Page 1

A FLEXIBLE IMAGING PLATFORM

AT AN AFFORDABLE PRICE

Superior flat-field, coma-free imaging

by the Celestron Engineering Team

Ver. 04-2013, For release in April 2013.

Page 2

The Celestron EdgeHD A Flexible

Imaging Platform at an Affordable Price

By the Celestron Engineering Team

ABSTRACT:

The Celestron EdgeHD is an advanced, flat-field, aplanatic

series of telescopes designed for visual observation and imaging

with astronomical CCD cameras and full-frame digital SLR

cameras. This paper describes the development goals and

design decisions behind EdgeHD technology and their practical

realization in 8-, 9.25-, 11-, and 14-inch apertures. We include

cross-sections of the EdgeHD series, a table with visual and

imaging specifications, and comparative spot diagrams for

the EdgeHD and competing “coma-free” Schmidt-Cassegrain

designs. We also outline the construction and testing process for

EdgeHD telescopes and provide instructions for placing sensors

at the optimum back-focus distance for astroimaging.

1. INTRODUCTION

The classic Schmidt-Cassegrain telescope (SCT) manufactured

by Celestron served an entire generation of observers and astrophotographers. With the advent of wide-field and ultra-wide-field

eyepieces, large format CCD cameras, and full frame digital SLR

cameras, the inherent drawbacks of the classic SCT called for a

new design. The EdgeHD is that new design. The EdgeHD offers clean, diffraction-limited images for high power observation

of the planets and the Moon. As an aplanatic, flat-field astrograph, the EdgeHD’s optics provide tight, round, edge-to-edge

star images over a wide, 42mm diameter flat field of view for

stunning color, monochrome, and narrow-band imaging of deep

sky objects.

2. SETTING GOALS FOR THE EDGEHD TELESCOPE

The story of the EdgeHD began with our setting performance

goals, quality goals, and price goals. Like the classic SCT, the

new Celestron optic would need to be light and compact.

Optically, we set twin goals. First, the new telescope had to

be capable of extraordinary wide-field viewing with advanced

eyepiece designs. Second, the optic had to produce sharp-tothe-edge astrophotography with both digital SLR cameras and

astronomical CCD cameras. Finally, we wanted to leverage

Celestron’s proven ability to manufacture high-performance

telescopes at a consumer-friendly price point. In short, we sought

to create a flexible imaging platform at a very affordable price.

Given an unlimited budget, engineering high-performance optics

is not difficult. The challenge Celestron accepted was to

control the price, complexity, and cost of manufacture without

compromising optical performance. We began with a comprehensive review of the classic SCT and possible alternatives.

Our classic SCT has three optical components: a spherical

primary mirror, a spherical secondary mirror, and a corrector plate

with a polynomial curve. As every amateur telescope maker and

professional optician knows, a sphere is the most desirable

optical figure. In polishing a lens or mirror, the work piece moves

over a lap made of optical pitch that slowly conforms to the glass

surface. Geometrically, the only surfaces that can slide freely

against one another are spheres. Any spot that is low relative to

the common spherical surface receives no wear; any spot that is

higher is worn off. Spherical surfaces result almost automatically.

A skilled optician in a well-equipped optical shop can reliably

produce near-perfect spherical surfaces. Furthermore, by

comparing an optical surface against a matchplate—a precision

reference surface—departures in both the radius and sphericity

can be quickly assessed.

In forty years of manufacturing its classic Schmidt-Cassegrain

telescope, Celestron had fully mastered the art of making

large numbers of essentially perfect spherical primary and

secondary mirrors.

In addition, Celestron’s strengths included the production of

Schmidt corrector plates. In the early 1970s, Tom Johnson,

Celestron’s founder, perfected the necessary techniques.

Before Johnson, corrector plates like that on the 48-inch

Schmidt camera on Palomar Mountain required many long

hours of skilled work by master opticians. Johnson’s innovative

production methods made possible the volume production of a

complex and formerly expensive optical component, triggering

the SCT revolution of the 1970s.

For more than forty years, the SCT satisfied the needs of

visual observers and astrophotographers. Its performance

resulted from a blend of smooth spherical surfaces and

Johnson’s unique method of producing the complex curve

on the corrector with the same ease as producing spherical

surfaces. As the 21st century began, two emerging technologies

—wide-field eyepieces and CCD cameras—demanded highquality images over a much wider field of view than the classic SCT could provide. Why? The classic SCT is well-corrected

optically for aberrations on the optical axis, that is, in the exact

center of the field of view. Away from the optical axis, however,

its images suffer from two aberrations: coma and field curvature.

Coma causes off-axis star images to flare outward; field curvature

causes images to become progressively out of focus away from

the optical axis. As wide-field eyepieces grew in popularity, and

as observers equipped themselves with advanced CCD cameras,

the classic SCT proved inadequate. To meet the requirements of

observers, we wanted the new Celestron optic to be both free of

coma and to have virtually zero field curvature.

