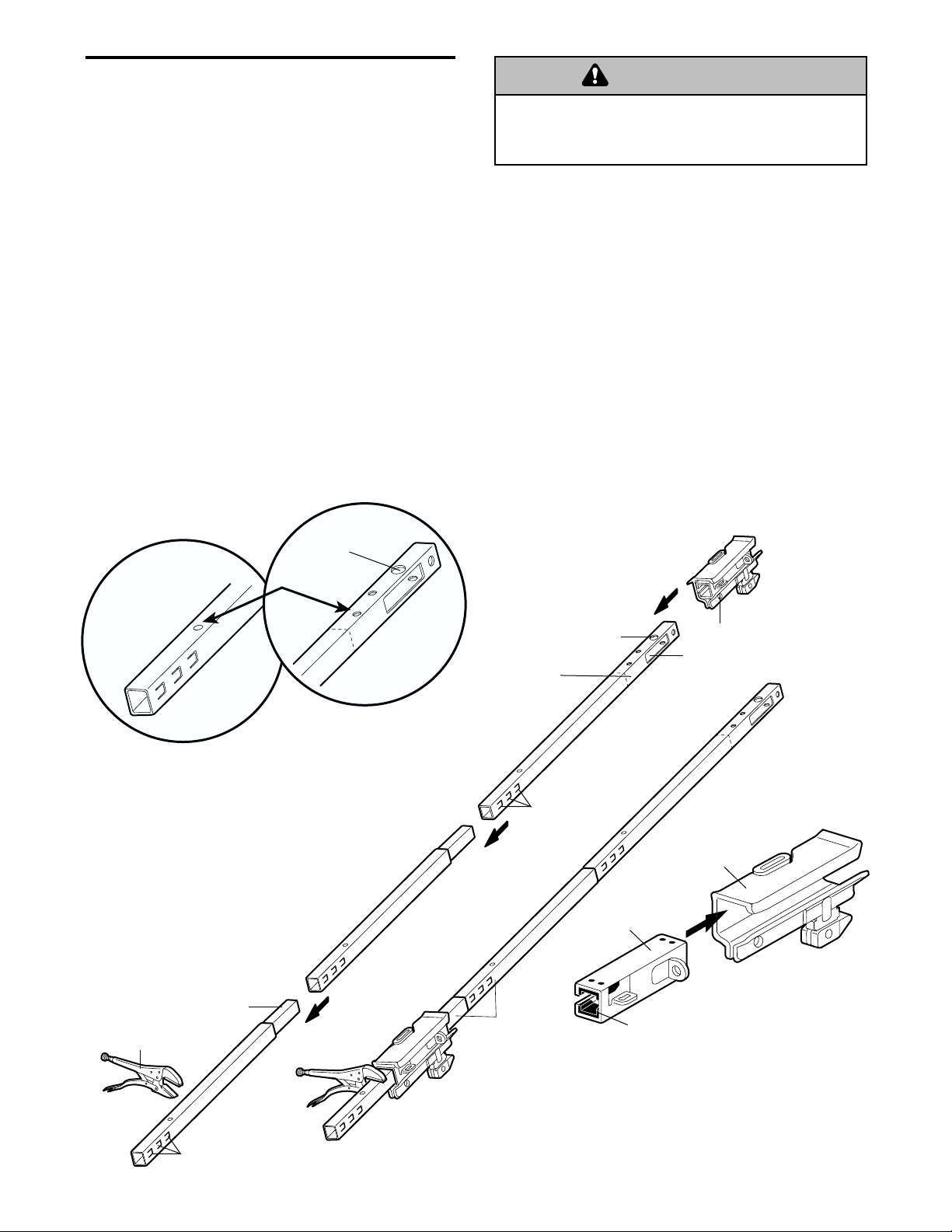

ASSEMBLY STEP 1

Assemble the Rail & Install

the Trolley

To avoid installation difficulties, do not run the

garage door opener until instructed to do so.

The front rail has a cut out “window” at the door end

(see illustration). The hole above this window is

larger on the top of the rail than on the bottom. A

smaller hole 3-1/2" (8.9 cm) away is close to the rail

edge. Rotate the back rail so it has a similar hole

close to the opposite edge, about 4-3/4" (12 cm)

from the far end. A 3-piece rail uses two back rails.

1. Align the rail sections on a flat surface exactly as

shown and slide the tapered ends into the larger

ones. Tabs along the side will lock into place.

2. Place the motor unit on packing material to protect

the cover, and rest the back end of the rail on top.

For convenience, put a support under the front

end of the rail.

3. As a temporary trolley stop, clamp a locking pliers

onto the rail, 8" (20 cm) from the end of the back

rail, as shown.

4. Check to be sure there are 4 plastic wear pads

inside the inner trolley. If they became loose

during shipping, check all packing material. Snap

them back into position as shown.

5. Connect the inner and outer trolleys as shown.

6. Slide the trolley assembly along the rail from the

front end to the locked pliers.

BACK RAIL

(TOP)

KEEP LARGER

HOLE ON TOP

FRONT RAIL

(TOP)

KEEP SMALL

HOLES ALONG

OPPOSITE

EDGE

OF RAILS

WARNING

Idler

Pulley

Hole

8" (20 cm) Distance from

Idler Pulley Hole

Trolley

Window

Cut-Out

Front Rail

(TO DOOR)

Locking Pliers

Tabs

Tapered

End

Tabs

Back Rails

(TO MOTOR

UNIT)

Outer Trolley

Inner Trolley

Wear Pads

Page 4

4

HARDWARE SHOWN ACTUAL SIZE

ASSEMBLY STEP 2

Fasten the Rail to the Motor Unit

• Insert a 1/4"-20 x 1-3/4 bolt into the cover

protection bolt hole on the back end of the rail as

shown. Tighten securely with a 1/4"-20 lock nut.

