Page 1

3 IN 1 ROLLER MACHINE

®

40 INCH

43353

ASSEMBLY AND OPERATING

INSTRUCTIONS

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at http://www.harborfreight.com

Copyright © 2000 by Harbor Freight Tools®. All rights reserved. No portion of

this manual or any artwork contained herein may be reproduced in any shape or

form without the express written consent of Harbor Freight Tools.

For technical questions and replacement parts, please call 1-800-444-3353

Revised 01/07

Page 2

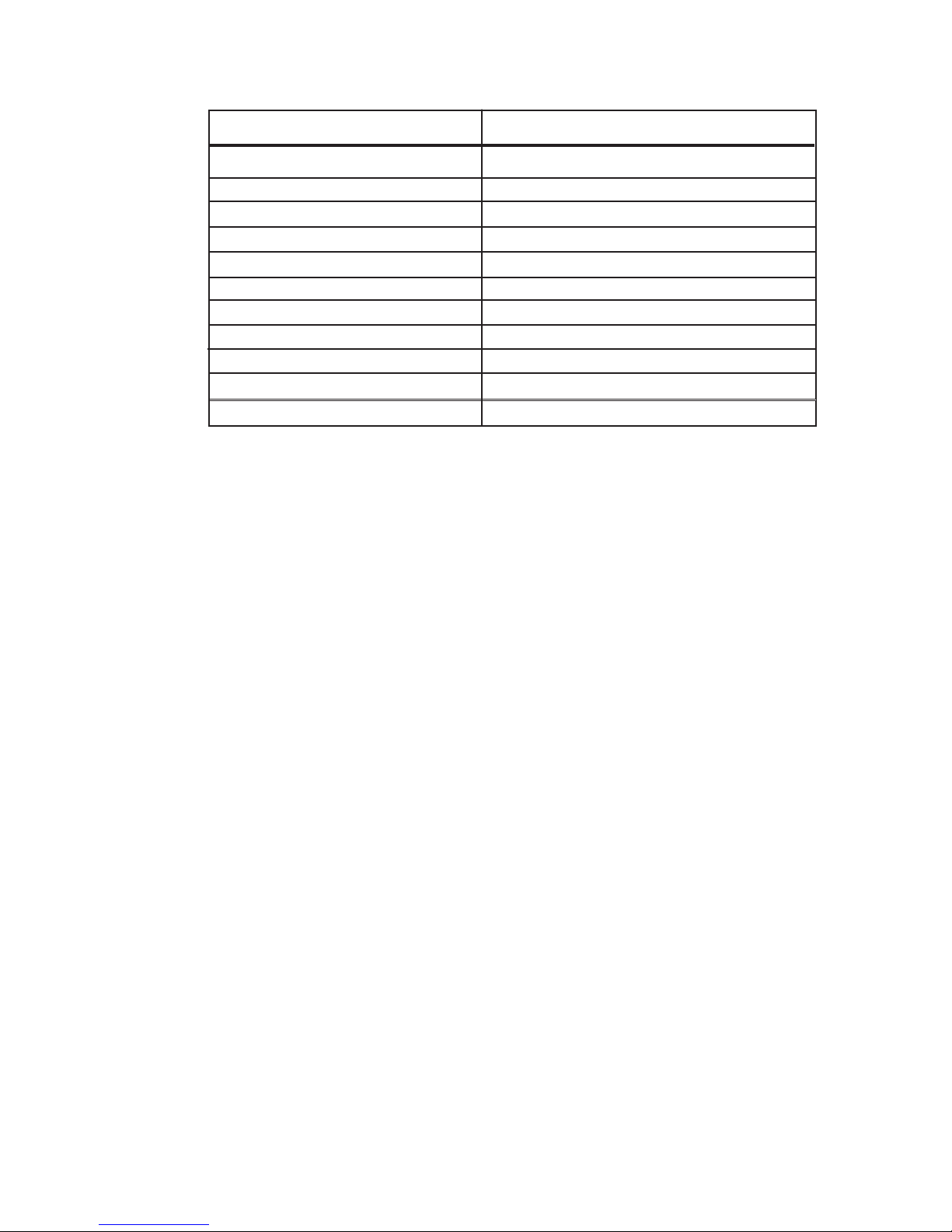

Specifications

Item Description

Stock Capacity 40 inches wide; 18 gauge sheet metal

Hold Down Bar 5/8 inch steel

Table Size 42-5/8 (L) x 4-7/8 (W)

Dies 1, 1-1/2, 2, 4, 7, 10, 15 inches

Roller Size 1-21/32 (dia.) x 39 (L) inches

Round Stock Grooves (3 sizes) 1/4, 5/16, 3/8 inches

Handle Dimensions 30 inches

Zerk Fittings Automotive

Overall Dimensions 49 x 15-1/2 x 24 inches

Weight 420 lbs.

