Page 1

1966 Cessna 182-J Skylane

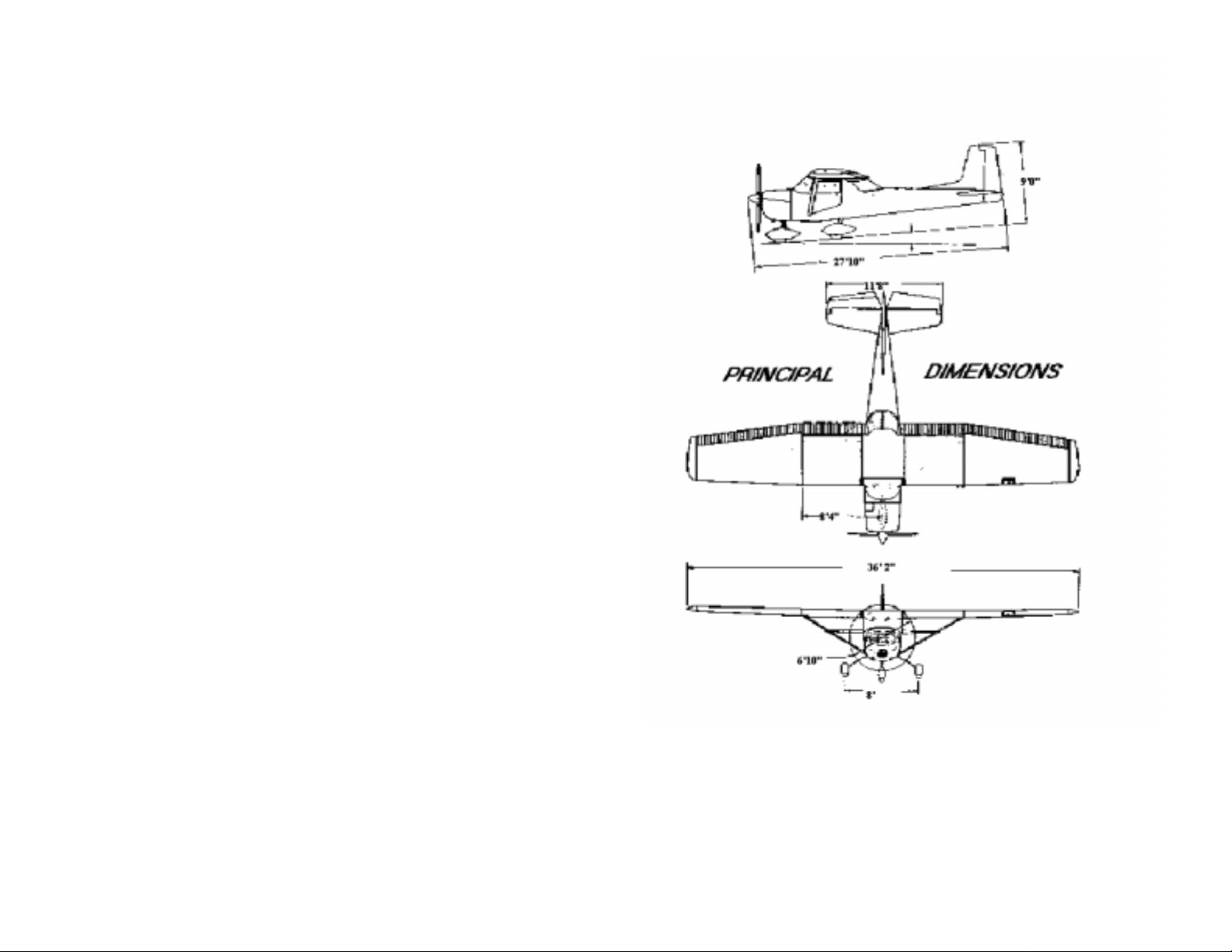

Performance and Specifications

Gross weight 2,800 lbs. Speed

Top Speed at sea level 170 mph

Cruise, 75% power at 6500 ft 162 mph

Range

Cruise, 75% Power at 6500 ft 695 mi.

79.0 Gallons 5.7 hours

162 mph

Optimum Range at 10,000 ft 1215 mi.

35.0 Gallons 10.0 hours

121 mph

Rate of Climb at sea level 980 fpm Service Ceiling 18,900 Takeoff

Ground Run 625 ft

Total Distance over 50’ obstacle 1,2055 ft

Landing

Landing Roll 590 ft

Total Distance over 50’ obstacle 1,350 ft

Empty Weight 1,620 lbs.

Baggage 120 lbs

Wing Loading 16.1 lb./sf.

Power loading 12.1 lb./HP

Fuel Capacity total 84 gal

Oil Capacity 12 US qts

Propeller, Fixed Pitch, metal, dia. 82 in

Power - - Continental O-470-R Engine, 230 HP at 2600 RPM

page i

page ii

Page 2

TABLE OF CONTENTS

SECTION I OPEATING CHECKLIST 1-1

SECTION II DESCRIPTION

AND OPERATING DETAILS 2-1

SECTION III OPEATING LIMITATIONS 3-1

SECTION IV CARE OF THE AIRPLANE 4-1

SECTION V OPERATIONAL DATA 5-1

ALPHABETICAL INDEX

page iii

page iv

Page 3

Section I

Operating Check List

One of the first steps in obtaining the utmost performance, service,

and flying enjoyment from your Cessna is to familiarize yourself with

your airplane’s equipment, systems, and controls. This can best be

done by reviewing this equipment while sitting in the airplane. Those

items whose functions and operation are not obvious are covered in

Section II

Section I lists, in the Pilot’s Check List form, the steps necessary to

operate your airplane efficiently and safely. It is not a checklist in its

true form as it is considerably longer, but it does cover briefly all of

the points that you would want to or should know concerning the

information you need for a typical flight.

Master Switch – On

4. Cowl Flaps –Open (Move lever out of locking hole to reposition)

5. Elevator and Rudder Trim – Takeoff setting

6. Fuel Selector –On

7. Turn all radio switches OFF

STARTING THE ENGINE

1. Carburetor Heat – Cold

2. Mixture – Rich

3. Propeller – High RPM

4. Throttle –Cracked (one-half inch)

5. Primer – As Required

6. Ignition switch – Start - Hold until engine fires, but not longer

than 30 seconds

7. Ignition Switch -- Release to BOTH immediately after engine

fires

The flight and operation characteristics of your airplane are normal in

all respects. There are no unconventional characteristics or

operations that need to be mastered. All controls respond in the

normal way within the entire range of operation. All airspeeds

mentioned in Sections I and II are indicated airspeeds.

Corresponding calibrated airspeeds may be obtained from the

Airspeed Correction Table in Section V.

