Page 1

1964 Cessna 150 Patroller

Performance and Specifications

Gross weight 1600 lbs Speed

Top Speed at sea level 125 mph

Cruise, 75% power at 7500 ft 122 mph

Range

Cruise, 75% Power at 7500 ft 760 mi

35.0 Gallons 6.2 hours

122 mph

Optimum Range at 10,000 ft 885 mi

35.0 Gallons 8.9 hours

99 mph

Rate of Climb at sea level 670 fpm Service Ceiling 12650 Takeoff

Ground Run 735 ft

Total Distance over 50’ obstacle 1385 ft

Landing

Landing Roll 445 ft

Total Distance over 50’ obstacle 1075 ft

Empty Weight 1015 lbs

Baggage 120 lbs

Wing Loading 10 lb/sf

Power loading 16 lb/HP

Fuel Capacity total 38 gal

Oil Capacity 6 US qts

Propeller, Fixed Pitch, metal, dia. 69 in

Power Continental O-200 A Engine, 100 HP at 2750 RPM

page i

page ii

Page 2

TABLE OF CONTENTS

SECTION I OPEATING CHECKLIST 1-1

SECTION II DESCRIPTION

AND OPERATING DETAILS 2-1

SECTION III OPEATING LIMITATIONS 3-1

SECTION IV CARE OF THE AIRPLANE 4-1

SECTION V OPERATIONAL DATA 5-1

ALPHABETICAL INDEX

page iii

page iv

Page 3

Section I

Operating Check List

One of the first steps in obtaining the utmost performance, service,

and flying enjoyment from your Cessna is to familiarize yourself with

your airplane’s equipment, systems, and controls. This can best be

done by reviewing this equipment while sitting in the airplane. Those

items whose functions and operation are not obvious are covered in

Section II

STARTING THE ENGINE

1. Carburetor Heat – Cold

2. Mixture – Rich

3. Primer – As Required

4. Ignition switch – Both

5. Throttle – Open ¼ inch

6. Propeller Area – Clear

7. Starter – On

BEFORE TAKE – OFF

Section I lists, in the Pilot’s Check List form, the steps necessary to

operate your airplane efficiently and safely. It is not a checklist in its

true form as it is considerably longer, but it does cover briefly all of

the points that you would want to or should know concerning the

information you need for a typical flight.

The flight and operation characteristics of your airplane are normal in

all respects. There are no unconventional characteristics or

operations that need to be mastered. All controls respond in the

normal way within the entire range of operation. All airspeeds

mentioned in Sections I and II are indicated airspeeds.

Corresponding calibrated airspeeds may be obtained from the

Airspeed Correction Table in Section V.

