CHAFFOTEAUX TALIA Product Manual

Product Guide

TALIA

Release 01_16.05.07

INDICE

1 VALUE PROPOSITIONS........................................................................................................................... 4

2 EASY TO SELL.......................................................................................................................................... 5

2.1 MULTILEVEL INTERFACE ................................................................................................................. 6

2.1.1 Interface description ................................................................................................................ 6

2.2 DISPLAY DESCRIPTION .................................................................................................................... 7

2.2.1 Week time programming zone................................................................................................. 7

2.2.2 Functioning and diagnostic zone............................................................................................. 8

2.2.3 Peripherals control................................................................................................................. 10

2.3 INFORMATION SYSTEM .................................................................................................................. 11

2.4 SELF-CHECK FUNCTION ................................................................................................................ 12

2.4.1 Malfunctions that can be reset by end user........................................................................... 12

2.4.2 Malfunctions that cannot be reset by end user...................................................................... 12

2.5 “ANTIFREEZE” FUNCTION .............................................................................................................. 13

2.6 DHW COMFORT ............................................................................................................................... 14

2.6.1 DHW performances & certification ........................................................................................ 14

2.6.2 The MSC system ................................................................................................................... 14

2.6.3 DHW timer program...............................................................................................................15

2.7 SOLAR PREDISPOSITION ............................................................................................................... 16

2.8 HEATING COMFORT........................................................................................................................ 17

2.8.1 Heating performances & certification .................................................................................... 17

2.8.2 System approach................................................................................................................... 17

2.8.3 Thermoregulation .................................................................................................................. 17

2.8.4 Built-in weekly timer............................................................................................................... 19

2.9 MSI FUNCTION: ACOUSTIC COMFORT......................................................................................... 20

3 EASY TO INSTALL.................................................................................................................................. 21

3.1 OVERALL DIMENSION..................................................................................................................... 22

3.2 HYDRAULICS CONNECTIONS ........................................................................................................ 24

3.2.1 The solar kit ........................................................................................................................... 25

3.2.2 Hydraulic connections cover.................................................................................................. 25

3.3 FLUE CONNECTIONS...................................................................................................................... 26

3.3.1 Open chamber system .......................................................................................................... 26

3.3.2 Coaxial system 60/100 .......................................................................................................... 26

3.3.3 Coaxial system 80/125 .......................................................................................................... 28

3.3.4 Twin Pipes system................................................................................................................. 29

3.4 OLD C&M BOILER RANGE REPLACEMENT .................................................................................. 31

3.4.1 Replacement Celtic boiler by TALIA...................................................................................... 31

3.4.2 Replacement Centora boiler by TALIA................................................................................. 32

3.5 COMPETITORS REPLACEMENT .................................................................................................... 33

3.5.1 Replacement SOUNIER DOUVAL boiler by TALIA .............................................................. 33

3.5.2 Replacement ELM GVM boiler by TALIA .............................................................................. 33

3.6 ELECTRICAL CONNECTIONS ......................................................................................................... 34

3.6.1 Installer zone ......................................................................................................................... 34

3.6.2 Thermoregulation device connections................................................................................... 35

3.7 INSTALLATION SETTING & FUNCTIONS ....................................................................................... 36

3.7.1 The personalisation Menu ..................................................................................................... 36

3.7.2 Automatic air purge function.................................................................................................. 36

3.7.3 Flue cleaner function ............................................................................................................. 37

3.8 SYSTEM PREDISPOSITION ............................................................................................................ 37

3.8.1 Clip IN in 2 relés .................................................................................................................... 38

3.8.2 Clip IN in solar ....................................................................................................................... 39

4 EASY TO MAINTAIN............................................................................................................................... 42

4.1 DIAGNOSTIC .................................................................................................................................... 43

4.1.1 Error codes ............................................................................................................................ 43

4.1.2 Complete information on boiler status................................................................................... 43

4.2 MSA: MODULAR SYSTEM APPROACH & BOILER OVERVIEW.................................................... 44

Page. 2 of 63

4.2.1 Open chamber overview........................................................................................................ 45

4.2.2 Sealed chamber overview ..................................................................................................... 46

4.2.3 Hydraulic diagram.................................................................................................................. 47

4.2.4 Hydraulic circuit ..................................................................................................................... 48

4.2.5 Hydraulic assembly ............................................................................................................... 49

4.2.6 By pass .................................................................................................................................. 49

4.2.7 New proportional flow meter.................................................................................................. 50

4.2.8 Hydraulic group maintenance................................................................................................ 51

4.2.9 Combustion group CF ........................................................................................................... 52

4.2.10 Combustion group FF............................................................................................................ 53

4.2.11 Combustion group maintenance............................................................................................ 54

5 BOILER CODES...................................................................................................................................... 55

6 ACCESSORY CODES............................................................................................................................. 56

6.1 INSTALLATION ACCESSORIES ...................................................................................................... 56

6.2 TERMOREGOLATION INTERFACES .............................................................................................. 57

6.3 TERMOREGOLATION ACCESSORIES ........................................................................................... 58

6.4 HYDRAULIC ACCESSORIES ...........................................................................................................60

7 TECHNICAL DATA..................................................................................................................................62

7.1 OPEN-CHAMBER ............................................................................................................................. 62

7.2 SEALED-CHAMBER ......................................................................................................................... 63

Page. 3 of 63

1 VALUE PROPOSITIONS

The new TALIA by Chaffoteaux is the result of a careful analysis of the installers and

service technicians needs in order to make their job easier.

EASY TO SELL

The result is the TALIA boiler, the solution that every customer will choose in terms

of easiness of use and its ability to totally satisfy every comfort needs.

All this in the more efficient way thanks to “new intelligence” able to make easy

most advanced thermoregulation systems used to achieve the maximum energy

saving and the minimum of the environment impact.

The TALIA boiler is also predisposed to optimize the use of a storage tank & solar

panel

EASY TO INSTALL

Always innovative to assuring the maximum installation easiness, TALIA boiler by

Chaffoteaux not only offers a wide range of simple pre-installation accessories,

replacement accessories or substitution but once again make breakthrough the

installer support.

TALIA boiler is in fact designed not to be only perfectly integrated in the Central

Heating and Domestic Hot Water but to become the heart of the “system” thanks to

its predisposition to manage a wide range of thermoregulation and hydraulics

accessories to ensure a personalized comfort in every room of the house.

Moreover, TALIA boiler is ready to work with the new renewable energies making

extremely easy the installation integrated with solar panels for the DHW production,

also for the installer less experienced in this new activity.

EASY TO MAINTAIN

The boiler’s real value is in the security of the service for witch the appliance has

been purchased.

For this reason TALIA has been designed to avoid whichever problem for the end

user.