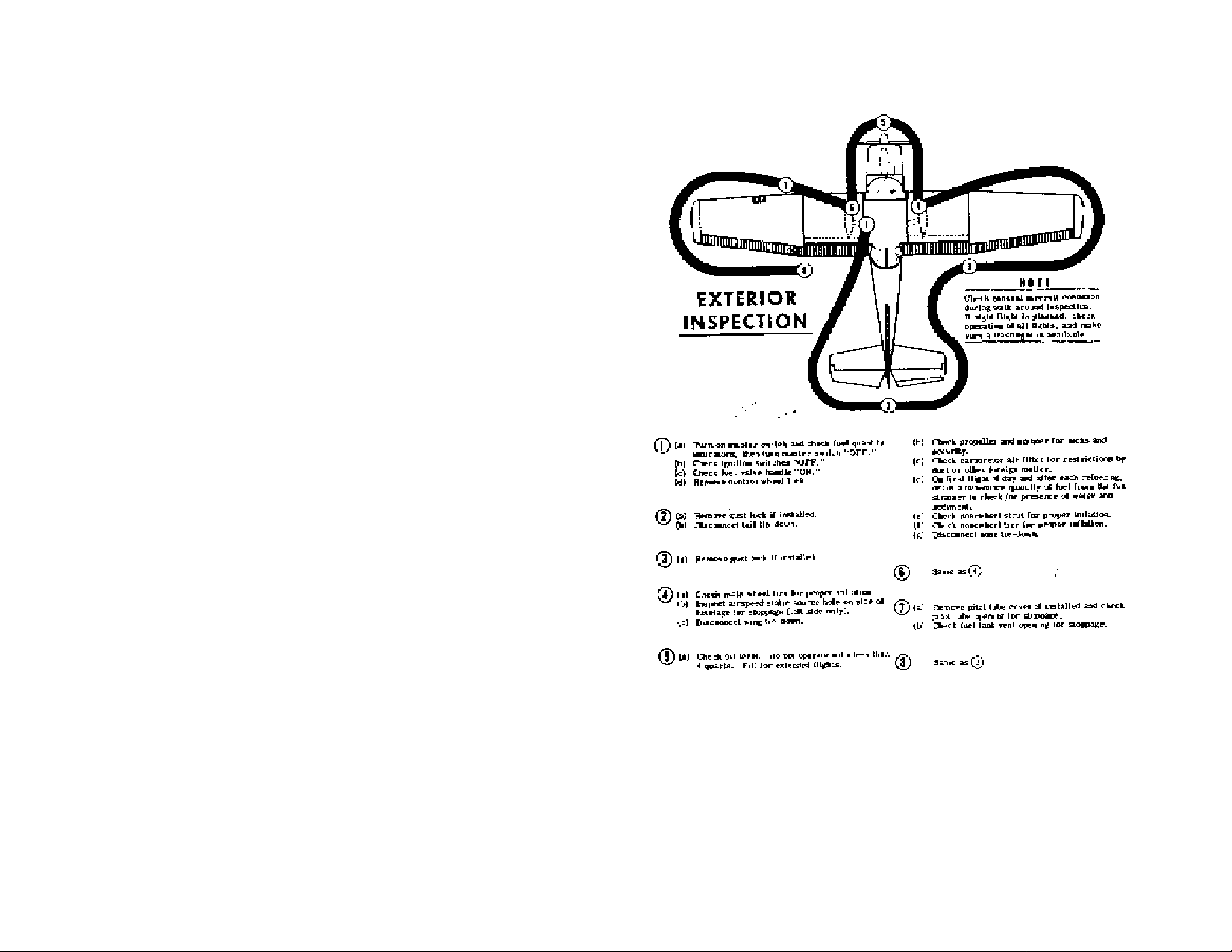

BEFORE ENTERING THE AIRPLANE

1. Make an exterior inspection in accordance with figure 1-1

BEFORE STARTING THE ENGINE

1. Seats and seat belts – Adjust and Lock

2. Flight Controls -- Check

3. Brakes – Test and set

Page 1-1

NOTE

If engine has been overprimed, start with throttle open ¼ to ½ full open. Reduce throttle to idle when engine fires.

NOTE

After starting, check for oil pressure indication within 30 seconds in

normal temperatures and 60 seconds in cold temperatures. If no

indication appears shut off engine and investigate.

BEFORE TAKE – OFF

1. Throttle Setting – 1700 RPM

2. Engine Instruments – Check

3. Carburetor Heat – Check operation, then set to cold unless icing

conditions prevail

4. Ammeter – Check

Page 1-2

Page 4

5. Suction gauge - - Check (4.6 to 5.4 inches of mercury

6. Magnetos – Check (50 RPM maximum differential between

magnetos)

7. Propeller – Cycle from high to low RPM; return to high RPM

(full in)

8. Flight Controls – Recheck

9. Wing Flaps - - Check operation and set 0° to 20°

10. Cowl Flaps _Full OPEN

11. Elevator and Rudder Tab – Takeoff

12. Cabin doors – Closed and locked

13. Flight Instruments and Radios – Set

CLIMB

NORMAL CLIMB

1. Air Speed – 100 to 120 MPH

2. Power – 23” and 2450 RPM

3. Mixture – Rich (unless engine is rough)

4. Cowl Flaps – Open as required

MAXIMUM PERFORMANCE CLIMB

TAKE OFF

NORMAL TAKE OFF

1. Wing flaps – Up

2. Carburetor Heat – Cold

3. Throttle – Full “Open” and 2600 RPM

4. Elevator Control – Lift nose wheel at 60 mph

5. Climb Speed – 90 MPH until all obstacles are cleared, then set up

climb speed as shown in NORMAL CLIMB paragraph

MAXIMUM PERFORMANCE TAKE OFF

1. Wing Flaps – 20°

2. Carburetor Heat – Cold

3. Brakes – Apply

4. Power – Full throttle and 2600 RPM

5. Brakes – release

6. Elevator Control – Slightly tail low

7. Climb Speed – 60 MPH until all obstacles are cleared, then set up

climb speed as shown in MAXIMUM PERFORMANCE CLIMB

8. Wing Flaps – Up after obstacles are cleared

1. Air Speed – 88 MPH (sea level) to 84 MPH (10,000)

2. Power – Full throttle and 2600 RPM

3. Mixture – Rich (unless engine is rough)

4. Cowl Flaps – Open as required

CRUISING

1. Power – 15” to 23" manifold pressure and 2200 to 2450 RPM

2. Cowl Flaps – Open as required

3. Elevator and Rudder Trim – Adjust

4. Mixture – Lean

LET DOWN

1. Mixture – Rich

2. Power – As desired

3. Carburetor Heat – Apply (if icing conditions exist)

BEFORE LANDING

1. Fuel Selector Valve –BOTH

2. Mixture – Rich

page 1-3

page 1-4

Page 5

3. Propeller – High RPM

4. Cowl Flaps – Closed

5. Carburetor Heat – Apply full heat before closing throttle

6. Airspeed – 80 to 90 MPH (flaps retracted)

7. Wing Flaps -- 0° to40° (below 110 MPH

8. Airspeed – 70 to 80 MPH with flaps extended

9. Elevator and Rudder Trim -- Adjust

NORMAL LANDING

1. Landing Technique – Conventional for all flap settings

AFTER LANDING

1. Cowl Flaps – OPEN

2. Wing Flaps – Up

3. Carburetor Heat – Cold

SECURE AIRCRAFT

1. Mixture – Idle Cut-off

NOTE

Do not open throttle as engine stops since this actuates the accelerator

pump.

2. All Switches – Off

3. Parking Brake – Set

4. Control Lock – Installed

Section II

Description and Operating Details

The following paragraphs describe the systems and equipment whose

function and operation is not obvious when sitting in the airplane.

This section also covers in somewhat greater detail some of the items

listed in checklist form in Section I

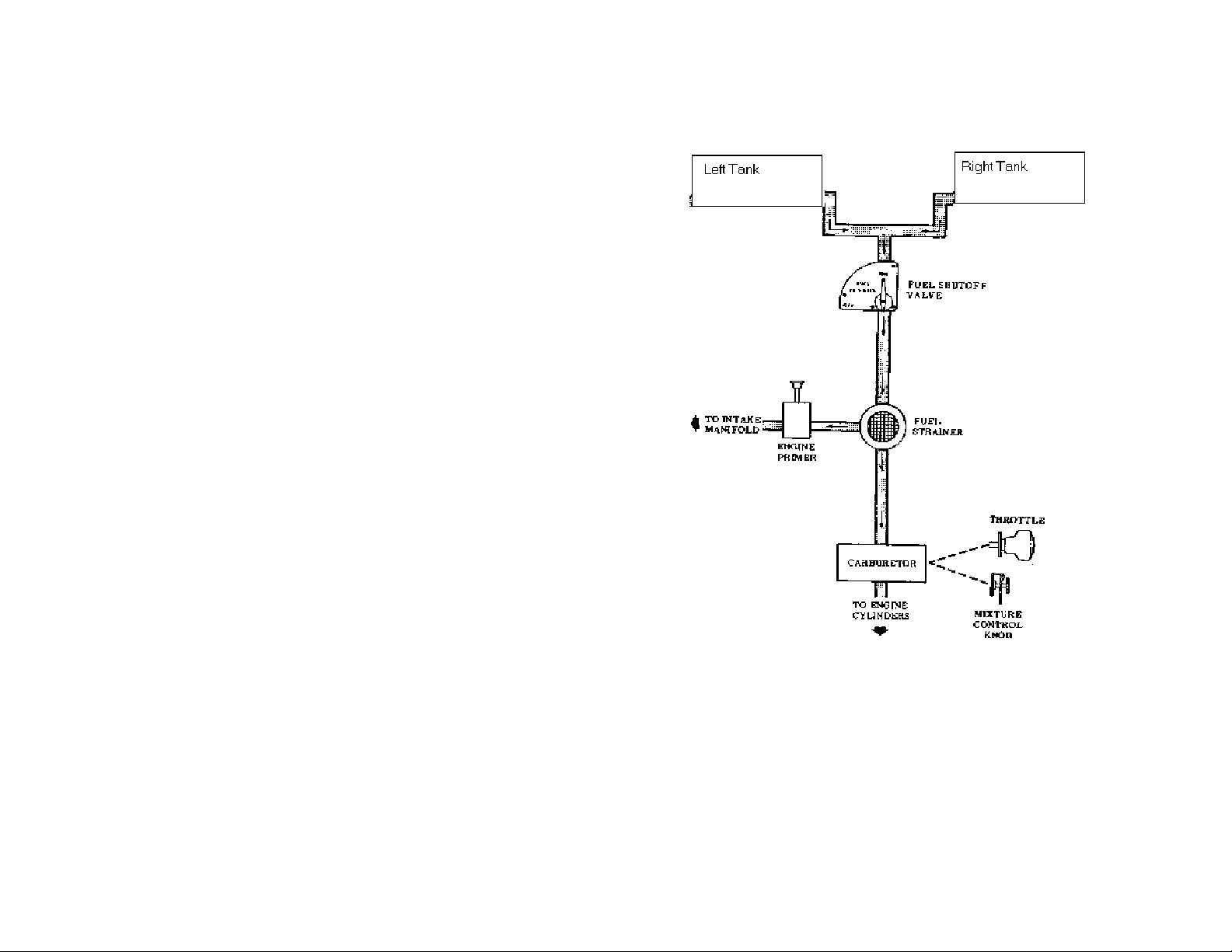

FUEL SYSTEM

Fuel is supplied to the engine from two tanks, one in each wing. The

total usable fuel, for all flight conditions, is 79 gallons for optional

long-range tanks.

