Centrimaster FV-600, FV-1000, FV-2000, FV-3000, FV-4000 Installation Manual

...

Desiccant Wheel Products

FV Preconditioner Series

FV-600

FV-1000

FV-2000

FV-3000

FV-4000

FV-5000

FV-7500

FV-9000

Owner’s Manual

Table of Contents

FV Outdoor Air Preconditioners .............................................................1

Model Description ...................................................................................2

Definitions ................................................................................................2

Receiving & Inspection ............................................................................4

Storage ......................................................................................................4

Overall Dimensions ..................................................................................4

Lifting Technique ....................................................................................5

Installation ................................................................................................5

Curb Mounting ........................................................................................7

Unit Configuration ..................................................................................8

Supply & Exhaust Airflow Dampers .......................................................9

Controls ..................................................................................................10

Basic Package ...................................................................................10

Optional Electric Preheat Frost Control ........................................11

Optional Stop/Jog Economizer And Wheel Frost Protection ......12

Optional Rotation Detector Sensor ................................................13

Thermostat Frost Control ...............................................................13

3Ø Circuit Diagram, FV-600 .................................................................14

3Ø Circuit Diagram, FV-1000 ...............................................................15

3Ø Circuit Diagram, FV-2000 through FV-9000 ..................................16

1Ø Circuit Diagram, FV-600 .................................................................17

1Ø Circuit Diagram, FV-1000 through FV-5000 ..................................18

3Ø Electric Preheat Frost Control Circuit Diagram ............................19

1Ø Electric Preheat Frost Control Circuit Diagram ............................19

Electric Preheat Layout..........................................................................20

Wheel Cassette ......................................................................................21

Service .....................................................................................................22

Maintenance ...........................................................................................22

AQFlow

PowerTwist

How To Reach SEMCO ........................................................................29

How To Reach Fenner Drives ................................................................29

®

Balancing Instructions...........................................................25

®

Plus V-Belts .......................................................................27

©

1993-2010 SEMCO LLC. All rights reserved.

The information in this owner’s manual is furnished for informational use only, is

subject to change without notice, and should not be construed as a commitment by

SEMCO LLC. SEMCO assumes no responsibility for any errors that may appear in

this owner’s manual.

No part of this publication may be reproduced, stored in a retrieval system or transmitted,

in any form or by any means, electronic, mechanical, recording, or otherwise, without

the prior written permission of SEMCO.

U.S. patented technology: 5,401,706 ; 5,496,397 ; 6,016,710

SEMCO, AQFlow, and EXCLU-SIEVE are registered trademarks of SEMCO LLC.

PowerTwist Plus is a registered trademark of Fenner Drives.