If case of not good operation, TALIA, thanks to its second generation of selfdiagnosis function, is able to identify and monitor in real time the boiler status,

check the causes and communicate it by clear text on multifunction digital display

And if the problem will require an intervention of the Authorized Assistance Centre,

the boiler will remind the name and telephone number to restore immediately the

correct functioning.

Indeed, each operation will result easy and quick thanks to the display that visualize

all parameters to manage the boiler and, in case of component replacement due to

a fault, this won’t be a problem thanks to frontal access to all components.

Page. 4 of 63

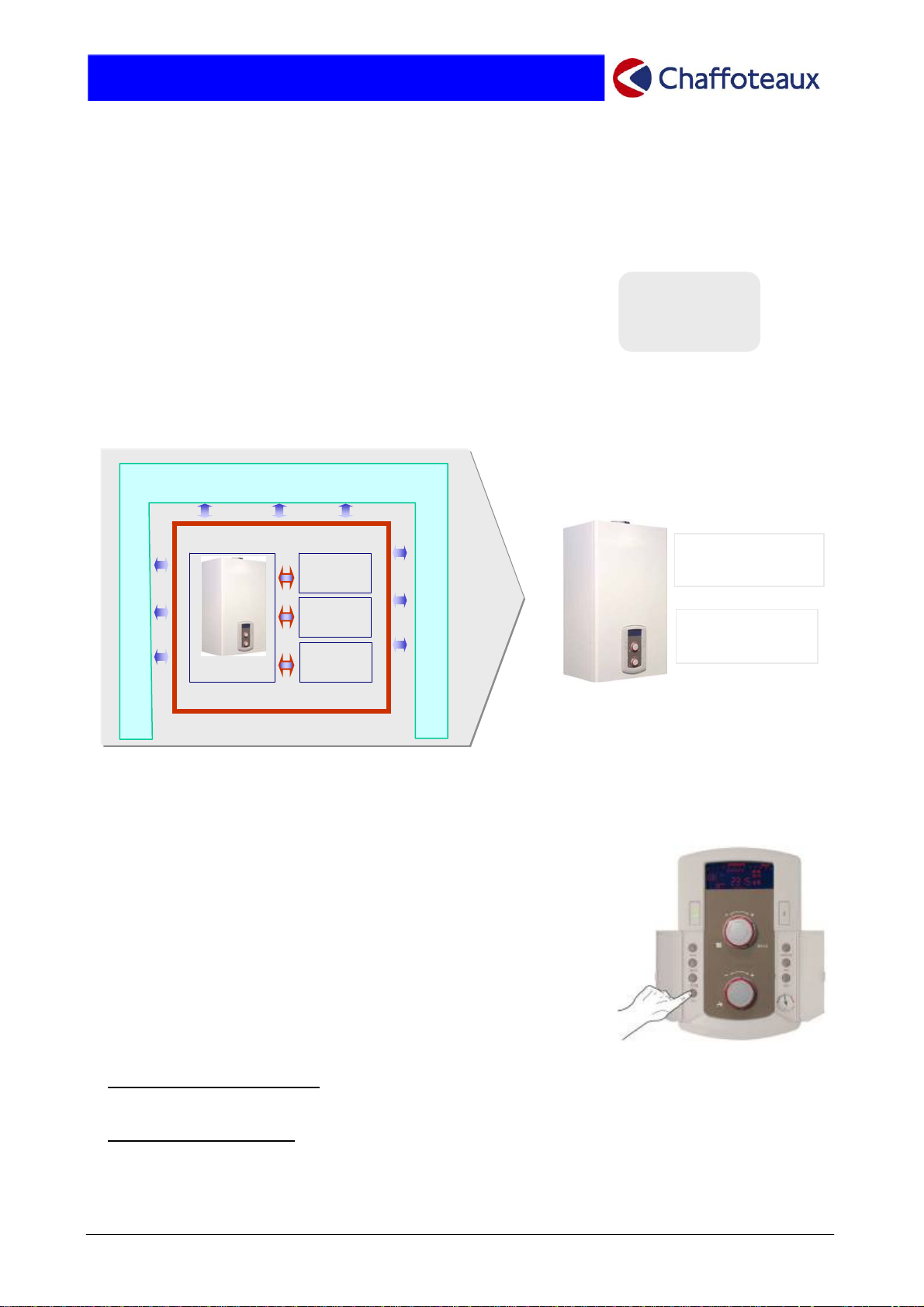

2 EASY TO SELL

The TALIA boiler and its features make the offer attractive for the installer for any requirement

Design & easy interaction

A new design, the materials quality and the attention to aesthetic details allow installing TALIA in every

place, also the most sophisticated.

The control interface has been carefully designed in order to guarantee an easy of use thanks to the digital

display and to the different definition levels to manage different functions.

From the simple CH and DHW temperature management through two big encoders, to the most sophisticate

functions use (left side door) to go the most complete customized functions through the programming keys

(right side door)

Moreover, the digital display through the INFO button, allow to have all informations in order to assuring a

correct operation of the boiler, the number of months remaining until the next scheduled service in addition to

the contact details of the Assistance Centre which will be responsible of carry on the service.