2 I The Celestron EdgeHD

Page 3

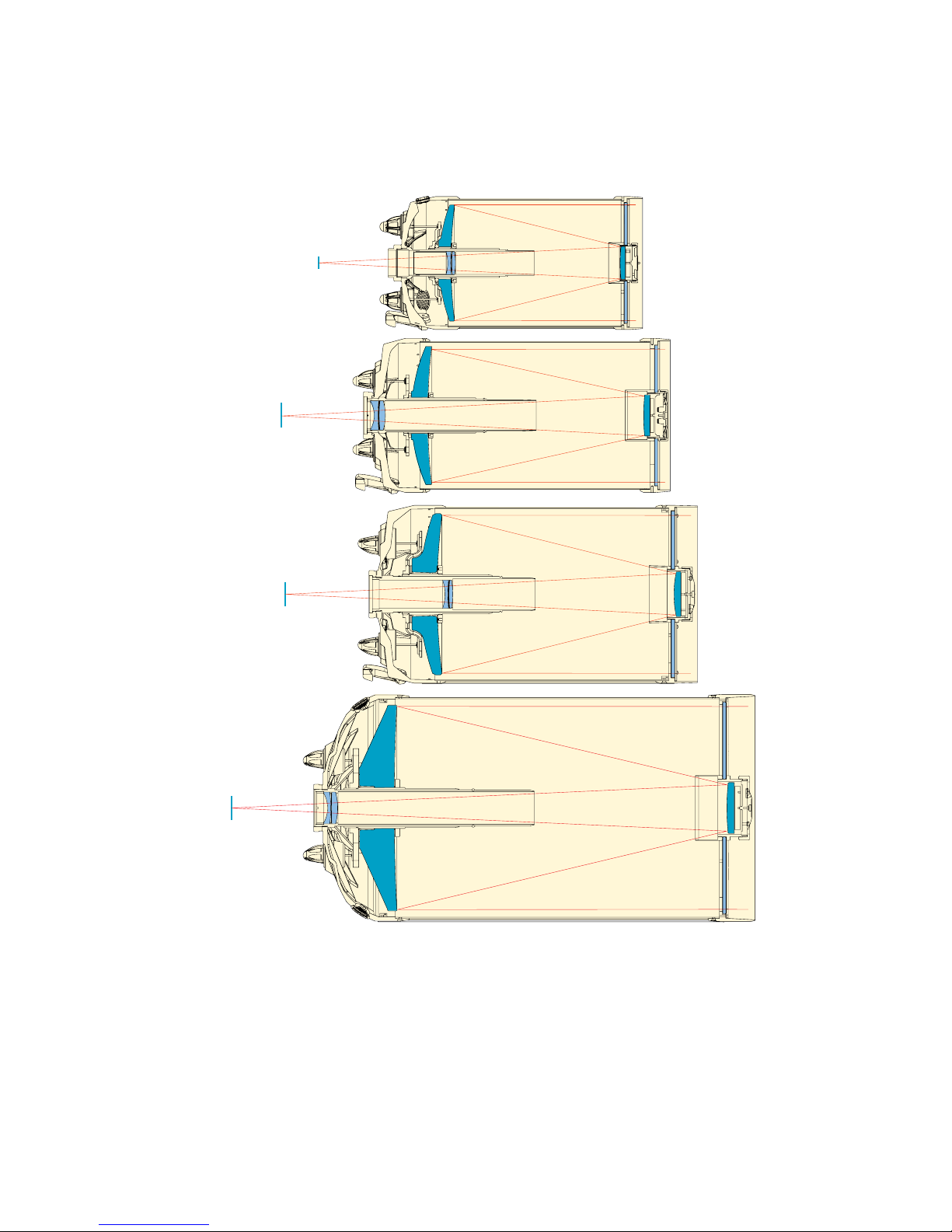

EdgeHD Series

Edge HD 800

Edge HD 925

Edge HD 1100

Edge HD 1400

FIGURE 1. Celestron’s EdgeHD series consists of four aplanatic telescopes with 8-, 9.25-, 11-, 14-inch apertures. The optical design

of each instrument has been individually optimized to provide a flat, coma-free focal plane. Each EdgeHD optic produces sharp images

to the edge of the view with minimal vignetting.

The Celestron EdgeHD 3

Page 4

OPTICAL ABERRATIONS

For those not familiar with the art of optical design, this brief

primer explains what aberrations are and how they appear in a

telescopic image.

OFF-AXIS COMA

Coma is an off-axis aberration that occurs when the rays from

successive zones are displaced outward relative to the principal

(central) ray. A star image with coma appears to have wispy “hair”

or little “wings” extending from the image. In a coma-free optical

system, rays from all zones are centered on the (central) ray, so

stars appear round across the field

FIELD CURVATURE

Field curvature occurs when the best off-axis images in an optical

system focus ahead or behind the focused on-axis image. The

result is that star images in the center of the field of view are

sharp, but off-axis images appear more and more out of focus. A

telescope with no field curvature has a “flat field,” so images are

sharp across the whole field of view.

SPHEROCHROMATISM

In the Schmidt-Cassegrain, spherochromatism is present, but

not deleterious in designs with modest apertures and focal

ratios. It occurs because the optical “power” of the Schmidt

corrector plate varies slightly with wavelength. Only in very large

apertures or fast SCTs does spherochromism become a problem.

3. ENGINEERING A NEW ASTROGRAPH

We did not take lightly the task of improving the classic SCT. Its

two spherical mirrors and our method of making corrector lenses

allowed us to offer a high-quality telescope at a low cost. We

investigated the pros and cons of producing a Ritchey-Chrétien

(R-C) Cassegrain, but the cost and complexity of producing its

hyperbolic mirrors, as well as the long-term disadvantages of

an open-tube telescope, dissuaded us. We also designed and

produced two prototype Corrected Dall-Kirkham (CDK)

telescopes, but the design’s ellipsoidal primary mirror led

inevitably to a more expensive instrument. While the R-C and

CDK are fine optical systems, we wanted to produce equally fine

imaging telescopes at a more consumer-friendly price.

As we’ve already noted, our most important design goal for the

new telescope was to eliminate coma and field curvature over

a field of view large enough to accommodate a top-of-theline, full-frame digital SLR camera or larger astronomical CCD

camera. This meant setting the field of view at 42 mm in

diameter. Of course, any design that would satisfy the

full-frame requirement would also work with the less expensive

APS-C digital SLR cameras (under $800) and less expensive

astronomical CCD cameras (under $2,000). There are several

ways to modify the classic SCT to reduce or eliminate coma.

Unfortunately, these methods do not address the problem of field

curvature. For example, we could replace either the spherical

primary or secondary with an aspheric (i.e., non-spherical)

mirror. Making the smaller secondary mirror into a hyperboloid

was an obvious choice. Although this would have given us a

coma-free design, its uncorrected field curvature would leave

soft star images at the edges of the field. We were also

concerned that by aspherizing the secondary, the resulting

coma-free telescopes would potentially have zones that would

scatter light and compromise the high-power definition that

visual observers expect from an astronomical telescope.

Furthermore, the aspheric secondary mirror places demands

on alignment and centration that often result in difficulty

maintaining collimation.

The inspiration for the EdgeHD optics came from combining

the best features of the CDK with the best features of the

classic SCT. We placed two small lenses in the beam of light

converging toward focus and re-optimized the entire telescope

for center-to-edge performance. In the EdgeHD, the primary and

secondary mirrors retain smooth spherical surfaces, and the

corrector plate remains unchanged. The two small lenses do

the big job of correcting aberrations for a small increment in

cost to the telescope buyer. Furthermore, because it retains key

elements of the classic SCT, the EdgeHD design is compatible

with the popular Starizona Hyperstar accessory.

4 I The Celestron EdgeHD

Page 5

THE OPTICAL PERFORMANCE OF THE EDGEHD COMPARED TO OTHER SCTS

CLASSIC SCT

“COMA-FREE” SCT

EDGEHD

100 μm

On-Axis 5.00 mm 10.00 mm 15.00 mm 20.00 mm

Off-axis distance (millimeters)