NOTE

Unusable fuel is at a minimum due to the design of the fuel system.

However, with ¼ tank or less, prolonged uncoordinated flight, such

as slips or skids can uncover the fuel tank outlets, causing fuel

starvation and engine stoppage when operating on a single tank.

Therefore, to avoid this problem with low fuel reserves, the fuel

selector should be set at BOTH position.

Fuel from each wing taken flows by gravity to a selector valve.

Depending upon the setting of the selector valve, fuel from the left,

right, or both tanks flows through a fuel strainer and carburetor to the

engine induction system.

page 1-5

page 2-1

Page 6

NOTE

Take off with the fuel selector valve handle in the BOTH position to

prevent inadvertent take-off on an empty tank. However, when the

selector is in the BOTH position, unequal fuel flow from each tank

may occur after extended flight if the wings are not maintained

exactly level. Resulting wing heaviness can be alleviated gradually

by turning the selector valve handle to the tank in the heavy wing.

The recommended cruise fuel management for extended flight is to

use the left and right tank alternately.

ELECTRICAL SYSTEM

Electrical energy is supplied by a 14-volt, direct-current system,

powered by an engine-driven alternator. The 12-volt storage batter y

is located aft of the rear baggage compartment wall.

CIRCUIT BREAKERS

All electrical circuits in the airplane, except the clock circuit, are

protected by circuit breakers. The clock has a separate fuse mounted

adjacent to the battery. The stall warning transmitter and horn circuit

and the optional turn-and-bank indicator circuits are protected by a

single automatically resetting circuit breaker mounted behind the

instrument panel. The cigar lighter is protected by a manually reset

type circuit breaker mounted directly on the back of the lighter behind

the instrument panel The remaining circuits are protected by push-toreset circuit breakers on the instrument panel.

ROTATING BEACON

The rotating beacon should not be used when flying through clouds or

overcast; the moving beams reflected from water droplets or particles

in the atmosphere, particularly at night, can produce vertigo and loss

of orientation.

page 2-2

page 2-3

Page 7

CABIN HEATING VENTILATING SYSTEM AND

DEFROSTING SYSTEM

The temperature and volume of airflow into the cabin can be

regulated to any degree desired by manipulation of the push-pull

CABIN HEAT and CABIN AIR knobs. Both control knobs are the

double-button type with friction locks to permit intermediate settings.

NOTE

Always pull out the CABIN AIR knob slightly when the CABIN

HEAT knob is out. This action increases airflow through the system,

increasing efficiency, and blends cool outside air with the exhaust

manifold heated air, thus eliminating the possibility of overheating

the system ducting.

The rotary type DEFROST know regulates the airflow for windshield

defrosting

Front cabin head and ventilating air is supplied by outlet holes spaced

across a cabin manifold just forward of the pilot’s and copilot’s feet.

Rear cabin heat and air is supplied by two ducts from the manifold,

one extending down each side of the cabin. Windshield defrost air is

also supplied by a duct leading from the cabin manifold.

Separate adjustable ventilators supply additional air;; one near each

upper corner of the windshield supplies air for the pilot and copilot,

and two in the rear cabin ceiling supply air to the rear seat passengers.

page 2-4

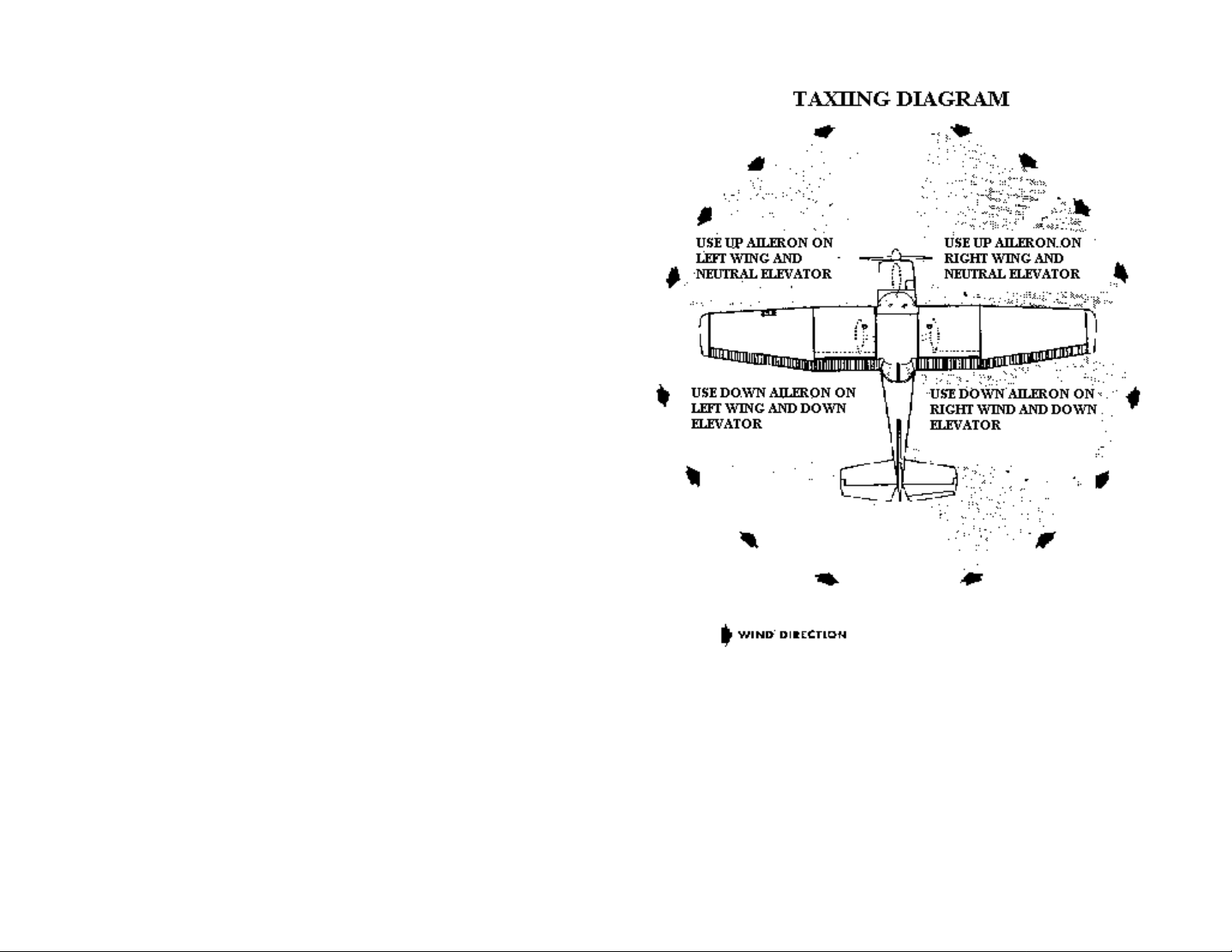

figure 2-2

NOTE:

Strong quartering tailwinds require caution. Avoid sudden bursts of

the throttle and sharp braking when the airplane is in this attitude.

Use the steerable nose-wheel and rudder to maintain direction

page 2-5

Page 8

STARTING ENGINE

Ordinarily the engine starts easily with one or two strokes of primer

in warm temperatures to six strokes in cold weather, with the throttle

open approximately 1/2 inch. In extremely cold temperatures, it may

be necessary to continue to priming while cranking. Weak

intermittent explosions followed by puffs of black smoke from the

exhaust stack indicates overpriming or flooding. Excess fuel can be

cleaned from the combustion chambers b y the following procedure:

Set the mixture control in full lean position, throttle full open, and

crank the engine trough several revolutions with the starter. Repeat

the starting procedure without any additional priming.

Full throttle checks on the ground are not recommended unless the

pilot has good reason to suspect that the engine is not turning up

properly.

The magneto check should be make at 1700 RPM as follows: Move

the ignition switch first to "R" position and note RPM. Then move

switch back to "BOTH" to clear the other set of plugs. Then move

switch to "L" position and note RPM. The difference between the

two magnetos operated individually should not be more than 50

RPM. If there is a doubt concerning the operation of the ignition

system, RPM checks at higher engine speeds will usually confirm

whether a deficiency exists

If the engine is underprimed (most likely in cold weather with a cold

engine) it will not fire at all, and additional priming will be necessary.

As soon as the cylinders begin to fire, open the throttle slightly to

keep it running.

