Page 1

D3, D5, A5

SLIDING GATE

AUTOMATION

Product Code: CP72SR5

INSTALLATION

MANUAL

Latest Revision: 02.02.2005

Document Ref.: 1010.D.01.00136_8

Page 2

Page 3

30

31

32

33

34

IMPORTANT

Oil Specifications:

GRADE: 75W90

Qty: 75ml

L

I

O

LLEVE

35

36

37

38

WARNING! (D5/A5 ONLY)

Fill with oil prior to running

gearbox.

For transport purposes this

unit has been supplied with

oil in a separate sealed

container.

1. Lift off the cover to the

operator.

2. Remove the control card

and battery so that you

can gain access to the

filler plug.

3. Unscrew the cap and

pour in the oil provided

NB. D3 is pre-filled with

fluid grease.

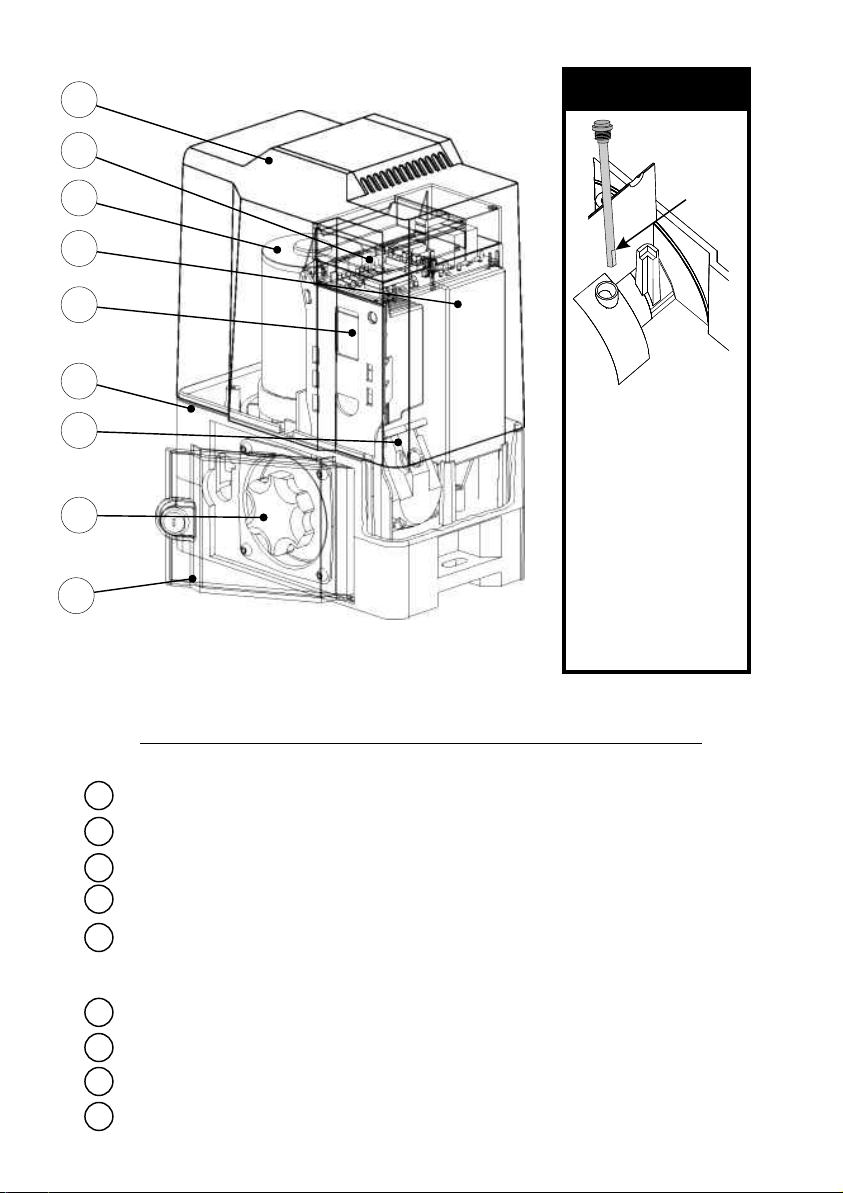

MAJOR COMPONENTS (TYPICAL D5 SHOWN)

0

3

- COVER

31

- CONTROLLER (CP80 FOR D3/D5; CP81 FOR A5)

32

- MOTOR (12V DC FOR D3/D5; 220V AC FOR A5)

33

- BATTERY (12V DC, 7A/H-D3/D5 ONLY) (OR PSU1/2, IF FITTED)

34

- CHARGER TRANSFORMER/POWER SUPPLY (CP84E for D3/D5

or CP83E for A5) (NOT FITTED WHEN PSU1/2 IS USED).

- GEARBOX CASING

35

- INTERNAL LIMIT SWITCH (DOSS)

36

- MANUAL RELEASE THUMBWHEEL

73

- LOCKABLE ACCESS DOOR

38

1

Page 4

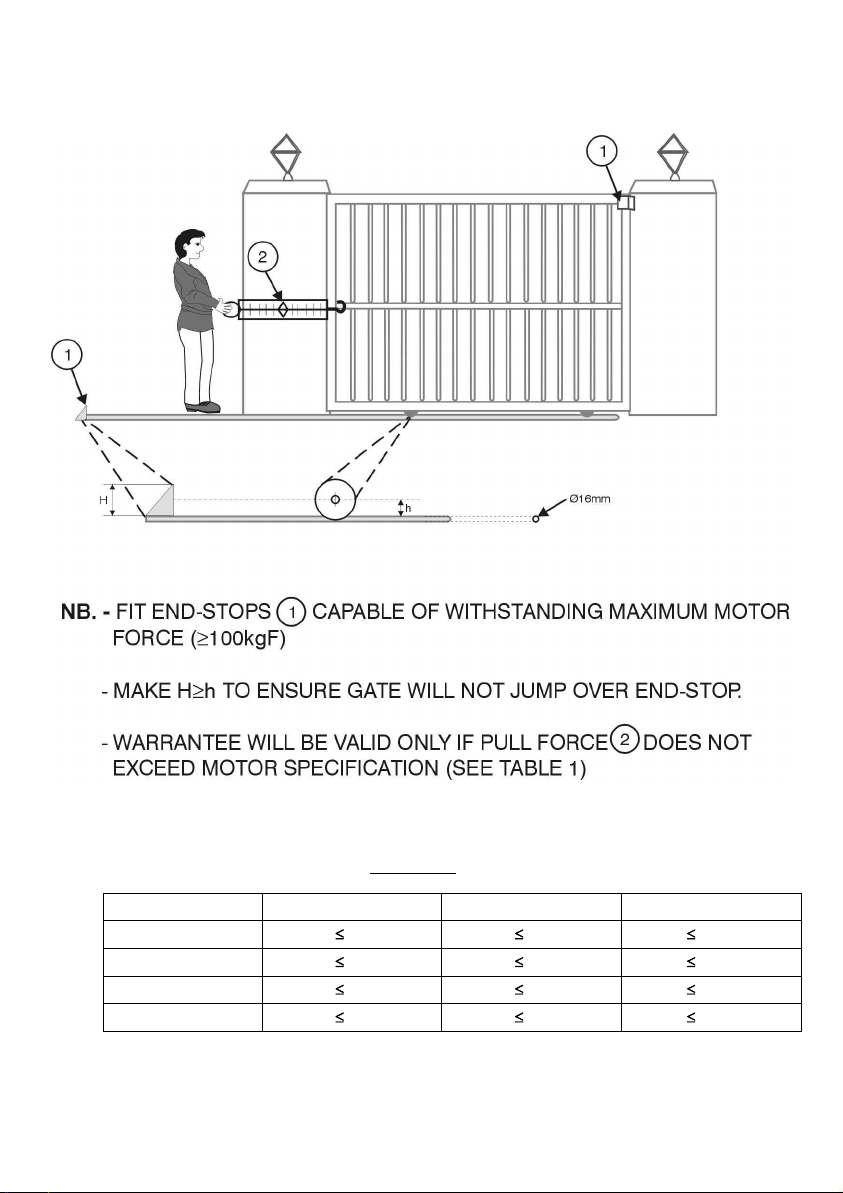

TABLE 1

D3

D5

D5 Light Industrial

A5

*LIMITED BY CAPACITY OF PSU

START (kgF)

