Page 1

WOOD BELWOOD BEL

®

WOOD BEL

WOOD BELWOOD BEL

6 X 48 INCHES6 X 48 INCHES

6 X 48 INCHES

6 X 48 INCHES6 X 48 INCHES

T SANDERT SANDER

T SANDER

T SANDERT SANDER

40643

ASSEMBLY AND OPERATING

INSTRUCTIONS

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our Web site at http://www.harborfreight.com

Copyright© 1999 by Harbor Freight Tools®. All rights reserved. No portion of this

manual or any artwork contained herein may be reproduced in any shape or

form without the express written consent of Harbor Freight Tools.

For technical questions and replacement parts, please call 1-800-444-3353

Page 2

Specifications

METINOITPIRCSED

rotoM

deepS

tupnIrewoP

elbaTseerged54:tliT;sehcni61/3-01x6

thgieWteN.sbl931

hctiwSrewoPyekgnikcole

eguaGretiMseergeD06ot0

stolSretiMsehcni)W(4/3x)L(4/3-6:raB;hcni4/3

daPgnidnaSsehcni21

BgnidnaSseergeD09ot0morfstliT

tle

MPR054,3,zH06

MPF044,1:tleB

MPR058,1:csiD

spma21:suounitnoC

;

spma8.7:daoLoN

lbavomerhtiwffO/nO

,esahPelgniS,V011,)kaep(PH1

Save This Manual

You will need the manual for the safety warnings and precautions, assembly instructions,

operating and maintenance procedures, parts list and diagram. Keep your invoice with this

manual. Write the invoice number on the inside of the front cover. Keep the manual and

invoice in a safe and dry place for future reference.

Safety Warnings and Precautions

WARNING: When using tool, basic safety precautions should always be followed to reduce

the risk of personal injury and damage to equipment.

Read all instructions before using this tool!

1. Keep work area clean. Cluttered areas invite injuries.

2. Observe work area conditions. Do not use machines or power tools in damp or wet

locations. Don’t expose to rain. Keep work area well lighted. Do not use electrically

powered tools in the presence of flammable gases or liquids.

3. Keep children away. Children must never be allowed in the work area. Do not let

them handle machines, tools, or extension cords.

4. Store idle equipment. When not in use, tools must be stored in a dry location to inhibit

rust. Always lock up tools and keep out of reach of children.

5. Do not force tool. It will do the job better and more safely at the rate for which it was

intended. Do not use inappropriate attachments in an attempt to exceed the tool

capacity.

REV 01/04; 09/05

SKU 40643 For technical questions, please call 1-800-444-3353. Page 2

Page 3

6. Use the right tool for the job. Do not attempt to force a small tool or attachment to do

the work of a larger industrial tool. Do not use a tool for a purpose for which it was not

intended.

7. Dress properly. Do not wear loose clothing or jewelry as they can be caught in

moving parts. Protective, electrically non-conductive clothes and non-skid footwear

are recommended when working. Wear restrictive hair covering to contain long hair.

8. Use eye and ear protection. Always wear ANSI approved impact safety goggles.

Wear a full face shield if you are producing metal filings or wood chips. Wear an ANSI

approved dust mask or respirator when working around metal, wood, and chemical

dusts and mists. Wear ear protection when sanding for long periods.

9. Do not overreach. Keep proper footing and balance at all times. Do not reach over or

across running machines.

10. Maintain tools with care. Keep tools sharp and clean for better and safer

performance. Follow instructions for lubricating and changing accessories. Inspect tool

cords periodically and, if damaged, have them repaired by an authorized technician.

The handles must be kept clean, dry, and free from oil and grease at all times.

11. Disconnect power. Unplug when not in use.

12. Remove adjusting keys and wrenches. Check that keys and adjusting wrenches

are removed from the tool or machine work surface before plugging it in.

13. Avoid unintentional starting. Be sure the switch is in the Off position when not in use

and before plugging in.

14. Stay alert. Watch what you are doing, use common sense. Do not operate any tool

when you are tired.