Hex Wrenches 5, 6, 8 mm

Save This Manual

You will need the manual for the safety warnings and precautions, assembly instructions,

operating and maintenance procedures, parts list and diagram. Keep your invoice with this

manual. Write the invoice number on the inside of the front cover. Keep the manual and

invoice in a safe and dry place for future reference.

Safety Warnings and Precautions

WARNING: When using tool, basic safety precautions should always be followed to

reduce the risk of personal injury and damage to equipment.

Read all instructions before using this tool!

1. Keep work area clean. Cluttered areas invite injuries.

2. Observe work area conditions. Do not use machines or power tools in damp or wet

locations. Don’t expose to rain. Keep work area well lighted. Do not use electrically

powered tools in the presence of flammable gases or liquids.

3. Keep children away. Children must never be allowed in the work area. Do not let

them handle machines, tools, or extension cords.

4. Store idle equipment. When not in use, tools must be stored in a dry location to

inhibit rust. Always lock up tools and keep out of reach of children.

5. Do not force tool. It will do the job better and more safely at the rate for which it was

intended. Do not use inappropriate attachments in an attempt to exceed the tool

capacity.

6. Use the right tool for the job. Do not attempt to force a small tool or attachment to do

the work of a larger industrial tool. There are certain applications for which this tool

was designed. Do not modify this tool and do not use this tool for a purpose for which

it was not intended.

Page 2SKU 43353

Rev 11/01

Page 3

7. Dress properly. Do not wear loose clothing or jewelry as they can be caught in

moving parts. Protective, electrically non-conductive clothes and non-skid footwear

are recommended when working. Wear restrictive hair covering to contain long hair.

8. Use eye and ear protection. Always wear ANSI approved impact safety goggles.

Wear a full face shield if you are producing metal filings or wood chips. Wear an ANSI

approved dust mask or respirator when working around metal, wood, and chemical

dusts and mists.

9. Do not overreach. Keep proper footing and balance at all times. Do not reach over or

across running machines.

10. Maintain tools with care. Keep tools sharp and clean for better and safer

performance. Follow instructions for lubricating and changing accessories. Inspect tool

cords periodically and, if damaged, have them repaired by an authorized technician.

The handles must be kept clean, dry, and free from oil and grease at all times.

11. Remove adjusting keys and wrenches. Check that keys and adjusting wrenches

are removed from the tool or machine work surface before using.

12. Stay alert. Watch what you are doing, use common sense. Do not operate any tool

when you are tired.

13. Check for damaged parts. Before using any tool, any part that appears damaged

should be carefully checked to determine that it will operate properly and perform its

intended function. Check for alignment and binding of moving parts; any broken parts

or mounting fixtures; and any other condition that may affect proper operation. Any

part that is damaged should be properly repaired or replaced by a qualified

technician.

14. Replacement parts and accessories. When servicing, use only identical

replacement parts. Use of any other parts will void the warranty. Only use accessories

intended for use with this tool. Approved accessories are available from Harbor

Freight Tools.

15. Do not operate tool if under the influence of alcohol or drugs. Read warning

labels on prescriptions to determine if your judgment or reflexes are impaired while

taking drugs. If there is any doubt, do not operate the tool.

16. Maintenance. For your safety, service and maintenance should be performed

regularly by a qualified technician.

Warning: The warnings, cautions, and instructions discussed in this instruction manual

cannot cover all possible conditions and situations that may occur. It must be understood by the operator that common sense and caution are factors which cannot be

built into this product, but must be supplied by the operator.

