Page 1

Training manual :PIGMA Gal Evo

Training

Handbook

FAMILY: Wall-mounting gas boilers

TYPE: Conventional design

NAME: PIGMA Gal Evo PT IT RDC

TRADE MARK: CHAFFOTEAUX

Issue : 1V0 24.07.2012

Technical support for market

Page 2

Page. 2 of 73

Training manual :PIGMA Gal Evo

Up-date lliisstt

.

1V0

24/07/12

MP VERSION

DATE

NAME

CHANGES ENTERED

Page 3

Page. 3 of 73

Training manual :PIGMA Gal Evo

INDEX

1 GENERAL INFORMATION .................................................................................................................................. 5

1.1 SIZE & DIMENSIONS ........................................................................................................................ 5

SEALED CHAMBER OVERALL VIEW (FF) ................................................................................................... 6

1.2 OPEN CHAMBER ASSEMBLY VIEW (CF) ...................................................................................... 7

1.3 CONTROL BOARD .......................................................................................................................... 8

1.3.1 General Indications ...................................................................................................................................... 8

1.4 SCREEN.............................................................................................................................................. 9

1.4.1 indications on display scree .......................................................................................................................... 9

1.4.2 Indications of operating modes displayed on the screen ............................................................................ 11

2 OPERATION .......................................................................................................................................................... 12

2.1 HEATING MODE ............................................................................................................................ 12

2.1.1 Assembly view of system in heating mode .................................................................................................. 14

2.2 SANITARY MODE ............................................................................................................................. 15

2.2.1 Assembly view of sanitary mode ................................................................................................................. 17

SOLAR SENSOR SANITARY MODE .......................................................................................................... 17

3 SPECIAL FUNCTIONS......................................................................................................................................... 18

3.1 FLUE CLEANER” FUNCTION ........................................................................................................... 18

3.2 “COMFORT” FUNCTION ................................................................................................................... 20

3.3 “ANTIFREEZE” FUNCTION .............................................................................................................. 22

3.4 “WATER FLOW CHECK” ............................................................................................................... 23

3.5 AIR PURGE” FUNCTION .................................................................................................................. 26

3.6 “SELF ADAPTIVE HEATING RESTART DELAY” .......................................................................... 27

4 HYDRAULIC BLOCK .......................................................................................................................................... 28

4.1 RIGHT HYDRAULIC BLOCK .................................................................................................................. 29

4.2 LEFT HYDRAULIC BLOCK .................................................................................................................... 30

4.3 WAY VALVE ....................................................................................................................................... 31

4.3.3-way valve motor ............................................................................................................................................... 31

4.4 PLATE TYPE HEAT EXCHANGER ................................................................................................ 32

Temperatura limite anticalcare ................................................................................................................................ 32

4.5 PUMP UNIT ....................................................................................................................................... 33

4.5.1 PUMP speed check ..................................................................................................................................... 33

4.5.2 Post-circulation. ......................................................................................................................................... 34

4.6 DRAIN PORT & PLUG ...................................................................................................................... 34

4.7 BY-PASS VALVE .............................................................................................................................. 35

4.8 PRIMARY HEAT EXCHANGER ............................................................................................................ 35

4.9 PRESSURE PICK-UPS (FF ONLY) ................................................................................................. 35

4.10 HEATING LINE STRAINER ............................................................................................................ 36

4.11 HEATING EXPANSION VESSEL ................................................................................................... 37

4.12 SANITARY FLOW RATE ................................................................................................................ 37

4.13 TEMPERATURE SENSORS .......................................................................................................... 39

5 GAS LINE ............................................................................................................................................................... 40

5.1 GAS VALVE TYPE SIT SIGMA 845 ................................................................................................ 40

5.2 SOLENOID VALVE ELECTROPNIC CONNECTION DIAGRAM. .................................................. 40

5.3 GAS REGULATIONS. .................................................................................................................... 41

5.3.1 Supply pressure check. ................................................................................................................................ 41

5.3.2 Maximum sanitary power check ................................................................................................................. 41

5.3.3 Minimum power check. ............................................................................................................................... 42

5.3.4 Soft ignition power checking ....................................................................................................................... 42

5.3.5 Clocking for heating restart aftr burner flame out ..................................................................................... 43

5.3.6 Control of maximum heating power ............................................................................................................ 43

5.3.7 TABE OF GAS ............................................................................................................................................ 46

5.4 BURNER ........................................................................................................................................ 47

5.5 FLUE EXHAUST PORTS (SUCTION TYPE MODEL) ........................................................................ 48

5.6. AIR PRESSURE SWITCH (SUCTION CAP TYPE DESIGN) ...................................................................... 48

5.6 EXTRACTOR (SUCTION CAP TYPE DESIGN)....................................................................................... 49

Page 4

Page. 4 of 73

Training manual :PIGMA Gal Evo

5.7.1.POST-VENTILATION ................................................................................................................................ 49

5.6.1 SPOTT UNIT ( MODEL CF) ...................................................................................................................... 50

5.7 FLUE EXHAUST / MODEL CF ........................................................................................................ 50

5.8 SUCTION CUP OUTLET / SUCTION CUPS MODELS / POSSIBLE CONFIGURATIONS ...................................... 51

EXHAUST SYSTEMS (SEALED CHAMBER FF) ............................................................................................... 51

6 ELECTRONIC PCBS ............................................................................................................................................ 55

MAIN CARD ................................................................................................................................................. 55

Electronic Wiring Diagram ...................................................................................................................................... 55

6.1.1 Diagramme électronique FF boiler ............................................................................................................ 56

6.1.2 Diagramme électronique CF boiler ............................................................................................................ 58

7 MENU AND SETTING .......................................................................................................................................... 59

7.1 USER MENU ...................................................................................................................................... 59

7.1.1 GUIDE TO NAVIGATING IN THE MENUS ............................................................................................. 59

7.1.2 MENUS ....................................................................................................................................................... 60

7.2 COMPLETE MENU ........................................................................................................................ 61

7.2.1 Menu 0 : Network ....................................................................................................................................... 61

7.2.2 MENU 2 : BOILER PARAMETERS ............................................................................................................ 61

7.2.3 MENU 4 : ZONE 2 PARAMETERS ............................................................................................................ 63

7.2.4 MENU 5 : ZONE 2 PARAMETERS ............................................................................................................ 63

7.2.5 MENU 6 : ZONE 3PARAMETERS ............................................................................................................. 64

7.2.6 MENU 8:SERVICE PARAMETER .............................................................................................................. 65

8 ERROR CODES ..................................................................................................................................................... 67

8.1 BOILER PROTECTION SYSTEMS. ............................................................................................... 67

8.1.1 Error codes ................................................................................................................................................. 67

9 FIRST STARTING AT WORK ............................................................................................................................ 69

10 PERIODICAL CHECKS .................................................................................................................................. 70

11 DONNEES TECHNIQUES URBIA................................................................................................ ................. 72

11.1 PIGMA CF ........................................................................................................................................ 72

11.1 PIGMA FF ......................................................................................................................................... 73

Page 5

Page. 5 of 73

Training manual :PIGMA Gal Evo

1 GENERAL INFORMATION

1.1 SIZE & DIMENSIONS

LEGEND

A

System delivery

B

Hot water outlet

C

Gas inlet

D

Cold water inlet

E

Heating system return

PIGMA EVO

PIGMA SYTEM

EVO

Page 6

Page. 6 of 73

Training manual :PIGMA Gal Evo

SEALED CHAMBER OVERALL VIEW (FF)