If prolonged cranking is necessary, allow the starter motor to cool at

frequent intervals, since excessive heat may damage the armature

TAXIING

The carburetor air heat know should be pushed full in during all

ground operations unless is absolutely necessary for smooth engine

operations. When the know is pulled out to the heat position, air

entering the engine is not filtered

Taxiing over loose gravel or cinders should be done at low engine

speed to avoid abrasion and stone damage to the propeller tips

BEFORE TAKEOFF

Since the engine is closely cowled for efficient in-flight-cooling,

precautions should be taken to avoid overheating on the ground.

page 2-6

An absence of RPM drop may be an indication of faulty grounding of

one side of the ignition system or should be cause for suspicion that

the magneto timing is set in advance of the setting specified.

TAKE-OFF

It is important to check full-throttle engine operation early in the

takeoff run. Any signs of rough engine operation or sluggish engine

acceleration is good cause for discontinuing the take-off.

Full throttle runups over loose gravel are especially harmful to

propeller tips. When take-offs must be made over a gravel surface, it

is very important that the throttle be advanced slowly. This allows

the airplane to start rolling before high RPM is developed, and the

gravel will be blow back of the propeller rather than pulled into it.

Most engine wear occurs from improper operations before the engine

is up to normal operating temperatures, and operating at high power

and RPMs. For this reason the use of maximum power for take-off

should be limited to that absolutely necessary for safety. Whenever

possible, reduce take-off power to normal climb power.

page 2-7

Page 9

Normal take-offs are accomplished with wing flaps up, cowl flaps

open, full throttle, and 2600 RPM. Reduce power to 23" of manifold

pressure and 2450 RPM as soon as practical to minimize engine wear.

Using 20º wing flaps reduces the ground run and total distance over

the obstacle by approximately 20 per cent. soft field take-offs are

performed with 20º flaps by lifting the airplane off the ground as soon

as practical in a slightly tail-low attitude. However the airplane

should be leveled off immediately to accelerate to a safe climb speed.

If 20º wing flaps are used for take-off, they should be left down until

all obstacles are cleared. To clear an obstacle with win g flaps 20º ,

the best angle-of-climb speed (60 MPH IAS) should be used. If no

obstructions are ahead, a best "flaps up" rate-of-climb sped (90MPH

IAS) would be most efficient. These speeds vary slightly with

altitude, but they are close enough for average field conditions

Flap deflections of 30º to 40º are not recommended at any time for

takeoff.

Take-offs into strong crosswinds normal are performed with the

minimum flap setting necessary for the field length, to minimize the

drift angle immediately after take-off. The airplane is accelerated to a

speed slightly higher than normal, then pull off abruptly to prevent

possible settling back to the runway while drifting. When clear of the

ground, make a coordinated turn into the wind to correct for drift.

CLIMB

If it is necessary to climb rapidly to clear mountains or reach

favorable winds at high altitudes, the best rate-of-climb speed should

be used with maximum power. This speed is 88 MPH at sea level,

decreasing 2 MPH for each 5000 feet above sea level.

CRUISE

Normal cruising is done at 65% to 75% power. The settings required

to obtain these powers at various altitudes and outside temperatures

can be determined by using your Cessna Power Computer.

OPTIMUM CRUISE PERFORMANCE

% BHP ALTITUDE TRUE A/S (mph

75 6,500 162

70 8,000 160

65 10,000 158

figure 2-3

The Optimum Cruise Performance table (figure 2-3), shows that

cruising cane done most efficiently at higher altitudes because very

nearly the same cruising speed can be maintained at much less power.

For a given throttle setting, select the lowest engine RPM in the green

arc range that will give smooth engine operation.

The cowl flaps should be adjusted to maintain the cylinder head

temperature near the middle of the normal operating (green arc) ran ge

to assure prolonged engine life.

A cruising climb at 23" of manifold pressure, 2450 RPM

(approximately 75% power) and 100 to 120 MPH is recommended to

save time and fuel for the overall trip. In addition, this type of climb

provides better engine cooling, less engine wear, and more passenger

comfort due to lower noise level.

page 2-8

to achieve the range figures shown in Section V, the mixture should

be leaned as follows: pull the mixture control out until engine

becomes rough; then enrich mixture slightly beyond this point. An y

change in altitude, power or carburetor heat will require a change in

the lean mixture setting.

page 2-9

Page 10

Application of full carburetor heat may enrich the mixture to the point

of engine roughness. To avoid this, lean the mixture as instructed in

the preceding paragraph.

STALLS

The stall characteristics are conventional and aural warning is

provided by a stall warning horn which sounds between 5 and 10

PMH above the stall in all configurations.

Power-off stall speeds at maximum gross weight and aft c.g. position

are presented in figure 5-2 as calibrated airspeeds since indicated

airspeeds are unreliable near the stall.

Spins

Intentional spins are prohibited in this airplane. Should an inadvertent

spin occur, standard light plane recovery techniques should be used.

LANDING

Landings are usually made on the main wheels first to reduce the

landing speed and the subsequent need for braking in the landing roll.

The nosewheel is lowered gently to the runway after the speed has

diminished to avoid unnecessary nose gear load. This procedure is

especially important in rough field landings.

For short field landings, make a power off approach at 69 MPH, IAS

with 40º flaps and land on the main wheels first. Immediately after

touchdown, lower the nose gear to the ground and apply heavy

braking as required. For maximum brake effectiveness, after all three

wheels are on the ground, retract the flaps, hold nose-up elevator and

apply maximum brake pressure without sliding the tires

CROSSWIND LANDINGS

When landing is a strong crosswind, use the minimum flap setting

required for the field length. Use a wing low, crab, or combination

method of drift correction and land in a nearly level attitude. Hold a

straight course with the steerable nosewheel and occasional br aking if

necessary.

COLD WEATHER OPEATION

Prior to starting on clod mornings, it is advisable to pull the propeller

through several times by hand to "break loose" or "limber" the oil,

thus conserving battery energy. In extremely cold (-20ºF) weather

the use of an external preheater is recommended whenever possible to

reduce wear and abuse to the engine and electrical system. Cold

weather starting procedures are as follows:

With preheat

1. Clear propeller

2. Master Switch -- On

3. With magneto switch "OFF" and throttle closed, prime the engine

four to ten strokes as the engine is being turned over

NOTE

Use heavy strokes of primer for best atomization of fuel. After

priming, push primer all the way in and turn to locked position to

avoid possibility of engine drawing fuel through the primer.

4. Turn magneto switch to "Both"

5. Open throttle to 1/4" and engage starter

page 210

page 2-11

Page 11

Without preheat

1. Prime the engine 8 to 10 heavy strokes while the propeller is

being turn by hand.

2. Clear propeller

3. Pull the master switch "On"

4. Turn magneto switch to "Both"

5. Open throttle 1/4"

6. Pull carburetor air heat knob to full on

7. Engage the starter and continue to prime engine until it is running

smoothly

8. Keep carburetor heat on until engine has warmed up.

NOTE

If the engine does not start the first time it is probable that the

spar plugs have been frosted over. Preheat must be used before

another start is attempted.

Section III

OPERATING LIMITATIONS

OPEATIONS AUTHORIZED

Your Cessna 182, with standard equipment as certified under FAA

Type Certificate 3A13 is approved for day and ni ght operation under

VFR.

Additional optional equipment is available to increase its utility and

to make it authorized under IFR day and night. An owner of a

properly equipped Cessna is eligible to obtain approval for its

operation on single-engine scheduled airline service under VFR.

Your Cessna Dealer will be happy to assist you in selecting

equipment best suited to your needs.

During cold weather operation, no indication will be apparent on the

oil temperature gauge prior to take of if outside air temperatures are

very cold. After a suitable warm-up period (2 to 5 minutes at 1000

RPM) accelerate the engine several times to higher engine RPM. If

the engine accelerates smoothly and the oil pressure r emains normal

and steady, the airplane is ready for take-off

When operating sub-zero temperature, avoid using partial carbureto r

heat. Partial heat may increase the carburetor air temperature to the

32º to 80ºF range, where icing is critical under certain atmospheric

conditions.

An optional winterization kit is available for use when operating to

temperatures below 20º F.

page 2-12

MANEUVERS - - NORMAL CATEGORY

The airplane exceeds the requirements for airworthiness of the

Federal Aviation Regulations, Part 23, set forth by the United States

Government. Spins and aerobatic maneuvers are not permitted

normal category airplanes in compliance with these regulations. In

connection with the foregoing, the following gross weight and flight

load factors apply:

Maximum Gross Weight 2800 lbs.

Flight Maneuvering Load factor, *Flaps Up +3.8 to -1.52

Flight Maneuvering Load Factor, *Flaps Down +3.5

* The design load factors are 150% of the above and in all cases the

structure meets or exceeds design loads.

page 3-1

Page 12

Your airplane must be operated in accordance with all FAA-approved

markings, placards and checklists in the airplane. If there is any

information in this section which contradicts the FAA-approved

markings, placards and checklists, it is to be disregarded.

