Cessna 310 1975 Owner's Manual

'--"

'-'

~

'-'

Cessna®

___,·

'--"

MORE

PEOPLE

BUY

AND

'--'

FLY

CESSNA

AIRPLANES

~

THAN

ANY

OTHER

MAKE

'---"""

'--'

'--'

'--'

1975

WORLD'S

LARGEST

PRO-

DUCER

OF

GENERAL

AVIATION

AIRCRAFT

SINCE

1956

MODEL

310

OWNER'S

MANUAL

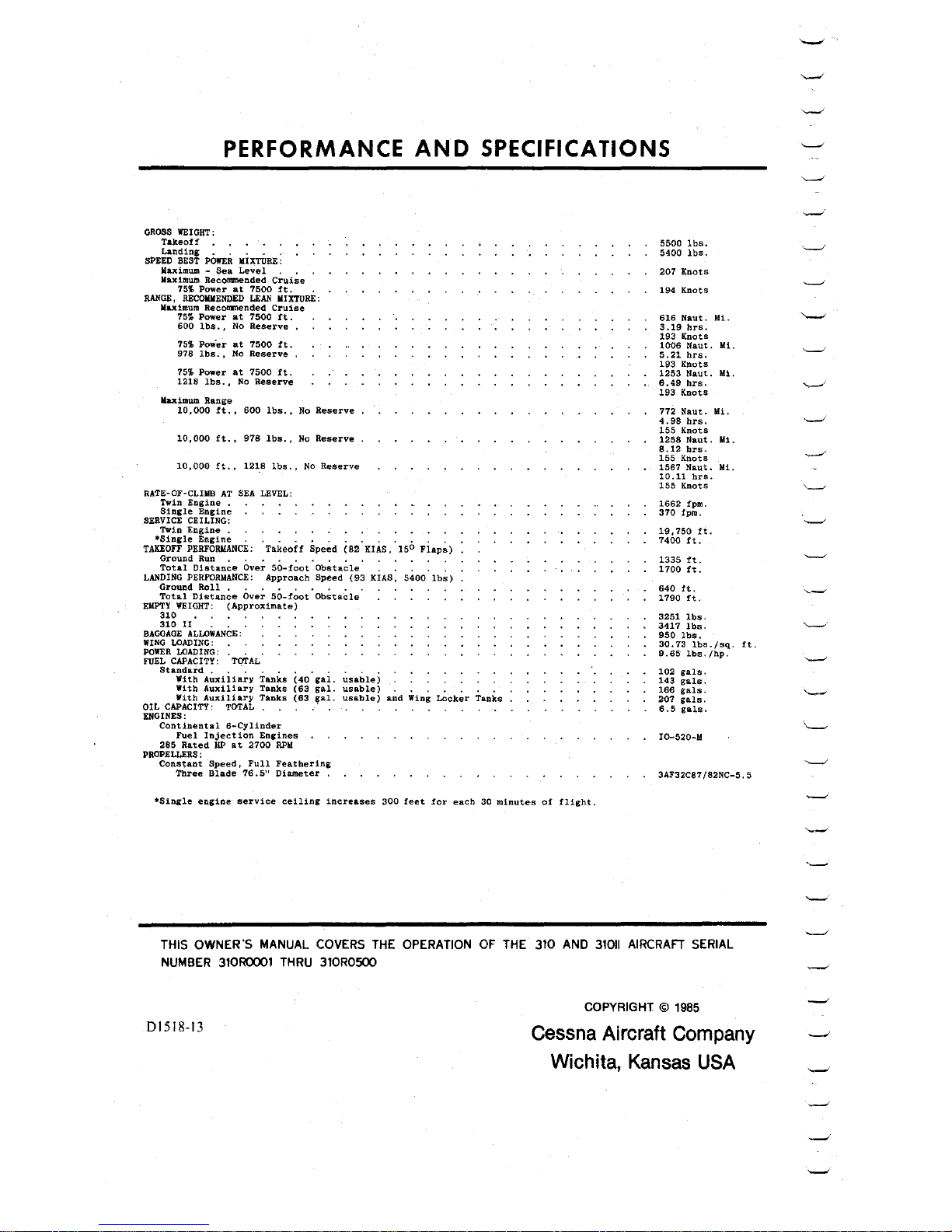

PERFORMANCE

AND

SPECIFICATIONS

GROSS

WEIGHT:

T&keoff

• • • • , •

La.nding . . . . .

SPEED BEST

POWER

MIXTURE:

Maximum -

Sea

Level

. ,

Maximum

Recommended

Cruise

75%

Power

at

7500

ft.

.

RANGE,

RECOMMENDED

LEAN

MIXTURE:

Maximum Recommended

Cruise

75%

Power

at

7500

ft.

600

lbs.

, No

Reserve

,

75'.£

Pow'er

at

7500

ft.

978

lbs.,

No

Reserve

,

75%

Power

at

7500

ft.

1218

lbs. , No

Reserve

Maximum Range

10,

000

ft.

,

600

lbs. , No

Reserve

10,000

ft.,

978

lbs.,

No

Reserve

10,000

ft.,

1218

lbs.,

No

Reserve

RATE-OF-CLHfB

AT

SEA

LEVEL:

Twin

Engine

. .

Single

Engine

.

SERVICE

CEILING:

Twin

Engine

.

TA~5;;i;E~~~~~cE:

·Takeoff

Spe~d

(s2

· KIAs, '150

Fiap~)

Ground

Run

. . . . . . , . .

Total

Distance

Over

50-foot

Obstacle

, .

LANDING

PERFORMANCE:

Approach

Speed

(93

KIAS,

5400

lbs)

Ground

Roll

, . . . , • . . .

Total

Distance

Over

50-foot

Obstacle

EMPTY

WEIGHT:

(Approximate}

310

310

II

. ,

BAGGAGE

ALLOWANCE:

WING

LOADING:

POWER

LOADING:

FUEL CAPACITY: TOTAL

Sta:~~~dA~xiiia~y

Tanks

(40°gai.

~sable)

With

Auxiliary

Tanks

(63

gal.

usable)

. . . . , . .

With

Auxiliary

Tanks

(63

gal.

usable)

and

Wing

Locker

Tanks

OIL

CAPACITY: TOTAL

ENGINES:

Continental

6-Cylinder

Fuel

Inject

ion

Engines

285

Rated

HP

at

2700

RPM

PROPELLERS :

Constant

Speed,

Full

Feathering

Three

Blade

76.

5"

Diameter

,

5500

lbs.

5400

lbs,

207

Knots

194

Knots

616

Naut.

Mi.

3.19

hrs.

193

Knots

1006

Naut.

Mi.

5.21

hrs.

193

Knots

1253

Na.ut.

Mi.

6.49

hrs.

193

Knots

772

Naut.

Mi.

4.98

hrs.

155

Knots

1258

Naut.

Mi.

8.12

hrs.

155

Knots

1567

Naut.

Mi,

10.11

hrs.

155

Knots

1662

fpm.

370

fpm.

19,750

ft.

7400

ft.

1335

ft.

1700

ft.

640

ft.

1790

ft.

3251

lbs.

3417

lbs.

950

lbs.

30.73

lbs./sq.

ft.

9.65

lbs.

/hp.

102

gals.

143

gals.

166

gals.

207

gals.

6.5

gals.

I0-520-M

3AF32C87

/82NC-5.

5

•Single

engine

service

ceiling

increases

300

feet

for

each

30

minutes

of

flight.

THIS OWNER'S MANUAL

COVERS

THE

OPERATION

OF

THE

310

AND

31011

AIRCRAFT

SERIAL

NUMBER

310R0001

THRU

310R0500

01518-13

COPYRIGHT ©

1985

Cessna Aircraft Company

Wichita, Kansas

USA

CONGRATULATIONS

...............

..

Welcome to

the

ranks

of

Cessna

owners!

Your

Cessna

has

been

designed

and

con-

structed

to

give

you

the

most

in

performance , economy,

and

comfort .

It

is

our

desire

that

you

will find

flying

it,

either

for

business

or

pleasure, a pleasant

and

profitable

experience.

This

Owner's

Manual

has

been

prepared

as a guide

to

help

you

get

the

most

pleas-

ure

and.utility

from

your

aircraft.

It

contains

information

about

your

Cessna's

equip-

ment,

operating

procedures,

and

performance;

and

suggestions

for

its

servicing

and

care.

We

urge

you

to

read

it

from

cover

to

cover,

and

to

refer

to it

frequently.

Our

interest

in

your

flying

pleasure

has

not

ceased

with

your

purchase

of a

Cessna.

Worldwide

the

Cessna

Dealer

Organization

backed

by

the

Cessna

Service

Department

stands

ready

to

serve

you.

The

following

services

are

offered

by

most

Cessna

Dealers:

THE

CESSNA WARRANTY --it

is

designed

to

provide

you

with

the

most

comprehen-

sive

coverage

possible:

a.

No

exclusions

b.

Coverage

includes

parts

and

labor

c.

Available

at

Cessna

Dealers

worldwide

d.

Best

in

the

industry

Specific

benefits

and

provisions

of

warranty

plus

other

important

benefits

for

you

are

contained

in

your

Customer

Care

Program

book

supplied

with

your

aircraft.

Warranty

service

is

available

to

you

at

any

authorized

Cessna

Dealer

throughout

the

world

upon

presentation

of

your

Customer

Care

Card

which

establishes

your

eligibility

under

the

warranty.

FACTORY TRAINED PERSONNEL

to

provide

you

with

courteous

expert

service.

FACTORY APPROVED SERVICE EQUIPMENT

to

provide

you

with

the

most

efficient

and

accurate

workmanship

possible.

A STOCK

OF

GENUINE CESSNA SERVICE PARTS

on

hand

when

you

need

them.

THE LATEST AUTHORITATIVE INFORMATION

FOR

SERVICING CESSNA AIRCRAFT,

since

Cessna

Dealers

have

all

of

the

Service

Manuals

and

Parts

Catalogs,

kept

cur-

rent

by

Service

Letters

and

Service

News

Letters,

published

by

Cessna

Aircraft

Company.

We

urge

all

Cessna

owners

to

use

the

Cessna

Dealer

Organization

to

the

fullest.

A

current

Cessna

Dealer

Directory

accompanies

your

new

aircraft.

The

Directory

is

revised

frequently,

and a current

copy

can

be

obtained

from

your

Cessna

Dealer.