LEGEND

1

Flue Manifold

16

Filling Tap

2

Air pressure switch

17

CH Filter

3

Air pressure switch pressure intake condensate exhaust

18

Pump

4

Main Heat Exchanger

19

Heating minimum pressure switch

6

NTC1 heating delivery temperature probe

20

NTC2 heating return temperature probe

7

Burner

21

3 Way Valve

8

Ignition electrodes

22

Detection electrode

9

Gas valve

23

Ceramic Fibers

10

Spark generator

24

Combustion Chamber

12

3 bar safety valve

25

Expansion Vessel

13

Secondary Heat Exchanger

26

Modulating Fan

14

CH draining tap

27

Combustion Analysis Test Point

15

Proportional sanitary flow meter

Page 7

Page. 7 of 73

Training manual :PIGMA Gal Evo

1.2 OPEN CHAMBER ASSEMBLY VIEW (CF)

LEGEND

1

Flue Manifold

14

CH draining tap

2

Flue Control Thermostat

15

Proportional sanitary flow meter

3

Flue Hood

16

Filling Tap

4

Main Heat exchanger

17

CH Filter

6

NTC1heating delivery temperature probe

18

Pump

7

Burner

19

NTC2 heating return temperature probe

8

Ignition electrodes

20

3 Way Valve

9

Gas valve

21

Detection electrode

10

Spark generator

22

Ceramic Fibers

12

3 bar safety valve

23

Combustion Chamber

13

Secondary Heat Exchanger

24

Expansion Vessel

Page 8

Page. 8 of 73

Training manual :PIGMA Gal Evo

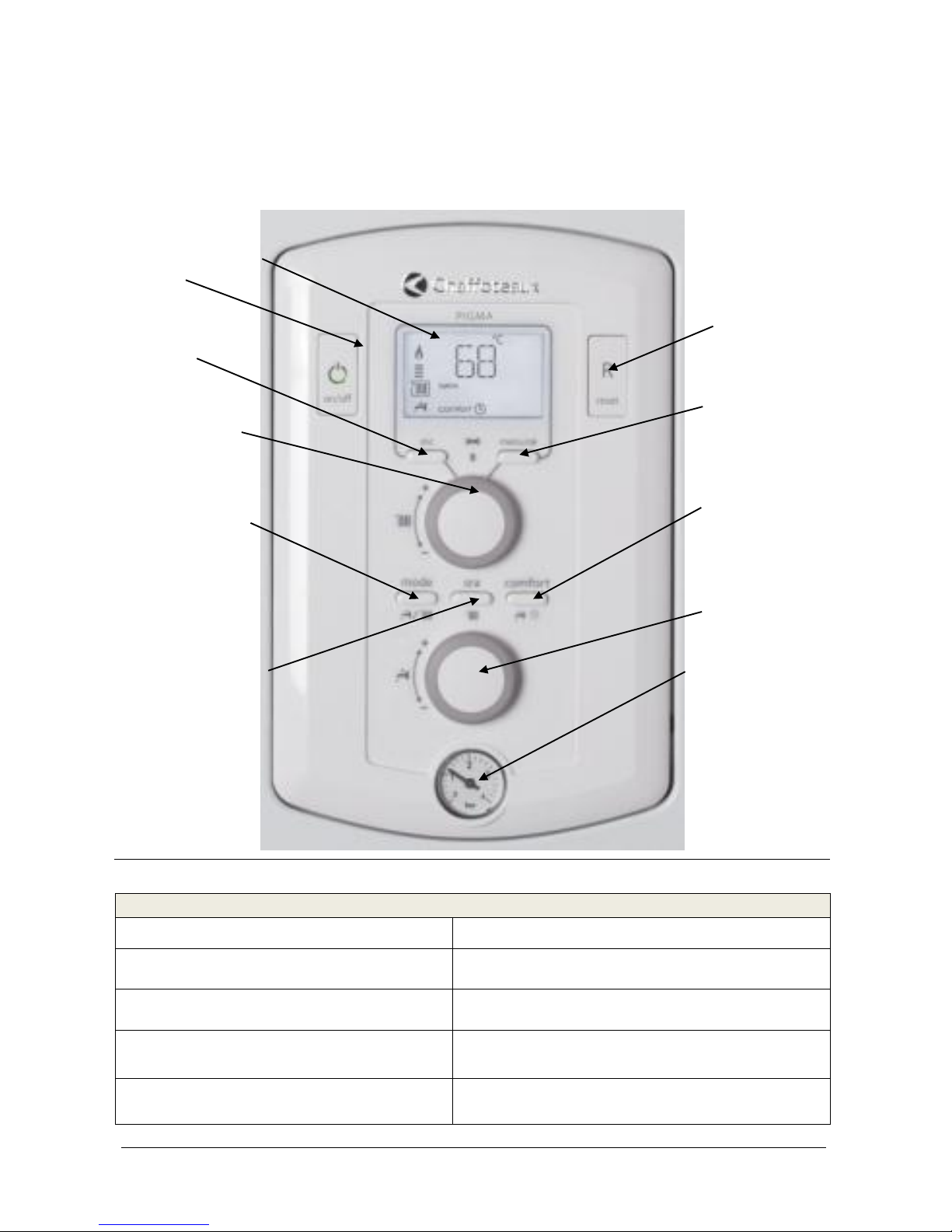

1.3 CONTROL BOARD

1.3.1 General Indications

LEGEND

1 Dysplay

7 manometer

2 Start / Stop button

8 Push button for Sanitary

3 « ESC » button

9 Push button sanitary CONFORT

4 Push button for heating

10 Access to menu /validation push-button

5 Select push button for modes : summer /

winter / anti-frost l

11 Touche « Reset

1

2

4

9

6

8

7

5

3

10

11

Page 9

Page. 9 of 73

Training manual :PIGMA Gal Evo

6 SRA push button

1.4 SCREEN

1.4.1 indications on display scree

ICON

DESCRIPTION

Navigation

Navigation Parameter

Code

Default Code

Flame and level of power

Flame error

Heating disable

Heating enable

Sanitary disable

Sanitary enable

Comfort function

Boiler OFF and Anti freeze function enable

Anti-freeze function activate

SRA activate

Solar system

Page 10

Page. 10 of 73

Training manual :PIGMA Gal Evo

Page 11

Page. 11 of 73

Training manual :PIGMA Gal Evo

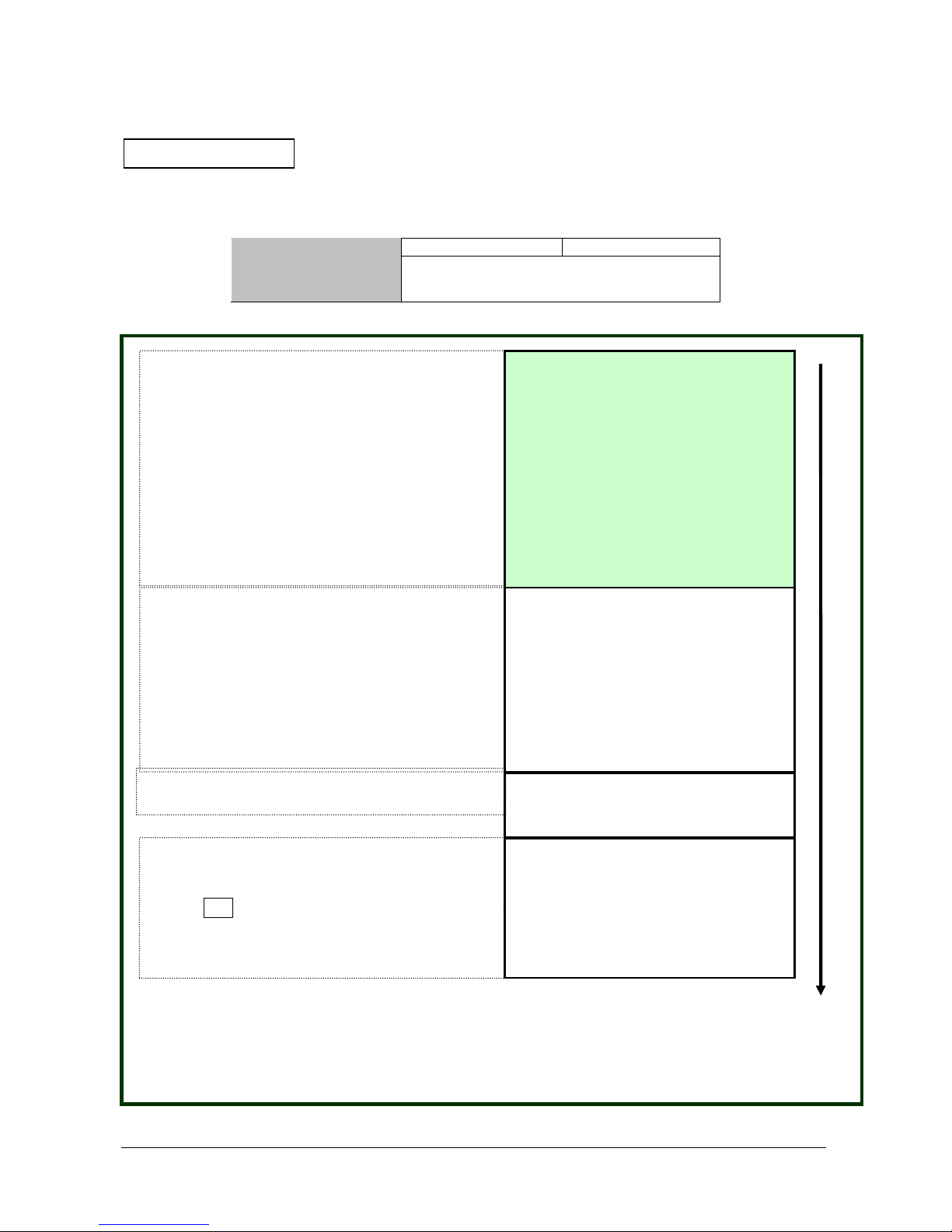

1.4.2 Indications of operating modes displayed on the screen

During the working of the appliance, it’s possible to verify the status of the boiler:

ECRAN

DESCRIPTION

ETAT CHAUDIERE

Stand-By

STAND-BY. No request.

Adjustment of

heating request

Adjustment of the heating request by the button n° 4.the

number indicates the set point. They blink during 5 s

Heating mode,

burner ON and SRA

function

The radiator who symbolise the heating circuit is surrounded,

that fame is enable and there is an indication of the level

power

Heating mode,

burner OFF and

SRA function

End of the heating request, the boiler is OFF but there is a

post-circulation of 3 min (default value)

Adjustment of

sanitary request

Adjustment of the sanitary request by the button n° 8.the

number indicates the control temperature. They blink during

5 s

Sanitary tapping,

burner ON n

The tap who symbolise the sanitary circuit is surrounded,

that fame is enable and there is an indication of the level

power

Comfort mode,

burner ON

The boiler is operating an tank heating mode, the 2 numbers

indicate the control temperature for sanitary system

En puisage sanitaire

brûleur éteint.

End of the sanitary request, the boiler is OFF but there is a

post-circulation of 3 min (default value)

Anti-frost function

ON

The anti- frost function is activate, management with the

NTC1 delivery sensor.

Solar system

connected by E-Bus

Solar system is connected by E-Bus to the boiler

TEST mode

Combustion analysis

Purge mode

Air purge function

Page 12

Page. 12 of 73

Training manual :PIGMA Gal Evo

2 OPERATION

2.1 HEATING MODE

CONTROL

RANGE

35°C

85°C

Temperature readout can be viewed from screen 4

second long, each time heating button is

manipulated.

Pump is powered 7 seconds after the 3-way

valve, with a view at avoiding surge in system.

Request for Heating

3-Way Valve

powered

Pump powered

The request for heating can be initiated by :

- a room thermostat ,

- a room sensor,

- a programmer or

- an Expert Control

The character appears in this moment on the

screen.

The temperature read by the sensor on the

primary start can be viewed on the screen.

Sanitary mode is the rest position for the 3-way

valve.

When a heating request is active, the motor

driving the 3-way valve is energized for shifting

to heating mode.

The stem of the valve is then in « retracted »

position.

Extractor powered

Before activating the extractor, a check of

pressure switch status is carried out (contact

shall be in open position, otherwise default code

symbol

6 07

is displayed on the screen).

The extractor is power-supplied (model FF only).

Page 13

Page. 13 of 73

Training manual :PIGMA Gal Evo

Burner ignition

Flame detection

Ignitor and gas valve

powered

When pressure switch contact is set to closure, the

gas valve and the igniters are power supplied.

A permanent check of flow rate is developed with the

aid of 2 primary sensors (Forward & Return).

Flow rate Control

Gas valve is fed by the ignition power (adjustable by

parameter 2 20).

Flame detection is obtained by the ionization

electrode. In the event that the ionization sensor does

not sense any current during the ignition phase (8

seconds maximum), the boiler turns into safety state

and code symbol 5 01 is displayed on the screen.

Model FF only: a functional test of extractor is

performed by use of air pressure switch. If no signal is

detected after 20 seconds, the boiler turns to stand-by,

and code symbol

6 P1

is displayed on the screen.