BEFORE ENTERING THE AIRPLANE

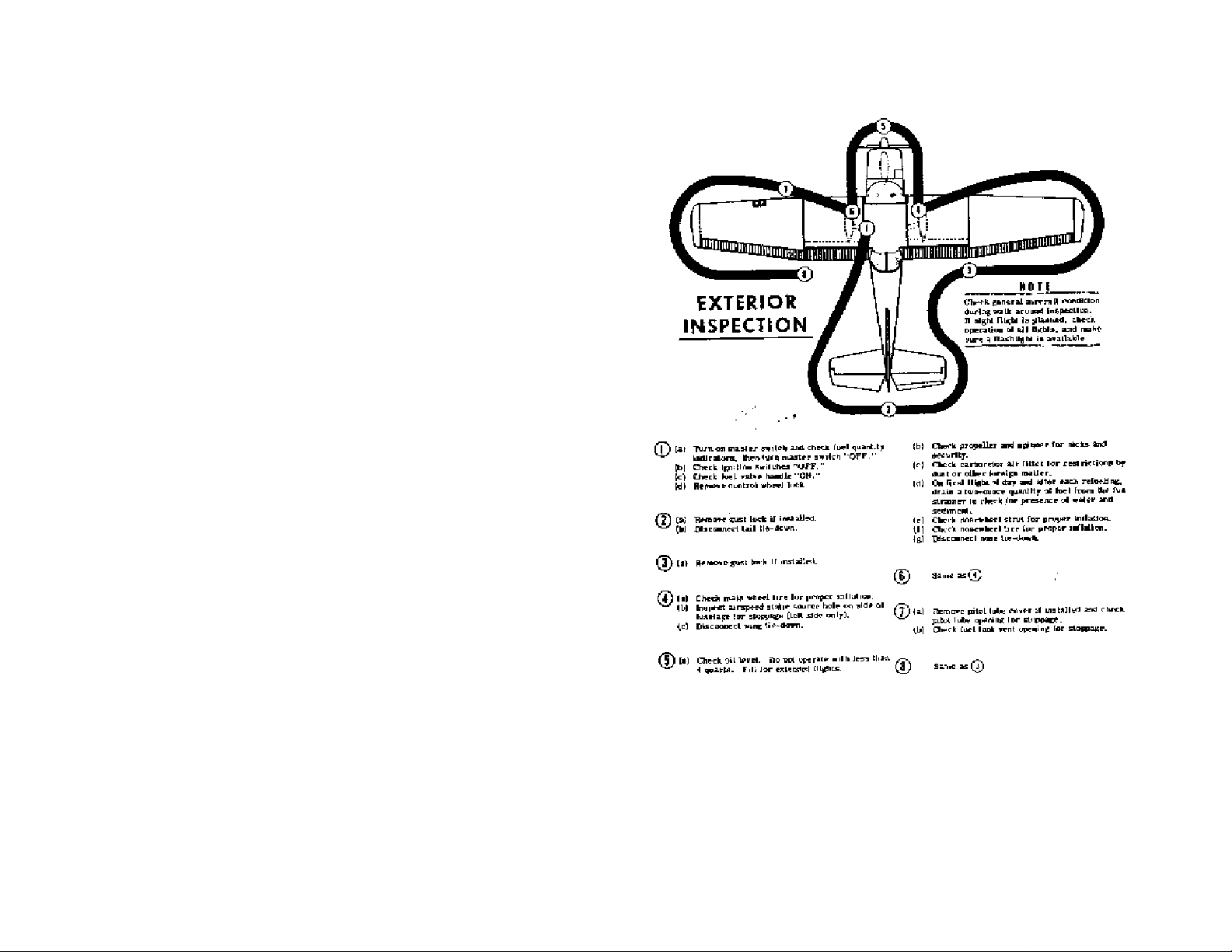

1. Make an exterior inspection in accordance with figure 1-1

BEFORE STARTING THE ENGINE

1. Seats and seat belts – Adjust and Lock

2. Brakes – Test and set

3. Master Switch – On

4. Fuel Valve Handle –On

page 1-1

1. Throttle Setting – 1700 RPM

2. Engine Instruments – Within green arc and generator light out

3. Magnetos – Check (75 RPM maximum differential between

magnetos

4. Carburetor Heat – Check operation

5. Flight Controls – check

6. Trim Tab – Takeoff

7. Cabin doors – latched

8. Flight Instruments and Radios – Set

TAKE OFF

NORMAL TAKE OFF

1. Wing flaps – Up

2. Carburetor Heat – Cold

3. Throttle – Full “Open”

4. Elevator Control – Lift nose wheel at 50 mph

5. Climb Speed – 72 MPH until all obstacles are cleared, then set up

climb speed as shown in NORMAL CLIMB paragraph

MAXIMUM PERFORMANCE TAKE OFF

1. Wing Flaps – Up

page 1-2

2. Carburetor Heat – Cold

3. Brakes – Hold

Page 4

4. Throttle – Full OPEN

5. Brakes – release

6. Elevator Control – Slightly tail low

7. Climb Speed – 52 MPH (with obstacles ahead)

AFTER LANDING

1. Wing Flaps – Up

2. Carburetor Heat – Cold

CLIMB

NORMAL CLIMB

1. Air Speed – 75 to 80 MPH

2. Power – Full throttle

3. Mixture – Rich (unless engine is rough)

MAXIMUM PERFORMANCE CLIMB

1. Air Speed – 72 MPH

2. Power – Full throttle

3. Mixture – Rich (unless engine is rough)

CRUISING

1. Power – 2000 to 2750 RPM

2. Elevator Trim – Adjust

3. Mixture – Lean to maximum RPM

BEFORE LANDING

SECURE AIRCRAFT

1. Mixture – Idle Cut-off

2. All Switches – Off

3. Parking Brake – Set

4. Control Lock – Installed

1. Mixture – Rich

2. Carburetor Heat – Apply full heat before closing throttle

3. Airspeed – 65 to 75 MPH

4. Wing Flaps -- As desired below 100 MPH

5. Airspeed – 60 to 70 MPH with flaps extended

page 1-3

NORMAL LANDING

1. Touch down – Main wheels first

2. Landing Roll – Lower nose wheel gently

3. Braking – Minimum required

page 1-4

Page 5

Section II

Description and Operating Details

The following paragraphs describe the systems and equipment whose

function and operation is not obvious when sitting in the airplane.

This section also covers in somewhat greater detail some of the items

listed in checklist form in Section I. Only those items of the checklist

requiring further explanation will be found here.

All airspeeds mentioned in this section are indicated airspeeds.

Corresponding calibrated airspeeds may be obtained from the

Airspeed Correction Table in Section V.

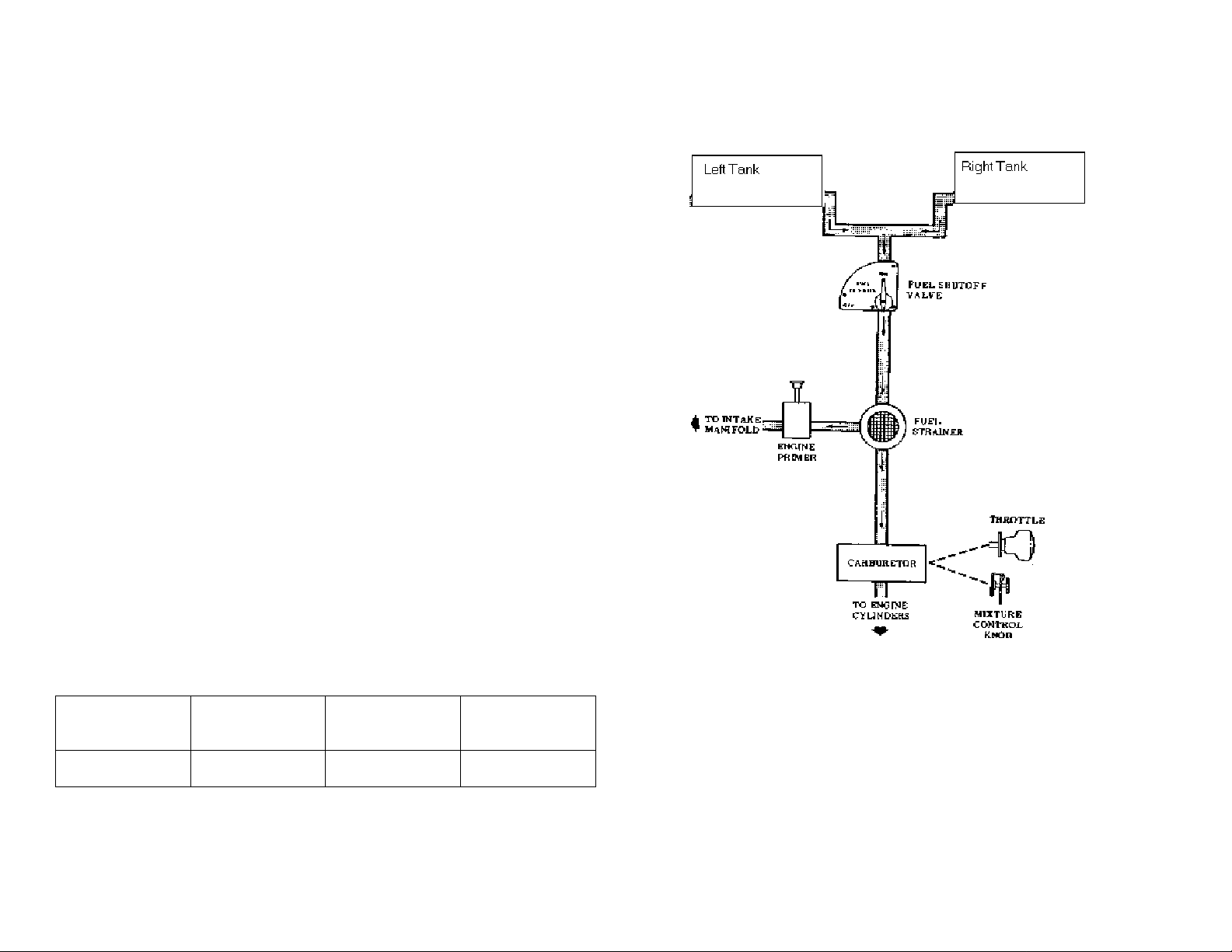

FUEL SYSTEM (Patroller)

Fuel is supplied to the engine from two 19-gallon wing tanks. From

these tanks, fuel flows by means of gravity through a fuel shutoff

valve and fuel strainer to the carburetor. The total usable fuel in all

flight conditions 35 gallons.

For fuel system service information refer to Lubrication and

Servicing Procedures in Section 4

FUEL STRAINER DRAIN

Refer to fuel strainer Servicing Procedure, Section 4

FUEL QUANTITY DATA (U. S. GALLONS)

TANKS USUABLE FUEL

ALL FLIGHT

CONDITIONS

TWO WING

19 GAL EACH

UNUSUABLE

FUEL

35 3.0 38.0

TOTAL FUEL

VOLUME

fig 2-1

page 2-1

page 2-2

Page 6

ELECTRICAL SYSTEM

CABIN HEATING AND VENTILATING SYSTEM

Electrical energy is supplied by a 14-volt, direct-current system,

powered by an engine-driven 20-amp generator. A 12-volt storage

battery is located on the right forward side of the firewall, just inside

the cowl access door. The master switch controls all electrical

circuits except the clock and the ignition system.