25 12 300

60 20 500

16*

22 22 500

RUN (kgF)

16*

2

GATE MASS (kg)

500

Page 5

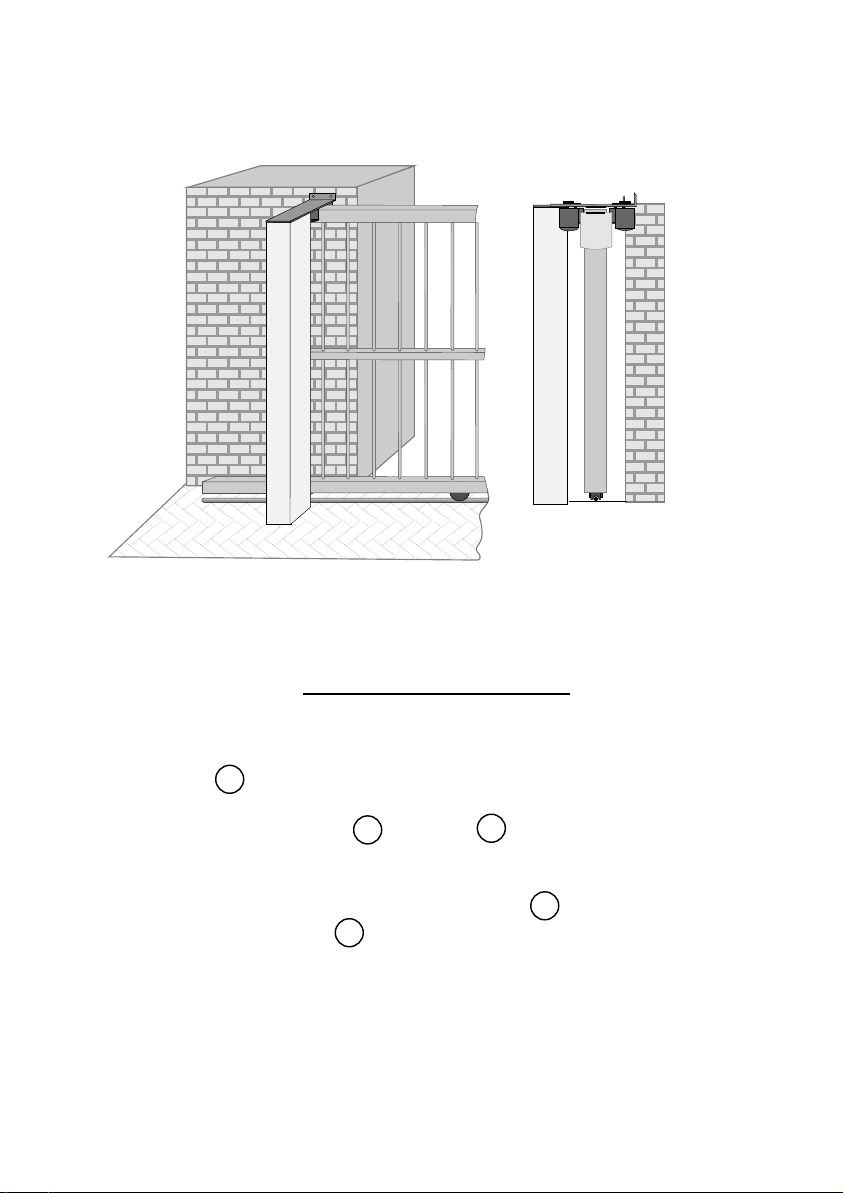

ANTI-LIFT BRACKETS

- Guide rollers must ensure that the gate is held vertically.

- Fit suitable anti-lift brackets . The gap should be <5mm to ensure

39

42

40

the gate cannot be lifted off the motor pinion.

- For improved safety fit additional support post to prevent gate from

falling over if guide rollers fail.

39

41

3

Page 6

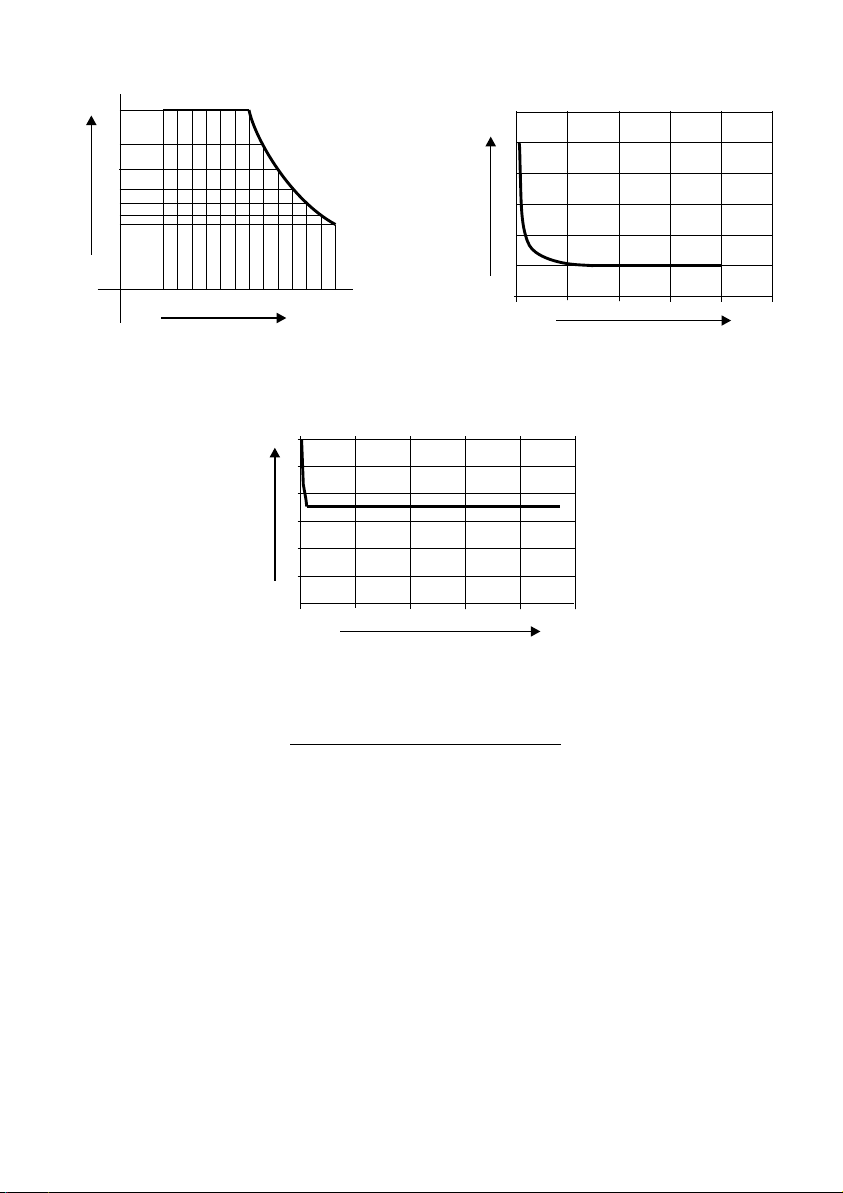

*

100

81

67

56

48

41

36

Duty Cycle ( % )

D5

8

6

12

10

22

18

14

16

20

Pull ( kgf )

28

30

24

26

120

100

80

60

40

Duty Cycle ( % )

20

A5

5

15

20

30

25

Time (hrs)

120

100

80

60

40

Duty Cycle ( % )

20

0

0

A5 with FAN

5

15

20

30

25

Time (hrs)

DUTY CYCLE CURVES

- FOR THE WARRANTY TO BE VALID, ENSURE THAT THE DUTY CYCLE

IS NOT EXCEEDED FOR THE PARTICULAR MOTOR BEING USED.