Testing air pressure

switch

Flame detection enables the gas valve and the

extractor to carry out modulation of flame intensity

according to heat request.

Heating system output is adjustable by parameter 2

31 in operating ranges

Minimum output can be controlled directly by acting

on the gas valve.

Burner flame turn-off will take place at the following

T° values:

In the 1st min after flame detection:

T°off = set point T° + 8°C

In the 2nd min after flame detection

T°off = T° set point T° + 6°C

After the 3rd min after flame detection:

T°off = set point T° + 4°C

This logic of operation allows to avoid possible

occurrence of delayed ignitions and extinctions by

Modulation of burner

flame

Overheat Control

Overheat control is provided through a thermostat

(102±4°C) located at the outlet of the primary heat

exchanger. Resetting to be effected manually from the

control panel.

Default 1 01 is shown on screen. Reset possible when

temperature reads 87°C.

Notice. Primary start sensor (NTC1) is to control that primary temperature may not exceed set value

88°C; in this occurrence, the sensor interdicts the burner to start ignition.

If flow circulation in the heating sytem is not sufficient to fulfill the purpose, an automatic by-pass valve

can open (maximum capacity = 350 l/h).

Page 14

Page. 14 of 73

Training manual :PIGMA Gal Evo

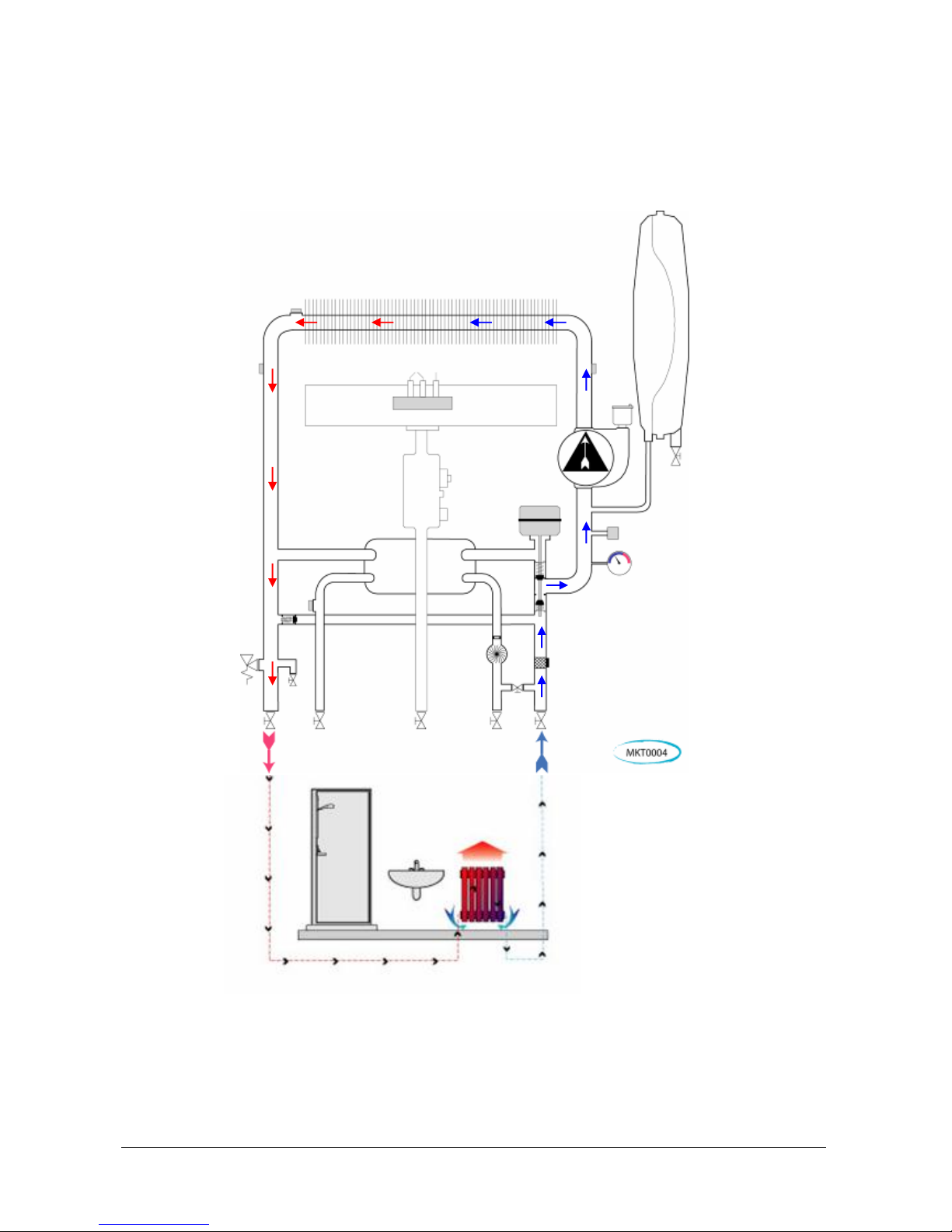

2.1.1 Assembly view of system in heating mode

Notice.

The primary start sensor (NTC1) checks to ensure that the primary circuit heat level

may never exceed 88°C in temperature; in this state, the sensor interdicts the burner

to start flame ignition.

When the circulation flow in the heating system is not enough to comply with the need ,

an autonatic by-pass valve can open ( maximum flow rate 350 l/h).

Page 15

Page. 15 of 73

Training manual :PIGMA Gal Evo

2.2 SANITARY MODE

OPERATION

RANGE

40°C

60°C

By pushing the buttons “+” o “-“,you can see on the

display (for 4 seconds) the set temperature .

HOT WATER REQUEST

FOR SANITARY

3-way valve

Heating request

ON

Heating request

OFF

Turning from

heating over to

sanitary

The 3-way valve

remains set for

sanitary

When a sanitary request is detected by the sanitary flow

meter (flow rate > 1,6 l/min), the symbol appears on

the display, together with the indication for temperature

control.

2 possibilities exist:

1. If boiler is in stand-by mode, the 3-way valve is

already set to sanitary position.

2. If boiler is in heating mode, the 3-way valve is being

fed for setting to sanitary mode.

During this change in mode, burner and pump are

both being fed.

Pump under supply

The pump is under supply.

Extractor powered

Prior to imparting command signals to the extractor,

a check is made to the pressure switch (contact

must be set to open position, otherwise default code

6 07

is displayed).

Extractor remains under power supply (FF model

only).

Air pressure switch

Control

Checking closure of air pressure switch contact in 20

seconds, otherwise

6 P1

is displayed.

(for model FF only ).

When the pressure switch contact is closed, gas

valve and igniters are both under power supply.

Ignitor and gas valve

powered

The gas valve is supplied with ignition power input

(adjustable by parameter 2 20).

Ignition of burner

Flame detection is carried out by the ionization

electrode. In the event where for the time of the

ignition cycle (8 seconds maximum), the ionization

sensor does not detect any input power, the boiler

turns into stand-by, and code symbol 5 01 is

displayed on the screen

Burner flame

test

Page 16

Page. 16 of 73

Training manual :PIGMA Gal Evo

.

A permanent check of flow rate is developed with the

aid of 2 primary sensors (Start & Return).

Flow rate Control

Burner performs flow modulation from minimum

output up to maximum output (control over gas

valve).

Burner will flame out if temperature read by the

sensor for primary return NTC2

Burner Modulation

Overheat Control

Control by burner is performed over the sensor for

primary return NTC2. Burner flame goes out when

temperature reading by primary return sensor is by

4°C higher than set point value.

Temperature Control

Overheat control is provided through a thermostat

(102±4°C) located at the outlet of the primary heat

exchanger. Resetting to be effected manually from the

control panel.

Default 1 01 is shown on screen. Reset possible when

temperature reads 87°C.

If there is a bad circulation through the heating system, the

automatic by-pass can be opened (max capacity 350 l/h).

Page 17

Page. 17 of 73

Training manual :PIGMA Gal Evo

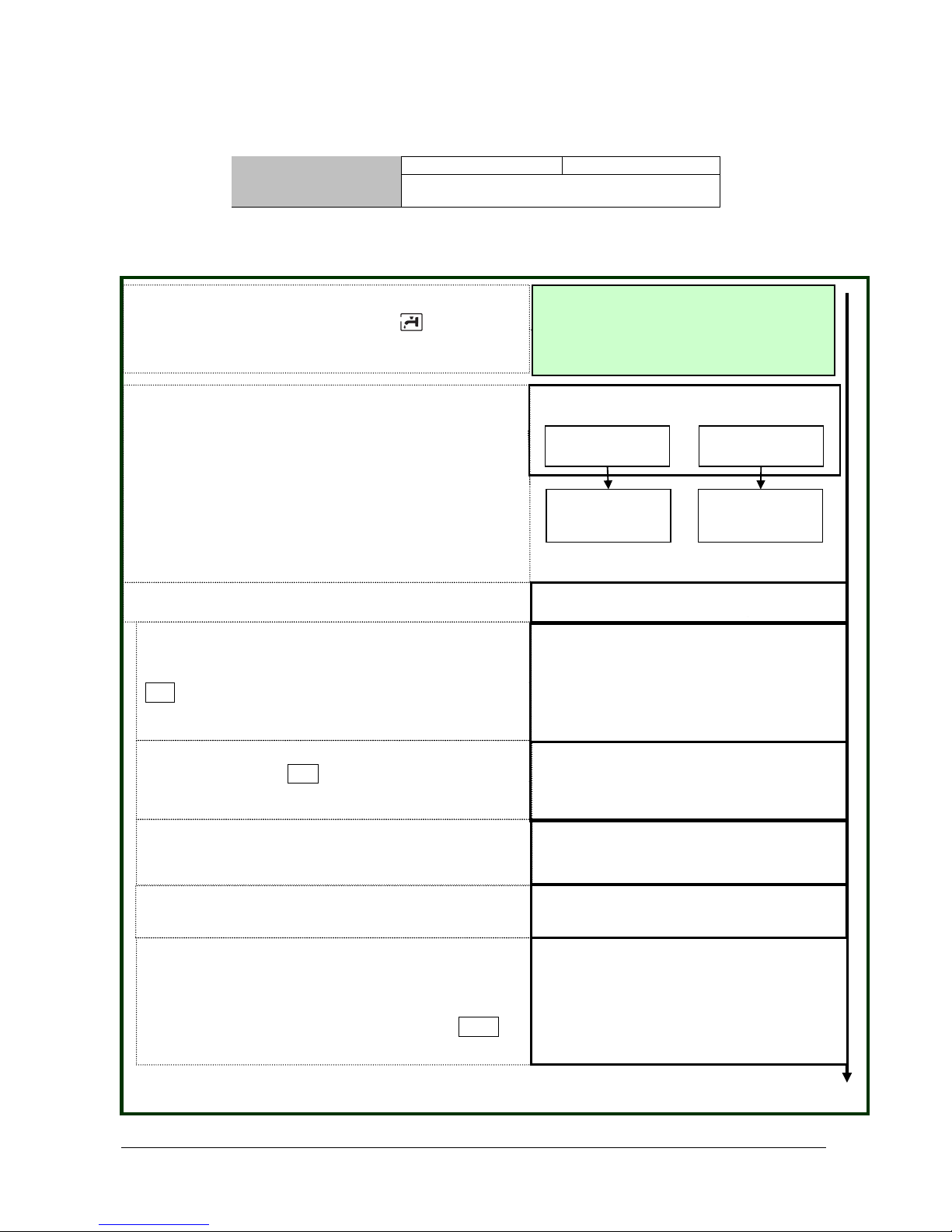

2.2.1 Assembly view of sanitary mode

SOLAR SENSOR SANITARY MODE

Boiler is fitted with a solar sensor.