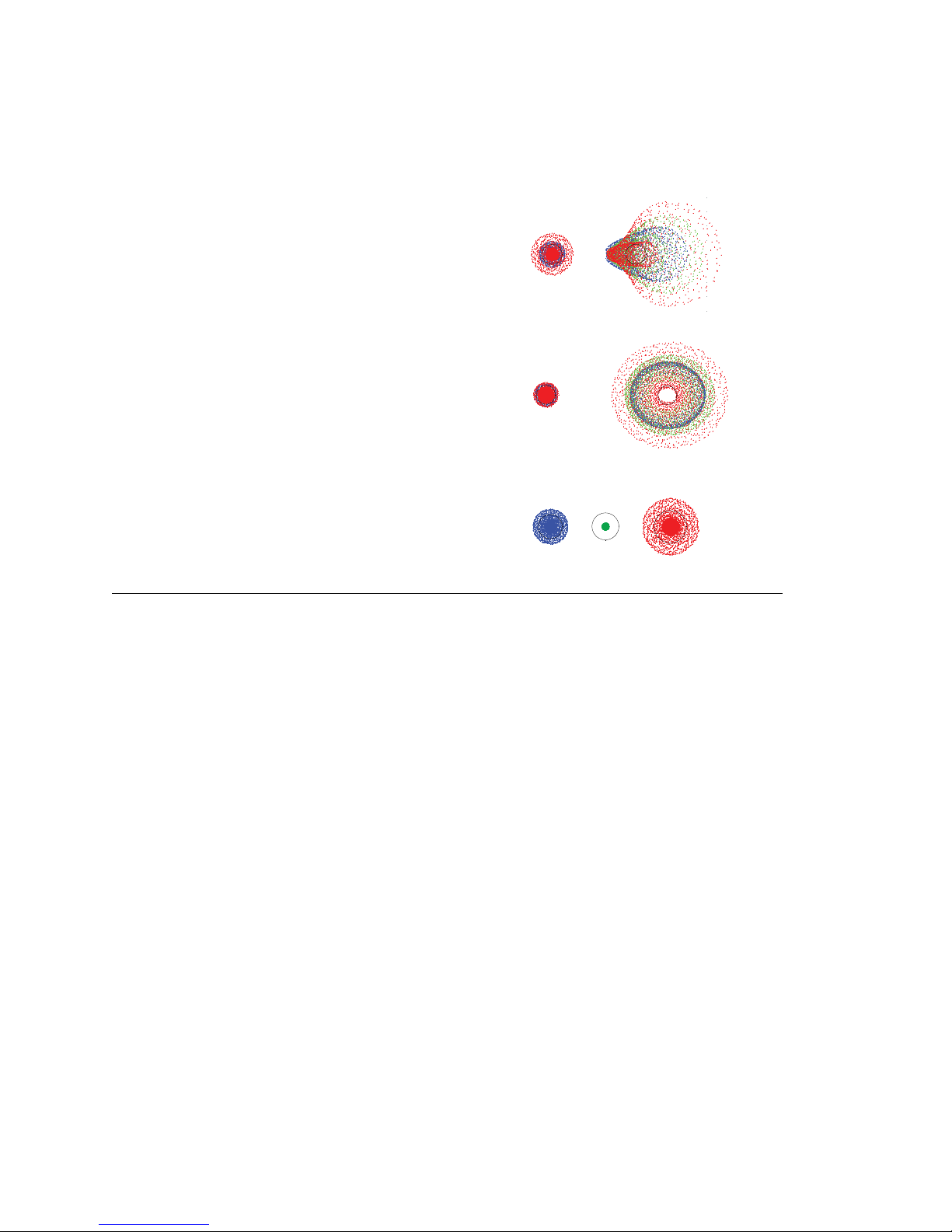

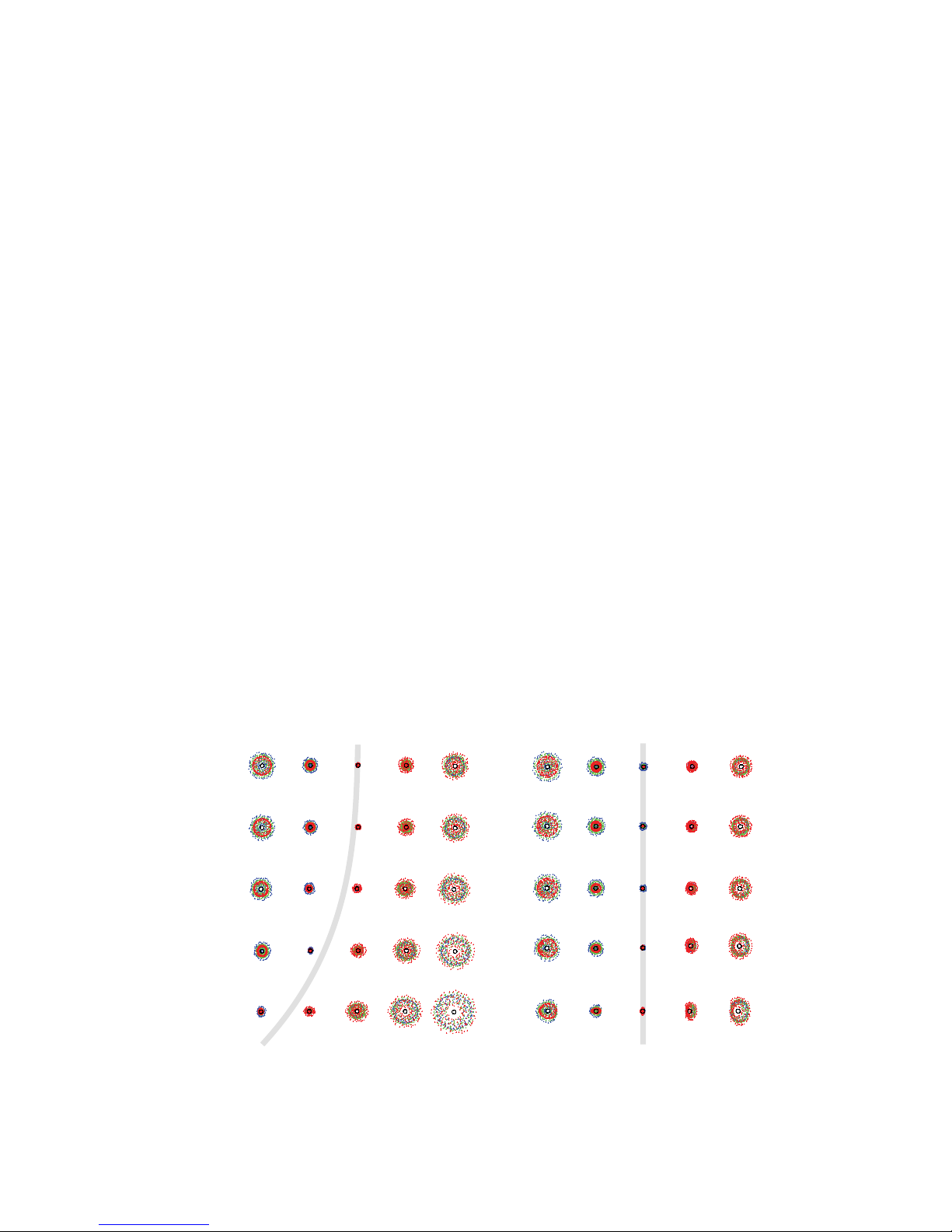

FIGURE 2. Matrix spot diagrams compare the center-to-edge optical performance of the classic SCT, “coma-free” SCT, and EdgeHD.

The EdgeHD clearly outperforms the other optical systems. The classic SCT shows prominent coma. The “coma-free” SCT is indeed

free of coma, but field curvature causes its off-axis images to become diffuse and out of focus. In comparison, the EdgeHD’s spot pattern

is tight, concentrated, and remains small from on-axis to the edge of the field.

The Celestron EdgeHD 5

Page 6

4. OPTICAL PERFORMANCE OF THE EDGEHD

Optical design involves complex trade-offs between optical

performance, mechanical tolerances, cost, manufacturability, and

customer needs. In designing the EdgeHD, we prioritized optical

performance first: the instrument would be diffraction-limited on

axis, it would be entirely coma-free, and the field would be flat

to the very edge. (Indeed, the name EdgeHD derives from our

edge-of-field requirements.)

Figure 2 shows ray-traced spot diagrams for the 14-inch

aperture classic SCT, coma-free SCT, and EdgeHD. All three are

14-inch aperture telescopes. We used ZEMAX

optical ray-trace software to design the EdgeHD and produce

these ray-trace data for you.

Each spot pattern combines spots at three wavelengths: red

(0.656µm), green (0.546µm), and blue (0.486µm) for five field

positions: on-axis, 5mm, 10mm, 15mm, and 20mm off-axis

distance. The field of view portrayed has diameter of 40mm—

just under the full 42mm image circle of the EdgeHD—and

the wavelengths span the range seen by the dark-adapted

human eye and the wavelengths most often used in deep-sky

astronomical imaging.

In the matrix of spots, examine the left hand column. These are

the on-axis spots. The black circle in each one represents the

diameter of the Airy disk. If the majority of the rays fall within

the circle representing the Airy disk, a star image viewed at

high power will be limited almost entirely by diffraction, and is

therefore said to be diffraction-limited. By this standard, all three

SCT designs are diffraction-limited on the optical axis. In each

case, the Schmidt corrector removes spherical aberration for

green light. Because the index of refraction of the glass used in

the corrector plate varies with wavelength, the Schmidt corrector

allows a small amount of spherical aberration to remain in red

and blue light. This aberration is called spherochromatism, that

is, spherical aberration resulting from the color of the light. While

the green rays converge to a near-perfect point, the red and

blue spot patterns fill or slightly overfill the Airy disk. Numerically,

the radius of the Airy disk is 7.2µm, (14.4µm diameter) while the

root-mean-square radius of the spots at all three wavelengths is

5.3µm (10.6µm diameter). Because the human eye is considerably

more sensitive to green light than it is to red or blue, images in

the eyepiece appear nearly perfect even to a skilled observer.