* - DUTY CYCLE IS SUBJECT TO BATTERY AND CHARGER SIZE.

4

Page 7

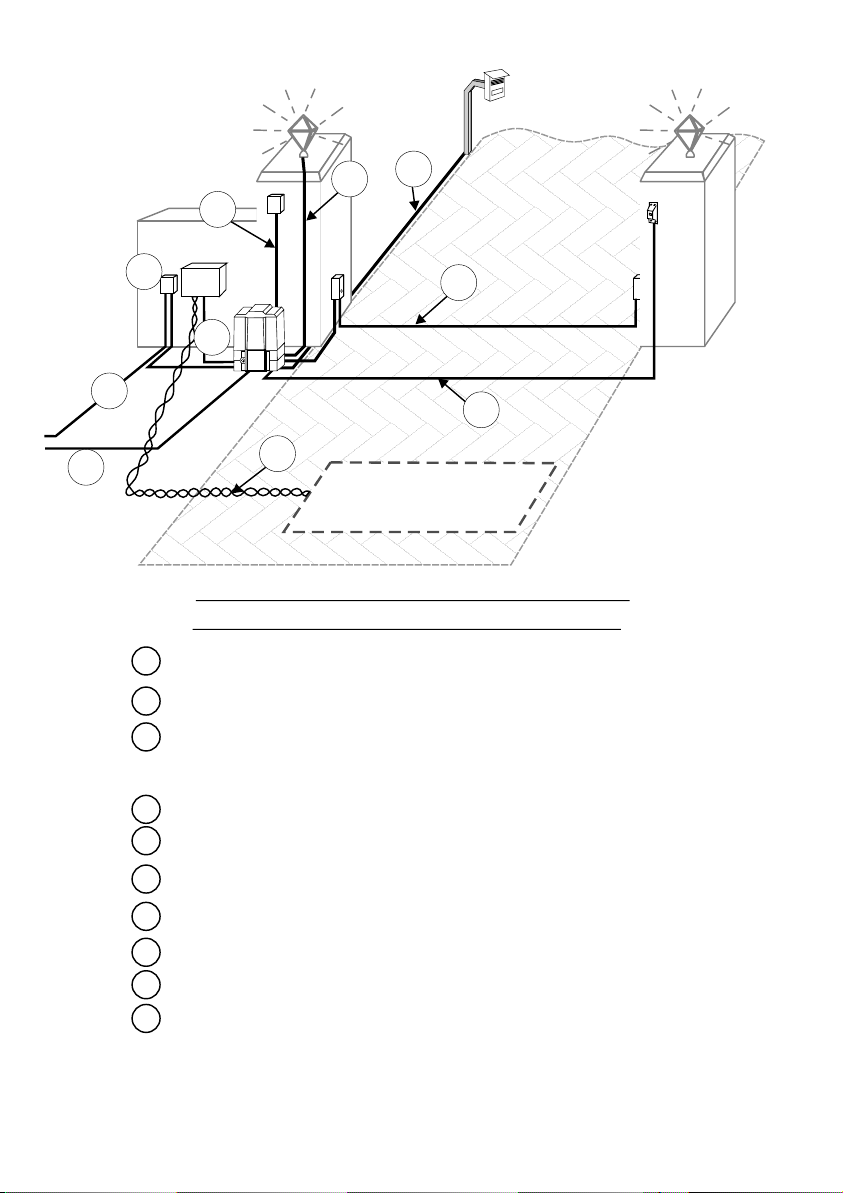

6

7

5

2

11

3

4

10

9

8

RECOMMENDED INSTALLATION AND

CABLE THICKNESS REQUIREMENTS

2

- LOCAL ISOLATOR

- MAINS SUPPLY (min 0.5mm² ‡, 2 CORE + EARTH)

3

- INTERCOM AND STATUS SIGNALING TO HOUSE

4

(0.2mm², *n1 + 6 CORE)

- INTERCOM TO GATE STATION (0.2mm², #n2 CORES)

5

6

- PILLAR LIGHTS (0.5mm², 2 CORE + EARTH)

†

- RADIO RECEIVER (0.2mm², 3 CORE)

7

- PEDESTRIAN KEYSWITCH (0.2mm², 2 CORE)

8

- INFRA RED BEAM (0.2mm², 3 CORE)

9

- FREE EXIT LOOP (1.5mm², multi stranded cable)

10

11

- FREE EXIT CONTACT (0.2mm², 2 CORE)

† For cable types to be used (e.g. SWA, Cabtyre, Intercom cable etc.) consult your

municipal authority for details.

* n1 = NUMBER OF CORES REQUIRED BY INTERCOM

# n2 = NUMBER OF CORES REQUIRED BY INTERCOM

‡ sufficient for motor only, increase to suit total load if pillar lights are fitted

