Page 1

Danger

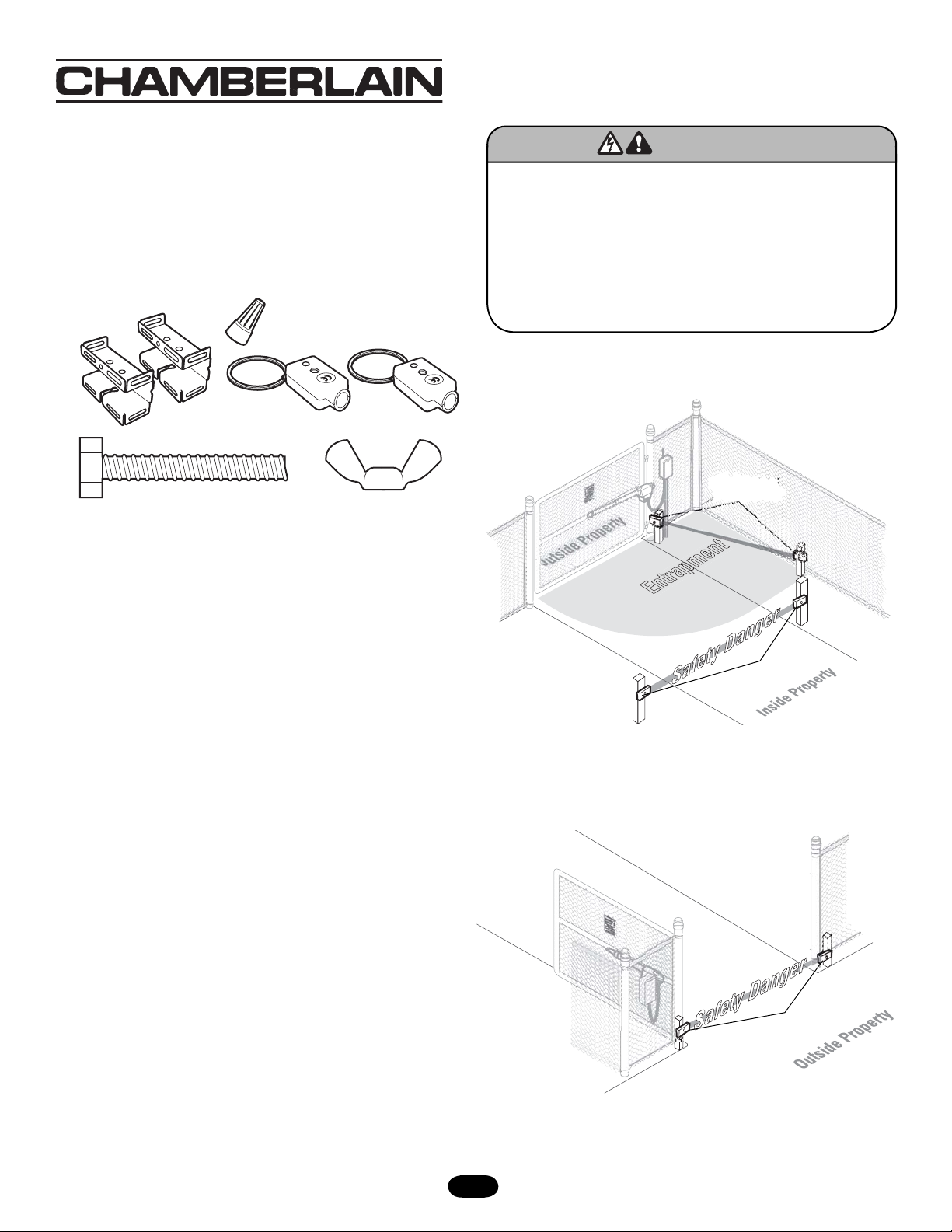

Inside Property

ENTRAPMENT

Safety Sensors

Entrapment

DangerDanger

WARNING

WARNINGWARNING

The Safety Sensor Kit is compatible with Chamberlain® Gate Access

Systems GA400D, GA420D, and GA200D. The Safety Sensors are

designed to detect an obstacle in the path of the electronic beam and

stop the gate operator.

CARTON INVENTORY

Verify carton inventory below.

Wire Nut (4)

®

THE PROTECTOR SYSTEM

®

SAFETY SENSORS MODEL 916GA

To prevent SERIOUS INJURY or DEATH:

• Disconnect ALL electric and battery power BEFORE performing

ANY service or maintenance.