OIL PRESSURE GUAGE

Minimum Idling 10 psi (red line)

Normal Operating Range 30 - 50 psi

Maximum 100 psi (red line)

AIRSPEED LIMITATIONS

The following are the certificated calibrated airspeed limits for your

Cessna

Maximum (Glide or dive, smooth air) 193 MPH (red line)

Caution Range 160 - 193 MPH (yellow arc)

Maximum Structural Cruising Speed 160 MPH

(Level flight or climb)

Normal Operation Range 67 - 160 MPH (green arc)

Maximum Speed, Flaps Extended 110 MPH

Flap Operation Range 60 - 110 MPH (white arc)

Maneuvering Speed * 128 MPH

* The maximum speed at which you can use abrupt control travel

without exceeding the design load factor

ENGINE OPEATION LIMITAIONS

Power and Speed 100 BHP at 2750 RPM

ENGINE OPERATION LIMITATINS

Power and Speed 230 BHP at 2600 RPM

MANIFOLD PRESSURE GAUGE

Normal Operating Range 15" to 23" Hg. (green arc)

CYLINDER HEAD TEMPERATURE GAUGE

Normal Operating Range 300º to 460º (green arc)

Do Not Exceed 460º (red line)

TACHOMETER

Normal Operating Range: 2200 -2450 (inner green arch)

Cautionary Range 2450 to 2600 RPM

Do Not Exceed 2600 RPM (red line)

FUEL QUANTITY INDICATORS

Empty E (red line)

ENGINE ISNTRUMENT MARKINGS

OIL TEMPERATURE GAUGE

Normal Operating Range Green Arc

Do Not Exceed 225º (red line)

Page 3-2

page 3-3

Page 13

WEIGHT AND BALANCE

The following information will enable you to operate your Cessna

within the prescribed weight and center of gravity limitations. To

figure the weight and balance for your particular airplane, use the

Sample Problem, Loading Graph, and Center of Gravity Moment

Envelope as follows:

Take the licensed Empty Weight and Moment/1000 from the Weight

and Balance Data Sheet, plus any changes noted on forms FAA-337

carried in your airplane, and write them down in the proper columns.

Using the Loading Graph, determine the moment/1000 of each item

to be carried. Total the weights and moments/1000 and use the

Center of Gravity Moment Envelope to determine whether the point

falls within the envelope and if the loading is acceptable.

SAMPLE

AIRPLANE

WT

SAMPLE

LOADING

PROBLEM

Licensed Empty

Weight (sample

airplane)

Oil 12 qts ** 22 -.03

Pilot and Passenger 340 12.2

Fuel (60 Gal at 6 #

/ gal

Rear Passengers 340 24.1

Baggage (or

passenger on

auxiliary seat

Total Aircraft

Weight

(lbs)

1660 57.9

2800 118.8

Moment (lb-

in)

/ 1000)

360 17.3

78 7.6

YOUR

AIRPLANE

WT

(lbs)

Moment (lb-

in)

/ 1000)

Locate this point (2800 at 118.8) on the Center of Gravity envelope chart and since

this falls within the envelope, the loading is acceptable.

** NOTE: Normally, full oil may be assumed for all flights

page 3-4

page 3-5

Page 14

Section IV

CARE OF THE AIRPLANE

If your airplane is to retain that new plane performance, stamina, and

dependability, certain inspection and maintenance requirements must

be followed. It is always wise to follow a planned schedule of

lubrication and maintenance based on the climatic and flying

conditions encountered in your locality.

Keep in touch with your Cessna dealer, and take advantage of his

knowledge and experience. He knows your airplane and how to

maintain it. He will remind you when lubrications and oil changes

are necessary and about outer seasonal and periodic services.

GROUND HANDLING

The airplane is most easily and safely maneuvered by hand with a

tow-bar attached to the nose wheel

NOTE

When using the tow-bar, never exceed the turning angle of 29º either

side of center, or damage to the gear will result.

page 3-6

MOORING YOUR AIRPLANE

Proper tie-down is the best precaution against damage to your parked

airplane by gusty or strong winds.

To tied down your airplane securely, proceed as follows:

1. Set parking brake and install control wheel lock

2. Install a surface control lock between each aileron and flap

3. Tie sufficiently strong ropes or chains (700 pounds tensile

strength) to wing, and tail tail-down fittings and secure each rope

to ramp tie-down

4. Install a pitot tube cover

page 4-1

Page 15

WINDSHIELD - - WINDOWS

The plastic windshield and windows should be kept clean and waxed

at all times. To prevent scratches and crazing, wash them carefully

with plenty of soap and water, using the palm of the hand to feel and

dislodge dirt and mud. A soft cloth, chamois or sponge may be used,

but only to carry water to the surface. Rinse thoroughly, then dry

with a clean moist chamois. Rubbing the surface of the plastic with a

dry cloth builds up an electrostatic charge so that it attracts dust

particles in the air. Wiping with a moist chamois will remove both

the dust and this charge

Remove oil and grease with a cloth moistened with kerosene. Never

use gasoline, benzine, alcohol, acetone, carbon tetrachloride, fire

extinguisher or anti-ice fluid, lacquer thinner or glass clean er. These

materials will soften the plastic and may cause it to craze.

After removing dirt and grease, if the surface is not badly scratched, it

should be waxed with a good grade of commercial wax. The wax

will fill in minor scratches and help prevent further scratching. Apply

a thin even coat of was and bring it to a high polish by rubbing lightly

with a clean, dry, soft flannel cloth. Do not use a power buffer; the

heat generated by the buffing pad may soften the plastic.

Do not use a canvas cover on the windshield unless freezing rain or

sleet is anticipated. Canvas covers may scratch the plastic surface.

ALUMINUM SURFACES

The clad aluminum surfaces of your Cessna require onl y a minimum

of care to keep them bright and cle an. The airplane may be washed

with clear water to remove dirt; oil and grease may be removed with

gasoline, naphtha, carbon tetrachloride or other non-alkaline solvents.

Dulled aluminum surfaces ma y be cleaned effecti vel y with an aircr aft

aluminum polish.

After cleaning and periodically thereafter, waxing with a good

automotive was will preserve the bright appearance and retard

corrosion. Regular waxing is especially recommended for airplanes

operated in salt-water areas as a protection against corrosion.

PAINTED SURFACES

The painted surfaces of your new Cessna require an initial curing

period which may be as long as 90 days after the finish is applied.

During this curing period some precautions should be taken to avoid

damaging the finish or interfering with the curing process. The finish

should be cleaned only by washing with clean water and mild soap,

followed by a rinse with water and drying with cloths or a chamois.

Do not use polish or wax, which would exclude air from the surface,

during this 90-day curing period. Do not rub or buff the finish and

avoid flying through rain, sleet or hail.

Once the finish has cured completely, it may be waxed with a good

automotive wax. A heavier coating of was on the leading edges of

the wings and tail and on the engine nose cap and propeller spinner

will help reduce the abrasion encountered in these areas.

PROPELLER CARE

Preflight inspection of propeller blades for nicks, and wiping them

occasionally with an oily cloth to clean off grass and bug stains will

assure long, trouble-free service. It is vital that small nicks on the

propellers, particularly near the tips and on the leading edges, are

dressed out as soon as possible since these nicks produce stress

concentrations, and if ignored, may result in cracks. Never use an

alkaline cleaner on the blades. Remove grass and dirt with carbon

tetrachloride or Stoddard solvent.

page 4-2

page 4-3

Page 16

INTERIOR CARE

INSPECTION SERVICE AND INSPECTION PERIODS

To remove dust and loose dirt from the upholstery, headliner, and

carpet, clean the interior regularly with a vacuum cleaner.

Blot up any spilled liquid promptly, with cleansing tissue or rags.

Don’t pat the spot; press the blotting material firmly and hold it for

several seconds. Continue blotting until no more liquid is taken up.

Scrape off sticky materials with a dull knife, then spot-clean the area.

Oily spots may be cleaned with household spot removers used

sparingly. Before using any solvent, read the instructions on the

container and test it on an obscure place on the fabric to be cleaned.

Never saturate the fabric with a volatile solvent; it may damage the

padding and backing materials.

Soiled upholstery and carpet may be cleaned with foam-type

detergent, and used according to the manu facturer's instructions. To

minimize wetting the fabric, keep the foam as dry as possible and

remove it with a vacuum cleaner,

The plastic trim, instrument panel and control knobs need only be

wiped off with a damp cloth. Oil and grease on the control wheel and

control knobs can be removed with a cloth moistened with kerosene.

Volatile solvents, such as mentioned in paragraphs on care of the

windshield, must never be used since they soften the craze the plastic.

With your airplane you will receive an Owner's Service Policy.

Coupons attached to the policy entitle you to an initial inspection and

the first 100-hour inspection at no charge. If you take delivery from

your Dealer, he will perform the initial inspection before delivery of

the airplane to you. If you pick up the airplane at the factor y, plan to

take it to your Dealer reasonably soon after you take deliver on it.

