Page 1

16” Variable Speed

Brought to You by Augusta Flint

Scroll Saw

Model

4188941889

41889

4188941889

Assembly & Operating Instructions

www.HarborFreight.com

Copyright 1999 by Harbor Freight Tools®. All Rights Reserved.

No portion of this manual or any artwork contained herein may be reproduced in any

manner, shape or form without the express written consent of Harbor Freight Tools.

For technical questions and replacement parts, please call 1-800-444-3353.

Page 2

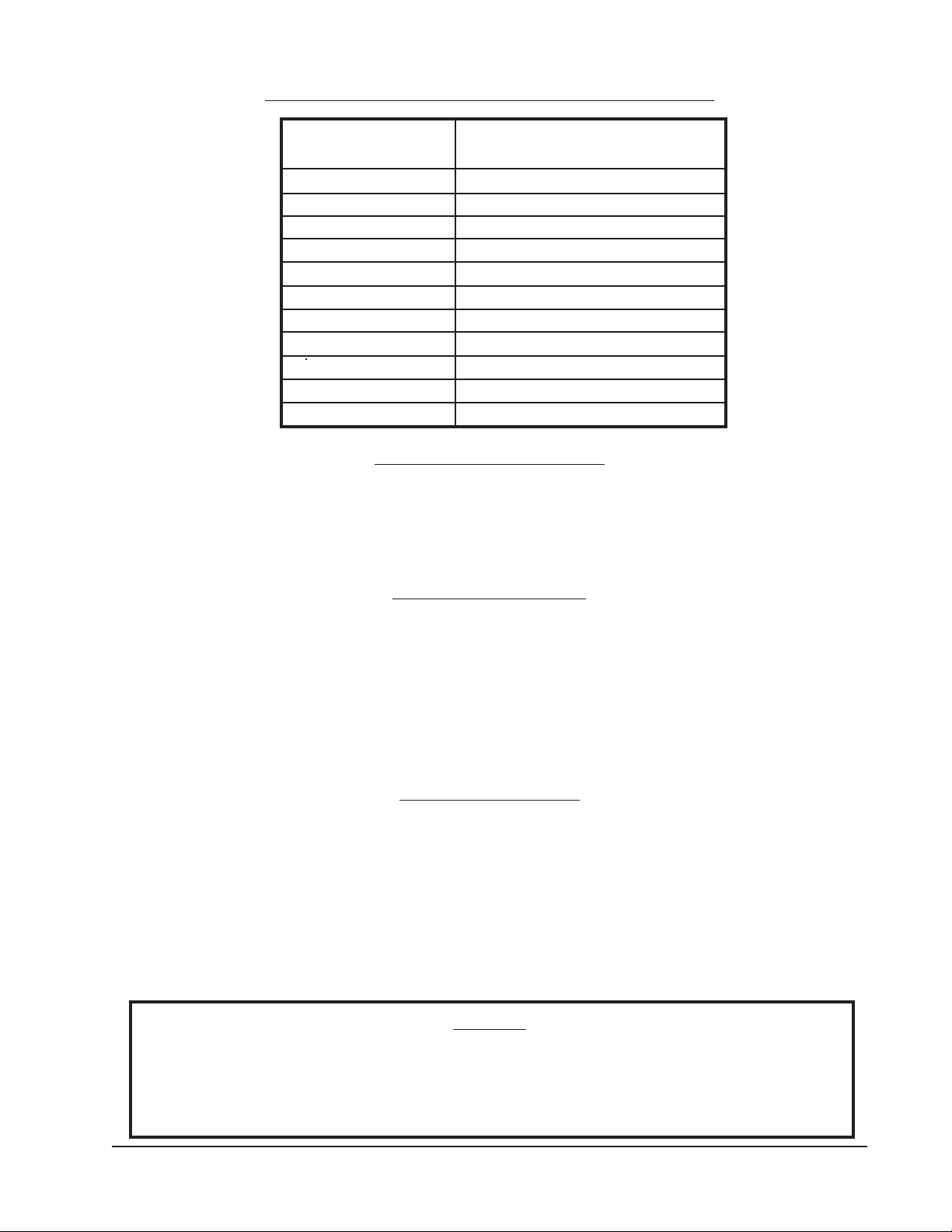

MODEL # 41889 16” SCROLL SAW SPECIFICATIONS

Brought to You by Augusta Flint

Electric Motor: 380 - 1500 RPM variable speed

110V / 60Hz, double insulated

Blade Speed: 350 to 1400 spm, variable speed

Blade Length: 5”, pin type

Throat Depth: 16”

Max. Stock Thickness: 2-1/4”

T able Dimensions: 16-1/4”L x 10”W tapered x 6-7/8”H

Table Angle Setting: 0O - 45O in 1O increments

Power Cord: 78”, UL approved, 3-wire grounded

Power Plug: CSA-approved, 3 prong grounded

Power Switch: CSA-approved

Overall Dimensions: 16-5/8”L x 12-1/8” W x 25-1/4”H

W eight: 26.8 Lbs.

