Centra CL-2 User manual

INSTRUCTION

MANUAL

IM-426

Revision 8

IEC Centra

INTERNATIONAL EQUIPMENT COMPANY

¨

CL2

Centra-CL2

Centrifuge

Cat. No. 426 -- For 120 VAC, 50/60 Hz

Cat. No. 427 -- For 240 VAC, 50/60 Hz

Table of Contents

1 INTRODUCTION.............................................................................................. 2

2 INSTALLATION................................................................................................ 3

3 OPERATION .................................................................................................... 4

3.1 Warnings and Cautions ............................................................................ 4

3.2 Opening The Cover .................................................................................. 4

3.3 Rotor Installation...................................................................................... 5

3.4 Starting And Stopping A Run.................................................................... 5

3.5 Rotor Removal.......................................................................................... 5

3.6 Balance..................................................................................................... 6

4 APPLICATIONS ............................................................................................... 7

4.1 Speed And Force Tables .......................................................................... 8

4.2 Derating Table for Dense Samples........................................................... 10

4.3 Chemical Resistance Table ...................................................................... 11

4.4 Compatible Processes For Decontamination............................................ 12

4.5 Nomograph ............................................................................................... 13

5 MAINTENANCE ............................................................................................... 14

5.1 Cleaning.................................................................................................... 14

5.2 Brush Replacement .................................................................................. 15

5.3 Fuse Replacement.................................................................................... 16

5.4 Cover Interlock Bypass............................................................................. 16

5.5 Calibration................................................................................................. 16

5.6 Power Cord Replacement......................................................................... 16

5.7 Warranty ................................................................................................... 17

5.8 Condition of Returned Equipment............................................................. 17

6 SPECIFICATIONS ........................................................................................... 18

7 SERVICE ......................................................................................................... 19

7.1 Warning Messages and Error Codes....................................................... 19

7.2 General ..................................................................................................... 19

7.3 Disassembly For Service .......................................................................... 20

7.4 Interlock .................................................................................................... 20

7.5 Timer PCB ................................................................................................ 21

7.6 Motor......................................................................................................... 21

7.7 Interlock PCB............................................................................................ 22

8 DRAWINGS ..................................................................................................... 23

IMPORTANT

This manual may not contain information on all changes that have occurred to the subject instrument since

the manual issue date. It was prepared for use by IEC authorized factory-trained service or dealer

personnel who are kept current through a program of service letters and bulletins and training seminars.

This manual contains

personal injury. It also contains

centrifuge or accessory equipment. Read this manual thoroughly before operating or servicing this

centrifuge.

Centra-CL2 Instruction Manual

warnings

against operating procedures which could result in an accident and/or

cautions

against procedures which could result in damage to your

1

1 INTRODUCTION

The IEC Centra-CL2 is a compact benchtop centrifuge designed for

multipurpose use in medical, industrial, and scientific laboratories.

There are two models:

• Cat. No. 426 for 120 V, 50/60 Hz

• Cat. No. 427 for 240 V, 50/60 Hz

The Centra-CL2 accommodates a wide variety of rotors, including fixed angle

and horizontal (swinging bucket). IEC AeroCarriers™ provide aerosol

containment along with autoclaveability. The CL2 can handle up to 300 ml

(801 rotor), and reach maximum speeds of up to 8500 rpm (841 fixed angle

rotor) and 3900 rpm (236 horizontal rotor).

Other important features of the CL2 are a cover interlock for safety, and a

'glove-friendly' membrane control panel with digital speed and time displays.

An 'At Speed' timer mode allowing for accurate separations, and a continuous

'hold' mode are also featured.

2

Centra-CL2 Instruction Manual

2 INSTALLATION

After unpacking, place the unit on a clean, level surface. The

surface must be level to ensure quiet, vibration-free operation. A

rigid, stable location is important since an improperly loaded unit can

vibrate or even move. Allow a space of 3 in. (7.6 cm) on each side and 4 in.

(10.2 cm) in the rear of the unit for ventilation. Ensure that the suction cup feet

grip the surface firmly.