FUSES AND CIRCUIT BREAKERS

Fuses protect many of the electrical circuits in your airplane. The

circuits controlled by each fuse are indicated above each fuse retainer.

The clock fuse is located adjacent to the battery. Fuse capacity is

indicated on each fuse retainer cap. Fuses are removed by pressin g

the fuse retainers inward and rotating them counterclockwise until

they disengage. The faulty fuse may then be lifted out and replaced.

Spare fuses are held in a clip on the inside of the map compartment

door.

The fuel quantity indicators, stall warning transmitter and warning

horn system, and optional turn-and-bank indicator circuits are

protected by an automaticall y – reset circuit breaker which provides

intermittent emergency operation of these devices in case of a faulty

circuit. In addition to the fuse in the instrument panel, the cigar

lighter is protected by a manually-reset type circuit breaker mounted

on the back of the lighter receptacle.

LANDING LIGHTS

A three position, push-pull type switch controls the optional landing

lights mounted in the leading edge of the left wing. To turn one lamp

on for taxiing, pull the switch out to the first stop. To turn both lamps

on for landing, pull the switch out to the second stop.

page 2-3

For heated ventilation air, pull the cabin heat know out the desired

amount. Additional ventilating air is provided by pulling out the

ventilators located in the upper corners of the windshield.

PARKING BRAKE SYSTEM

To set the parking brake, apply toe pressure to the pedals, pull out on

the parking brake knob, then release toe pressure. To release the

parking brake, push the knob in, then apply and release toe pressure.

STARTING ENGINE

Ordinarily the engine starts easily with one or two strokes of primer

in warm temperatures to six strokes in cold weather, with the throttle

open approximately ¼ inch. In extremely cold temperatures, it may

be necessary to continue to priming while cranking.

Weak intermittent explosions followed by puffs of black smoke from

the exhaust stack indicates overpriming or flooding. Excess fuel can

be cleaned from the combustion chambers by the following

procedure: Set the mixture control in full lean position, throttle full

open, and crank the engine trough several r evolutions with the starter.

Repeat the starting procedure without any additional priming.

If the engine is underprimed (most likely in cold weather with a cold

engine) it will not fire at all, and additional priming will be necessary.

As soon as the cylinders begin to fire, open the throttle slightly to

keep it running.

After starting, if the oil gauge does not begin to show pressure within

30 seconds in the summertime and about twice that long in ver y cold

weather, stop engine and investigate. Lack of oil pressure can cause

serious engine damage. After starting, avoid the use of carburetor

heat unless icing conditions prevail.

page 2-4

Page 7

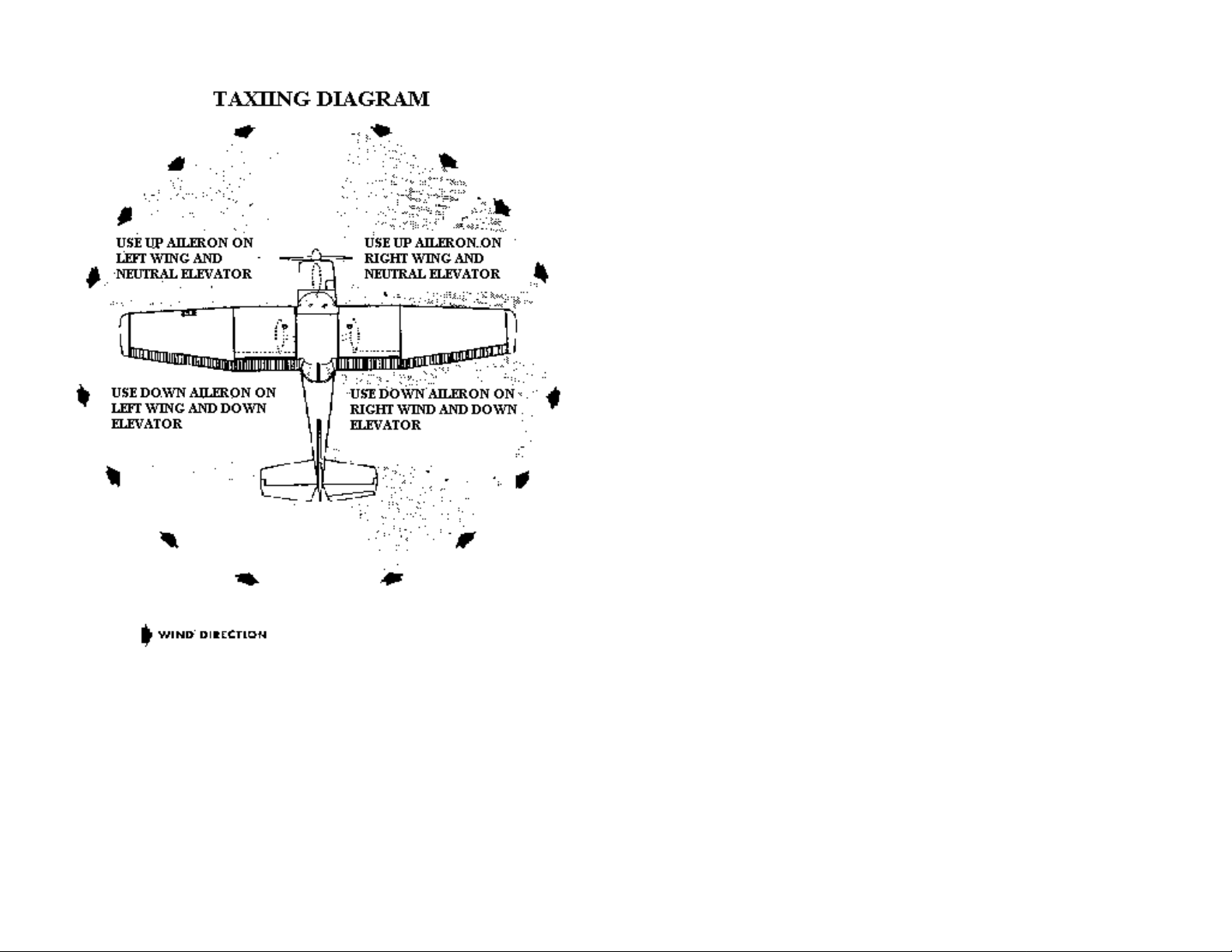

TAXIING

When taxiing it is important that speed and use of brakes be held to a

minimum and that all controls be utilized. (see figure 2-2) to maintain

directional control and balance

Taxiing over loose gravel or cinders should be done at low engine

speed to avoid abrasion and stone damage to the propeller tips. Full

throttle run-ups over loose gravel are especially harmful to propeller

tips. When takeoffs must be made over a gravel surface, it is very

important that the throttle be advanced slowly. This allows the

airplane to start rolling before the high RPM is developed, and the

gravel will be blown back of the propeller rather than pulled into it.

When unavoidable small dents appear in the propeller, blade, they

should be immediately corrected as described in Section 4.