Spherochromatism depends on the amount of correction, or

the refractive strength, of the Schmidt lens. To minimize

spherochromatism, high-performance SCTs have traditionally

been ƒ/10 or slower. When pushed to focal ratios faster than

ƒ/10 (that is, when pushed to ƒ/8, ƒ/6, etc.) spherochromatism

increases undesirably.

Next, comparing the EdgeHD with the classic SCT and the

“coma-free” SCT, you can see that off-axis images in the classic

SCT images are strongly affected by coma. As expected, the

images in the coma-free design do not show the characteristic

comatic flare, but off-axis they do become quite enlarged. This is

the result of field curvature.

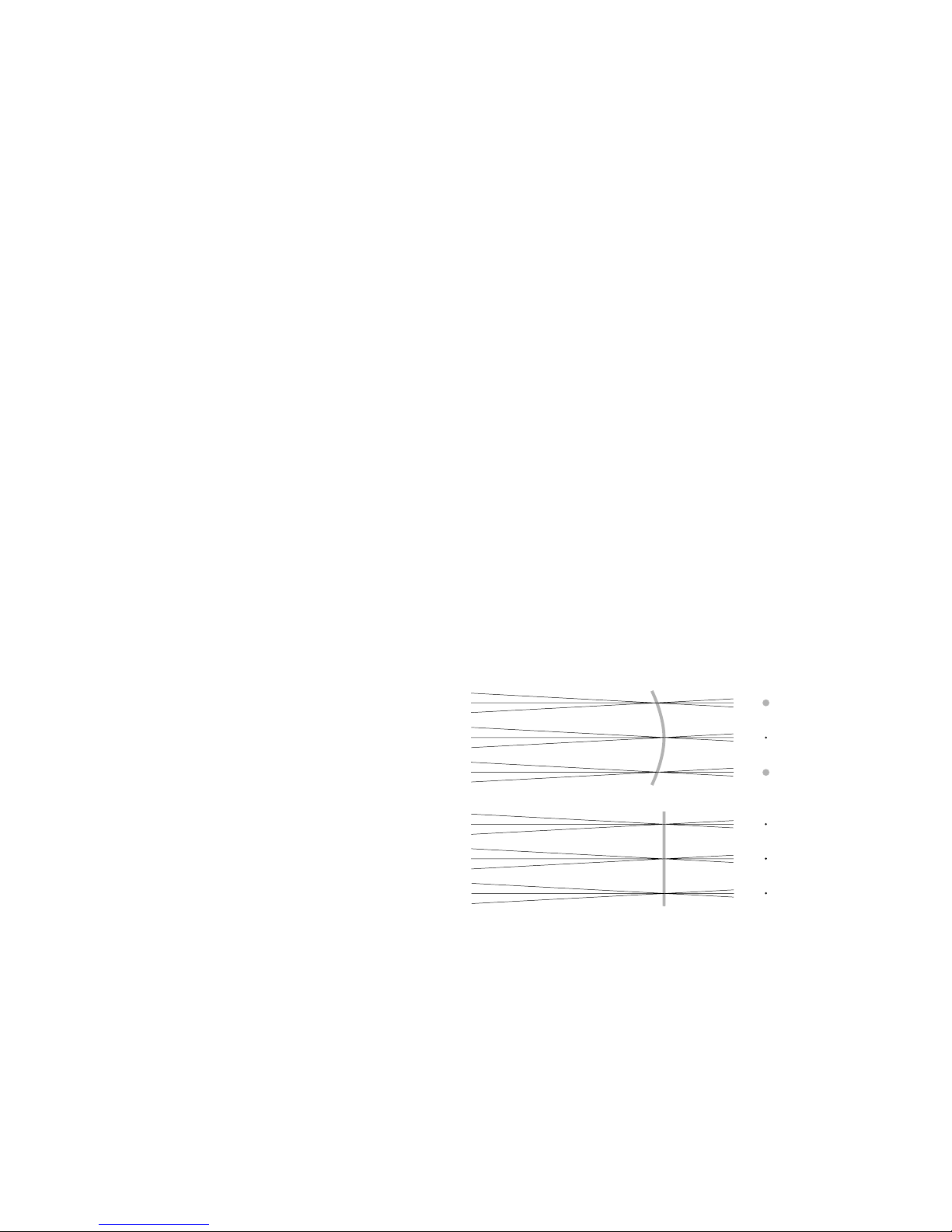

Figure 3 illustrates how field curvature affects off-axis images.

In an imaging telescope, we expect on-axis and off-axis rays

to focus on the flat surface of a CCD or digital SLR image

sensor. But unfortunately, with field curvature, off-axis rays come

to sharp focus on a curved surface. In a “coma-free” SCT, your

off-axis star images are in focus ahead of the CCD.

At the edge of a 40mm field, the “coma-free” telescope’s stars

have swelled to more than 100µm in diameter. Edge-of-field star

images appear large, soft, and out of focus.

®

professional

Meanwhile, at the edge of its 40mm field, the EdgeHD’s

images have enlarged only slightly, to a root-mean-square

radius of 10.5µm (21µm diameter). But because the green rays

are concentrated strongly toward the center, and because every

ray, including the faint “wings” of red light, lie inside a circle only

50µm in diameter, the images in the EdgeHD have proven to be

quite acceptable in the very corners of the image captured by a

full-frame digital SLR camera.

Field curvature negatively impacts imaging when you want

high-quality images across the entire field of view. Figures 4 and

5 clearly demonstrate the effects of field curvature in 8- and

14-inch telescopes. Note how the spot patterns change with

off-axis distance and focus. A negative focus distance means

closer to the telescope; a positive distance mean focusing

outward. In the EdgeHD, the smallest spots all fall at the same

focus position. If you focus on a star at the center of the field,

stars across the entire field of view will be in focus.

In comparison, the sharpest star images at the edge of the

field in the “coma-free” telescope come to focus in front of the

on-axis best focus. If you focus for the center of the image, star

images become progressively enlarged at greater distances. The

best you can do is focus at a compromise off-axis distance, and

accept slightly out-of-focus stars both on-axis and at the edge

of the field.

Any optical designer with the requisite skills and optical ray-tracing

software can, in theory, replicate and verify these results. The

data show that eliminating coma alone is not enough to guarantee

good images across the field of view. For high-performance

imaging, an imaging telescope must be diffraction-limited

on-axis and corrected for both coma and field curvature off-axis.

That’s what you get with the EdgeHD, at a very affordable price.

Field Curvature

Telescope with Field Curvature

Flat-Field Telescope

FIGURE 3. In an optical system with field curvature, objects

are not sharply focused on a flat surface. Instead, off-axis rays

focus behind or ahead of the focus point of the on-axis rays at

the center of the field. As a result, the off-axis star images are

enlarged by being slightly out of focus.

6 I The Celestron EdgeHD

Page 7

5. MECHANICAL DESIGN IMPROVEMENTS

To ensure that the completed EdgeHD telescope delivers the

full potential of the optical design, we also redesigned key

mechanical components. With classic SCT designs, for example,

an observer could bring the optical system to focus at different

back focus distances behind the optical tube assembly,

changing effective focal length of the telescope. This caused

on-axis spherical aberration and increased the off-axis

aberration. In the EdgeHD series, the back focus distance is

optimized and set for one specific distance. Every EdgeHD

comes equipped with a visual back that places the eyepiece

at the correct back focus distance, and our Large T-Adapter

accessory automatically places digital SLR cameras at the

optimum back focus position.