i • FV Preconditioner Series Owner’s Manual

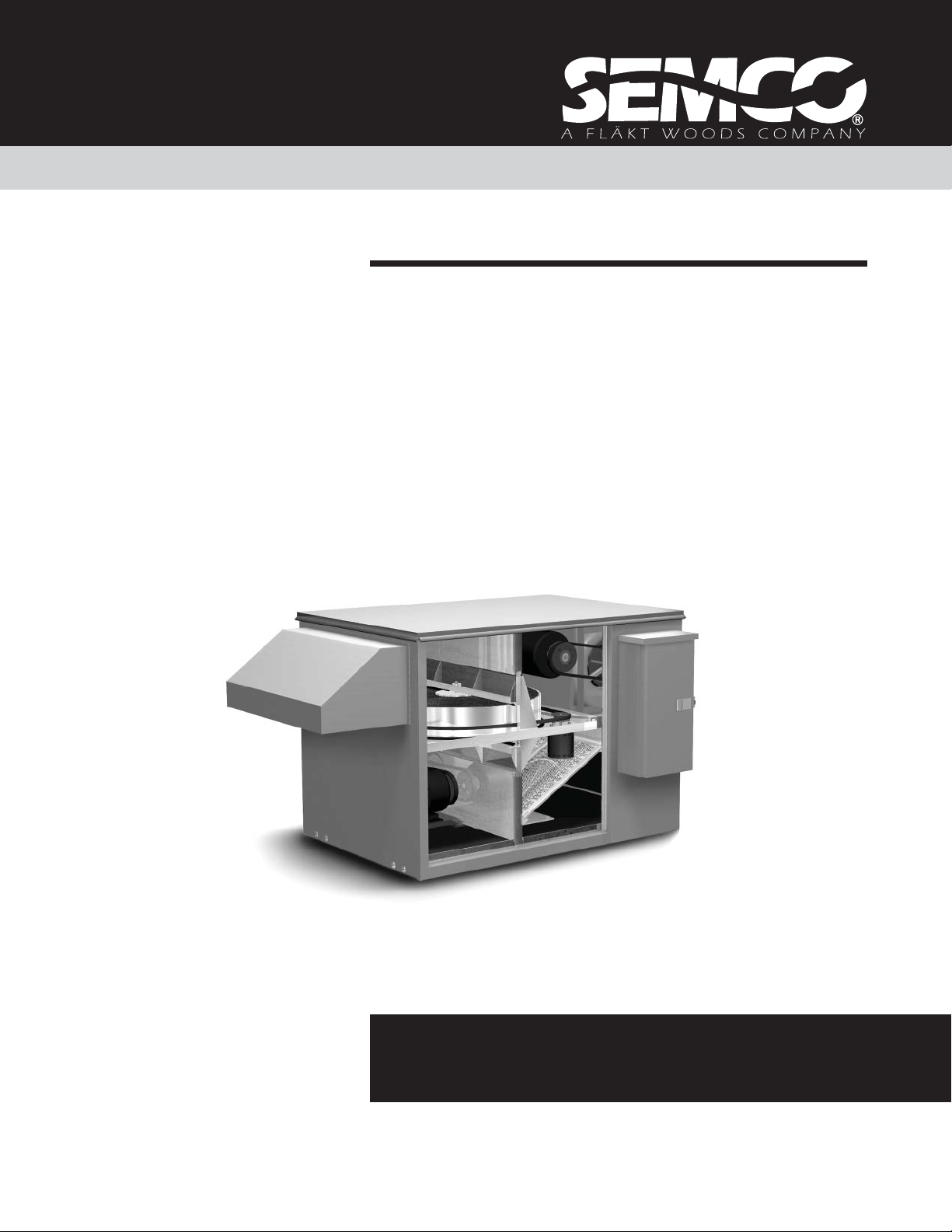

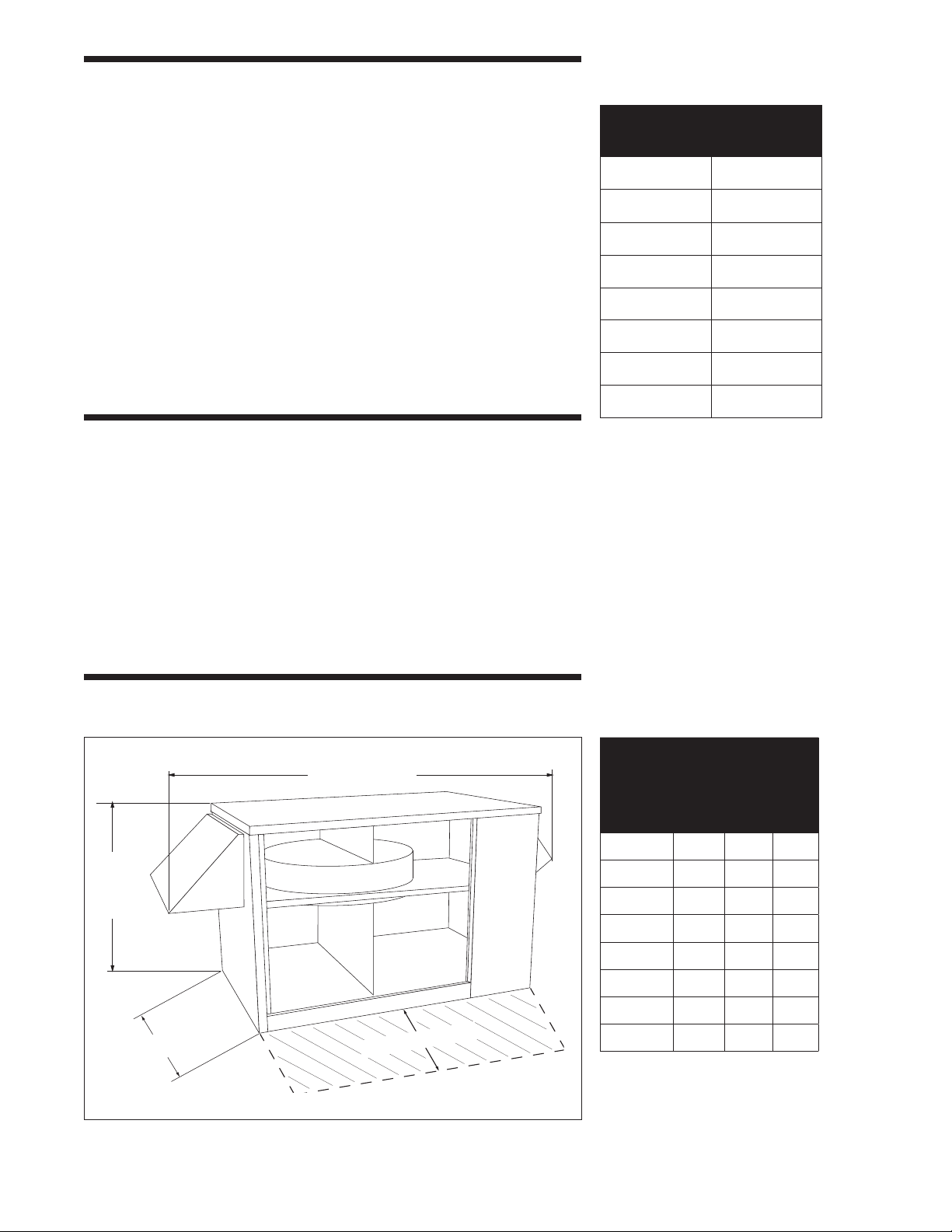

FV Outdoor Air Preconditioners

Outdoor Air

(C) 95°F, 110 gr/lb

(H) 5°F, 4 gr/lb

Supply Air

(C) 80°F, 76 gr/lb

(H) 54°F, 25 gr/lb

Return Air

(C) 75°F, 65 gr/lb

(H) 70°F, 32 gr/lb

Exhaust Air

(C) 90°F, 99 gr/lb

(H) 21°F, 9 gr/lb

The SEMCO FV Series of outdoor air preconditioners have been

specifically designed to reduce the energy required to heat and cool

outdoor air by as much as 80 percent. This unique capability allows

both new and existing buildings to benefit from a healthy indoor

environment by supplying high amounts of outside air in a very costeffective manner.

