Centrimaster IQTB User Manual

Chilled Beam Flexicool® IQTB

Chilled Beam Flexicool® IQTB

Functions

• FPC

• High Air-flow

• Controls

• Comfort control

• Heating

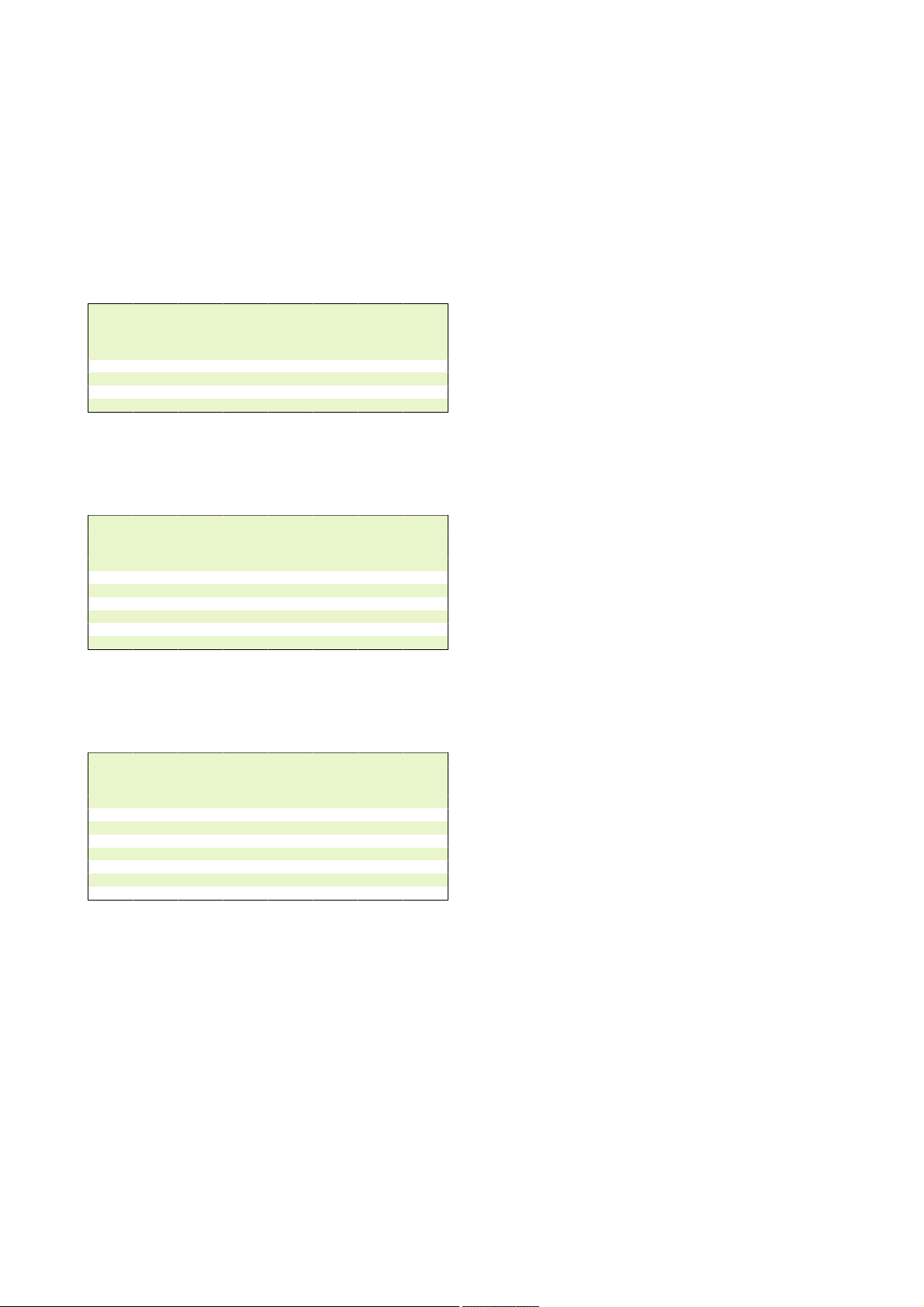

The chilled beam Flexicool® IQTB is an integrated system for ventilation,

cooling and heating, fulfilling most needs for indoor climate. These supply

air beams are designed to manage high cooling effects that, because of good

mixing with room air, provide comfort and low air velocities in the occupied

zone. The topside of IQTB is covered, and it is designed for mounting in roof

angle.

