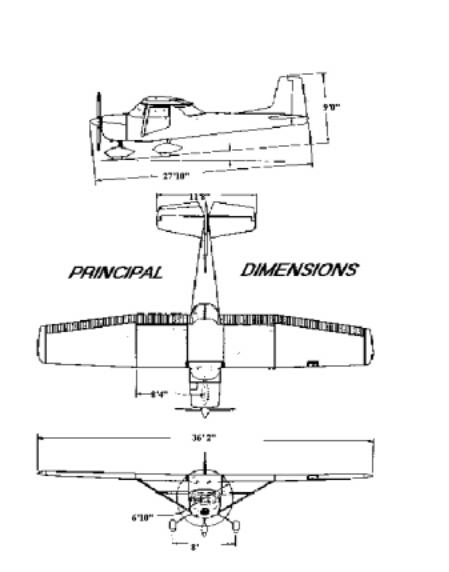

Cessna 182 schematic

1966 Cessna 182-J Skylane

Performance and Specifications

Gross weight |

2,800 lbs. |

Speed |

|

Top Speed at sea level |

170 mph |

Cruise, 75% power at 6500 ft |

162 mph |

Range |

|

Cruise, 75% Power at 6500 ft |

695 mi. |

79.0 Gallons |

5.7 hours |

|

162 mph |

Optimum Range at 10,000 ft |

1215 mi. |

35.0 Gallons |

10.0 hours |

|

121 mph |

Rate of Climb at sea level |

980 fpm |

Service Ceiling |

18,900 |

Takeoff |

|

Ground Run |

625 ft |

Total Distance over 50’ obstacle |

1,2055 ft |

Landing |

|

Landing Roll |

590 ft |

Total Distance over 50’ obstacle |

1,350 ft |

Empty Weight |

1,620 lbs. |

Baggage |

120 lbs |

Wing Loading |

16.1 lb./sf. |

Power loading |

12.1 lb./HP |

Fuel Capacity total |

84 gal |

Oil Capacity |

12 US qts |

Propeller, Fixed Pitch, metal, dia. |

82 in |

Power - - Continental O-470-R Engine, 230 HP at 2600 RPM

page i |

page ii |

TABLE OF CONTENTS

SECTION I |

OPEATING CHECKLIST |

1-1 |

SECTION II |

DESCRIPTION |

|

AND OPERATING DETAILS |

2-1 |

|

SECTION III OPEATING LIMITATIONS |

3-1 |

|

SECTION IV CARE OF THE AIRPLANE |

4-1 |

|

SECTION V |

OPERATIONAL DATA |

5-1 |

ALPHABETICAL INDEX

page iii |

page iv |

|

Section I

Operating Check List

One of the first steps in obtaining the utmost performance, service, and flying enjoyment from your Cessna is to familiarize yourself with your airplane’s equipment, systems, and controls. This can best be done by reviewing this equipment while sitting in the airplane. Those items whose functions and operation are not obvious are covered in Section II

Section I lists, in the Pilot’s Check List form, the steps necessary to operate your airplane efficiently and safely. It is not a checklist in its true form as it is considerably longer, but it does cover briefly all of the points that you would want to or should know concerning the information you need for a typical flight.

The flight and operation characteristics of your airplane are normal in all respects. There are no unconventional characteristics or operations that need to be mastered. All controls respond in the normal way within the entire range of operation. All airspeeds mentioned in Sections I and II are indicated airspeeds. Corresponding calibrated airspeeds may be obtained from the Airspeed Correction Table in Section V.

BEFORE ENTERING THE AIRPLANE

1. Make an exterior inspection in accordance with figure 1-1

BEFORE STARTING THE ENGINE

1.Seats and seat belts – Adjust and Lock

2.Flight Controls -- Check

3.Brakes – Test and set

Master Switch – On

4.Cowl Flaps –Open (Move lever out of locking hole to reposition)

5.Elevator and Rudder Trim – Takeoff setting

6.Fuel Selector –On

7.Turn all radio switches OFF

STARTING THE ENGINE

1.Carburetor Heat – Cold

2.Mixture – Rich

3.Propeller – High RPM

4.Throttle –Cracked (one-half inch)

5.Primer – As Required

6.Ignition switch – Start - Hold until engine fires, but not longer than 30 seconds

7.Ignition Switch -- Release to BOTH immediately after engine fires

NOTE

If engine has been overprimed, start with throttle open ¼ to ½ full open. Reduce throttle to idle when engine fires.