This will permit him to check it over and to make any minor

adjustments that may appear necessary. Also, plan an inspection by

your Dealer at 100 hours or 90 days, which ever comes first. This

inspection also is performed by your Dealer for you at no charge.

While these important inspections will be performed for you by any

Cessna Dealer, in most cases you will prefer to have the Dealer from

whom you purchased the airplane accomplish this work.

Federal Air Regulations required that all airplanes have a periodic

(annual) inspection as prescribed by the administrator, and performed

a person designated by the administrator. In addition, 100-hour

periodic inspections made by an "appropriately-rated mechanic" are

required if the airplane is flown for hire. The Cessna Aircraft

Company recommends the 100-hour periodic inspection for your

airplane. The procedure for this 100-hour inspection has been

carefully worked out by the factory and is followed by the Cessna

Dealer Organization. The complete familiarity of the Cessna Dealer

Organization with Cessna equipment and factory-approved

procedures provides the highest type of service possible at lower cost.

page 4-4

page 4-5

Page 17

AIRPLANE FILE

There are miscellaneous data, info rmation and licenses that are a part

of the airplane file. The following is a checklist for that file. In

addition, a periodic check should be made of the latest Civil Air

Regulations in insure that all data requirements are met.

LUBRICATION AND SERVICING PROCEDURES

Specific servicing information is provided here for items requiring

daily attention. A Service Frequency checklist is included to inform

the pilot when to have other items checked and serviced

1) To be displayed in the airplane at all times:

a) Aircraft Airworthiness Certificate (Form FAA-1362)

b) Aircraft Registration Certificate (Form FAA -500A)

c) Airplane Radio Station License (Form FCC-404, if transmitter

installed)

2) To be carried in the airplane at all times

a) Weight and Balance, and associated p apers (latest copy of the

Repair and Alteration Form, FAA-337 if applicable)

b) Airplane Equipment List

3) To be made available upon request:

a) Airplane Log Book

b) Engine Log Book

NOTE

Cessna recommends that these items, plus the Owner's Manual and

the 'Cessna Flight Guide" (Flight Computer) be carried in the airplane

at all times.

Most of the items listed are required by the United States Federal

Aviation regulations. Since the regulations of other nations may

require other documents and data, owners of exported airplanes

should check with their own aviation officials to determine their

individual requirements.

DAILY

Fuel Tank Filler

Service after each flight with 80/87 minimum grade fuel. The

capacity of each wing tank is 42.0 gallons with optional long-range

tanks

Fuel Strainer

On the first flight of the day and after each re fueling, drain for about

four seconds, to clear fuel strainer of possible water and sediment.

Turn the drain knob, then check that strainer drain is close after

draining.

Oil Dipstick

Check oil level before each flight. Do not operate on less than 9

quarts. To minimize loss of oil through breather, fill to 10-quart level

for normal flights of less than 3 hours. For extended flight, fill to 12

quarts. If optional oil filter is installed, one additional quart is

required when the filter element is changed.

page 4-6

page 4-7

Page 18

Oil Filler

When preflight check shows low oil level, service with aviation grade

engine oil: SAE 20 below 40ºF and SAE 40 above 40ºF. Your

Cessna was delivered from the factory with straight mineral oil (nondetergent) and should be operated with straight mineral oil for the

first 25 hours. The use of mineral oil during the 25-hour break-in

period will help seat the piston rings and will result in less oil

consumption. After the first 25 hours, either mineral oil or detergent

oil may be used. If a detergent oil is used, it must conform to

Continental Motors Corporation Specification MHS-24. Your Cessna

Dealer can supply an approved brand.

SERVICING INTERVALS CHECKLIST

EACH 100 HOURS

FUEL STRAINER - - Disassemble and clean

FUEL TANK SUMP DRAIN PLUGS - Remove and drain

FUEL LINE DRAIN PLUG - - Remove and drain

BRAKE MASTER CYLENDERS - -Check and Fill

SHIMMY DAMPENER - - Check and Fill

VACUUM SYSTEM OIL SEPARATOR (OPT) - - Clean

SUCTION RELIEF VALVE INLET SCREEN (OPT) - -Clean

EACH 50 HOURS

BATTERY- - Check and Service. Check oftener (at least every 30

days) if operating in hot weather)

ENGINE OIL AND OIL FILTER - - Change engine oil and replace

filter element. If optional oil filter is not installed changed oil and

clan screen every four months even thought less than 50 hours hav e

been accumulated. Reduce periods for prolonged oper ation in dusty

area, cold climates, or when short flights and long idle periods result

in sludging conditions.

CARBURETOR AIR FILTER - -Clean or replace. Under extremely

dusty conditions, daily maintenance of the filter is recommended

NOSE GEAR TORQUE LINKS - - Lubricate

page 4-8

EACH 500 HOURS

WHEEL Bearings - -Lubricate. Lubricate at first 100 hours and at

500 hours thereafter

VACUUM SYSTEM AIR FLITER (OPT) - - Replace filter element.

Replace sooner if suction gauge reading drops to 4.6" Hg.

AS REQUIRED

NOSE GEAR SHOCK STRUT - - Keep inflated and filled

Gyro instrument air filters (OPT) - - Replace at instrument overhaul

page 4-9

Page 19

Section V

OPERATIONAL DATA

The operational data shown on the following pages are pr esented for

two purposes: first, so that you may know what to expect f rom your

airplane under various conditions, and second, to enable you to plan

your flights in detail and with reasonable accuracy.

AIRSPEED CORRECTION TABLE

The data in the charts has been compiled from actual flight tests with

the airplane and engine in good condition and using average piloting

techniques. Note also that the range charts make on allowances fo r

wind, navigational error, warm-up, take-off, climb, etc. You must

estimate these variables for yourself and make allowances

accordingly.

Remember that the charts contained herein are based on standard da y

conditions. Form more precise power, fuel consumption, and

endurance information, consult the Cessna Flight Guide (Power

Computer) supplied with your aircraft. With the flight Guide, you

can easily take into account temperature variations from standard at

any flight altitude..

FLAPS

UP

FLAPS

DOWN

20°-40°

IAS 60 80 100 120 140 160 180 -CAS 68 83 100 118 137 156 175 --

IAS405060708090100110

CAS586368758492101110

Maximum Flap Speed 110 MPH, CAS

figure 5-1

STALLING SPEEDS

Power off, (mph)

Gross

Weight

2800 lbs.

Flaps 0º 64 69 91

Flaps 20º 57 61 81

Flaps 40º 55 59 78

ANGLE OF BANK

0º 30º 60º

page 5-1

figure 5-2

page 5-2

Page 20

----------------- TAKE – OFF DISTANCE ------------------

TAKEOFF DISTANCE WITH 20° FLAPS FROM HARD

SURFACE RUNWAY

At Sea Level, 59°F At 2,500 ft, 50°FGROSS

GROUND

RUN

295

160

65

440

255

115

625

380

190

At 5,000 ft, 41°F At 7,500 ft, 32°FGROSS

GROUND

RUN

415

235

105

630

380

190

895

565

305

TO

CLEAR

50’ OBS.

655

425

235

895

600

355

1205

830

515

TO

CLEAR

50’ OBS.

855

570

35

1210

835

515

1695

1200

780

GROUND

RUN

350

195

80

525

310

150

745

460

240

GROUND

RUN

500

290

135

765

470

245

1095

700

390

TO

CLEAR

50’ OBS.

745

490

280

1035

705

425

1420

990

630

TO

CLEAR

50’ OBS.