As part of the optical redesign, we placed the primary and

secondary mirrors closer than they had been in the classic SCT,

and designed new baffle tubes for both mirrors that allow a larger illuminated field of view.

To ensure full compatibility with the remarkable Starizona Hyperstar accessory that enables imaging at ƒ/1.9 in the EdgeHD 800

and ƒ/2.0 in the EdgeHD 925, 1100, and 1400, all EdgeHDs

have a removable secondary mirror.

Because it covers a wide field of view, the optical elements of

the EdgeHD must meet centering and alignment tolerances

considerably tighter than those of the classic SCT design. For

example, because the corrector plate must remain precisely

centered, we secure it with alignment screws tipped with soft

Nylon plastic. The screws are set on the optical bench during

assembly while we center the corrector plate. Once this

adjustment is perfect, the screws are tightened and sealed with

®

Loctite

to secure the corrector in position. This seemingly small

mechanical change ensures that the corrector plate and the

secondary mirror mounted on the corrector plate stay in

permanent optical alignment.

Centering the primary mirror is even more demanding. In

the classic SCT, the primary mirror is attached to a sliding

“focus” tube. When you focus the telescope, the focus knob

moves the primary mirror longitudinally. When you reverse the

direction of focus travel, the focus tube that carries the primary

can “rock” slightly on the baffle tube, causing the image to shift.

In the classic SCT, the shift does not significantly affect on-axis

image quality. However, in the EdgeHD, off-axis images could

be affected. Because the baffle tube carries the sub-aperture

corrector inside and the primary mirror on the outside, we

manufacture it to an extremely tight diametric tolerance.

The tube that supports the primary was redesigned with a

centering alignment flange, which contacts the optical (front)

surface of the primary mirror. When the primary mirror is assembled

onto the focus tube and secured with RTV adhesive, this small

mechanical change guarantees precise optical centration.

Following assembly, the focus tube carrying the primary is placed

in a test jig. We rotate the mirror and verify that the primary is

precisely squared-on to ensure that the image quality expected

from the optics is maintained.

In any optical system with a moveable primary mirror, focus

shift—movement of the image when the observer changes

focusing direction—has been an annoyance. In Celestron’s SCT

and EdgeHD telescopes, we tightened the tolerances. During

assembly and testing, we measure the focus shift; any unit with

more than 30 arcseconds focus shift is rejected and returned to

an earlier stage of assembly for rework.

In the classic SCT, astrophotographers sometimes experience

an image shift as the telescope tracks across the meridian. The

focus mechanism serves as one support point for the mirror. In

the EdgeHD, we added two stainless steel rods to the back of

the cell that supports the primary mirror. When the two mirror

clutches at the back of the optical tube assembly are engaged,

aluminum pins press against the stainless steel rods, creating

two additional stabilizing support points (see Figure 6).

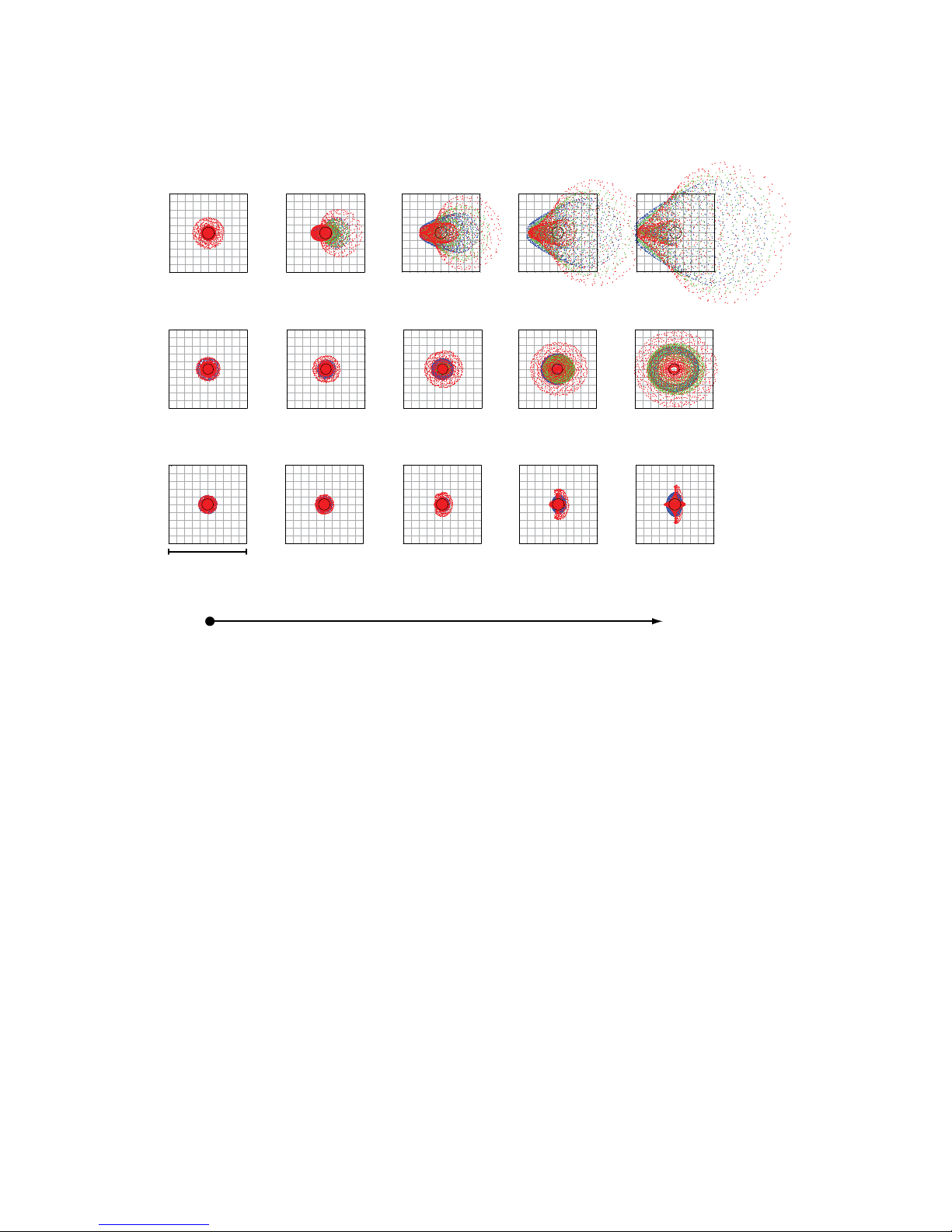

8” ƒ/10 Flat-Field EdgeHD8” ƒ/10 Coma-Free SCT

-0.8 mm -0.4 mm 0.0 mm +0.4 mm +0.8 mm-0.8 mm -0.4 mm 0.0 mm +0.4 mm +0.8 mm

On-axis

3.5 mm

off-axis

7 mm

off-axis

10.5 mm

off-axis

14 mm

off-axis

Spot diagrams plotted for 0.0, 3.5, 7, 10.5, and 14 mm off-axis; showing λ = 0.486, 0.546, and 0.656 μm.

FIGURE 4. Compare star images formed by a 8-inch coma-free SCT with those formed by an EdgeHD. The sharpest star images in

the coma-free SCT follow the gray curve, coming to focus approximately 0.6mm in front of the focal plane. In the EdgeHD, small, tight

star images are focused at the focal plane across the field of view, meaning that your images will be crisp and sharp to the very edge.