BEFORE TAKEOFF

WARM-UP

Most of the warm up will have been conducted during the taxi, and

additional warm up before take-off should be restricted to the checks

outlined in Section II. Since the engine is closely cowled for efficient

in-flight cooling, precautions should be taken to avoid overheating on

the ground.

figure 2-2

NOTE:

Strong quartering tailwinds require caution. Avoid sudden bursts of

the throttle and sharp braking when the airplane is in this attitude.

Use the steerable nose-wheel and rudder to maintain direction

page 2-5

MAGNETO CHECK

The magneto check should be make at 1700 RPM as follows: Move

the ignition switch first to "R" position and note RPM. Then move

switch back to "BOTH" to clear the other set of plugs. Then move

switch to "L" position and note RPM. The difference between the

two magnetos operated individually should not be more than 75

RPM.

HIGH RPM MAGNETO CHECKS

page 2-6

Page 8

If there is a doubt concerning the operation of the ignition system,

RPM checks at higher engine speeds will usually confirm whether a

deficiency exists If a full throttle run up is necessary, the engine

should be run smoothly and turn approximately 2375 to 2475 RPM

with carburetor heat off.

An absence of RPM drop may be an indication of faulty grounding of

one side of the ignition system or should be cause for suspicion that

the magneto has been "bumped up" and is set in advance of the

setting specified.

TAKE-OFF

If 10º flaps are used in ground runs, it is preferable to leave them

extended rather than retract them in the climb to the obstacle. The

exception to this rule would be in a high altitude takeoff in hot

weather where would be marginal with the 10º flaps (1st notch)

Flap deflections of 10º flaps and 10º flaps are not recommended at

any time for takeoff.

PERFOMRANCE CHARTS

Consult the take-off chart in Section 5 for take-off distances under

various gross weight, altitude, and headwind conditions.

POWER CHECKS

Since the use of full throttle is not recommended in the static run-up,

it is important to check full-throttle engine operation early in the takeoff run. Any signs of rough engine operation or sluggish engine

acceleration is good cause for discontinuing the take-off. If this

occurs, you are justified in making a thorough full-throttle, static runup before another take-off is attempted.

Prior to take-off from fields above 5000 ft. elevation, the mixture

should be leaned to give maximum RPM in a full throttle, static runup.

FLAP SETTINGS

Normal and obstacle clearance t ake-offs are perfo rmed with flaps up.

The use of 10º flaps will shorten the ground run approximately 10%,

but this advantage is lost in the climb to a 50-ft. obstacle. Therefore,

the use of 10º flaps is reserved for minimum ground runs, or for takeoffs from soft or rough fields with no obstacles ahead.

page 2-7

CROSSWIND TAKE-OFFS

Take-offs into strong crosswinds normal are performed with the

minimum flap setting necessary for the field length, to minimize the

drift angle immediately after take-off. The airplane is accelerated to a

speed slightly higher than normal, then pull off abruptly to prevent

possible settling back to the runway while drifting. When clear of the

ground, make a coordinated turn into the wind to correct for drift.

CLIMB

For detailed data, see the Climb Performance Chart in Section 5

CLIMB SPEEDS

Normal climbs are conducted at 75 MPH to 80 MPH with flaps up

and full throttle for best engine cooling. The mixture should be full

rich unless engine is rough due to too rich a mixture. The best rateof-climb speeds range from 72 MPH at sea level to 66 MPH at 10,000

ft. In an obstruction dictates the use of a steep climb angle, the best

angle-of-climb speed should be used with flaps up and full throttle.

These speeds vary from 52 MPH and sea level to 60 MPH at 10.000

ft.

page 2-8

Page 9

NOTE

Steep climbs at these low speeds should be of short duration to allow

improved engine cooling.

CRUISE

The stalling speeds are shown in Section 5 for forward c.g., full

weight conditions. The are presented as calibrated airspeeds because

indicated airspeeds are inaccurate nea r the st all . Other l oadin gs r esult

in slower stalling speeds. The stall warning horn produces a steady

signal 5 to 10 MPH before the actual stall is reached and remains on

until the airplane flight attitude is changed.

Normal cruising is done at 65% to 75% of METO power. The

settings required to obtain these powers at various altitudes and

outside temperatures can be determined by using your Cessna Power

Computer.

Cruising can be done most efficiently at high altitude because of

lower airplane drag due to lower air density. This is illustrated in the

following table for 70% power:

ALTITUDE RPM TRUE A/S (mph

Sea Level 2430 * 111

5,000 ft 2550 * 116

9,000 ft full throttle 120

* 70% power

For detailed cruise performance, refer to the Cruise Performance

chart in Section 5.

STALLS

The stall characteristics are conventional for the flaps up and flaps

down condition Slight elevator buffeting may occur just before the

stall with flaps down.

LANDING

Normal landings are made power off with any flap setting. Approach

glides are normally made at 65 to 75 MPH with flaps up, or 60 to 70

MPH with flaps down, depending upon the turbulence of the air.

SHORT FIELD LANDINGS

For a short field landing, make a power off approach at 8 MPH with

flaps 40º (fourth notch) and land on the main wheels first.

Immediately after touchdown, lower the nose gear to the ground and

apply heavy braking as required. Raising the flaps after landing will

provide more efficient braking.

CROSSWIND LANDINGS

When landing is a strong crosswind, use the minimum flap setting

required for the field length. Use a wing low, crab, or combination

method of drift correction and land in a nearly level attitude. Hold a

straight course with the steerable nosewheel and occasional br aking if

necessary.

COLD WEATHER OPEATION

page 2-9

page 2-10

Page 10

Prior to starting on clod mornings, it is advisable to pull the propeller

through several times by hand to "break loose" or "limber" the oil,

thus conserving battery energy. In extremely cold (-20ºF) weather

the use of an external preheater is recommended whenever possible to

reduce wear and abuse to the engine and electrical system. Cold

weather starting procedures are as follows:

With preheat

1. Clear propeller

2. Master Switch -- On

3. With magneto switch "OFF" and throttle closed, prime the engine

four to ten strokes as the engine is being turned over

NOTE

Use heavy strokes of primer for best atomization of fuel. After

priming, push primer all the way in and turn to locked position to

avoid possibility of engine drawing fuel through the primer.

4. Turn magneto switch to "Both"

5. Open throttle to 1/4" and engage starter

Without preheat

NOTE

If the engine does not start the first time it is probable that the

spar plugs have been frosted over. Preheat must be used before

another start is attempted.

During cold weather operation, no indication will be apparent on the

oil temperature gauge prior to take of if outside air temperatures are

very cold. After a suitable warm-up period (2 to 5 minutes at 1000

RPM) accelerate the engine several times to higher engine RPM. If

the engine accelerates smoothly and the oil pressure r emains normal

and steady, the airplane is ready for take-off

When operating sub-zero temperature, avoid using partial carbureto r

heat. Partial heat may increase the carburetor air temperature to the

32º to 80ºF range, where icing is critical under certain atmospheric

conditions.

An optional winterization kit is available for use when operating to

temperatures below 20º F.

1. Prime the engine 8 to 10 heavy strokes while the propeller is

being turn by hand.