1005

680

405

1400

1020

645

2090

1505

1000

WT

LBS

2000 52

2400 57

2800 61

WT

LBS

2000 52

2400 57

2800 61

NOTE

IAS

MPH

IAS

MPH

HEAD

WIND

MPH

0

15

30

0

15

30

0

15

30

HEAD

WIND

MPH

0

15

30

0

15

30

0

15

30

Increase distance 10% for each 25° F above standard temperature

figure 5-3

page 5-3

MAXIMUM RATE OF CLIMB DATA

At Sea Level, 59°FGROSS

WT

LBS

2000

2400

2800

WT

LBS

2000

2400

2800

WT

LBS

2000

2400

2800

WT

LBS

2000

2400

2800

WT

LBS

2000

2400

2800

IAS

MPH

84

86

88

IAS

MPH

82

84

86

IAS

MPH

79

82

84

IAS

MPH

76

79

82

IAS

MPH

74

77

80

RATE OF

At 5,000 ft, 41°FGROSS

RATE OF

At 10,000 ft, 23°FGROSS

RATE OF

At 15,000 ft, 23°FGROSS

RATE OF

At 20,000 ft, 23°FGROSS

RATE OF

CLIMB

FPM

1710

1295

980

CLIMB

FPM

1350

1005

745

CLIMB

FPM

995

720

510

CLIMB

FPM

640

435

280

CLIMB

FPM

280

150

50

FUEL

USED,

GAL

1.5

1.5

1.5

FUEL

USED,

GAL

2.7

3.1

3.7

FUEL

USED,

GAL

4.1

5.0

6.3

FUEL

USED,

GAL

5.9

7.6

10.2

FUEL

USED,

GAL

9.2

12.9

20.5

NOTE: Flaps up, full throttle and 2600 RPM. M mixture leaned to smooth

operation above 5000 ft. Fuel used includes warm-up and takeoff

allowance

page 5-4

Page 21

CRUISE PERFORMANCE

Standard Conditions -- Zero Wind – Gross Weight 2800 Pounds

RPM MP %

2450 23

22

21

20

2300 23

22

21

20

2200 23

22

21

20

2000

MAXIMUM

RANGE

SETTINGS

2450 23

2300 23

2200 23

2000

MAXIMUM

RANGE

SETTINGS

20

19

18

17

22

21

20

22

21

20

22

21

20

19

18

17

16

LEAN MIXTURE

BHP

GAL/

HR

2500 FEET

76

72

68

63

71

67

62

59

67

63

59

55

47

43

39

35

14.2

13.4

12.7

12.0

13.1

12.2

11.5

11.0

12.1

11.4

10.8

10.2

8.7

8.2

7.5

7.0

5000 FEET

78

73

70

65

73

69

64

60

68

64

60

57

45

41

37

34

14.5

13.6

13.0

12.2

13.4

12.6

11.9

11.2

12.4

11.7

11.0

10.5

8.5

7.9

7.3

6.8

TAS

MPH

158

154

151

148

154

149

145

142

149

146

142

138

126

121

113

105

163

159

156

151

158

155

151

146

155

151

146

143

126

118

111

103

END

HOURS

(

5.6

5.9

6.2

6.6

6.0

6.5

6.9

7.2

6.5

6.9

7.3

7.7

9.1

9.6

10.5

11.3

5.4

5.8

6.1

6.5

5.9

6.3

6.6

7.1

6.4

6.8

7.2

7.5

9.3

10.0

10.8

11.6

CRUISE PERFORMANCE

LEAN MIXTURE

Standard Conditions -- Zero Wind – Gross Weight 2800 Pounds

.

RANGE

MILES

)

(

)

885

910

940

995

925

970

055

10220

980

1010

1040

1045

1135

1170

1185

1190

885

925

950

985

930

965

1005

1035

985

1020

1050

1075

1175

1190

1200

1190

RPM MP %

2450 21

20

19

18

2300 21

20

19

18

2200 21

20

19

18

2000

MAXIMUM

RANGE

SETTINGS

2450 19

2300 19

2200 19

2000

MAXIMUM

RANGE

SETTINGS

19

18

17

16

18

17

16

18

17

16

18

17

16

18

17

16

15

BHP

GAL/

HR

7,500 FEET

71

67

62

58

66

62

58

54

62

58

54

51

47

43

39

36

13.1

12.4

11.7

11.0

12.2

11.6

11.0

10.5

11.4

10.7

10.2

9.7

8.7

8.1

7.6

7.0

10,000 FEET

63

60

55

51

60

56

51

47

56

52

49

45

44

40

38

35

11.9

11.2

10.6

10.0

11.1

10.5

9.8

9.2

10.4

9.8

9.3

8.7

8.4

7.8

7.4

6.9

TAS

MPH

161

157

152

147

156

151

147

142

152

148

143

138

131

123

116

107

156

152

146

141

152

147

141

134

148

142

136

129

128

120

14

105

END

HOURS

(

6.0

6.4

6.8

7.2

6.5

6.8

7.2

7.5

6.9

7.4

7.7

8.1

9.1

9.8

10.4

11.3

6.6

7.1

7.5

7.9

7.1

7.5

8.1

8.6

7.6

8.1

8.5

9.1

9.4

10.1

10.7

11.4

.

RANGE

MILES

)

(

)

960

1005

1025

1055

1005

1025

1050

1065

1055

1090

1105

1130

1185

1200

1210

1210

1035

1055

1090

1105

1080

1105

1130

1145

1120

1155

1160

1175

1200

1215

1215

1200

page 5-5

figure 5.4 (Sheet 1 of 3)

figure 5.4 (Sheet 2 of 3)

page 5-6

Page 22

CRUISE PERFORMANCE

Standard Conditions -- Zero Wind – Gross Weight 2800 Pounds

RPM MP %

2450 16

15

14

2300 16

15

14

2200 16

15

14

2000

MAXIMUM

RANGE

SETTINGS

2450 13

2300 13

2200 13

16

15

14

12

12

12

LEAN MIXTURE

BHP

GAL/

HR

15,000 FEET

54

50

46

50

47

42

47

44

40

40

37

34

10.4

9.8

9.2

9.6

9.1

8.5

9.1

8.6

8.0

7.8

7.3

6.8

20,000 FEET

44

40

42

38

39

35

9.0

8.3

8.4

7.7

7.8

7.2

TAS

MPH

150

142

135

143

136

127

138

130

120

122

112

101

133

122

126

113

118

103

END

HOURS

(

7.6

8.1

8.6

8.2

8.7

9.3

8.7

9.2

9.9

10.1

10.8

11.6

8.8

9.5

9.4

10.3

10.1

11.0

.

RANGE

MILES

)

(

)

1135

1155

1160

1170

1185

1185

1200

1200

1190

1240

1210

1175

1175

1155

1190

1155

1190

1135

page 5-7

figure 5.4 (Sheet 3 of 3)

page 5-8

Page 23

Section VI

OPTIONAL SYSTEMS

This section contains a description, operating procedures, and

performance data (when applicable) for some of the optional

equipment which may be installed in your Cessna. Owner’s Manual

Supplements are provided to cover operation of other optional

equipment systems when installed in your airplane. Contact your

Cessna Dealer for a complete list of available optional equipment.

LONG RANGE FUEL TANKS

Special wings with long-range fuel tanks are avail able to replace the

standard wings and fuel tanks for greater endurance and r ange. Wh en

these tanks are installed, the total usable fuel, for all flight conditions

is 79 gallons.

COLD WEATHER EQUIPMENT

WINTERIZATION KIT AND NON-CONGELALING OIL

COOLER

(not installed)

Page 5-9

GROUND SERVICE PLUG RECEPTACLE

A ground service plug receptacle may be installed to permit the use of

an external power source for cold w eather start ing and durin g len gthy

maintenance work on the electrical system.

Before connecting a generator type external power source, it is

important that the master switch be turned on. This will enable the

battery to absorb transient voltages which otherwise might damage

the semiconductors in the electronic equipment. When using a

battery type external power source, the master switch should be

turned off to prevent an unnecessary power drain form the power

source batteries to the airplane’s battery.

page 6-1

Page 24

IMPORTANT

Be certain that the polarity of any external power source or batteries

is correct (positive to positive and negative to negative). A polarity

reversal will result in immediate damage to semiconductors in the

airplane’s electronic equipment.

OIL DILUTION SYSTEM

(not installed)

STATIC PRESSURE ALTERNATE SOURCE

A static pressure alternate source valve may be installed in the static

system for use when the external static sources are malfunctioning.

This valve also permits draining condensate from the static lines.

If erroneous instrument reading are suspected du e to water or ice in

the static pressure lines, the static pressure alternate source valve

should be opened, thereby supplying static pressure from the cabin.

Cabin pressures will vary, however, with open cabin ventilators or

windows. The most adverse combinations will result in airspeed and

altimeter variations of no more than 2 mph and 20 feet respectively.

RADIO SELECTOR SWITCHES

RADIO SELECTOR SWITCH OPERATION

Operation of the radio equipment is normal as covered in the

respective radio manuals. When more than one radio is installed, an

audio switching is necessary. The operation of this switching system

is described below.

TRANSMITTER SELECTOR SWITCH

The transmitter selector switch has two positions. When two

transmitters are installed, it is necessary to switch the microphone to

the radio unit the pilot desires to use for transmission. This is

accomplished by placing the transmitter selector switch in the

position corresponding to the radio unit which is to be used.

page 6-2

SPEAKER-PHONE SWITCHES

The speaker-phone switches determine whether the output of the

receiver is use is fed to the headphones or through the audio amplifier

to the speaker. Place the switch for the desired receiving system

either in the up position for speaker operation or in the down position

for headphones

AUTOPILOT –OMNI SWITCH

When a Nav-O-Matic autopilot is installed with two compatible omni

receivers, an autopilot-omni switch is utilized. This switch select the

omni receiver to be used for the omni course sensing function of t he

autopilot. The up position selects the upper receiver in the radio

panel stack, and the down position selects the lower omni receiver.

page 6-3

Page 25

OXYGEN SYSTEM – not installed

CESSNA ECONOMY MIXTUERE INDICATOR

NOTES

Changes in altitude or power setting require the EGT to be rechecked

and the mixture re-set

The Cessna Economy Mixture Indicator is an exhaust gas temperature

sensing device which is used to aid the pilot in selecting the most

desirable fuel-air mixture for cruising flight at less than 75% power.