Page. 5 of 63

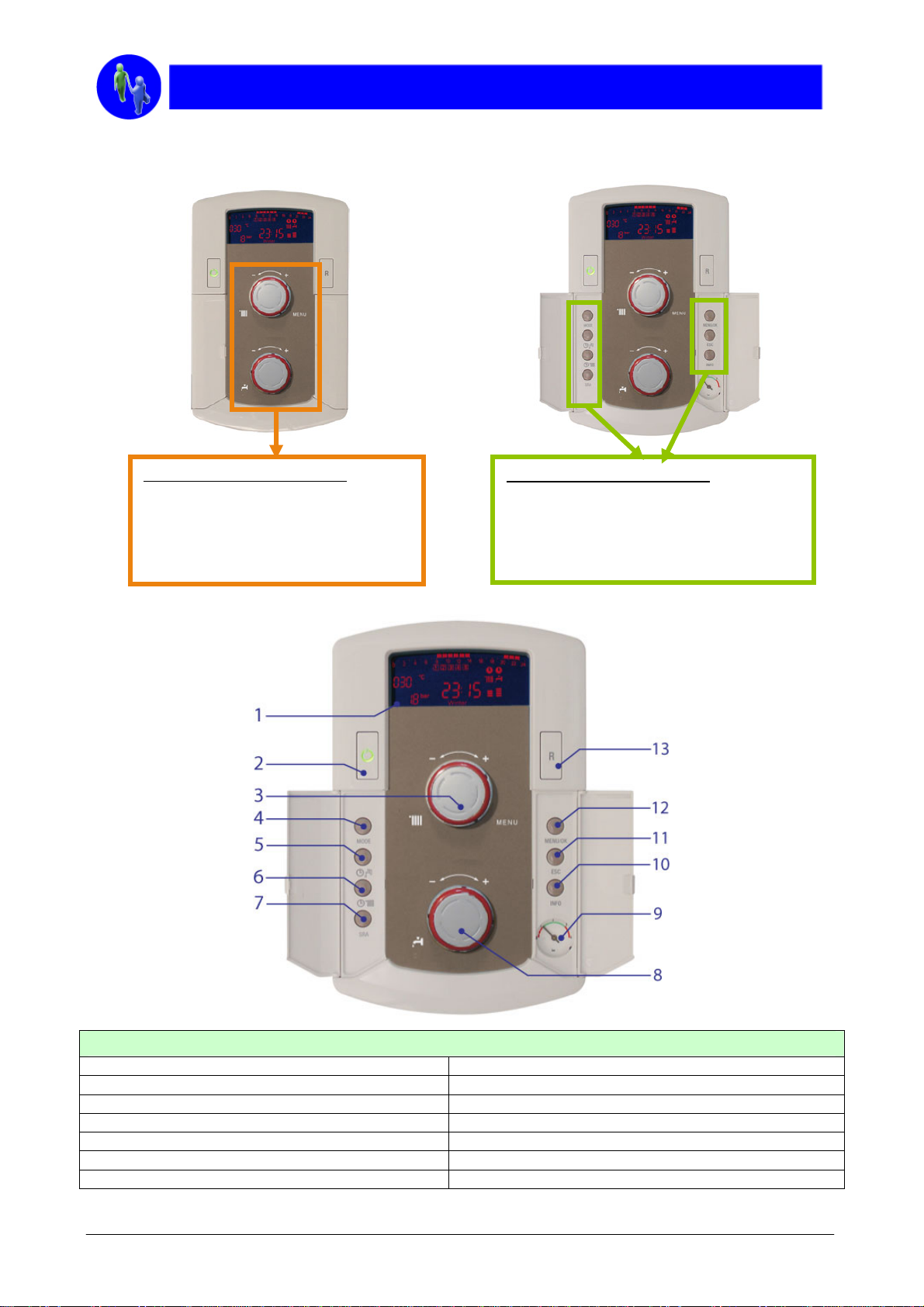

2.1 MULTILEVEL INTERFACE

Different level of accessibility:

A first level with two simple encoders

to set the standard temperature of

Central Heating and Domestic Hot

Water

2.1.1 Interface description

Different level of accessibility:

A second level for main user functions

A third level to access to the complete set

of parameters by Menu

LEGEND

1. Multifunctional LCD display 8. Domestic hot water temperature control knob

2. Main switch 9. Manometer

3. Central Heating temperature control knob 10. INFO button

4. “Mode” button 11. “Esc” button

5. DHW timer button 12. “Menu/Ok” button

6. CH timer button 13. “Reset” button

7. “Auto” function button

Page. 6 of 63

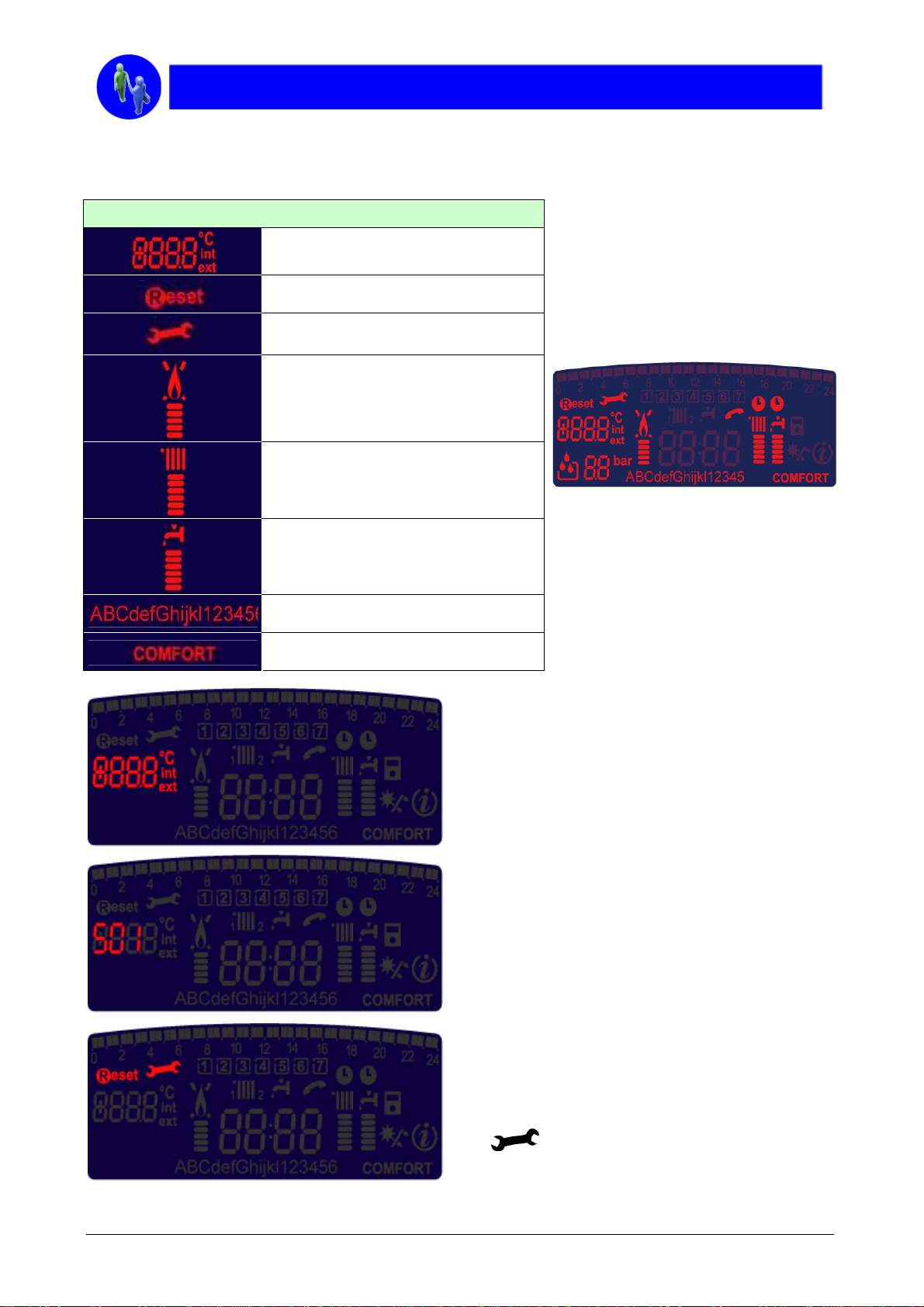

2.2 DISPLAY DESCRIPTION

The new LCD display enables the end user to check the operating status of the boiler at any time. Principal

informations are displayed on the display for a better comprehension of operation and adjustments of the boiler.