2. Clear propeller

3. Pull the master switch "On"

4. Turn magneto switch to "Both"

5. Open throttle 1/4"

6. Pull carburetor air heat knob to full on

7. Engage the starter and continue to prime engine until it is running

smoothly

8. Keep carburetor heat on until engine has warmed up.

page 2-11

page 2-12

Page 11

Section III

OPERATING LIMITATIONS

OPEATIONS AUTHORIZED

MANEUVER RECOMMENDED ENTRY SPEED

Chandelles 109 MPH (95 knots)

Lazy Eights 109 MPH (95 knots)

Steep Turns 109 MPH (95 knots)

Spins Use slow Deceleration

Stalls Use slow Deceleration

Your Cessna 150, with standard equipment as certified under FAA

Type Certificate is approved for day and night operation under VFR.

Additional optional equipment is available to increase its utility and

to make it authorized under IFR day and night.

Your airplane must be operated in accordance with all FAA approved

markings placards and checklists in the airplane. If there is any

information in this section, which contradicts the FAA approved

markings, placards and checklists, it is to be disregarded.

MANEUVERS - - UTILITY CATEGORY

This airplane is not designed for purely aerobatic flight. However, in

the acquisition of various certificates such as commercial pilot,

instrument pilot and flight instructor, certain maneuvers are re quired

by the FAA. All of these maneuvers are permitted in the Cessna 150.

In connection with the foregoing, the following gross weights and

flight load factors apply, with recommended entry speed for

maneuvers as shown.

Maximum Design Weight 1600 lbs

Flight Maneuvering Load factor, *Flaps Up +4.4 to -1.76

Flight Maneuvering Load Factor, *Flaps Down +3.5

During prolonged spins the aircraft engine may stop; however, spin

recovery is not adversely affected by engine stoppage.

Aerobatics that may impose high inverted loads should not be

attempted. The important thing to bear in mind in-flight maneuvers is

that the Cessna 150 is clean in aerodynamic design and will build up

speed quickly with the nose down. Proper speed control is an

essential requirement for execution of any maneuver, and care should

always be exercised to avoid excessive speed which, in turn, can

impose excessive loads. In the execution of all maneuvers, avoid

abrupt use of controls.

AIRSPEED LIMITATIONS

The following are the certificated calibrated airspeed limits for the

Cessna 150:

Maximum (Glide or dive, smooth air) 162 MPH (red line)

Caution Range 120-162 MPH (yellow arc)

Normal Range 56-120 MPH (green arc)

Flap Operating Range 49-100 MPH (white arc)

Maneuvering Speed * 109 MPH

* The maximum speed at which you can use abrupt control travel

without exceeding the design load factor

* The design load factors are 150% of the above and in all cases the

structure meets or exceeds design loads.

No aerobatic maneuvers are approved except those listed below:

page 3-1

ENGINE OPEATION LIMITAIONS

Power and Speed 100 BHP at 2750 RPM

Page 3-2

Page 12

ENGINE ISNTRUMENT MARKINGS

OIL TEMPERATURE GAUGE

Normal Operating Range Green Arc

Maximum Allowable Red Line

OIL PRESSURE GUAGE

Minimum Idling 10 psi (red line)

Normal Operating Range 30 - 50 psi

Maximum 100 psi (red line)

FUEL QUANTITY INDICATORS

Empty (1.75 gallons unusable each tank) E (red line)

TACHOMETER

Normal Operating Range:

At sea level 2000 - 2550 (inner green arch)

At 5000 feet 2000 - 2650 (middle green arc)

At 10,00 2000 - 2750 (outer green arc)

Maximum Allowable 2750 (red line)

WEIGHT AND BALANCE

SAMPLE

AIRPLANE

SAMPLE

LOADING

PROBLEM

Licensed Empty

Weight (sample

airplane)

Oil 6 qts ** 11 -0.1

Pilot and

Passenger

Fuel (22.5 gal @

6 lb/ gal

Baggage 76 4.9

Total Aircraft

Weight

WT

(lbs)

1038 34.2

340 13.3

135 5.7

1600 58

Moment

(lb-in)

/ 1000)

YOUR

AIRPLANE

WT

(lbs)

Moment

(lb-in)

/ 1000)

Locate this point (1600 at 58.0) on the Center of Gravity envelope

chart and since this falls within the envelope, the loading is

acceptable.

The following information will enable you to operate your Cessna

150 within the prescribed weight and center of gravity limitations.

To figure the weight and balance for your particular airplane, use the

Sample Problem, Loading Graph, and Center of Gravity Moment

Envelope as follows:

Take the licensed Empty Weight and Moment/1000 from the Weight

and Balance Data Sheet, plus any changes noted on forms FAA-337

carried in your airplane, and write them down in the proper columns.

Using the Loading Graph, determine the moment/1000 of each item

to be carried. Total the weights and moments/1000 and use the

Center of Gravity Moment Envelope to determine whether the point

falls within the envelope and if the loading is acceptable.

page 3-3

** NOTE: Normally, full oil may be assumed for all flights

page 3-4

Page 13

page 3-5

page 3-6

Page 14

Section IV

CARE OF THE AIRPLANE

If your airplane is to retain that new plane performance, stamina, and

dependability, certain inspection and maintenance requirements must

be followed. It is always wise to follow a planned schedule of

lubrication and maintenance based on the climatic and flying

conditions encountered in your locality.

Keep in touch with your Cessna dealer, and take advantage of his

knowledge and experience. He knows your airplane and how to

maintain it. He will remind you when lubrications and oil changes

are necessary and about outer seasonal and periodic services.

GROUND HANDLING

5. Install a pitot tube cover

6. Tie a rope to an exposed portion of the engine mount and secure

the opposite end to a ramp tie-down

WINDSHIELD - - WINDOWS

The plastic windshield and windows should be kept clean and waxed

at all times. To prevent scratches and crazing, wash them carefully

with plenty of soap and water, using the palm of the hand to feel and

dislodge dirt and mud. A soft cloth, chamois or sponge may be used,

but only to carry water to the surface. Rinse thoroughly, then dry

with a clean moist chamois. Rubbing the surface of the plastic with a

dry cloth builds up an electrostatic charge so that it attracts dust

particles in the air. Wiping with a moist chamois will remove both

the dust and this charge

The airplane is most easily and safely maneuvered by hand with a

tow-bar attached to the nose wheel

NOTE

When using the tow-bar, never exceed the turning angle of 30º either

side of center, or damage to the gear will result.

MOORING YOUR AIRPLANE

Proper tie-down is the best precaution against damage to your parked

airplane by gusty or strong winds.

To tied down your airplane securely, proceed as follows:

1. Set parking brake and install control wheel lock

2. Install a surface control lock between each aileron and flap

3. Tie sufficiently strong ropes or chains (700 pounds tensile

strength) to wing, and tail tail-down fittings and secure each rope

to ramp tie-down

4. Install a surface control lock over the fin and rudder

page 4-1

Remove oil and grease with a cloth moistened with kerosene. Never

use gasoline, benzine, alcohol, acetone, carbon tetrachloride, fire

extinguisher or anti-ice fluid, lacquer thinner or glass clean er. These

materials will soften the plastic and may cause it to craze.

