Cessna 152 schematic

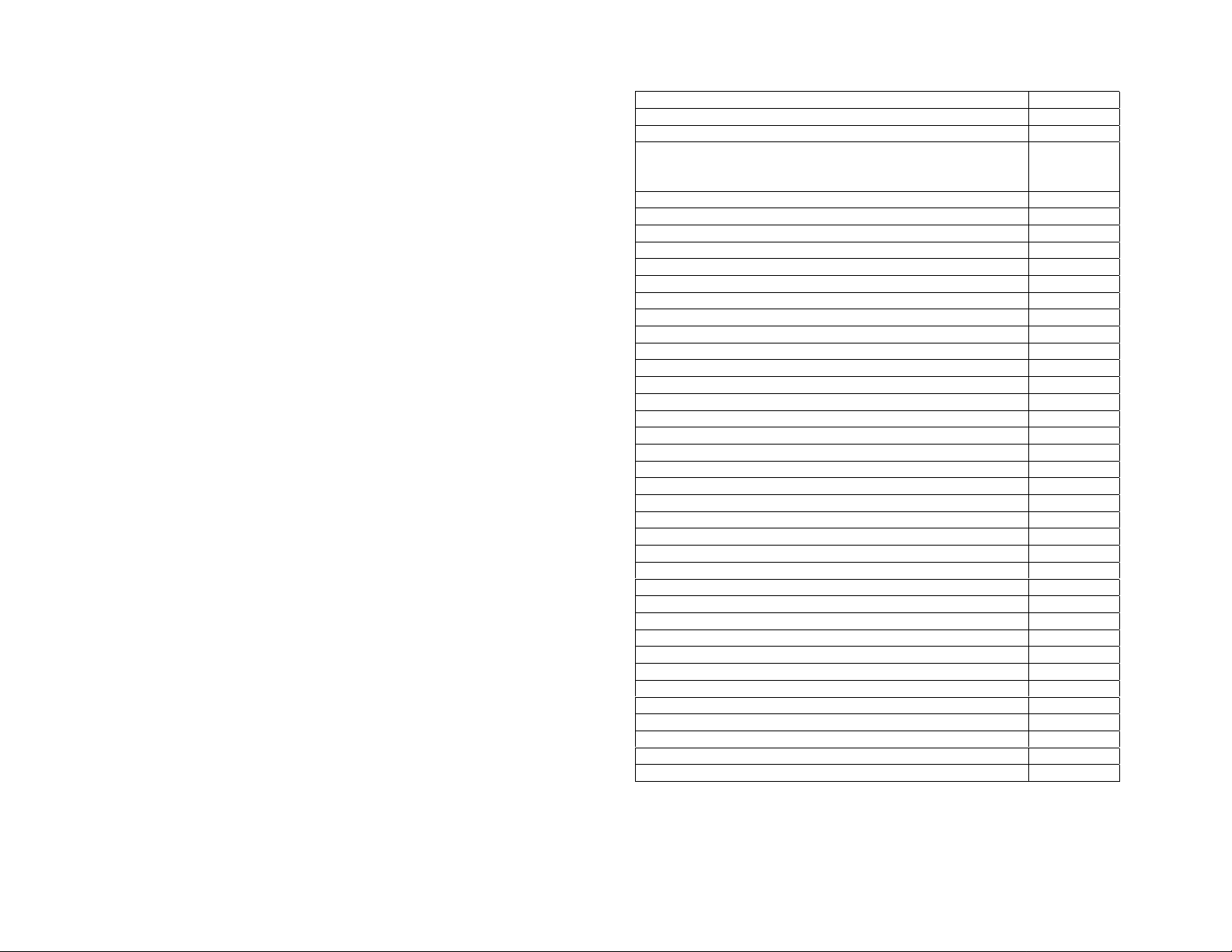

Performance - Specifications

Pilot’s Operating Handbook

And

FAA Approved Airplane Flight Manual

(abridged for KC N Aero Club)

N49696

For complete information, consult Pilot’s operating Manual

This abbreviated pilot’s handbook contains excerpts of the Cessna 152 Pilot’s

Operating Handbook.

Standard Temperature Chart added January 2, 2003

Speed *

Maximum at Sea Level ……………………………………. 110 knots

Cruise, 75% Power at 8,000 ft …………………………….. 107 knots

CRUISE: Recommended lean mixture with fuel allowance for

engine start, taxi, takeoff, climb and 45 minutes reserve at 45%

power

75% Power at 8,000 ft ………………………………….. Range 350 NM

24.5 Gallons usable fuel ………………………………. .Time 3.4 hours

75% Power at 8,000 ft ………………………………….... Range 580 NM

37.5 Gallons usable fuel ………………………………. Time 5.5 hours

Maximum Range at 10,000 ft …………………………….. Range 415 NM

24.5 Gallons usable fuel ……………………………….. Time 5.2 hours

Maximum Range at 10,000 ft …………………………….. Range 690 NM

37.5 Gallons usable fuel ……………………………….. Time 8.7 hours

RATE OF CLIMB AT SEA LEVEL ……………………………. 715 FPM

SERVICE CEILING ……………………………………………… 14,700 FT

TAKEOFF PERFORMANCE

Ground Roll ……………………………………….………….. 725 ft

Total Distance over 50 ft obstacle ……………………………… 1340 ft

LANDING PERFORMANCE

Ground roll ………………………………………..…………… 475 ft

Total Distance over 51 ft obstacle ………………..……………. 1200 ft

STALL SPEED (CAS)

Flaps up, power off ……………………………….…………… 48 knots

Flaps down, power off ………………………………………….. 43 knots

MAXIMUM WEIGHT

Ramp ………………………………………………..…………. 1675 lbs

Takeoff or landing …………………………………..…………. 1670 lbs

STANDARD EMPTY WEIGHT

152 ………………………………………………………………. 1101 lbs

152 II ………………………………………………………..…. 1133 lbs

MAXIMUM USEFUL LOAD

152 ……………………………………………………………. 574 lbs

152 II …………………………………………………………… 542

BAGGAGE ALLOWANCE ……………………………………… 120 LBS

WING LOADING (Pounds / s.f.) ………………………………… 10.5

POWER LOADING (Pounds / HP) ……………………………… 15.2

FUEL CAPACITY 26 gal

OIL CAPACITY ………………………………………………… 6 qt s

ENGINE: Avco Lycoming O235-L2C 110 bhp at 255o rpm

PROPELLER: Fixed Pitch, diameter ……………………………. 69 in

Speed performance is shown for an airplane equipped with optional speed fai ri ngs which increa se

•

the speeds by approximat ely 2 kts. There is a corresponding difference in ra nge while all other

performance figures are unchanged when speed fairings are insta lled.