Make

your

Directory

one

of

your

cross-country

flight

planning

aids; a warm

welcome

awaits

you

at

every

Cessna

Dealer.

i

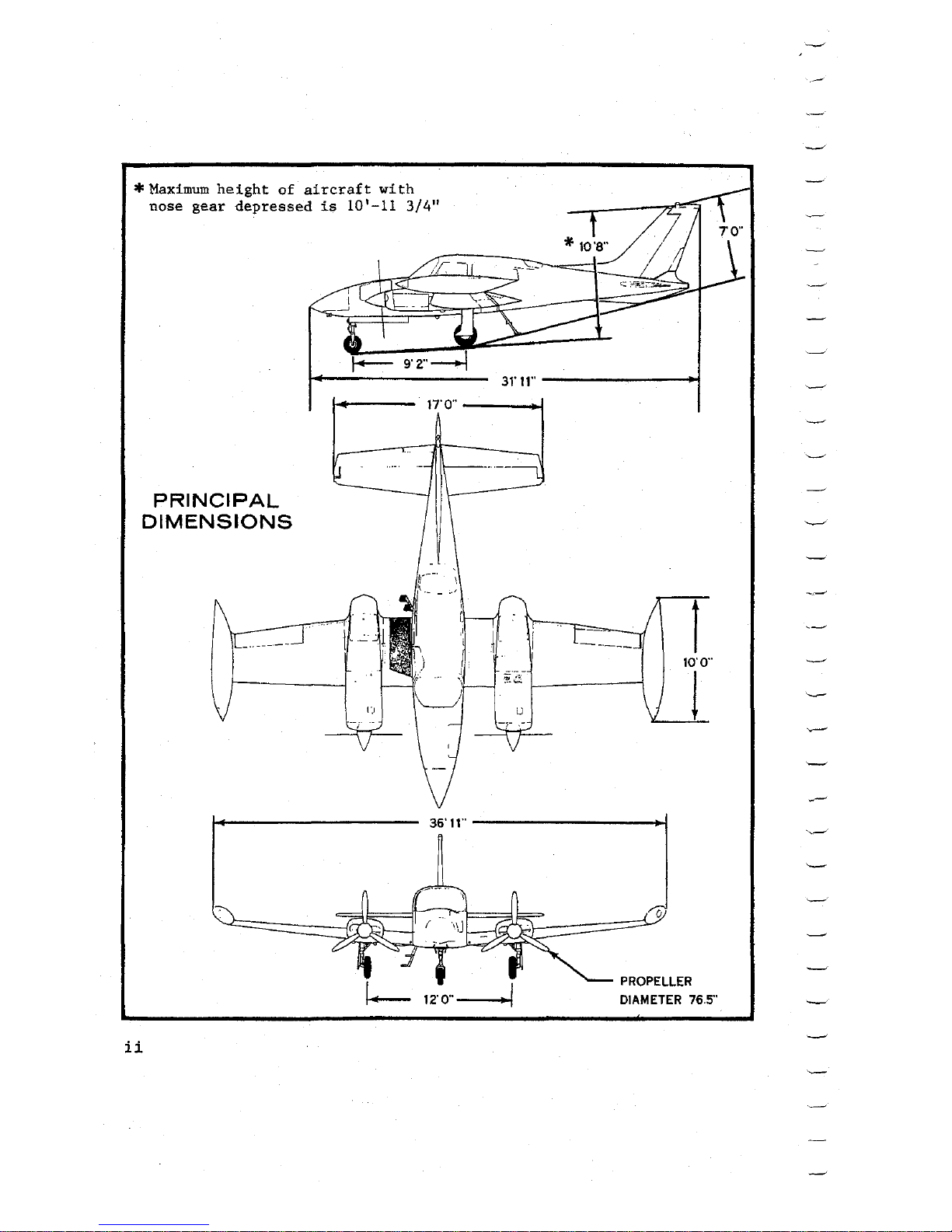

*Maximum

height

of

aircraft

with

nose

gear

depressed

is

10'-11

3/4"

31'

11''

---------..i

17'0"

----.!

PRINCIPAL

DIMENSIONS

ii

36'11"----------i

DIAMETER 76.5"

TABLE

OF

CONTENTS.

Page

SECTION I

- OPERATING CHECKLIST··················

1-1

SECTION

II

- DESCRIPTION

AND

OPERATING

DETAILS

.......................

2-1

SECTION

Ill

-

EMERGENCY

PROCEDURES

..........

3-1

SECTION

IV

- OPERATING LIMITATIONS ..........

4-1

SECTION

V - CARE OF

THE

AIRCRAFT

.............

5-1

OWNER

FOLLOW-UP

SYSTEM

.................

5-8

SECTION

VI

- OPERATIONAL

DATA

...................... 6-1

SECTION

VII

- OPTIONAL SYSTEMS* ..................... 7-1

ALPHABETICAL

INDEX

............................................

Index

- 1

*This

manual

describes

the

operation

and

performance

of

both

the

Cessna

310

and

310

lI

aircraft.

Equipment

described

as

"Optional"

de-

notes

that

the

subject

equipment

is

optional

on

the

310

aircraft.

Much

of

this

equipment

is

standard

on

the

310

II.

iii.

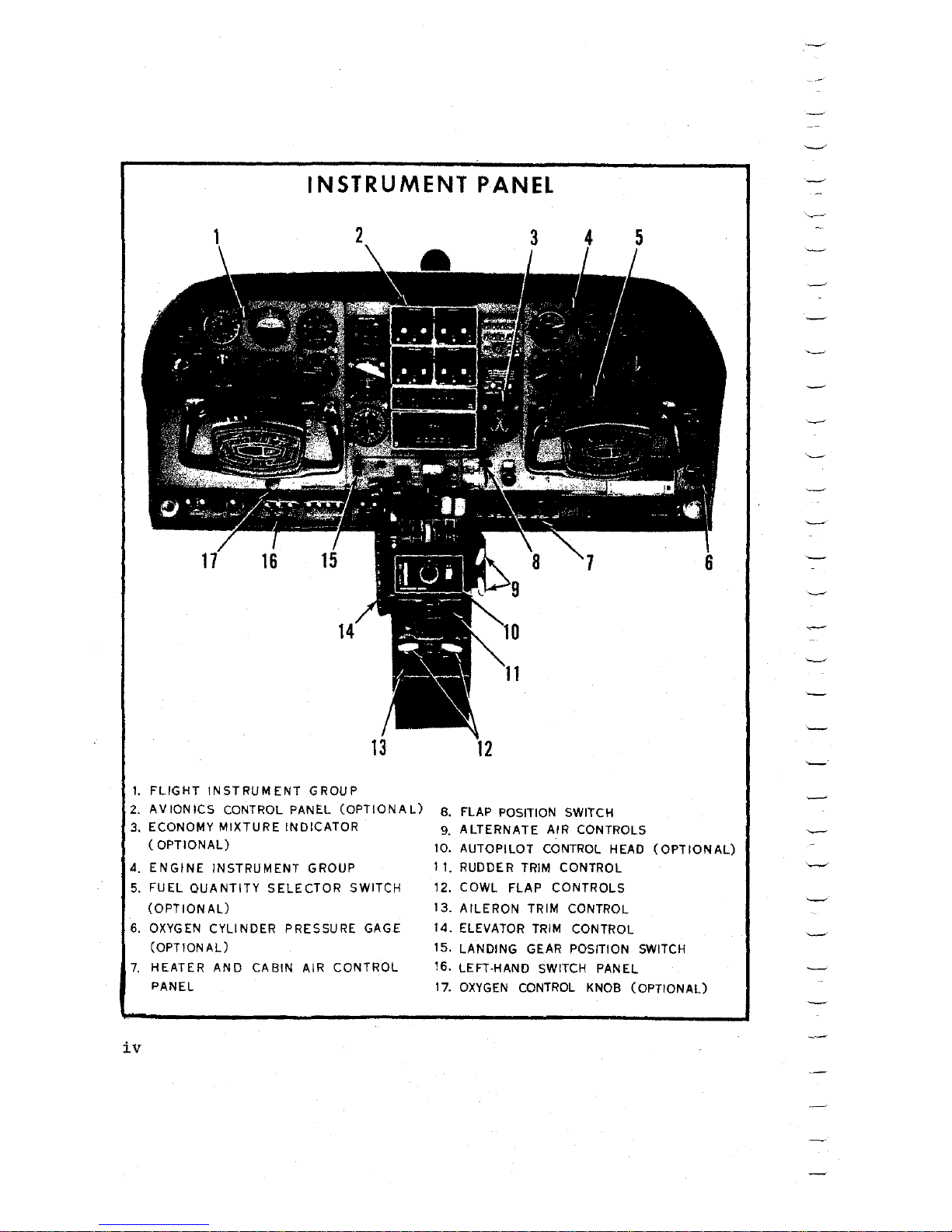

INSTRUMENT

PANEL

1.

FLIGHT

INSTRUMENT

GROUP

2.

AVIONICS

CONTROL PANEL

(OPTIONAL)

3.

ECONOMY

MIXTURE

INDICATOR

(OPTIONAL)

4.

ENGINE

INSTRUMENT

GROUP

5.

FUEL

QUANTITY

SELECTOR

SWITCH

(OPTIONAL)

6.

OXYGEN

CYLINDER

PRESSURE GAGE

(OPTIONAL)

7.

HEATER

AND

CABIN

AIR

CONTROL

PANEL

iv

12

8. FLAP POSITION SWITCH

9.

ALTERNATE

AIR

CONTROLS

10. AUTOPILOT CONTROL HEAD

(OPTIONAL)

11.

RUDDER TRIM CONTROL

12. COWL

FLAP

CONTROLS

13.

AILERON

TRIM CONTROL

14.

ELEVATOR TRIM CONTROL

15. LANDING GEAR POSITION SWITCH

16. LEFT-HAND SWITCH PANEL

17.

OXYGEN

CONTROL

KNOB

(OPTIONAL)

~~©lTD®~

0

OPERATING

CHECKLIST

One

of

the

first

steps

in

obtaining

the

utmost

perfor-

mance,

service,

and

flying

enjoyment

from

your

Cessna

is

to

familiarize

yourself

with

your

aircraft's

equipment,

systems,

and

controls.

This

can

best

be

done

by

reviewing

this

equip-

ment

while

sitting

in

the

aircraft.

Those

items

whose

func-

tion

and

operation

are

not

obvious

are

covered

in

Section

II.

Section

I

lists,

in

Pilot's

Checklist

form,

the

steps

necessary

to

operate

your

aircraft

efficiently

and

safely.

It

covers

briefly

all

the

points

that

you

should

know

con-

cerning

the

information

you

need

for a typical

flight.

The

flight

and

operational

characteristics

of

your

aircraft

are

normal

in

all

respects.

All

controls

respond

in

the

normal

way

within

the

entire

range

of

operation.

MAKE A PREFLIGHT

INSPECTION

IN

ACCORDANCE

WITH

FIGURE

1-1.

BEFORE

STARTING

THE

ENGINES

(1)

Preflight

Inspection

-

COMPLETE.

(2)

Control

Lock(s)

-

REMOVE.

(3)

Seats,

Seat

Belts

and

Shoulder

Harness -ADJUST

and

SECURE.

