Page 1

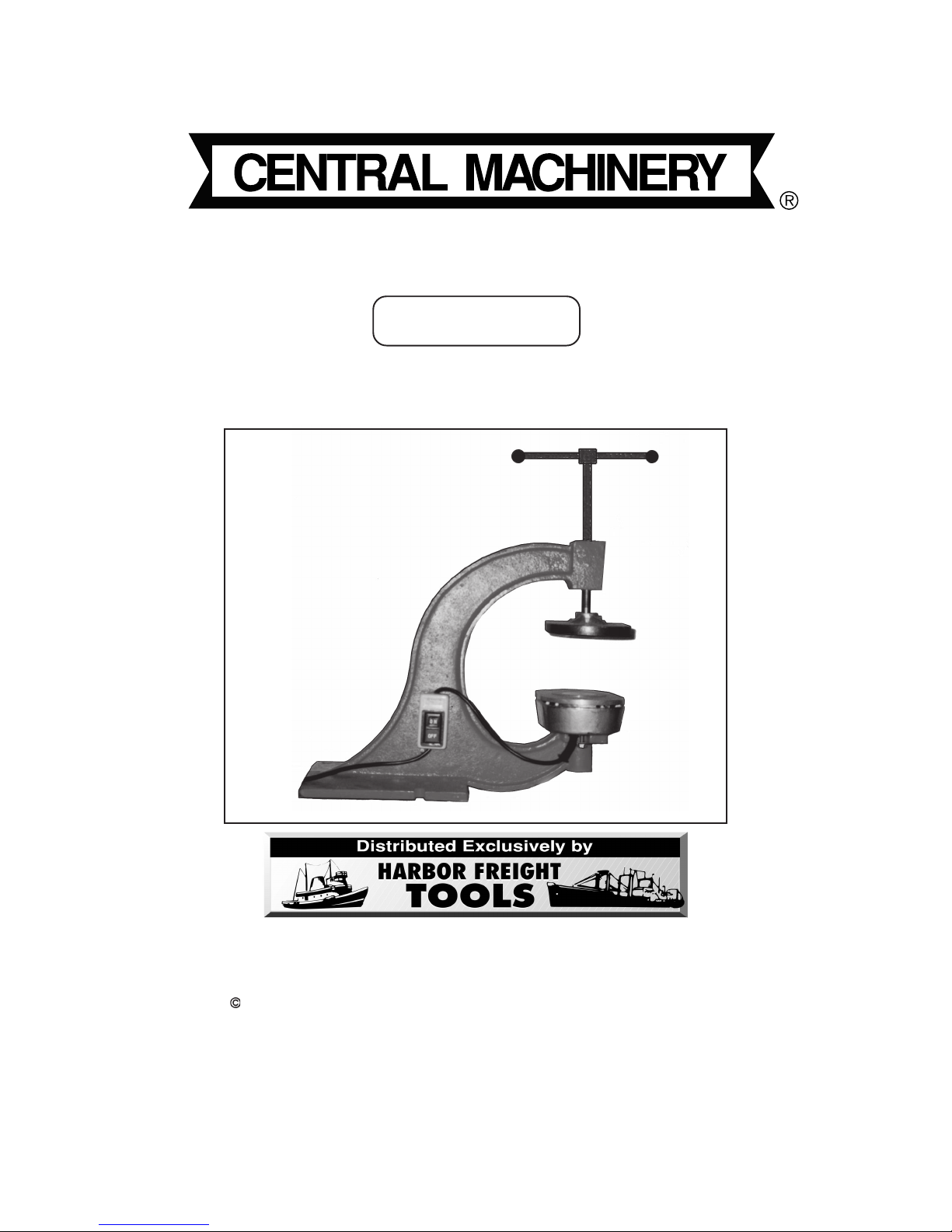

TIRE PATCHING MACHINE

®

Model 46616

ASSEMBLY AND OPERATING INSTRUCTIONS

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at: http://www.harborfreight.com

Copyright 2002 by Harbor Freight Tools®. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or form with-

out the express written consent of Harbor F reight Tools.

For technical questions, please call 1-800-444-3353.