•

Page 1-2

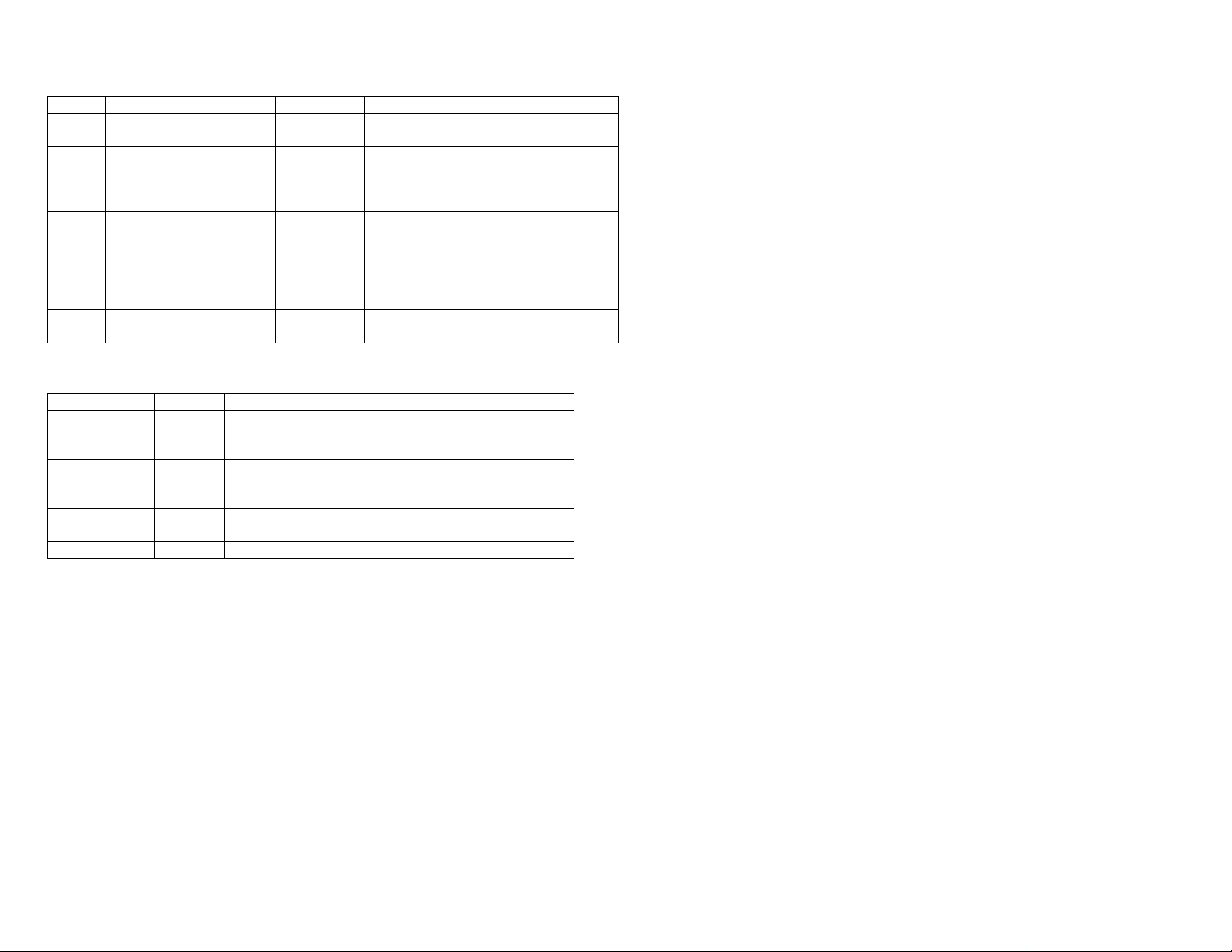

AIRSPEED LIMITATIONS

SPEED KCAS KIAS REMARKS

V

V

V

AIRSPEED INDICATOR MARKINGS

Never Exceed Speed 145 149 Do not exceed this

NE

Maximum Structural

NO

Cruising Sped

V

Maneuvering Speed:

A

1670 lbs.

1500 lbs.

1350 lbs.

Maximum Flap Extended

FE

Speed

Maximum Window Open

Speed

speed in any operation

108 111 Do not exceed this

speed except in smooth

air, and then only with

caution

Do not make full or

101

96

91

104

98

93

abrupt control

movements above this

speed

87 85

145 149

No aerobatic maneuvers are approved except those listed below

Maneuver Recommended Entry Speed

Chandelles 95

Lazy Eight s 95

Steep Turns 95

Spins Slow Deceleration

Stalls (except whip stalls) Slow Deceleration

Higher speeds can be used i f abrupt use of controls if avoided

The baggage compartment and / or child’s seat must not be occupied during aerobatics

Aerobatics that may impose high loads should not be attempted. The important thing to bear

in mind in flight maneuvers is that the airplane is that the airplane is clean in aerodynamic

design and will build up speed quickly with the nose down. Proper speed control is an

essential requirement for execution of any maneuver and care should always be exercised to

avoid excessive speed which , in turn, can impose excessive loads. In the execution of all

maneuvers, avoid abrupt of controls.

MARKING KIAS SIGNIFICANCE

White arc 35 - 85 Full flap operating range. Lower limit is maximum weight

V-so in landing configuration. Upper limit is maximum

speed permissible with flaps extend ed

Green arc 40 – 111 Normal operation range. Lover limit is maximum weight

Vs at most forward C.G. with flaps retracted. Upper limit

is maximum structural cruising speed

Yellow arc 111 –

149

Operations must be conducted with caution and only in

smooth air

Red Line 149 Maximum speed for all operations

Power Plant Limitations and Markings

Engine Operating Limits for Takeoff and Continuous Operations

Maximum Power – 110 BHP

Maximum Engin e speed – 2550 RPM

Maximum Oil Temperature 24 5° F (118°C)

Oil Pressure

Minimum – 25 psi

Maximum – 100 psi

Maneuver limits

This airplane is certificated in the utility category and is designed for limited aerobatic flight.

In the acquisition of various certificates such as commercial pil ot and flight instructor, certain

maneuvers are required. All of these maneuvers are permitted in this airplane

Page 1-3

Flight Load Factor Limits

Flaps Up + 4.4 g to –1.76 g

Flaps Down + 3.5 g

Fuel Limitations

Total fuel capacity 26 gal (13 gal each tank)

Usable fuel, all conditions 24.5 gal

Approved Fuel Grades

100 LL Grade Aviation

100 Grade Aviation

Automotive (91 octane minimum)

Mixed fuel (automotive and aviati on)

Section 2- Placards Not Incl uded

Page 1-4

SECTION 3

EMERGENCY PROCEDURES

Table of Contents

Page

Introduction.......................................................................................................... 3-3

Airspeeds for Emergency Operation..................................................................... 3-3

OPERATIONAL CHECKLISTS

Engine Failures..................................................................................................... 3-3

Engine Failure During Takeoff Run............................................................. 3-3

Engine Failure Immediately After Takeoff. ................................................. 3-3

Engine Failure during Flight......................................................................... 3-3

Forced Landings................................................................................................... 3-4

Emergency Landing Without Engine Power.................................................3-4

Precautionary Landing With Engine Power.................................................. 3-4

Ditching........................................................................................................ 3-4

Fires...................................................................................................................... 3-5

During Start On Ground ...............................................................................3-5

Engine Fire In Flight..................................................................................... 3-5

Electrical Fire In Flight................................................................................. 3-5

Cabin Fire..................................................................................................... 3-6

Wing Fire...................................................................................................... 3-6

Icing...................................................................................................................... 3-6

Inadvertent Icing Encounter..........................................................................3-6

Landing With A Flat Main Tire ........................................................................... 3-7

Electrical Power Supply System Malfunctions.....................................................3-7

Ammeter Shows Excessive Rate Of Charge (Full Scale Deflection)............3-7

Low-Voltage Light Illuminates During Flight (Ammeter Indicates Discharge)3-7

Carburetor Icing..........................................................................................3-11