(4)

Brakes

-

TEST

and

SET.

(5)

Landing

Gear

Switch -DOWN.

(6)

Emergency

Alternator

Field

Switch

- OFF.

(7)

Emergency

Avionics

Power

Switch -OFF.

(8)

Avionics

Master

Switch -OFF.

(9)

Circuit

Breakers

- IN.

(10)

All

Switches

- OFF.

(11)

Battery

and

Alternators

-

ON.

1-1

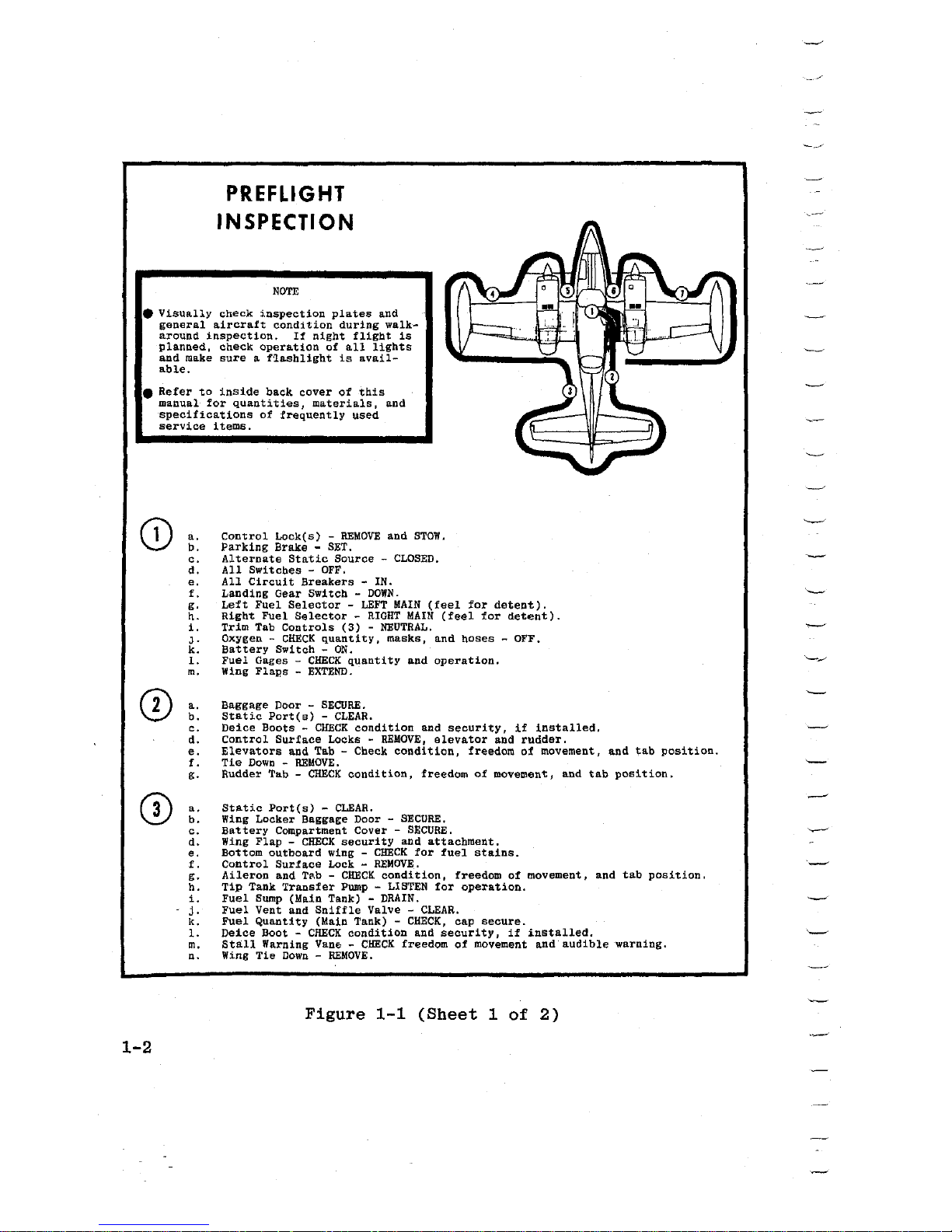

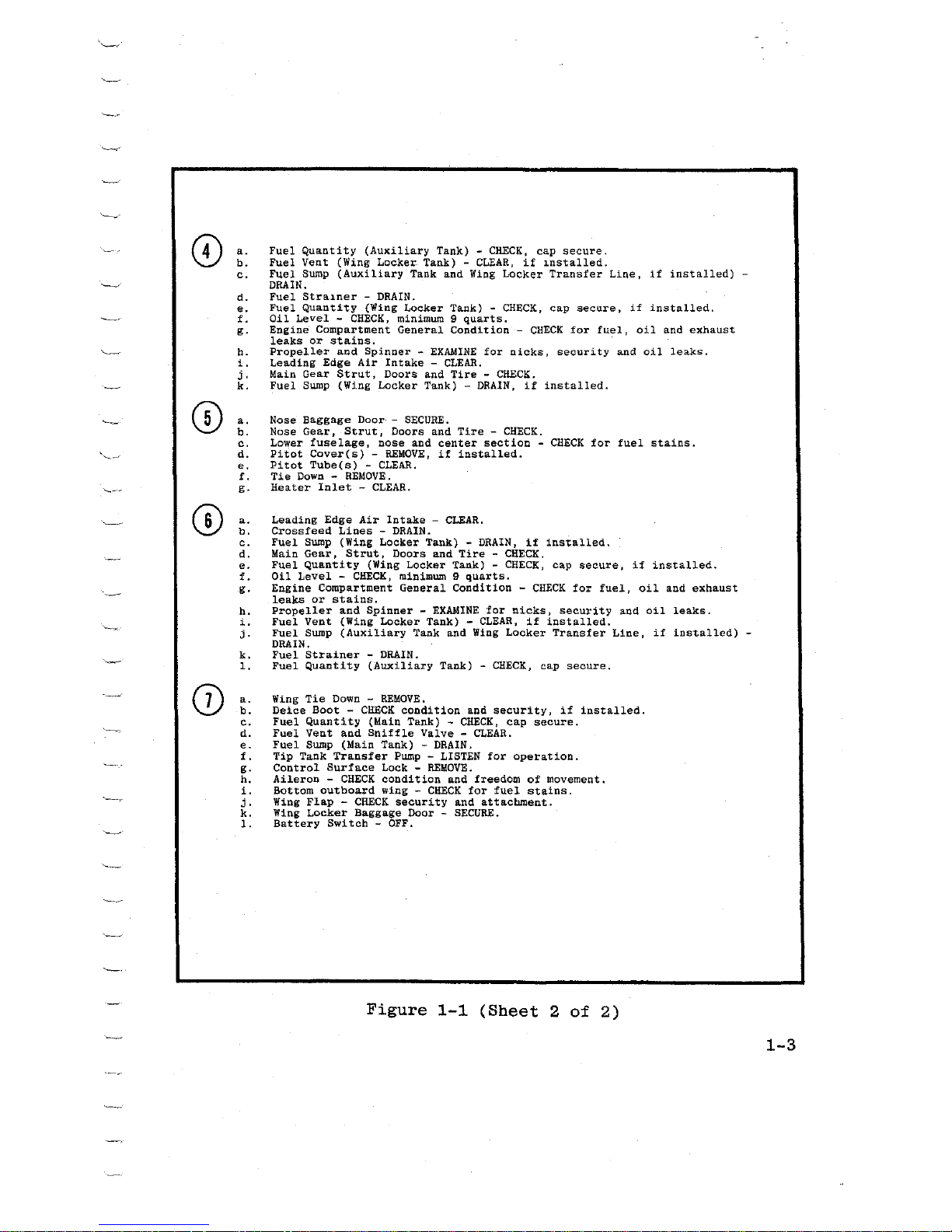

PREFLIGHT

INSPECTION

NOTE

e

Visually

check

inspection

plates

and

general

aircraft

condition

during

walk-

around

inspection.

If

night

flight

is

planned,

check

operation

of

all

lights

and

make

sure a flashlight

is

avail-

able.

e

Refer

to

inside

back

cover

of

this

manual

for

quantities,

materials,

and

specifications

of

frequently

used

service

items.

CD

a.

b.

c.

d.

e.

f.

g.

h.

i.

J.

k.

l.

m.

0

a.

b.

c.

d.

e.

f.

g.

0

a.

b.

c.

d.

e.

f.

g.

h.

i.

j.

k.

l.

m.

n.

1-2

Control

Lock(s) -REMOVE

and

STOW.

Parking

Brake

- SET.

Alternate

Static

Source -CLOSED.

All

Switches

- OFF.

All

Circuit

Breakers

- IN.

Landing

Gear

Switch -DOWN.

Left

Fuel

Selector -LEFT

MAIN

(feel

for

detent).

Right

Fuel

Selector -RIGHT

MAIN

(feel

for

detent).

Trim

Tab

Controls

(3) -NEUTRAL.

Oxygen -CHECK

quantity,

masks,

and

hoses -OFF.

Battery

Switch -ON.

Fuel

Gages -CHECK

quantity

and

operation.

Wing Fla11s -

EXTEND.

Baggage

Door -SECURE.

Static

Port(s) -CLEAR.

Deice

Boots -CHECK

condition

and

security,

if

installed.

Control

Surface

Locks -REMOVE,

elevator

and

rudder.

Elevators

and Tab - Check

condition,

freedom

of

movement, and

tab

position.

Tie

Down -REMOVE.

Rudder Tab -

CHECK

condition,

freedom

of

movement, and

tab

position.

Static

Port(s) -CLEAR.

Wing

Locker

Baggage

Door

- SECURE.

Battery

Compartment

Cover -SECURE.

Wing

Flap -CHECK

security

and

attachment.

Bottom

outboard

wing -CHECK

for

fuel

stains.

Control

Surface

Lock -

REMOVE.

Aileron

and

T~.b

-

CHECK

condition,

freedom

of

movement, and

tab

position.

Tip

Tank

Transfer

Pump - LISTEN

for

operation.

Fuel

Sump

(Main

Tank)

- DRAIN.

Fuel

Vent

and

Sniffle

Valve -CLEAR.

Fuel

Quantity

(Main

Tank) -CHECK,

cap

secure.

Deice

Boot -CHECK

condition

and

security,

if

installed.

Stall

Warning Vane -

CHECK

freedom

of

movement and

audible

warning.

Wing

Tie

Down -REMOVE.

Figure

1-1

(Sheet

1

of

2)

©

a.

b.

c.

d.

e.

f.

g.

h.

i.

j'

k.

®

a.

b.

c.

~~

d.

e.

f.

g.

©

a.

b.

c.

d.

e.

f.

g.

h.

i.

j.

k.

l,

(J)

a.

b.

c.

d.

e.

f.

g.

h.

i.

j.

k.

l.