The Celestron EdgeHD 7

Page 8

14” ƒ/11 Flat-Field EdgeHD14” ƒ/10 Coma-Free SCT

-0.8 mm -0.4 mm 0.0 mm +0.4 mm +0.8 mm-0.8 mm -0.4 mm 0.0 mm +0.4 mm +0.8 mm

On-axis

5 mm

off-axis

10 mm

off-axis

15 mm

off-axis

20 mm

off-axis

Spot diagrams plotted for 0.0, 5, 10, 15, and 20mm off-axis; showing λ = 0.486, 0.546, and 0.656μm.

FIGURE 5. In a 14-inch coma-free SCT, the smallest off-axis star images lie on the curved focal surface indicated by the gray line.

Since CCD or digital SLR camera sensors are flat, so star images at the edge of the field will be enlarged. In the aplanatic EdgeHD

design, the smallest off-axis images lie on a flat surface. Stars are small and sharp to the edge of the field.

Telescope tubes must “breathe” not only to enable cooling, but

also to prevent the build-up of moisture and possible condensation

inside the tube. In the classic SCT, air can enter through the open

baffle tube. In the EdgeHD, the sub-aperture lenses effectively

close the tube. To promote air exchange, we added ventilation

ports with 60µm stainless steel mesh that keeps out dust but

allows the free passage of air.

In a telescope designed for imaging, users expect to

attach heavy filter wheels, digital SLRs, and astronomical CCD

cameras. We designed the rear threads of the EdgeHD 925,

1100, and 1400 telescopes with a heavy-duty 3.290×16 tpi

thread, and we set the back focus distance to a generous 5.75

inches from the flat rear surface of the baffle tube locking nut.

The rear thread on the EdgeHD 800 remains the standard

2.00×24 tpi, and the back-focus distance is 5.25 inches.

Many suppliers offer precision focusers, rotators, filter wheels,

and camera packages that are fully compatible with the

heavy-duty rear thread and back focus distance of the EdgeHD.

6. MANUFACTURING THE EDGEHD OPTICS

Each EdgeHD has five optical elements: an aspheric Schmidt

corrector plate, a spherical primary mirror, a spherical secondary

mirror, and two sub-aperture corrector lenses. Each element is

manufactured to meet tight tolerances demanded by a highperformance optical design. Celestron applies more than forty

years of experience in shaping, polishing, and testing astronomical

telescope optics to every one of the components in each EdgeHD

telescope. Our tight specifications and repeated, careful testing

guarantee that the telescope will not only perform well for highpower planetary viewing, but will also cover a wide-angle field

for superb edge-to-edge imaging. Nevertheless, we don’t take

this on faith; both before and after assembly, we test and tune

each set of optics.

FIGURE 6. The mirror clutch mechanism shown in this cross-

section prevents the primary mirror from shifting during the long

exposures used in imaging.

Celestron’s founder, Tom Johnson, invented the breakthrough

process used to make Celestron’s corrector plates. Over the

years, his original process has been developed and refined. At

present, we manufacture corrector plates with the same level of

ease, certainty, and repeatability that opticians expect when they

are producing spherical surfaces.

Each corrector plate begins life as a sheet of water-white, hightransmission, low-iron, soda-lime float glass. In manufacturing

float glass, molten glass is extruded onto a tank of molten tin,

where the glass floats on the dense molten metal. The molten

tin surface is very nearly flat (its radius of curvature is the radius

of planet Earth!), and float glass is equally flat.

8 I The Celestron EdgeHD

Page 9

We cut corrector blanks from large sheets of the glass, then run

them through a double-sided surfacing machine to grind and

polish both surfaces to an optical finish. The blanks are inspected

and any with defects are discarded.

The Johnson/Celestron method for producing the polynomial

aspheric curve is based on precision “master blocks” with the

exact inverse of the desired curve. We clean the master block

and corrector blank, and then, by applying a vacuum from the

center of the block, pull them into intimate optical contact,

excluding any lint, dust, or air between them, gently bending

the flat corrector blank to match the reverse curve of the block.

We then take the combined master block and corrector blank

and process the top surface of the corrector to a polished

concave spherical surface. With the corrector lens still on the

master block, an optician tests the radius and figure of the new

surface against a precision reference matchplate (also known as

an optical test plate or test glass) using optical interference to

read the Newton’s rings or interference fringes, as shown in

Figure 7. If the surface radius lies within a tolerance of zero to

three fringes (about 1.5 wavelengths of light, or 750nm concave),

and the surface irregularity is less than half of one fringe (¼–

wavelength of light), the corrector is separated from the master

block. The thin glass springs back to its original shape, so that

the side that was against the master block becomes flat and the

polished surface assumes the profile of a Schmidt corrector lens.

The corrector is tested again, this time in a double-pass auto

collimator. Green laser light at 532nm wavelength (green)

enters through an eyepiece, strikes an EdgeHD secondary and

primary mirror, passes through the corrector lens under test,

reflects from a precision optical flat, goes back through the

corrector to reflect again from the mirrors, and finally back to

focus. Because the light passes twice through the Schmidt

corrector lens, any errors are seen doubled. The double-pass

autocollimation test (see Figure 9) ensures that every Schmidt

corrector meets the stringent requirements of an EdgeHD

optical system.

FIGURE 7. Matchplates use interference fringes to check

the radius and smoothness of the correction. In this picture, a

corrector blank is attached to a master block. The matchplate

rests on top; interference fringes appear as green and blue

circles. The circular pattern indicates a difference in radius.

Primary mirrors begin as precision-annealed molded castings of

low-expansion borosilicate glass with a weight-saving conical

back surface and a concave front surface. The molded casting

is edged round, its central hole is cored, and the radius of the

front surface is roughed in. Celestron grinds the front surface of

primary mirrors with a succession of progressively finer diamond

abrasive pellet tools using high-speed spindle machines, then

transfers them to an abrasive free room where they are polished

to a precise spherical surface. Each mirror is checked for both

radius and optical spherical figure against a convex precision

reference matchplate. When the interference fringes indicate

the radius is within ±1 fringe from the nominal radius and the

surface irregularity is less than one fourth of one fringe, the

mirror receives a final check using the classic mirror-maker’s

null test familiar to every professional optican. Afterwards,

every primary mirror is taken to the QA Interferometry Lab—shown

in Figure 10—where the surface irregularity of each mirror is

verified, via interferometer, to be within specification.

The smaller secondary mirrors are also made of low-expansion

borosilicate glass. Like the primaries, the secondaries are edged

and centered, then ground and polished. The secondary is a

convex mirror so during manufacture it is tested against a

concave precision reference matchplate to check both its radius

of curvature and figure. The secondary mirrors are also brought

to the QA Interferometry Lab where the radius and irregularity of

each mirror is verified through interferometric measurement to

assure that each one lies within specification.

When we designed the EdgeHD optical system, we strongly

favored spherical surfaces because a sphere can be tested by

optical interference to high accuracy in a matter of minutes. If we

had specified a hyperboloidal surface for the secondary mirror,

we would have been forced to use slower, less accurate testing

methods that might miss zonal errors. Furthermore, coma-free

SCT designs with hyperboloidal mirrors still suffer from field

curvature—an aberration that we specifically wished to avoid in

the EdgeHD design.

Finally, the sub-aperture corrector lenses are made using the

same manufacturing techniques used for high-performance

refractor objectives. The EdgeHD design specifies optical glass

from Schott AG. The 8-, 9.25-, and 11-inch use N-SK2 and K10

glasses, while the 14-inch uses N-SK2 and N-BALF2 glasses.