Spark Plug Fouling .....................................................................................3-11

Magneto Malfunction ................................................................................. 3-11

Low Oil Pressure ........................................................................................ 3-12

Electrical Power Supply System Malfunctions................................................... 3-12

Excessive Rate of Charge ...........................................................................3-12

Insufficient Rate of Charge ......................................................................... 3-12

AMPLIFIED PROCEDURES

Engine Failures..................................................................................................... 3-8

Forced Landings................................................................................................... 3-8

Landing without elevator control.......................................................................... 3-9

Fires...................................................................................................................... 3-9

Emergency Operation In Clouds (Vacuum System Failure)................................. 3-9

Executing A 1800 Turn In Clouds................................................................ 3-9

Emergency Descent Through Clouds......................................................... 3-10

Recovery From A Spiral Dive.................................................................... 3-10

Inadvertent Flight Into Icing Conditions............................................................. 3-10

Spins................................................................................................................... 3-11

Page 3-1

Rough Engine Operation Or Loss Of Power...................................................... 3-11

Page 3-2

INTRODUCTION

Section 3 provides checklist and amplified procedures for coping with emergencies

that may occur. Emergencies cau sed by airplane or engine malfunctions are extremely rare if

proper preflight inspections and maintenance are practiced. Enroute weather emergencies can

be minimized or eliminated by careful flight planning and good judgment when unexpected

weather is encountered. However, should an emergency arise, the basic guidelines described

in this section should be considered and applied as necessary to correct the problem..

ENGINE FAILURE DURING FLIGHT

1. Airspeed -- 60 KIAS.

2. Carburetor Heat -- ON.

3. Primer -- IN and LOCKED.

4. Fuel Shutoff Valve -- ON.

5. Mixture -- RICH.

6. Ignition Switch -- BOTH (or START if propeller is stopped).

FORCED LANDINGS

AIRSPEEDS FOR EMERGENCY OPERATION

Engine Failure After Takeoff....................................................................... 60 KIAS

Maneuvering Speed:

1670 Lbs.....................................................................................................104 KIAS

1500 Lbs...................................................................................................... 98 KIAS

1350 Lbs...................................................................................................... 93 KIAS

Maximum Glide........................................................................................... 60 KIAS

Precautionary Landing With Engine Power................................................. 55 KIAS

Landing Without Engine Power:

Wing Flaps Up............................................................................................. 65 KIAS

Wing Flaps Down........................................................................................ 60 KIAS

OPERATIONAL CHECKLISTS

ENGINE FAILURES

ENGINE FAILURE DURING TAKEOFF RUN

1. Throttle -- IDLE.

2. Brakes -- APPLY.

3. Wing Flaps -- RETRACT.

4. Mixture -- IDLE CUT-OFF.

5. Ignition Switch -- OFF.

6. Master Switch -- OFF.

ENGINE FAILURE IMMEDIATELY AFTER TAKEOFF

1. Airspeed -- 60 KIAS.

2. Mixture -- IDLE CUT-OFF.

3. Fuel Shutoff Valve -- OFF.

4. Ignition Switch -- OFF.

5. Wing Flaps -- AS REQUIRED.

6. Master Switch -- OFF.

EMERGENCY LANDING WITHOUT ENGIN E POWER

1. Airspeed –65 KIAS (flaps up

60 KIAS (flaps DOWN).

2. Mixture -- IDLE CUT-OFF.

3. Fuel Shutoff Valve -- OFF.

4. Ignition Switch -- OFF.

5. Wing Flaps -- AS REQUIRED (30° recommende d).

6. Master Switch -- OFF.

7. Doors -- UNLATCH PRIOR TO TOUCHDOWN.

8. Touchdown -- SLIGHTLY TAIL LOW.

9. Brakes -- APPLY HEAVILY.

PRECAUTIONARY LANDING WITH ENGINE POWER

1. Airspeed -- 60 KIAS.

2. Wing Flaps -- 20°.

3. Selected Field -- FLY OVER, noting terrain and obstruction s, then retract flaps upon

reaching a safe altitude and airspeed.

4. Radio and Electrical Switches -- OFF.

5. Wing Flaps -- 30° (on final approach).

6. Airspeed -- 55 KIAS.

7. Master Switch -- OFF.

8. Doors -- UNLATCH PRIOR TO TOUCHDOWN.

9. Touchdown -- SLIGHTLY TAIL LOW.

10. Ignition Switch -- OFF.

11. Brakes -- APPLY HEAVILY.

DITCHING

1. Radio - - TRANSMIT MAYDAY on 121.5 MHz, giving location and intentions and

SQUAWK 7700 if transponder is installed.

2. Heavy Ob jects (in baggage area) -- SECURE OR JETTISON.

3. Approach -- High Winds, Heavy Seas -- INTO THE WIND.;

Light Winds, Heavy Swells -- PARALLEL TO SWELLS.

Page 3-4

Page 3-5

4. Wing Flaps -- 30°.

5. Power -- ESTABLISH 300 FT/MIN DESCENT AT 55 KIAS.

6. Cabin Doors -- UNLATCH.

7. Touchdown -- LEVEL ATTITUDE AT 300 FT/MIN DESCENT.

8. Face -- CUSHION at t ouchdown with folded coat.

9. Airplane -- EVACUATE through cabin doors. If necessary, open windows and flood

cabin to equalize pressure so doors can be opened.

10. Life Vests and Raft -- INFLATE.

1. Master Switch -- OFF.

2. All Other Switches (except ignition switch) -- OFF.

3. Vent s/Cabin Air/Heat -- CLOSED.

4. Fire Extinguisher -- ACTIVATE (if available)

WARNING

FIRES

DURING START ON GROUND

1. Cranking—CONTINUE ,to get a start which would suck the flames and accumulated fuel

through the carburetor and into the engine.

If engine starts:

2. Power -- 1700 RPM for a few minutes.

3. Engine -- SHUTDOWN and inspect for damage.

If engine fails to start:

4. Cranking -- CONTINUE in an effort to obtain a start.

5. Fire Extinguisher - - OBTAIN (have ground attendants obtain if not installed).

6. Engine -- SECURE.

a. Master Switch -- OFF.

b. Ignition Switch -- OFF.

c. Fuel Shutoff Valve -- OFF.

7. Fire – EXTINGUISH using fire extinguisher ,wool blanket ,or dirt.

8. Fire Damage -- INS PECT, repair damage or replace damaged components or wiring

before conducting another flight.

ENGINE FIRE IN FLIGHT

1. Mixture -- IDLE CUT-OFF.

2. Fuel Shutoff Valve -- OFF.

3. Master Switch -- OFF.

4. Cabin Heat and Air -- OFF (except wing root vents).

5. Airspeed -- 85 KIAS (If fire is not extinguished, increase glide speed to find an airspeed

which will provide an incombustible mixture).

6. Forced Landing -- EXECUTE (as described in Emergency Landing Without Engine

Power).

After discharging an extinguisher within a closed cabin,

ventilate the cabin.

5. If fire appears out and electrical power is necessary for continuance of flight:

6. Master Switch --

7. Circuit Breakers -- CHECK for faulty circuit, do not reset.

8. Radio/Electrical Switches -- ON one at a time, with delay after each until short circuit is

localized.

9. Vents/ Cabin Air/ Heat -- OPEN when it is ascertained that fire is completely

extinguished.