Page 3SKU 43353

Page 4

Roller Machine Safety Precautions

1. Avoid cuts by always wearing gloves when handling sheet metal.

2. Keeps hands and clothes out of the path of the rollers.

3. The Roller Machine should only be used by an experienced operator.

Unpacking

When unpacking, check to make sure the following parts are included:

- Roller Machine - 7 Dies - 3 Hex Wrenches

If any parts are missing or broken, please call Harbor Freight Tools at the number on the

cover of this manual as soon as possible. Parts of this machine come coated with a rust

inhibitor. It must be removed before using. Refer to the Maintenance section on page 8.

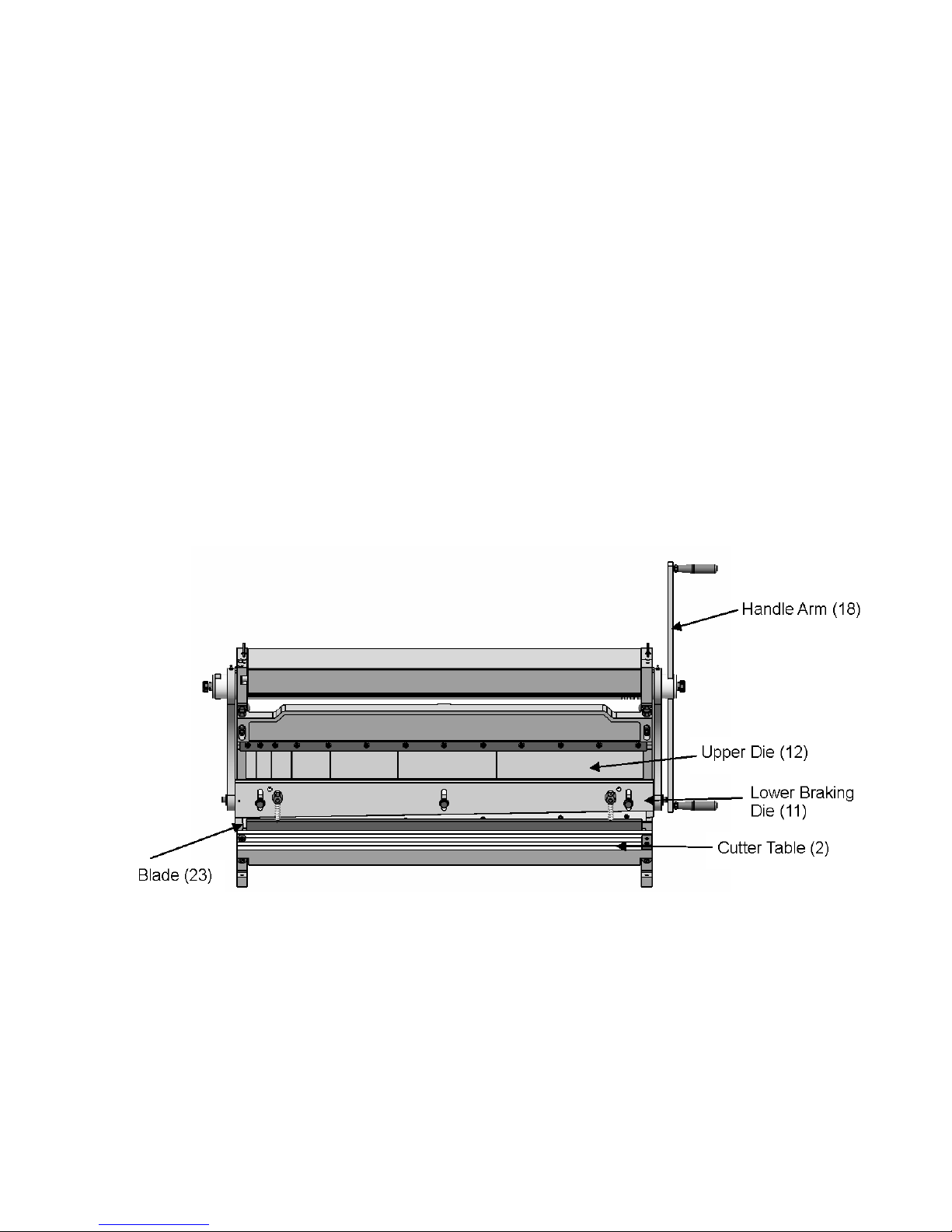

Operation

The Roller Machine is used for shearing and rolling sheet metal up to 18 gauge. The Roller

Machine comes pre-adjusted from the factory. Before using it, however, check that all the

necessary adjustments are made (Refer to the section on Adjustments).

