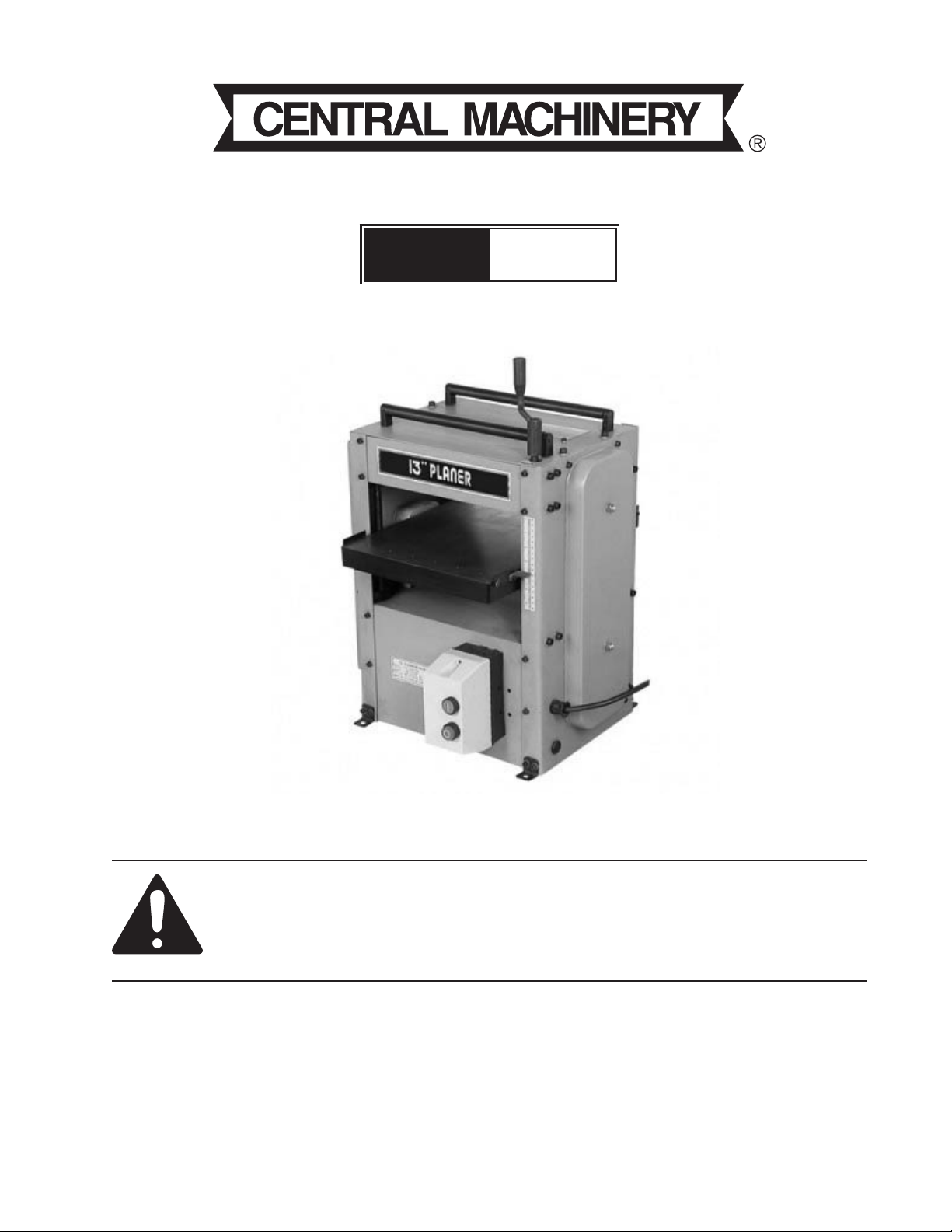

Central Machinery 39860 User Manual

13” INDUSTRIAL PLANER

Model

39860

ASSEMBLY AND OPERATING INSTRUCTIONS

Visit our website at: http://www.harborfreight.com

Read this material before using this product.

Failure to do so can result in serious injury.

SAVE THIS MANUAL.

Copyright© 1999 by Harbor Freight Tools®. All rights reserved. No portion of this manual or any artwork con-

tained herein may be reproduced in any shape or form without the express written consent of Harbor Freight

Tools. Diagrams within this manual may not be drawn proportionally. Due to continuing improvements, actual

product may differ slightly from the product described herein. Tools required for assembly and service may not

be included.

For technical questions or replacement parts, please call 1-800-444-3353.

Manual Revised 10h

THANK YOU for choosing a HARBOR FREIGHT TOOLS product. For future reference, please complete the

owner’s record below:

Model________ Serial No. Purchase Date

SAVE THE RECEIPT, WARRANTY AND THESE INSTRUCTIONS. It is important that you read the entire

manual to become familiar with the unit BEFORE you begin assembly.