5

Page 8

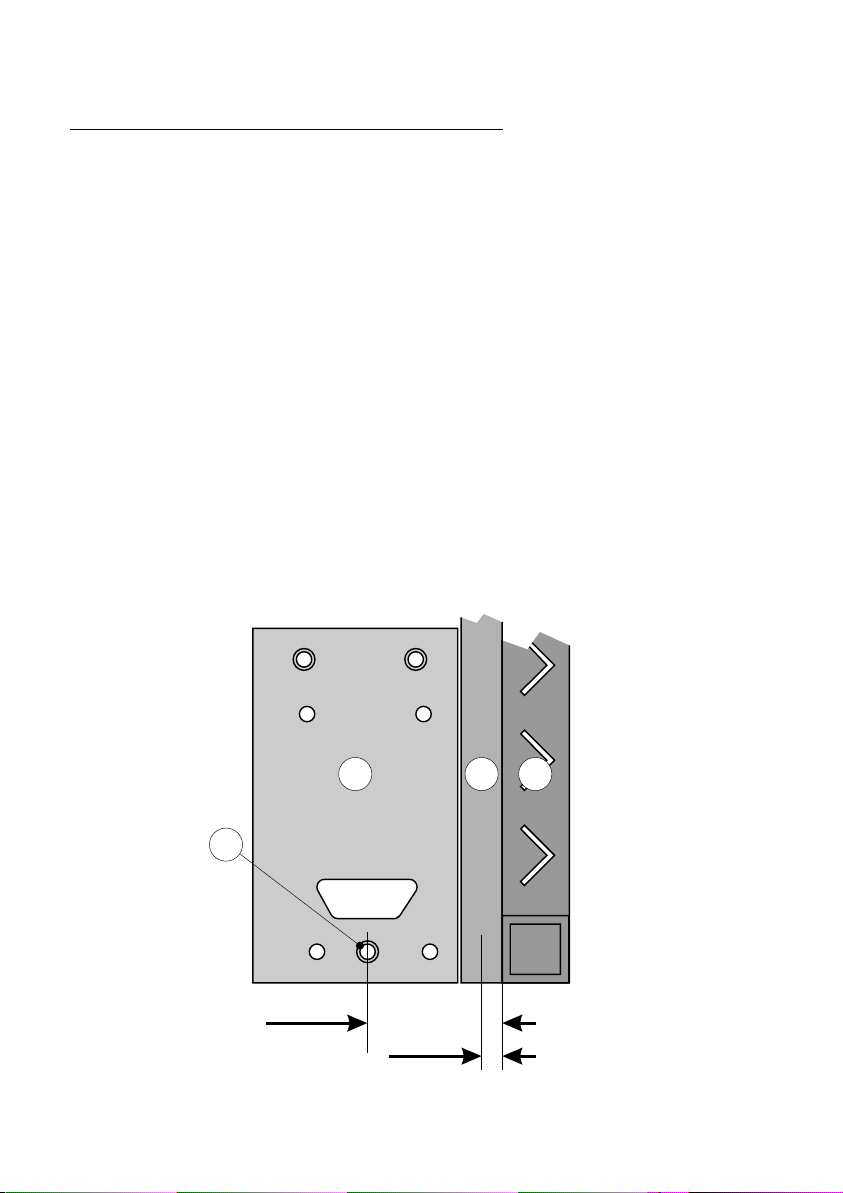

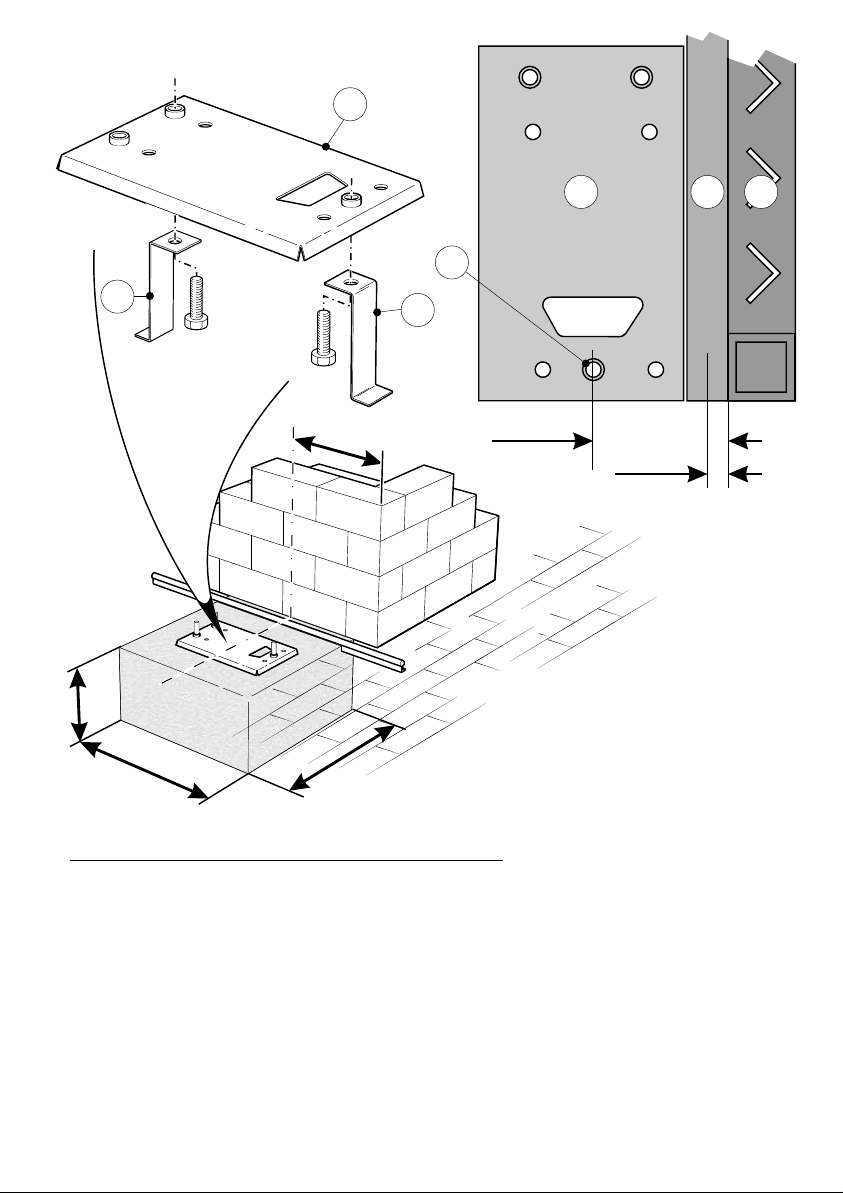

MECHANICAL MOUNTING DETAILS

Option 1 - Bolt down onto concrete plinth

- Ensure motor does not protrude into drive-way install baseplate

with centre line 250mm off pillar centre.

- Position baseplate (43) with centre of single support stud (45) 105mm

from edge of gate (46). (This dimension assumes centre line of rack (47)

is 20mm from edge of gate).

- Using the baseplate as a template mark and drill the 4 mounting holes

into the concrete for the four M10 x 95 expansion studs.

- Use two M12 plated nuts per expansion stud as spacers below the

foundation plate.

- Secure the baseplate to the expansion studs using one M10 washer and

nut per expansion stud.

4545

105mm

4343 4747 4646

20mm

C

L

6

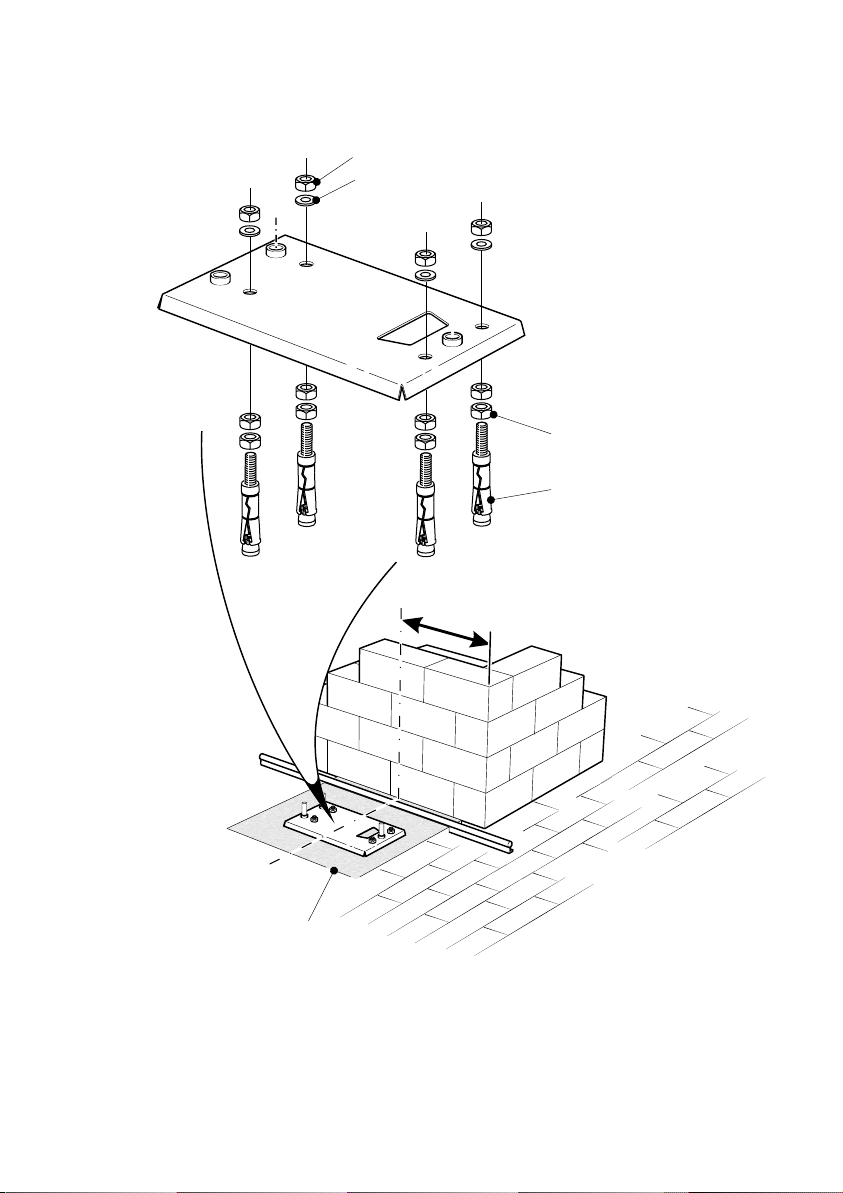

Page 9

M10 Nut

M10 Washer

2 m5

Use two M12 plated

nuts as spacers.

M10 x 95 expansion stud

0m

C

L

Existing concrete plinth

7

Page 10

4343

4343 4747 4646

4545

4444

25

0

m

m

C

400mm

L

m

0 m

04

300mm

MECHANICAL MOUNTING DETAILS

Option 2 - Set into concrete plinth

4444

105mm

20mm

C

L

- Ensure motor does not protrude into drive-way install baseplate

with centre line 250mm off pillar centre.