Pressing

1. Raise the Lower Braking Die (11) to its highest level by rotating the Handle Arm (18).

2. Slide the Press Plate Brackets (8) of the Press Plate Assembly (8,9,10,54) into the

receiver holes of the Lower Braking Die (11).

Note that the Press Plate (10) should be facing down.

3. Raise the Press Plate (10) as necessary by turning the Hex Bolt (54) clockwise.

4. Place the workpiece so that it is centered under the Press Plate (10).

5. Rotate the Handle Arm (18) to press the workpiece.

Page 4SKU 43353

Page 5

Shearing

1. Scribe the cutting mark on the sheet metal.

2. Slide the sheet metal between the upper Blade (23) and the lower Blade (23) so that

the upper Blade (23) is positioned directly over the cutting mark.

If additional cuts of identical size are needed, the Backstop (21) can be adjusted to the

required depth. The sheet metal will stop on the Backstop (21) when inserted. Refer to

the Adjustments section, Adjusting the Backstop.

3. While holding the material steady, rotate the Handle Arm (18) until the material has

been cut.

For large pieces of sheet metal, it may be necessary to use a front table to support the

metal, or have someone hold it for you.

Angle Bending

1. Mark the sheet metal where it is to be bent.

2. Place the sheet metal above the Lower Braking Die (11).

3. Align the bending mark with the front edge of the Upper Die (12).

If multiple bends of identical size and angle sheet metal are needed, the Backstop (21)

can be adjusted to the required depth. The sheet metal will stop on the Backstop (21)

when inserted. Refer to the Adjustments section, Adjusting the Backstop.

4. Rotate the Handle Arm (18) until the desired angle been formed.

Use a protractor or other measuring tool to ensure accuracy.

Radius Bending

Radius bending is most commonly used to make cylinders and cones. Both shapes are

formed by making a series of small, closely spaced bends in the work piece. For cylinders,

the bends are even spaced. For cones, move one side of the sheet metal further out each

time a bend is made.

Pan Bending

The Angle Bending feature can be used to make various sizes of pans out of sheet metal.

The maximum lip (side) height is 1 inch.

1. Pre-measure and cut your material before bending.

Notch the corners to the desired lip (side) height.

2. Place the sheet metal above the Lower Braking Die (11).

3. Align the bending mark with the front edge of the Upper Die (12).

4. Rotate the Handle Arm (18) until 90 degree angle been formed.

Page 5SKU 43353

Page 6

Use a protractor or other measuring tool to ensure accuracy.

5. Rotate the sheet metal 90 degrees counterclockwise.

Allow the completed side to extend just beyond the Dies.

6. Bend the sheet metal. Repeat step 5 for the 3rd side.

7. Rotate to the final side and insert the sheet metal lip between the Dies.

The formed sides will be on the outside of the Dies.

8. Before bending the 4th side, tap one corner nearer the middle of the machine.

This will allow the sides to clear the upper Die (12) when raised.

Rolling

1. Lift the front Cover (33) and flip backward, out of the way.

2. Drop the Rear Roll Bar (24) by loosening the Adjustment Knob (25b).

3. Insert only the leading edge of the sheet metal between the Upper Roll Bar (32) and

the Lower Roll Bar (31), tighten the Adjustment Keys (27) until the Roll Bars are just

snug against the sheet metal.

4. Advance the Adjustable Bolt (25b) to the desired tightness for the roll.

The more the Adjustable Bolt (25b) is advanced, the tighter the roll.

5. Turn the Handle Arm (18) until the desired roll is achieved.

The sheet metal should feed itself through the rollers as the Handle Arm (18) is turned.

Wire Rolling

1. Select the proper size groove in the Upper Roll Bar (32) depending upon the gauge of

the wire being rolled.

2. Follow steps 2 through 5 (above), under Rolling.

Adjustments

While making adjustments, it may be necessary to refer to the Assembly Drawing at the end

of this manual

Handle Removal and Adjustment

The Handle Arm (18) may be adjusted or removed by removing one of the Handle Knob

Assemblies (26a, 26b, 61) and loosening the Knob (59) that holds the Handle Arm (18) in

place. It may then be slid out of the handle socket.

Bending Die Adjustment and Removal

The Upper Die (12) is segmented and can be used for varying sizes of box and pan forming.