Page 2

SPECIFICATIONS TABLE

Item Descript i on

Electrical Require m ents 120 V / 60 Hz / 7 Amp / Single Phase

Maximum Controlled Temperature 275 Degrees Fahrenheit

Hot Plate 4-7/8” x 8” Oval Shape

Height 16” Closed Position

22” Open Po sition

Depth 14-3/8” Front to Back

Width 8” At Plate

Handle Sliding w/Handle

Weight 31.40 Pounds

SAVE THIS MANU AL

You will need this manual for the safety warnings and precautions, assembly,

operating, inspection, maintenance and cleaning procedures, parts list and

assembly diagram. Keep your invoice with this manual. Write the invoice number on the inside of the front cover. Keep this manual and invoice in a safe and

dry place for future reference.

GENERAL SAFETY WARNINGS AND PRECAUTIONS

1. KEEP WORK AREA CLEAN AND DRY. Cluttered, damp, or wet work areas

invite injuries.

2. KEEP CHILDREN AWAY FROM WORK AREA. Do not allow children to handle

this product.

3. STORE IDLE EQUIPMENT. When not in use, tools and equipment should be

stored in a dry location to inhibit rust. Always lock up tools and equipment, and

keep out of reach of children.

4. DO NOT USE THIS PRODUCT IF UNDER THE INFLUENCE OF ALCOHOL OR

DRUGS. Read warning labels on prescriptions to determine if your judgement or

reflexes are impaired while taking drugs. If there is any doubt, do not attempt to

use this product.

5. USE EYE AND HAND PROTECTION. Wear ANSI approved safety impact

goggles and heavy-duty work gloves when using this product. ANSI approved

safety impact goggles and heavy-duty work gloves are available from Harbor

Freight Tools.

SKU 46616 PAGE 2

Page 3

6. DRESS SAFELY. Do not wear loose clothing or jewelry, as they can become

caught in moving parts. Wear a protective hair covering to prevent long hair from

becoming caught in moving parts. If wearing a long-sleeve shirt, roll sleeves up

above elbows.

7. DO NOT OVERREACH. Keep proper footing and balance at all times to prevent

tripping, falling, back injury, etcetera.

8. INDUSTRIAL APPLICATIONS MUST FOLLOW OSHA REQUIREMENT.

9. STAY ALERT. Watch what you are doing at all times. Use common sense. Do

not use this product when you are tired or distracted from the job at hand.

10. CHECK FOR DAMAGED PARTS. Before using this product, carefully check that

it will operate properly and perform its intended function. Check for damaged

parts and any other conditions that may affect the operation of this product.

Replace or repair damaged or worn parts immediately.

11. REPLACEMENT PARTS AND ACCESSORIES: When servicing, use only

identical replacement parts. Only use accessories intended for use with this

product. Approved accessories are available from Harbor Freight Tools.

12. MAINTAIN THIS PRODUCT WITH CARE. Keep this product clean and dry for

better and safer performance.

13. MAINTENANCE: For your safety, service and maintenance should be performed

regularly by a qualified technician.

14. USE THE RIGHT TOOL FOR THE JOB. Do not attempt to force a small tool or

attachment to do the work of a larger industrial tool. There are certain

applications for which this tool was designed. It will do the job better and more

safely at the rate for which it was intended. Do not modify this tool, and do not

use this tool for a purpose for which it was not intended.

15. WARNING: The warnings, precautions, and instructions discussed in this

manual cannot cover all possible conditions and situations that may occur. The

operator must understand that common sense and caution are factors, which

cannot be built into this product, but must be supplied by the operator.

SPECIFIC PRODUCT WARNINGS AND PRECAUTIONS

1. TO AVOID ACCIDENTAL FIRE, DO NOT USE TIRE TUBE CEMENTS OR

SOLVENTS HAVING A FLASH/IGNITION POINT OF LESS THAN 350

DEGREES FAHRENHEIT.

SKU 46616 PAGE 3

Page 4

1. (cont.)When turned on, the Tire Patching Machine quickly heats up and maintains a maximum temperature of 275 degrees Fahrenheit. Before using the Tire

Patching Machine, make sure you read and fully understand the warnings and

precautions as outlined in the manufacturer’s manual of the cement or solvent

you are using.