- Fasten concrete anchors (44) to the baseplate (43) using the M10x45

bolts provided. Ensure that the bolts are well tightened.

- Position baseplate (43) with centre of single support stud (45) 105mm

from edge of gate (46). (This dimension assumes centre line of rack (47)

is 20mm from edge of gate).

8

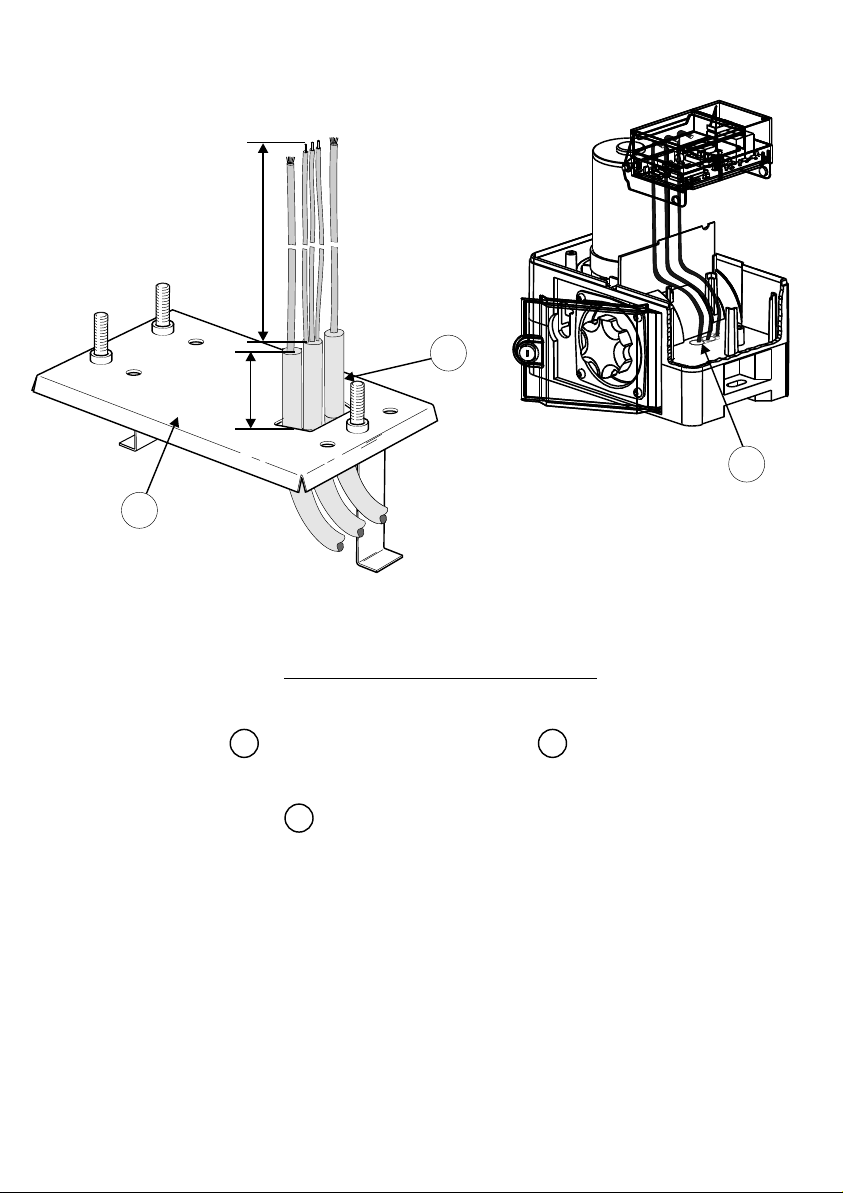

Page 11

43

350 mm

46

30 mm

47

PROVISION FOR CABLES

- Ensure cables are fitted through base plate before concreting

46 43

in place.

- Remove knock-outs from gearbox to allow for cable entry.

47

- Route cables in front of battery (D3/D5 motors) as shown above.

- Seal cable entry holes with silicone sealer.

9

Page 12

54

7

52

mm

54

GEARBOX MOUNTING DOWN DETAILS

53

51

- Leave at least 7mm clearance between the lower gearbox nuts and

52

the baseplate to allow for later adjustment.

- Gearbox MUST be firmly located between top & bottom nuts and washers

54 51 53

as shown at . Use spring washer to lock top nut in place.

- Slide gearbox forwards or backwards to give ±8mm clearance between

front of pinion and edge of gate.

10

Page 13

±300 mm

57

MOUNTING RACK

55

56

- Attach steel rack to gate using 25x25x2mm angle brackets . Distance

between centerline of rack and edge of gate should be 20mm (see ).

55

56

- For best results support rack every 300mm.

- Rack must be mounted level with a 2 - 3mm clearance .

57

USEFUL TIP

l

Raise gearbox by an additional 3mm.

l

Put gearbox into manual mode

(see on page 22)

........

l

l

37

Mesh rack and pinion fully and mount rack.

Slide gate backwards and forwards

ensuring that rack mesh is smooth and

never tight.

Drop gearbox by 3mm to create 3mm tooth

clearance.

11

Page 14

LEVEL

59

58

200 - 300mm

200mm

60

MOUNTING RACK CONTINUED

- A simple way of ensuring correct pitch spacing when joining steel rack is

to clamp a small offcut between the two pieces.

- Check that weld does not foul with meshing surfaces.

- If RAZ ™ rack is used, then start installing from the right hand side of

59

60

58

the gate working towards the LHS. Use fastening screws e.g. “TEK” screws

at least every 200mm.

12

Page 15

>100mm

64

IDLER

PULLEYS

65

61

62

>100mm

63

INSTALLING CHAIN DRIVE SYSTEMS

- Weld rear anchor plate onto gate such that centre line of tensioner

pin is in line with top of the shaft on the idler pulley . Allow at least

100mm between idler pulleys and anchor brackets.

- Align fixed anchor bracket as for .

- Ensure chain direction over sprocket is as shown (see ).

61

6462

63 61

65

13

Page 16

6mm

13mm

<15kgF

SETTING MECHANICAL CLUTCH (A5 ONLY)

- Isolate MAINS POWER.

- Remove fan from motor to expose the motor shaft (where applicable).

Ensure fan has stopped turning.

- Lock shaft using 13mm spanner and use 6mm allen key to adjust

sensitivity - Clockwise to increase force.

- Recommended maximum push force should not exceed 15kgF.

14

Page 17

MOUNTING CONFIGURATION

BOLT USING

FASTENERS

PROVIDED

FOR STEEL RACK

66

MOUNTING

PROVIDED TO

STEEL RACK

WELD

BRACKET

A

68

5 0mm

ORIGIN MARKER

BRACKET

66

GREATER THAN 500mm

MOUNTING OF GATE SENSOR

66

CC

R TE THAN

G EA R 0

66

13-20mm

68

B

- With the gate in the CLOSED position, mount the origin marker (66) a minimum

500mm from the origin sensor (68). (See isometric view (A) or plan view (B)

above).Please note this distance will affect the pedestrian opening distance. For

minimum pedestrian opening, mount the origin marker at 500mm. The

maximum distance of the origin marker is limited by the marker having to pass

the sensor by no less than 500mm before the gate opens fully. If a longer

crawling distance is required, the position of the marker needs to be changed

(see table 3 on page 30).

- Manually slide gate OPEN until origin marker (66) is in line with the origin

sensor (68). Ensure distance between face of marker (66) and front face of

sensor (68) is between 13 and 20mm. (See (C) above)

- Adjust distance by sliding the origin marker (66) along the slotted mounting

holes until desired distance is achieved.