Following, the principal informations displayed on the display for a better comprehension of operation and

adjustments of the boiler.

2.2.1 Week time programming zone

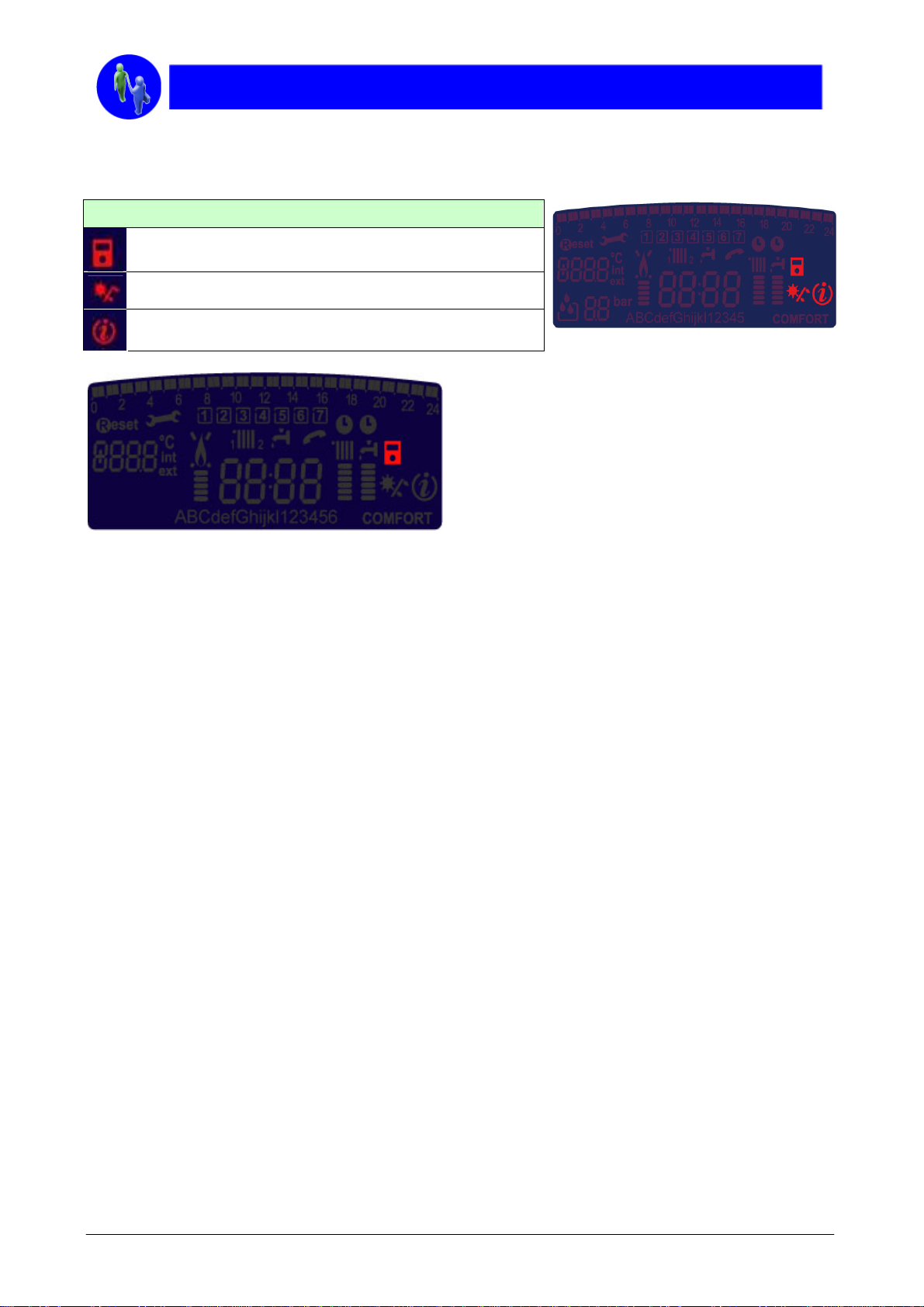

LEGEND

Hours programming

Week/day programming

Programming indication

(zone 1 or zone 2) for heating

Programming indication for DHW

Date and time

Hours programming activated

• Operation with weekly/schedule

Central Heating programming

The display shows (if set) the weekly/schedule

programming for up to two heating zones.

• Operation with weekly/schedule

programming

The display shows if the programming for

D.H.W. comfort is activated.

Page. 7 of 63

2.2.2 Functioning and diagnostic zone

LEGEND

Indication : menu setting, temperature,

default code

Reset requested

Technical assistance requested

Flame indication and power used

Heating functioning and temperature

level setting

Domestic hot water functioning and

temperature level setting

Clear text for all information

Comfort function activated

• Temperature monitoring

By pressing the INFO button, the end user can

check the indoor temperature (if a “room sensor”

is connected) or the outdoor temperature (if an

outdoor sensor is connected).

Page. 8 of 63

• Error code indication

If the boiler experiences an operating error, the

display will show the relevant error code,

thereby enabling the Technical Assistance

Service to identify the problem immediately.

• Assistance Service

If the boiler is lock-out, the display shows the

text RESET and the relevant error code. To

restore boiler operation, simply press the

RESET button on the control panel.

If the user is not able to resolve the problem,

the

advising that the Technical Assistance Service

is needed.

icon will appear on the display,

• Burner flame symbol and relative power

level

Whenever the burner is producing a flame, the flame

symbol appears on the display. The power level at

which the boiler is operating is visualised underneath

this symbol.

• “Heating” operating mode

Operation in “Heating” mode is displayed by the

radiator symbol and the operating temperature level

of the boiler.

• “Hot water” operating mode

Operation in “Hot water” mode is displayed by the tap

symbol and the operating temperature level of the

boiler.

• Informative text

At the bottom of the display, a text string guides the

user and the Technical Assistance Service through

every operation, making the boiler extremely easy to

manage.

• “Comfort” function

When the COMFORT function is active (instantaneous

production of domestic hot water) the display shows

the following indication.

Page. 9 of 63

2.2.3 Peripherals control

LEGEND

Thermoregulation activated

Installation with solar panels

Info menu

• Temperature control functions

When the SRA function is activated the boiler

automatically recognizes whether a Room Sensor, an

Outdoor Sensor or a Clima Manager is connected to

the system, adjusting its operation for getting the best

efficiency and comfort.