When forming a smaller box or pan, choose the desired size Upper Die (12) finger, center it

and remove the others.

Page 6SKU 43353

Page 7

The Roller Machine can be used to bend sheet metal up to 18 gauge. The space between

the Upper Die (12) and the Lower Braking Die (11) is adjustable as described below.

1. Place a piece of flat, straight wood (or metal place) between the Upper Die (12) and

Lower Braking Dies (11) and raise the Lower Braking Die (11) so that the material just

touches the Upper Die (12).

2. Loosen the Hex Head Screws (51) holding the Upper Die (12) in place.

Do not remove the Screws.

3. Remove any unnecessary Upper Die (12) fingers.

4. Raise the Lower Braking Die (11), using the long piece of wood or metal plate as a

level guide, adjust the alignment of the Upper Die (12) fingers.

5. When aligned, retighten the Hex Head Screw (51).

Removal and Installation of the Upper Cutting Blade (23)

1. Remove the six Hex Head Screws (55) holding in the upper cutting Blade (23).

2. Remove (or replace) the upper cutting Blade (23), and replace the Screws but do not

tighten completely.

3. Align the upper cutting Blade (23) so that it is flush with the Lower Braking Die (11).

4. Tighten all the Hex Head Screws (55).

Adjustment of the Upper Cutting Blade

1. Place a 30 inch piece of thin cardboard or paper between the upper and lower Blades

(23).

2. Rotate the Handle Arm (18) and cut the material.

3. Use a straightedge to determine the straightness of the cut and if the Blade (23) is in

need of adjustment.

4. If the Blade (23) is bowed out (away from the front of the machine), turn the adjustment

Nut (48) counterclockwise.

This will tighten the Adjustment Bar (22) and push the middle of the upper Blade (23)

out, while pulling in its ends.

5. If the Blade (23) is bowed in (towards the back of the machine), turn the adjustment Nut

(48) clockwise.

This will loosen the Adjustment Bar (22) and pull the middle of the upper Blade (23) in,

while pushing its ends out.

Removal and Installation of the Lower Blade

1. Remove the Hex Head Screws (57) from the lower cutting Blade (23).

2. Remove (or replace) the lower cutting Blade (23).

Page 7SKU 43353

Page 8

3. Replace the Hex Head Screws (57).

Adjustment of the Lower Cutting Blade (23)

1. Turn the Handle Arm (18) and lower the upper Blade (23) to its lowest position.

2. Loosen the two inset Hex Head Screws (58) located on top of the Cutter Table (2).

3. Adjust the lower cutting Blade (23) by turning its Adjusting Bolts (17).

The distance between the lower and upper cutting Blade (23) should be 5 to 8 percent

of the thickness of the workpiece.

4. Tighten the two inset Hex Head Screws (58) located on top of the Cutter Table (2).

Installation and Adjustment of the Backstop (21)

1. Screw the two Support Rods (19) into the back of the Crossbeam (3).

2. Slide the two Support Blocks (20) onto the Support Rods.

3. Attach the Backstop (21) to the Support Blocks using the Hex Head Screws (42).

- If used for bending, attach the Backstop on top of the Support Blocks.

- If used for shearing, attach the Backstop on the bottom of the Support Blocks.

4. Adjust the Backstop to the desired depth and tighten the Knob (41).

Maintenance

1. Before using this machine, certain parts coated with rust inhibitor must be first cleaned

using varnish thinner.

2. Lubricate the eccentric mechanism daily with machine oil.

3. Periodically check all nuts, bolts, and screws for tightness.

4. Periodically lubricate the rollers surface with a clean rag and machine oil.

5. Place the Cover over the rollers when not in use.

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM IN THIS

MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER NOR DISTRIBUTOR

MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR

SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE IS

QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER

AND/OR DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS

SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS AND NOT BY THE

BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER

REPAIRS TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING

OUT OF HIS OR HER INSTALLATION OF REPLACEMENT PARTS THERETO.

Page 8SKU 43353

Page 9

Parts List

NOTE: Some parts are listed and shown for illustration purposes only and are not available

individually as replacement parts.

Page 9SKU 43353

Page 10

Page 10SKU 43353

Page 11

WARRANTY

Page 11SKU 43353

Loading...

Loading...