The FV preconditioner also allows HVAC systems to effectively

and economically accommodate the increased outdoor air quantities

recommended by the American Society of Heating, Refrigerating and Air

Conditioning Engineers (ASHRAE) Standard 62. This standard guides

the amount of ventilation air that should be introduced to a building

to achieve acceptable indoor air quality.

The SEMCO FV system is a packaged system which includes supply

and exhaust air fans, outdoor and return air filtration, and SEMCO’s

EXCLU-SIEVE

recovers both sensible (temperature) and latent (moisture) energy.

Therefore, it cools and dehumidifies the outdoor air during the cooling

season, while heating and humidifying the air in the heating season.

The EXCLU-SIEVE wheel utilizes a fluted aluminum sheet which

is coated with a fast-acting, adsorbent desiccant. As the transfer media

slowly rotates between the outdoor and exhaust airstreams, the higher

temperature air gives up its sensible energy to the aluminum. This energy

is then given up to the cooler airstream during the second half of the

revolution. (See Figure 1.)

Just as the temperature is captured and released, so is the moisture.

The EXCLU-SIEVE’s molecular sieve desiccant coating has a strong

attraction to water vapor. Since the opposing airstreams have different

temperature and moisture contents, they also have different vapor

pressures. This difference provides the driving force that causes the

transfer of latent energy.

Through the use of a patented 3Å molecular sieve desiccant coating,

EXCLU-SIEVE recovers the moisture from an exhaust airstream without

transferring the airborne pollutants contained within the exhaust

airstream to the supply airstream. This important and unique feature

has been well documented through independent laboratory and field

testing. A copy of the report is available upon request.

®

total energy recovery wheel. The EXCLU-SIEVE wheel

Figure 1. An inside view of the FV

Series Preconditioner with typical

operating temperatures during the

cooling (C) and heating (H) season

respectively.