• Remove the two bolts from the top of the motor

unit.

• Attach spreaders to the U bracket by snapping

them into place.

• Place the U bracket, flat side down, on the motor

unit and align the bracket holes with the screw

holes. Fasten with the previously removed screws.

• Align the rail assembly with the top of the motor

unit. Slide the rail end onto the U-bracket, all the

way to the stops that protrude on the top and sides

of the bracket.

Motor Unit

Sprocket

"U" Bracket

Lock Nut

Bolts

SLIDE RAIL TO STOPS

ON TOP AND SIDES

OF BRACKET

Cover

Protection

Bolt Hole

Bolt

Hook Spreader

into Back Slots,

then Snap Tab

Into Front Slot

To avoid SERIOUS damage to opener, ONLY use bolts

mounted in the top of the motor unit.

WARNING

WARNING

WARNING

ASSEMBLY STEP 3

Install the Idler Pulley

• Lay the chain/cable beside the rail, as shown.

Grasp the end with the cable loop and pass

approximately 6' of cable through the window.

Allow it to hang until Assembly Step 5.

• Remove the tape from the idler pulley. The inside

center should be pre-greased. If dry, regrease to

ensure proper operation.

• Place the idler pulley into the window as shown.

• Insert the idler bolt from the top through the rail

and pulley. Tighten with a 3/8" lock washer and nut

underneath the rail until the lock washer is

compressed.

• Rotate the pulley to be sure it spins freely.

• Insert a 1/4"-20 x 1-3/4 bolt into the trolley stop

hole in the front of the rail as shown. Tighten

securely with a 1/4"-20 lock nut.

HARDWARE SHOWN ACTUAL SIZE

CAUTION

Bolt 1/4"-20 x 1-3/4

Lock Nut

1/4"-20

Chain and

Cable

Idler

Bolt

3/8" Lock

Washer

Trolley

Stop Hole

3/8" Nut

Pulley

Washer

Grease

Inside Pulley

Idler

Pulley

Cable Loop

Bolt

Rail

Nut

Trolley

Stop Hole

Idler Pulley

Bolt

Idler Bolt

Bolt 1/4"-20 x 1-3/4

Lock Nut 1/4"-20

Nut 3/8"

Lock Washer 3/8"

Page 5

5

ASSEMBLY STEP 4

Install the Chain/Cable

and Attach the Sprocket Cover

1. Pull the cable around the idler pulley and toward

the trolley.

2. Connect the cable loop to the retaining slot on the

trolley, as shown:

• From below, push pins of master link bar up

through cable loop and trolley slot.

• Push master link cap over pins and past pin

notches.

• Slide clip-on spring over cap and onto pin

notches until both pins are securely locked in

place.

3. With the trolley against the pliers, dispense the

remainder of the cable/chain along the rail toward

the motor unit and around the sprocket. The

sprocket teeth must engage the chain.

4. Check to make sure the chain is not twisted, then

connect it to the threaded shaft with the

remaining master link.

5. Thread the inner nut and lock washer onto the the

trolley shaft.

6. Insert the trolley threaded shaft through the hole

in the trolley. Be sure the chain is not twisted.

7. Loosely thread the outer nut onto the trolley shaft.

8. Remove the locking pliers.

9. Align the tabs on the sprocket cover with the

slots in the mounting plate. Squeeze

cover and insert tabs in slots.

To avoid possible SERIOUS INJURY to fingers from

moving garage door opener:

• ALWAYS keep hand clear of sprocket while

operating opener.

• Securely attach sprocket cover BEFORE operating.

WARNING

Idler

Pulley

Round

Hole

Master

Link Clip-On

Spring

Master

Link Cap

Trolley

Threaded

Shaft

Master

Link Bar

Master

Link Bar

Pin

Notch

Cable

Install Chain

and Cable

in this Direction

Opener

Back Tab

Slot

Mounting

Plate

Sprocket

Cover

WARNING

Dispensing Carton

Leave Chain and Cable

Inside Dispensing

Carton to Prevent Kinking.

Keep Chain and Cable

Taut When Dispensing

Page 6

ASSEMBLY STEP 5

Tighten the Chain

• Spin the inner nut and lock washer down the

threaded shaft, away from the trolley.

• To tighten the chain, turn outer nut in the direction

shown (Figure 1).

• When the chain is approximately 1/2" (1 cm) above

the base of the rail at its midpoint, re-tighten the

inner nut to secure the adjustment.

Sprocket noise can result if chain is too loose.

When installation is complete, you may notice some

chain droop with the door closed. This is normal. If

the chain returns to the position shown in Figure 2

when the door is open, do not re-adjust the chain.

NOTE: During future maintenance, ALWAYS pull the

emergency release handle to disconnect trolley

before adjusting chain.

NOTE: You may notice loosening of chain after

Adjustment (Test the Safety Reversal System).

Check for proper tension and readjust chain if

necessary. Then repeat Adjustment.

Figure 1

Figure 2

INSTALLATION

6

NOTE: It is recommended that you attach fine mesh or screening across the inside of swinging or sliding doors

in order to prevent intruders from reaching through the bars and releasing the trolley from the door arm or

pressing the door control button.