To ensure homogeneity, optical glass is made in relatively small

batches, extruded in boules. The raw glass is then diamondmilled to the correct diameter, thickness, and radius. Each lens

blank is blocked, ground, and polished, then the radius and figure

are compared to matchplates to ensure they meet EdgeHD’s

tight tolerances.

Our assembly workstations resemble the optical benches used

to qualify corrector plates. The primary mirror and corrector plate

slip into kinematic support jigs, and we place the secondary

mirror in its holder. The sub-aperture corrector lenses meet

specifications so reliably that a master set is used in the assembly workstation. Laser light from the focus position passes in

reverse through the optics, reflects from a master autocollimation

flat, then passes back through the optics. Tested in autocollimation,

the optician can see and correct surface errors considerably

smaller than a millionth of an inch.

If the combined optics set shows any slight residual under-or

over-correction, zones, astigmatism, upturned or downturned

edges, holes, or bulges, the optician marks the Foucault test

shadow transitions on the secondary mirror, then removes the

secondary mirror from the test fixture and translates these

markings into a paper pattern. The pattern is pressed against

a pitch polishing tool, and the optician applies corrective polishing

to the secondary mirror—as we show in Figure 11—until the

optical system as a whole displays a perfectly uniform illumination

(no unwanted zones or shadows) under the double-pass

Foucault test and smooth and straight fringes under the doublepass Ronchi test. The in-focus Airy disk pattern is evaluated for

roundness, a single uniform diffraction ring, and freedom from

scattered light. In addition, the intra- and extra-focal diffraction

pattern must display the same structure and central obscuration

on both sides of focus, and it must appear round and uniform.

The Celestron EdgeHD 9

Page 10

EDGEHD’S CLOSE-UP ON THE PELICAN NEBULA

FIGURE 8. After all the testing is done, the ultimate test is the night sky. This close-up image of the Pelican Nebula testifies to the

EdgeHD’s ability to focus clean, neat, round star images from center to edge. The telescope was a 14-inch EdgeHD on a CGE Pro

Mount; the CCD camera was an Apogee U16m. The mage above shows a 21.5×29.8mm section cropped from the original 36.8mm

square image.

10 I The Celestron EdgeHD

Page 11

Autocollimation Testing

Telescope being checked

Precision optical flat

Beamslitter

Eyepiece and Ronchi grating

Green Laser (532 nm)

FIGURE 9. In autocollimation testing, light goes through an

optical system, reflects from a plane mirror, and passes through

again. This super-sensitive test method doubles the apparent size

of all errors.

FIGURE 10. We test all of our primary mirrors on an optical

bench by means of laser interferometry. In the picture, stacks of

polished primary mirrors await testing.

FIGURE 11. To correct any remaining optical errors, the figure of

the secondary mirror is fine-tuned against the entire optical system

in double-pass autocollimation setup. This delicate match process

ensures that every telescope performs to the diffraction limit.

After we remove each set of optics from the autocollimator, we

send the components to our in-house coating chamber. Here,

the primary and secondary mirrors receive their high-reflectance

aluminum coatings, and the corrector lens is anti-reflectance

coated. Each set of optics is then installed into an optical tube

assembly (OTA).

Completed OTAs undergo the Visual Acceptance Test. In a

temperature-stabilized optical test tunnel, green laser light at

532nm wavelength is reflected from a precision paraboloidal

mirror to act as an artificial star. With a high-power ocular, a QA

Inspector views the artificial star critically.

To pass the Visual Acceptance Test, an optical tube assembly

must meetthe following requirements:

• The in-focus Airy disk must be round, free of scattered light

around the disk, and display only one bright ring.

• Inside and outside focus, the diffraction patterns must be

round, uniform, and appear similar on both sides of focus.

• Observed with a 150 line-pairs-per-inch Ronchi grating, the

bands must be straight, uniformly spaced, and high in contrast.

Because its optics have been tested and tuned in error-revealing

double-pass mode, and because each assembled OTA has been

tested again and qualified visually, the telescope’s images should

be flawless when observing and imaging the night sky.

7. FINAL ACCEPTANCE TESTING

AND CERTIFICATION

Before it can leave Celestron’s facilities, every EdgeHD must

pass its Final Acceptance Test, or FAT. We conduct the FAT on

an optical test bench in a specially-constructed temperaturecontrolled room (Figure 12). Rather than use laser light for this

test, we use white light so that the FAT reproduces the same

conditions an observer would experience while viewing or

photographing the night sky. To avoid placing any heat sources

in the optical path, the light for our artificial star is carried to the

focus of a precision parabolic mirror through a fiber-optic cable.

After striking the parabolic mirror, the parallel rays of light travel

down the optical bench to the EdgeHD under test, through the

telescope, to a full-frame format digital SLR camera placed at

its focus.

Using a set of kinematic test cradles, there is no need to change

the test configuration between different EdgeHD telescopes.

We simply place the telescope in its test cradle on the bench,

and it’s ready for testing. The Final Acceptance Test verifies an

EdgeHD’s ability to form sharp star images in the center and

on the edges of a full-frame (24×36mm format, with a 42mm

diagonal measurement) digital SLR camera. The QA Inspector

attaches the camera to the telescope, focuses carefully, and

takes an on-axis image. The telescope is then pointed so the

artificial star image falls in the corner of the frame, and without refocusing, the inspector takes another image. The process

is repeated for each corner of the camera frame, and another

picture is taken at the center of the frame.

To pass the test, the telescope must form a sharp image at the

center of the field, at each corner of the camera frame, and

again at the center. The images are examined critically. To pass,

every one of the test images must be tight, round, and in perfect

focus. Any EdgeHD that does not pass the FAT is automatically

returned to the assembly room to recheck the collimation and

centering of its corrector plate. No EdgeHD can leave the

factory until it has passed its FAT.

The Celestron EdgeHD 11

Page 12

Throughout the telescope-building process, we maintain a

EdgeHD Field of View

quality-assurance paper trail for each instrument. All test

images are numbered and cross referenced. Should a telescope

be returned to Celestron for service, we can consult our records

to see how well it performed before it left our facility. Once a telescope has passed the FAT, we apply Loctite® to the set screws

to permanently hold the alignment of the corrector plate. The

instrument is then inspected carefully for cosmetic defects. It is

cleaned and packaged for shipment to our dealers and customers.

To your discerning eye—as an observer with experience—on a

night with steady air and good seeing, a properly cooled EdgeHD

performs exceptionally well on stars. You will see a round, clean

Airy disk, a single well-defined diffraction ring, and symmetrical

images inside and outside of focus. Every EdgeHD should

resolve double stars to the Dawes limit, reveal subtle shadings

in the belts of Jupiter, and reveal the Cassini Division in Saturn’s

rings. On deep-sky objects viewed with a high-quality eyepiece,

star images appear sharp and well defined to the edge of the

field of view. The EdgeHD reveals faint nebular details as fine as

the sky quality at the observing site will allow.

KAF-3200

KAF-8300

42 mm ∅

KAF-16803

FIGURE 12. In the Final Acceptance Test, the EdgeHD optics

must demonstrate the ability to form sharp images at the center

and in the corners of a full-frame digital SLR camera, with a

sensor that measures 42mm corner-to-corner.

8. VISUAL OBSERVING WITH THE EDGEHD

Because both the Celestron EdgeHD and our classic SCTs

are diffraction-limited on-axis, their performance is essentially

the same for high-magnification planetary or lunar viewing,

splitting close double stars, or any other visual observing task

that requires first-rate on-axis image quality. However, the

EdgeHD outshines the classic SCT when it comes to observing

deep-sky objects with the new generation of high-performance

wide-field eyepieces.