FV Preconditioner Series Owner’s Manual • 1

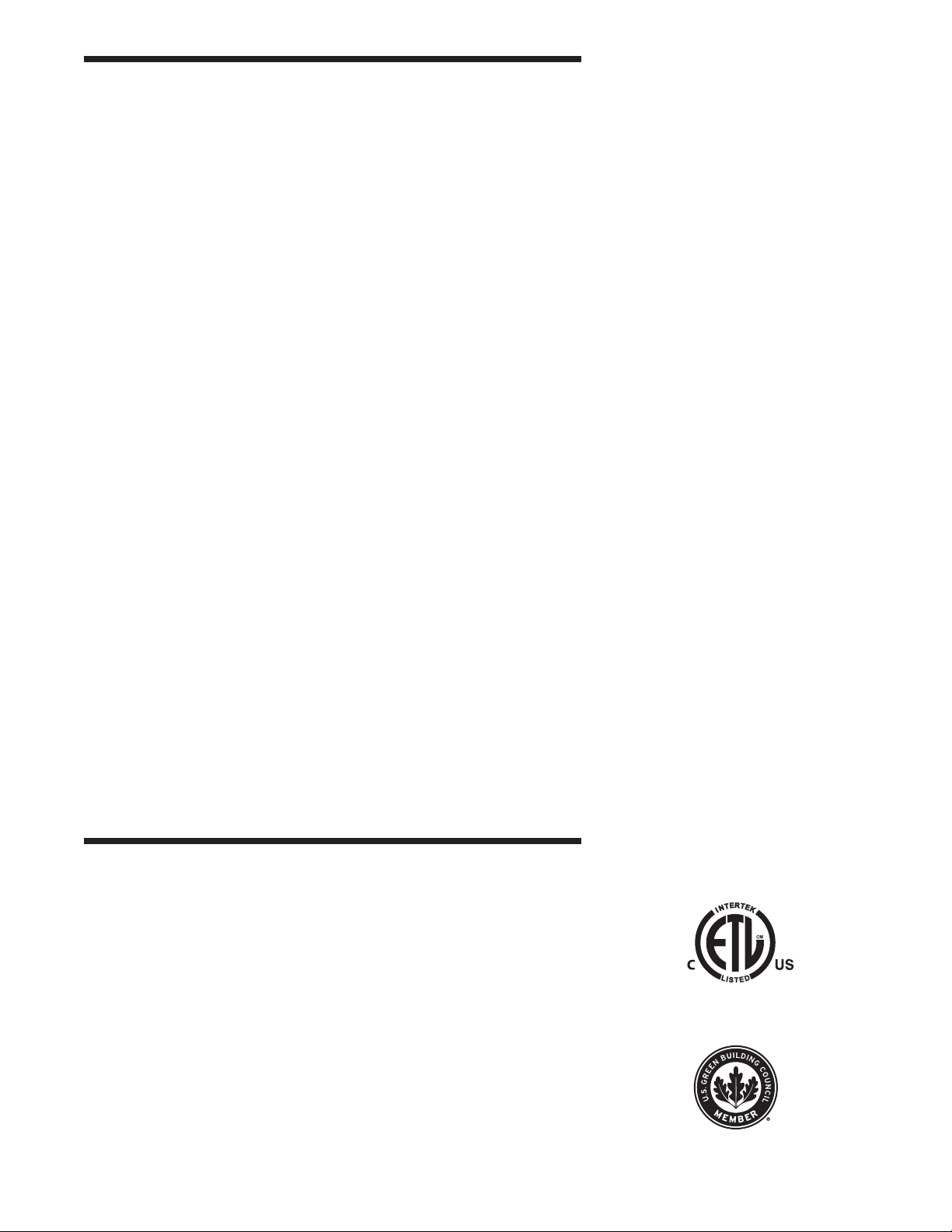

Model Description

On the front of the FV unit is an identification label. The specifications

on the label correspond to the actual unit. The model number (600,

1000, 2000, etc.) refers to the nominal air volume (in cfm) that the FV

preconditioner is capable of supplying.

Figure 2. Typical FV nameplate

with electrical data.

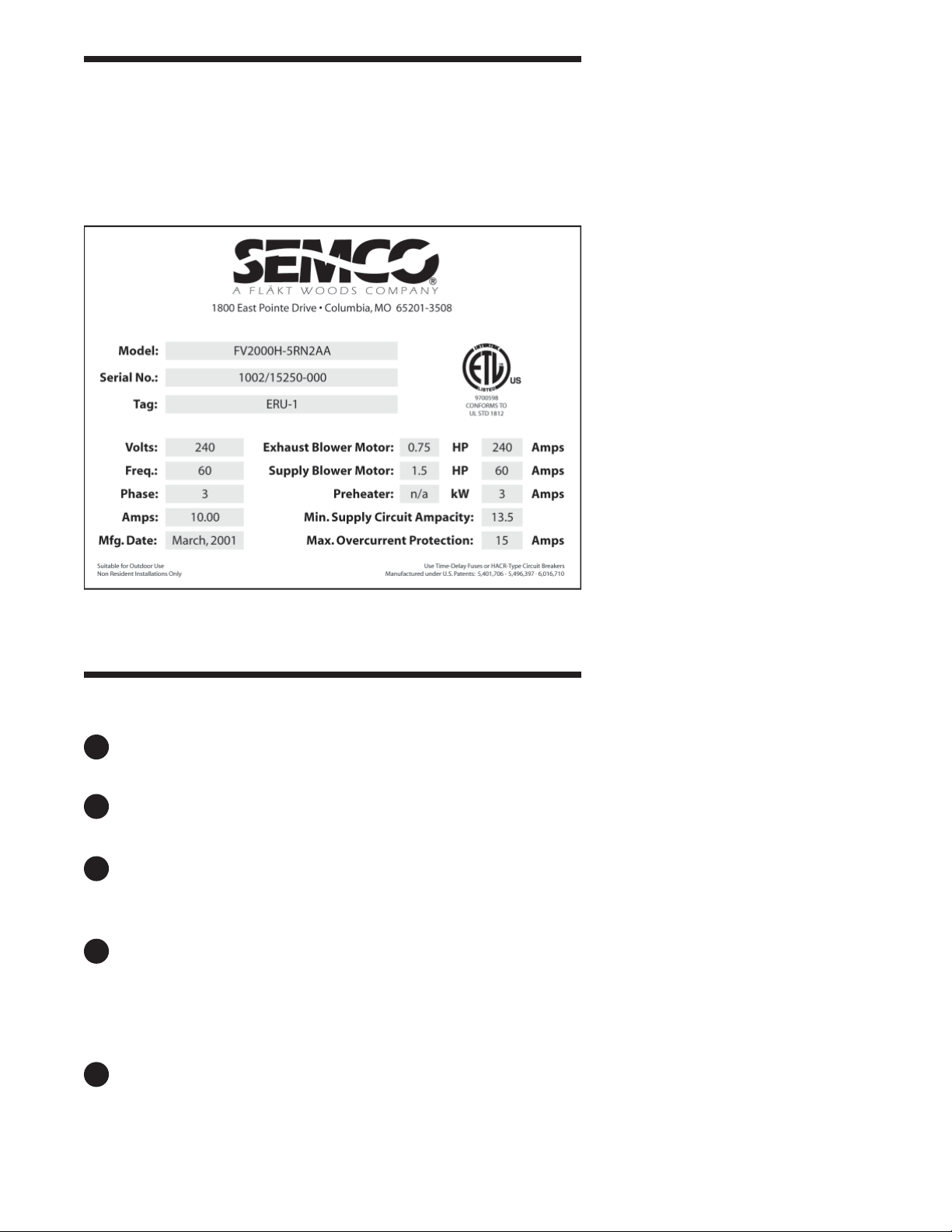

Definitions

Adsorption – The physical bonding of water vapor on the surface

1

of the desiccant.

2

Cassette – The framework supporting the wheel. (See also

Wheel.)

3

Desiccant – A naturally occurring or man-made material with a high

affinity for water vapor. SEMCO uses a highly selective 3Å molecular

sieve desiccant material which minimizes cross contamination.