15. Check for damaged parts. Before using any tool, any part that appears damaged

should be carefully checked to determine that it will operate properly and perform its

intended function. Check for alignment and binding of moving parts; any broken parts

or mounting fixtures; and any other condition that may affect proper operation. Any part

that is damaged should be properly repaired or replaced by a qualified technician. Do

not use the tool if any switch does not turn On and Off properly.

16. Guard against electric shock. Prevent body contact with grounded surfaces such as

pipes, radiators, ranges, and refrigerator enclosures.

17. Replacement parts and accessories. When servicing, use only identical

replacement parts. Use of any other parts will void the warranty. Only use accessories

intended for use with this tool. Approved accessories are available from Harbor Freight

Tools.

18. Do not operate tool if under the influence of alcohol or drugs. Read warning

labels on prescriptions to determine if your judgment or reflexes are impaired while

taking drugs. If there is any doubt, do not operate the tool.

19. Avoid causing fires. When sanding metals remove dust collecting bags and hoses

from the machine. Sparks or hot metal could start a fire. Clean all wood dust before

and after sanding metal.

SKU 40643 For technical questions, please call 1-800-444-3353. Page 3

Page 4

20. Avoid flammable liquids. To avoid possible fires, never use sander near flammable

liquids, vapors, or gases.

21. Avoid breathing dust. Wear a dust mask over your mouth and nose.

Note: Performance of this tool may vary depending on variations in local

line voltage. Extension cord usage may also affect tool performance.

Warning: The warnings, cautions, and instructions discussed in this instruction manual cannot cover all possible conditions and situations that

may occur. It must be understood by the operator that common sense and

caution are factors which cannot be built into this product, but must be

supplied by the operator.

Unpacking

When unpacking, check to make sure the tool is assembled and all parts present. Refer to

the Assembly Drawing at the end of this manual. If any parts are missing or broken, please

call Harbor Freight Tools at the number on the cover of this manual as soon as possible.

Using Extension Cords

When using extension cords, they must have a minimum wire size depending on the amperage of the tool and the length of the extension cord. This size is signified by its AWG rating;

the smaller the gauge, the greater the cable’s capacity. The extension cord must have a

grounding prong. For this Belt Sander, use an extension cord rated at 16 AWG for lengths up

to 50 feet.