You have now finished assembling your garage

door opener. Please read the following warnings

before proceeding to the installation section.

IMPORTANT INSTALLATION INSTRUCTIONS

To reduce the risk of severe injury or death to persons:

WARNING

1. READ AND FOLLOW ALL INSTALLATION

INSTRUCTIONS

2. Install ONLY on a door which is in good repair and

moves freely.

3. Disable all locks and remove all ropes connected to

the door before installing the opener. Ropes connected

to a door can cause entanglement and DEATH.

4. If possible, install the opener 7 feet or more above

floor with manual release handle mounted 6 feet

above the floor. Removing the manual release rope

and handle and/or disabling the trolley release lever

can cause SERIOUS PERSONAL INJURY or DEATH.

5. Do not connect the opener to power source until

instructed to do so.

6. Locate the door control push button within sight of

the door at a minimum height of 5 feet where small

children cannot reach and away from all moving

parts of the door. Operating a door control push

button that is located out of sight of the door can

lead to SERIOUS PERSONAL INJURY or DEATH

from entrapment.

7. Install the User Safety Instruction Label on the wall

adjacent to the control button and the Maintenance

Instruction Label in a prominent location on the

inside or alongside of the door.

8. Upon completion of the installation, the door must

reverse when it comes in contact with a 2x4 board

inserted between the wall and the door or between

the swinging door sections (see page 8).

9. Do not wear watches, rings or loose clothing while

installing or servicing an opener. Jewelry or loose

clothing can be caught in the mechanism of the door

or the opener.

10. For opener security, install a guard to protect the rear

panel from being activated from outside the door.

To Tighten Outer Nut

Outer

Nut

Lock

Washer

To Tighten

Inner Nut

Trolley

Shaft

Inner Nut

Chain

(1 cm)

1/2 Inch

Base of Rail

Mid length of Rail

WARNING

Page 7

7

IMPORTANT SAFETY INSTRUCTIONS

To reduce the risk of severe injury or death to persons:

WARNING

1. READ AND FOLLOW ALL WARNINGS AND

INSTRUCTIONS.

2. ALWAYS keep remote controls out of reach of children.

NEVER permit children to operate or play with garage

door control push buttons or remote controls.

3. ONLY activate garage door when it can be seen clearly,

it is properly adjusted, and there are no obstructions to

door travel.

4. ALWAYS keep garage door in sight until completely

closed. NO ONE SHOULD CROSS THE PATH OF THE

MOVING DOOR.

5. Safety Reversal system MUST be tested every month.

The door MUST reverse on contact with a 2x4 board

inserted between the wall and the sliding door or

between the swinging door sections (see page 8).

6. If one control (force or travel limits) is adjusted, the

other control may also need adjustment.

7. After any adjustments are made, the safety reversal

system MUST be tested.

8. Disabling the trolley manual release lever or removing

the emergency release rope and handle will prevent

the door from being opened in an emergency, and can

cause SERIOUS INJURY OR DEATH.

9. Keep door in good repair and make sure it moves

freely. An improperly operating swinging or sliding

door could result in SEVERE PERSONAL INJURY OR

DEATH. Any necessary repairs should be made by a

qualified person.

10. Disconnect the electric power to the opener before

making any repairs or removing the covers.

11. The opener chassis MUST be protected from rain

and/or moisture.

12.

SAVE THESE INSTRUCTIONS

.