15

Page 18

M1

1212

CP81

M3

CP80

LIGHT

MOTOR

MOTOR

L

BROWN

LIGHT COMN EM2

BLUE

GREEN/YELLOW

15

M

16

BATT -

17

LIGHT

BATT +

COM

16

15

MOTOR

M

CP80 PSU1

MOTOR

BATT -

BATT +

LIGHT

LIGHT

COM

15

EE

NN

LL

L

13

N

14

E

20

19

EE

NN

LL

L

L

N

13

21

18

N

E

E

19

L

N

13

E

21

POWER WIRING (SEE PAGE 15 FOR SIGNAL WIRING)

- 220V AC MOTOR WITH STARTING CAPACITOR

12

- 220V AC, 1Ø, MAINS SUPPLY FOR CP84E / CP83E USING

13

REMOVABLE CONNECTORS

- CP83E POWER SUPPLY TRANSFORMER (A5 MODEL ONLY)

14

- 220V AC PILLAR LIGHT (NOT AVAILABLE ON CP84XTE PSU)

15

- 12V DC MOTOR

16

- 12V DC LEAD ACID BATTERY (Amp/HOUR RATING TO SUIT)

17

- CP84E CHARGER TRANSFORMER (D3/D5 MODEL)

18

(OR CP84XTE WHEN USED WITH PLUG-IN TRANSFORMER)

19

- LIGHTNING EARTH POINT

20

- 12V DC PLUG TO CP81 CONTROLLER

- 14.2V DC CHARGE PLUG TO CP80 CONTROLLER

21

- PSU1/2 - POWER SUPPLY UNIT

75

- MAINS FUSE - PSU1/2

76

NOTE: External battery not necessary but if fitted then CP80 PSU1

*

*

controller must be fitted.

75

BATT -

BATT +

76

17

*

16

Page 19

CP80 / CP81

TRG

IRB

FRX

LED

LIGHT

LIGHT

COM

COM

+12V

LCK

PED

SET

NEG

22

COM

NEG

23

NEG

24

COM

25

26

27

28

29

12V

N/O

12V

12V

N/C

SIGNAL WIRING (CP80 AND CP81)

- RADIO RECEIVER (OR OTHER TRIGGER e.g. INTERCOM)

2

2

- INFRA RED BEAM TRANSMITTER

23

- INFRA RED BEAM RECEIVER (N/C CONTACT)

24

52

- FREE EXIT TRIGGER (N/O CONTACT)

- REMOTE STATUS LED (MAX 3 IN PARALLEL)

62

†

- PEDESTRIAN TRIGGER (N/O CONTACT)

27

- HOLIDAY LOCKOUT CONTROL (N/C LATCHING CONTACT)

28

29

- REMOTE PILLAR LIGHT CONTROL (N/O CONTACT)

= LED INDICATORS ON P.C.B. SHOWING STATUS OF INPUT SIGNALS

† = USE MULTI LED DRIVER CARD (CP78) FOR MORE LED’S

17

Page 20

34

31

N

E

L

220V AC

INPUT

220V AC OUTPUT

TO CP80/CP81

PCB "DC IN”

LNE

50

49

43

48

RECOMMENDED LIGHTNING PROTECTION

- For optimum lightning protection ensure earth cable from charger/PSU unit

34

is adequately earthed.

- Use ring lug to bond to baseplate mounting stud.

- For additional protection bond baseplate to earth spike .

- In event of damage to charger/PSU unit disconnect quick release link

50

and push-on connector on controller.

49

34

43

48

18

Page 21

1 2

3 4 5

COMMISSIONING BLOCK DIAGRAM

- Check correct motor direction (pg. 20)

1

- Select programme mode (pg. 21)

2

- Setting of gate limits (pg. 22-27)

3

NOTE: D3/D5 LIMITS ARE SET AUTOMATICALLY.

A5 LIMITS ARE SET MANUALLY

- Function Selections(optional) (pg. 27-28)

4

END

- Timer/counter settings (optional) (pg. 29-30)

5

Steps 1 to 3 must be done on initial commissioning.

Steps 4 & 5 are optional.

19

Page 22

CP80 CP81

12V DC 220V AC

MOTOR M1 M2 M3

b

a

TO 12V DC MOTOR

a

b

SETTING MOTOR DIRECTION

c

TO 220V AC MOTOR

GATE CLOSES: -

TOWARDS LEFT (ABOVE)

TOWARDS RIGHT

CP80

a a

BLACK

BLUE BLUE

b b c

BLUE BLUE

BLACK

RED

CP81

BLACK

BLACK

ENSURE THAT MOTOR WIRE COLOURS ARE AS PER TABLE ABOVE

20

RED

Page 23

CP80/CP81

1 2 3

L1 L2

STATUS

CP80/CP81

SET

13.8V

L1 L2

STATUS

CP80/CP81

SET

L1

STATUS

L2

72

SET

BLACK

70

RED

69

71

SELECTING PROGRAMME MODE

STEP 1 - Remove power from control card:

- for A5 remove electronics power only

- for D3/D5 remove battery power as well as electronics

power .

STEP 2 - Fit “SET” link .

69

71

STEP 3 - Reapply power (reversal of STEP 1). STATUS LED will flash 5 times

on power up. Check that LED L2 and “SET” are ON.

LED L2 indicates controller is in “programme mode”.

72

69

70

21

Page 24

1/2 1/2

73

Fig.1

37

Fig.2

SETTING GATE LIMITS

- Rotate manual release thumbwheel fully clockwise, or until clutch is

fully dis-engaged and gate can be moved by hand.

D3/D5 ONLY

- Slide gate approximately half way open. See above (FIG. 1).

- Re-engage gearbox.

A5 ONLY

- Slide gate to fully closed position (FIG. 2).

- Leave gearbox dis-engaged.

- Skip to page 25-27 and follow START MANUAL GATE LIMITS ROUTINE.

37

73

22

Page 25

CP80/CP81

control card

L2

L1

TEST

STATUS

SET

SETTING GATE LIMITS (continued)

NB. Ensure you follow the correct procedure!

The procedure for setting D3/D5 and A5 motors is DIFFERENT.

The A5 limits have to be set manually (see page 25 and 26), while

the D3/D5 motors set their limits automatically (see page 21 to 23).

D3/D5 ONLY (PAGE 23, 24, 25)

- Press the TEST pushbutton while monitoring LED L1.

- When L1 flashes once, release TEST pushbutton. L2 will go out,

L1 will continue to flash once per second. Controller is now in MENU 1

which sets gate limits.

NB. Understand the procedure detailed on page 24 before continuing.

The controller is about to perform the fully automatic setup routine.

CP80/CP81

control card

L1

TEST

STATUS

L2

SET

START AUTOMATED GATE LIMITS ROUTINE

- Press TEST pushbutton until STATUS LED illuminates.

- AUTOMATIC set up routine (described on page 24) starts as soon as TEST

button is released.

23

Page 26

D3/D5 MOTOR AUTOMATIC SET-UP

1

1- Gate starts at “crawl” speed to open

gate.

NB. If gate closes, remove power and

reverse motor wires (see page 20)

2

2- Gate hits “open” end stop and reverses

direction running at crawl speed.

3

3 - Gate hits “closed” end stop and

reverses direction running at “FULL”

speed until the marker, then at

CRAWL speed to end.

4

4 - Gate hits “open” end stop and

reverses but now runs at “FULL”

speed.

5

6

5 - As gate sensor passes the motor, the

speed reduces to CRAWL. Gate hits

“closed” end stops and reverses

at FULL SPEED.

6 - Gate stops at “pedestrian” (PED)

position. If required, widen PED

opening by pulsing PED input.

24

Page 27

TURBO MODE: If desired the set up time can be shortened by manually

overriding the automatic “crawl”speed in steps 1, 2, 3 shown on page 24.

This is done by pressing and holding the TEST button. The speed increases

to FULL speed while the button is depressed.

NB. Do not run the gate into the end stops at full speed.

CP80

control card

L1

TEST

STATUS

L2

SET

CP80

control card

L1

L2

TEST

STATUS

74

SET

EXIT GATE LIMITS ROUTINE (D3/D5 ONLY)

- After the gate stops at the required pedestrian position (see step 6 on

page 24) ie either at the automatic minimum or the manually over-ridden

position, press the TEST button for a moment and release.