Assembly

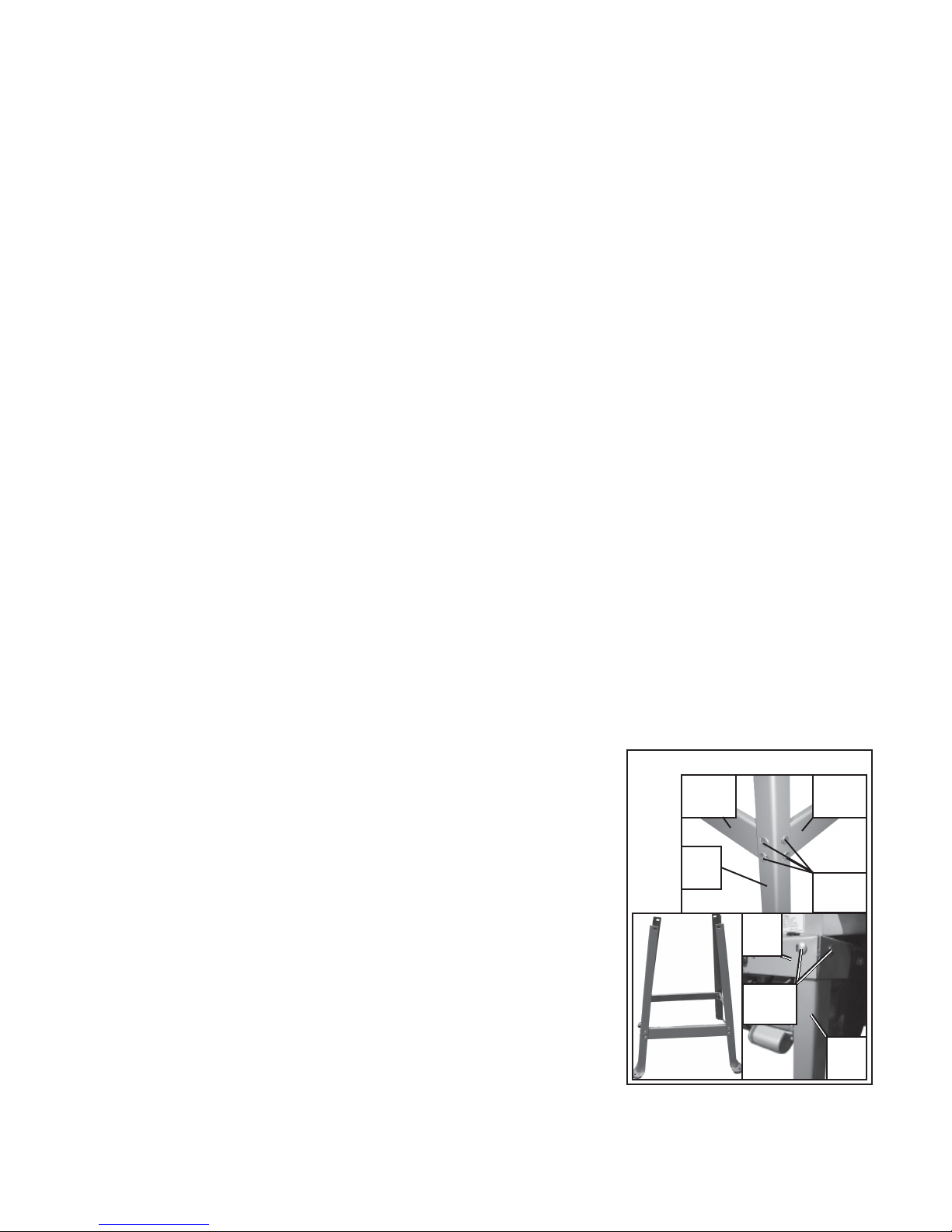

Stand Assembly

1. Join each Leg (74) to both a short Frame (75) and a long

Frame (76) using 4 Screws (73), Nuts (12), and Washers

(13), as shown in Stand Assembly A. The two short

Frames should be on opposite sides from each other

giving the stand a rectangular shape, if viewed from the

top.

2. The Nuts should be snug and hold the stand together but

B

not be fully tightened yet- see Stand Assembly B.

Warning! This entire unit weighs 139 Lbs.

At least 2 able assistants should be

used to put this tool on its stand safely.

3. Have at least two assistants hold the Base (46) over the

stand. Line up one of the narrower ends of the stand with

one of the smaller ends of the Base (46) (for example, the end that the on/off switch is

located on.) Place the top of the Leg (74) under the corner of the Base, lining up the

SKU 40643 For technical questions, please call 1-800-444-3353. Page 4

Stand Assembly

Frame

(75)

Leg

(74)

A

Base

(46)

Screw

(73)

C

Frame

(76)

Screw

(73)

Leg

(74)

REV 01/04

Page 5

holes. Attach using 2 Screws (73), Nuts (12), and Washers (13). Repeat for all corners,

leaving all hardware snug, not tight. Once all hardware is in place, tighten all Nuts securely,

including the Nuts from step 1. After all hardware is secure, the assistants can release

the base.- see Stand Assembly C,

previous page.

Disc Sander Table Assembly

1. Remove both Trunnions (33) from the sides of the

Table (41), set the Screws (38) and Washers (13)

aside.

2. Place a Trunnion (33) on the side of the Disc

Cover (42) so that the groove on the underside

of the Trunnion fits over the Slide (35). Secure

with a Lock Handle (32) and Washer (13). Leave

the Lock Handle loose for now so the Trunnion

can still pivot. (See Table Assembly A.) Repeat

for the other side.

3. Place the Table (41) on top of both Trunnions (33)

lining up the bolt holes. Reattach the Table to

the Trunnions using the Screws (38) and Washers

(13) set aside in step 1. (See Table Assembly

B.) Level the table, as described in Leveling

Table Assembly below, and tighten all hardware.