INCLUDED ACCESSORIES

1. 2.5mm, 3mm, 4mm L Hex W renches

2. Blade Adapters

3. Pin Blade

PRODUCT FEA TURES

1. High powered, variable-speed tool delivers impressive wood cutting power.

2. Double insulated construction, with 18 Gauge UL approved power cord.

3. Easily adjustable table angle, with scale for accurate measurement.

4. Built in blower keeps blade clean, and affords clear view of cutting operation.

5. Uses readily-available standard 5” pin blades.

SAVE THIS MANUAL

Y ou will need this manual for the safety warnings and cautions, assembly instructions, operating procedures,

maintenance procedures, trouble shooting, parts list, and diagram. Keep your invoice with this manual.

Write the invoice number on the inside of the front cover . Keep both this manual and your invoice in a safe,

dry place for future reference.

NOTICE

The Warnings, Cautions, and Instructions discussed in this instruction manual cannot

cover all possible conditions and situations that may occur. It must be understood by

the operator that common sense and caution are factors which cannot be built into this

product, but must be supplied by the operator.

Page 2 SKU # 41889

Page 3

SAFETY WARNING & CAUTIONS

Brought to You by Augusta Flint

WARNING: When using powered equipment, basic safety precautions should

always be followed to reduce the risk of personal injury and hazards.

1. KEEP WORK AREA CLEAN. Cluttered areas invite injuries.

2. OBSER VE WORK AREA CONDITIONS. Do not use tools in damp, wet, or poorly lit locations.

Don’t expose to rain. Keep work area well lit. Do not use electrically powered equipment in the

presence of flammable gases or liquids.

3. KEEP CHILDREN A W AY. Children must never be allowed in the work area. Do not let them

handle machines, tools, or equipment.

4. STORE IDLE EQUIPMENT . When not in use, tools must be locked up in a dry location to inhibit

rust. Always lock up tools and keep out of reach of children.

5. DO NOT FORCE THE TOOL. It will do the job better and more safely at the rate for which it

was intended. Do not use inappropriate attachments in an attempt to exceed the tool’ s capacities.

6. USE THE RIGHT TOOL FOR THE JOB. Do not use a tool for a purpose for which it was not

intended.

7. DRESS PROPERL Y. Do not wear loose clothing or jewelry , as they can be caught in moving

parts. Non-skid footwear is recommended. W ear restrictive hair covering to contain long hair .

Always wear appropriate work clothing.

8. USE EYE, EAR AND BREATHING PROTECTION. Always wear ANSI approved impact

safety goggles if you are producing metal filings or wood chips. W ear an ANSI approved dust mask

or respirator when working around metal, wood, and chemical dusts and mists. Use ANSI

approved ear protection when working in a loud or noisy environment.

9. DO NOT ABUSE THE POWER CORD. Protect the power cord from damage, either from

impacts, pulling or corrosive materials. Do not yank machine’ s cord to disconnect it from the

receptacle.

10. DO NOT OVERREACH. Keep proper footing and balance at all times. Do not reach over or

across running machines.

11. MAINT AIN TOOLS WITH CARE. Keep tools sharp and clean for better and safer performance.

Follow instructions for lubricating and changing accessories. Inspect power cord periodically and, if

damaged, have it repaired by an authorized technician. Inspect all moving parts and mounting bolts

prior to use. Control handle and power switch must be kept clean, dry , and free from oil and grease.

12. REMOVE ADJUSTING KEYS AND WRENCHES. Be sure that keys and adjusting wrenches

are removed from the tool or machine work surface before operation.

13. AVOID UNINTENTIONAL ST AR TING . Be sure that you are prepared to begin work before

turning the start switch on.

14. ST A Y ALER T . W atch what you are doing. Do not operate this machine when you are tired.

15. DO NOT OPERA TE THIS MACHINE WHILE UNDER THE INFLUENCE OF ALCOHOL,

DRUGS, OR PRESCRIPTION MEDICINES.