Technical Specifications

Tool Name: 13” Industrial Planer

Item Number: 39860

Motor: 3 HP, 220 V~, 60 Hz, Single Phase, 3450 RPM

Cutter Head: 5200 RPM

Maximum Depth of Cut: 3/16”

Stock Capacity: 6-1/4” H x 13” W

Cutter Head: 2.289” Diameter

Feed Rate: 13 FPM

Blade Dimensions: 13-1/16” x .795” x .015”

Table Dimensions: 19” L x 12-1/8” W

Accessories: 8 mm - 10 mm Combination Wrench, 3 mm Hex Wrench,

5 mm Hex Wrench, 6 mm Hex Wrench

Warning: The warnings, cautions and instructions discussed in this instruction manual

cannot cover all possible conditions and situations that may occur. It must

be understood by the operator that COMMON SENSE AND CAUTION ARE

FACTORS WHICH CANNOT BE BUILT INTO THIS PRODUCT, BUT

MUST BE SUPPLIED BY THE OPERATOR.

The Operator

PLEASE REMEMBER:

Do not operate the product if under the influence of alcohol or drugs. Read warning labels on prescriptions to

determine if your judgment/reflexes might be impaired.

Do not wear loose clothing or jewelry as they can be caught in moving parts.

Protective gloves and non-skid footwear are recommended.

Wear restrictive hair covering to contain long hair.

Use eye and ear protection. Always wear ANSI-approved impact safety goggles and dust mask or respirator

when working around metal, wood and chemical dusts and mists. Wear a full face shield if your are producing

wood filings.

Always stand off to one side of the machine.

Do not reach over or across running machines.

Maintain proper footing and balance at all times.

Do not abuse the power cord. Do not yank on cord to disconnect it from outlet. Keep the cord away from

heat, oil and sharp edges.

REV 03d; 06b

For technical questions, please call 1-800-444-3353.

Page 2SKU 39860

Work Area

TO AVOID RISK OF PERSONAL INJURY, EQUIPMENT DAMAGE, FIRE AND SHOCK, MAKE SURE YOUR

WORK AREA IS:

Free of damp, wet or rainy conditions.

Free of children (never let them handle tools or machinery).

Well-lit, clean and uncluttered.

Before Operating

Before using any tool, any part that appears damaged should be carefully checked to determine that it will

operate properly and perform its intended function.

Before operating your Planer check for damaged parts. You should also check the feed rollers to be sure

chips and sawdust are not caught in them. If the Rollers are not seated firmly, the Feed Rolls will not hold the

stock firmly against the bed. This may result in kickback during operation.

Give the Planer a test run. If it makes an unfamiliar noise or vibrates irregularly, turn it off, unplug it and have

the problem corrected by a qualified technician.

Make certain to turn off and unplug the Planer when doing any maintenance. The tool should always be

turned off, unplugged when not in use and Guards kept in place and in working order.

Feed the work into the blade or cutter against the direction and rotation of the blade or cutter.