Fuel

Quantity

(Au><iliary

Tank) -CH.ECK,

cap

secure.

Fuel

Vent

(Wing

Locker

Tank) -CLEAR,

if

installed.

Fuel

Sump

(Auxiliary

Tank

and

Wing

Locker

Transfer

Line,

if

installed)

-

DRAIN.

Fuel

Strainer

- DRAIN.

Fuel

Quantity

(Wing

Locker

Tank)

- CHECK,

cap

secure,

if

installed.

Oil

Level -CHECK,

minimum 9

quarts.

Engine

Compartment

General

Condition -CHECK

for

fuel,

oil

and

exhaust

leaks

or

stains.

Propeller

and

Spinner -EXAMINE

for

nicks,

security

and

oil

leaks.

Leading

Edge

Air

Intake -CLEAR.

Main

Gear

Strut,

Doors

and

Tire -CHECK.

Fuel

Sump

(Wing

Locker

Tank)

- DRAIN,

if

installed.

Nose

Baggage

Door

- SECURE.

Nose

Gear,

Strut,

Doors

and

Tire -CHECK.

Lower

fuselage,

nose

and

center

section -CHECK

for

fuel

stains.

Pitot

Cover(s) -REMOVE,

if

installed.

Pitot

Tube(s) -CLEAR.

Tie

Down -

REMOVE

.

Heater

Inlet

- CLEAR.

Leading

Edge

Air

Intake -CLEAR.

Cross

feed

Lines -DRAIN.

Fuel

Sump

(Wing

Locker

Tank)

- DRAIN,

if

installed,

Maio

Gea.r,

Strut 1 Doors

and

Tire -CHECK,

Fuel

Quantity

(Wing

Locker

Tank) -CHECK,

cap

secure,

if

installed.

Oil

Level -CHECK,

minimum 9

quarts.

Engine

Compartment

General

Condition -CHECK

for

fuel,

oil

and

exhaust

leaks

or

stains.

Propeller

and

Spinner -EXAMINE

for

nicks,

secu:ri

ty

and

oil

leaks.

Fuel

Vent

(Wing

Locker

Tank) -CLEAR,

if

installed.

Fuel

Swnp

(Auxiliary

Tank

and

Wing

Locker

Transfer

Line,

if

installed)

-

DRAIN.

Fuel

Strainer

- DRAIN.

Fuel

Quantity

(Auxiliary

Tank) -CHECKJ

cap

secure.

Wing

Tie

Down -

REMOVE.

Deice

Boot -CHECK

condition

and

security,

if

installed.

Fuel

Quantity

(Main

Tank) -CHECK,

cap

secure.

Fuel

Vent

and

Sniffle

Valve -CLEAR.

Fuel

Sump

(Main

Tank)

- DRAIN.

Tip

Tank

Transfer

Pump - LISTEN

for

operation.

Control

Surface

Lock -REMOVE.

Aileron -CHECK

condition

and

freedom

of

movement.

Bottom

outboard

wing -CHECK

for

fuel

stains.

Wing

Flap -CHECK

security

and

attachment.

Wing

Locker

Baggage

Door

- SECURE.

Battery

Switch

- OFF.

Figure

1-1

(Sheet

2

of

2)

1-3

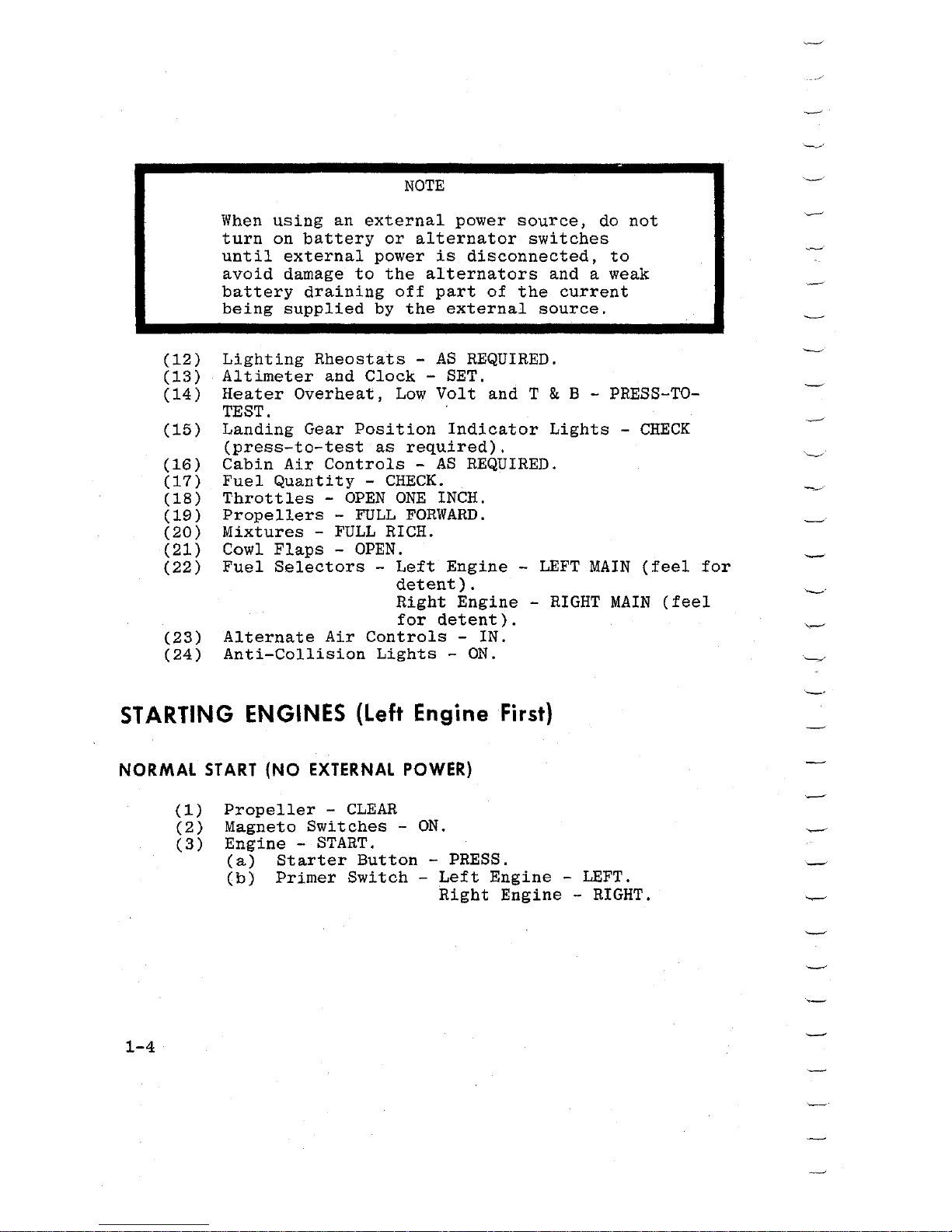

NOTE

When

using

an

external

power

source,

do

not

turn

on

battery

or

alternator

switches

until

external

power

is

disconnected,

to

avoid

damage

to

the

alternators

and a weak

battery

draining

off

part

of

the

current

being

supplied

by

the

external

source.

(12)

Lighting

Rheostats

-

AS

REQUIRED.

(13)

Altimeter

and

Clock

- SET.

(14)

Heater

Overheat,

Low

Volt

and T & B - PRESS-TO-

TEST.

(15)

(16)

(17)

(18)

(19)

(20)

(21)

(22)

(23)

(24)

Landing

Gear

Position

Indicator

Lights

-

CHECK

(press-to-test

as

required).

Cabin

Air

Controls

-

AS

REQUIRED.

Fuel

Quantity

-

CHECK.

Throttles

-

OPEN

ONE

INCH.

Propellers

-

FULL

FORWARD.

Mixtures

-

FULL

RICH.

Cowl

Flaps -OPEN.

Fuel

Selectors

-

Left

Engine -LEFT

MAIN

(feel

for

detent).

Right

Engine -RIGHT

MAIN

(feel

for

detent).

Alternate

Air

Controls

- IN.

Anti-Collision

Lights

-

ON.

STARTING

ENGINES

(Left

Engine

First}

NORMAL

ST

ART

(NO

EXTERNAL

POWER)

1-4

(1)

Propeller

-

CLEAR

(2)

Magneto

Switches

-

ON.

(3)

Engine -START.

(a)

Starter

Button

- PRESS.

(b)

Primer

Switch -Left

Engine -LEFT.

Right

Engine -RIGHT.