4

Enthalpy wheel – A common term used to describe all rotating,

wheel-shaped heat transfer devices that exchange sensible

(temperature) and latent (water vapor) energy from one airstream

to another. The word, enthalpy, means heat content or total heat.

The term, enthalpy exchanger, may also be used.

Exhaust air – The air from indoors that passed through the energy

5

recovery wheel and is being ducted outdoors.

2 • FV Preconditioner Series Owner’s Manual

6

Heat wheel – This generally describes all rotating devices which

transfer only sensible energy.

7

Media – The corrugated material inside the wheel.

Outdoor air – The fresh outside air that is being drawn in the energy

8

recovery wheel. Once it passes through the wheel it becomes the

supply air.

9

Return air – Air from the indoor space that is pulled through the

energy recovery wheel. Once it passes through the wheel it is referred

to as exhaust air.

Rotor – The media-filled wheel that rotates. It transfers heat energy

10

and water vapor from one ducted airstream to the other. Often, the

rotor will be referred to as a wheel.

11

Seal – The soft material that closely surrounds the rotor to limit

the amount of bypass air around the rotor.

12

Supply air – Air provided to the indoor space. Outside air that passes

through the energy recovery wheel becomes supply air.

Figure 3. Typical FV unit with

components highlighted per

definitions above.

13

Unit – Used frequently throughout this manual to mean the

EXCLU-SIEVE

Energy Recovery Wheel and attendant components

such as cabinets, motors, fans and other parts that work together

to make an effective energy recovery product.

14

Wheel – Refers to the rotating wheel containing the coated media.

The stationary framework supporting the wheel is the wheel

cassette.

FV Preconditioner Series Owner’s Manual • 3

Receiving & Inspection

L = Overall Length

H = Height

W = Width

Service Clearance

Upon delivery, confirm that the quantity and model(s) received matches

the Bill of Lading. If there is any discrepancy, immediately notify

SEMCO.

Inspect the skidded FV(s) for signs of damage. If damage is suspected,

sign the Bill of Lading “damaged”. If no visible damage is apparent, the

unit should be properly lifted and stored until installation.

While skidded, the FV can be lifted by a forklift using the skid. Once

removed from the skid, lifting must only be performed with spreader

bars, cable and hooks. Do not attempt to lift the FV by grasping the

hoods.

Note: In the table of weights on the right, the package weighs

approximately 100 lbs. more than the net weight.

Storage

If the FV is to be stored for any time before installation, it must be

protected from the weather. Indoor storage is recommended. The unit

has openings provided for ducting. These openings make the internal

equipment (motors, belts, fans and insulation) vulnerable to inclement

weather conditions (prior to installation) and can cause standing water

to accumulate inside the enclosure. This is to be absolutely avoided.

Model

FV-600 450

FV-1000 500

FV-2000 550

FV-3000 1,000

FV-4000 1,150

FV-5000 1,150

FV-7500 1,800

FV-9000 1,800

Net Weight

(lbs)

Overall Dimensions

Unit L H W

Dimensions in

inches

FV-600 69.5 31.0 29.0

FV-1000 69.5 31.0 29.0

FV-2000 80.6 32.4 37.0

FV-3000 96.0 47.7 45.0

FV-4000 126.5 51.5 54.0

FV-5000 126.5 51.5 54.0

FV-7500 143.5 58.6 64.6

FV-9000 143.5 58.6 64.6

Service clearance is equal to the

width of the unit.