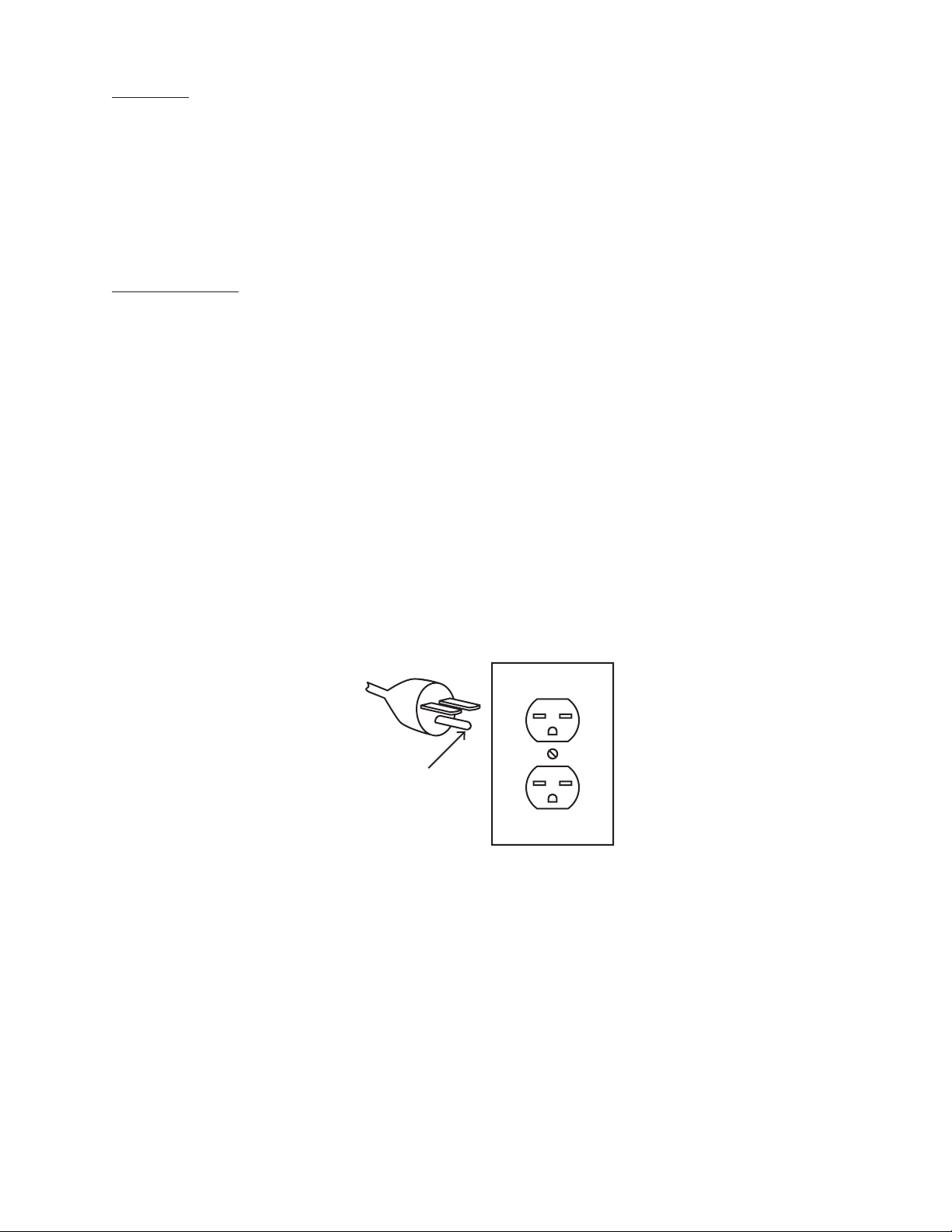

Grounding/Voltage Warning 220-240 V~ Tools

This 13” Industrial Planer is pre-wired for 220 Volts.

Grounding

Pin

250 V~ 3-Prong Plug and Outlet

(for up to 250 V~ and up to 15 A)

This tool is intended for use on a circuit that has an outlet that looks like the one illustrated above. The 1.

tool has a grounding plug that looks like the plug illustrated above in 250 V~ 3-Prong Plug and Outlet.

Make sure the tool is connected to an outlet having the same configuration as the plug. No adapter is

available or should be used with this tool. If the tool must be reconnected for use on a different type of

electric circuit, the reconnection should be made by qualified service personnel; and after reconnection,

the tool should comply with all local codes and ordinances.

The 250 V~ plug does not come pre-installed and will need to be installed by a certified electrician.2.

The plug above is for use on a 15 A circuit. A different 250 V~ plug and outlet combination may be 3.

used, provided it is rated to handle the electrical requirements of the tool and is installed by a certified

electrician.

DO NOT M O D I F Y Y O U R P L U G I N A N Y w A Y . IF Y O U H A V E A N Y D O U b T , C A L L A Q U A L I F I E D E L E C T R I C I A N .4.

For technical questions, please call 1-800-444-3353.

REV 10h

Page 3SKU 39860

Assembly

Your Planer requires only limited assembly as indicated below; otherwise it is fully assembled. To assist you

with assembly and operation please refer to the Assembly Diagram and Parts List located on pages 8,9,10

and 11. Lay out all parts onto a clear section of your workbench prior to assembly.

The Planer has four (4) legs so that it can be mounted to a table or a work bench. Each of these legs/1.

angles (4) should be attached at one side (bottom corners) to the Planer and then 2 of the 5/16” bolts

should be bolted onto the workbench with a washer between the Bolt and the workbench or table.

To put the Handle (part #150) onto the Planer, insert it into the hole on the right front side of the Planer 2.

and press it into place. WARNING! Check blade setting and tightness before initial use.

Operation

When operating your Planer, refer to the Parts List and Assembly Diagram on the last pages of this manual.

Never force the tool or attachment to do the work of a larger industrial tool. It is designed to do the job better

and more safely at the rate for which it was intended. Plane only wood boards.

After planing approximately 50 feet of material, stop machine and check Cutterhead Jib screws and blades for

tightness.

Do not force feed your work through the machine. Allow the Planer to feed at the designated rate of feed.

Step 1) Use the Height Adjusting Handle (part #150) to set the blade height. Set the height according

to the indicating scale on the Planer beneath the Handle.

Note: This Planer is specifically designed for the planing of lumber. Before planing any lumber,

check for any foreign materials such as nails, screws, or hard impurities in the wood. Also

check for loose knots in the wood. If not cleaned off these may cause damage to the blade or

machine. Never make a Planer cut deeper than 1/8”.