Page. 10 of 63

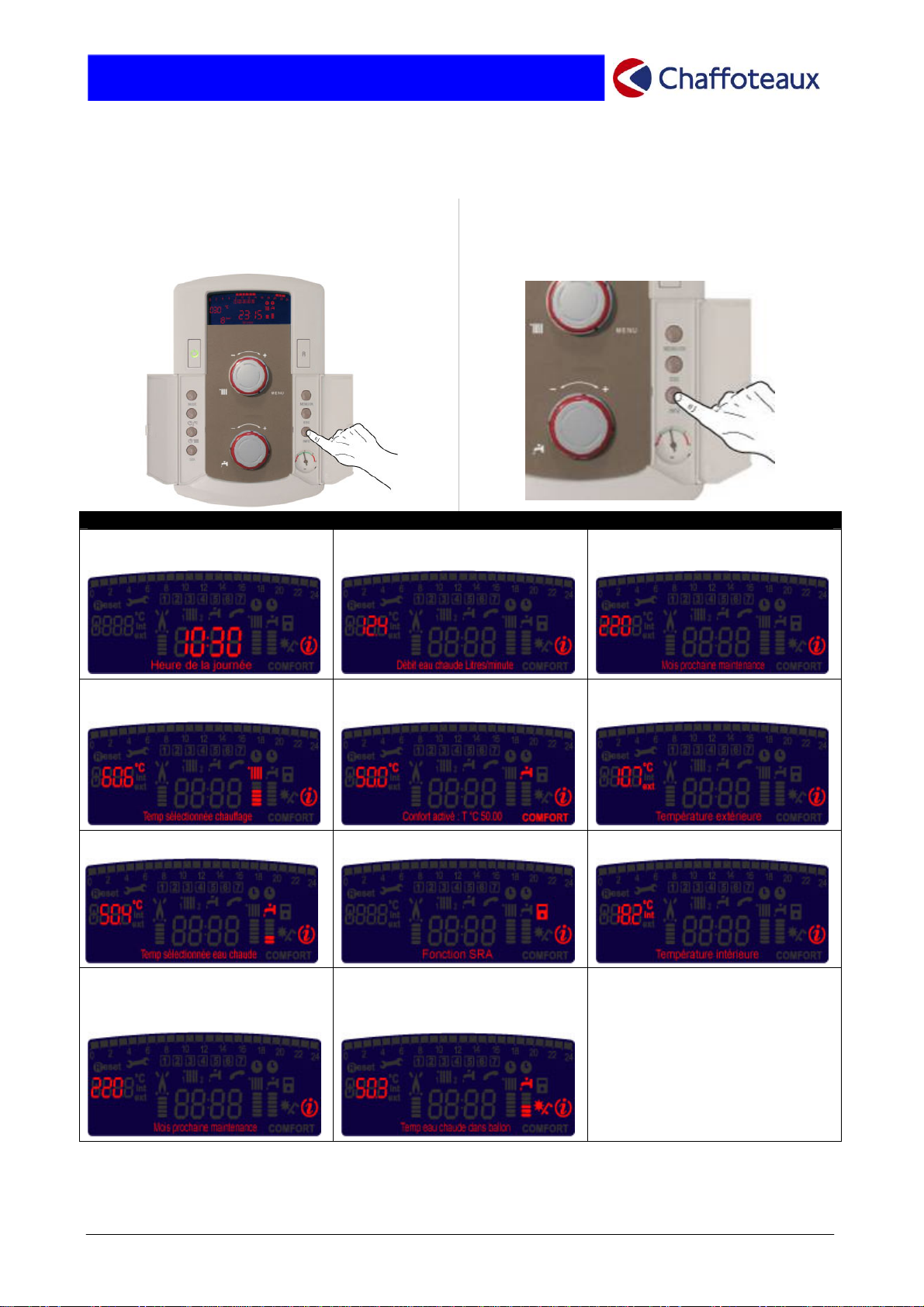

2.3 INFORMATION SYSTEM

The simple and practical key information is very useful for the customer and the service after sale

Simply by pressing the “INFO” button, the

end user may immediately view a whole

range of informations which are necessary

to the correct operation of the boiler.

To move from one piece of information to the

next, press again the “INFO” button. The text

string at the bottom of the display indicates

which information is being shown.

“INFO TOP” SYSTEM DISPLAY EXAMPLES

• Time of day • Hot water flow rate (litres/min) • Telephone number and

name of Assistance Centre

• Set heating temperature • COMFORT function activated

with hot water at 50°C

• Outdoor temperature °C (if an

outdoor sensor is connected)