Using a voltmeter, measure the line voltage to ensure it is within the limits for

your model. For Cat. No. 426 the line voltage should be between 108 and 132

VAC. For Cat. No. 427 the line voltage should be between 216 and 264 VAC.

Variations in line voltage or frequency will affect the unit’s speed and

acceleration.

Before moving, unplug the centrifuge and remove all accessories and the rotor.

Clearance Envelope International Electrotechnical Commission standard 1010 part 2-20 limits

the permitted movement of a laboratory centrifuge to 300mm in the event of a

disruption. The user should therefore mark the clearance envelope boundary

around the centrifuge, or laboratory management procedures should require

that no person or any hazardous materials are within such a boundary while

the centrifuge is operating.

Centra-CL2 Instruction Manual

3

3.1 Warnings and Cautions

Warnings To Avoid Electric Shock:

• Plug the power cord into a grounded outlet.

• Never remove the grounding prong from the power plug, or use any

adapter which does not complete the grounding circuit.

3 OPERATION

• Always unplug the power cord before attempting to clean or service

Cautions

• DO NOT exceed maximum rated speed for each rotor/accessory

• Samples of specific gravity higher than 1.2 require the maximum

• Ensure that loads are properly balanced around the rotor to minimize

• Do not block the vents, otherwise, airflow will be restricted.

• Be sure the rotor and accessories are properly installed before

3.2 Opening The Cover

Once the red light over the STOP button is steadily illuminated (no longer

flashing) pressing the COVER OPEN button on the control panel will release

STOP/COVER

OPEN

the interlock, allowing the cover to be opened.

the centrifuge.

combination. Maximum speeds can be found in Section 4.1 Speed

And Force Tables. All IEC rotors and accessories are stamped with

their cat. no. for easy identification.

speed to be derated.

vibration. All IEC accessories are stamped with their weight for easy

balancing.

attempting to start a run.

4

Centra-CL2 Instruction Manual

3.3 Rotor Installation

When the unit has power, the red light over the STOP button is illuminated.

This is also an indication that the rotor is stopped and the cover can be

opened. Push the COVER OPEN lever to the right and lift the cover. Lower

the rotor straight onto the shaft. Screw the knurled metal locking nut

(clockwise) onto the shaft to hold the rotor down (on some rotors, you must

remove any sample tubes first.). Tighten the nut with your fingers; do not use a

tool.

Rotors with or without a keyway can be used on the Centra-CL2 since there is

no key on the shaft.

3. 4 Starting And Stopping A Run

To start a run, use the ARROW buttons to set the desired run time (0 to 30

minutes) in the TIME display, and the desired rpm in the SPEED display.

Press the START button. The green light under the START button will

illuminate, and the time display will begin counting down. The actual speed is

ARROW

displayed in the SPEED display. The centrifuge will run for the set duration

and decelerate to a stop. To terminate a run before time expires, press the

STOP button. The red light over the STOP button illuminates when STOP is

pressed or time expires, and it flashes until the rotor comes to a stop.

TIME

SPEED

START

STOP

3.5 Rotor Removal

Note: The cover may be opened when the rotor speed is below 20 RPM.

The time and speed settings cannot be changed during a run. A new run

cannot be started until the rotor has come to a complete stop.

For infinite spins (hold mode), use the arrow keys to scroll up past 30 minutes.

The word 'HOLD' appears in the display. Pressing the START button will begin

a run which can only be terminated by pressing the STOP button. In the hold

mode, the timer counts up.

To select the timing mode, use the arrow buttons to scroll down past 0

seconds. The letters 'Spd' or 'Acc' will appear. Press the arrow buttons to

toggle between the two timing modes. 'Spd' is the 'At Speed' timing mode

where the timer starts counting down when rotor reaches 95% of set speed.

'Acc' is the normal timing mode where the timer begins to count down as soon

as the run button is pressed.