4 • FV Preconditioner Series Owner’s Manual

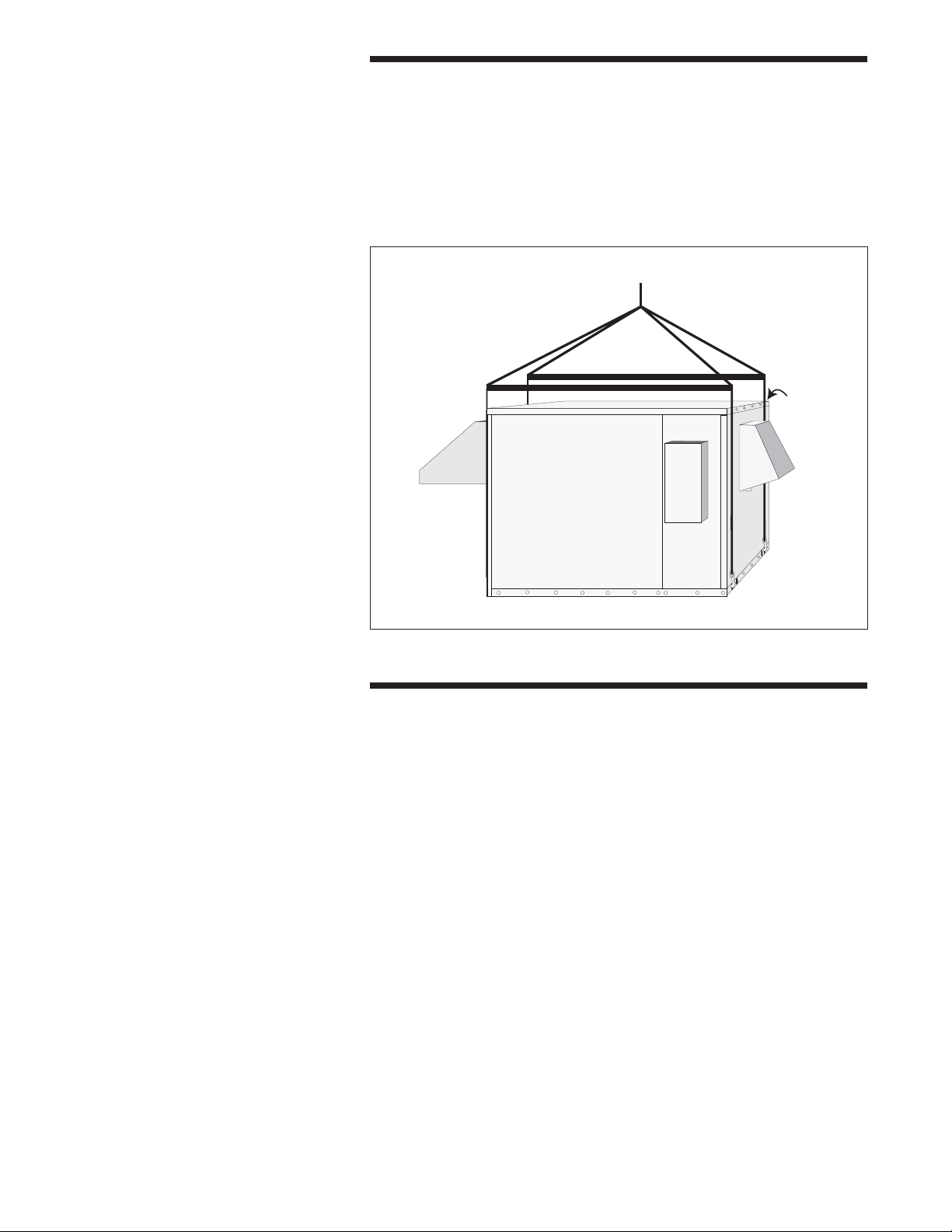

Figure 4. Correct lifting technique

using spreader bars.

Lifting Technique

When rigging the FV unit, spreader bars must be used. Padding must be

inserted between the straps and the unit to avoid scratching the paint.

Lifting holes are provided at four points located on the base perimeter

of the FV unit. The weights shown on page 4 may be used as maximum

weights for rigging.

padding

Installation

Installation of the FV is a relatively simple procedure, but should be

undertaken in a methodical fashion, following the directions outlined

in this manual.

Note: Prior to starting unit, open access door and;

Remove loose parts shipped inside;

Remove wheel shipping restraint (FV-3000 thru FV-9000 only).

The installation location should be chosen to provide easy, convenient

access. As with all mechanical equipment, routine maintenance and

inspection is necessary. Choose a site from which connecting duct is

visible. Avoid locations that are near or downwind of smoke, fumes or

exhaust outlets of other equipment. The front access panel should have

clearance space equal to the depth of the unit to allow for service.

Once the installation location is determined, the FV should be

skidded and closely examined. Any defects or problems should be

reported to SEMCO immediately.

Several ducting arrangements are possible. Make sure your duct plans

match the FV duct opening arrangement. (See Unit Configuration,

p.8).

FV Preconditioner Series Owner’s Manual • 5

The FV can be ordered for indoor or outdoor installation. An outdoor

unit is identified by the existence of two hoods that are shipped on top

of the FV unit. It will be necessary to attach the outdoor air intake hood

(larger one with filter rack) and the exhaust air outlet hood (smaller one

with damper) on their designated openings (see Figure 6a-d). The indoor

unit is identified by a rectangular duct shipped on top of the unit. This

indoor intake duct must be installed over the outdoor air intake opening

(see Figure 6a-d). Use the given alignment holes to place the hood or duct

in the correct position.

If the unit is a rooftop unit, it may be installed on a curb. If SEMCO

supplies the curb, then it will have been shipped separately. The curb must

be installed before a rooftop FV can be placed. Proper care should be taken

to ensure correct placement of the curb before holes are cut for ducting

through the roof itself. Effective waterproofing of the rooftop interface is

necessary. That means sealing around the roof curb to prevent any leakage

into the building or the air ducts. The curb and FV must be installed and

operated in a horizontal position.

If the unit is not installed on the roof, then a concrete or paved pad to

support the FV must be provided. The pad must be of sufficient height

and located to assure proper water drainage in any weather.

Inspect the interior of the unit for any damage. On the floor inside the

unit is the outdoor air metal filter. This filter is to be installed at the outdoor

air intake opening after the hood (outdoor FV only) has been attached.

On the FV-3000, FV-4000, FV-5000, FV-7500, and FV-9000 remove wheel

shipping restraint.

The SEMCO energy recovery wheel is mounted horizontally inside

the FV. The motor and belt arrangement that turn the wheel are visible

next to the wheel at the access panel opening. The motor wires running

to the control panel are attached by a quick release disconnect. The quick

disconnect must be separated before sliding out the wheel cassette. The

wheel cassette need not be moved for installation or hookup, but it can be

pulled out for easy maintenance and inspection purposes.