• Correctly connect and align the safety sensors.

• Install the sensor so beam is NO HIGHER than 24" (61 cm) above

ground.

• This product is for use with Chamberlain

GA200D gate operators ONLY.

OPEN and ENTRAPMENT Safety Sensors

®

GA400D, GA420D, and

Brackets

Hex Head Bolt (2)

IMPORTANT INFORMATION ABOUT THE SAFETY SENSORS

When properly connected and aligned, the sensor will detect an obstacle

in the path of its electronic beam.

The sensors must be installed so that the sending and receiving eyes

face each other across the gate, no more than 24" (61 cm) above the

ground. The sensors can be installed on the left or right of the gate as

long as the sun never shines directly into the receiving eye lens.

The safety sensors must be securely fastened to a solid surface such as

metal or a treated wood post (not provided). The light beam path must

be unobstructed during normal operation of the gate.

NOTE: Due to the variety of gates and mounting applications, PVC

conduit, wire, mounting hardware and posts are not provided. Refer to

your local hardware store for additional hardware.

(Includes receiving and sending sensor)

Safety Sensors

Wing Nut (2)

APPLICATIONS

ENTRAPMENT SAFETY SENSORS

This will pause an opening gate until the obstruction has been

removed. Upon removing the obstruction, the gate will continue to

open. This will have no effect on the gate closing.

OPEN (PHOTO EYE/IR) SAFETY SENSORS

• GA400D/GA420D - This will pause an opening gate until the

obstruction has been removed. Upon removing the obstruction, the

gate will continue to open. This will have no effect on the gate closing.

• GA200D - This will stop a closing or opening gate, once the

obstruction is removed the gate will continue to operate normally

upon the next command given.

CLOSE (PHOTO EYE/IR) SAFETY SENSORS

• GA400D/GA420D - This will reverse a closing gate to the full open

position (open limit). This will have no effect on a gate opening.

• GA200D - This will stop a closing or opening gate, once the

obstruction is removed the gate will continue to operate normally

upon the next command given.