• Set hot water temperature • SRA function enabled • Internal temperature °C

• Set number of days until the

next scheduled maintenance

operation

• Hot water temperature

inside the solar indirect

cylinder

Page. 11 of 63

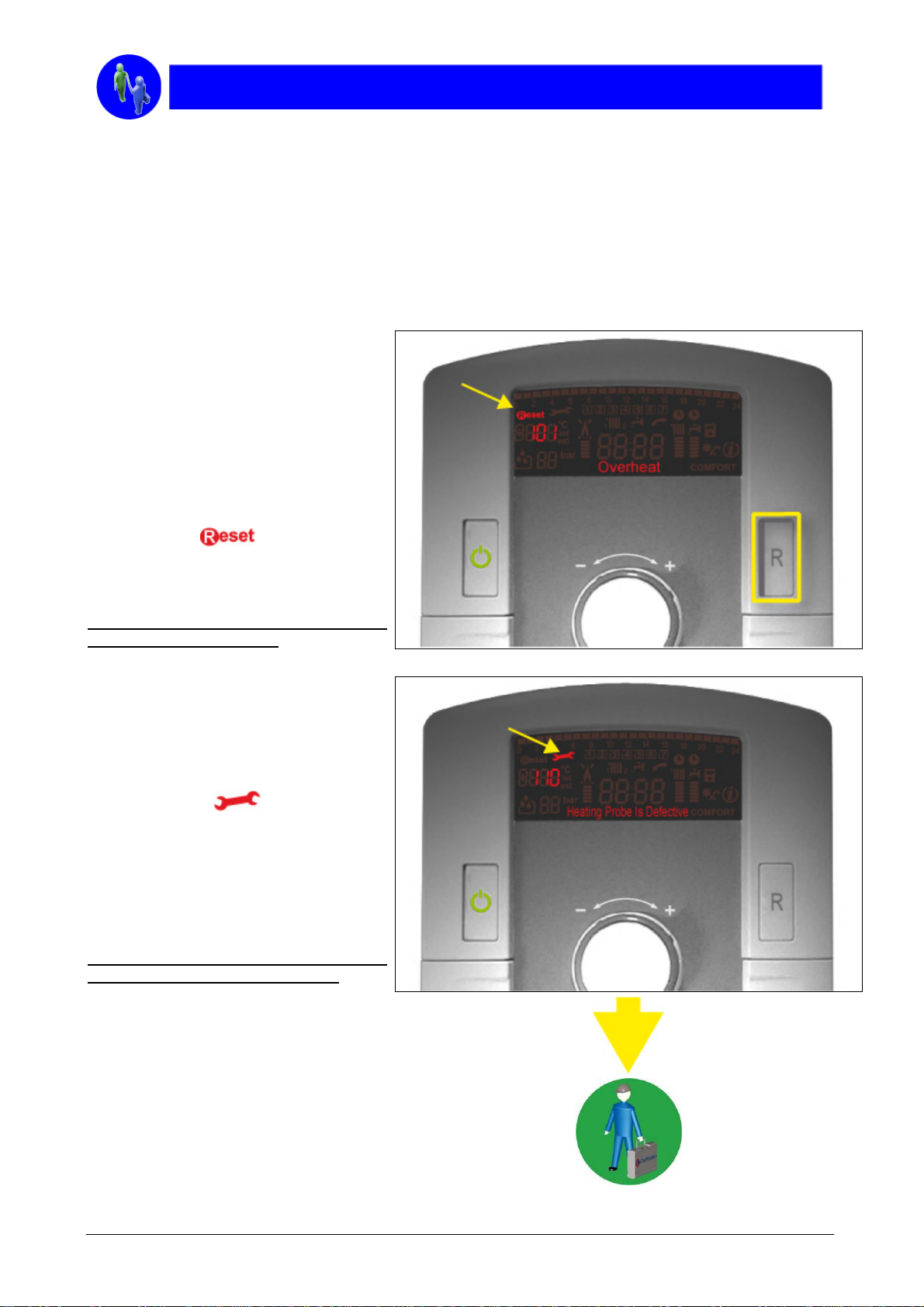

2.4 SELF-CHECK FUNCTION

TALIA boiler monitors its own functions and operation status by means of a latest-generation self-check

system.

The display clearly indicates any anomalies and suggests what to do in the simplest way. It also helps the

Technical Service to find the cause of the fault showing an error code, together with an explanation of the

type of malfunction.

We have two types of information:

• Malfunctions that CAN BE RESET BY END USER without an intervention of Technical Service;

• Malfunctions that CANNOT BE RESET BY END USER and needs an intervention of Technical Service.

2.4.1 Malfunctions that can be reset by

end user

Let’s see how the boiler reacts in the case

of an error that can be reset (for example,

when the safety thermostat switches the

system off).

This thermostat intervenes when the

temperature of the heating water reaches

105 °C, to make sure that no damage is

caused to any part of the boiler.

The error code: (in this case, the number

101) and the “

The display also gives a description of the

problem (in example using the word

“Overheat”).

” flash alternately.

When the reset key is pressed, the boiler

returns to normal operation.

2.4.2 Malfunctions that cannot be reset

by end user

When there is a NO RESET error , such as

a malfunction of the heating-water delivery

probe, the display shows the error code: in

this case, the number 110 flashes

alternately with a “

” symbol.

The display gives a description of the

problem, (in example Heating Probe Is

Defective).

In this case, the error cannot be reset and

an intervention of Technical Assistance is

required (press INFO button to show the

name and telephone number).

When the fault has been repaired, the

boiler will return to normal operation.

Page. 12 of 63

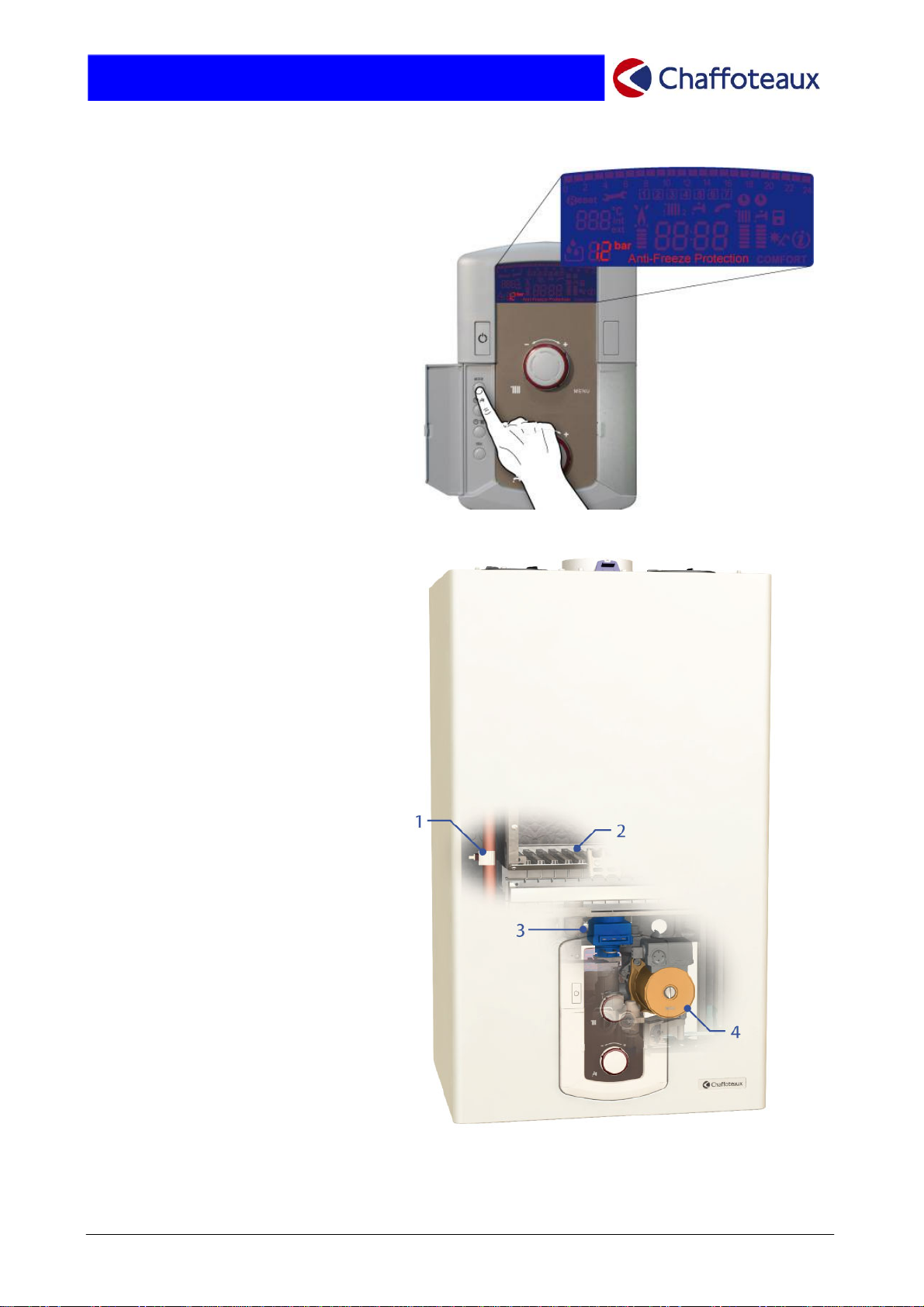

2.5 “ANTIFREEZE” FUNCTION

TALIA boiler is fitted with an AntiFreeze Protection system for the

central heating and the hot water

systems.