When the unit has been placed in its permanent location, duct work

should be brought up to and attached to the unit. Duct work may be flanged

and screwed to the unit face for horizontal connections. Duct work for a

vertical unit should be flanged and gasketed level with the curb to allow

the unit weight to form the seal. Penetrations through the unit floor must

be avoided to prevent any water penetrating into the cabinet.

If the unit has been ordered with electric preheat, it is shipped installed.

The main power connection to the unit is made at the electric coil instead

of the unit control panel. For the indoor version of the FV, the electric coil

should be externally insulated after installation.

On the front right side of the FV is the unit identification tag. It states

the electrical requirements for the unit. (If electric preheat option has been

ordered, the unit ID tag is located on the heater.) Make sure the power

provided to the installation site matches that required by the unit. Note

and verify that voltage/phase/capacity needed and provided are the same,

and the line voltage must not vary more than +/-5%.

6 • FV Preconditioner Series Owner’s Manual

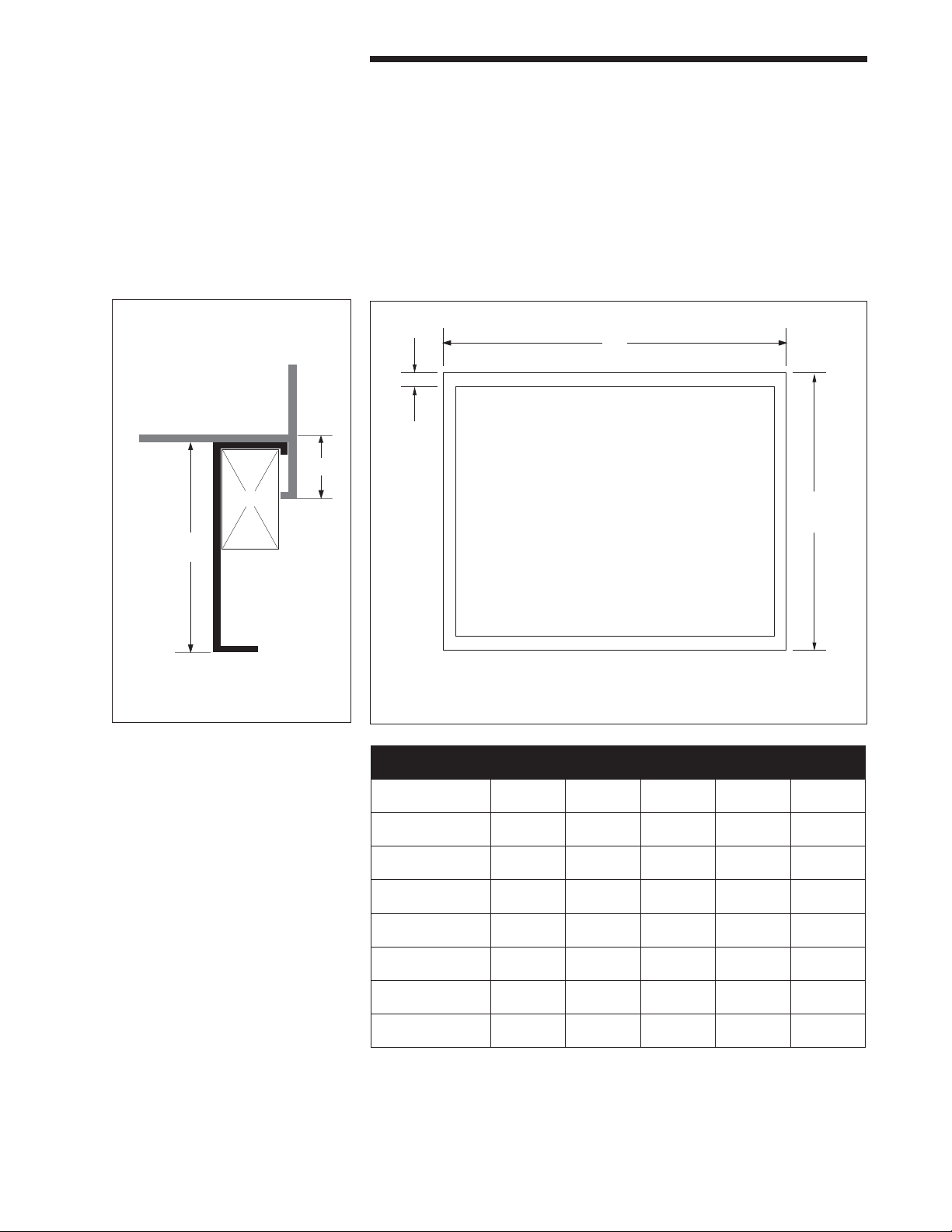

Curb detail

A

B

C

Plan View

Nailer

E

D

Roof Curb

Elevation

FV-Unit

Curb Mounting

The FV series is generally installed on a curb (unless mounted indoors).

The curb ships separately for preinstallation to simplify rigging. The

dimensions of the curbs required for the FV units are listed below.

All FV configurations have the same curb dimensions. The curb

for an FV unit can be provided by SEMCO or purchased from a curb

manufacturer provided it is designed to support the weight of the FV

unit specified in this manual and conforms to the dimensions listed in

the table below.

Figure 5. Curb dimensions.