On occasion of a sanitary water draw-off from the solar hot

water tank , the conrol of burner is accomplished in the

following manner :

the solar sensor will enable or not, the burner to operate

according to the specified sanitary temperature values

set to the Control Board (see Table on the right).

Setpoint T°for sanitary

set on Control Board

[°C]

Ignition T° read by solar

sensor

[°C]

36

36

40

39

45

43

50

47

55

50

60

54

Inlet

Example :

Page 18

Page. 18 of 73

Training manual :PIGMA Gal Evo

3 SPECIAL FUNCTIONS

3.1 FLUE CLEANER” FUNCTION

This function is used to perform proper boiler combustion analysis and maximum and minimum gas

calibration.

Follow the instructions below to enable it:

PRESS

DISPLAY

The display will show this indication

Press Reset button for 5 continuous seconds

With the boiler on “Winter” mode, the 3-way valves is positioned on “heating” and the burner turns on

even without heating requested.

With the boiler on “summer” mode:

o without sanitary demand the burner turns on in heating;

o with sanitary demand the burner turns on in sanitary.

The delivery temperature (NTC1) is checked during the “Flue cleaner” function, as follows:

“summer” mode → Off: 86°C; On: 81°C;

“winter” mode → Off: 89°C; On: 84°C.

Three different powers can be selected when the function is enabled

PRESS

DISPLAY

POWER

Turn the knob

anticlockwise

Maxi power in

heating mode

Max power in

sanitary mode

Turn the knob

anticlockwise

Minimum power

Page 19

Page. 19 of 73

Training manual :PIGMA Gal Evo

To exit the “Flue cleaner” function, press the RESET button. However after 30 minutes the function will be

disabled automatically.

Page 20

Page. 20 of 73

Training manual :PIGMA Gal Evo

3.2 “COMFORT” FUNCTION

This function allows the user either to activate or not the function « temperature holding in the sanitary water

reserve tank.

At workshop level this function remains active over a time range 24h/24h, 7days/7days. Wording

« COMFORT », is displayed at the screen bottom and it enables adapting Temperature Hold in the sanitary

reserve according to user’s needs.

To program it, comply with the directions given below :

Whit the menu 250, it’s possible to validate this function COMFORT:

0 = Disable

1 = timer

2 = Always activate

How to Program the comfort function

Workshop outgoing

configuration.

The term

« COMFORT »indicates that

temperature holding

condition is set

permanently..

Programming COMFORT

function

pressing Comfort button

allows setting this function n

L’icon « Timer » is displayed

on the screen.

Function disabling

Pressing this button for the

third time turn off completely.

The boiler is an instant

mode. The screen does not

indicate the clock symbol

any more nor working

Comfort mode

Page 21

Page. 21 of 73

Training manual :PIGMA Gal Evo

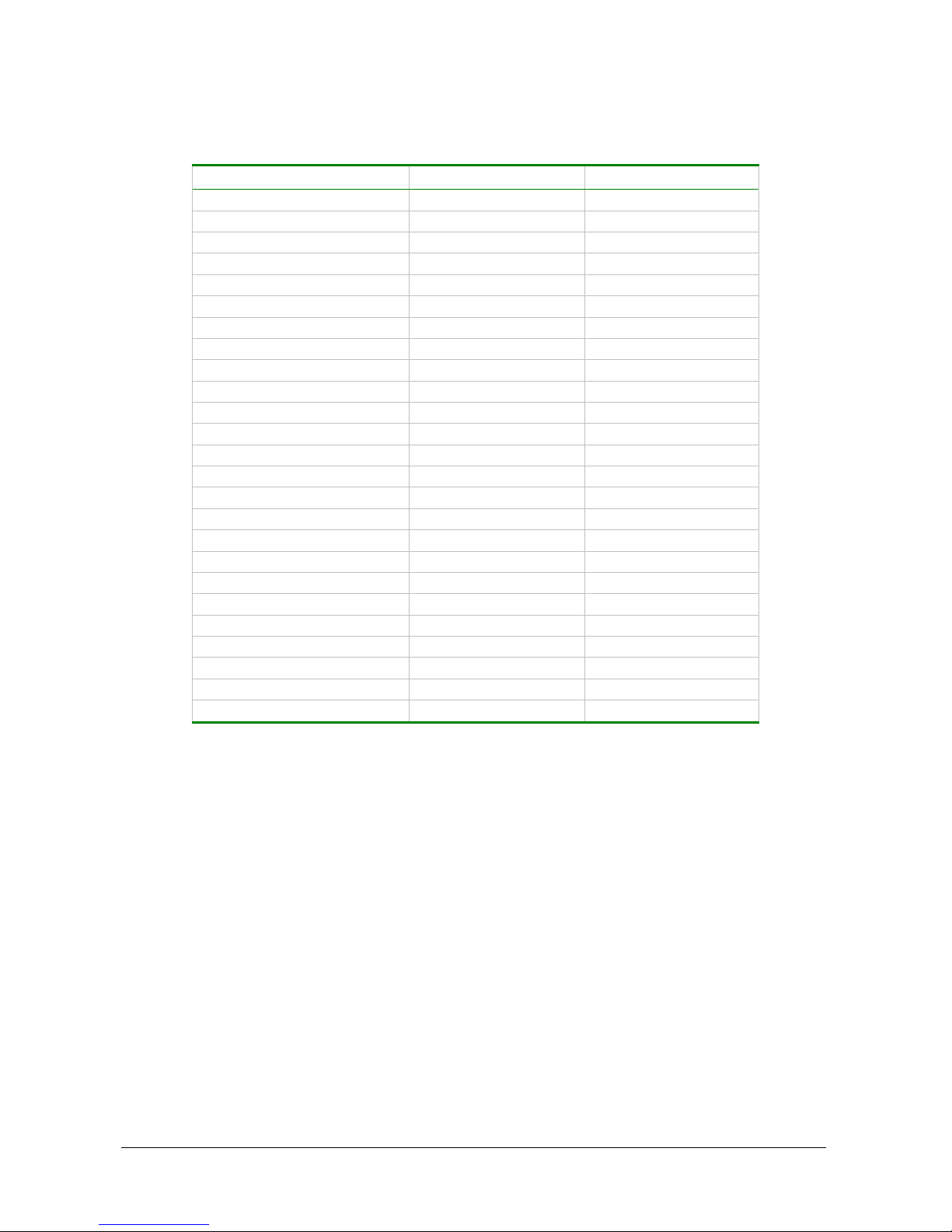

The operating range is variable and depends on the temperature set for the sanitary mode:

TEMP. SET FOR SANITARY MODE

OFF TEMPERATURE

ON TEMPERATURE

36

40

34

37

41

35

38

42

36

39

44

38

40

45

39

41

46

40

42

47

41

43

49

43

44

50

44

45

51

45

46

53

47

47

54

48

48

56

50

49

58

52

50

59

53

51

61

55

52

63

57

53

64

58

54

66

60

55

68

62

56

70

64

57

71

65

58

72

66

59

73

67

60

74

68

Page 22

Page. 22 of 73

Training manual :PIGMA Gal Evo

3.3 “ANTIFREEZE” FUNCTION

This function is enabled only if the ON/OFF selector is turned on position ON. It is operated by means of

the temperature detected by the heating delivery probe (NTC1).

CONDITION

EVENTS

TIME

1

ST

CASE

The temperature

detected by probe

NTC1:

Ranges between 3°C

and 8°C

- The PUMP is supplied on speed III

- The 3-WAY VALVE alternatively

switches the position of the shaft from

1 minute on “heating” to 1 minute on

“sanitary” mode

- The DISPLAY shows the icon

Until the

NTC1

temperature is

9°C

If, after 20 minutes,

the CONDITIONS described in the 1st CASE are still present (3°C<NTC1<8°C)

automatically check the EVENTS of the 2nd CASE

CONDITION

EVENTS

TIME

2

nd

CASE

The temperature

detected by probe

NTC1:

Is below 3°C

- The BURNER turns on, supplied with

minimum power;

- The 3-WAY VALE is positioned on

“sanitary” and switch every 30 s

DHW/CH

- When the temperature is 40°C the

burner turn OFF. For 15 minutes the

boiler maintain the temperature

between 35°C and 40°C

- After 15 minutes there is 2 minutes of

post circulation in heating

- Into 90 minutes if the temperature

decreases again less than 8°C the

burner switch on immediately.

- The DISPLAY shows the icon .

Until the

NTC1

temperature is

30°C

If the NTC1 delivery probe is not working (open or short circuit) the “antifreeze” function check is followed by

the NTC2 heating return probe but in these cases only the pump works (the burner doesn’t light). The display

doesn’t show the antifreeze enabling code, but the error code of the NTC1 open or short circuit 1 10 or

1 11.