2. NEVER LEAVE THE TIRE PATCHING MACHINE UNA TTENDED WHEN IT IS

HOT. At all times, stay with the Tire Patching Machine when it is turned on. After

turning off the Tire Patching Machine, stay with it until it’s Heating Plate (part

#12) cools to room temperature.

3. MAINTAIN A SAFE WORKING ENVIRONMENT. Keep the work area well lit.

Make sure there is adequate surrounding workspace. Always keep the work

area free of obstructions, grease, oil, trash, and other debris. Do not use the Tire

Patching Machine in areas near flammable chemicals, dusts, and vapors.

4. GROUND THIS PRODUCT . The electrical Power Cord for this product is

equipped with a grounded, 3-prong Plug. Never remove the grounding prong or

modify the Plug in any way. Do not use adapter plugs with this product. To

comply with the National Electric Code, and to provide additional protection from

the risk of electrical shock, this product should only be connected to a 120 Volt,

3-hole electrical outlet that is protected by a Ground Fault Circuit Interrupter

(GFCI).

5. IF AN EXTENSION CORD (not provided) IS USED, MAKE SURE TO USE

ONLY UL APPROVED CORDS HAVING THE CORRECT GAUGE AND

LENGTH. (See Figure A.)

AWG RATING CHART - 120 VOLT

FIGURE A

6. Important Note: When using the Tire Patching Machine f or the first time, the tool

may smoke when plugged in and turned ON, due to forming oil being burnt off the cast

iron plate inside the housing. This is a normal occurance; the machine should be turned

on for appro ximately 15 minutes to allow this to occur, before the first use of the machine.

7. WARNING: This product contains or produces a chemical known to the State of

California to cause cancer and birth defects (or other reproductive harm).

(California Health & Safety Code 25249.5 et seq.)

SKU 46616 PAGE 4

REV 03/04

Page 5

8. WARNING: People with pacemakers should consult their physician(s) before

using this product. Operation of electrical equipment in close proximity to a heart

pacemaker could cause interference or failure of the pacemaker.

UNPACKING

When unpacking, check to make sure all the parts shown on the Parts List (page 8) are

included. If any parts are missing or broken, please call Harbor Freight Tools at the

number shown on the cover of this manual as soon as possible.

ASSEMBLY AND OPERATING INSTRUCTIONS

NOTE: For additional references to the par ts listed below, refer to the Assembly Dia-

gram (page 8).

To Mount The Tire Patching Machine On A Workbench:

1. Caution: Make sure the Tire Patching Machine is securely mounted on a flat,

level, sturdy, wor kbench capable of supporting the weight of the Tire Patching

Machine, tools, accessories, and work piece.

2. There are two 1/2” wide mounting slots located at the bottom right and left sides

of the Main Frame (part #3). (See Assy. Diagram.)

3. With assistance, set the Tire Patching Machine in the desired location on the top

of the workbench. Using the two mounting slots as a template, mark the two

holes that are to be drilled through the top of the workbench. Then, temporarily

remove the Tire Patching Machine.

4. Using a drill and 1/2” drill bit (not provided), drill the two previously marked holes

completely through the top of the workbench.

5. Align the two 1/2” mounting slots at the right and left ends of the Main Frame

(part #3) with the two previously drilled holes in the workbench. Then, firmly

secure the Tire Patching Machine to the workbench with two appropriate length

1/2” bolts, two lock washers, and two nuts (not provided).

To Prepare The Tire Tube For Patching:

1. Carefully remove the tube valve stem from the tire tube, and allow all of its air to

escape. Then, remove the tube from the tire.

SKU 46616 PAGE 5

REV 03/04

Page 6

2. Firmly screw the tube valve stem back into the tire tube. Then, re-inflate the tube

according to the tire tube manufacturer’s recommended PSI air pressure.

3. Fully submerge the tire tube in a tank of water, and observe air bubbles escaping

from the hole in the tube. Then remove the tube from the water tank and, with

chalk, mark the location of the hole.

4. Carefully remove the tube

valve stem from the tire tube, and allow all of its air to

escape.

5. Using

sandpaper, or a scraper made especially for this pur pose, rough up the

area around the hole.