NOTE

After starting, check for oil pressure indication within 30 seconds in normal temperatures and 60 seconds in cold temperatures. If no indication appears shut off engine and investigate.

BEFORE TAKE – OFF

1.Throttle Setting – 1700 RPM

2.Engine Instruments – Check

3.Carburetor Heat – Check operation, then set to cold unless icing conditions prevail

4.Ammeter – Check

Page 1-1 |

Page 1-2 |

5.Suction gauge - - Check (4.6 to 5.4 inches of mercury

6.Magnetos – Check (50 RPM maximum differential between magnetos)

7.Propeller – Cycle from high to low RPM; return to high RPM (full in)

8.Flight Controls – Recheck

9.Wing Flaps - - Check operation and set 0° to 20°

10.Cowl Flaps _Full OPEN

11.Elevator and Rudder Tab – Takeoff

12.Cabin doors – Closed and locked

13.Flight Instruments and Radios – Set

TAKE OFF

NORMAL TAKE OFF

1.Wing flaps – Up

2.Carburetor Heat – Cold

3.Throttle – Full “Open” and 2600 RPM

4.Elevator Control – Lift nose wheel at 60 mph

5.Climb Speed – 90 MPH until all obstacles are cleared, then set up climb speed as shown in NORMAL CLIMB paragraph

MAXIMUM PERFORMANCE TAKE OFF

1.Wing Flaps – 20°

2.Carburetor Heat – Cold

3.Brakes – Apply

4.Power – Full throttle and 2600 RPM

5.Brakes – release

6.Elevator Control – Slightly tail low

7.Climb Speed – 60 MPH until all obstacles are cleared, then set up climb speed as shown in MAXIMUM PERFORMANCE CLIMB

8.Wing Flaps – Up after obstacles are cleared

CLIMB

NORMAL CLIMB

1.Air Speed – 100 to 120 MPH

2.Power – 23” and 2450 RPM

3.Mixture – Rich (unless engine is rough)

4.Cowl Flaps – Open as required

MAXIMUM PERFORMANCE CLIMB

1.Air Speed – 88 MPH (sea level) to 84 MPH (10,000)

2.Power – Full throttle and 2600 RPM

3.Mixture – Rich (unless engine is rough)

4.Cowl Flaps – Open as required

CRUISING

1.Power – 15” to 23" manifold pressure and 2200 to 2450 RPM

2.Cowl Flaps – Open as required

3.Elevator and Rudder Trim – Adjust

4.Mixture – Lean

LET DOWN

1.Mixture – Rich

2.Power – As desired

3.Carburetor Heat – Apply (if icing conditions exist)

BEFORE LANDING

1.Fuel Selector Valve –BOTH

2.Mixture – Rich

page 1-3 |

page 1-4 |

3.Propeller – High RPM

4.Cowl Flaps – Closed

5.Carburetor Heat – Apply full heat before closing throttle

6.Airspeed – 80 to 90 MPH (flaps retracted)

7.Wing Flaps -- 0° to40° (below 110 MPH

8.Airspeed – 70 to 80 MPH with flaps extended

9.Elevator and Rudder Trim -- Adjust

NORMAL LANDING

1. Landing Technique – Conventional for all flap settings

AFTER LANDING

1.Cowl Flaps – OPEN

2.Wing Flaps – Up

3.Carburetor Heat – Cold

SECURE AIRCRAFT

1. Mixture – Idle Cut-off

NOTE

Do not open throttle as engine stops since this actuates the accelerator pump.