The antifreeze is enabled even if the NTC2 return probe is not working (open or short circuit) but only the

pump works (the burner doesn’t light). In this case the display doesn’t show the antifreeze enabling code, but

the error code of the NTC2 open or short circuit 1 12 or 1 13.

The antifreeze is enabled even if the boiler is shutdown due to no flame detection 5 01 or blocked for over

heat 1 01, but in these cases only the pump works (the burner doesn’t light), and the display shows the error

code of blocking and not the antifreeze enabling one.

If there is an interruption of the power supply, the boiler maintains in memory all the setting and when the

power supply is on the boiler returns in the condition that had before the turning off.

Page 23

Page. 23 of 73

Training manual :PIGMA Gal Evo

3.4 “WATER FLOW CHECK”

Check

When

What happens

Gradient Tman > 7°C/sec

(checked every 100ms)

Check always with the

flame on, except during

the first 4 seconds after

flame detection.

1. Immediate safety shutdown 1 P1:

- 10sec of post-circulation

- 10 sec of post-ventilation

The boiler restarts after 10sec.

2. If the error occurs other 2 times within the

following 4 minutes it will be shutdown 1 03 :

- 20sec of post ventilation

- 1min of post circulation.

Gradient Tman > 20°C/sec

or

Gradient Trit > 20°C/sec

(checked every 100ms)

Check always with the

flame on, and up to 7 sec

after each turn off for

temperature set or safety

shutdown.

1. Shutdown 1 04:

- 20sec of post ventilation

- 1min of post-circulation.

Tman – Trit > 55°C

Check always with the

flame on, and up to 7 sec

after each turn off for

temperature set or safety

shutdown.

1. Immediate safety shutdown 1 P2:

- 10sec of post-circulation;

- 10sec of post ventilation.

After 10sec the boiler restarts.

2. If within 4 minutes from the first safety

shutdown the defect occurs again there will be

a safety shutdown 1 P2 :

- 10sec of post-circulation;

- 10sec of post ventilation.

After 10sec the boiler restarts but the timer is

zeroed.

3. If within 4 minutes from the first safety

shutdown the defect occurs again it will be

shutdown 1 05 :

- 20sec of post ventilation

- 1min of post circulation.

Trit > Tman + 10°C

Check always with the

flame on.

1. If the defect occurs for 20 continuous seconds

there will be a safety shutdown 1 P3 :

- 10sec of post-circulation;

- 10sec of post ventilation.

After 10sec the boiler restarts.

2. If the defect occurs for 20 continuous seconds

another 2 times within 4 minutes it will

shutdown 1 06 :

- 20sec of post ventilation;

- 1min of post circulation.

Trit > Tman + 30°C

Check always with the

flame on.

20sec of post ventilation;

- 1min of post circulation

“

Page 24

Page. 24 of 73

Training manual :PIGMA Gal Evo

ON

OFF

ON

OFF

ON

OFF

Burner

Extractor

1 04

Evolvement of start T° or return T° > 20°C/sec

>20°C/sec

Evolvement

<20°C/sec

1 04

<7 sec

60 sec (post-circ.)

20 sec (post-vent.)

Case “A”

Case “B”

20 sec (post-vent.)

60 sec (post-circ.)

Pump

ON

OFF

ON

OFF

ON

OFF

Burner

Extractor

1 P1

Evolvement of start T° > 7°C/sec

ON

OFF

>7°C/sec

Times

Evolvement

<7°C/sec

1 03

1 P1

10 sec

10 sec

10 sec

255 sec

60 sec (post-circ.)

20 sec (post-vent.)

Pump

Page 25

Page. 25 of 73

Training manual :PIGMA Gal Evo

ON

OFF

ON

OFF

ON

OFF

Burner

Extractor

1 P3

Return T° > Start T° + 10°C

ON

OFF

>StartT°+10°C

Time

RetT°

<StartT°+10°C

1 06

1 P3

10 sec

10 sec

10 sec

255 sec

60 sec (post-circ.)

20 sec (post-vent.)

Pump

ON

OFF

ON

OFF

ON

OFF

Burner

Extractor

1 P2

Start T° or Return T° > 55°C

ON

OFF

>55°C

Time

StartT°-RetT°

<55°C

1 05

1 P2

10 sec

10 sec

10 sec

255 sec

60 sec (post-circ.)

20 sec (post-vent.)

Check also 7 seconds after each burner shut down

Pump

Page 26

Page. 26 of 73

Training manual :PIGMA Gal Evo

3.5 AIR PURGE” FUNCTION

This function can be activated by the installer by the parameter 2 01 (or pressing of the key ESC for 5 sec

(continues till to the finish (about 6’) or pressing of the key ESC).

It’s aim is to help to purge the residual air inside the primary circuit after a filling cycle.

At the activation the following cycle is begun

This cycle can be repeated several times, till the boiler and the heating system are completely purged from

air.

3 way valve in heating

Pump on 60 sec.

Pump off 30 sec.

3 way valve in sanitary

Pump on 60 sec.

Pump on 60 sec.

3 way valve in heating

Pump on 60 sec.

Pump off 30 sec.

Pump on 60 sec.

ON

OFF

ON

OFF

ON

OFF

Burner

Extractor

Return T° > Start T° + 30°C

>startT°+30°C

RetT°

<ReturnT°+30°C

1 07

60 sec (post-circ.)

20 sec (post-vent.)

Pump

Page 27

Page. 27 of 73

Training manual :PIGMA Gal Evo

3.6 “SELF ADAPTIVE HEATING RESTART DELAY”

With the parameter 2 35 it is possible chose the heating restart delay type:

0: manual;

1: automatic.

MANUAL: with the parameter 2 36 it is possible set the heating restart delay between 0 and 7 min.

AUTOMATIC: the heating restart delay is calculated in base of the heating set-point temperature, see table

below:

Consigne Chauffage

< 50°C

51-60°C

61-70°C

71-80°C

> 80°C

Temps de retard

redémarrage

chauffage (minute)

5 4 3 2 1

Page 28

Page. 28 of 73

Training manual :PIGMA Gal Evo

4 HYDRAULIC BLOCK

LEGEND

1

Expansion vessel

8

Retuyrn heating sensor

2

Delivery heating sensor

9

Primary heat exchanger

3

Sanitary plate heat exchanger

10

No back-flow valve

4

3 bar safety valve and by-pass

11

Filling tap

5

3 way valve

12

Deareator

6

Sanitary flow meter

13

Minimum pressure switch

7

Pump

14

Drain tap

Page 29

Page. 29 of 73

Training manual :PIGMA Gal Evo

4.1 RIGHT HYDRAULIC BLOCK

Composite block with integrated functions :

- CH and DHW filter

- Electrical diverter valve

- All components fitted by clips

- Pump unit with deareator valve and Heating pressure switch

- Brass connectors for installation

- Primary filling system

LEGEND

1

3-way valve motor

6

Heating filter

2

3-way valve

7

Pump

3

Sanitary flow meter

8

Minimum pressure switch

4

No back flow valve

9

Deareator

5

Filling tap

1

2

3

4

5

6

7

8

9

Page 30

Page. 30 of 73

Training manual :PIGMA Gal Evo

4.2 LEFT HYDRAULIC BLOCK

By Composite module for CH and domestic hot water outlet.

Components integrated in the block :

- CH safety valve 3bar

- Automatic by-pass

- Brass connections

- All copper pipes connected by clips

LEGEND

1. 3 bar safety valve and by-pass

3. Sanitary plate heat exchanger

2. By-pass pipe connection

1 2 3

Page 31

Page. 31 of 73

Training manual :PIGMA Gal Evo

4.3 WAY VALVE

Boiler is fitted with a 3-way valve, 230 volts motor-driven, installed on the return line.

When no operating, it is set to sanitary mode.

PARTS DESIGNATION

1. 3-way valve motor

2. Motor hanging clip

3. Valving assembly

hanging clip

4. Valving parts

5. Valve assembly

Noteworth is here that the compensation spring is embodied directly into the valve drive motor.

4.3.3-way valve motor

The movement of the 3-way valve is assured by an ELBI l electric motor that is easy to disassemble.

The boiler does not have to be emptied in order to replace it but you just have to take out the clip and

disconnect the supply wire.

The PCB supply always reaches the electric motor according to the function selected (mixed or just sanitary)

on the control panel.

« HEATING » POSITION

« SANITARY » POSITION

Wiring connections:

Alimentation

1

2

3

STM0011

Supply voltage : 230Vac

Ohmic Resistance of each winding : 10 kohms

Winding

Sanitary position

2-1

Heating position

2-3

1

4

2

3

5

Page 32

Page. 32 of 73

Training manual :PIGMA Gal Evo

4.4 PLATE TYPE HEAT EXCHANGER

The sanitary plate type heat exchanger is secured to the hydraulic assemblies, right side and left side, by 2

screws, that are accessible from the front side.

Plates made from stainless steel are deep-drawn fabricated parts and welded one to the others. Tightness

is ensured by 4 seal lip joints.

Temperatura limite anticalcare

Serve a ridurre la formazione di calcare

all’interno dello scambiatore secondario.

Durante il funzionamento in MODO

SANITARIO lo spegnimento e la

conseguente riaccensione del bruciatore è

vincolato ai valori di temperatura rilevati dalle

sonde NTC1 e NTC2 indicati qui a fianco.

T set

Temp. limite

anticalc.

START

NTC1

(sonda

mandata)

Non

influente

85°C

81°C

NTC2

(sonda ritorno)

> 52°C

65°C

64°C

<52°C

62°C

61°C

SANITARY PLATE-TYPE HEAT

EXCHANGER

Main side :

Hot water coming from the exchanger enters

«A», and flows out from «B».

Secondary side:

Cold water for sanitary use enters «C» and

flows out from «D» reheated.

Fluids stream in parallel and in counterflow

with a view at ensuring a maximum heat

exchange.

Sanitary exchanger : 12 plates provided for 25 KW

rating and 14 plates for 30 KW rating

Page 33

Page. 33 of 73

Training manual :PIGMA Gal Evo

4.5 PUMP UNIT

Pump type:

Wilo INMTSL 15/5 HE-2: ( 24 28 kW);

Wilo INTMTSL 15/6.7 HE-2: ( 32 kW).

The P.C.B. controls modulation of the circulation pump at two different speeds V2 (55w) and V3 (80w).