16. CHECK FOR DAMAGED P AR TS. Before using any tool, any part that appears damaged should

be carefully checked to determine that it will operate properly and perform its intended function.

Check for alignment and binding of moving parts, any broken parts or mounting fixtures, and any

other condition that may affect proper operation. Any part that is damaged should be properly

repaired or replaced by a qualified technician. Do not use the tool if any switch does not turn on and

off properly .

17. REPLACEMENT P AR TS AND ACCESSORIES. When servicing, use only identical replacement

parts, which are available from Harbor Freight T ools. Use of any other parts will void the warranty .

Page 3 SKU # 41889

Page 4

SPECIAL WARNINGS WHEN USING THIS SCROLL SAW

Brought to You by Augusta Flint

Using this powerful tool may create special hazar ds.

Operating the Saw.

1. Avoid overloading the saw . If the speed drops abnormally , decrease the pressure immediately .

2. Always use sharp blades which are suited to the material you are cutting. If the blade stops abruptly,

or becomes blocked, turn off the power switch immediately .

3. Do not apply excessive pressure to the work piece while cutting.

4. Be careful to use the power switch properly . Be aware that the saw will continue to

operate while the power switch is ON. Y ou must manually turn the switch to OFF to stop the motor .

5. Never start the saw while the blade is in contact with any material. Allow the saw to reach its

normal operating speed before applying the workpiece to the blade.

6. Never operate the saw if the metal safety guard (drop foot) is not in place.

7. Never touch the blade, upper blade holder or any other moving parts while the saw is in operation.

8. Never walk away from the saw until it has stopped operating completely.

9. Before cutting, adjust the drop foot to ride on the surface of the workpiece. This will prevent the

workpiece from “jumping” up and down, which can damage the workpiece, the saw , and the blade.

10. Hold the workpiece firmly while cutting. The action of the blade against the workpiece can cause it

to “kick out”. If you experience excessive “kick out” check your blade to assure that it is the proper

type for the material being cut, that it is installed with the teeth down, and that it is sharp.

11. Always wear ANSI certified eye protection, and do not allow others nearby when using this tool.

Cuttings and splinters can be ejected at high speed while cutting.

12. Do not handle the blade immediately after use; it may be very hot, potentially causing burns

or injury .

13. Make sure the workpiece is free of nails or other debris which can interfere with the cutting process,

and possibly cause damage or injury .

14. Y our saw must be bolted or clamped to the workbench prior to use.

Ensure the safety of the workplace.

1. Always wear ANSI-approved eye protection when trimming.

2. Clear the work area of any parts or debris that could cause injury by interfering with the

cutting process.

3. Remove trimmed off sections immediately to prevent their being ejected by the saw .

4. Keep children and unauthorized persons away from the area when cutting.

5. Avoid distractions while cutting.

6. Never leave the saw unattended where children or unauthorized persons can use it without

supervision.

Inspect the Scroll Saw before use.

1. Before cutting, run the tool for about 10 seconds to ensure that all moving parts are running

smoothly and there are no loose parts, rattles, or sparking that would indicate damage.

2. Repair any damage before using this tool.

3. Be sure the blade is firmly and properly installed before use. Improperly installed blades may eject

suddenly at high speed from the saw .

Page 4 SKU # 41889

Page 5

ELECTRICAL LIMITS AND WARNINGS

Brought to You by Augusta Flint

1. If using an extension cord, observe the minimum gauge requirements found in the following

chart. Improper extension cord use can result in electrical hazard and poor tool performance.

AMP Total Extension Cord Length in Feet

RA TING 25 50 75 100 125 150 175 200

0-10 Amp 18 18 16 16 14 14 12 12

10.1-13 Amp 16 16 14 14 14 12 12 12

13.1-15 Amp 14 14 12 12 12 12 12 --

Use only UL approved extension cord.

2. Avoid wet conditions when using electrical equipment.

3. Use only a grounded outlet with appropriate breaker switch in-line.

4. Always inspect power cords and extension cords for damage before use. Never plug in a

power cord that is not in good condition.

5. Harbor Freight Tools can supply UL listed and outdoor rated power cords in various AWG

gauge ratings as needed.

BASIC OPERA TION

This saw uses a very thin, very fine blade, which moves up and

down at high speed. This type of saw is ideal for making

detailed curved cuts in relatively thin materials. Fretwork, signs,

and gingerbread decorations can be readily made with a scroll saw.

Figure 1. Electrical Contr ols

and Fuse Cover.

1. After selecting and installing the proper blade for the work at hand, position the workpiece on the

table.