Exhaust gas temperature (EGT) varies with the ratio of fuel-to-air

mixture entering the engine cylinders.

OPERATING INSTRUCTIONS

1. In take-off and full power climb, use full rich mixture

2. In level flight (or cruising climb at less than 75% power), lean the

mixture to peak EGT; then enrichen as desire using the following

table as a guide

MIXTURE

DESCRIPTION

EGT TAS LOSS

FROM BEST

POWER

RANGE

INCREASE

FROM BEST

POWER

BEST POWER

(Maximum

speed)

NORMAL

LEAN (Owner’s

Manual &

Peak minus

125°

(enrichen)

Peak minus

75°

(enrichen)

0 MPH 0 %

1 MPH 10 %

Computer

Performance)

MAXIMUM

LEAN

Peak minus

25°

3 MPH 20 %

(enrichen)

Operation at peak EGT is not authorized for normal continuous

operation, except to establish peak EGT for reference. Op eration on

the lean side of peak EGT or within 25° of peak EGT is not approved.

3. Use rich mixture (or mixture appropriate for field elevation) in

idle descents or landing approaches. Leaning techniques for

cruise descents may be with EGT reference method (at least every

5000 feet) or by simply enriching to avoid engine roughness if

numerous power reductions are made.

TRUE AIRSPEED INDICATOR

A true airspeed indicator is available to replace the standard airspeed

indicator in your airplane. The true airspeed indicator ha a calibrated

rotatable ring which works in conjunction with the airspeed indicator

dial in a manner similar to the operation of a flight computer.

To obtain True airspeed, rotate ring until pressure altitude is aligned

altitude is aligned with outside temperature in degrees Fahrenheit.

Then read true airspeed on rotatable ring opposite airspeed needle.

NOTE

Pressure altitude should not be confused with indicated altitude. To

obtain pressure altitude, set barometric scale on altimeter to 29.92”

and read pressure altitude on altimeter. Be sure to return altimeter

barometric scale to original barometric setting after pressure altitude

has been obtained.

page 6-4

page 6-5

Page 26

Altitude Temp (F) Temp (C)

Sea Level- 59 15

1,000 55.5 13

2,000 52 11

3,000 48.5 9

4,000 45 7

5,000 41.5 5

6,000 38 3

7,000 34.5 1

8,000 31 -1

9,000 27.5 -3

10,000 2 4 -5

11,000 20.5 -7

12,000 1 7 -9

13,000 13.5 -11

14,000 10 -13

15,000 6.5 -15

16,000 3 -17

17,000 -0.5 -19

18,000 -4 -21

19,000 -7.5 -23

20,000 -11 -25

Standard Temperatures

Page 27

ALPHABETICAL INDEX

A

After landing, 1-5

Air Filter

carburetor 4-8

gyro instrument 4-8

vacuum system 4-8

Airplane

before entering, 1-1

file, 4-6

ground handling, 4-1

mooring, 4-1

secure, 1-5

Airspeed correction table, 5-2

Airspeed limitatio ns, 3- 2

Aluminum surfaces, 4-2

Authorized operations, 3-1

B

Baggage capacity, i

Battery 4-78Beacon, rotating 2-2

Before entering airplane, 1-1

Before landing, 1-4

Before starting engine, 1-2

Before takeoff, 1-2, 2-6

Brake Master cylinders 4-9

C

Cabin heating and ventilating system, 2-4

Capacity

fuel, i

oil, i

Carburetor, 2-2

Care

interior, 4-34 propeller, 4-3

Center of gravity moment envelope, 3-6

Checklist, servicing intervals, 4-8, 4-9

Circuit Breakers 2-2

Climb, 1-4

maximum performance, 1-4

normal, 1-4

Cold Weather Equipment. 6-1

Cold weather operation, 2-11

operations 2-11

starting 2-11

Correction Table, airspeed, 5-2

Cruise performance table, 5-4

Cruising, 1-4

D

Diagram, exterior inspection, iv

Dimensions, principal, ii

Dipstick, oil 4-7

E

Economy Mixture Indicator 6-4

operating instructions, 6-4

Electrical system, 2-2

circuit breakers, 2-2

ground service receptacle 6-1

rotating beacon 2-2

Empty weight, i

Engine,

before starting, 1-1

instrument markings, 3-2

operation limitations, 3-2

primer, 2-2

starting, 1-2

Equipment, cold weather 6-1

Exterior Inspection , iv

F

File, airplane, 4-5

Fuel System, 2-1

Page 28

capacity, i

carburetor, 2-2

engine primer, 2-2

fuel line drain plug 4-7

fuel strainer,,2-2, 4-6, 4-7

fuel tank fillers, 4-6

fuel tank sump drains, 4-7

mixture control, 2-2

schematic, 2-2

selector valve 2-2

throttle, 2-2

wing tanks, 2-2,6-1

Graph,

center of gravity moment

envelope, 3-6

Loading, 3-5

Gross weight, i

Ground handling, 4-1

Ground Service Plug Receptacle, 6-1

Gyro Instrument Air Filters, 4-7

Landing, i, 2-9

after, 1-4

before, 1-3

distance table, 6-2

normal, 1-3

Let Down, 1-4

Limitations,

airspeed, 3-2

Loading graph, 3-5

Loading problem, sample, 3-4

Lubrications and servicing procedures, 4-6

M

G

Maneuvers, utility category, 3-1

Master Cylinders, brake, 4-7

Maximum Glide, 5-8

Maximum performance climb, 1-3

Maximum performance takeoff, 1-2

Mixture Control 2-2

Moment Envelope, Center of Gravity, 3-6

Mooring your airplane, 4-1

N

H

Handling Airplane on ground, 4-1

Heating and ventilation system, cabin, 2-4

Hot Weather operation, 2-12

Hydraulic Fluid (after index)

I

Inspection diagram, exterior, iv

Inspection service and inspection periods, 4-4

Instrument markings, engine,3-3

Interior care, 4-3

L

Normal Category -Maneuvers, 3-1

Normal climb, 1-3

Normal landing, 1-3

Normal takeoff, 1-2

Nose Gear Shock Strut, 4-7

Nose Gear Torque Links, 4-7

O

Oil System

capacity, i

Dipstick, 4-7

Filler, 4-6

Temperature gauge, 3-3

Pressure gauge, 3-3

Operation, cold weather 2-10

Operation, hot weather, 2-12

Page 29

Operations, limitations, engine, 3-2

Operations, authorized, 3-1

Optimum Cruise Performance. 2-8

Owner follow-up system, 4-5

Painted Surfaces, 4-2

Performance - specifications, i

Power checks, 2-7

Power, i

Power loading, i

Pressure, Tire, after inde x

Primer, engine, 2-2

Principal dimensions, ii

Propeller care, 4-3

Stalls, 2-9

speed chart, 5-2

Starting engine, 1-2, 2-4

Static Pressure, alternate source, 6-3

Strainer, fuel, 2-2

P

Suction relief valve inlet, screen, 4-7

Surfaces,

aluminum, 4-2

painted, 4-2

System

cabin heating and ventilating, 2-4

electrical, 2-3

fuel, 2-1

owner follow-up, 4-5

T

R

Radio Selector Switches, 6-4

autopilot-omni switch, 6-4,6-5

operations, 6-4

speaker-phone,6-4,6-5

transmitter selector, 6-4

Range, i, 5-4

Rate of climb, i

Rotating Beacon, 2-3

S

Sample loading problem, 3-4

Secure aircraft, 1-4

Selector valve, Fuel, 3-2

Service ceiling, i

Servicing and lubrication, 4-6

Servicing intervals, check list, 4-7, 4-8

servicing requirements table , after index

Shimmy Dampener, 4-7

Shut-off valve, fuel, 2-2

Specifications, performance, i

Speed, i

Spins, 2-9

Tachometer, 3-3

Takeoff, i, 1-2, 2-7

before takeoff, 1-2, 2-6

crosswind, 2-8

distance table, 5-3

maximum performance, 1-2

normal, 1-2

Taxiing, 2-4

diagram, 2-5

Throttle, 2-2

Tire pressure (after index)

True Airspeed indicator, 6-11

V

Vacuum System Air filter, 4-7

Vacuum System oil separator, 4-7

Valve, fuel shutoff, 2-2

W

Weight,

empty, i

gross, i

Page 30

Weight and balance, 3-3

center of gravity moment envelope, 3-6

loading graph, 3-6-5

sample loading problem, 3-4

Windshield - windows, 4-2

Wing loading, i

Page 31

Servicing Requirements

FUEL

Aviation Grade 80/87 Minimum, grade

Capacity, each 42 gallons

ENGINE OIL

aviation grade SAE 20 below 40º

SAE 24 above 40º

Capacity of sump 12 quarts

HYDRAULIC FLUID

MIL - H - 5606 Hydraulic fluid

TIRE PRESSURE

Nose gear 32 psi

Main gear 32 psi (5:00 x 5 tire)

Loading...

Loading...