Model A B C D E

FV-600 40.1 25.0 1.7 14.0 3.0

FV-1000 40.1 25.0 1.7 14.0 3.0

FV-2000 47.4 33.0 1.7 14.0 2.0

FV-3000 60.6 41.0 1.7 14.0 3.0

FV-4000 74.6 49.9 1.7 14.0 3.0

FV-5000 74.6 49.9 1.7 14.0 3.0

FV-7500 91.0 60.3 1.7 14.0 3.0

FV-9000 91.0 60.3 1.7 14.0 3.0

All dimensions in inches.

FV Preconditioner Series Owner’s Manual • 7

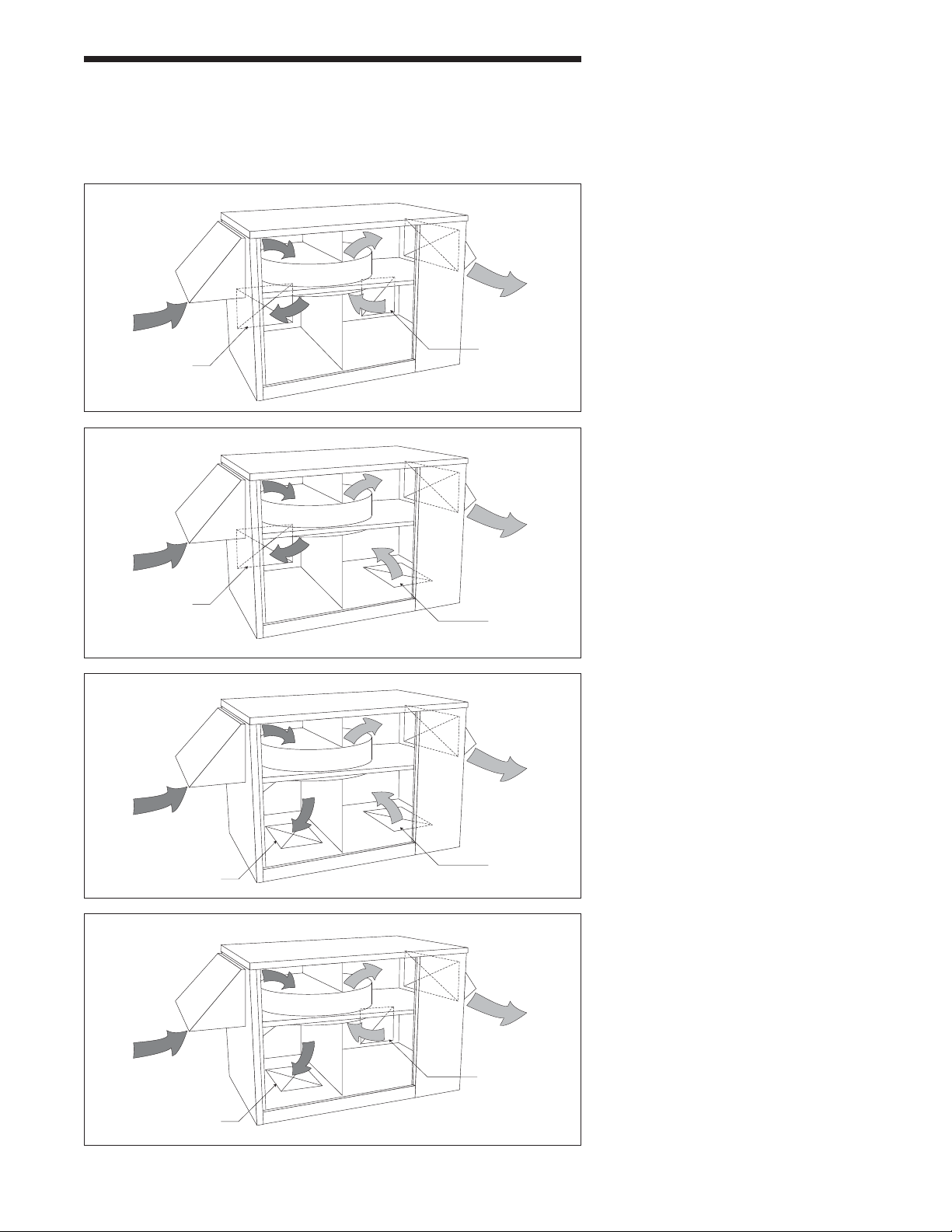

Unit Configuration

Outdoor Air In

Supply Air

Exhaust Air Out

Return Air

Outdoor Air In

Supply Air

Exhaust Air Out

Return Air

Outdoor Air In

Supply Air

Exhaust Air Out

Return Air

Outdoor Air In

Supply Air

Exhaust Air Out

Return Air

The FV preconditioner can be installed in one of four possible configurations depending on the arrangement of the supply and return air

openings.

Figure 6a. H Series configuration

with horizontal supply air

and horizontal return air duct

arrangement.

Figure 6b. HS Series configuration

with horizontal supply air and

vertical return air duct arrangement.

Figure 6c. V Series configuration

with vertical supply air and vertical

return air duct arrangement.

Figure 6d. VS Series configuration

with vertical supply air and horizontal

return air duct arrangement.

8 • FV Preconditioner Series Owner’s Manual

Loading...

Loading...