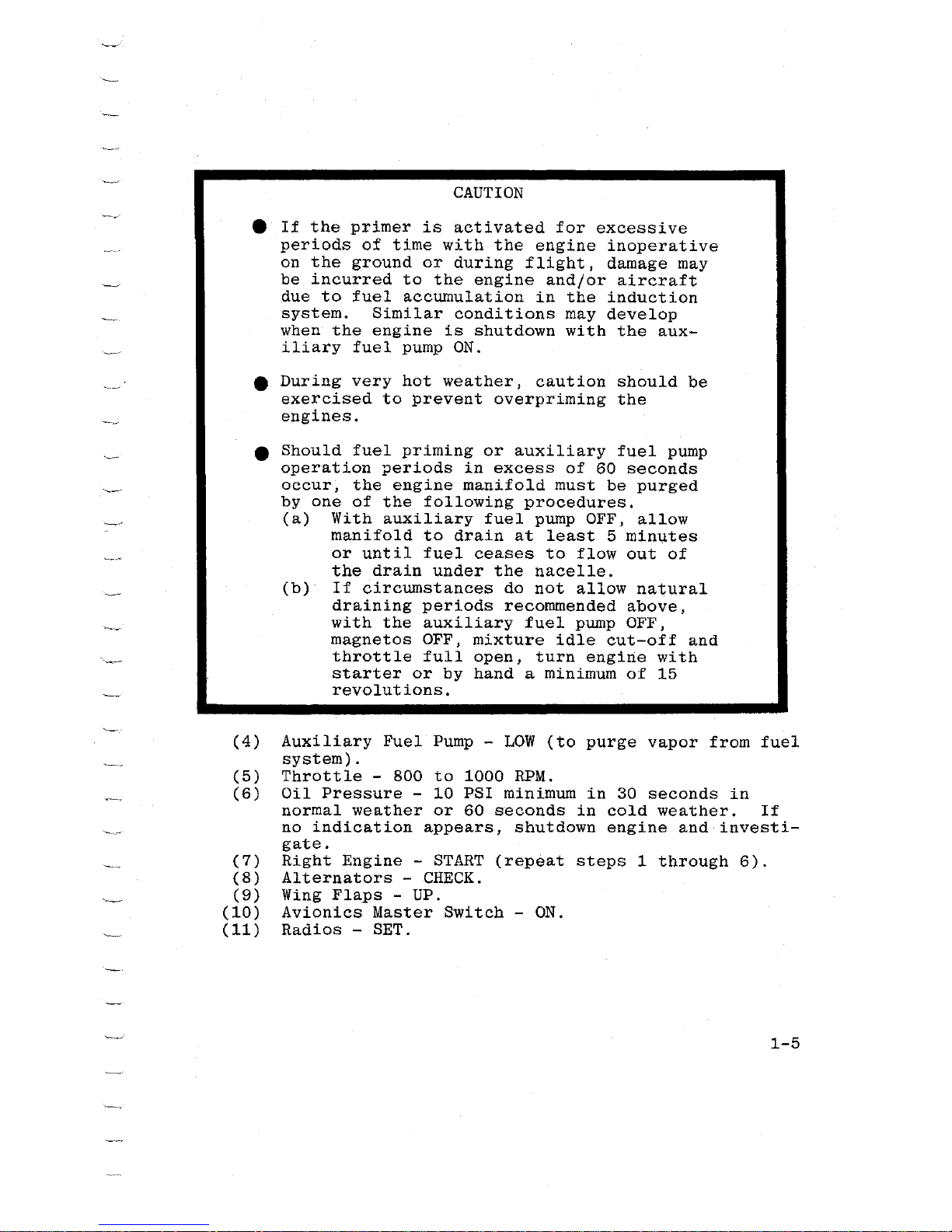

CAUTION

e

If

the

primer

is

activated

for

excessive

periods

of

time

with

the

engine

inoperative

on

the

ground

or

during

flight,

damage may

be

incurred

to

the

engine

and/or

aircraft

due

to

fuel

accumulation

in

the

induction

system.

Similar

conditions

may

develop

when

the

engine

is

shutdown

with

the

aux-

iliary

fuel

pump

ON.

e

During

very

hot

weather,

caution

should

be

exercised

to

prevent

overpriming

the

engines.

e

Should

fuel

priming

or

auxiliary

fuel

pump

operation

periods

in

excess

of

60

seconds

occur,

the

engine

manifold

must

be

purged

by

one

of

the

following

procedures.

(a)

With

auxiliary

fuel

pump OFF,

allow

manifold

to

drain

at

least

5

minutes

or

until

fuel

ceases

to

flow

out

of

the

drain

under

the

nacelle.

(b)

If

circumstances

do

not

allow

natural

draining

periods

recommended

above,

with

the

auxiliary

fuel

pump OFF,

magnetos

OFF,

mixture

idle

cut-off

and

throttle

full

open,

turn

engine

with

starter

or

by

hand

a minimum

of

15

revolutions.

(4)

Auxiliary

Fuel

Pump -LOW

(to

purge

vapor

from

fuel

system).

(5)

Throttle

- 800

to

1000

RPM.

(6)

Oil

Pressure

-

10

PSI

minimum

in

30

seconds

in

normal

weather

or

60

seconds

in

cold

weather.

If

no

indication

appears,

shutdown

engine

and

investi-

gate.

(7)

Right

Engine -START

(repeat

steps

1

through

6).

(8)

Alternators

-

CHECK.

(9)

Wing

Flaps

- UP.

(10)

Avionics

Master

Switch -ON.

(11)

Radios

- SET.

1-5

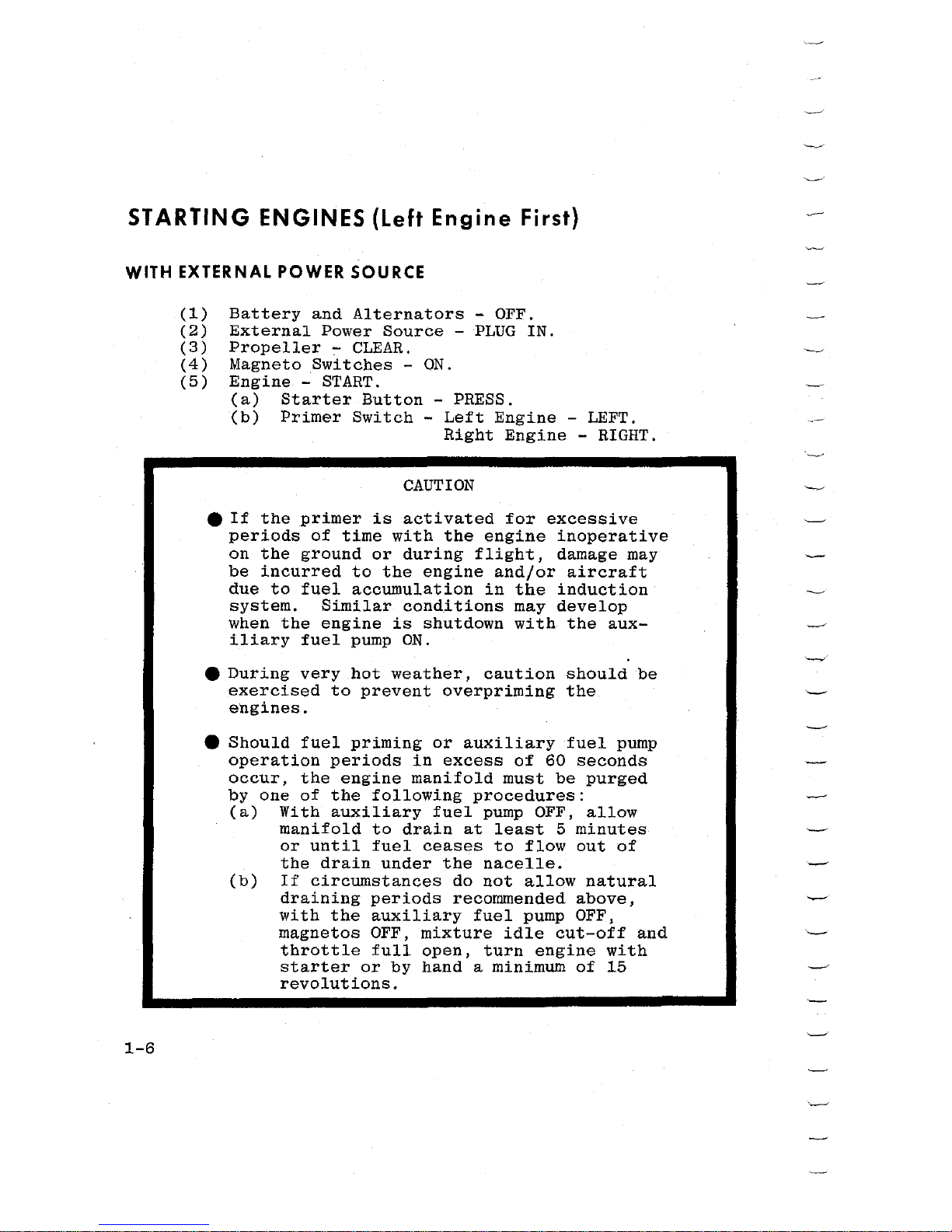

STARTING ENGINES {Left Engine First)

WITH EXTERNAL POWER SOURCE

1-6

(1)

Battery

and

Alternators

- OFF.

(2)

External

Power

Source -PLUG

IN.

(3)

Propeller

-

CLEAR.

(4)

Magneto

Switches

-

ON.

(5)

Engine -START.

(a)

Starter

Button

- PRESS.

(b)

Primer

Switch -Left

Engine

- LEFT.

Right

Engine -RIGHT.

CAUTION

e

If

the

primer

is

activated

for

excessive

periods

of

time

with

the

engine

inoperative

on

the

ground

or

during

flight,

damage

may

be

incurred

to

the

engine

and/or

aircraft

due

to

fuel

accumulation

in

the

induction

system.

Similar

conditions

may

develop

when

the

engine

is

shutdown

with

the

aux-

iliary

fuel

pump

ON.

e

During

very

hot

weather,

caution

should

be

exercised

to

prevent

overpriming

the

engines.

e

Should

fuel

priming

or

auxiliary

fuel

pump

operation

periods

in

excess

of

60

seconds

occur,

the

engine

manifold

must

be

purged

by

one

of

the

following

procedures:

(a)

With

auxiliary

fuel

pump

OFF,

allow

manifold

to

drain

at

least

5

minutes

or

until

fuel

ceases

to

flow

out

of

the

drain

under

the

nacelle.

(b)

If

circumstances

do

not

allow

natural

draining

periods

recommended

above,

with

the

auxiliary

fuel

pump OFF,

magnetos

OFF,

mixture

idle

cut-off

and

throttle

full

open,

turn

engine

with

starter

or

by

hand

a minimum

of

15

revolutions.

(6)

Auxiliary

Fuel

Pwnp -

LOW

(to

purge

vapor

from

fuel

system).

(7)

Throttle

-

800

to

1000

RPM.

{8)

Oil

Pressure

-

10

PSI

minimum

in

30

seconds

in

normal

weather

or

60

seconds

in

cold

weather.

If

no

indication

appears,

shutdown

engine

and

investi-

gate.

(9)

Right

Engine -START

(repeat

steps

3

through

8).

(10)

External

Power

Source -UNPLUG.

(11)

Battery

and

Alternators

-

ON.

(12)

Alternators

-

CHECK.

(13)

Wing

Flaps

- UP.

(14)

Avionics

Master

Switch -ON.

(15)

Radios

- SET.

BEFORE

TAKEOFF

(1)

Brakes

- SET.

(2)

Engine

Runup:

(a)

Throttles

-

1700

RPM.

(b)

Alternators

-

CHECK.

(c)

Magnetos -CHECK

(150

RPM

maximum

drop

with

a

maximum

differential

of

50

RPM).

(d)

Propellers

-

CHECK

feathering

to

1200

RPM;

return

to

high

RPM

(full

forward

position).

(e)

Engine

Instruments

-

CHECK

green

arc.

(f)

Vacuum

System -CHECK

(4.75

to

5.25

inches

Hg.).

(g)

Throttles

-

1000

RPM.

NOTE

It

is

important

that

the

engine

oil

temp-

erature

be

within

the

normal

operating

range

prior

to

applying

takeoff

power.

(3)

Flight

Controls

-

CHECK

free

and

correct.

(4)

Trim

Tabs

- SET.

(5)

Cowl

Flaps -OPEN.

(6)

Alternate

Air

Controls

-

Check

IN.

(7)

Fuel

Selectors

-

RECHECK -Left

Engine -LEFT

MAIN

(feel

for

detent).

Right

Engine -RIGHT

MAIN

(feel

for

detent).

1-7

(8)

Wing

Flaps

-

UP.

(9)

Cabin

Door and

Window -CLOSED

and

LOCKED.

(10)

Fuel

Quantity

-

CHECK.

(11)

If

Electric

Gyro

Horizon

is

installed,

Gyro

Hori-

zon -PULL

to

erect.

(12)

Flight

Instruments

and

Radios

- SET.