2. Lower the foot onto the workpiece, so that it just rests on the surface of the material. Tighten the

foot into position with the knob.

3. With the material not touching the blade, turn the power ON by pressing the upper part of the

rocker switch.

4. When the saw has come up to full speed, gently push the edge of the workpiece into the blade.

Notice how well the blade makes the cut. Adjust the speed if necessary .

NOTE: In general, harder and thinner materials r equire finer saw teeth and higher speeds. Softer and

thicker materials generally requir e slower speeds. Finding the ideal saw blade and speed combination may require some experimentation and experience.

5. As you work, remove cut off pieces of work material.

6. For cutting enclosed areas, first drill a hole through the cut-out area, install the blade through the

hole, then cut out the enclosed area with the scroll saw .

7. Keep your hands away from the saw blade while using this saw. Where possible, use a push stick to

guide the workpiece into the blade, keeping your hands away .

Page 5 SKU # 41889

Page 6

Figure 2. Basic Components

Brought to You by Augusta Flint

and Features of Your Scroll Saw .

1. T able. Provides a working surface to support the workpiece.

2. Sawdust Blower . Keeps your workpiece clean for more accurate scroll cuts. For best results, adjust the

blower to the point at which the blade is cutting. T o adjust, loosen the set screw in the drop foot, position the

blower and retighten the screw . CAUTION: do not overtighten the screw , which may collapse the tube.

3. Power Cord. This is a 3-wire UL approved cord and CSA-approved grounded plug for use in a 110-120 V olt,

60Hz outlet only . Be sure your power supply is protected with an appropriate breaker switch.

4. Drop Foot. The foot should always be adjusted so it just rests on top of the workpiece.. You want to prevent the

workpiece from lifting, but not create drag on the surface.

5. Drop Foot Lock Knob. Loosen and tighten this knob as you adjust the drop foot.

6. Blade T ension Knob. Allows you to loosen or tighten the blade tension. Y ou also use this knob when replacing

the blade.

7. T able Lock Knob. This knob allows you to adjust the table angle up to 45 degrees.

8. Degree Scale. This scale indicates the degree from horizontal that you have the table set.

9. Power Switch. Turn the switch up to turn ON, and down to turn OFF .

10. ElectricalBreaker Switch. This fuse will automatically cut off power to the saw in the event of a short or

surge in the power supply. If the fuse activates, find and repair the source of the problem before replacing the fuse.

11. Speed Control. Turn this knob to the right to increase saw blade speed, and to the left to reduce speed.

12. T able Insert. This should always be in place and flush with the table during the cutting operation.

Page 6 SKU # 41889

Page 7

INSTALLING THE SA W BLADE

Brought to You by Augusta Flint

Fig. 3. Installing the Blade

Your new scroll saw accepts 5” pin-type blades. Your saw is also equipped with blade

adapters that allow you to use a variety of 5” plain-end blades.

WARNING: To prevent personal injury, always disconnect the plug from the power source

before changing blades or making adjustments.

1. Rotate the blade tension knob counter-clockwise to release blade tension.

2. Remove the table insert and remove the blade from the upper and lower blade holders by pulling

forward on the blade and then lifting the blade through the access hole in the table. Slight downward

pressure against the upper holder may be helpful when removing the blade from upper holder.

3. Look at the blade holders closely and notice the blade slots and recesses in the blade holders. The

blade holders are made so you can position the blade for cutting from the front or from the side of

the saw as shown in Figure 3 above. Cutting from the side of the saw will be necessary if your

workpiece exceeds 16 inches in length. This allows your scroll saw to cut like a band saw . This

option is for 0O table setting only .

4. In order to cut, and to avoid uncontrollable lifting of the workpiece, the teeth of the blade used on

the scroll saw should always point downward.

5. Install the blade by inserting one end of the blade through the access hole in the table and hook the

blade pin in the pin recess in the lower blade holder. Slide the top blade pin into the pin recess of the

inner upper blade holder. Y ou may need to press down lightly on the upper blade holder to install

the blade.

6. Carefully tighten the blade by rotating the blade tension knob clockwise until you feel the slack in the

blade removed. Double check to see that pins are properly located in the blade holder . Then turn

the blade tension knob ONE full turn clockwise. This amount of blade tension should do well for

most cutting operations and blades.

Page 7 SKU # 41889

Page 8

ADJUSTING AND USING THE TABLE ALIGNMENT FEATURE

Brought to You by Augusta Flint

Fig. 4. Aligning the Table

and adjusting the Scale

Aligning the Degree Scale Pointer

1. Loosen the table lock knob and move the table until it is

approximately perpendicular, that is, at a right angle to

the blade.