THIS FUNCTION DISABLE ANY

HEATING REQUEST.

In order to activate it, to repeat

press key MODE until that the

display will show:

If the temperature detected by the

“main heat exchanger probe” (1)

ranges between 3°C and 8°C, the

pump (4) runs and the 3 way valve

(3) switches alternatively its

position from domestic hot water to

central heating.

If, after 20 minutes, this

temperature remains between 3°C

and 8°C, also the BURNER (2)

turns on, supplied with minimum

power until raises

Page. 13 of 63

2.6 DHW COMFORT

2.6.1 DHW performances & certification

The hot water production represents the most important value for any boiler and the TALIA has achieved

successfully the best level according to EN13203 – part 1 (performance of DHW delivery) in terms of:

• SPECIFIC RATE

• TEMPERATURE STABILITY

• NO WAITING TIME

• MINIMUM NOMINAL WATER FLOW RATE

TALIA satisfies not only the EN13203-part1.

It take into consideration also the need of the end user in terms of saving according to EN13203-part 2, with

the following checks:

• ENERGY CONSUMPTION IN STAND BY MODE

• ENERGY RECOVERED BY THE USEFUL WATER

• GAS ENERGY

• ELECTRICAL ENERGY

• AUXILIARY ENERGY COSUMPTION WITH THE OFF MODE.

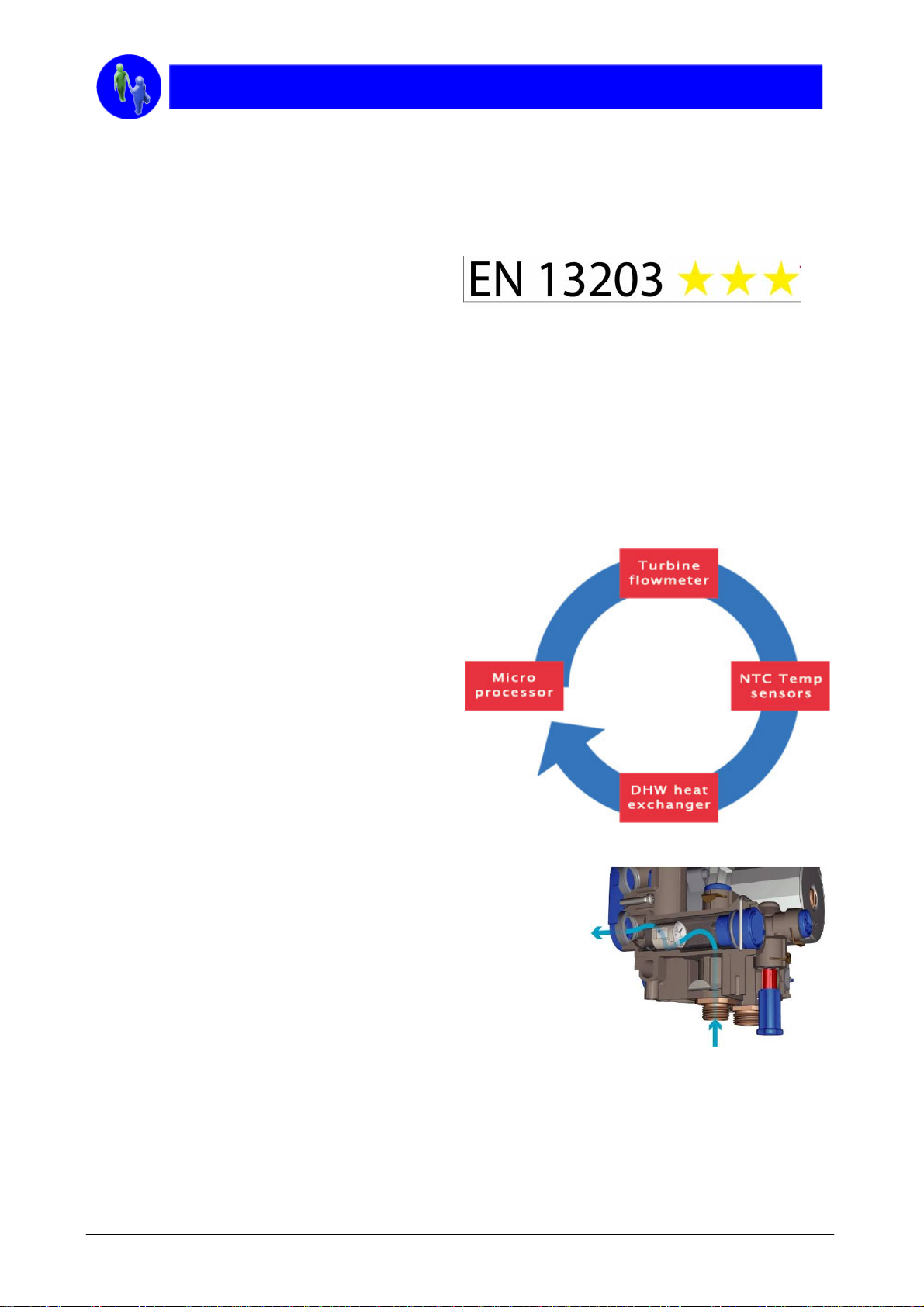

2.6.2 The MSC system

The new system MSC (Multi Modulation Sanitary

Control), bring the best answer in term of DHW

waiting time, temperature stability even with fast,

successive tapping or with small water flow

demand. This is the most severe test for a boiler.

The new system MSC guaranties moreover the optimization of the

boiler management thanks to his progressive intelligence and the new

flow sensor with turbine is able to adapt instantaneously the boiler

output according to efficiency needed minimizing the consumption

The turbo sensor advantages:

perfect gas power adaptation to the DHW flow rate

DHW regulation more sensitive

very quick answer time

low overheating or downheating during transient water flow rate

Not sensitive to hammer shock

Repeatability

Save time and energy

30 signals/second transmits by the turbine sensor to the microprocessor

Provides immediately hot water even at reduce flow rates

Page. 14 of 63

2.6.3 DHW timer program

A saving even more important and subsequently achievable through the weekly DHW programming, built in

on the boiler which allows the comfort customizing according to the real need of the customer.

A new function that allows setting the DHW weekly timer integrated

This function permit to maintain the temperature of the plate heat exchanger for shorter DHW waiting

time.

It’s possible to program period of reheating for each day.