OPERATION

WARNING

Page 8

114A1633B ©2002 Printed in Mexico

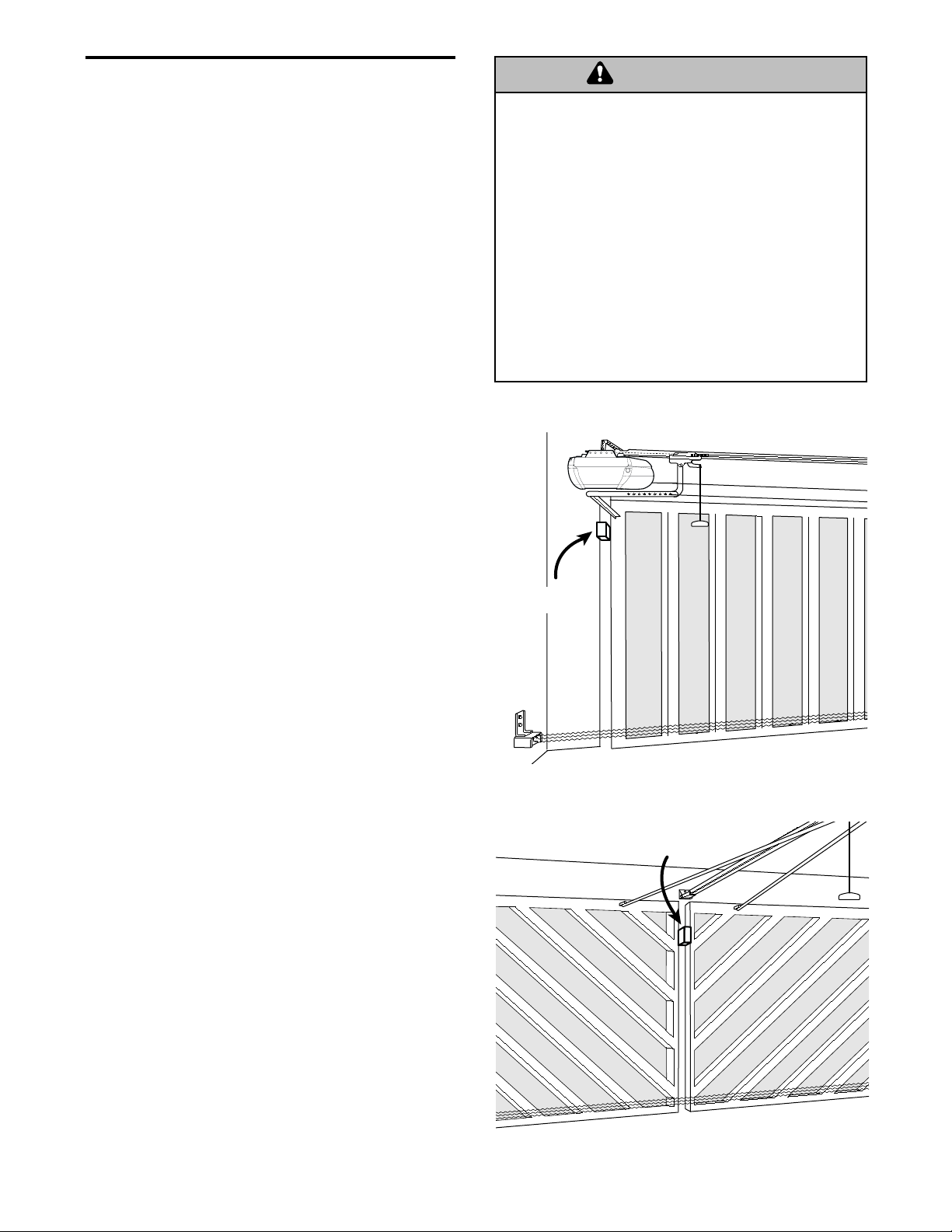

SLIDING DOOR INSTALLATION

SWINGING DOOR INSTALLATION

ADJUSTMENT

Follow the Adjustment Steps below

for proper testing of the Safety

Reverse System.

1. The opener must reverse if the door comes in

contact with an obstruction. A closing door should

reverse with little effort, and open completely.

Refer to Adjustment Step 2 in Owners Manual

for instructions.

2. At completion of installation of opener and testing

of reversing feature in #1 above, the 1 inch

reversal test must be completed. (Use 2x4 board

laid flat against the wall or door edge.)

• On a sliding door door, place a 2x4 board

between the door and wall of a closing door.

Door must reverse on the board and open

completely. Repeat at opposite wall if two

openers are installed.

• On a swing out door, insert a 2x4 board between

the closing door sections. Door sections must

reverse and swing open completely.

• If the door stops on the obstruction, it is not

traveling far enough in the closing direction.

Increase the DOWN limit adjustment screw

counterclockwise 1/4 turn. Repeat test.

• When the door reverses on a 2x4 board, remove

the obstruction and run the opener through

complete travel cycle to test adjustment.

• If the door will not reverse after repeated

adjustment attempts, call for trained door

systems technician.

IMPORTANT SAFETY CHECK

Repeat Adjustment Steps in Owners Manual

after:

• Each adjustment of door arm length, force controls

or limit controls.

• Any repair to or adjustment of the garage door

(including springs and hardware).

• Any repair to or buckling of the garage floor.

• Any repair to or adjustment of the opener.

Without a properly installed safety reversal system,

persons (particularly small children) could be

SERIOUSLY INJURED or KILLED by a closing garage door.

• Too much force on garage door will interfere with

proper operation of safety reversal system.

• NEVER increase force beyond minimum amount

required to close garage door.

• NEVER use force adjustments to compensate for a

binding or sticking garage door.

• If one control (force or travel limits) is adjusted, the

other control may also need adjustment.

• After ANY adjustments are made, the safety reversal

system MUST be tested. Door MUST reverse on

contact with one-inch high object (or 2x4 laid flat)

on floor.

WARNING

WARNING

2x4

Door/Wall

Obstruction

2x4 Obstruction

Page 9

ANEXO AL MANUAL

DEL PROPIETARIO ABRIDOR

PARA PUERTA DE COCHERA

Instrucciones Complementarias

Instalación y Prueba del Abridor en un Portón

con Bisagras o Corredizo

Si el abridor de portón no se instala, se opera, se prueba y

recibe el mantenimiento estrictamente de acuerdo a estas

instrucciones, el resultado puede ser lesiones personales serias

e inclusive la muerte si una persona queda atrapada.

• Siga cuidadosamente todas las instrucciones de instalación y

de seguridad.

• Conservar este instructivo.