ON.

CABIN FIRE

1. Master Switch -- OFF.

2. Vents/Cabin Air/Heat -- CLOSED (to avoid drafts).

3. Fire Extinguisher -- ACTIVATE (if available).

WARNING

After discharging an extinguisher within a closed cabin,

ventilate the cabin.

4. Land the airplane as soon as possible to inspect for damage,

WING FIRE

1. Navigation Light Switch -- OFF.

2. Strobe Light Switch (if installed) -- OFF.

3. Pitot Heat Switch (if installed) -- OFF.

NOTE

Perform a sideslip to keep the flames away from the fuel tank an d cabin, and land as soon as

possible, with flaps retracted.

Page 3-6

ELECTRICAL FIRE IN FLIGHT

Page 3-7

ICING

INADVERTENT ICING ENCOUNTER

1. Turn pitot heat switch ON (if installed).

2. Turn back or change altitude to obtain an outside air temperature that is less conducive to

icing.

3. Pull cabin heat control full out to obtain maximum defroster air temperature. For greater

air flow at reduced temperatures, adjust the cabin air control as requi red.

4. Open the throttle to increase engine speed and minimize ice buildup on propeller blades.

5. Watch for signs of carburetor air filter ice and apply carburetor heat as required. An

unexpected loss in engine speed could be caused by carburetor ice or air intake filter ice.

Lean the mixture for maximu m RPM, if carburetor heat is used continuously.

6. Plan a landing at the nearest airpo r t. With an extremely rapid ice build-up, select a

suitable "off airport" landing site.

7. With an ice accumulation of 1/ 4 inch or more on the wing leading edges, be prepared for

significantly higher stall speed.

8. Leave wing flaps retracted. With a severe ice build-up on the horizon tal tail, the change

in wing wake airflow direction caused by wing flap extension could result in a loss of

elevator effectiveness.

9. Open left window and, if practical, scrape ice from a portion of the windshield for

visibility in the landing approach.

10. Perform a landing approach using a forward slip, if necessary, for improved visibility.

11. Approach at 65 to 75 KIAS depending upon the amount of ice accumulation.

12. Perform a landing in level attitude.

LANDING WITH A FLAT MAIN TIRE

1. Wing Flaps -- AS DESIRED.

2. Approach -- NORMAL.

3. Touchdown—GOOD TIRE FIRST hold airplane off flat tire as long as possible with

aileron control.

LOW-VOLTAGE LIGHT ILLUMINATES DURING FLIGHT

(Ammeter Indicates Discharge)

NOTE

Illumination of the low-voltage light may occur during low RPM conditions with an electrical

load on the system such as during a low RPM taxi. Under these conditions, the light will go

out at higher RPM. The master switch need not be recycled since an over-voltage condition

has not occurred to de-activate th e alternator system.

1. Radios -- OFF.

2. Master Switch -- OFF (both sides).

3. Master Switch -- ON.

4. Low-Voltage Light -- CHECK OFF.

5. Radios -- ON.

If low-voltage light illuminates again:

6. Alternator -- OFF.

7. Nonessential Radio and Electrical Equipment -- OFF.

8. Flight -- TERMINATE as soon as practical.

ELECTRICAL POWER SUPPLY SYSTEM MALFUNCTIONS

AMMETER SHOWS EXCESSIVE RATE OF CHARGE (Full

Scale Deflection)

1. Alternator -- OFF.

2. Nonessential Electrical Equipment -- OFF.

3. Flight -- TERMINATE as soon as practical.

Page 3-8

Page 3-9

AMPLIFIED PROCEDURES

FORCED LANDINGS

ENGINE FAILURE

If an engine failure occurs during the takeoff run, the most important thing to do is

stop the airplane on the remaining runway. Those extra items on the checklist will provide

added safety after a failure of this type.

Prompt lowering of the nose to maintain airspeed and establish a glide attitude is the

first response to an engine failure after takeoff. In most cases, the landing should be planned

straight ahead with only small changes in direction to avoid obstructions. Altitude and

airspeed are seldom sufficient to execute a 1800 gliding turn necessary to return to the runway.

The checklist procedures assume that adequate time exists to secure the fuel and igni tion

systems prior to touchdown.

After an engine failure in flight, the best glide speed as shown in figure 3-1 should

be established as quickly as possible. While gliding toward a suitable landing area, an effort

should be made to identify the cause of the failure. If time permits, an engine restart should be

attempted as shown in the checklist. If the engine cannot be rest arted, a forced landing

without power must be completed.

If all attempts to restart the engine fail and a forced landing

suitable field and prepare for the landing as discussed under the ”Emergency Landing Without

Engine Power” checklist.

Before attempting an "off airport" landing with engine power available, one should

fly over the landing area at a safe but low altitude to inspect the terrain for obstructions and

surface conditions, proceeding as discussed under the Precautionary Landing With Engine

Power checklist.

Prepare for ditching by securing or jettisoning heavy objects located in the baggage

area and collect folded coats for protection of occupants' face at touchdown. Transmit

Mayday message on 121.5 MHz giving location and intentions, and squawk 7700 if a

transponder is installed. Avoid a landing flare because of difficulty in judging height over a

water surface.

imminent, select a

is,

LANDING WITHOUT ELEVATOR CONTROL

Trim for horizontal flight (with an airspeed of approximately 55 KIAS and flaps

lowered to 200) by using throttle and elevator trim controls. Then do not change the

elevator trim control setting;

exclusively.

At flareout, the nose-down moment resulting from power reduction is an adverse

factor and the airplane may hit on the nose wheel. Consequently, at flareout, the trim control

should be set at the full nose-up position and the power adjusted so that the airplane will rotate

to the horizontal attitude for touchdown. Close the throttle at touchdown.

control the glide angle by adjusting power

Page 3-10

FIRES

Although engine fires are extremely rare in flight, the steps of the appropriate

checklist should be followed if one is encountered. After completion of this procedure,

execute a forced landing. Do not attempt to restart the engine.

The initial indication of an electrical fire is usually the odor of burning insulation.

The checklist for this problem should result in elimination of the fire.

Page 3-11

EMERGENCY OPERATION IN CLOUDS

(Vacuum System Failure)

7. Check trend of compass card movement and make cautious corrections with rudder to

stop turn.

8. Upon breaking out of clouds, resume normal cruising flight.

In the event of a vacuum system failure during flight, the directional indicator and

attitude indicator will be disabled, and the pilot will have to rely on the turn coordinator if he

inadvertently flies into clouds. The following instructions assume that only the electricallypowered turn coordinator is operative, and that the pilot is not completely proficient in

instrument flying.

EXECUTING A 180 °°°° TURN IN CLOUDS

Upon inadvertently entering the clouds, an immediate plan sh ould be made to turn back as

follows:

1. Note the compass heading.

2. Note the time of the minute hand and observe the position of the sweep second hand on

the clock.

3. When the sweep second hand indicates the nearest half-minute, initiate a standard rate

left turn, holding the turn coordinator symbolic airplane wing opposite the lower left

index mark for 60 seconds. Then roll back to level flight by leveling the miniature

airplane.

4. Check accuracy of the turn by observing the compass heading which should be the

reciprocal of the origin al heading.

5. If necessary, adjust heading primaril y with skidding motions rather than roll in g motions

so that the compass will read more accurately.