After removing dirt and grease, if the surface is not badly scratched, it

should be waxed with a good grade of commercial wax. The wax

will fill in minor scratches and help prevent further scratching. Apply

a thin even coat of was and bring it to a high polish by rubbing lightly

with a clean, dry, soft flannel cloth. Do not use a power buffer; the

heat generated by the buffing pad may soften the plastic.

Do not use a canvas cover on the windshield unless freezing rain or

sleet is anticipated. Canvas covers may scratch the plastic surface.

page 4-2

Page 15

PAINTED SURFACES

The painted surfaces of your new Cessna require an initial curing

period which may be as long as 90 days after the finish is applied.

During this curing period some precautions should be taken to avoid

damaging the finish or interfering with the curing process. The finish

should be cleaned only by washing with clean water and mild soap,

followed by a rinse with water and drying with cloths or a chamois.

Do not use polish or wax, which would exclude air from the surface,

during this 90-day curing period. Do not rub or buff the finish and

avoid flying through rain, sleet or hail.

PROPELLER CARE

Preflight inspection of propeller blades for nicks, and wiping them

occasionally with an oily cloth to clean off grass and bug stains will

assure long, trouble-free service. It is vital that small nicks on the

propellers, particularly near the tips and on the leading edges, are

dressed out as soon as possible since these nicks produce stress

concentrations, and if ignored, may result in cracks. Never use an

alkaline cleaner on the blades. Remove grass and dirt with carbon

tetrachloride or Stoddard solvent.

INTERIOR CARE

Once the finish has cured completely, it may be waxed with a good

automotive wax. A heavier coating of was on the leading edges of

the wings and tail and on the engine nose cap and propeller spinner

will help reduce the abrasion encountered in these areas.

ALUMINUM SURFACES

The clad aluminum surfaces of your Cessna require onl y a minimum

of care to keep them bright and cle an. The airplane may be washed

with clear water to remove dirt; oil and grease may be removed with

gasoline, naphtha, carbon tetrachloride or other non-alkaline solvents.

Dulled aluminum surfaces ma y be cleaned effecti vel y with an aircr aft

aluminum polish.

After cleaning and periodically thereafter, waxing with a good

automotive was will preserve the bright appearance and retard

corrosion. Regular waxing is especially recommended for airplanes

operated in salt water areas as a protection against corrosion.

page 4-3

To remove dust and loose dirt from the upholstery, headliner, and

carpet, clean the interior regularly with a vacuum cleaner.

Blot up any spilled liquid promptly, with cleansing tissue or rags.

Don’t pat the spot; press the blotting material firmly and hold it for

several seconds. Continue blotting until no more liquid is taken up.

Scrape off sticky materials with a dull knife, then spot-clean the area.

Oily spots may be cleaned with household spot removers used

sparingly. Before using any solvent, read the instructions on the

container and test it on an obscure place on the fabric to be cleaned.

Never saturate the fabric with a volatile solvent; it may damage the

padding and backing materials.

Soiled upholstery and carpet may be cleaned with foam-type

detergent, and used according to the manufacturer's instructions. To

minimize wetting the fabric, keep the foam as dry as possible and

remove it with a vacuum cleaner,

page 4-4

Page 16

The plastic trim, instrument panel and control knobs need only be

wiped off with a damp cloth. Oil and grease on the control wheel and

control knobs can be removed with a cloth moistened with kerosene.

Volatile solvents, such as mentioned in paragraphs on care of the

windshield, must never be used since they soften the craze the plastic.

INSPECTION SERVICE AND INSPECTION PERIODS

With your airplane you will receive an Owner's Service Policy.

Coupons attached to the policy entitle you to an initial inspection and

the first 100-hour inspection at no charge. If you take delivery from

your Dealer, he will perform the initial inspection before delivery of

the airplane to you. If you pick up the airplane at the factor y, plan to

take it to your Dealer reasonably soon after you take deliver on it.

This will permit him to check it over and to make any minor

adjustments that may appear necessary.

Also, plan an inspection by your Dealer at 100 hours or 90 days,

which ever comes first. This inspection also is performed by your

Dealer for you at no charge. While these important inspections will

be performed for you by any Cessna Dealer, in most cases you will

prefer to have the Dealer from whom you purchased the airplane

accomplish this work.

Civil Air Regulations required that all airplanes have a periodic

(annual) inspection as prescribed by the administrator, and performed

a person designated by the administrator. In addition, 100-hour

periodic inspections made by an "appropriately-rated mechanic" are

required if the airplane is flown for hire. The Cessna Aircraft

Company recommends the 100-hour periodic inspection for your

airplane. The procedure for this 100-hour inspection has been

carefully worked out by the factory and is followed by the Cessna

Dealer Organization. The complete familiarity of the Cessna Dealer

Organization with Cessna equipment and factory-approved

procedures provides the highest type of service possible at lower cost.

page 4-5

AIRPLANE FILE

There are miscellaneous data, information and licenses that are a part

of the airplane file. The following is a checklist for that file. In

addition, a periodic check should be made of the latest Civil Air

Regulations in insure that all data requirements are met.

1) To be displayed in the airplane at all times:

a) Aircraft Airworthiness Certificate (Form FAA-1362)

b) Aircraft Registration Certificate (Form FAA -500A)

c) Airplane Radio Station License (Form FCC-404, if transmitter

installed)

2) To be carried in the airplane at all times

a) Weight and Balance, and associated p apers (latest copy of the

Repair and Alteration Form, FAA-337 if applicable)

b) Airplane Equipment List

3) To be made available upon request:

a) Airplane Log Book

b) Engine Log Book

LUBRICATION AND SERVICING PROCEDURES

Specific servicing information is provided here for items requiring

daily attention. A Service Frequency checklist is included to inform

the pilot when to have other items checked and serviced

DAILY

Fuel Tank Filler

Service after each flight with 80/87 minimum grade fuel. The

capacity of each wing tank is 19 gallons for optional patroller tanks

Fuel Strainer

On the first flight of the day and after each refueling, drain for about

four seconds, to clear fuel strainer of possible water and sediment.

Turn the drain knob, then check that strainer drain is close after

draining.

page 4-6

Page 17

Oil Filler

When preflight check shows low oil level, service with aviation grade

engine oil: SAE 20 below 40ºF and SAE 40 above 40ºF. Your

Cessna was delivered from the factory with straight mineral oil (nondetergent) and should be operated with straight mineral oil for the

first 25 hours. The use of mineral oil during the 25-hour break-in

period will help seat the piston rings and will result in less oil

consumption. After the first 25 hours, either mineral oil or detergent

oil may be used. If a detergent oil is used, it must conform to

Continental Motors Corporation Specification MHS-24. Your Cessna

Dealer can supply an approved brand.

EACH 100 HOURS

Brake Master Cylinders Check and Fill

Gyro Instrument Air Filters Replace. Replace sooner if erratic

or sluggish responses are noted with normal suction gauge readings.