ADVERTENCIA

ADVERTENCIA

Page 10

2

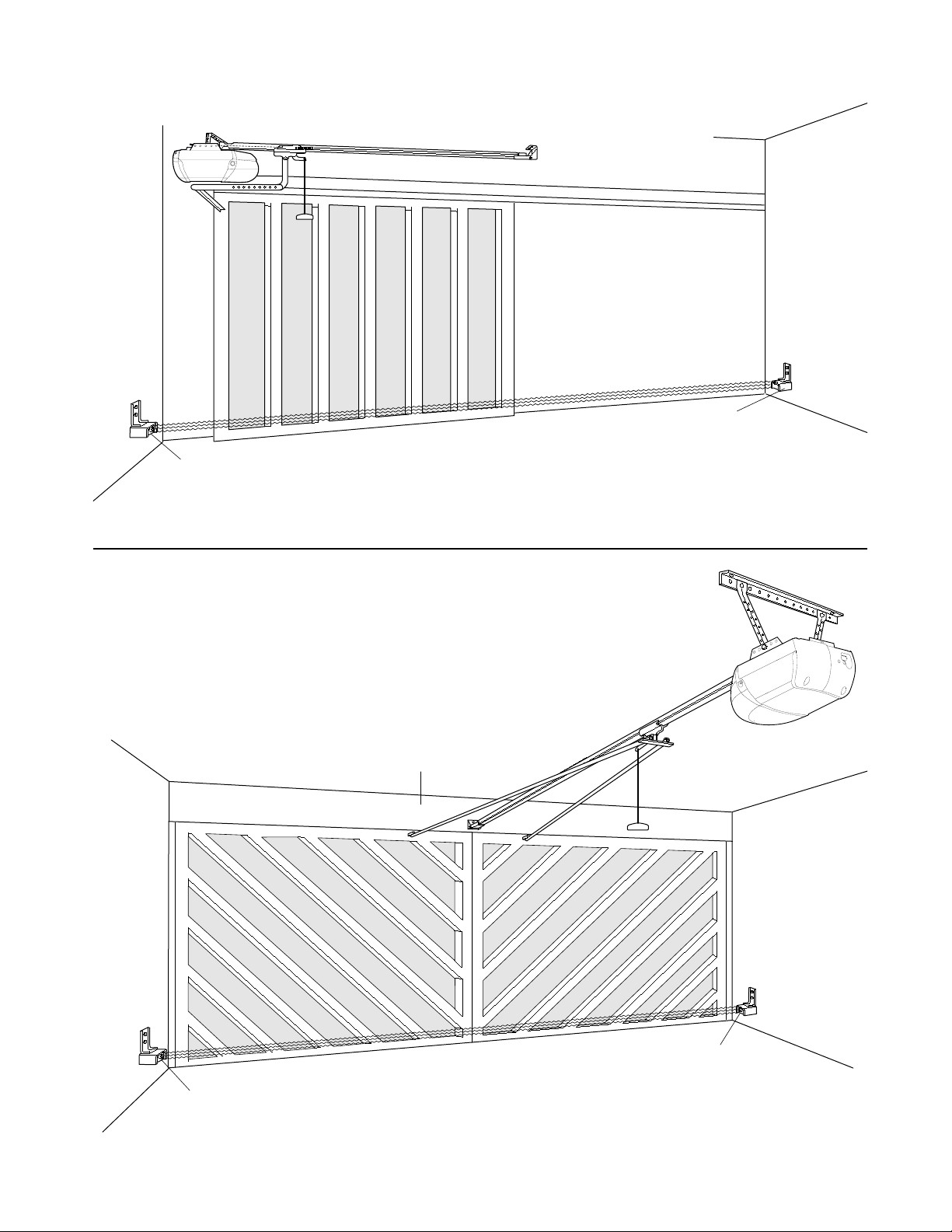

VISTA DE UNA INSTALACIÓN TERMINADA DE UN ABRIDOR EN UN PORTÓN CORREDIZO

VISTA DE LA INSTALACIÓN TERMINADA

DE UN ABRIDOR EN UN PORTÓN CON BISAGRA

Rayo del sensor a una distancia

Sensor de

Reversa de

Seguridad

máxima de 15 cm (6 pulg.)

Sensor de

Reversa de

Seguridad

Pared Frontal

Sensor de

Reversa de

Seguridad

Rayo del sensor a una distancia

máxima de 15 cm (6 pulg.)

Sensor de

Reversa de

Seguridad

Page 11

El riel delantero tiene una "ventana" cortada en el extremo

de la puerta (vea la ilustración). El orificio que se

encuentra arriba de esta ventana es más grande en la

parte superior del riel que en la parte inferior. Hay un

orificio más pequeño que se encuentra a 8.75 cm (3-1/2

pulg.) y está cerca de la orilla del riel. Gire el riel posterior

de manera que tenga un orificio similar cerca de la orilla

opuesta, más o menos a 11.87 cm (4-3/4 pulg.) del

extremo. Un riel de tres partes utiliza dos rieles posteriores

1. Alínee las secciones del riel sobre una superficie plana

exactamente como se indica y luego deslice los

extremos más pequeños dentro de los más grandes.

Las pestañas que se encuentran a lo largo de los lados

del riel se van a ajustar en su lugar.

2. Coloque el motor sobre el material de empaque para

proteger la cubierta del mismo y apoye el extremo

posterior del riel encima. Para que le resulte más

cómodo, ponga algún tipo de apoyo bajo el extremo

delantero del riel.

3. Como un tope temporario del trole, coloque tenazas de

calce a manera de mordaza sobre el riel a 20 cm

(8 pulg.) del extremo del riel posterior, según ilustrado.

4. Inspeccione para asegurarse que hayan 4 zapatas

plásticas de desgaste detro del trole interno. Si los

cojinetes se han soltado durante el transporte, revise

todo el material de empaque. Ponga los cojinetes de

desgaste en su lugar como se indica.

5. Conecte los troles interno y externo como aparece en la

ilustración.

6. Deslice el conjunto del trole a lo largo del riel desde el

extremo delantero a las tenazas calzadas.

3

Para asegurar la operación adecuada del dispositivo de

seguridad de reversa, sustituir las instrucciones de ensamble

del Manual del propietario con los siguientes pasos para el

ensamble.

ADVERTENCIA

MONTAJE, PASO 1

Monte el riel e instale el trole

Para evitar problemas en la instalación, no opere el

abridor hasta que se le ordene hacerlo.