OPEN

Safety Sensors

CLOSE Safety Sensors

CLOSE

Safety Sensors

1

Page 2

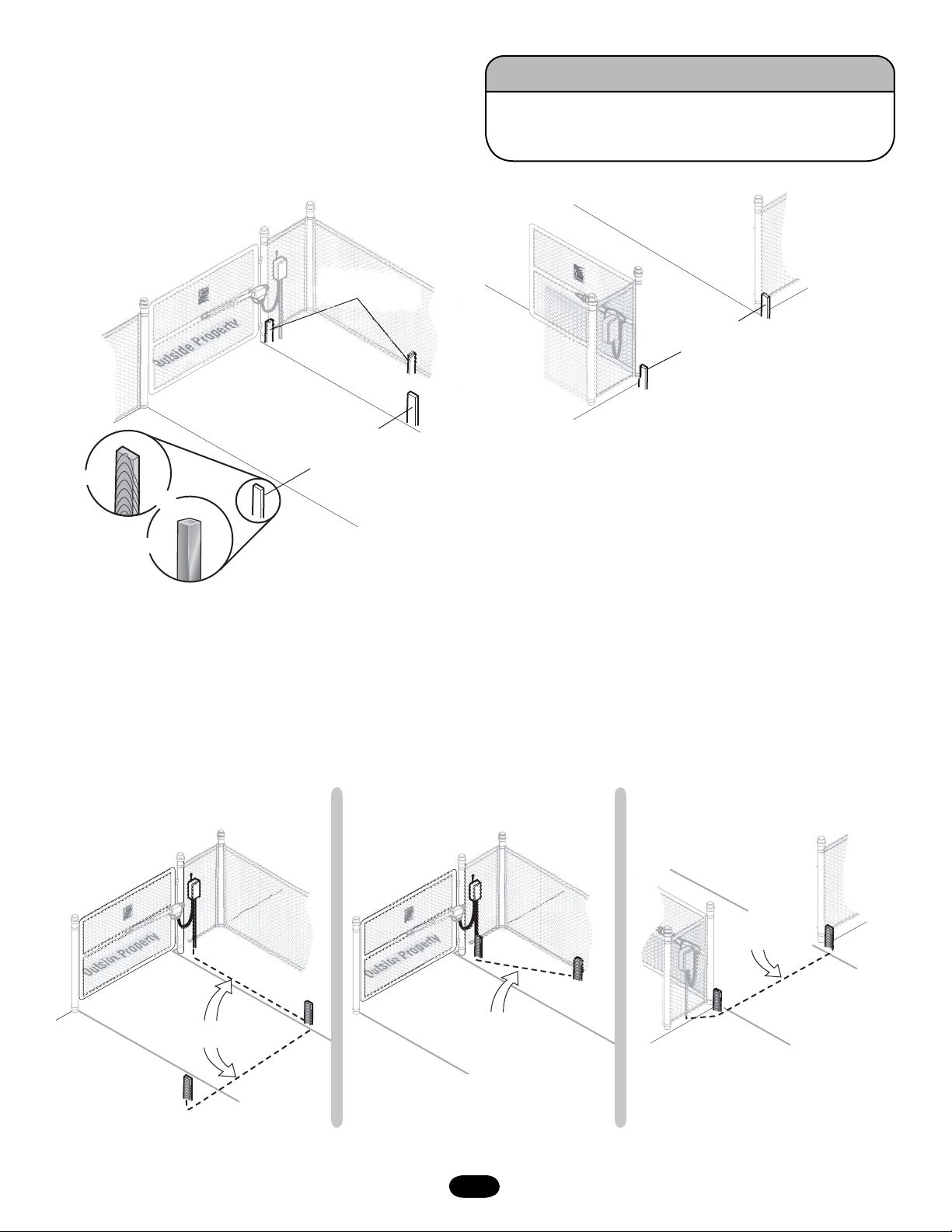

Inside Property

Metal

OR

Wood

ENTRAPMENT

Safety Sensor Posts

OPEN

Safety Sensor Posts

Inside Property

Outside Property

CLOSE

Safety Sensor Posts

Inside Property

6" (15 cm) trench for

safety sensor wires

Inside Property

6" (15 cm) trench for

safety sensor wires

Outside Property

6" (15 cm) trench

for safety sensor

wires

WARNING

CAUTIONCAUTION

WARNING

WARNING

POWER

Disconnect power and batteries to the operator.

SAFETY SENSOR POSTS

Use a metal or treated wood post (not provided) to elevate the sensors.

Safety sensors must be installed no higher than 24" (61 cm) above the

ground.

To AVOID damaging gas, power or other underground utility lines,

contact underground utility locating companies BEFORE digging.

NOTE: For ideal protection the safety sensors should be installed as close

to one another as possible with the maximum distance up to 30' (9.1 m).

TRENCH FOR WIRING

Before digging, contact local underground utility locating companies.

Dig a narrow trench 6" (15 cm) deep from control box to safety sensor

posts. Be careful not to damage any buried wire. Run conduit from

control box to safety sensor posts and run low voltage wire* (not

provided) through conduit.

OPEN SAFETY SENSORS

CLOSE SAFETY SENSORSENTRAPMENT SAFETY SENSORS

* UL approved Class 1 or Class 3 direct burial/underground, sunlight/UV resistant 16 gauge 2-conductor/standard wire.

2

Page 3

ASSEMBLE SAFETY SENSORS

Insert hex head bolt through safety sensor and slide safety sensor into

bracket. Secure with wing nut.

MOUNT SAFETY SENSORS

Mount safety sensor assembly to post using appropriate hardware (not

provided). Safety sensors must be installed no higher than 24" (61 cm)

above the ground.

NOTE: Install safety sensor assembly with the two holes in the bracket

facing up and the LEDs visible at the top.

Safety Sensor Post

Mark Safety

Sensor Post No

Higher than 24"

(61 cm)