(13)

Lights

-

AS

REQUIRED.

(14)

Auxiliary

Fuel

Pumps ~ ON.

(15)

Brakes -RELEASE.

TAKEOFF

NORMAL

TAKEOFF

1-8

(1)

Power -

FULL

THROTTLE

and

2700

RPM.

NOTE

Apply

full

throttle

smoothly

to

avoid

propeller

surging.

(2)

Mixtures

-

LEAN

for

field

elevation.

NOTE

Leaning

during

the

takeoff

roll

at

low

altitudes

is

normally

not

necessary

for

smooth

engine

operation;

however,

fuel

flows

should

be

adjusted

to

match

field

elevation

to

obtain

maximum

aircraft

performance.

(3)

Elevator

Control

-

Raise

nosewheel

at

83 KIAS.

(4)

Minimum

Control

Speed

- 81 KIAS.

(5)

Break

Ground

at

92 KIAS.

MAXIMUM PERFORMANCE

TAKEOFF

(1)

Wing

Flaps

-

DOWN

15°.

NOTE

Apply

full

throttle

smoothly

to

avoid

propeller

surging.

(2)

Power -

FULL

THROTTLE

and

2700

RPM.

NOTE

Leaning

during

the

takeoff

roll

at

low

altitudes

is

normally

not

necessary

for

smooth

engine

operation;

however,

fuel

flows

should

be

adjusted

to

match

field

elevation

to

obtain

maximum

aircraft

performance.

(3)

Mixtures

-

LEAN

for

field

elevation.

(4)

Elevator

Control

-

Raise

nosewheel

at

70

KIAS.

(5)

Minimum

Control

Speed

-

81

KIAS.

(6)

Break

Ground

at

82

KIAS -Hold

speed

until

all

obstacles

are

cleared.

AFTER

TAKEOFF

(1)

Brakes

-

APPLY

momentarily.

(2)

Landing

Gear -RETRACT

(check

red

light

OFF).

(3)

Wing

Flaps

-

UP

(after

obstacles

are

cleared

if

maximum

performance

takeoff)

(4)

Climb

Speed

-

107

KIAS

(multi-engine

best

rate-of-

climb

speed).

(5)

Auxiliary

Fuel

Pumps - OFF.

1-9

CLIMB

NORMAL

CLIMB

(1)

Power -24.5

inches

Hg. and 2500

RPM.

(2)

Airspeed

-

115-130

KIAS.

(3)

Mixtures

-

ADJUST

to

climb

fuel

flow.

(4)

Cowl

Flaps -AS

REQUIRED.

(5)

Auxiliary

Fuel

Pumps -

ON

(above

12,000

feet

alti-

tude

to

minimize

vapor

formation).

NOTE

During

very

bot

weather,

if

there

is

an

indication

of

vapor

in

the

fuel

system

(fluctuating

fuel

flow)

or

anytime

when

climbing

above

12,000

feet,

turn

the

aux-

iliary

fuel

pumps

ON

until

cruising

alti-

tude

has

been

obtained

and

the

system

is

purged

(usually

5

to

15

minutes

after

establishing

cruising

flight).

MAXIMUM PERFORMANCE

CLIMB

1-10

(1)

Power -FULL

THROTTLE

and

2700

RPM.

(2)

Airspeed

- 107

KIAS

at

sea

level;

99

KIAS

at

10,000

feet.

(3)

Mixtures

-

ADJUST

for

altitude

and

power.

(4)

Cowl

Flaps

-

AS

REQUIRED.

(5)

Auxiliary

Fuel

Pumps -

ON

(above

12,000

feet

alti-

tude

to

minimize

vapor

formation).

NOTE

During

very

hot

weather,

if

there

is

an

indication

of

vapor

in

the

fuel

system

(fluctuating

fuel

flow)

or

anytime

when

climbing

above

12,000

feet,

turn

the

aux-

iliary

fuel

pumps

ON

until

cruising

altitude

has

been

obtained

and

the

system

is

purged

(usually

5

to

15

minutes

after

establishing

cruising

flight).

It

is

recommended

that

the

mixture

remain

at

the

climb

mixture

setting

for

approximately

5

minutes

after

establishing

cruising

flight

before

leaning

is

initiated.

CRUISING

(1)

Cruise

Power -15

to

24.5

inches

Hg.

and

2100

to

2500

RPM

(2)

Mixtures

-

LEAN

for

desired

cruise

fuel

flow

as

determined

from

your

power

computer.

Recheck

mixtures

if

power,

altitude

or

OAT

changes.

(3)

Cowl

Flaps

-

AS

REQUIRED.

(4)

Fuel

Selectors

-

Left

Engine -LEFT

MAIN

(feel

for

detent).

Right

Engine -RIGHT

MAIN

(feel

for

detent).

(a)

If

optional

40

gallon

auxiliary

tanks

are

installed,

fuel

selectors

-

MAIN

TANKS

for

60

minutes.

(b)

If

optional

63

gallon

auxiliary

tanks

are

installed,

fuel

selectors

-

MAIN

TANKS

for

90

minutes.

(c)

Usable

auxiliary

fuel

quantity

is

based

on

level

flight.

(d)

If

wing

locker

tanks

are

installed,

fuel

selectors

-

MAIN

TANKS

or,

after

wing

locker

tanks

are

transferred

and

main

tank

quantity

is

less

than

180

pounds

each -AUXILIARY

TANKS.

1-11

NOTE

e

Turn

auxiliary

fuel

pumps

to

LOW

and

mix-

tures

to

FULL

RICH

when

switching

tanks.

e The

auxiliary

fuel

tanks

are

to

be

used

in

cruise

flight

only.

(e)

If

wing

locker

tanks

are

installed,

cross-

feed -SELECT

as

required

to

maintain

fuel

balance

after

wing

locker

tank

fuel

transfer.

(4)

Trim

Tabs -ADJUST.

LETDOWN

(1)

Power -

AS

REQUIRED.

(2)

Mixtures

-

ADJUST

for

smooth

operation

with

gradual

enrichment

as

altitude

is

lost.

(3)

Cowl

Flaps

-

AS

REQUIRED.

BEFORE

LANDING

1-12

(1)

Fuel

Selectors

-

Left

Engine -LEFT

MAIN

(feel

for

detent).

Right

Engine -RIGHT

MAIN

(feel

for

detent).

(2)

Auxiliary

Fuel

Pumps -

ON.

(3)

Cowl

Flaps -AS

REQUIRED.

(4)

Alternate

Air

Controls

-

Check

IN.

(5)

Mixtures

-

AS

REQUIRED

for

smooth

operation.

(6)

Propellers

-

FULL

FORWARD.

(7)

Wing

Flaps -DOWN

15°

below

160

KCAS.

(8)

Landing

Gear -DOWN

below

140

KCAS.

(9)

Landing

Gear

Position

Indicator

Lights

-

CHECK

down

lights

ON;

unlocked

light

- OFF.

(10)

Wing

Flaps -DOWN

15°

to

35o

below

140

KCAS.

(11)

Minimum

Multi-Engine

Approach

Speed

- 93 KIAS.

(12)

Minimum

Single-Engine

Control

Speed

- 81 KIAS.

LANDING

(1)

Touchdown

-

Main

wheels

first.

(2)

Landing

Roll

-

Lower

nosewheel

gently.

(3)

Brakes

-

AS

REQUIRED.

GO-AROUND

(Multi-Engine)

(1)

Increase

engine

speed

to

2700

RPM

and

apply

full

throttle

if

necessary.

(2)

Reduce

flaps

setting

to

15°

(3)

Trim

aircraft

for

climb.

(4)

Cowl

Flaps

- OPEN.

(5)

Retract

wing

flaps

as

soon

as

all

obstacles

are

cleared

and a safe

altitude

and

airspeed

are

ob-

tained.

NOTE

Do

not

retract

landing

gear

if

another

landing

approach

is

to

be

conducted.

AFTER

LANDING

(1)

Auxiliary

Fuel

Pumps -LOW

(during

landing

roll).

(2)

Cowl

Flaps

- OPEN.

(3)

Wing

Flaps

- UP.

SECURE AIRCRAFT

(1)

Auxiliary

Fuel

Pumps

- OFF.

(2)

Avionics

Master

Switch

- OFF.

(3)

All

Switches

except

Battery,

Alternator

and

Magneto

Switches

- OFF.

(4)

Throttles

- IDLE.

(5)

Mixtures

- IDLE CUT-OFF.

1-13

1-14

(6)

Fuel

Selectors

-

OFF

(if

a

long

period

of

inactivi-

ty

is

anticipated).

NOTE

Do

not

leave

the

fuel

selectors

in

the

intermediate

position

as

fuel

from

the

main

tip

tanks

will

transfer

into

the

auxiliary

tanks.

(7)

Magnetos

Switches

- OFF,

after

engines

stop.

(8)

Battery

and

Alternators

- OFF.

(9)

Parking

Brake

- SET.

(10)

Control

Lock(s)

-

INSTALL.

(11)

Cabin

Door -

CLOSE.

NOTE

To

securely

latch

the

cabin

door

from

the

outside,

the

exterior

door

handle

must

be

rotated

clockwise

to

its

stop.

~~©LFD®~

DD

DESCRIPTION AND

OPERATING

DETAILS

The

following

paragraphs

supply

a

general

description

of

some

systems

and

equipment

in

the

aircraft.

This

section

also

covers,

in

somewhat

greater

detail,

some

of

the

items

in

Checklist

Form

in

Section

I.

Only

those

items

of

the

Check-

list

requiring

further

explanation

will

be

covered

here.

PREFLIGHT INSPECTION

The

preflight

inspection,

described

in

Section

I,

is

recommended

for

the

first

flight

of

the

day.

Inspection

procedures

for

subsequent

flights

are

normally

limited

to

brief

checks

of

the

tail

surface

hinges,

fuel

and

oil

quanti-

ty,

and

security

of

fuel

and

oil

filler

caps.

If

the

air-

craft

has

been

in

extended

storage,

has

had

recent

major

maintenance,

or

has

been

operated

from

marginal

airports,

a

more

extensive

preflight

inspection

is

recommended.

After

major

maintenance

has

been

performed,

the

flight

and

trim

tab

controls

should

be

double-checked

for

free

and

correct

movement

and

security.

The

security

of

all

inspection

plates

on

the

aircraft

should

be

checked

following

periodic

inspection.

Since

radio

maintenance

requires

the

mechanic

to

work

in

the

forward

nose

compartment,

the

nose

cap

is

removed

for

access

to

equipment.

Therefore,

it

is

important

after

such

maintenance

to

double-check

the

security

of

the

nose

cap.

If

the

aircraft

has

been

waxed

or

polished,

check

the

external

static

pressure

source

holes

for

stoppage.