On “sanitary” the pump always works on V.3 to allow excellent heat exchange

On “heating” the circulating device has 2 speeds that are operated by the heating del-ret ΔT control.

Operated as follows:

ΔTdel-ret < ΔT – 2°C → V2;

ΔTdel-ret > ΔT → V3;

where: ΔT= 20°C (default value, which can be set by parameter 2 39 between 10 and 30°C).

Speed switching is performed with a 5 minute delay (value that cannot be set) up or down.

It is possible to exclude the pump modulation with the parameter 2 38:

- 0: speed 2 fix;

- 1: speed 3 fix;

- 2: modulating.

The antisticking function switch on the pump and 3 way valve for 15 sec avery 21 h after the last l sistema

antibloccaggio attiva il circolatore e la valvola 3 vie per 15 sec. ogni 21 ore dall’ultimo funzionamento.

CLAS 24 e 28 CLAS 32

4.5.1 PUMP speed check

The speed of the pump can be checked by the parameter 8 23 or by measuring the voltage (Vac) between

pins 5 and 6 of the electronic card CN10 connector:

- 145 Vac: maximum speed;

- 0 Vac: minimum speed.

145 Vac: maximum speed;

0 Vac: minimum speed

Page 34

Page. 34 of 73

Training manual :PIGMA Gal Evo

4.5.2 Post-circulation.

4.6 DRAIN PORT & PLUG

Drainage of primary cicuit is possible by removing the plug

from the drain hole at the bottom of the hydraulic assembly of

boiler. The plug can be screwed out by use of a hexagon

head wrench size 9.

Post-circulation after:

3 way valve

position

Time of post circulation

Speed pump

Switching off due to:

Room thermostat opening

Heating

3 min

(set by parameter 237

beetwen 0 e 15’)

Low

Heating Off by Summer/Winter

button

Heating

3 min

(set by parameter 237

beetwen 0 e 15’)

Low

NTC delivery > T set +4

Heating

continuasly

Low

NTC return > 62°C or 67°C

Sanitary

continuasly

High

End of sanitary demand

Sanitary

Par. 254=0 30 sec

if:Tdel<75°C ; 3 min

if Tdel>75°C;

Post circulation: 30sec

High

Par. 254=1 3 min

End of comfort cycle

Sanitary

30 sec

High

End of antifreeze function

Heating /

Sanitary

2 min

High

End of chimney sweeping

function

Heating

1 min

Low

Solar sensor

Sanitary

30 sec

Low

Errors

Pressure sensor (102), Low

pressure (108, 111)

Heating

40 sec

Low

No circulation (103, 104, 105,

106, 107)

Heating

1 min

High

Flame missing, flame lift

(501, 504)

Heating

2 min

Low

Overheat (101), Thermo fuse

opening (610)

Heating

2 min

Low

No circulation (1P1, 1P2, 1P3)

Heating

10 sec

High

Floor thermostat opened (116)

Heating

90 sec

Low

Page 35

Page. 35 of 73

Training manual :PIGMA Gal Evo

4.7 BY-PASS VALVE

The boiler is equipped with an automartic by-pass valve allowing protection from the occurrence of a poor

flow rate from the system, which may be originated for instance from some closures of the thermostatic

cocks.

This DP is governed by a valve and a spring which open more or less for an extent depending on applied

load.

The by-pass valve ensures, in the main heat exchanger, a minimum flow rate of 50l/h. It is mounted

behind the main valve with 3 bar rating.

4.8 PRIMARY HEAT EXCHANGER

Primary heat exchanger is made from cupper metal. It is coated with an aluminum and silicone base paint

with high temperature resistant property.

The function of this exchanger consists in transfering heat from products of combustion to water flowing in

the heating circuit lines or in the sanitary heat exchanger.

The exchanger is rack-mounted in the upper part of the combustion chamber. It is held in positiin by two

screws secured to the side panels in the chamber.

4.9 PRESSURE PICK-UPS (FF ONLY)

Pressure pick-ups are to verify in real time the pressure

availabe in the primary circuit.

Contact closed > 0,6 b

Contact open < 0,4 b

Page 36

Page. 36 of 73

Training manual :PIGMA Gal Evo

4.10 HEATING LINE STRAINER

A heating filter is placed in the hydraulic assembly, on the right (see picture below) on the return line from the

heating flow circuit. strainer mesh measures 1,5 mm in cross-section.

To clean it, follow the instructions given below.

Heating strainer

Page 37

Page. 37 of 73

Training manual :PIGMA Gal Evo

4.11 HEATING EXPANSION VESSEL

Expansion vessel consists of two distinct parts assembled, made from metal sheet 1,8 mm thick. Inside, the

tank is separated through a SBR rubber membrane (see, pictures shown below).

The expansion vessel is located in the frame behind the boilere. Inflating pressure is 1 bar. Maximum

capacity of the system is about 175 litres.

A valve allows the u technician to make a yearly check of inflating pressure in the expansion vessel.

4.12 SANITARY FLOW RATE

When set to sanitary mode, because water flow rate is higher than 1,6 litres minute, the turbine fitted inside

the sanitary flow meter transfers through a « reed » relay the command to the electronic PCB to initiate the

ignition sequence.

A sanitary filtre is embodied in the flow meter with a view at protecting the turbine and the sanitray

exchanger from penetration of impurities. To prevent any delayed start up caused by surge arising in the

cold water pipe network, a time control can be organised through parameter 2 52 within 0.5 sec and 20 sec

( 0.5 sec by default). With the aid of parameter 8 25 and key INFO it is possible to have a reading of sanitary

water flow rate.

Operation check data of turbine by measuring voltage on CN14 of the electronic PCB is :

- 0Vdc = no flow rate

- 5Vdc = no flow rate

- between 2Vdc and 3Vdc = flow rate

ON for a flow rate > à 1,6 l/min

OFF for a flow rate < à 1,3 l/min

Flow rate limit

8 l/min

25 kW

10 l/min

30kW

Technical Data

Capacity

8 litres

Maximum temperature

90°C

Inflating pressure

1 bar

Maximum pressure in primary circuit

3.0 bar

Reed relay

Water

Page 38

Page. 38 of 73

Training manual :PIGMA Gal Evo

DESIGNATION

1. Sanitary Flow Rate

2. Hold Clip for flkow meter

inside the hydrauylic

assembly

A Flow rate limiter

B Flow meter casing

C Turbine

D Plug with sanitary filtre

incorpoorated

Disassembly and re-assembly of

sanitary flow meter are made

easier by use of a hold clip and

of a device fitted to the flow

meter casing, to prevent wrong

actions from being caused.

2 1 B C D

A

Page 39

Page. 39 of 73

Training manual :PIGMA Gal Evo

4.13 TEMPERATURE SENSORS

To check the delivery and return temperature use the two contact sensor. To read the sanitary water

temperature the NTC1 heating delivery is used.

IMPORTANT!!!! Do not use conducting paste for the contact sensors because they alter the resistance

value.

TEMPERATURE (°C)

RESISTANCE (kOmh)

0

27

10

17

20

12

30

8

40 5 50 4 60 3 70

2

80

1,5

PROBE ERROR CODES

1 10

NTC1 heating delivery probe open or short

circuit

1 12

NTC2 heating return probe open or short

circuit

NTC1

NTC2

Page 40

Page. 40 of 73

Training manual :PIGMA Gal Evo

5 GAS LINE

5.1 GAS VALVE TYPE SIT SIGMA 845

The gas valve installed in the boiler is type SIT 845 SIGMA embodying 2 solenoid safety valves supplied

from a 230 Vac source and a pressure modulation valve, 24 Vdc, for control of flow to the burner.

Flow modulation management is obtained through the electronic PCB, by an output data reading from the 3

temperature sensors.

This sort of gas valve can operate both with natural gas and liquid gas as well. In case gas quality needs be

changed , it is simply necessary that also injectors in the gas storage tank be changed. Highest allowable

pressure to the valve is 60 mb.

An igniter typeNAC504 is secured to the gas valve body.

This gas valve allows to control :

► maximum power to burner

► minimum power to burner

5.2 SOLENOID VALVE ELECTROPNIC CONNECTION DIAGRAM.

1

2

4

3

7

8

5

6

1 gas outlet to the burner

2 outlet pressure gauge

3 max power adjusting nut

4 intlet pressure gauge

5 gas inlet pipe

6 ignitior device

7 min power adjusting screw

8 compensation gauge

Page 41

Page. 41 of 73

Training manual :PIGMA Gal Evo

5.3 GAS REGULATIONS.

5.3.1 Supply pressure check.

.

1. Loosen screw “1” (fig. A) and insert the pressure gauge fitting pipe in the

pressure intake.

2. Put the boiler on maximum operating power (hot water tap open). The supply

pressure must correspond with the one foreseen for the type of gas for which the

boiler has been prearranged (refer to table below).

3. After checking tighten screw “1” and check the seal

5.3.2 Maximum sanitary power check

1. To check maximum power, loosen screw “2” (fig.B)

and insert the pressure gauge fitting pipe in the pressure

intake.

2. Disconnect the compensation pipe of the air

chamber (fig.B).

3. Start the boiler at maximum power with the flue

cleaner function (press Reset button for 5 sec.).

4. The supply pressure must correspond with the one

foreseen for the type of gas for which the boiler has

been prearranged (refer to table below). If it does not,

remove the protection cap and act on adjusting hexagon

nut “3” (fig. C).

5. After checking tighten screw “2” and check the seal.

6. Reassemble the protection cap of the modulator.

7. Reconnected the compensation pipe

MINIMUM SUPPLY PRESSURE

METHANE G 20

BUTHANE G 30

PROPANE G 31

17 mbar

25 mbar

25 mbar

OUTLET PRESSURE SANITARY MAX POWER (mbar)

G20

G30

G31

24 kW CF

12

27,8

35,6

28 kW CF

12,4

27,5

35,3

24 kW FF

12,7

28,1

35,7

28 kW FF

12,4

27,7

35,7

32 kW FF

11

28

35,8

Fig. A

Compensation

Fig. B

Fig. C

Page 42

Page. 42 of 73

Training manual :PIGMA Gal Evo

5.3.3 Minimum power check.

1. To check the minimum power loosen screw “2” (fig.B) and insert the pressure

gauge fitting pipe in the pressure intake.