To remove a rotor, first remove any sample tubes, shields, and other

accessories from the rotor. Next, unscrew (counterclockwise) approximately

one full turn the knurled locking nut. Then place both thumbs on the knurled

locking nut and grip the rotor with the fingers. Push your thumbs down and at

the same time pull the rotor up with your fingers. This should dislodge the rotor

from the shaft. If unsuccessful, lightly tap the knurled metal locking nut with a

rubber/plastic mallet or other similar object. The nut and the rotor can now be

removed from the shaft.

Centra-CL2 Instruction Manual

5

3.6 Balance

A balanced load is essential with all centrifuges. An unbalanced load

produces vibration and can damage the unit. A 2-gram load imbalance, at a

speed of 4600 rpm, imparts force equivalent to 9.1 kg at rest (20 pounds).

Therefore, always ensure that the rotor is loaded symmetrically and with a full

(or paired) set of tubes. Tube adapters should also be installed

symmetrically.

IEC rotors are dynamically balanced at the factory. IEC matches removable

parts (trunnion rings, shields, cups and carriers) to within 1 gram and stamps

the weight on each piece. Check these markings whenever you interchange

parts, to ensure that opposite parts are matched. Ensure that the total weight

of samples and removable parts loaded in opposing positions are equal in

weight to within 1 gram. The position numbers, present on many rotors and

adapters, identify opposing tube positions.

To obtain good dynamic balance, the opposite loads must not only be equal in

mass, but must also have the same center of gravity. Opposing containers

must be alike in shape, thickness, and distribution of glass or plastic. This is

especially important for large containers.

Tubes loaded into swinging bucket rotors must likewise be symmetric around

the axis of rotation. Verify this by rotating the entire rotor 180° by hand: the

loads should be in the same apparent positions (not in the mirror image). In

addition, the loads within each bucket must also be symmetric around the

bucket’s pivot axis. Verify this by ensuring that each bucket is loaded so that

it does not tilt from the vertical when the rotor is at rest. Maintaining balance

within each bucket ensures that the bucket and the tubes swing out to

horizontal when the rotor reaches operating speed, applying centrifugal force

toward the bottom of the tubes. Failure to achieve full swing-out causes

vibration and premature wear.