If

the

aircraft

has

been

exposed

to

much

ground

handling

in a crowded

hangar,

it

should

be

checked

for

dents

and

scratches

on

wings,

tip

tanks,

fuselage,

and

tail

surfaces,

as

well

as

damage

to

navigation

and

landing

lights,

deice

boots,

and

radio

antenna.

Outside

storage

for

long

periods

may

result

in

water

and

obstructions

in

airspeed

system

lines,

condensation

in

fuel

tanks,

and

dust

and

dirt

on

the

intake

air

filters

and

engine

cooling

fins.

Outside

storage

in

windy

or

gusty

areas,

or

adjacent

to

taxiing

aircraft

2-1

calls

for

special

attention

to

control

surface

stops,

hinges

and

brackets

to

detect

the

presence

of

wind

damage.

If

the

aircraft

has

been

operated

from

muddy

fields

or

in

snow

and

slush,

check

the

main

gear

wheel

and

nose

gear

wheel

wells

for

obstructions

and

cleanliness.

Operation

from

a

gravel

or

cinder

field

will

require

extra

attention

to

propeller

tips

and

abrasion

on

leading

edges

of

the

horizon-

tal

tail.

Stone

damage

to

the

outer

six

inches

of

the

pro-

peller

tips

can

seriously

reduce

the

fatigue

life

of

the

blades.

Aircraft

that

are

operated

from

rough

fields,

especially

at

high

altitudes,

are

subjected

to

abnormal

landing

gear

abuse.

Check

frequently

all

components

of

the

landing

gear

retracting

mechanisms,

shock

struts,

tires

and

brakes.

Undue

landing

and

taxi

loads

will

be

subjected

on

the

aircraft

structure

when

the

shock

struts

are

insufficiently

extended.

A

completely

collapsed

(zero

extension)

shock

strut

could

cause a malfunction

in

the

landing

gear

retraction

system.

To

prevent

loss

of

fuel

in

flight,

make

sure

main

and

auxiliary

fuel

tank

filler

caps

are

tightly

sealed.

The

main

fuel

tank

vents

beneath

the

tip

tanks

should

also

be

inspect-

ed

for

obstructions,

ice

or

water,

especially

after

operation

in

cold,

wet

weather.

The

interior

inspection

will

vary

according

to

the

mission

and

the

optional

equipment

installed.

Prior

to

high-

altitude

flights,

it

is

important

to

check

the

condition

and

quantity

of

oxygen

face

masks

and

hose

assemblies.

The

oxygen

supply

system

should

be

functionally

checked

to

insure

that

it

is

in

working

order.

The

oxygen

pressure

gage

should

indicate

between

300

and

1800

PSI

depending

upon

the

antici-

pated

requirements.

Satisfactory

operation

of

the

pitot

tube,

stall

warning

transmitter

and

fuel

tank

vent

heating

elements

is

determined

by

observing

a

discharge

on

the

ammeter when

the

pitot

heat

and

stall

vent

heat

switches

are

turned

ON.

The

effective-

ness

of

these

heating

elements

may

be

verified

by

cautiously

feeling

the

heat

of

these

devices

while

the

switches

are

ON.

Flights

at

night

and

in

cold

weather

involve

a

careful

check

of

other

specific

areas

which

will

be

discussed

later

in

this

section.

2-2

STARTING

ENGINES

The

left

engine

is

normally

started

first

because

the

cable

from

the

battery

to

this

engine

is

much

shorter

permit-

ting

more

electrical

power

to

be

delivered

to

the

starter.

If

battery

is

low,

the

left

engine

should

start

more

readily.

When

using

an

external

power

source,

it

is

recommended

to

start

the

aircraft

with

the

battery

and

alternator

switch-

es

OFF.

NOTE

Release

starter

switch

as

soon

as

engine

fires

or

engine

will

not

accelerate

and

flooding

can

result.

The

continuous

flow

fuel

injection

system

will

start

spraying

fuel

in

the

engine

intake

ports

as

soon

as

the

primer

switch

is

actuated

and

the

throttle

and

mixture

con-

trols

are

opened.

If

the

auxiliary

pump

is

turned

on

acci-

dentally

while

the

engine

is

stopped,

with

the

throttle

open

and

the

mixture

rich,

liquid

fuel

will

collect

temporarily

in

the

cylinder

intake

ports.

The

quantity

of

fuel

collected

will

depend

upon

the

amount

of

throttle

opening

and

the

length

of

time

the

pump

has

been

operating.

If

this

happens,

it

is

advisable

to

wait

a few

minutes

until

the

fuel

drains

away,

then

turn

the

propeller

through

15

complete

revolu-

tions.

This

is

done

to

prevent

the

possibility

of

engine

damage due

to

hydrostatic

lock

before

starting

the

engine.

To

avoid

flooding,

begin

cranking

the

engine

prior

to

priming

the

engine.

NOTE

Caution

should

be

exercised

to

prevent

overpriming

the

engine

in

hot

weather.

Engine

mis-starts

characterized

by

weak,

intermittent

explosions,

followed

by

black

puffs

of

smoke

from

the

exhaust

are

the

result

of

flooding

or

overpriming.

This

situation

is

more

apt

to

develop

in

hot

weather,

or

when

the

engines

are

2-3

hot.

If

it

occurs,

repeat

the

starting

procedure

with

the

throttle

approximately

1/2

open,

the

mixture

in

IDLE

CUT-OFF

and

the

primer

switch

OFF.

As

the

engine

fires,

move

the

mixture

control

to

FULL

RICH

and

close

the

throttle

to

idle.

If

an

engine

is

underprimed,

as

may

occur

in

cold

wea-

ther

with a cold

engine,

repeat

the

starting

procedure

while

holding

the

primer

switch

on

for

5

to

10

seconds

until

the

engine

fires.

If

cranking

longer

than

30

seconds

is

required,

allow

starter-motor

to

cool

five

minutes

before

cranking

again,

since

excessive

heat

may damage

the

armature

windings.

After

the

engines

are

started,

the

auxiliary

fuel

pumps

should

be

switched

to

LOW

to

provide

for

improved

purging

and

vapor

clearing

in

the

fuel

system.

TAXIING

A

steerable

nosewheel,

interconnected

with

the

rudder

system,

provides

positive

control

up

to

1s

0

left

or

right,

and

free

turning

from

18°

to

55°

for

sharp

turns

during

taxiing.

Normal

steering

may

be

aided

through

use

of

dif-

ferential

power

and

differential

braking

on

the

main

wheels.

These

aids

are

listed

in

the

preferred

order

of

use.

NOTE

If

the

aircraft

is

parked

with

the

nosewheel

castered

in

either

direction,

initial

taxi-

ing

should

be

done

with

caution.

To

straight-

en

the

nosewheel,

use

full

opposite

rudder

and

differential

power

instead

of

differen-

tial

braking.

After

a few

feet

of

forward

travel,

the

nosewheel

will

steer

norm~lly.

At some

time

early

in

the

taxi

run,

the

brakes

should

be

tested,

and

any

unusual

reaction,

such

as

uneven

braking,

should

be

noted.

If

brake

operation

is

not

satisfactory,

the

aircraft

should

be

returned

to

the

tie-down

location

and

the

malfunction

corrected.

The

operation

of

the

turn-and-bank

indicator

and

directional

gyro

should

also

be

checked

during

taxiing.

2-4

Most

of

the

engine

warm-up

should

be

done

during

taxi-

ing,

with

just

enough

power

to

keep

the

aircraft

moving.

Engine

speed

should

not

exceed

1000

RPM

while

the

oil

is

cold.

BEFORE

TAKEOFF

(Use

the Pilot's Checklist}

Use

the

Pilot's

Checklist

in

the

aircraft

to

prevent

the

possibility

of

overlooking

an

important

check

item.

Most

of

the

warm-up

will

have

been

conducted

during

taxi,

and

additional

warm-up

before

takeoff

should

be

re-

stricted

to

the

checks

outlined

in

Section

I.

Full

throttle

checks

on

the

ground

are

not

recommended

unless

there

is

good

reason

to

suspect

that

the

engines

are

not

operating

properly.

Do

not

runup

the

engines

over

loose

gravel

or

cinders

because

of

possible

stone

damage

or

abra-

sion

to

the

propeller

tips.

If

the

ignition

system

produces

an

engine

speed

drop

in

excess

of

150

RPM,

or

if

the

drop

in

RPM

between

the

left

and

right

magnetos

differs

by

more

than

50

RPM,

continue

warmup a

minute

or

two

longer,

before

rechecking

the

~stem.

If

there

is

doubt

concerning

operation

of

the

ignition

system,

checks

at

higher

engine

speed

will

usually

confirm

if a deficiency

exists.

In

general,

a

drop

in

excess

of

150

RPM

is

not

considered

acceptable.

If

instrument

flights

are

contemplated,

a

careful

check

should

be

made

of

the

vacuum

system.

The minimum

and

maximum

allowable

suctions

are

4.75

and

5.25

inches

Hg.,

respective-

ly,

on

the

instrument.

Good

alternator

condition

is

also

important

for

instrument

flight,

since

satisfactory

operation

of

all

radio

equipment

and

electrical

instruments

is

essen-

tial.

The

alternators

are

checked

during

engine

runup

(1700

RPM)

by

positioning

the

selector

switch

in

the L ALT

and

R

ALT

position

and

observing

the

charging

rate

on

the

volt-

ammeter.

A

simple

last

minute

recheck

of

important

items

should

include

a

quick

glance

to

see

if

all

switches

are

ON,

the

mixture

and

propeller

pitch

levers

are

forward,

all

flight

controls

have

free

and

correct

movement,

and

the

fuel

selec-

tors

are

properly

positioned.

2-5

A

mental

review

of

all

single-engine

speeds,

procedures,

and

field

length

requirements

should

be

made

prior

to

takeoff.

TAKEOFF

Since

the

use

of

full

throttle

is

not

recommended

in

the

static

runup,

closely

observe

full-power

engine

operation

early

in

the

takeoff

run.

Signs

of

rough

engine

operation,

unequal

power

between

engines,

or

sluggish

engine

accelera-

tion

are

good

cause

for

discontinuing

the

takeoff.

If

this

occurs,

you

are

justified

in

making a thorough,

full

throt-

tle,

static

runup

before

another

takeoff

is

attempted.

For

maximum

engine

power,

the

mixture

should

be

adjusted

during

the

initial

acceleration

to

the

recommended

fuel

flow

for

the

field

elevation.

The

engine

acceleration

is

increas-

ed

significantly

with

fuel

leaning

above

3000

feet

and

this

procedure

always

should

be

employed

for

field

elevations

greater

than

5000

feet

above

sea

level.

Refer

to

the

Pilot's

Checklist

for

recommended

fuel

flows.

Full

throttle

operation

is

recommended

on

takeoff

since

it

is

important

that

a

speed

well

above

minimum

single-engine

control

speed

(81

KIAS)

be

obtained

as

rapidly

as

possible.