Riel delantero

(A LA PUERTA)

Ventana

Pinzas con seguro

Orificio de

la polea loca

Distancía de 20 cm (8 pulg.)

desde el orificio

de la polea loca

Pestañas

Pestañas

Rieles

posteriores

(AL MOTOR)

Trole

Extremo más

pequeño

Trole interno

Cojinetes de desgaste

Trole externo

Extremo más

pequeño

MANTENGA

EL ORIFICIO

MÁS GRANDE

HACIA ARRIBA

RIEL DELANTERO

(PARTE

SUPERIOR)

MANTENGA LOS

ORIFICIOS PEQUEÑOS

A LO LARGO DE LA

ORILLA OPUESTA

DE LOS RIELES

RIEL POSTERIOR

(PARTE

SUPERIOR)

ADVERTENCIA

Page 12

4

Para evitar un daño SEVERO al abridor, use SOLO pernos

montados en la parte superior de la unidad del motor.

ADVERTENCIA

ADVERTENCIAADVERTENCIA

ESTAS PIEZAS SE MUESTRAN EN

SU TAMAÑO NORMAL

MONTAJE, PASO 2

Sujete el riel al motor

• Coloque un perno de 1/4-20x1-3/4 de pulg. dentro del

orificio de la cubierta de protección que se encuentra en

el extremo posterior del riel, como se indica en la

ilustración. Apriete bien el perno con tuerca de

1/4-20 de pulg.

• Extraiga los dos pernos del tope de la unidad del motor.

• Coloque los desplegadores en la ménsula en 'U'.

Escuchará un chasquido cuando quedan en su lugar.

• Ponga la ménsula en 'U' sobre el motor con el lado

plano hacia abajo y alínee los orificios de la ménsula

con los orificios de los tornillos. Sujete con los tornillos

que quitó antes.

• Alínee el riel con la parte superior del motor. Deslice el

extremo del riel en la ménsula en 'U', hasta los topes

que sobresalen en la parte superior y a los lados de la

ménsula.

MONTAJE, PASO 3

Instale la polea loca

• Acomode la cadena o cable a un lado del riel, como se

ilustra. Tome el extremo del cable que tiene una lazada

y pase aproximadamente 6' de cable a través de la

ventana. Deje el cable colgando hasta llegar al Paso 5

de Montaje.

• Retire la cinta de la polea loca. El interior del centro

debe estar engrasado. Si se ha secado, vuelva a

engrasarlo para asegurar que la operación sea

adecuada.

• Coloque la polea loca dentro de la ventana como

aparece en la ilustración.

• Inserte el perno loco desde la parte superior y a través

del riel y la polea. Apriete con una roldana y una tuerca

de 3/8 de pulg. por debajo del riel hasta que la roldana

quede comprimida.

• Haga girar la polea para cerciorarse de que da vuelta

libremente.

• Pase un perno de 1/4-20x1-3/4 de pulg. por el orificio de

paro del trole que se encuentra en la parte delantera del

riel, como aparece en la ilustración. Apriete bien con

una tuerca de 1/4-20 de pulg.

ESTAS PIEZAS SE MUESTRAN EN SU TAMAÑO NORMAL

PRECAUCIÓN

Pernos

Ménsula en 'U'

Perno

Orificio para

el perno en

la cubierta

de protección

DESLICE EL RIEL HASTA

LOS TOPES QUE ESTÁN EN

Tuerca

LA PARTE SUPERIOR Y A LOS

LADOS DE LA MÉNSULA

Polea del motor

Enganche

el desplegador

en las ranuras

posteriores,

luego coloque

las pestañas

dentro de la

ranuras delanteras.

Perno de 1/4-20x1-3/4 de pulg.

Tuerca de

1/4-20 de pulg.

Cadena y

cable

Perno

loco

Roldana de

3/8 de pulg.

Orificio de

paro del trole

Tuerca de

3/8 de pulg.

Per no

Polea

Roldana

Engrase el interior

de la polea

Polea loca

Lazada del cable

Riel

Tuerca

Per no

Orificio de

paro del trole

Polea loca

Perno loco

Perno de 1/4-20x1-3/4 de pulg.

Tuerca de

1/4-20 de pulg.

Tuerca de

3/8 de pulg.

Roldana de

3/8 de pulg.

Page 13

MONTAJE, PASO 4

Instale la cadena o cable y coloque

la cubierta de la polea

1. Jale el cable alrededor de la polea loca y hacia el trole.

2. Conecte la lazada del cable a la ranura de retención del

trole, como aparece en la ilustración:

• Empuje los pernos de la barra de enlace maestro

desde abajo hacia arriba y páselos a través de la

lazada del cable y la ranura del trole.

• Empuje la tapa del enlace maestro sobre los pernos y

las ranuras de los pernos.

• Deslice el resorte de clip sobre la tapa y sobre las

ranuras de los pernos hasta que los dos pernos estén

bien colocados y seguros en su lugar.

3. Con el trole contra las pinzas, alimente el resto del

cable o cadena a lo largo del riel, hacia el motor y

alrededor de la polea. Los dientes de la polea deben

engancharse en la cadena.

4. Revise para cerciorarse de que la cadena no esté

torcida, luego conéctela a la flecha roscada con el

enlace maestro restante.

5. Enrosque la tuerca interna y la roldana en la flecha del

trole.

6. Pase la flecha roscada del trole a través del orificio que

tiene el trole. Cerciórese de que la cadena no esté

torcida.

7. Ponga la tuerca externa en la flecha del trole, dejándola

floja.