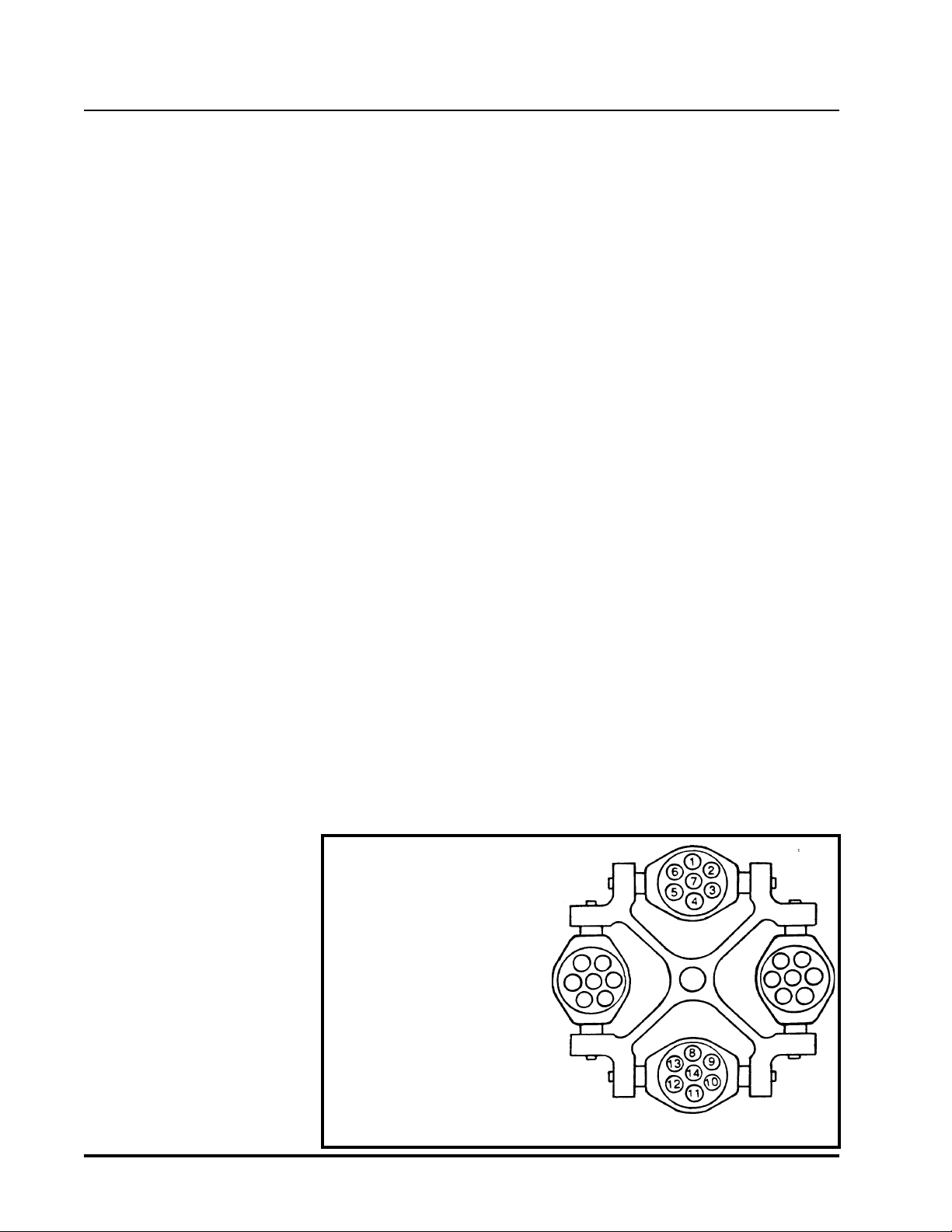

Samples of different specific gravities can be processed in the same run,

provided that the samples of a given type are balanced around the rotor as

though they were the only ones in the rotor.

For example, load tubes in the

following manner:

1. Load four tubes.

Positions 3, 6, 10, 13

or 2,5,9,12

or 1,4,8,11

2. Load six tubes.

Positions 6,7,3,13,14,10

or 5,7,2,12,14,9

or 1,7,4,8,14,11

3. Load an odd number of tubes.

Not recommended (unless a

dummy tube is used for balance.)

6

Centra-CL2 Instruction Manual

4 APPLICATIONS

This section describes the use of specific rotors and accessories. More

detailed information is often shipped with the rotor or accessory itself. This

section contains four reference tables:

4.1 Speed And Force Table

4.2 Derating Table for Dense Samples

4.3 Chemical Resistance Table

4.4 Decontamination Table

4.5 Nomograph

Relative centrifugal force (RCF or G-force) at a given speed varies with the

rotor, and with the length of the sample tube, because the distance of the

tube’s tip from the center of rotation is different. The Speed and Force Table

indicates the maximum speed and RCF the Centra-CL2 can achieve with

various rotor/accessory combinations.

The Derating Table specifies reductions in rpm when spinning samples with

specific gravity above 1.2.

Misapplication of any tube can cause tube rupture. To avoid this, compare the

G forces specified in the Speed and Force Table with the ratings for the tubes

you are using. If the tubes are not rated for the force the centrifuge will apply,

reduce the speed to the G force limit of your tubes.

Your IEC centrifuge is made of materials designed to resist attack from most

laboratory chemicals. The interior of the rotor chamber is Painted steel.

Rotors and accessories placed in the chamber are made of a variety of

materials, including aluminum and polypropylene. The Chemical Resistance

Table shows the suitability of each material with different classes of reagents.

The Decontamination Table lists compatible methods of decontamination

which may be used on the IEC Centra-CL2 centrifuge.

The Nomograph provides an easy method of converting RPM to RCF (or xg).

Section 5.1 describes how to clean and remove corrosion from the chamber,

rotors, and accessories. Follow these instructions, and clean spills promptly,

to minimize the effects of corrosive chemicals, before any resulting chemical

attack requires more expensive repair. Replace metal locking nut, rotors, or

accessories if they become cracked, deformed, or gouged.

Centra-CL2 Instruction Manual

7

Loading...

Loading...