6. Maintain altitude and airspeed by cautious applicatio n of elevator control. Avoid

overcontrolling by keeping the hands off the control wheel as much as possible and

steering only with rudder.

EMERGENCY DESCENT THROUGH CLOUDS

If conditions preclude reestablishment of VFR flight by a 1801 turn, a descent through a cloud

deck to VFR conditions may be appropriate. If possible, obtain radio clearance for an

emergency descent through clouds. To guard against a spiral dive, choose an easterly or

westerly heading to minimize co mpass card swings due to changing bank angles. In addition,

keep hands off the control wheel and steer a straight course with rudder control by monitoring

the turn coordinator. Occasionally check the compass h eading and make minor corrections to

hold an approximate course. Before descending into the clouds, set up a stabilized let-down

condition as follows:

RECOVERY FROM A SPIRAL DIVE

If a spiral is encountered, proceed as follows:

1. Close the throttle.

2. Stop the turn by using coordinated aileron and rudder control to align the symbolic

airplane in the turn coordinator with the horizon reference line.

KIAS.

3. Cautiously apply elevator backpressure to slowly reduce the airspeed to 70

4. Adjust the elevator trim control to maintain a 70 KIAS glide.

5. Keep hands off the control wheel, using rudder control to hold a straight heading.

6. Apply carburetor heat.

7. Clear en gine occasionally, bu t avoid using enough power to disturb the trimmed glide.

8. Upon breaking out of clouds, resume normal cruising flight.

INADVERTENT FLIGHT INTO ICING CONDITIONS

Flight into icing conditions is prohibited. An inadvertent encounter with these conditions can

best be handled using the checklist procedures. The best procedure, of course. is to turn back

or change altitude to escape icing conditions.

SPINS

Should an inadvertent spin occur, the following recovery pro cedure

should be used:

1. P LACE AILERONS IN NEUTRAL POSITION.

2. RE T ARD THR O T TLE TO ID LE P O SI TI ON .

3. APPLY AND HOLD FULL RUDDER OPPOSITE TO THE DIRECTION OF

ROTATION.

4. JUST AFTER THE RUDDER REACHES THE STOP, MOVE THE CONTROL

WHEEL BRISKLY FORWARD FAR ENOUGH TO BREAK THE STALL. Full down

elevator may be required at aft cent er of gravity loadings to assure op timu m recoveries.

5. HOLD THESE CONTROL INPUTS UNTIL ROTATION STOPS. Premature

relaxation of the control inputs may extend the recovery.

6. AS ROTATION STOPS, NEUTRALIZE RUDDER, AND MAKE A SMOOTH

RECOVERY FROM THE RESULTING DIVE.

1. Apply full rich mixture.

2. Use full carburetor heat.

3. Reduce power to set up a 500 to 800 ft/min rate of descent.

4. Adjust the elevator trim for a stabilized descent at 70 KIAS.

5. Keep hands off control wheel.

Page 3-12

6. 6Monitor turn coordinator and make corrections by rudder alone.

NOTE

If disorientation precludes a visual determination of the direction of rotation, the

symbolic airplane in the turn coordinator may be referred to for this information.

Page 3-13

For additional information on spins and spin recovery, see the discussion under

SPINS in Normal Procedures (Section 4).

ROUGH ENGINE OPERATION OR LOSS OF POWER

CARBURETOR ICING

A gradual loss of RPM and eventual engine roughness may result from the

formation of carburetor ice. To clear the ice, apply full throttle and pull the carburetor heat

knob full out until the engine runs smoothly; then remove carburetor heat and readjust the

throttle. If conditions require the continued use of carburetor heat in cruise flight, use the

minimum amount of heat necessary to prevent ice from forming and lean the mixture slightly

for smoothest engine operation.

SPARK PLUG FOULING

A slight engine roughness in flight may be caused by one or more spark plugs

becoming fouled by carbon or lead deposits. This may be verified by turning the ignition

switch momentarily from BOTH to either L or R position. An obvious power loss in single

ignition operation is evidence of spark plug or magneto trouble. Assuming that spark plugs

are the more likely cause, lean the mixture to the recommended lean setting for cruising flight.

If the problem does not clear up in several minutes, determine if a richer mixture setting will

produce smoother operation . If not, proceed to the nearest airport for repair s using the BOTH

position of the ignition switch unless extreme roughness dictates the use of a single ignition

position.

malfunctions is usually difficult to determine. A broken alternator drive belt or wiring is most

likely the cause of alternator failures, although other factors could cause the problem. A

damaged or improperly adjusted alternator control unit can also cause malfunctions. Problems

of this nature constitute an electrical emergency and should be dealt with immediately.

Electrical power malfuncti ons usually fall into two categori es: excessive rate of charge and

insufficient rate of charge. The paragraphs below describe the recommended remedy for each

situation.

EXCESSIVE RATE OF CHARGE

After engine starting and heavy electrical usage at low engine speeds (such as

extended taxiing) the battery condition will be low enough to accept above normal charging

during the initial part of a flight. However, after thirty minutes of cruising flight, the ammeter

should be indicating less than two needle widths of charging current. If the charging rate were

to remain above this value on a long flight, the battery would overheat and evaporate the

electrolyte at an excessive rate.

Electronic components in the electrical system can be adversely affected by higher

than normal voltage. The alternator control unit includes an over-voltage sensor that normally

will automatically shut down the alternator if the charge voltage reaches approximately 31.5

volts. If the over-voltage sensor malfunctions or is improperly adjusted, as evidenced by an

excessive rate of charge shown on the ammeter, the alternator should be turned off,

nonessential electrical equipment turned off and the flight terminated as soon as practical.

MAGNETO MALFUNCTION

A sudden engine roughness or misfiring is usually evidence of magneto problems.

Switching from BOTH to either L or R ignition switch position will identify which magneto is

malfunctioning. Select different power settings and enrich the mixture to determine if

continued operation on BOTH magnetos is practicable. If not, switch to the good magneto

and proceed to the nearest airpo r t for repai r s-

LOW OIL PRESSURE

If low oil pressure is accompanied by normal oil temperature, there is a possibility

the oil pressure gage or relief valve is malfunctioning. A leak in the line to the gage is not

necessarily cause for an immediat e precautionary landing because an orifice in this line will

prevent a sudden loss of oil from the engine sump. However, a landing at the nearest airport

would be advisable to inspect the source of trouble.

If a total loss of oil pressure is accompani ed by a rise in oil temperature, there is

good reason to suspect an engine failure is imminent. Reduce engine power immediately and

select a suitable forced landing field. Use only the minimum power required to reach the

desired touchdown spot.

Page 3-14

ELECTRICAL POWER SUPPLY SYSTEM MALFUNCTIONS

Malfunctions in the electrical power supply system can be detected by periodic

monitoring of the ammeter and low-voltage warning light; however, the cause of these

INSUFFICIENT RATE OF CHARGE

NOTE

Illumination of the low-voltage light and ammeter discharge indications may occur

during low RPM condi tions with an electrical load on th e syst em, such as during a low RPM

taxi. Under these conditions, the light will go out at higher RPM. The master switch need not

be recycled since an over-voltage condition has not occurred to de-activate the alternator

system.

If the over-voltage sensor should shut down the alternator, a discharge rate will be

shown on the ammeter followed by illumination of the low voltage warning light. Since this

may be a "nuisance" trip-out, an attempt should be made to reactivate the alternator system.