To Operate The Tire Patching Machine:

1. Apply an all-purpose, fast dry, rubber cement on the area around the hole. Make

sure to allow the cement to dry. Then, apply the prepared side of an

appropriate size tube patch to the tire tube (the side with the colored peel-off).

2. Place the tire tube on the Heating Box Cover (part #7) of the Tire Patching

Machine. Make sure the tube patch is resting downward, directly on the

surface of the Heating Box Cover. (See Assy. Diagram.)

3. Turn the Handle (par t #16)

clockwise

to lower the Press Plate (part #4) until the

tire tube is held firmly in place between the Heating Box Cover (part #7) and the

Press Plate. (See Assy. Diagram.)

4. Connect the Power Cord/Plug (part #17) to a grounded, 3-prong, 120 volt,

electrical outlet. (See Assy. Diagram.)

5. Turn the Switch (part #19) to its “ON” position. (See Assy. Diagram.)

6. Allow 20 to 30 minutes for the Tire Patching Machine to heat up and firmly

adhere the tube patch to the tire tube.

7. Then, turn the Switch (part #19) to its “OFF” position, and disconnect the Power

Cord/Plug (part #17) from its electrical outlet. (See Assy. Diagram.)

8. Turn the Handle (part #16)

#4), and remove the tire tube from the Tire Patching Machine. (See Assy.

Diagram.)

9. Firmly screw the tire tube valve stem back into the tube. Then, re-inflate the tube

according to the tire tube manufacturer’s recommended PSI air pressure.

SKU 46616 PAGE 6

counterclockwise

to fully raise the Press Plate (part

Page 7

10. Fully submerge the tire tube in a tank of water to make sure no air bubbles are

escaping from the tube. If no air bubbles are observed, the tire tube has

been successfully patched.

11. Carefully remove the tube

valve stem from the tire tube, and allow all of its air to

escape. Then, re-install the tire tube in the tire.

INSPECTION, MAINTENANCE, AND CLEANING

1. CAUTION: Always disconnect the Tire Patching Machine from its electrical power

source before performing any inspection, maintenance, or cleaning.

2. BEFORE EACH USE, inspect the general condition of the Tire Patching

Machine. Check for loose screws, misalignment or binding of moving parts,

cracked or broken parts, damaged electrical wiring, any other condition that may

affect its safe operation. If abnormal noise or vibration occurs, have the problem

corrected before further use. Do not use damaged equipment.

3. PERIODICALLY, use a premium quality, lightweight machine oil to lubricate all

moving parts.

4. When necessary, wipe with a damp cloth, using a mild detergent or mild solvent.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUF ACTURER AND/OR DISTRIBUT OR HAS PRO VIDED THE PARTS LIST AND ASSEMBLY

DIAGRAM IN THIS MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER OR

DISTRIBUTOR MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER

THA T HE OR SHE IS QU ALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT, OR THA T HE OR SHE

IS QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTUER AND/

OR DISTRIBUTOR EXPRESSLY STATES THA T ALL REP AIRS AND PAR TS REPLACEMENTS SHOULD

BE UNDERT AKEN BY CERTIFIED AND LICENSED TECHNICIANS, AND NOT BY THE BUYER. THE

BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE

ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER

INSTALLATION OF REPLACEMENT PARTS THERET O .

SKU 46616 PAGE 7

Page 8

#

#

PARTS LIST / ASSEMBLY DIAGRAM

Part

1 Handle Ball 2 11 Nut 2

2 Adjusting Screw 1 12 Heating Plate 1

3 Main Frame 1 13 Big Adapter 1

4 Press Plate 1 14 Small Adapter 1

5 Bolt (M5 x 15) 2 15 Heating Pipe 1

6 Heating Box 1 16 Handle 1

7 Heating Box Cover 1 17 Power Cord/Plug 1

8 Temperature Monitor 1 18 Rubber Grommet 1

9 Bolt (M5 x 10) 1 19 Switch 1

10 Washer 2

Description Qty. Part

Description Qty.

NOTE: Some parts are listed and shown for illustration purposes only, and are not

available individually as replacement parts.

SKU 46616 PAGE 8

Loading...

Loading...