- L2 will illuminate when TEST button is released.

- Remove SET link and position as shown above, , to exit programming

unless proceeding to other menus.

NB. If automatic routine does not complete (indicated by STATUS flashing

5 times & L2 illuminating) then it may be necessary to set collision

sensitivity to MED or LOW (see page 28)

74

START MANUAL GATE LIMITS ROUTINE

A5 ONLY (PAGE 26 & 27)

25

Page 28

A5 MOTOR MANUAL SET-UP

STEP 1 ALIGN ORIGIN SWITCH

- Start with gate fully closed.

- Push gate open (origin marker must have

moved well past origin switch).

- Push gate closed again.

STEP 2 - ENSURE PCB IS IN PROGRAMME

MODE (refer procedure page 21)

STEP 3 - SET LIMITS

- Press TEST pushbutton until LED L1 flashes

once and release.

- L1 will continue to flash once and L2 will

go out.

- Press TEST pushbutton until STATUS LED

comes ON and release (check that L1, L2 &

STATUS are OFF)

STEP 4

- Push gate to fully “OPEN” position and do not

allow gate to reverse.

- Press TEST pushbutton until STATUS LED

comes ON and release.

“PED”

STEP 5

- Push gate to fully “CLOSED” position hard

up against endstop and do not allow gate

to reverse.

- Press TEST pushbutton until STATUS LED

comes ON and release.

STEP 6

- Push gate to “PEDESTRIAN” open position.

- Press TEST pushbutton until STATUS LED

comes ON and release. If STATUS LED

does not come ON, increase pedestrian

opening until it does.

26

Page 29

CP81

control card

L1

TEST

STATUS

L2

CP81

control card

L1

L2

TEST

STATUS

74

SET

SET

EXIT GATE LIMITS ROUTINE (A5 ONLY)

If the gate limits described on page 26 are successfully completed,

then LED L2 will be ON.

- Position SET link as shown above to exit programming unless

74

proceeding to other menus.

FUNCTIONS SELECT

Several different functions can be programmed. The procedure which is similar for all

functions is described below in conjunction with TABLE 2 on page 28

STEP 1 - Ensure controller is in Programme Mode (see page 21).

STEP 2 - Press and hold the TEST pushbutton while monitoring LED L1.

STEP 3 - L1 will flash once then go off, twice in short succession then go off, 3 times

then go off, etc. The number of flashes represents the menu number.

STEP 4 - Release TEST button when the required main menu (see Table 2, page 28) is

selected.

STEP 5 - To select the sub-division of the main menu (see RHS of Table 2), press and

hold the TEST pushbutton, while monitoring the STATUS LED to count

flashes. The number of times the STATUS LED flashes represents the sub

menu number.

STEP 6 - Release TEST pushbutton when the required subdivision is selected. L2 will

come ON to indicate that the controller is back in PROGRAMME MODE and

another FUNCTION or TIMER (refer to procedure on page 29) can be

programmed.

STEP 7 - Remove SET link when all programming is complete.

27

Page 30

TABLE 2

AUTO CLOSE

MODE

COLLISION

SENSITIVITY

POSITIVE

CLOSE MODE

MAIN

MENU

No of times

L1 flashes

2

4

7

9

SUB DIVISION

OF MAIN MENU

No of times

STATUS must flash

1

2

1

2

3

4

1

2

3

1

2

STANDARD

CONDOMINIUM

REVERSING

ON

OFF

PIRAC

HIGH

MEDIUM

LOW

ON

OFF

PREFLASHING*

FACTORY DEFAULTS HIGHLIGHTED

10

28

1

2

3

4

MODE1

MODE 2

MODE 3

OFF

Page 31

*The PREFLASHING MODES mentioned on page 28 are described below:

MODE 1 - COURTESY LIGHT PREFLASHES AT 1 HZ, THEN ACTS AS

COURTESY LIGHT.

MODE 2 - COURTESY LIGHT FLASHES AT 1 HZ FOR PREFLASH TIME

AND THEN FLASHES IN SYNCHRONISM WITH THE STATUS LED

WHILE THE MOTOR RUNS.

MODE 3 - COURTESY LIGHT ON CONTINUOUSLY FOR PREFLASH TIME

AND MOTOR RUN TIME ONLY.

TIMER and COUNTER SETTING

Various timers and counters can be programmed. The procedure is described

below in conjunction with Table 3, page 30.

STEP 1 - Ensure controller is in Programme Mode (see page 21).

STEP 2 - Press and hold the TEST pushbutton while monitoring LED L1.

STEP 3 - L1 will flash once then go off, twice in short succession then go off, 3

times then go off, etc.

STEP 4 - Release TEST pushbutton when the desired MAIN MENU item in Table

3 is required.

STEP 5 - To select required time (or count) hold TEST pushbutton while

monitoring STATUS LED. After a short time STATUS will flash

continuously and regularly. Each flash represents a unit of measure

(i.e. time, distance or count).

Release TEST pushbutton when the required subdivision is selected.

L2 will come ON to indicate that the controller is back in PROGRAMME

MODE and another TIMER or FUNCTION (refer to procedure on page

27) can be programmed.

STEP 6 - Remove SET link when all programming is complete.

29

Page 32

TABLE 3

NORMAL AUTOCLOSE

PEDESTRIAN AUTOCLOSE

COURTESY LIGHT

AUTOCLOSE OVERRIDE

PREFLASH TIME

COLLISION COUNTER

CRAWL DISTANCE (D3/D5)

COAST MODE (A5)

MAIN

MENU

No of times

L1 flashes

3

5

6

8

11

12

13

13

UNIT OF

MEASURE

Each flash

of STATUS

represents

1 SEC

1 SEC

10 SEC

1 SEC

1 SEC

1 COUNT

350 MM †

10 MM

FACTORY

DEFAULTS

15 SEC

5 SEC5 SEC

12x10 SEC

3 SEC

5 SEC

4 COUNTS

1x350mm

30mm

† THE CRAWL DISTANCE IS A LENGTH OF TRAVEL WHICH ALLOWS

THE GATE TO SLOW DOWN BEFORE REACHING THE END STOP. FOR

HEAVIER GATES WITH LESS FRICTION, THE CRAWL DISTANCE MAY

HAVE TO BE INCREASED. WHEN INCREASING THE CRAWL

DISTANCE, THE POSITION OF THE ORIGIN MARKER (ITEM 66 PAGE

15) MUST BE MOVED.

CRAWL

DISTANCE

350mmDEFAULT

700mm

1050mm

TURBO MODE: TO SPEED UP THE COUNTING WHILE SELECTING MAIN

MENU ITEMS TEMPORARILY CONNECT “PED” TERMINAL TO “COM”

STATUS FLASH

COUNT

1

2

3

DISTANCE BETWEEN

MARKER AND PINION

500mm

750mm

1100mm

30

Page 33

PROCEDURE TO PROGRAMME CONTROLLER

BACK TO FACTORY SETTINGS

1. REMOVE POWER (POWER SUPPLY AND BATTERY IF D3 or D5).

2. FIT THE "SET" LINK.

3. CONNECT "PED" AND "FRX" TO "COM".

4. RECONNECT POWER. L1 AND L2 WILL ILLUMINATE.

5. REMOVE THE POWER (BATTERY AND POWER SUPPLY).

6. REMOVE THE "SET" LINK AND DISCONNECT "PED" AND "FRX" FROM "COM".

7. THE CARD IS NOW PROGRAMMED TO DEFAULT SETTINGS AS SHOWN IN

TABLES 2 (see page 28) AND TABLE 3 (see page 30) (GATE END POINTS ARE

NOT AFFECTED).