To do this, turn the radios off, then turn both sides of the master switch off and then on again.

If the problem no longer exists, normal alternator charging will resume and the low-voltage

light will go off. The radios may then be turned back on. If the light illuminates again, a

malfunction is confirmed. In this event, the flight should be terminated and/or the current

drain on the battery minimized because the battery can supply the electrical system for only a

limited period of time. If the emergency occurs at night, power must be conserved for later

use of the landing light and flaps during landing.

Page 3-15

SECTION 4

NORMAL PROCEDURES

Table of Contents

Page

Introduction.......................................................................................................... 4-3

Speed for Normal Operation.................................................................................4-3

Checklist Procedures

Preflight Inspection.............................................................................................. 4-4

Cabin .................................................................................................... 4-4

Empennage...........................................................................................4-5

Right Wing, Trailing Edge.................................................................... 4-5

Right Wing ........................................................................................... 4-5

Nose...................................................................................................... 4-5

Left Wing.............................................................................................. 4-5

Left Wing, Trailing Edge...................................................................... 4-6

Before Starting Engine......................................................................................... 4-6

Starting Engine (Temperatures Above Freezing) ................................................. 4-6

Before Takeoff......................................................................................................4-6

Takeoff .............................................................................................................. 4-7

Normal Takeoff....................................................................................4-7

Short Field Takeoff............................................................................... 4-7

Enroute Climb...................................................................................................... 4-7

Cruise .............................................................................................................. 4-7

Before Landing..................................................................................................... 4-7

Landing .............................................................................................................. 4-7

Normal Landing.................................................................................... 4-8

Short Field Landing.............................................................................. 4-8

Balked Landing.....................................................................................4-8

After Landing....................................................................................................... 4-8

Securing Airplane................................................................................................. 4-8

Wing Flap Settings..............................................................................4-12

Crosswind Takeoff..............................................................................4-12

Enroute Climb.....................................................................................................4-12

Cruise ............................................................................................................4-13

Fuel Savings Procedures For Flight Training Operations...................................4-14

Stalls ............................................................................................................ 4-14

Spins ............................................................................................................ 4-14

Landing ............................................................................................................4-16

Short Field Landing............................................................................ 4-16

Crosswind Landing.............................................................................4-16

Balked Landing................................................................................... 4-16

Cold Weather Operation.....................................................................................4-16

Noise Abatement................................................................................................4-18

Amplified Procedures

Starting Engine (Temperatures Above Freezing) ................................................. 4-8

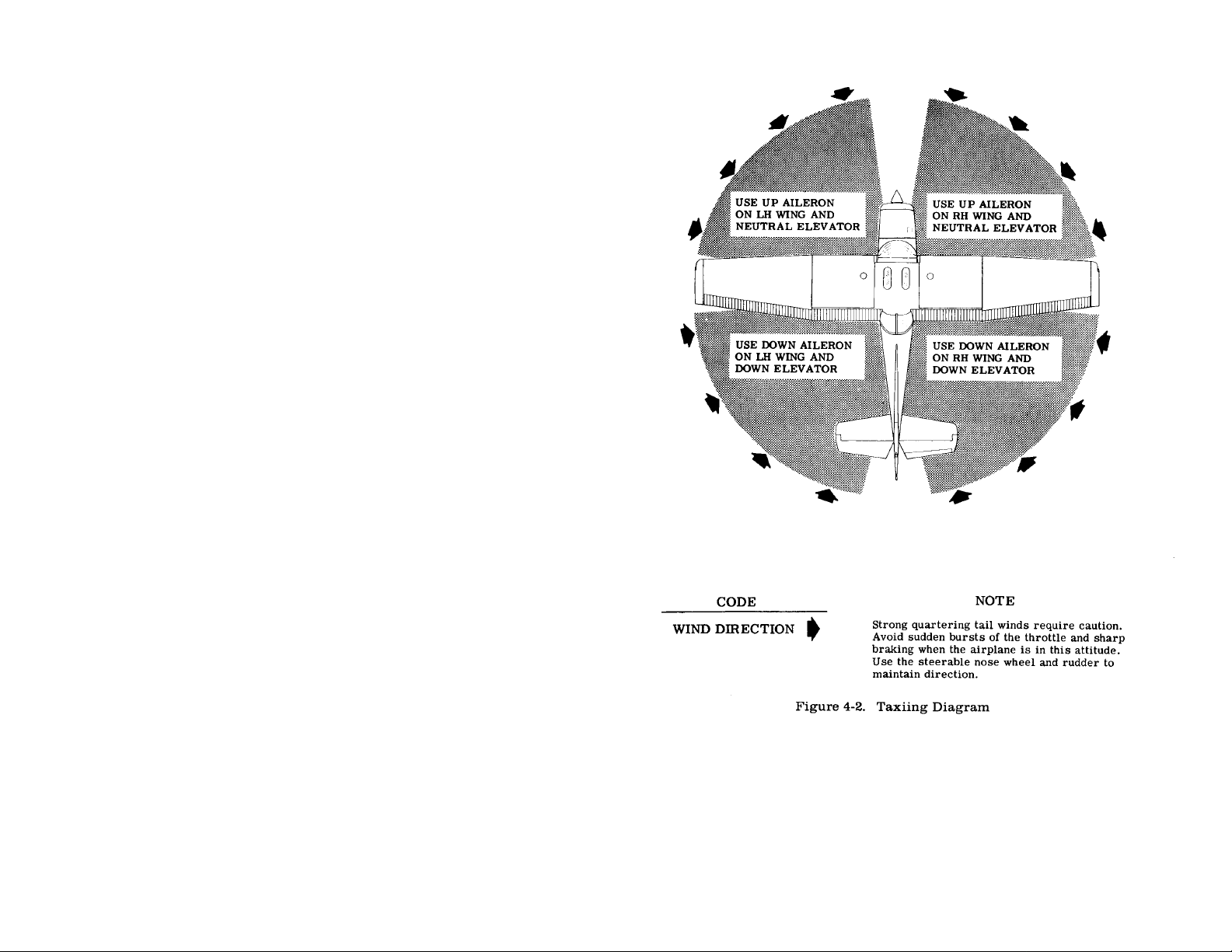

Taxiing . . . . . . . . . . . . . . ................................................................................. 4-10

Before Takeoff....................................................................................................4-11

Warm-Up............................................................................................ 4-11

Magneto Check................................................................................... 4-11

Alternator Check................................................................................. 4-11

Takeoff ............................................................................................................ 4-11

Power Check....................................................................................... 4-11

Page 4-1

Page 4-2

INTRODUCTION

Section 4 provides checklist and amplified procedures for the conduct of normal operation.

Normal procedures associated with optional systems can be found in Section 9.