Page. 15 of 63

2.7 SOLAR PREDISPOSITION

Natural circulation solar

or centralized

solar installation

Serie solution

with combi boiler

& forced circulation

Parallel solution

with heating only boiler

& forced circulation

Page. 16 of 63

p

2.8 HEATING COMFORT

2.8.1 Heating performances & certification

In line with the most severe European standard in term of energetic efficiency, Talia is certified *** according

to the European standard 92/42/EEC, one certificate which offer also a guaranty of saving.

This result thanks to the quality of the components and the intelligence of the boiler capable to optimize the

performances of the combustion & hydraulic group equipped by

• New burner

• New primary exchanger

• Modulating fan

• Modulating pump

2.8.2 System approach

The boiler value is measured by the capability to give the right answer to the specific request independent of

the change of the external (climatic) or internal condition.

Climatic conditions

Ambient conditions

Boiler

erformances

Zone 1

Zone 2

Zone 3

2.8.3 Thermoregulation

The SRA function (new Automatic Regulation System), permits the access to the thermoregulation world

without any worry in terms of explanations, management or installation

Efficiency

& Saving

thermoregulation

Hydraulic

distribution

The SRA function is the essence of the project logic:

o Ease of use (only one push on the integrated button)

o Customized comfort in heating guaranteed.

The new intelligence of the boiler will manage in auto-adaptative way the

main values of the boiler, to reach the best result in terms of requested

comfort in every installations & conditions.

► Central heating temperature:

It will adjust automatically and permanently according to the outside temperature and/or of the temperature

in the house.

► Boiler power modulation:

It will adapt the power to the burner according to the operating conditions.

Page. 17 of 63

Depending on the different installation configuration

Basic

with room thermostat (on/off)

Climatic

with external probe & room

thermostat on/off

Ambient

with modulating room

sensor

Complete

thermoregulation

Comfort

level

++

+++

++++

++++

Saving

level

The new SRA function assures to reach the following results:

Maximum personalisation

Best efficiency

Maximum comfort

Acoustic comfort

Better reliability

Less environment impact

Heating distribution

A large range of accessories for a large range of heating configurations.

The installer can give easily to the client the best solution for each need

Monozone

For big

installation

Double zone

Triple zone

Mono

temperature

Multi

temperature

Page. 18 of 63

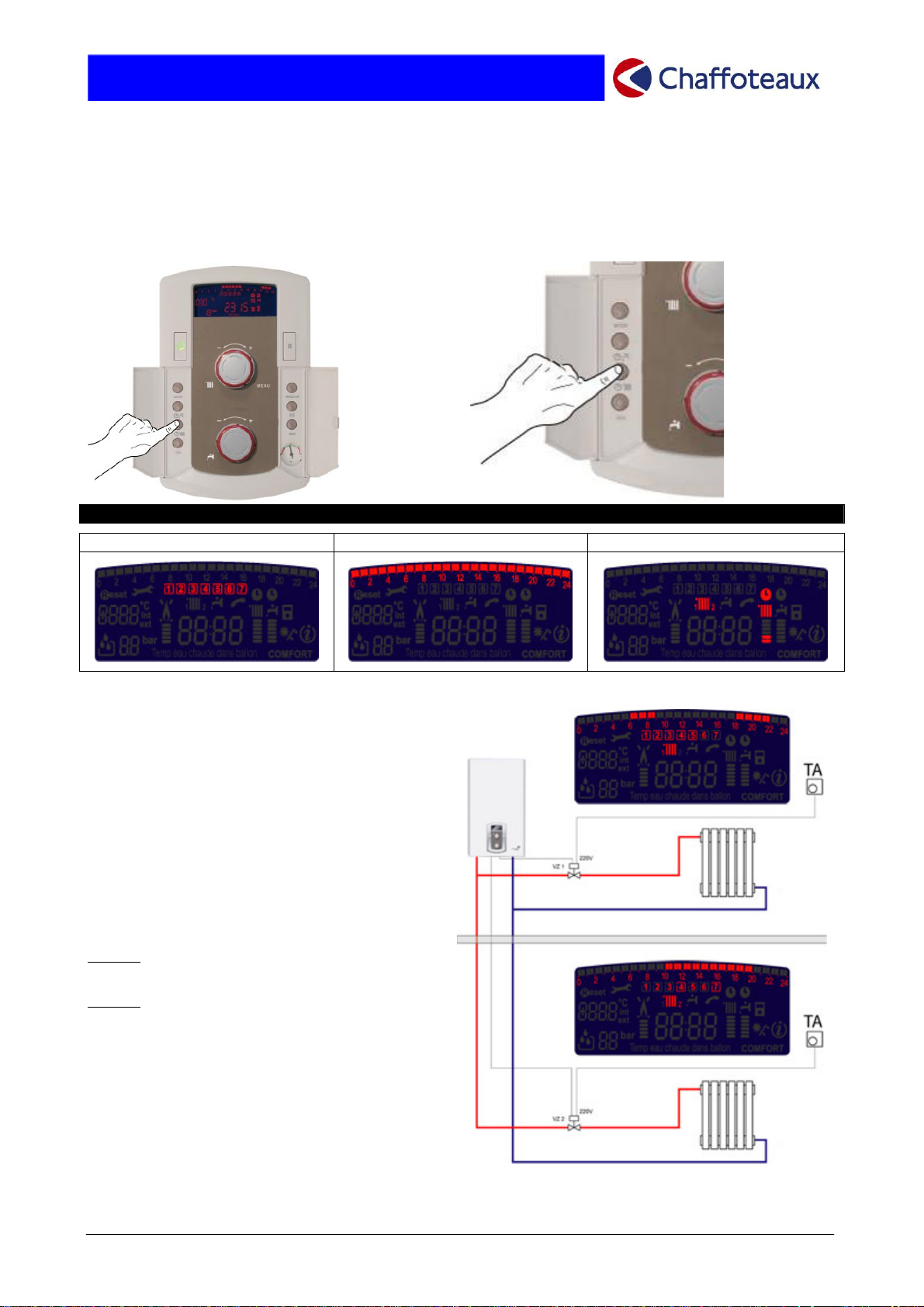

2.8.4 Built-in weekly timer.

The new electronic controls enable the user to programme the boiler at intervals of 15 minutes for every

single day of the week.

For this type of operation, it is not necessary to purchase an external timer. Programming is

activated/desactivated by pressing the button.

The end user can use 3 pre-set programmes which may obviously be easily customised by the user.

PROGRAMMING: THE DISPLAY

.

Weekly programming 24-hour programming Controlling 2 zones

An heating system which has been divided into

two zones is shown.

TALIA boiler is able to control timer programming

(intervals of 15 minutes) and weekly programming

an independent and specific way for each

programme.

EXAMPLE:

Zone 1

: from Monday to Friday, between 6.00

and 9.00 and 18.00 and 22.00.

Zone 2

: Thursday and Sunday, between 10.15

and 19.45.

Page. 19 of 63

Loading...

Loading...