IQTB is based on the same technical conditions as the IQFC chilled beam, but

with extend casing, 30 cm ( 125 mm connection, 60 cm ). IQTB is designed for

horizontal air connection. The chilled beam is equipped with adjusting rails,

comfort control, for the adjustment of airflow, cooling effect and flow pattern.

The simple adjustment of flow pattern makes it possible to adapt to changing

conditions in the room.

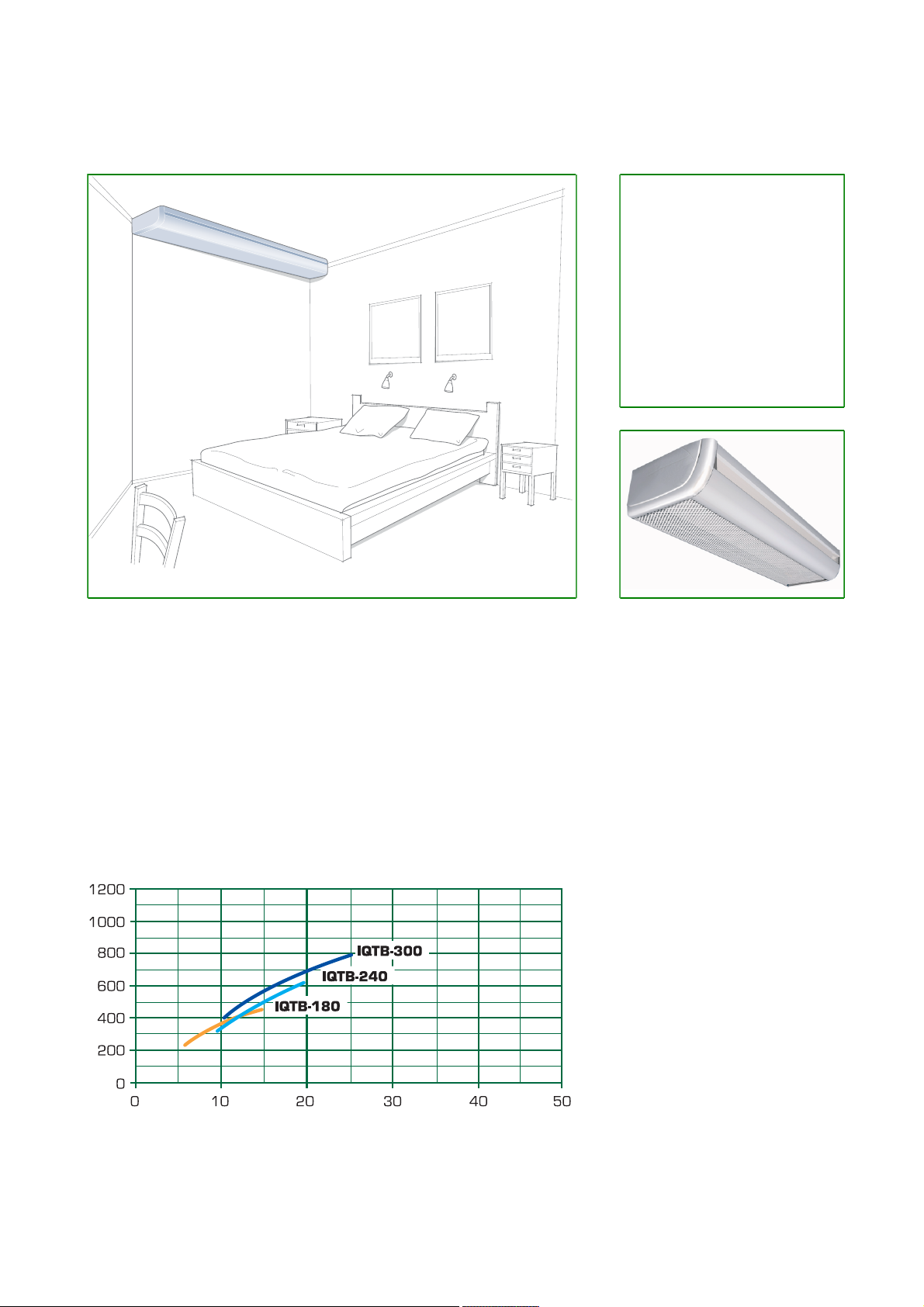

Quick Selection

Cooling effect in W incl supply air

Product Facts

• Chilled Beam IQTB for mounting

in roof angle

• Air and water connection within

extended casing ( 30 cm / 60 cm )

• Available in three standard

lengths, 180 , 240 and 300 cm

• Installed using special brackets

attached to the wall or ceiling

• The bottom plate can be pushed

aside to enable inspection and

cleaning

Product code example

Chilled beam IQTB for mounting in

roof angle. With stepless adjustment

of air flow and flow pattern. Chilled

beam IQTB-240-3-2-1

The diagram shows the approximate cooling ef fect P

difference between room air and supply air ∆t = 8 °C , difference between room air and average water

temperature ∆t = 8 °C , pressure drop 60 Pa on the airside and max. sound pressure level L

dB(A).