SPEEDS FOR NORMAL OPERATION

Unless otherwise noted, the following speeds are based on a maximum

weight of 1670 pounds and may be used for any lesser weight. (All speeds in KIAS)

Takeoff:

Normal Climb Out............................................................................................ 65-75

Short Field Takeoff. Flaps 101, Speed at 50 Feet..................................................54

Climb, Flaps Up:

Normal.............................................................................................................. 70-80

Best Rate of Climb, Sea Level................................................................................67

Best Rate of Climb, 10,000 Feet.............................................................................61

Best Angle of Climb, Sea Level thru 10,000 Feet ..................................................55

Landing Approach:

Normal Approach, Flaps Up............................................................................. 60-70

Normal Approach, Flaps 30.............................................................................. 55-65

Short Field Approach, Flaps 30..............................................................................54

Balked Landing:

Maximum Power, Flaps 20.....................................................................................55

Maximum Recommended Turbulent Air Penetration Speed:

1670 Lbs.....................................................................................................104

1500 Lbs.......................................................................................................98

1350 Lbs.......................................................................................................93

Maximum Demonstrated Crosswind Velocity..............................................12 knots

PREFLIGHT INSPECTION

Visually check airplane for general condition during walk-around inspection. In cold weather,

remove even small accumulations of frost, ice, or sno w from wing, tail, and control surfaces.

Also, make sure that control surfaces contain no intern al accumulatio ns of ice o r debris. Prior

to flight, check that pitot heater (if installed is warm to touch with 30 seconds with battery and

pitot heat switches on. If a night flight is planned, check operation of all lights and make sure

a flashlight is available.

Page 4-3

CABIN

1. Pilot’s Operating Handbook –AVAILABLE IN THE AIRPLANE

2. Con trol Wheel Lock REMOVE

3. Ignition Switch –OFF

4. Avionics Master Switch – OFF

5. Master Switch – ON

WARNING

When turning on the master switch, using an external power source, or pulling the propeller

through by hand, treat the propeller as if the ignition switch were on. Do not stand, nor allow

anyone else to stand, within the arc of the propeller, since a loose or broken wire, or a

component malfunction could cause the propeller to rotate.

Page 4-4

6. Fuel Quantity Indicators – CHECK QUANTITY

7. External and Interior lights – ON (if night fligh t is contemplated—check to ensure that all

are working)

8. Pitot Heat –ON (if flight in instrument conditions is contemplated – check to ensure that

pitot tube is warm to touch within 30 seconds)

9. Lights and pitot heat – OFF

10. Master Switch – OFF

11. Fuel valve – ON

EMPANNAGE

1. Rudder Gust Lock REMOVE

2. Tail Tie –down – DISCONNECT

3. Con t rol Su rfaces – CHE C K for freedom of movement and security

RIGHT WING- TRAILING EDGE

1. Aileron –CHECK freedom of movement and security

RIGHT WING

1. Wing tiedown – DISCONNECT

2. Main Wheel Tire – CHECK for proper inflation, cut s, wear

3. Brake lin es – CHECK for leaks

4. Fuel sump – CHECK before first flight of day, and after each refueling, drain fuel sample

from sump, checking for water and other contaminants

5. Fuel Quantity – CHECK VISUALLY

6. Fuel Filler Cap --- SECURE

NOSE

1. Engine Oil –4 qts minimum –5 qts maximum for flights less than 3 hours—6 qts

maximum

2. Engine Oil cap --SECURE

3. Before first flight of day, and after each refueling, pull out fuel strainer knob for 4

seconds

4. Propeller and spinner – CHECK for nicks and cracks

5. Air intake – CHECK for obstructions

6. Nose wheel strut– CHECK for inflation,

7. Nose wheel tire – CHECK for inflation, cuts, wear

8. Nose tiedown -- REMOVE

LEFT WING

1. Wing tiedown – DISCONNECT

2. Pitot tube –REMOVE COVER –CHECK for obstruction, damage

Page 4-5

7. Main Wheel Tire – CHECK for proper inflation, cuts, wear

3. Brake lin es – CHECK for leaks

4. Stall warning vane -- CHECK

5. Fuel sump – CHECK before first flight of day, and after each refueling, drain fuel sample

from sump, checking for water and other contaminants

6. Fuel Quantity – CHECK VISUALLY

7. Fuel Filler Cap --- SECURE

LEFT WING- TRAILING EDGE

1. Aileron –CHECK freedom of movement and security

BEFORE STARTING ENGINE

1. Preflight Inspection – COMPLETE

2. Seats, Belts, Shoulder Harnesses -- ADJUST and LOCK.

3. Fuel Shutoff Valve -- ON.

4. Radios, Electrical Equipment -- OFF.

5. Brakes -- TEST and SET.

6. Circuit Breakers -- CHECK IN.

STARTING ENGINE (Temperatures Above Freezing)

1. Mixture -- RICH.

2. Carburetor Heat -- COLD.

3. P rime -- AS REQUIRED (up to 3 strokes).

4. Throttle -- OPEN 1/2 INCH.

5. P rop eller Area -- CLEAR.

6. Master Switch -- ON.

7. Ignition Switch -- START (release when engine starts).

8. Throttle -- ADJUST for 1000 RPM or less.

9. Oil Pressure -- CHECK.

BEFORE TAKEOFF

1. P arking Brake -- SET.

2. Cabin Doors -- CLOSED and LATCHED.

3. Flight Controls -- FREE and CORRECT.

4. Flight Instruments SET.

5. Fuel Shutoff Valve ON.

6. Mixture -- RICH (below 3000 feet).

7. Elevator Trim -- TAKEOFF.

8. Throttle -- 1700 RPM.

a. Magnetos -- CHECK (RPM drop should not exceed 125 RPM on either magneto or

50 RPM differential between magnetos).

b. Carburetor Heat -- CHECK (for RPM drop).

c. Engine Instruments and Ammeter -- CHECK.

d. Suction Gage -- CHECK.

Page 4-6

9. Radios -- SET.

10. Flashing Beacon, Navigation Lights and /or Strobe Lights—ON as required.

11. Throttle Friction Lock -- ADJUST.

12. Brakes -- RELEASE.

TAKEOFF

NORMAL TAKEOFF

1. Wing Flaps -- 00- 100.

2. Carburetor Heat -- COLD.

3. Throttle -- FULL OPEN.

4. Elevator Control -- LIFT NOSE WHEEL at 50 KIAS.

5. Climb Speed -- 65-75 KIAS.

SHORT FIELD TAKEOFF

1. Wing Flaps -- 100.

2. Carburetor Heat -- COLD.

3. Brakes -- APPLY.

4. Throttle -- FULL OPEN.

5. Mi xture - - RICH (above 3000 feet, LEAN to obtain maximum RPM).

6. Brakes -- RELEASE.

7. Elevator C ontrol -- SLIGHTLY TAIL LOW.

8. Climb Speed -- 54 KIAS (until all obstacles are cleared).

9. Wing Flaps -- RETRACT slowly after reaching 60 KIAS.

ENROUTE CLIMB

2. Mixture -- RICH.

3. Carburetor Heat -- ON (apply full heat before closing throttle).

NORMAL LANDING

1. Airspeed -- 60-70 KIAS (flaps UP).

2. Wing Flaps -- AS DESIRED (below 85 KIAS).

3. Airspeed -- 55-65 KIAS (flaps DOWN).

4. Touchdown -- MAIN WHEELS FIRST.

5. Landing Roll -- LOWER NOSE WHEEL GENTLY.

6. Braking -- MINIM UM REQUIRED.

SHORT FIELD LANDING

1. Airspeed -- 60-70 KIAS (flaps UP).

2. Wing Flaps -- 301 (below 85 KIAS).

3. Airspeed -- MAINTAIN 54 KIAS.

4. Power -- REDUCE to idle as obstacle is cleared.

5. Touchdown -- MAIN WHEELS FIRST.

6. Brakes -- APPLY HEAVILY.

7. Wing Flaps -- RETRACT.

BALKED LANDING

1. Throttle -- FULL OPEN.

2. Carburetor Heat -- COLD.

3. Wing Flaps -- RETRACT to 201.

4. Airspeed -- 55 KIAS.

5. Wing Flaps -- RETRACT (slowly).

1. Airspeed -- 70 -80 KIAS.

NOTE

If a maximum performance climb is necessary, refer to section 5 of handbook –67 KIAS at sea