8. Quite las pinzas con seguro.

9. Alínee las pestañas de la cubierta de la polea con las

ranuras de la placa de montaje. Oprima la cubierta e

inserte las pestañas en las ranuras.

Para evitar posibles LESIONES GRAVES en los dedos causadas

por las partes móviles del abridor de puerta de cochera:

• SIEMPRE tenga las manos lejos de la polea mientras esté

funcionando el abridor.

• Ponga la cubierta de la polea ANTES de hacer funcionar

el abridor.

5

ADVERTENCIA

Abridor

Polea

loca

Orificio

redondo

Flecha

roscada

del trole

Cable

Indentación

del perno

Tapa del

enlace maestro

Resorte

de clip del

enlace

maestro

Barra del

enlace maestro

Cubierta

de la polea

Placa de

montaje

Ranura de la

pestaña posterior

Instale la Cadena

y Cable en

esta Dirección

ADVERTENCIA

Cartón para alimentar

el cable/cadena

Deje la cadena y

el cable dentro del cartón

para evitar que se tuerza.

Mientras alimente la cadena y

el cable debe mantenerlos tensos

Page 14

Figura 1

Figura 2

6

Ya terminó de armar su abridor de puerta de cochera,

por favor lea les siguientes advertencias antes de

continuar a la Sección de instalación.

IMPORTANTES INSTRUCCIONES DE INSTALACION

:

Para reducir el riesgo de lesiones personales severas

e inclusive la muerte:

ADVERTENCIAADVERTENCIA

1. LEER Y SEGUIR TODAS LAS INSTRUCCIONES DE INSTALACION

2. Instalar solamente en un portón que se encuentre en buenas

condiciones de operación y se mueva libremente.

3. Inhabilitar todos los seguros y quitar todas las cuerdas

conectadas al portón antes de instalar el abridor. Las cuerdas

conectadas al portón pueden enredarse y ocasionar inclusive

la muerte.

4. De ser posible, instalar el abridor a una altura de 7 pies o más

del piso, con la manija del desenganchador manual montado

a 6 pies del piso. Remover la cuerda y la manija del

desenganchador manual y/o inhabilitar la palanca que

desengancha el carrito puede ocasionar lesiones personales

serias e inclusive la muerte.

5. No conectar el abridor al suministro de energía hasta que se

indique hacerlo.

6. Colocar el botón de control del portón a la vista desde el

portón y a una altura mínima de 5 pies, donde los niños

pequeños no puedan alcanzarlo y lejos de las piezas móviles

del portón. Colocar el botón de control del portón en un lugar

donde no se vea desde el portón puede conducir a serias

lesiones personales e inclusive la muerte si una persona

queda atrapada.

7. Colocar la etiqueta de Instrucciones de seguridad del usuario

sobre la pared, junto al botón de control y colocare la etiqueta

de Instrucciones de mantenimiento en un lugar prominente en

el interior o a lado del portón.

8. Una vez terminada la instalación, el portón debe dar marcha

atrás al entrar en contacto con una tabla de 2 x 4 que se

coloque entre la pared y la puerta corrediza del portón, o bien

entre las secciones del portón con bisagras (ver la página 8).

9. No usar relojes de pulso, anillos ni prendas de ropa sueltas al

instalar o dar servicio a un abridor. Las piezas de joyería o las

prendas de ropa sueltas pueden atorarse en el mecanismo del

portón o del abridor.

10. Por razones de seguridad, instalar una guarda para proteger

el panel trasero y evitar que se active desde fuera del portón.

NOTA: Se recomienda colocar una malla fina a través del portón corredizo o con bisagras, con el objeto de evitar que

cualquier intruso alcance el botón de control o el brazo que desengancha el carrito.

MONTAJE, PASO 5

Apriete la cadena

• Gire la tuerca interna y ajuste la roldana; baje ambas por

la flecha roscada, alejándolas del trole.

• Para apretar la cadena, gire la tuerca externa en la

dirección que se indica en la Figura 1.

• Una vez que la cadena esté aproximadamente 1.25 cm

(1/2 pulg.) arriba de la base del riel en su punto medio,

vuelva a apretar la tuerca interna para asegurar el ajuste.

Si la cadena queda demasiado floja la polea puede hacer

ruido.

Una vez terminada la instalación, es posible que observe

que la cadena cuelga un poco cuando la puerta está

cerrada, pero esto es normal. Si la cadena regresa a la

posición que se ilustra en la Figura 2 cuando la puerta

está abierta, no vuelva a ajustar la cadena.

NOTA: En el futuro, cuando le dé mantenimiento

SIEMPRE jale la manija de emergencia para desconectar

el trole antes de ajustar la cadena.

NOTA: Usted puede notar que la cadena se ha aflojado

después del ajuste (Prueba el sistema reversible de

seguridad). Verifique que la tensión sea correcta y reajuste

la cadena de ser necesario. A continuación repita el ajuste.

INSTALACIÓN

Para apretar

la tuerca externa

Cadena

Base del riel

Tuerca

externa

Mitad del riel

Roldana

Para apretar

la tuerca interna

1/2 pulg.

Flecha

del trole

Tuerca interna

ADVERTENCIA

Page 15

7

INSTRUCCIONES IMPORTANTES DE SEGURIDAD

Para reducir el riesgo de lesiones personales

severas inclusive la muerte:

ADVERTENCIAADVERTENCIA

1. LEA Y RESPETE TODAS LAS ADVERTENCIAS Y LAS

INSTRUCCIONES DE OPERACIÓN

2. SIEMPRE conserve los controles remotos lejos del alcance de

los niños. NUNCA permita que los niños operen o jueguen con

los botones del control de la puerta de la cochera ni con los

controles remotos.