2. Disconnect the compensation pipe of the air chamber (fig.B).

3. Have the boiler work on minimum power and disconnect a cable from the

modulator (fig.D). The supply pressure must correspond with the one foreseen for

the type of gas for which the boiler has been prearranged (refer to table below). If it

does not correspond, act on adjusting screw “4” (fig.D) while holding the hexagon

nut steady “3”(fig.C).

4. After checking tighten screw “2” and check sealing.

5. Reconnect the cable of the modulator.

6. Reconnect the compensation pipe

OUTLET PRESSURE MIN. POWER (mbar)

G20

G30

G31

24 kW CF

2,2

5,5

6,9

28 kW CF

2,5

5,3

7,5

24 kW FF

2,3

5,5

7,2

28 kW FF

2,5

5,1

7,2

32 kW FF

2,3

5,2

6,8

5.3.4 Soft ignition power checking

Regulation carried out on parameter 2 20

1. To check the slow ignition power, loosen screw “2” (fig.B) and insert the pipe of the pressure gauge in the pressure

intake.

2. Disconnect the air chamber compensation pipe (fig.B)(sealed chamber).

3. Open the tap of the hot water, the burner turns on, disconnect the detection electrode in order to have the slow

ignition pressure for 8 seconds before safety block.

4. Change parameter 2 20 (see paragraph 6.2 and 6.3).

OUTLET PRESSURE SOFT IGNITION (mbar)

G20

G30

G31

24 kW CF

2,2

5,5

6,9

28 kW CF

2,5

5,3

7,5

24 kW FF

6,3

10

12,7

28 kW FF

5,1

9,5

13,7

32 kW FF

5,6

12

12

Fig. D

Page 43

Page. 43 of 73

Training manual :PIGMA Gal Evo

5.3.5 Clocking for heating restart aftr burner flame out

Control measure acted by parameter 2 36

It is possible to set up a clocking between 0 and 7 min in the time interval between burner shut off and

the following re-ignition . This set up is accomplished by parameter 2 36 provided that parameter 2 35

is set to 0.

5.3.6 Control of maximum heating power

There are 2 different types of maximun power in heating mode :

1. Absolute power in heating can be adjusted by use of parameter 2 30. This value allows

the operator to set a maximum « limit » to the gas valve, which differs from usual maximun

power. This limit must be verified and changed, if necessary, in the event gas quality or the

electronic PCB are changed.

G20

G25

G30

G31

PUISSANCE

UTILE kW

Pression

gaz

mbar

réglage

%

Pression

gaz

mbar

réglage

%

Pression

gaz

mbar

réglage

%

Pression

gaz

mbar

réglage

%

25 kW CF

11,37

62

***

***

26,5

84

34,0

91

25 kW FF

12,0

62

***

***

25,9

90

34,5

93

30 kW FF

12

63

***

***

25,98

85

35,3

92

35 kW FF

10,3

59

***

***

25,3

83

33

93

2. Heating system power is adjustable by use of partameter 2 31. This value shall be adjusted

systematically at the time when the installator sets the system into operation.

This value is adjustable as from minimum power level up to conrolled power level in menu 2 30.

PIGMA 24 CF

G20

G25

G30

G31

POWER kW

Pressure

gas

mbar

Setting

%

Pressure

gas

mbar

Setting

%

Pressure

gas

mbar

Setting

%

Pressure

gas

mbar

Setting

%

9,9

2,2

0,0

***

***

5,5

0,0

6,0

0,0

11,0

2,7

37,0

***

***

6,8

50,0

7,4

52,0

12,0

3,2

39,0

***

***

8,0

54,0

8,8

56,0

13,0

3,8

42,0

***

***

9,4

58,0

10,3

59,0

14,0

4,4

44,0

***

***

11,0

61,0

12,0

63,0

15,0

5,0

47,0

***

***

12,6

64,0

13,7

66,0

16,0

5,7

49,0

***

***

14,3

67,0

15,6

70,0

17,0

6,5

52,0

***

***

16,2

71,0

17,6

72,0

18,0

7,2

54,0

***

***

18,1

73,0

19,8

76,0

20,0

7,6

55,0

***

***

18,9

75,0

23,5

80,0

21,0

8,3

57,0

***

***

20,8

77,0

26,0

83,0

22,0

9,1

59,0

***

***

22,9

80,0

28,5

87,0

23,0

10,0

61,0

***

***

25,0

83,0

31,1

90,0

23,7

10,6

64,0

***

***

26,5

84,0

33,0

93,0

Page 44

Page. 44 of 73

Training manual :PIGMA Gal Evo

PIGMA 28 CF

G20

G25

G30

G31

POWER kW

Pressure

gas

mbar

Setting

%

Pressure

gas

mbar

Setting

%

Pressure

gas

mbar

Setting

%

Pressure

gas

mbar

Setting

%

11,2

2,3

0,0

***

***

5,3

0,0

7,5

0,0

13,0

3,1

34,0

***

***

7,1

48,0

10,1

56,0

14,0

3,6

37,0

***

***

8,3

51,0

11,7

59,0

15,0

4,1

39,0

***

***

9,5

54,0

13,5

63,0

16,0

4,7

41,0

***

***

10,8

57,0

15,3

66,0

17,0

5,3

43,0

***

***

12,2

60,0

17,3

70,0

18,0

5,9

45,0

***

***

13,7

63,0

19,4

72,0

19,0

6,6

48,0

***

***

15,3

66,0

21,6

75,0

20,0

7,3

50,0

***

***

16,9

68,0

23,9

79,0

23,0

8,2

53,0

***

***

20,2

75,0

26,0

83,0

24,0

9,0

55,0

***

***

22,0

78,0

28,3

86,0

25,0

9,7

57,0

***

***

23,8

80,0

30,7

89,0

26,0

10,5

59,0

***

***

25,8

83,0

33,2

92,0

26,7

11,1

62,0

***

***

27,2

85,0

35,0

97,0

PIGMA 25 FF

G20

G25

G30

G31

POWER kW

Pressure

gas

mbar

Setting

%

Pressure

gas

mbar

Setting

%

Pressure

gas

mbar

Setting

%

Pressure

gas

mbar

Setting

%

9,8

2,3

0,0

***

***

5,5

0,0

6,8

0,0

10,5

2,6

37,0

***

***

6,3

54,0

7,8

59,0

11,5

3,2

40,0

***

***

7,6

59,0

9,4

64,0

12,5

3,7

43,0

***

***

8,9

62,0

11,1

68,0

13,5

4,4

46,0

***

***

10,4

66,0

12,9

72,0

14,5

5,0

49,0

***

***

12,0

70,0

14,9

76,0

15,5

5,8

52,0

***

***

13,8

73,0

17,0

79,0

16,5

6,5

55,0

***

***

15,6

77,0

19,3

82,0

17,5

7,3

58,0

***

***

17,5

79,0

21,7

85,0

20,0

8,0

59,0

***

***

17,7

80,0

22,5

86,0

21,0

8,8

62,0

***

***

19,5

82,0

24,8

89,0

22,0

9,7

64,0

***

***

21,4

85,0

27,3

92,0

23,0

10,6

66,0

***

***

23,4

87,0

29,8

95,0

24,2

11,7

69,0

***

***

25,9

90,0

33,0

98,0

Page 45

Page. 45 of 73

Training manual :PIGMA Gal Evo

PIGMA 30 FF

G20

G25

G30

G31

POWER kW

Pressure

gas

mbar

Setting

%

Pressure

gas

mbar

Setting

%

Pressure

gas

mbar

Setting

%

Pressure

gas

mbar

Setting

%

11,6

2,3

0,0

***

***

5,1

0,0

6,2

0,0

13,0

2,9

34,0

***

***

6,4

48,0

7,8

51,0

14,0

3,4

36,0

***

***

7,4

51,0

9,0

54,0

15,0

3,8

38,0

***

***

8,5

53,0

10,4

58,0

16,0

4,4

41,0

***

***

9,7

57,0

11,8

61,0

17,0

4,9

43,0

***

***

11,0

59,0

13,3

64,0

18,0

5,5

45,0

***

***

12,3

62,0

14,9

67,0

19,0

6,2

47,0

***

***

13,7

65,0

16,6

70,0

20,0

6,8

49,0

***

***

15,2

69,0

18,4

73,0

24,0

8,9

57,0

***

***

19,1

76,0

24,4

83,0

25,0

9,6

59,0

***

***

20,7

79,0

26,5

86,0

26,0

10,4

61,0

***

***

22,4

81,0

28,6

89,0

27,0

11,3

63,0

***

***

24,2

83,0

30,9

92,0

28,0

12,1

64,0

***

***

26,0

84,0

33,2

95,0

PIGMA 30 FF

G20

G25

G30

G31

POWER kW

Pressure

gas

mbar

Setting

%

Pressure

gas

mbar

Setting

%

Pressure

gas

mbar

Setting

%

Pressure

gas

mbar

Setting

%

13,2

2,0

0,0

***

***

5,2

0,0

6,8

0,0

14,5

2,4

33,0

***

***

6,3

50,0

8,2

56,0

16,0

2,9

36,0

***

***

7,6

54,0

10,0

61,0

17,5

3,5

39,0

***

***

9,1

59,0

12,0

65,0

19,0

4,1

42,0

***

***

10,8

62,0

14,1

68,0

20,5

4,8

44,0

***

***

12,5

66,0

16,4

72,0

22,0

5,6

47,0

***

***

14,4

69,0

18,9

77,0

23,5

6,3

50,0

***

***

16,5

72,0

21,6

81,0

25,0

7,2

52,0

***

***

17,9

74,0

23,4

83,0

28,0

7,8

54,0

***

***

19,1

76,0

25,0

84,0

29,0

8,4

56,0

***

***

20,5

79,0

26,8

86,0

30,0

8,9

57,0

***

***

22,0

80,0

28,6

89,0

31,0

9,5

59,0

***

***

23,4

81,0

30,6

91,0

32,2

10,3

61,0

***

***

25,3

83,0

33,0

93,0

Page 46

Page. 46 of 73

Training manual :PIGMA Gal Evo

5.3.7 TABE OF GAS

25 CF

30 CF

G20

G30

G31

G20

G30

G31

Lower Wobbe index (15°C 1013 mbar)

(Mj/m3)