2.All Switches – Off

3.Parking Brake – Set

4.Control Lock – Installed

Section II

Description and Operating Details

The following paragraphs describe the systems and equipment whose function and operation is not obvious when sitting in the airplane. This section also covers in somewhat greater detail some of the items listed in checklist form in Section I

FUEL SYSTEM

Fuel is supplied to the engine from two tanks, one in each wing. The total usable fuel, for all flight conditions, is 79 gallons for optional long-range tanks.

NOTE

Unusable fuel is at a minimum due to the design of the fuel system. However, with ¼ tank or less, prolonged uncoordinated flight, such as slips or skids can uncover the fuel tank outlets, causing fuel starvation and engine stoppage when operating on a single tank. Therefore, to avoid this problem with low fuel reserves, the fuel selector should be set at BOTH position.

Fuel from each wing taken flows by gravity to a selector valve. Depending upon the setting of the selector valve, fuel from the left, right, or both tanks flows through a fuel strainer and carburetor to the engine induction system.

page 1-5 |

page 2-1 |

NOTE

Take off with the fuel selector valve handle in the BOTH position to prevent inadvertent take-off on an empty tank. However, when the selector is in the BOTH position, unequal fuel flow from each tank may occur after extended flight if the wings are not maintained exactly level. Resulting wing heaviness can be alleviated gradually by turning the selector valve handle to the tank in the heavy wing. The recommended cruise fuel management for extended flight is to use the left and right tank alternately.

ELECTRICAL SYSTEM

Electrical energy is supplied by a 14-volt, direct-current system, powered by an engine-driven alternator. The 12-volt storage battery is located aft of the rear baggage compartment wall.

CIRCUIT BREAKERS

All electrical circuits in the airplane, except the clock circuit, are protected by circuit breakers. The clock has a separate fuse mounted adjacent to the battery. The stall warning transmitter and horn circuit and the optional turn-and-bank indicator circuits are protected by a single automatically resetting circuit breaker mounted behind the instrument panel. The cigar lighter is protected by a manually reset type circuit breaker mounted directly on the back of the lighter behind the instrument panel The remaining circuits are protected by push-to- reset circuit breakers on the instrument panel.

ROTATING BEACON

The rotating beacon should not be used when flying through clouds or overcast; the moving beams reflected from water droplets or particles in the atmosphere, particularly at night, can produce vertigo and loss of orientation.

page 2-2 |

page 2-3 |

CABIN HEATING VENTILATING SYSTEM AND DEFROSTING SYSTEM

The temperature and volume of airflow into the cabin can be regulated to any degree desired by manipulation of the push-pull CABIN HEAT and CABIN AIR knobs. Both control knobs are the double-button type with friction locks to permit intermediate settings.

NOTE

Always pull out the CABIN AIR knob slightly when the CABIN HEAT knob is out. This action increases airflow through the system, increasing efficiency, and blends cool outside air with the exhaust manifold heated air, thus eliminating the possibility of overheating the system ducting.

The rotary type DEFROST know regulates the airflow for windshield defrosting

Front cabin head and ventilating air is supplied by outlet holes spaced across a cabin manifold just forward of the pilot’s and copilot’s feet. Rear cabin heat and air is supplied by two ducts from the manifold, one extending down each side of the cabin. Windshield defrost air is also supplied by a duct leading from the cabin manifold.

Separate adjustable ventilators supply additional air;; one near each upper corner of the windshield supplies air for the pilot and copilot, and two in the rear cabin ceiling supply air to the rear seat passengers.

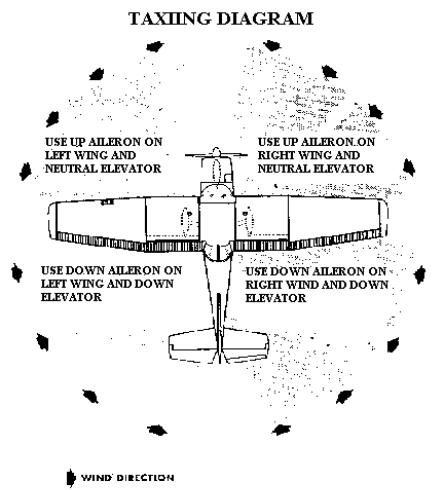

figure 2-2

NOTE:

Strong quartering tailwinds require caution. Avoid sudden bursts of the throttle and sharp braking when the airplane is in this attitude. Use the steerable nose-wheel and rudder to maintain direction

page 2-4 |

page 2-5 |

|

STARTING ENGINE

Ordinarily the engine starts easily with one or two strokes of primer in warm temperatures to six strokes in cold weather, with the throttle open approximately 1/2 inch. In extremely cold temperatures, it may be necessary to continue to priming while cranking. Weak intermittent explosions followed by puffs of black smoke from the exhaust stack indicates overpriming or flooding. Excess fuel can be cleaned from the combustion chambers by the following procedure: Set the mixture control in full lean position, throttle full open, and crank the engine trough several revolutions with the starter. Repeat the starting procedure without any additional priming.

If the engine is underprimed (most likely in cold weather with a cold engine) it will not fire at all, and additional priming will be necessary. As soon as the cylinders begin to fire, open the throttle slightly to keep it running.

If prolonged cranking is necessary, allow the starter motor to cool at frequent intervals, since excessive heat may damage the armature

TAXIING

The carburetor air heat know should be pushed full in during all ground operations unless is absolutely necessary for smooth engine operations. When the know is pulled out to the heat position, air entering the engine is not filtered

Taxiing over loose gravel or cinders should be done at low engine speed to avoid abrasion and stone damage to the propeller tips

BEFORE TAKEOFF

Since the engine is closely cowled for efficient in-flight-cooling, precautions should be taken to avoid overheating on the ground.

page 2-6

Full throttle checks on the ground are not recommended unless the pilot has good reason to suspect that the engine is not turning up properly.

The magneto check should be make at 1700 RPM as follows: Move the ignition switch first to "R" position and note RPM. Then move switch back to "BOTH" to clear the other set of plugs. Then move switch to "L" position and note RPM. The difference between the two magnetos operated individually should not be more than 50 RPM. If there is a doubt concerning the operation of the ignition system, RPM checks at higher engine speeds will usually confirm whether a deficiency exists

An absence of RPM drop may be an indication of faulty grounding of one side of the ignition system or should be cause for suspicion that the magneto timing is set in advance of the setting specified.

TAKE-OFF

It is important to check full-throttle engine operation early in the takeoff run. Any signs of rough engine operation or sluggish engine acceleration is good cause for discontinuing the take-off.

Full throttle runups over loose gravel are especially harmful to propeller tips. When take-offs must be made over a gravel surface, it is very important that the throttle be advanced slowly. This allows the airplane to start rolling before high RPM is developed, and the gravel will be blow back of the propeller rather than pulled into it.

Most engine wear occurs from improper operations before the engine is up to normal operating temperatures, and operating at high power and RPMs. For this reason the use of maximum power for take-off should be limited to that absolutely necessary for safety. Whenever possible, reduce take-off power to normal climb power.

page 2-7

Normal take-offs are accomplished with wing flaps up, cowl flaps open, full throttle, and 2600 RPM. Reduce power to 23" of manifold pressure and 2450 RPM as soon as practical to minimize engine wear.

Using 20º wing flaps reduces the ground run and total distance over the obstacle by approximately 20 per cent. soft field take-offs are performed with 20º flaps by lifting the airplane off the ground as soon as practical in a slightly tail-low attitude. However the airplane should be leveled off immediately to accelerate to a safe climb speed.

If 20º wing flaps are used for take-off, they should be left down until all obstacles are cleared. To clear an obstacle with wing flaps 20º , the best angle-of-climb speed (60 MPH IAS) should be used. If no obstructions are ahead, a best "flaps up" rate-of-climb sped (90MPH IAS) would be most efficient. These speeds vary slightly with altitude, but they are close enough for average field conditions

Flap deflections of 30º to 40º are not recommended at any time for takeoff.