level, decreasing to 60 KIAS at 12,000 ft MSL

2. Throttle -- FULL OPEN.

3. Mixture—RICH below 3000 feet; LEAN for maximum RPM above 3000 feet.

CRUISE

1. Power -- 1900-2550 RPM (no more than 75%).

2. Elevator Tri m -- ADJUST.

3. Mixture -- LEAN.

BEFORE LANDING

1. Seats, Belts, Harnesses -- ADJUST and LOCK.

Page 4-7

AFTER LANDING

1. Wing Flaps -- UP.

2. Carburetor Heat -- COLD.

SECURING AIRPLANE

1. Parking Brake -- SET.

2. Radios, Electrical Equipment -- OFF.

3. Mixture -- IDLE CUT-OFF (pull full out).

4. Ignition Switch -- OFF.

5. Master Switch -- OFF.

6. Control Lock -- INSTALL.

AMPLIFIED PROCEDURES

STARTING ENGINE (Temperatures Above Freezing)

Page 4-8

During engine starting, open the throttle approximately 1/2 inch. In warm weather, one stroke

of the primer should be sufficient. In temperatures near freezing, up to 3 strokes of the primer

may be necessary. As the engine starts, slowly adjust the throttle as required for 1000 RPM or

less.

NOTE

The carburetor used on this airp lan e does no t have an accelerat or pu mp; th erefore, p u mping of

the throttle must be avoided during starting because doing so will only cause excessive

leaning.

Weak intermittent firing followed by puffs of black smoke from the exhaust stack indicates

overpriming or flooding. Excess fuel can be cleared from the combustion chambers by the

following procedure: set the mixture control in the idle cut-off position, the throttle full open,

and crank the engine through several revolutions with the starter. Repeat the starting

procedure without any additional priming.

If the engine is underprimed (most likely in cold weather with a cold engine) it will not fire at

all, and additional priming will be necessary.

After starting, if the oil gage does not begin to show pressure within 30 seconds in the

summertime and about twice th at long in very cold weather, stop t he engine and investigate.

Lack of oil pressure can cause serious engine damage. After starting, avoid the use of

carburetor heat unless icing conditions prevail.

NOTE

Details concerning cold weather starting and operation at temperatures below freezing may be

found under Cold Weather Operation paragraphs in this section.

Page 4-9

TAXIING

When taxiing, it is important that speed and use of brakes be held to a minimum and that all

controls be utilized (see Taxiing Diagram, figure 4-2) to maintain directional control and

balance.

Page 4-10

The carburetor heat con trol knob sho uld be push ed full in durin g all grou nd op erations un less

heat is absolutely necessary. When the kn ob is pu lled out to the heat po sition , air entering th e

engine is not filtered.

Taxiing over loose gravel or cinders should be done at low engine speed to avoid abrasion and

stone damage to the propeller tips.

The nose wheel is designed to automatically center straight ahead when the nose strut is ful ly

extended. In the event the no se strut is overinflated and the airpl ane is loaded to a rearward

center of gravity position, it may be necessary to partially compress the strut to permit

steering. This can be accomplished prior to t axiing by depressi ng the airplan e nose (by hand)

or during taxi by sharply applying brakes.

It is important to check full-throttle engine operation early in the takeoff run. Any sign of

rough engine operation or sluggish engine acceleration is good cause for discontinuing the

takeoff. If this occurs, you are justified in making a thorough full-throttle static runup before

another takeoff is attempted. The engine should run smoothly and turn approximately 2280 to

2380 RPM with carburetor heat off and mixture leaned to maximum RPM.

Full throttle runups over loose gravel are especially harmful to propeller tips. When takeoffs

must be made over a gravel surface, it is very important that the throttle be advanced slowly.

This allows the airplane to start rolling before high RPM is developed, and the gravel will be

blown back of the propeller rather than pulled into it. When unavoidable small dents appear in

the propeller blades, they should be immediately corrected as described in Section 8 under

Propeller Care.

BEFORE TAKEOFF

WARM-UP

Most of the warm-up will have been conducted during taxi, and additional warm-up before

takeoff should be restricted to the checklist procedures. Since the engine is closely cowled for

efficient in-flight cooling, precautions should be taken to avoid overheati ng on the ground.

MAGNETO CHECK

The magneto check should be made at 1700 RPM as follows. Move ignition switch first to R

position and note RPM. Next move switch back to BOTH to clear the other set of plugs.

Then move switch to the L position, note RPM and return the switch to the BOTH position.

RPM drop should not exceed 125 RPM on either magneto or show greater than 50 RPM

differential between magn eto s. If th ere is a do ubt concern in g operat ion o f the igni tion system,

RPM checks at higher engine speeds will usually confirm whether a deficiency exists.

An absence of RPM drop may be an indication of faulty grounding of one side of the ignition

system or should be cause for suspicion that the magneto timing is set in advance of the setting

specified.

ALTERNATOR CHECK

Prior to flights where verification of proper alternator and alternator control unit operation is

essential (such as night or instrument flights), a positive verification can be made by loading

the electrical system momentarily (3 to 5 seconds) with the landing light, or by operating the

wing flaps during the engine runup (1700 RPM). The ammeter will remain within a needle

width of its initial position if the alternator and alternator control unit are operating properly.

TAKEOFF

Prior to takeoff from fields above 3000 feet elevation, the mixture should be leaned to .give

maximum RPM in a full-throttle, static runup.

After full throttle is applied, adjust the throttle friction lock clockwise to prevent the throttle

from creeping back from a maximum power position. Similar friction lock adjustment should

be made as required in other flight conditions to maintain a fixed throttle setting.

WING FLAP SETTINGS

Normal takeoffs are accomplish ed with wing flaps 0 °- 10°. Using 10° wing flaps reduces the

total distance over an ob stacle by approximately 10%. F lap deflections greater than 101 are

not approved for takeoff. If 10° wing flaps are used for takeoff, they should be left down until

all obstacles are cleared and a safe flap retraction speed of 60 KIAS is reached.

On a short field, 10° wing flaps and an obstacle clearance speed of 54 KIAS should be used.

This speed provides the best overall climb speed to clear obstacles when taking into account

turbulence often found near ground level.

Soft or rough field takeoffs are performed with 10° wing flaps by lifting the airplane off the

ground as soon as practical in a slightly tail-low attitude. If no obstacles are ahead, the

airplane should be leveled off immediately to accelerate to a higher climb speed.

CROSSWIND TAKEOFF

Takeoffs into strong crosswinds normally are performed with the minimum flap setting

necessary for the field length, to minimize the drift angle immediately after takeoff. With the

ailerons partially deflected into the wind, the airplane is accelerated to a speed slightly higher

than normal, and then pulled off abruptly to prevent possible settling back to the runway while

drifting. When clear of the ground, make a coordinated turn into the wind to correct for drift.

POWER CHECK

Page 4-11

ENROUTE CLIMB

Page 4-12

Loading...

Loading...