45,7

80,6

70,7

45,7

80,6

70,7

Nominal pressure gas mbar

20

28/30

37

20

28/30

37

Maximal pressure sanitary mbar

12

27,8

35,6

12,4

27,5

35,3

Soft ignition mbar

(Parameter 220)

2,2

(0)

5,5

(0)

6,9

(0)

2,5

(0)

5,3

(0)

7,5

(0)

Adjustable heating power CH mbar

(Parameter 230)

11,4

(62)

26,5

(84)

34,0

(91)

11,2

(62)

27,2

(85)

35

(97)

Maxi power heating %

(parameter 231)

75

74

78

77

66

72

CH Anti-cycling

(parameter 235)

Automatique

Main burner jets

13

15

Diameter burner jets

1,25

0,76

0,76

1,25

0,75

0,75

Max/min

consumption

(15°C 1013

mbar)

Maxi D H W

2,86

2,13

2,10

3,23

2,41

2,37

Maxi Heating

2,73

2,03

2,00

3,12

2,33

2,29

Mini

1,16

0,87

0,85

1,38

1,03

1,01

25 FF

30 FF

35 FF

G20

G30

G31

G20

G30

G31

G20

G30

G31

Lower Wobbe index (15°C 1013 mbar)

(Mj/m3)

45,7

80,6

70,7

45,7

80,6

70,7

45,7

80,6

70,7

Nominal pressure gas mbar

20

28/30

37

20

28/30

37

20

28/30

37

Maximal pressure sanitary mbar

12,7

28,1

35,7

12,4

27,7

35,7

11,3

28

35,8

Soft ignition mbar

(Parameter 220)

6,3

(50)

10

(65)

12,7

(65)

5,1

(50)

9,51

(58)

13,7

(66)

4,9

(45)

7,7

(56)

8,2

(56)

Adjustable heating power CH mbar

(Parameter 230)

12

(62)

25,9

(90)

34,5

(93)

12,0

(63)

26

(85)

35,3

(92)

10,3

(59)

25,3

(83)

33,0

(93)

Maxi power heating %

(parameter 231)

74

71

79

77

66

78

80

62

70

CH Anti-cycling

(parameter 235)

Automatique

Main burner jets

11

13

16

Diameter burner jets

1,32

0,8

0,8

1,32

0,8

0,8

1,32

0,78

0,78

Max/min

consumption

(15°C 1013

mbar)

Maxi D H W

2,86

2,13

2,10

3,31

2,47

2,43

3,81

2,84

2,80

Maxi Heating

2,73

2,03

2,00

3,17

2,37

2,33

3,65

2,72

2,68

Mini

1,16

0,87

0,85

1,38

1,03

1,01

1,59

1,18

1,17

Page 47

Page. 47 of 73

Training manual :PIGMA Gal Evo

5.4 BURNER

Technology used : Multiple gas burner model POLIDORO, installed in rack frame in the combustiin

chamber. The burner assembly is equipped with :

1. one multiple-gas type burner

2. one a storage tank fitted with own injectors secured by screws

3. one ignition electrode array and one ionization sensor

DIAMETER OF THE NOZZLES

Number

G20

G30

G31

25 kW CF

13

1,25 mm

0,76 mm

0,76 mm

28 kW CF

15

1,25 mm

0,75 mm

0,75 mm

25 kW FF

11

1,32 mm

0,80 mm

0,80 mm

30 kW FF

13

1,32 mm

0,80 mm

0,80 mm

35 kW FF

13

1,32 mm

0,80 mm

0,80 mm

Page 48

Training manual :PIGMA Gal Evo

5.5 FLUE EXHAUST PORTS (SUCTION TYPE MODEL)

On the boiler top there is installewd an outlet socket (60/100) for connection with suction type exhaust pipes .

Two pressure ports allow measuring quality of combustion during the COMBUSTION ANLYSIS mode as well

as 2 pressure taps are provided for pressure switch tests.

5.6. AIR PRESSURE SWITCH (SUCTION CAP TYPE DESIGN)

The boiler is fitted with an air pressure switch to check the vacuum state in suction caps and the extractor

for regular functioning.

25kW: Off = 50Pa/0,50 mbar

On = 60Pa/0,60 mbar

30kW: Off = 74Pa/0,74 mbar

On = 89Pa/0,89 mbar

The pressure tap (-) of the pressure switch is jointed to the pressure tap in the extractor.

The pressure tap (+) is measured directly in the casing of the air pressure switch.

A measurement of Dp is taken during every sequence of ignition. If the read value is correct, the burner can

ignite a flame.

In thepresence of any trouble, faults of 2 types are likely to be found:

6 07 : pressure switch contact closed while extractor is not powered yet.

6 P1 : pressure switch contact remains open while extractor is being energized.

For preventing condensation risks from occuring in the pressure switch tube, a regenerator for

condensate is fitted in the tube.

Page 41 of 59

Combustion

Reset

OFF

1

3

Taps for pressure

switch testing

Page 49

Pag. 49 de 73

Manuale Didattico – ACO

Training manual :PIGMA Gal Evo

5.6 EXTRACTOR (SUCTION CAP TYPE DESIGN)

Technical data :

- 25kW: Motor 35W

- 30kW: Motor 45W

- 35 kW Motor 60 W

5.7.1.POST-VENTILATION

Different cycles of post ventilation according to the cases

of figures:

during a setting to safety 5 01 : 40 seconds

during a setting to safety linked to water circulation 1 03, 1 04, 1 05, 1 06 or 1 07 : 20 seconds

during a fault in water flow circulation 1 P1, 1 P2 or 1 P3 : 10 seconds

►Post-ventilation after a heating request:

parameter 2 43= 0 5 seconds ( at each burner firing stop)

parameter 2 43= 1 3 minutes ( at each burner firing stop)

►Post-ventilation after a sanitary request:

parameter 2 54= 0 T°Dép<75°C = No post-ventilation; start T°>75°C = 3 min

parameter 2 54= 1 fix 3 min (at each burner flame out).

Connector CN 22

(brackets 11 and 12) of

electronic PCB

Connector CN 22

(brackets 11 and 12) of

electronic PCB

FAN OFF

Pressure

tap (-)

Pressure

tap(+)

FAN ON

Page 50

Pag. 50 de 73

Manuale Didattico – ACO

Training manual :PIGMA Gal Evo

5.6.1 SPOTT UNIT ( MODEL CF)

The SPOTT unit is to control the flue stack for a good thermal draught. This valve is located in the antibackflow device.

This is a sort of thermal contact that opens when temperature is 75±3°C Its opening causes the burner to

flame out, and it brings the boiler to stop; code symbol 6 01 is displayed on screen. Reset takes place

automatically 12 minutes after flame out.

5.7 FLUE EXHAUST / MODEL CF

The boiler is equipped with an anti-return

device measuring 130 mm in diameter in

its upper part and 125 mm in lower part.

Installatiom of the flue stack must be in

compliance with the regulations in force in

the country concerned.

THERMAL DRAUGHT FAILURE

6 01 : Opening contavt of SPOTT unit.

SPOTT

Page 51

Pag. 51 de 73

Manuale Didattico – ACO

Training manual :PIGMA Gal Evo

5.8 SUCTION CUP OUTLET / SUCTION CUPS MODELS / POSSIBLE CONFIGURATIONS

EXHAUST SYSTEMS (SEALED CHAMBER FF)

The boiler is arranged for both coaxial smoke exhaust 60/100mm and for the split 80/80mm (two ways to

connect the intake pipes). Combustion analysis intakes are built-in the smoke exhaust neck.

SISTEMA DI SCARICO COASSIALE

COAXIAL 80/100 e 80/125

C12

C32

C42

TWIN PIPE 80/80

C12

C32

C42

C52

C82

Page 52

Pag. 52 de 73

Manuale Didattico – ACO

Training manual :PIGMA Gal Evo

Page 53

Pag. 53 de 73

Manuale Didattico – ACO

Training manual :PIGMA Gal Evo

TYPE OF

EXHAUST

Length (L)

DIAPHRAME

[mm]

from [m]

to [m]

24

kW

60/100

COAXIAL

SYSTEMS

C12,C32,C42,

B32

0,5

0,75

Ø44

0,75 4

NO

80/125

COAXIAL

SYSTEMS

C12,C32,C42,

B32

0,75 3

Ø44

3 11

NO

80/80 SPLIT

SYSTEMS

C12, C32,C42

(Air/Flue)

0,5 / 0,5

9 / 9

Ø44

9 / 9

21 / 21

NO

C52,C82

(Air/Flue)

1 / 0,5

1 / 23

Ø44

1 / 23

1 / 44

NO

B22

(Flue)

0,5 23

Ø44

23 45

NO

TYPE OF

EXHAUST

Length (L)

DIAPHRAME

[mm]

from [m]

to [m]

28

kW

60/100

COAXIAL

SYSTEMS

C12,C32,C42,

B32

0,5

0,75

Ø44

0,75 4

NO

80/125

COAXIAL

SYSTEMS

C12,C32,C42,

B32

0,5 3

Ø44

3 11

NO

80/80 SPLIT

SYSTEMS

C12, C32,C42

(Air/Flue)

0,5 / 0,5

11 / 11

Ø44

11 / 11

24 / 24

NO

C52,C82

(Air/Flue)

1 / 0,5

1 / 27

Ø44

1 / 27

1 / 50

NO

B22

(Flue)

0,5 27

Ø44

27 50

NO

Page 54

Pag. 54 de 73

Manuale Didattico – ACO

Training manual :PIGMA Gal Evo

TYPE OF

EXHAUST

Length (L)

DIAPHRAME

[mm]

from [m]

to [m]

32

kW

60/100

COAXIAL

SYSTEMS

C12,C32,C42,

B32

0,5

0,75

Ø46

0,75 4

NO

80/125

COAXIAL

SYSTEMS

C12,C32,C42,

B32

0,5 2

Ø46

2 8

NO

80/80 SPLIT

SYSTEMS

C12, C32,C42

(Air/Flue)

0,5 / 0,5

9 / 9

Ø46

9 / 9

23 / 23

NO

C52,C82

(Air/Flue)

1 / 0,5

1 / 17

Ø46

1 / 17

1 / 23

NO

B22

(Flue)

1 17

Ø46

17 23

NO

Page 55

Pag. 55 de 73

Manuale Didattico – ACO

Training manual :PIGMA Gal Evo