Shimmy Dampener Check and Fill

Suction Relief Valve Inlet Screen Check inlet screen for dirt or

obstruction

Fuel Tank Sump Drains Drain water and sediment

Fuel Line Drain Plug Drain water and sediment

Vacuum System Oil Separator Clean

Oil Dipstick

Check oil level before each flight. Do not operate on less than 4

quarts and fill if an extended flight is planned. The oil capacity of

each engine is 7 quarts (optional oil filter has been installed)

SERVICING INTERVALS CHECKLIST

EACH 25 HOURS

Battery Check and Service

Engine Oil Change

Engine Oil Screen Clean

Induction Air Filter Clean or Replace

Nose Gear Torque Links Lubricate

EACH 50 HOURS

Engine Oil Filter Change

page 4-7

EACH 500 HOURS

Wheel Bearings Lubricate. Lubricate at first 100 hours and at

500 hours thereafter

page 4-8

Page 18

Section V

OPERATIONAL DATA

The operational data shown on the following pages are compiled

from actual tests with airplane and engine in good condition, and

using average piloting technique and best power mixture. You will

find this data a valuable aid when planning your flights. However,

inasmuch as the number of variables included precludes great

accuracy, an ample fuel reserve should be provided. The range

performance show makes no allowance for wind, navigation error,

pilot technique, warm-up, take-off, climb etc., which may different on

each flight you make. All of these factors must be considered when

estimating fuel reserve.

AIRSPEED CORRECTION TABLE

FLAPS UP

IAS 40 50 60 70 80 90 100 110 120 130 140

CAS 51 57 65 73 82 91 100 109 118 127 136

FLAPS DOWN

To realize the maximum usefulness from your Cessna 150, you

should take advantage of its high cruising speeds. However, if range

is of primary importance, it may pay you to fly at a low cruising RPM

thereby increasing your range and allowing you to make the trip nonsop with ample fuel reserve. The range table on page 6-3 should be

used to solve flight-planning problems of this nature.

In the table (figure 5-4) range and endurance are given for lean

mixture from 2500 feet to 12,500 feet. All figures are based on zero

wind, 35 gallons of fuel for cruise, McCauley 1A100/MCM6950

propeller, 1600 pounds gross weight, and standard atmospheric

conditions. Mixture is leaned to maximum RPM. Allowances for

fuel reserve, headwinds, takeoffs and climb, and variation in mixture

leaning technique should be made as no allowances are shown on the

chart. Other indeterminate variables such as carburetor metering

characteristics, engine and propeller conditions, and turbulence of the

atmosphere may account for variations of 10% or more in maximum

range.

page 5-1

IAS 40 50 60 70 80 90 100 110 120 130 140

CAS49556372818998

figure 5-1

STALLING SPEEDS

Power off, (mph)

Gross

Weight

1600 lbs

Flaps 0º 55 57 63 78

Flaps 20º 49 51 56 70

Flaps 40º 48 49 54 67

0º 20º 40º 60º

ANGLE OF BANK

figure 5-2

page 5-2

Page 19

figure 5-3

page 5-3

CRUISE PERFORMANCE

(WITH LEAN MIXTURE)

NOTE: Maximum performance cruise is limited to 75% power

ALTITUDE RPM

2750

2500

5000

7500

10,000

12,500

2700

2600

2500

2400

2300

2200

2100

2750

2700

2600

2500

2400

2300

2200

2100

2700

2600

2500

2400

2300

2200

2100

2700

2600

2500

2400

2300

2200

2650

2600

2500

2400

2300

* NOTE: No allowance is made for takeoff or reserve

BHP TAS

%

94

89

79

71

63

56

50

45

87

82

74

66

58

53

47

44

76

68

61

55

50

46

44

71

64

58

52

48

45

63

60

55

51

48

MPH

126

124

119

114

108

102

95

87

126

124

119

113

107

100

92

86

123

117

111

104

97

90

85

122

116

109

101

94

89

117

113

105

99

89

figure 5.4

page 5-4

GAL

HR

7.2

6.8

6.0

5.3

4.7

4.2

3.8

3.5

6.6

6.2

5.5

4.9

4.4

4.0

3.7

3.4

5.7

5.1

4.6

4.2

3.8

3.6

3.4

5.3

4.8

4.4

4.0

3.7

3.6

4.7

4.5

4.2

3.9

3.7

/

END

*

HOURS

(

4.9

5.2

5.9

6.6

7.4

8.3

9.1

10.0

5.3

5.6

6.3

7.1

7.9

8.7

9.5

10.2

6.1

6.8

7.6

8.3

9.1

9.7

10.2

6.6

7.3

8.0

8.7

9.4

9.8

7.4

7.7

8.4

9.0

9.5

.

)

RANGE

*

MILES

(

610

640

700

755

805

845

865

870

670

700

755

800

845

865

875

875

755

805

845

865

880

875

870

805

840

870

880

887

875

860

875

885

890

845

)

Altitude Temp (F) Temp (C)