When feeding your lumber, use a Push Block to feed the lumber, rather than using your

hands. The Push Block must be thinner than 3 inches.

Step 2) The ON and OFF switch is located on the front of the Planer. Press the GREEN button to

START the Planer, and RED button to turn the Planer OFF.

Step 3) The planing depth of the planer is controlled by turning the Handle and setting the depth of

the Planer by the Ruler. The settings on the Ruler run from 0” to 6”.

Step 4) Feed lumber through Planer. After each planing, you can use the Roller Bars on top of the

planer to roll the workpiece back to the Feed position, rather than carrying it back and forth.

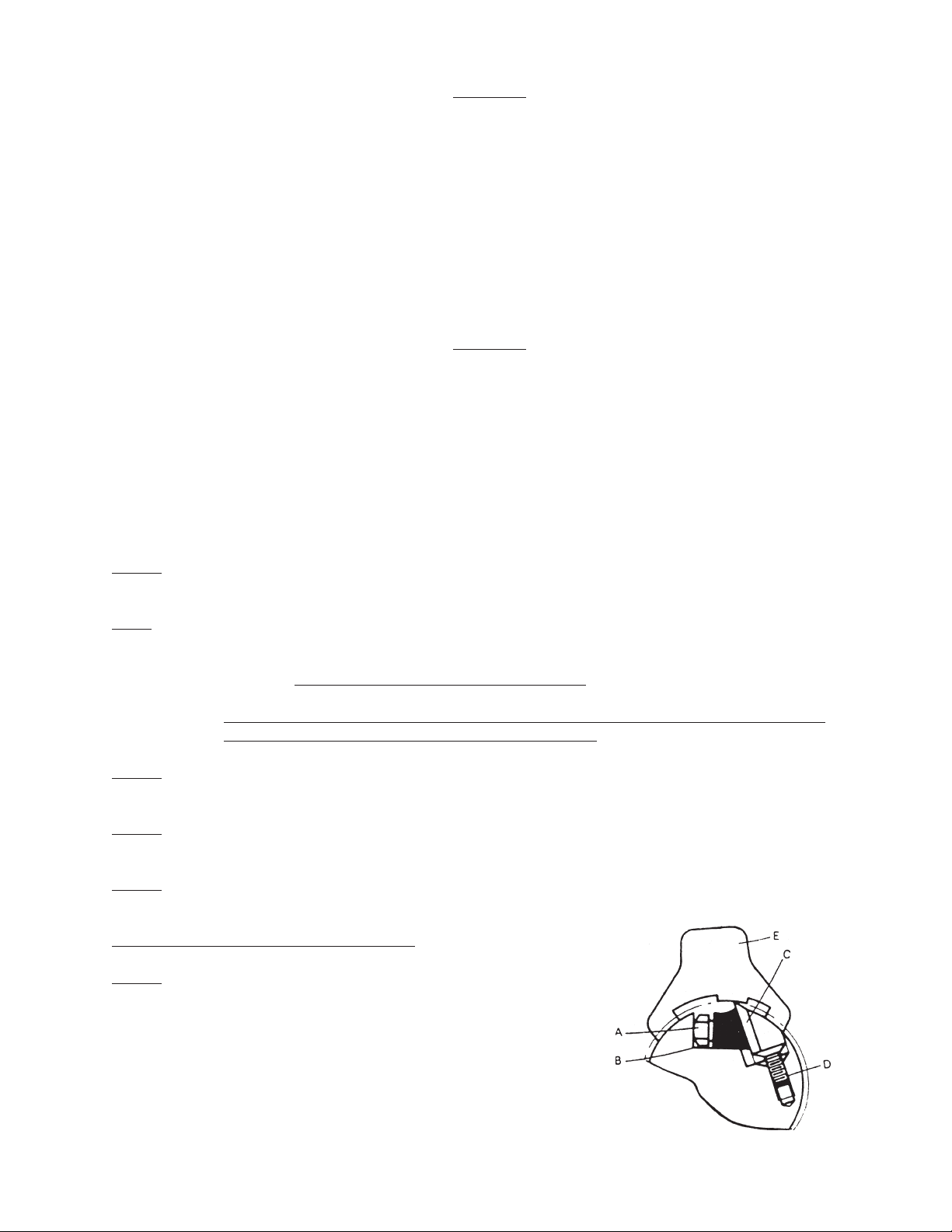

Checking the Knife Gauge for Proper Height

Step 1) Loosen all screws. Place the knife gauge as shown

in Figure 1 and Figure 2. Use the wrench key and the

turn screw (D) until the blade (C) touches the knife

gauge.

Figure 1

For technical questions, please call 1-800-444-3353.

REV 06a; 10h

Page 4SKU 39860

Loading...

Loading...