3. SÓLO active la puerta de la cochera siempre y cuando la

puedan ver con claridad, esté debidamente ajustada y no haya

ninguna obstrucción en el recorrido de la puerta al cerrarse.

4. SIEMPRE tenga la puerta de la cochera a la vista hasta que esté

completamente cerrada. NADIE DEBE ATRAVESAR EL

RECORRIDO DE LA PUERTA CUANDO ESTÁ EN MOVIMIENTO.

5. El sistema reversible de seguridad DEBE probarse cada mes.

La puerta DEBE revertirse al tocar la tabla de 2x2 insertada

entre la pared y la puerta corrediza o entre las secciones de la

puerta giratoria (vea la página 8).

6. Si se ajusta uno de los controles (límites de la fuerza o del

recorrido), es posible que sea necesario ajustar también el

otro control.

7. Después de llevar a cabo cualquier ajuste, SE DEBE probar el

sistema de reversa de seguridad.

8. El inhabilitar la palanca de desenganche manual del trole o el

extraer la soga y manija de desenganche de emergencia

impide que la puerta se abra en una emergencia, y puede

causar LESIONES GRAVES O LA MUERTE.

9. Mantega la puerta en buen estado y asegúrese que se mueve

libremente. Una puerta giratoria o corrediza mal ajustada

puede resultar en LESIONES PERSONALES GRAVES O LA

MUERTE. Toda reparación necesaria debe ser efectuada por

una persona calificada.

10. Desconectar el suministro de energía del abridor antes de

hacer cualquier reparación o de quitar las cubiertas.

11. El chasis del abridor debe estar protegido contra la lluvia y/o

la humedad.

12.

CONSERVAR ESTAS

INSTRUCCIONES.

OPERACIÓN

ADVERTENCIA

Page 16

Si el sistema de reversa de seguridad no se ha instalado

debidamente, las personas (y los niños pequeños en

particular) podrían sufrir LESIONES GRAVES o incluso LA

MUERTE cuando se cierra la puerta de la cochera.

• Si el límite de la fuerza de la puerta de la cochera es excesivo

habrá de interferir con la operación adecuada del sistema de

reversa de seguridad.

• NUNCA aumente la fuerza más allá de la cantidad mínima que

se requiera para cerrar la puerta de la cochera.

• NUNCA use los ajustes de la fuerza para compensar si la

puerta de la cochera se pandea o se atora.

• Si se ajusta uno de los controles (límites de la fuerza o del

recorrido), es posible que sea necesario ajustar también el

otro control.

• Después de llevar a cabo cualquier ajuste, SE DEBE probar el

sistema de reversa de seguridad. La puerta DEBE retroceder

al entrar en contacto con un objeto de 2.5 cm (1 pulg) de

altura (o bien un pedazo de madera de 5 x 10 cm (2x4)

acostado en el piso.

114A1633B ©2002 Impreso en México

INSTALACIÓN DE UN PORTÓN CORREDIZO

INSTALACIÓN DE UN PORTÓN

CON BISAGRA

AJUSTE

Siga los Pasos de Ajuste de abajo para

una prueba apropiada del Sistema

Reversible de Seguridad.

1. El abridor debe dar marcha atrás al entrar en contacto

con una obstrucción. Un portón que está cerrándose

debe dar marcha atrás con muy poco esfuerzo y abrir

completamente. Consultar las instrucciones que

aparecen en el Paso 2 del ajuste del Manual del

Propietario.

2. Una vez terminada la instalación del abridor y hecha la

prueba del dispositivo de reversa como se indica en el

punto 1 anterior, deberá realizarse la prueba de reversa

de una pulgada. (Usar una tabla de 2 x 4 colocada

sobre la pared o en la orilla del portón).

• En un portón corredizo, colocar una tabla de 2 x 4

entre la puerta y la pared cuando el portón se esté

cerrando. El portón debe dar marcha atrás sobre la

tabla y abrirse completamente. Repetir en la pared

opuesta si se han instalado dos abridores.

• En un portón con bisagras que abran hacia fuera,

insertar una tabla de 2 x 4 entre las secciones del

portón que se están cerrando. Las secciones del

portón deben dar marcha atrás y abrirse

completamente.

• Si el portón se detiene ante la obstrucción, el recorrido

no es suficiente en la dirección de cerrado. Aumentar

el límite HACIA ABAJO, girando el tornillo de ajuste 1/4

de vuelta en dirección opuesta a las manecillas del

reloj. Repetir la prueba.

• Cuando el portón dé marcha atrás al toparse con la

tabla de 2 x 4, retirar la obstrucción y hacer funcionar

el abridor un ciclo completo de su recorrido para

probar el ajuste.

• Llame a un técnico capacitado de sistemas de puerta,

si la puerta no se revierte después de repetidos

intentos de ajuste.

IMPORTANTE VERIFICACIÓN DE SEGURIDAD

Repita los pasos de ajuste del Manual del

Propietario después de:

• Hacer ajustes al largo del brazo de la puerta, a los

controles de fuerza o a los controles de límite

• Reparar o ajustar la puerta de cochera (incluyendo

resortes o piezas de ferretería).

• Reparar el piso de la cochera

• Reparar o ajustar el abridor.

ADVERTENCIA

ADVERTENCIA

Obstrucción

de 2x4 en la

pared y puerta

Obstrucción de 2x4

Loading...

Loading...