WIRE SAFETY SENSORS

1. Separate wires.

2. Strip 7/16" (11 mm) of insulation from low voltage wires.

3. Combine all like-colored wires and twist together with wire nuts.

Wire Nuts

Safety Sensor Wires

Safety Sensor Post

Safety Sensor

Assembly

Safety Sensor Post

Low Voltage

Wires to

Control Box

Conduit

3

Page 4

CLOSE

EDGE

R93

L1

K2

OPEN EDGE/

OPEN

PHOTO

CLOSE

PHOTO

Z22

P1

F2

MOV1

D1

Q12

U4

CONTROL

INPUTS

FORCE

TIMER TO

CLOSE

OFF MAX

OPEN

SINGLE BUTTON

RESET

STOP

SHADOW

INTERRUPT

CHGR

OVLD

COM

COM

CTRL

LOOP

INPUTS

D129

Z4

U3

D2

D44

C11

C13

C12

K1

F3

K3

K4

F7

CTRL

OVLD

TIMER

RUNNING

GATE 2

SET

OPEN

LIMIT

SET

CLOSE

LIMIT

LEARN

LIMITS

DIAGNOSTIC

GATE 1

LEARN

XMITTER

LOCK /

ON OFF

PWR

C69

OFF MAX

J2

Ø

PWR

SINGLE BUTTON

AC PWR

/SOLAR

D8

D4

R9

R329

R27

MOV2

R4

C2

BIPART DELAY

F12

Q9

Q6

Q1

J19

0VLD

C75

C73

C72

C71

C7

Ø

C66 C65

C68

C33

F11

R186

R42

Ø

R423

30

C64

R22

U2

J18

K6

JU1

JU1

JU2

DB1

R184

CLOSE

PHOTO

OPEN

PHOTO

CLOSE

Z8

Open

Safety

Sensors

OPEN EDGE/

PHOTO

CLOSE

Z9

Entrapment

Safety

Sensors

Close Safety Sensors

Black

striped

wires

Black

striped

wires

Black

Black

Black

striped

wires

Red

Red

Black

Black

Red

Red

Black

Black

Red

Red

YEL

T ALARM

JU1

R6

SWITCHIR

++

__

GRN

BRN

WHT

RED

BLU

SWITCHIR

++

__

Entrapment/Open

Safety Sensors

Black

striped

wires

Red

wires

Black

Striped Wire

Black

Striped Wire

Red

Red

Close

Safety Sensors

NOTE: If the safety sensor wires need to be extended, the polarity must

be maintained when connecting the safety sensors to the control board.

The black striped wire connects to the negative (-) terminal and the red

wire connects to the positive (+) terminal.

MODEL GA200D ONLY

• Insert red lead wire into IR+ terminal.

• Insert black striped lead wire into IR- terminal.

MODELS GA400D AND GA420D ONLY

Entrapment Safety Sensors

• Connect ENTRAPMENT safety sensor wires to P8 terminal.

Open Safety Sensors

• Connect OPEN (Photo Input) safety sensor wires to P7 terminal.

Close Safety Sensors

• Connect CLOSE (Photo Input) safety sensor wires to P9 terminal.

ALIGN SAFETY SENSORS

1. Reconnect power and batteries to the operator. The indicator lights in

both the sending and receiving eyes will glow steadily if wiring

connections and alignment are correct.

NOTE: The sending eye indicator light will glow regardless of alignment

or obstruction. If the indicator light in the receiving eye is off, dim, or

flickering (and the invisible light beam path is not obstructed), alignment

is required.

2. Loosen the sending eye wing nut and readjust, aiming directly at

the receiving eye. Lock in place.

3. Loosen the receiving eye wing nut and adjust sensor until it

receives the sender’s beam. When the indicator light glows

steadily, tighten the wing nut.

NOTE: When properly aligned, the indicator lights in both the sending

and receiving eyes will glow steadily.

TEST THE SYSTEM

1. Press the remote control button to open the gate.

2. Place an obstruction in the path of the close or entrapment safety

sensor.

3. Press the remote control button to close the gate. The gate

should stop.

4. Remove the obstruction and the operator will resume normal function.

The gate operator will not function from a remote control if the indicator

light in either sensor is off indicating the sensor is misaligned or

obstructed. If the system continues to fail the test, call for a trained gate

systems technician.

Verify all other safety devices operate correctly.

TROUBLESHOOTING

If the sending or receiving LEDs do not light up after installation, please

check the following:

• Power supply to the operator. Operator may be in stand-by mode,

press the reset button to wake up the operator. Verify voltage at

inputs.

• A short in the wires. Check wires.

• Incorrect wire connections between the safety sensors and operator.

Verify wiring.

• A broken wire. Check wires.

If both sensors are flashing:

• Align sensors.

• Remove obstruction.

• GA200D - Disconnect safety sensors then turn power on unit.

• GA400D/GA420D - Erase the programming for the safety

sensors - remove safety sensor. Press learn limits button then

press reset button.

© 2008, The Chamberlain Group, Inc.

01-33959C All Rights Reserved

MODEL GA200D

Red

Black

Lead

Striped

Wire

Lead

Wire

MODEL GA400D AND GA420D

Indicator Light

Loading...

Loading...