Take-offs into strong crosswinds normal are performed with the minimum flap setting necessary for the field length, to minimize the drift angle immediately after take-off. The airplane is accelerated to a speed slightly higher than normal, then pull off abruptly to prevent possible settling back to the runway while drifting. When clear of the ground, make a coordinated turn into the wind to correct for drift.

CLIMB

A cruising climb at 23" of manifold pressure, 2450 RPM (approximately 75% power) and 100 to 120 MPH is recommended to save time and fuel for the overall trip. In addition, this type of climb provides better engine cooling, less engine wear, and more passenger comfort due to lower noise level.

If it is necessary to climb rapidly to clear mountains or reach favorable winds at high altitudes, the best rate-of-climb speed should be used with maximum power. This speed is 88 MPH at sea level, decreasing 2 MPH for each 5000 feet above sea level.

CRUISE

Normal cruising is done at 65% to 75% power. The settings required to obtain these powers at various altitudes and outside temperatures can be determined by using your Cessna Power Computer.

OPTIMUM CRUISE PERFORMANCE

% BHP |

ALTITUDE |

TRUE A/S (mph |

75 |

6,500 |

162 |

70 |

8,000 |

160 |

65 |

10,000 |

158 |

|

figure 2-3 |

|

The Optimum Cruise Performance table (figure 2-3), shows that cruising cane done most efficiently at higher altitudes because very nearly the same cruising speed can be maintained at much less power.

For a given throttle setting, select the lowest engine RPM in the green arc range that will give smooth engine operation.

The cowl flaps should be adjusted to maintain the cylinder head temperature near the middle of the normal operating (green arc) range to assure prolonged engine life.

to achieve the range figures shown in Section V, the mixture should be leaned as follows: pull the mixture control out until engine becomes rough; then enrich mixture slightly beyond this point. Any change in altitude, power or carburetor heat will require a change in the lean mixture setting.

page 2-8 |

page 2-9 |

Application of full carburetor heat may enrich the mixture to the point of engine roughness. To avoid this, lean the mixture as instructed in the preceding paragraph.

STALLS

The stall characteristics are conventional and aural warning is provided by a stall warning horn which sounds between 5 and 10 PMH above the stall in all configurations.

Power-off stall speeds at maximum gross weight and aft c.g. position are presented in figure 5-2 as calibrated airspeeds since indicated airspeeds are unreliable near the stall.

Spins

Intentional spins are prohibited in this airplane. Should an inadvertent spin occur, standard light plane recovery techniques should be used.

LANDING

Landings are usually made on the main wheels first to reduce the landing speed and the subsequent need for braking in the landing roll. The nosewheel is lowered gently to the runway after the speed has diminished to avoid unnecessary nose gear load. This procedure is especially important in rough field landings.

For short field landings, make a power off approach at 69 MPH, IAS with 40º flaps and land on the main wheels first. Immediately after touchdown, lower the nose gear to the ground and apply heavy braking as required. For maximum brake effectiveness, after all three wheels are on the ground, retract the flaps, hold nose-up elevator and apply maximum brake pressure without sliding the tires

CROSSWIND LANDINGS

When landing is a strong crosswind, use the minimum flap setting required for the field length. Use a wing low, crab, or combination method of drift correction and land in a nearly level attitude. Hold a straight course with the steerable nosewheel and occasional braking if necessary.

COLD WEATHER OPEATION

Prior to starting on clod mornings, it is advisable to pull the propeller through several times by hand to "break loose" or "limber" the oil, thus conserving battery energy. In extremely cold (-20ºF) weather the use of an external preheater is recommended whenever possible to reduce wear and abuse to the engine and electrical system. Cold weather starting procedures are as follows:

With preheat

1.Clear propeller

2.Master Switch -- On

3.With magneto switch "OFF" and throttle closed, prime the engine

four to ten strokes as the engine is being turned over

NOTE

Use heavy strokes of primer for best atomization of fuel. After priming, push primer all the way in and turn to locked position to avoid possibility of engine drawing fuel through the primer.

4.Turn magneto switch to "Both"

5.Open throttle to 1/4" and engage starter

page 210 |

page 2-11 |

|

Loading...

Loading...