It

is

desirable

to

accelerate

the

aircraft

to

92

KIAS

(re-

commended

safe

single-engine

speed)

while

still

on

the

ground

for

additional

safety

in

case

of

an

engine

failure.

This

safety

may

have

to

be

compromised

slightly

where

short

and

rough

fields

prohibit

such

high

speed

before

takeoff.

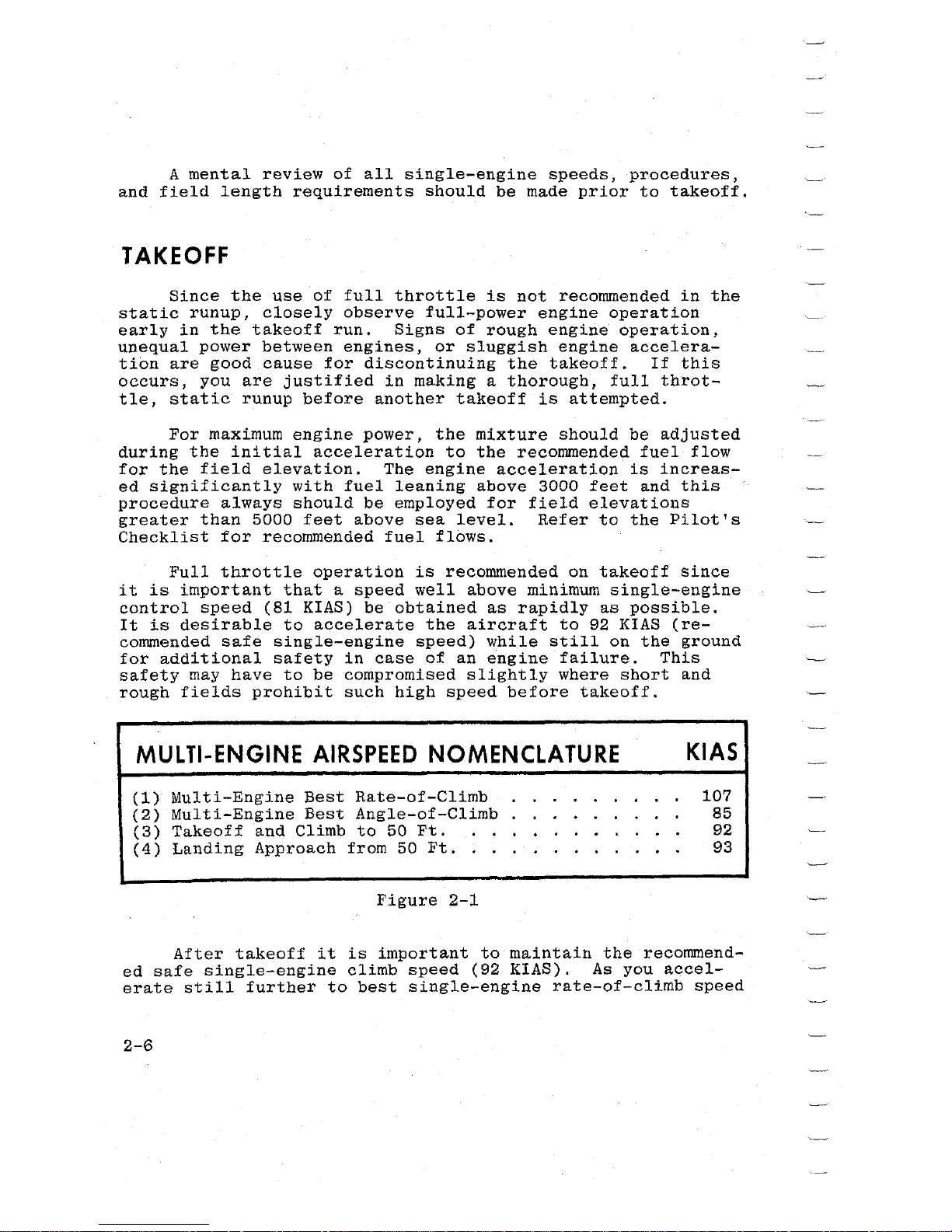

MULTI-ENGINE

AIRSPEED

NOMENCLATURE

(1)

Multi-Engine

Best

Rate-of-Climb

(2)

Multi-Engine

Best

Angle-of-Climb

(3)

Takeoff

and

Climb

to

50

Ft.

(4)

Landing

Approach

from

50

Ft

..

Figure

2-1

KIAS

107

85

92

93

After

takeoff

it

is

important

to

maintain

the

recommend-

ed

safe

single-engine

climb

speed

(92

KIAS).

As

you

accel-

erate

still

further

to

best

single-engine

rate-of-climb

speed

2-6

(107 KIAS),

it

is

good

practice

to

climb

rapidly

to

an

alti-

tude

at

which

the

aircraft

is

capable

of

circling

the

field

on

one

engine.

After

obstruction

height

is

reached,

power

may

be

re-

duced

and

climb

speeds

may

be

established

as

described

in

Section

I.

For

crosswind

takeoffs,

additional

power

may

be

carried

on

the

upwind

engine

until

the

rudder

becomes

effective.

The

aircraft

is

accelerated

to a slightly

higher

than

normal

takeoff

speed,

and

then

is

pulled

off

abruptly

to

prevent

possible

settling

back

to

the

runway

while

drifting.

When

clear

of

the

ground,

a

coordinated

turn

is

made

into

the

wind

to

correct

for

drift.

A

takeoff

with

one

tip

tank

full

and

the

opposite

tank

empty

creates

a

lateral

unbalance

at

takeoff

speed.

This

is

not

recommended

since

gusty

air

or

premature

lift-off

could

create

a

serious

control

problem.

Performance

data

for

normal

takeoff,

accelerate

stop

distance

and

single-engine

takeoff

are

presented

in

Section

VI.

AFTER

TAKEOFF

To

establish

climb

configuration,

retract

the

landing

gear,

adjust

power

for

climb,

turn

off

the

auxiliary

fuel

pumps

and

adjust

the

mixture

for

the

power

setting

selected.

Before

retracting

the

landing

gear,

apply

the

brakes

momentarily

to

stop

the

main

wheels.

Centrifugal

force

caused

by

the

rapidly-rotating

wheels

expands

the

diameter

of

the

tires,

and

if

ice

or

mud

has

accumulated

in

the

wheel

wells,

the

rotating

wheels

may

rub

as

they

enter.

On

long

runways,

the

landing

gear

should

be

retracted

at

the

point

over

the

runway

where a wheels-down

forced

landing

on

that

runway

would

become

impractical.

However,

on

short

runways

it

may

be

preferable

to

retract

the

landing

gear

after

the

aircraft

is

safely

airborne.

Power

reduction

will

vary

according

to

the

requirements

of

the

traffic

pattern

or

surrounding

terrain,

gross

weight,

field

elevation,

temperature

and

engine

condition.

However,

2-7

a

normal

"after

takeoff"

power

setting

is

24.5

inches

Hg.

and

2500

RPM.

CLIMB

To

save

time

and

fuel

for

the

over-all

trip,

it

is

recommended

that

the

normal

cruising

climb

be

conducted

at

115-130

KIAS

using

approximately

75%

power

(24.5

inches

Hg.

manifold

pressure

and

2500 RPM).

Cruising

climbs

should

be

conducted

at

the

recommended

fuel

flow;

refer

to

the

Pilot's

Checklist.

If

it

is

necessary

to

climb

rapidly

to

clear

mountains

or

reach

favorable

winds

at

high

altitudes,

the

best

rate-of-

climb

speed

should

be

used

with

maximum

power.

This

speed

varies

from

107

KIAS

at

sea

level

to

99

KIAS

at

10,000

feet.

During

maximum

performance

climbs,

the

mixture

should

be

leaned

to

the

recommended

fuel

flow.

It

is

recommended

that

the

auxiliary

fuel

pumps

be

on

at

altitudes

above

12,000

feet

for

the

duration

of

the

climb

and

approximately

5

to

15

minutes

after

establishing

cruising

flight.

It

is

also

recommended

that

the

mixture

remain

at

the

climb

mixture

setting

for

approximately

5

minutes

after

establishing

cruis-

ing

flight

before

leaning

is

initiated.

These

procedures

will

eliminate

fuel

vaporization

problems

likely

to

occur

from

rapid

altitude

changes.

If

an

obstruction

ahead

requires

a

steep

climb

angle,

the

aircraft

should

be

flown

at

the

best

angle-of-climb

speed

with

flaps

up

and

maximum

power.

The

speed

varies

from

85

KIAS

at

sea

level

to

89

KIAS

at

15,000

feet.

Performance

data

for

maximum

climb,

cruise

climb

and

single-engine

climb

are

presented

in

Section

VI.

CRUISE

Tabulated

cruising

information

is

provided

for

normal

power

and

altitudes

in

Section

VI.

These

charts

are

based

on

600,

978

and

1218

pounds

of

fuel

for

cruise,

recommended

lean

mixture,

5500

pounds

gross

weight,

zero

wind,

and

no

fuel

reserve.

Allowances

for

warm-up,

headwinds,

variations

in

mixture

leaning

technique,

and

fuel

reserve

should

be

es-

2-8

timated,

and

the

endurance

and

range

shown

in

the

charts

should

be

modified

accordingly.

Fuel

allowances

for

takeoff

and

climb

are

given

in

Section

VI.

Normal

cruising

requires

between

50%

and

70%

power.

The

manifold

pressure

and

RPM

settings

required

to

obtain

these

powers

at

various

altitudes

and

outside

air

temperatures

can

be

determined

with

your

power

computer.

A maximum

cruising

power

of

approximately

75%

(24.5

inches

Hg.,

and

2500

RPM)

may

be

used

if

desired.

Various

percent

powers

can

be

ob-

tained

with a number

of

combinations

of

manifold

pressures,

engine

speeds,

•altitudes,

and

outside

air

temperatures.

However,

at

full

throttle

and

constant

engine

speed,

a

speci-

fic

power

can

be

obtained

at

only

one

altitude

for

each

given

air

temperature.

For a given

throttle

setting,

select

the

lowest

engine

speed

in

the

green

arc

range

that

will

give

smooth

engine

operation

without

evidence

of"'laboring.

The

use

of

lower

power

settings

and

the

selection

of

cruise

altitude

on

the

basis

of

the

most

favorable

wind

conditions

are

significant

factors

that

should

be

considered

on

every

trip

to

reduce

fuel

consumption.

Additional

range

can

be

achieved

when

operating

at

55%

power

or

less

by

lean-

ing

to

peak

exhaust

gas

temperature

(EGT)

for

Best

Economy

mixture.

Refer

to

Economy

Mixture

Indicator

in

Section

VII

if

the

optional

EGT

system

is

installed.