Fläkt Woods 8277 GB 2010.11 1

in W with water flow q w = 0,05 l/s , temperature

tot

= 30

A10

Supply air flow, l/s

Specifications are subject of alteration without further no tice.

Chilled Beam Flexicool® IQTB

Technical data for cooling and heating effect

Cooling effect for one-way chilled beam at static pressure

drop 60 Pa on the air side

Beam length 1) = 1,8 m (Coil length = 1,6 m)

Water flow, q w = 0,05 l/s

Pressure drop water, Δp w = 2,1 kPa

P

q l , l/s Δt, °C Δt, °C L

6 8 10 6 8 10

6 180 220 260 120 160 200 <20

8 240 290 345 160 215 270 <20

10 290 355 420 195 260 325 25

12 335 405 480 220 290 365 28

, W P

tot

, W

coil

A10

dB(A)

Beam length 1) = 2,4 m (Coil length = 2,2 m)

Water flow, q w = 0,05 l/s

Pressure drop water, Δp w = 2,7 kPa

P

q l , l/s Δt, °C Δt, °C L

6 8 10 6 8 10

8 160 210 265 160 210 265 25

10 300 365 435 205 270 340 25

12 350 430 510 235 315 395 25

14 400 490 580 265 355 445 27

16 440 540 635 290 385 480 27

18 475 580 680 305 405 505 29

, W P

tot

, W

coil

A10

dB(A)

Beam length 1) = 3,0 m (Coil length = 2,8 m)

Water flow, q w = 0,05 l/s

Pressure drop water, Δp w = 3,5 kPa

P

q l , l/s Δt, °C Δt, °C L

6 8 10 6 8 10

10 290 355 420 195 260 325 25

12 355 435 515 240 320 400 25

14 410 505 595 280 370 465 25

16 465 570 670 310 415 520 27

18 515 630 740 340 455 570 28

20 555 675 800 365 485 605 28

22 595 720 850 385 510 640 29

1)

without expanded casing.

, W P

tot

, W

coil

A10

dB(A)

Conditions for cooling effect tables

Total cooling effect of beam, P

+ cooling effect of supply air, Pair.

coil

The assumed pressure drop on the air side is 60 Pa .

The cooling effect of supply air is based on an

undertemperature of 8 °C for the supply air, when

compared to the room temperature.

The effects for other water flows can be found in the Fläkt

,

Woods product selection program WinDon.

Note! The tables here are based on tests done according

to the Nordtest method. The purpose of this method is to

be able to compare different chilled beams on the same

terms. The method requires a non-existing temperature

difference between the air entering the beam coil and the

air at 1,1 m above floor surface. To achieve this, the walls

in the test room are cooled.

In actual conditions, the temperature difference

is normally 1 – 2 °C . This is why the temperature

difference Δt should be increased by 1 – 2 °C to avoid

,

overdimensioning of the beam.

This means that the table value concerned can be

increased by 10 - 20 %.

With top connection the sound generation increases by 2 3 dB(A).

The chilled beam can be supplied with a special

construction for higher air flows than listed in these

tables.

= cooling effect of coil, P

tot

Heating effect for one-way chilled beam

Heating effects can be found in separate catalogue section,

Heating.

,

Definitions

q

l

P

tot

P

coil

P

coil heat

L

A10

Δt Difference between room air

Δp

w

Δtw Temperature change in the coil, °C.

Supply air flow, l/s

Total cooling effect, W

Cooling effect of the coil, W

Heating effect of the coil, W

Sound pressure level in a room with 10

m2 room absorption, dB(A)

temperature and average water

temperature, °C

Pressure drop water, kPa

Calculated with the formula: t w = P

/ 208

coil

Fläkt Woods 8277 GB 2010.11 2

Specifications are subject of alteration without further no tice.

Loading...

Loading...