Page 20

Sea Level 59 15

1,000 55.5 13

2,000 52 11

3,000 48.5 9

4,000 45 7

5,000 41.5 5

6,000 38 3

7,000 34.5 1

8,000 31 -1

9,000 27.5 -3

10,000 24 -5

11,000 20.5 -7

12,000 17 -9

13,000 13.5 -11

14,000 10 -13

15,000 6.5 -15

16,000 3 -17

17,000 -0.5 -19

18,000 -4 -21

19,000 -7.5 -23

20,000 -11 -25

Standard Temperatures

Page 21

ALPHABETICAL

INDEX

A

After landing, 1-4

Airplane

before entering, 1-1

file, 4-5

ground handling, 4-1

mooring, 4-1

secure, 1-4

Airspeed correction table, 5-2

Airspeed limitatio ns, 3- 2

Aluminum surfaces, 4-3

Authorized operations, 3-1

B

Baggage capacity, i

Before entering airplane, 1-1

Before landing, 1-3

Before starting engine, 1-1

Before takeoff, 1-2, 2-6

Brake system, parking 2-4

C

Cabin heating and ventilating

system, 2-4

Capacity

baggage, i

fuel, i

oil, i

Carburetor, 2-2

Care

exterior, 4-2

interior, 4-3

propeller, 4-3

Center of gravity moment

envelope, 3-6

Checklist, servicing intervals, 4-

7,4-8

Climb, 1-3

data table, 5-3

maximum performance, 1-3

normal, 1-3

speeds, 2-8

Cold weather operation, 2-10

Correction Table, airspeed, 5-2

Cruise performance table, 5-4

Cruising, 1-3

D

Diagram, exterior inspection, iv

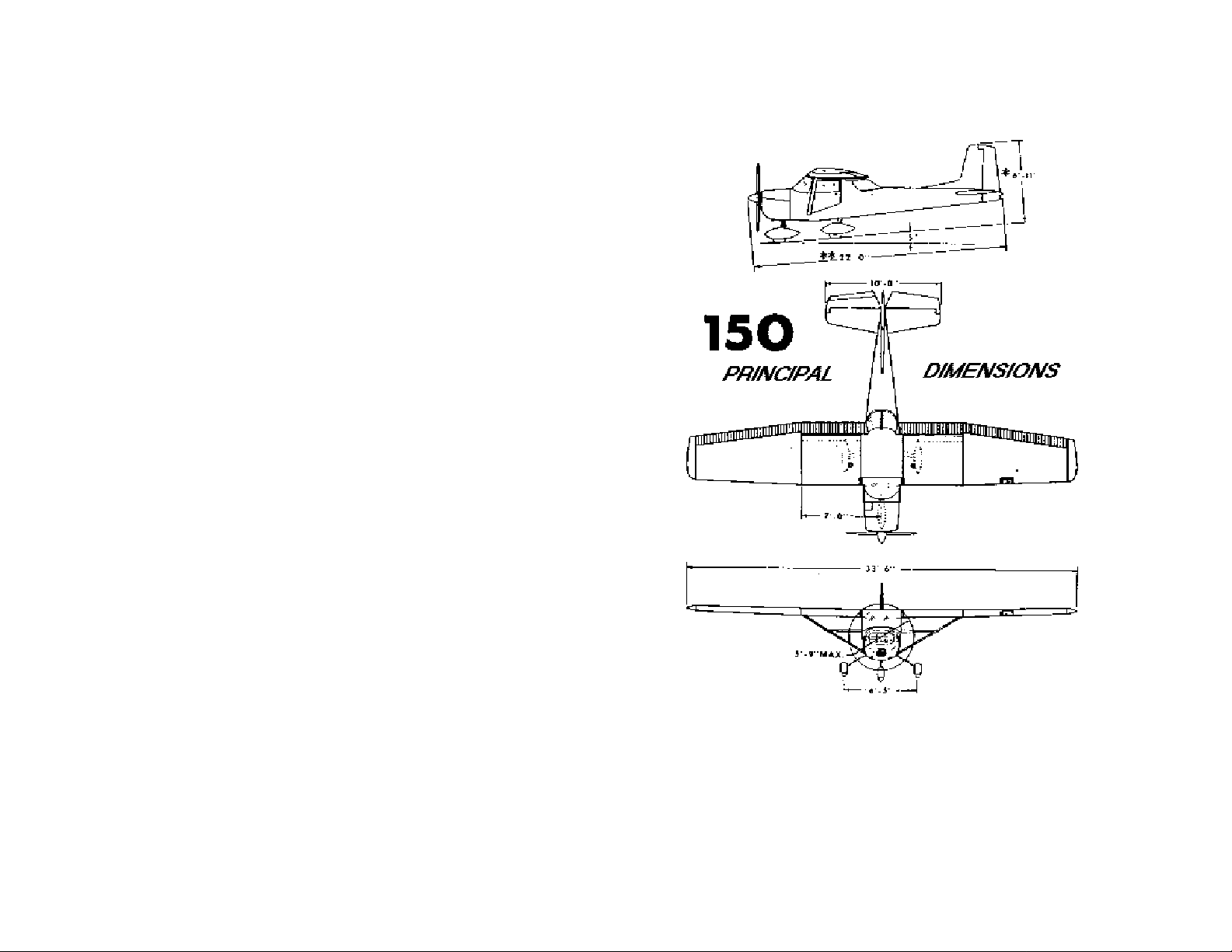

Dimensions, principal, ii

Distance table

landing, 5-3

takeoff, 5-3

E

Electrical system, 2-3

fuses and circuit breakers, 2-3

generator warning light, 2-3

Empty weight, i

Engine,

Before starting, 1-1

instrument markings, 3-3

operation limitations, 3-2

primer, 2-2

starting, 1-2

Exterior care, 4-2

Exterior Inspection , iv

F

File, airplane, 4-5

Fuel System, 2-1

capacity, i

carburetor, 2-2

primer, 2-2

quantity, 2-1

quantity indicators, 3-3

schematic, 2-2

shutoff valve, 2-2

strainer, 2-2,4-6

tank fillers, 2-7

Flap Settings, 2-7

Fuses and Circuit Breakers, 2-3

G

Generator warning light, 2-3

Gross weight, i

Ground handling, 4-1

H

Heating and ventilation system,

cabin, 2-4

I

Indicator, fuel quantity, 3-3

Inspection diagram, exterior, iv

Inspection service and inspec tio n

periods, 4-4

Instrument markings, engine,3-3

Interior care, 4-3

L

Landing, i, 2-9

after, 1-4

before, 1-3

distance table, 6-2

lights, 2-3

normal, 1-3

short field, 2-9

Light, landing, 2-3

Limitations,

airspeed, 3-2

engine operation, 3-2

Loading graph, 3-5

Loading problem, sample, 3-4

Lubrications and servicing

procedures, 4-6

M

Magneto check, 2-6

Maneuvers, utility category, 3-1

Markings, instrument 3-3

Maximum performance climb, 1-

3

Maximum performance takeoff,

1-2

Mooring your airplane, 4-1

N

Normal climb, 1-3

Normal landing, 1-3

Normal takeoff, 1-2

O

Oil capacity, i

Dipstick, 4-7

Filler, 4-6

Temperature gauge, 3-3

Pressure gauge, 3-3

Operation, cold weather 2-10

Operations, authorized, 3-1

Owner follow-up system, 4-5

P

Performance - specifications, i

Page 22

Power checks, 2-7

Power, i

Power loading, i

Primer, engine, 2-2

Principal dimensions, ii

Propeller care, 4-3

Q

Quantity data, fuel, 2-1

Quantity indicators, fuel, 3-3

R

Range, i, 5-4

Rate of climb, i

parking brake, 2-4

T

Tachometer, 3-3

Takeoff, i, 1-2, 2-7

before takeoff, 1-2, 2-6

crosswind, 2-8

distance table, 5-3

maximum performance, 1-2

normal, 1-2

Taxiing, 2-4

diagram, 2-5

U

Utility category, maneuvers, 3-1

S

Sample loading problem, 3-4

Secure aircraft, 1-4

Service ceiling, i

Servicing and lubrication, 4-6

Servicing intervals, check list, 4-

7, 4-8

servicing requirements table ,

after index

Shut-off valve, fuel, 2-2

Specifications, performance, i

Speed, i

Stalls, 2-9

speed chart, 5-2

Starting engine, 1-2, 2-4

before, 1-1

Strainer, fuel, 2-2

System

cabin heating and ventilating,

2-4

electrical, 2-3

fuel, 2-1

owner follow-up, 4-5

V

Valve, fuel shutoff, 2-2

W

Weight,

empty, i

gross, i

Weight and balance, 3-3

center of gravity moment

envelope, 3-6

loading graph, 3-6-5

sample loading problem, 3-4

Windshield - windows, 4-2

Wing loading, i

Page 23

Servicing Requirements

FUEL

Aviation Grade 80/87 Minimum, grade

Capacity, each 19 gallons capacity of sump 7

qts with oil filter

do not operate with less than 4 qts

ENGINE OIL

aviation grade SAE 20 below 40º

SAE 24 above 40º

HYDRAULIC FLUID

MIL - H - 5606 Hydraulic fluid

TIRE PRESSURE

Nose gear 30 psi

Main gear 30 psi (5:00 x 5 tire)

21 psi (6:00 x 6 tire, optional

Loading...

Loading...