Lock

Handle (32)

B

Trunnion

(33)

Screw (38)

and

Washer (13)

Table Assembly

Slide

(35)

Trunnion

(33)

A

Tabl e

(41)

Operation

Sanding Safety Tips

1. Always maintain a maximum of 1/16 inch clearance between the table and the

Sanding Belt or Disc.

2. Do not use the right side of the disc for sanding. The material could kick back.

3. Hold material securely while sanding to avoid kick back.

Leveling Table Assembly

During this and other procedures, refer to the photo on the next page and the Assembly

Drawing on the last page.

1. Place a combination square on the Table (41) so that it also touches the sanding Paper

(23).

If the Table is 90 degrees to the Pad, the square is flush on the Pad.

2. If the Table is not 90 degrees with the Pad, loosen the table angle Lock Handle (32)

and tilt the Table until the square is flush with the Pad.

REV 01/04

SKU 40643 For technical questions, please call 1-800-444-3353. Page 5

Page 6

3. Retighten the Knob to secure the table.

4. Loosen the pointer screw below the Lock Handle and adjust so that it points to 90

degrees. Retighten screw.

Lock Handle (32)

Pointer (39)

Adjusting the Sanding Belt

1. Turn the Belt Sander On.

If the belt looks like it was going to slide off either roller, the belt tracking needs to be

adjusted (described in the next step).

2. Loosen locking Knob (61).

3. Turn the tracking Knobs (66) on both sides of the Idle Roller (64) until the belts rides on

the center of the Idle Roller (64) and the Driving Roller (11).

4. Retighten the locking Knob (61).

Tracking Knobs (66)

Locking Knob (61)

Switch (49)

SKU 40643 For technical questions, please call 1-800-444-3353. Page 6

REV 12/00

Page 7

Adjusting the Sanding Belt for Vertical Operation

Caution: Never make adjustments to the Sander without first unplugging the line cord

from the electrical outlet.

1. Using a wrench, loosen Nut (12) until the Belt Frame (8) can be moved.

2. Push the Belt Frame to the desired angle (0 to 90 degrees). View Angle Scale.

3. Tighten Nut (12).

4. Begin sanding.

Belt Frame (8)

Angle Scale

Nut (12)

On/Off Switch

The locking On/Off Switch (49) needs to have the switch key inserted before the switch can

be used. This feature prevents unauthorized use of the sander. The Locking Switch operates

as follows.

1. Insert plastic Switch Key into locking Switch (49).

2. Press the Switch to the On position to start.

3. Press the Switch to the Off position to stop.

4. To lock switch in Off position, pull out the key and store in a secure place.

CAUTION: Never walk away from sander when the machine is running.

Always lock the switch in the Off position when not in use.

SKU 40643 For technical questions, please call 1-800-444-3353. Page 7

REV 09/00

Page 8

Maintenance

1. Apply a light coat of paste wax to the worktable to make feeding stock easier.

2. Use compressed air to blow out dust and debris from sander and motor.

Mounting Sanding Disc and Guard

1. Remove hardware surrounding Sanding Disc (22).

2. Locate Sanding Paper disc (23) and peel backing off paper disc.

3. Align perimeter of Sanding Paper (23) disc over Sanding Disc. When aligned, press

disc firmly onto disc.

4. Replace hardware and realign table.

Drive Belt Replacement

1. Using a Phillips screwdriver, remove the Screw (44) from Pulley Cover (47), and

remove cover.

2. Loosen Knob (14) to allow Motor Pulley (58) to shift enough to place V-Belt (25) around

it.

3. Place V-Belt around Pulley (26), then Motor Pulley (58).

4. Retighten Knob (14) finger tight.

5. Adjust tension of V-Belt by placing a standard screwdriver in the adjusting hole by

pushing up on the screwdriver to apply tension to the V-Belt.

6. Tighten the Knob (14) completely.

7. Grab the V-Belt with two fingers on the outside-center and squeeze. There should be

about 1/4 inch give to the V-Belt for proper tension.

NOTE: Too much tension on the V-Belt can load-down motor and cause

possible damage. If the V-Belt is loose, it may fail prematurely.