2. Place a small square on the table next to the blade as

shown in Figure 4 to check if the table is 90

O

to the

blade. If adjustment is needed, raise or lower the table

until it is as close to 90O as possible. Securely tighten the

table lock knob.

3. Loosen the screw holding the degree scale pointer, as

shown in Figure 4. Move the pointer to the 0O degree

marker on the scale, and securely tighten the screw .

Remember the scale is a convenient guide, but should not

be relied upon for extremely accurate cutting. Make

practice cuts in scrap wood to determine if your angle

settings are correct.

Setting the Table for Horizontal or Bevel Cutting.

1. Loosen the table lock knob, and the saw table can be

tilted to the left and locked in any angle from 0O degree

horizontal cutting position up to 45O for bevel cutting.

2. A degree scale is also provided under the work table as a

convenient reference for setting the approximate table

angle for bevel cutting. When greater precision is

required, make practice cuts and adjust the table as

necessary for your requirements.

3. NOTE: When cutting at angles, the drop foot can be tilted

so it is parallel with the table surface, and rests flush

against the workpiece. T o tilt drop foot, loosen the allen

screw , tilt the foot so it is parallel with the table, and then

securely retighten the screw .

Fig. 5. Adjusting the Table Angle

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM IN THIS MANUAL AS

A REFERENCE TOOL ONLY: NEITHER THE MANUFACTURER NOR DISTRIBUTOR MAKES ANY

REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE IS QUALIFIED TO MAKE

ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS OF THE

PRODUCT: IN FACT THE MANUFACTURER A ND/OR DISTRIBUTOR EXPRESSLY STATES THATALL REPAIRS

AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS AND

NOT BY THE BUYER. THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS

TO THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER

INSTALLATION OF REPLACEMENT PARTS THERETO.

Page 8 SKU # 41889

Page 9

PARTS DIAGRAM #41889 SCROLL SA W

Brought to You by Augusta Flint

Please see Parts Diagram on Following Page

P/N Description

1 Adjustment Assembly

2 Power Supply

3 Spring Washer m6

4 Hex Nut m6

5 Pan Head Screw m5 x 10

6 Plate Cover

7 Spring Washer m8

8 Hex Head Screw m8 x 25

9 Base

10 Hex Head Screw m6 x 20

11 Housing Set

12 Support Table

13 Indicator

14 Pan Head Screw m5 x 10

15 Bracket T ilt

16 Spring W asher m5

17 Spring

18 Flat Washer m6

19 Hex Head Bolt m6 x 40

20 Spring

21 Bolt T ension

22 Lower Rocker Arm Asembly

23 Spring W asher m4

24 Hex Head Bolt m4 x 10

25 Bearing Flamge

26 Pan Head Screw m5 x 6

27 Round Head Screw m6 x 25

28 Retainer

29 Upper Rocker Arm Assembly

30 Hex Nut m5

31 Hex Head Bolt m5 x 30

32 Spacer Bearing

33 Spacer Bearing

34 Link Assembly

35 Allen Wrenches, 2.5, 3, 4mm

36 Cord Clamp

37 Upper Holder

38 Hex Head Bolt m5 x 25

P/N Description

39 Flat W asher

40 Lower Holder

41 T ooth Washer

42 Hex Head Bolt m4 x 10

43 T able Insert

44 Knob

45 Blade

46 Pan Head Screw m4 x 16

47 Blade Guard

48 T ooth washer m5

49 Pan Head Screw m5 x 10

50 Switch Cover

51 Motor

52 Eccentric

53 Table

54 Hex Head Bolt m6 x 40

55 PVC Pipe

56 Support Rod

57 Bellows Lock

58 Bellows

59 Tooth W asher m4

60 Set Screws m8 x 8

61 Pan Head Screw m4.2 x 8

63 Pan Head Screw m4 x 20

64 Pan Head Screw m4 x 6

65 Pan Head Screw m5 x 35

66 Pan Head Screw m5 x 30

67 Blower Tube

68 Knob

69 Bearing Fence

70 Set Plate

71 Switch Case

72 Power Switch

73 Fuse Box

75 Motor Base

76 Pan Head Screw m4 x 16

Page 9 SKU # 41889 REV 09/04

Page 10

PARTS DIAGRAM #41889 SCROLL SA W

Brought to You by Augusta Flint

Please see Parts List on Previous Page

Page 10 SKU # 41889

Loading...

Loading...