FAULT FINDERS GUIDE D3 / D5 OPERATORS

REF: CP157 EFFECTIVE: 19/09/2001 SUPERCEDE: 29/11/2000

SOME TYPICAL FAULTS

1. GATE RUNS A SHORT DISTANCE AND STOPS.

1.1 Battery low condition (Status flashing 3 times)

1.1.1 Old battery

1.1.2 Check battery charger

1.1.2.1 Charge voltage (13.8V no battery connected)

1.1.2.2 Charge rate (Check recovery rate of charger)

1.1.3 Check duty cycle of system (battery capacity sufficient)

1.1.4 Check condition of battery leads and connectors.

1.2 Multiple collision condition (Status flashing 4 times)

1.2.1 Adjust collision sensitivity (high to medium or to low)

1.2.2 Check for something physically obstructing the movement of gate

1.2.2.1 Rack pressing down onto pinion

1.2.2.2 Bad rack joints

1.2.2.3 Seized or badly running wheels

1.2.2.4 Top guide rollers restricting the gate

1.2.2.5 Dirt on rail

1.2.2.6 Physical damage to the rail

1.2.2.7 Wheel catching side of pinion

1.2.2.8 Gate hitting endstop

1.2.3 DOSS feedback problem

1.2.3.1 Dirt inside the DOSS

1.2.3.2 Poor connection between the DOSS and the controller (check cable and connector)

1.2.3.3 Doss cable fitted back to front

1.2.3.4 Doss not being driven due to missing coupling or faulty bevel drive.

1.2.3.5 Faulty DOSS controller

1.2.4 Faulty motor circuit

1.2.4.1 Motor fuseholder making intermittent contact.

1.3 Spurious trigger

1.4 Faulty controller

31

Page 34

2. GATE DOES NOT RUN BUT THE RELAYS ENERGISE WHEN THE UNIT IS ACTIVATED.

2.1 Faulty motor circuit

2.1.1 Faulty motor relay / FET

2.1.2 Motor fuse blown (replace with 16/20A slow blow 5x20mm)

2.1.3 Fuseholder making bad contact.

2.1.4 Worn motor brushes

2.1.5 Loose motor wire

2.1.6 Faulty controller

3. GATE OPENS ON ITS OWN.

3.1 Permanent trigger input

3.1.1 Check for latched Rx or latched house pushbutton

3.2 Intermittent fault on pushbutton line (underground joint with moisture build-up)

3.3 Outside transmitter with the same code (typically only possible with compatible remotes QD black / TSM etc))

3.4 Faulty Rx

4. INTERMITTENT AUTO-CLOSE.

4.1 Latching Rx overrides auto-close

4.2 Long pulse on trigger input overrides auto-close (check pulse time of intercom gate release)

4.3 Faulty infra red beam input

4.4 Faulty controller

5. GATE DOES NOT RECOGNISE ITS LIMITS.

5.1 Magnet incorrectly mounted (Check page 13 of installation manual)

5.2 Faulty magnetic switch

5.3 Check connection between switch and controller via DOS S.

5.4 Faulty controller

6. GATE DOES NOT TRIGGER AT ALL. (USING TEST PUSHBUTTON)

6.1 LCK input activated (Check state of LCK)

6.2 Latched input on TRG or FRX input

6.3 IRB input activated

6.4 Faulty controller

7. GATE OPENS TO PEDESTRIAN AND CLOSES.

7.1 Faulty key switch

7.2 Faulty wiring on pedestrian input

8. GATE STARTS CLOSING BUT STOPS AND RE-OPENS.

8.1 Intermittent IRB trigger (Check alignment and that the supply voltage for beams is compatible with the operator.)

8.2 Collision sensitivity set too sensitive

8.3 Spurious signal on FRX (if used) or TRG if in Condo / Pirac / Reverse mode

WHILE COMMISSIONING (automatic Setup Routine)

9. GATE OPENS TO THE FULLY OPEN POSITION AND DOES NOT RETURN

9.1 Check the battery. (battery voltage should stay above 11.0v while gate is running).

10. GATE DOES SHORT OPEN AND CLOSE CYCLES (L2 COMES ON AGAIN

10.1 Poor connection between the DOSS and the controller (check cable and connector).

10.2 DOSS not being driven due to missing coupling.

10.3 Adjust collision sensitivity (high to medium or to low).

11. GATE DOES NOT RUN BUT THE RELAYS ENERGISE WHEN THE UNIT IS ACTIVATED

11.1 Check motor wires are securely terminated.

11.2 Check motor fuse (replace with 16/20A slow blow 5x20mm)

11.3 Check battery connections are leads.

11.4 Check that battery is not flat.

12. THE OPERATOR COMPLETES SETUP ROUTINE CORRECTLY. HOWEVER WHEN ACTIVATED AFTERWARDS,

DRIVES AT FULL SPEED INTO MECHANICAL END STOP.

12.1 Check that origin marker (magnet) is correctly positioned for the “Crawl Distance” selected (main menu item 13). If

in doubt restore controller factory default settings. Refer to the Installation Manual, Table 3 for table of distances.

12.2 On an upgraded system, ensure that controller has been restored back to Factory default settings

32

Page 35

Page 36

CENTURION

THE AUTOMATIC CHOICE

CENTURION SYSTEMS (PTY) LTD HEAD OFFICE:

TEL: +27 (0)11 699-2400, FAX: +27 (0)11 704-3412 or 462-6669

148 EPSOM AVENUE, NORTH RIDING

P.O. BOX 506, CRAMERVIEW, 2060

SOUTH AFRICA

WEB: http://www.centsys.co.za General information e-mail: info@centsys.co.za

SOUTH AFRICA

FOR TECHNICAL SUPPORT CONTACT:

EAST RAND. . . . . . . . . . . . . . . (011) 397-6401

DURBAN .................(031) 701-9583

NELSPRUIT . . . . . . . . . . . . . . . (013) 752-8074/5

PRETORIA . . . . . . . . . . . . . . . . (012) 362-8819/8893

CAPE TOWN . . . . . . . . . . . . . . (021) 447-1295

AFRICA

ECHO-LINE, NAMIBIA.............................................................Tel: (61) 220-8309

MOLECULAR CONSULTANTS, NIGERIA...............................................Tel: 803-3123182

SECURITY DISTRIBUTORS, ZIMBABWE................................................Tel: (4) 795-873

SEKANYOLYA TIMBER WORKS, UGANDA...............................................Tel: (41) 231-40

EUROPE

AUTOMATISME BATIMENT, FRANCE.................................................Tel: (1) 697-93120

CROWN AXXESS LTD U.K. UNITED KINGDOM. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Tel: (1483) 450-011

NESTOR, BELGIUM ...............................................................Tel: (9) 380-4020

NORTH AMERICA

BILLY GATES, CANADA ..........................................................Tel: (250) 334-1553

AUSTRALASIA

ABA GATES, WESTERN AUSTRALIA.................................................Tel: (8) 933-03061

DOMINATOR SYSTEMS, NEW ZEALAND ..............................................Tel: (3) 384-5145

ICBT, VICTORIA..................................................................Tel: (3) 933-54213

ROTECH, QUEENSLAND..........................................................Tel: (7) 326-47330

SA GATES, SOUTHERN AUSTRALIA.................................................Tel: (8) 826-64235

SECURITE DU PACIFIQUE, NEW CALEDONIA..............................................Tel: 283-760

INDIAN OCEAN

SECULOGIX LTD, MAURITIUS..........................................................Tel: 467-8509

SECURITE AUTOMATISMES REUNION, REUNION ..........................................Tel: 280-368

ASIA & PACIFIC

VAST VIDEO, MALAYSIA...........................................................Tel: (3) 214-34931

BLT ASSOCIATES, THAILAND .......................................................Tel: (2) 691-6793

PORT ELIZABETH. . . . . . . . . . . (041) 581-6994/5

EAST LONDON . . . . . . . . . . . . . . (043) 743-4923

BLOEMFONTEIN . . . . . . . . . . . . . (051) 448-1714

KIMBERLEY . . . . . . . . . . . . . . . . . (053) 832-3231

VEREENIGING . . . . . . . . . . . . . . . (016) 422-5667

Loading...

Loading...