8. Replace Pulley Cover (47).

SKU 40643 For technical questions, please call 1-800-444-3353. Page 8

Page 9

Troubleshooting

MOTPMYSESUACELBABORPYDEMER

teltuollawotnideggulptoN

etarepotonseodrednaS

iwsrewoP

detresnitonyekgnikcoL

evitcefedhct

melborpgniriwrorotoM

thgitoottleBgnimiT

gnidnasnehwswolsrotoM

hcumootgniylppA

eceipkrownoerusserp

teltuollawotnigulP

yeKgnikcoLtresnI

hctiwsecalpeR

naicinhcetdeifilauqaotekaT

noisnetesaerceD

krowoterusserpsselylppA

gnidnasnehweceip

smurdffosnurtleBgnidnaSylreporpgnikcarttoNgnikcarttsujdA

gnidnaselihwsnrubdooW

T

evissecxesekamrednaS

esion

sitleBrocsiDgnidnaS

sirbedhtiwdedaol

thgitoottleBgnimi

liodeensgniraeB

noisnetesaerceD

sgniraebliO

tleBrocsiDecalperronaelC

PLEASE READ THE FOLLOWING CAREFULLY

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM IN THIS

MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER NOR DISTRIBUTOR

MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR

SHE IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE IS QUALIFIED TO REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR

DISTRIBUTOR EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD

BE UNDERTAKEN BY CERTIFIED AND LICENSED TECHNICIANS AND NOT BY THE BUYER.

THE BUYER ASSUMES ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO

THE ORIGINAL PRODUCT OR REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR

HER INSTALLATION OF REPLACEMENT PARTS THERETO.

SKU 40643 For technical questions, please call 1-800-444-3353. Page 9

Page 10

Parts List

traPnoitpircseDytQ

1revoC1

221-SgniRgniniateR9

3Z1026gniraeBllaB3

4tfahSrelloRgnivirD1

5tleBgnidnaS1

6X5yeK1

771SgniRgninia

8emarFtleB1

9petSkcaB1

0101x8MwercSteS3

11relloRgnivirD1

218MtuN03

318rehsaW05

4101x8MbonK3

51gniraeBllaB1

61RNgniraeBllaB1

7

1pilc-C1

8104x8MwercS2

91ediuGretiM1

02raBretiM1

1251x8MbonK1

22"21,csiDgnidnaS1

32"21,repaPgnidnaS1

42etalPrevoCcsiD1

52318At

62yelluP1

7201x8MwercSteS2

8252x8MwercS3

92droCrewoP1

0301x8MbonK1

138rehsaw-S2

23eldnaHkcoL3

33noinnurT3

43"4,niP6

53edilS3

6

3lebaLelgnA2

73elbaT1

8352x8MwercS31

teR1

leb-V1

traPnoitpircseDytQ

93retnioP3

04tekcarB1

14elbaT1

24revoCcsiD1

34etalPtroppuS1

4401x8MwercS01

5401x5MwercS01

64esaB1

74revoCyellu

P1

84xoBhctiwS1

94hctiwS1

05eveelScitsalP1

15dooHtsuD1

2521MtuN1

35esaBdooHtsuD1

45561x21MwercS1

55etalProtoM1

65tekcarBpUgnaH1

75r

85yelluProtoM1

95tfahS1

06yeK1

1651x8MbonKgnikcoL2

26etalPknarC2

36bonK1

46relloRreldI1

56reveL1

66bonKgnikcarT2

76gnirpS2

8652x

966MtuN2

076rehsaw-S2

17raBtnemtsujdA2

275x5MwercSteS1

3721x8MwercS42

47geL4

57emarF2

67emarF2

otoM1

6MwercSteS2

SKU 40643 For technical questions, please call 1-800-444-3353. Page 10

REV 12/00

Page 11

Assembly Drawing

NOTE: Some parts are listed and shown for illustration purposes only and are not available indi-

vidually as replacement parts.

SKU 40643 For technical questions, please call 1-800-444-3353. Page 11

Loading...

Loading...