The classic SCT exhibits off-axis coma and field curvature

which are absent from the EdgeHD design. Modern wide-field

eyepieces, such as the 23mm Luminos, have an apparent field

of view of 82 degrees, so they show you a larger swatch of

the sky. Gone are the light-robbing radial flares of coma and

annoying, out-of-focus peripheral images so sadly familiar

to observers. With the EdgeHD, stars are crisp and sharp to

the edge.

The back of the EdgeHD 800 features an industry standard

2.00×24 tpi threaded flange. A large retaining ring firmly

attaches the 1¼-inch visual back, and this accepts a 1¼-inch

Star Diagonal that will accept any standard 1¼-inch eyepiece.

The EdgeHD 925, 1100, and 1400 feature a heavy-duty flange

with a 3.290×16 tpi threaded flange. This oversize flange allows

you to attach heavy CCD cameras and digital SLR cameras.

For visual observing, use the adapter plate supplied with each

telescope to attach the Visual Back. The 2-inch Diagonal

(also supplied with these telescopes) accepts eyepieces with

1¼-inch and 2-inch barrels.

APS-C DSLR

Full-Frame DSLR

KAI-10002

FIGURE 13. EdgeHD telescopes are designed to provide

good images across a flat 42mm diameter field of view.

Compare this with the size of a variety of image sensor formats.

The popular APS-C digital SLR format fits easily. The full-frame

DSLR format is fully covered. EdgeHD even covers the 36.8mm

square KAF-16803 format remarkably well.

12 I The Celestron EdgeHD

Page 13

Imaging with Celestron EdgeHD Telescopes

EdgeHD Aperture

Focal Ratio

Focal Length

Secondary Ø

Obstruction1

Back Focus

Distance

Adapter

Thread Size

EdgeHD

800

203.2mm

ƒ/10.456

68.6mm

34 %

133.35mm

2.00”-24 tpi

2125mm

EdgeHD

925

235mm

ƒ/9.878

85.1mm

36%

146.05mm

3.29”-16 tpi

2321mm

EdgeHD

110 0

279.4mm

ƒ/9.978

92.3mm

33%

146.05mm

3.29”-16 tpi

2788mm

EdgeHD

1400

355.6mm

ƒ/10.846

114.3mm

32%

146.05mm

3.29”-16 tpi

3857mm

1.

The Ø symbol means diameter. Central obscuration is given as a percentage of the aperture.

2.

The Rayleigh Limit for resolving doubles with equally bright components. The “ symbol means arcseconds.

9. IMAGING WITH THE EDGEHD

The Celestron EdgeHD was designed and optimized for imaging

with astronomical CCD cameras, digital SLR cameras, video

astronomy sensors, electronic eyepieces, and webcams. We

designed the EdgeHD 800 to deliver the best images 5.25

inches (133.35mm) behind the surface of the telescope’s rear

cell 2.00×24 tpi threaded baffle tube lock nut. The EdgeHD

925, 1100, and 1400 form their best images 5.75 inches

(146.05mm) behind the telescope’s rear cell 3.290×16 tpi

threaded baffle tube lock nut. For best results, the image sensor

should be located within ±0.5mm of this back-focus distance.

It is easy to place a digital SLR (DSLR) camera at the proper

distance using the Small T-Adapter (item #93644) for the

EdgeHD 800, or the Large T-Adapter (item #93646) for the

EdgeHD 925, 1100, and 1400. The small adapter is 78.35mm

long while the large adapter adds 91.05mm, in both cases

placing the best focus 55mm behind the T-Adapter. Because

55mm is the industry standard T-mount to sensor distance, add

a T-Ring adapter (T-Ring for Canon EOS, item #93419; T-Ring

for Nikon, item #93402) and attach your camera to it. That’s

all there is to placing your digital SLR camera at the correct

back-focus location. (By the way, if you’ve never heard of the

T-mount system, you need to know about it. The T-mount is a

set of industry standard sizes and distances for camera lenses.

A standard T-mount thread (M42×0.75) is available for most

astronomical CCD cameras. The standard T-mount flange-tosensor distance is 55mm.)

The T-mount system also makes spacing an astronomical CCD

camera easy. Consult your CCD camera’s documentation to find

the flange-to-sensor distance for your CCD camera. Attaching

the Celestron T-Adapter to your EdgeHD gives you the standard

55mm spacing. If your CCD’s front flange-to-sensor distance

is 35mm, you need an additional 20mm distance. A 20mm

T-mount Extension Tube, available from many astronomy

retailers, will help you achieve the correct back focus distance. If

you require a more complex optical train for your CCD camera,

consult a trusted astronomy retailer.

Image Circle

Linear Ø

Angular Ø

42mm Ø

68.0 arcmin

Airy Disk

Angular Ø

Linear Ø

Rayleigh

1.36” Ø

14.0μm Ø

Image Scale

arcsec/pixel

2

(6.4 μm

pixel)

0.62”/pix

0.68”

42mm Ø

62.2 arcmin

1.18” Ø

13.2μm Ø

0.57”/pix

0.59”

42mm Ø

51.8 arcmin

0.99” Ø

13.3μm Ø

0.47”/pix

0.50”

42mm Ø

37.4 arcmin

0.78” Ø

14.4μm Ø

0.34”/pix

0.39”

For imaging, we recommend using T-system components

because threaded connections place your CCD camera or

digital SLR at the correct back focus distance for optimum

performance. Not only are they strong, but they also hold your

camera perfectly square to the light path.

To mount a high-performance video camera, add the T-Adapter

plus a T-to-C adapter. (Like the T-mount system, the C-mount

system is an industry standard. It uses 1×32 tpi threads with a

back-focus distance of17.5mm.)

For consumer video systems such as electronic eyepieces,

planetary cameras, and webcams that attach to the telescope

using a standard 1.25-inch eyepiece barrel, simply use the same

components that you use for visual observing. Just remove the

eyepiece from the telescope and replace it with the camera.

Many imaging programs allow you to shoot short exposures

through the telescope. On a solid, polar-aligned equatorial

mounting, you may be able to expose for 30 seconds or more.

With such exposure times, you can capture wonderful images of

the Moon, planets, eclipses, bright star clusters, and objects like

the Orion Nebula.

However, for long exposures on deep-sky objects, you will need

to guide the telescope. The days of guiding by eye are over;

electronic auto-guiders are the new standard. A functional and

relatively inexpensive autoguiding setup consists of a small

refractor mounted piggyback on your EdgeHD telescope. You

will need a dovetail bar attached to the EdgeHD tube. Celestron

offers an 80mm guide telescope package (item #52309) to

be used with the NexGuide Autoguider (item #93713). For

sub-exposures exceeding 10 minutes or so, piggybacked guide

telescopes potentially suffer from differential flexure; for such

imaging, consider the Off-Axis Guider (item #93648).

The Celestron EdgeHD 13

Page 14

Celestron’s EdgeHD: The Versatile Imaging Platform

Celestron's EdgeHD: The Versatile Imaging Platform

EdgeHD

800

EdgeHD

925, 1100,

and 1400

5.25 inches

133.35±0.5 mm

5.75 inches

146.05±0.5 mm

Small T-Adapter

Camera Adapter

Digital SLR

Reducing Ring

Small T-Adapter

T-to-1.25” Adapter

Webcam

Large T-Adapter

T-Ring Adapter

Digital SLR

Large T-Adapter

T-to-C Adapter

Astro Video Camera

Large T-Adapter

T-system Spacer

CCD Camera

FIGURE 14. It is easy to position your digital SLR camera, an astronomical CCD camera, a high-performance video camera, or an

inexpensive webcam at the focus plane of your EdgeHD telescope. For the sharpest wide-field imaging, your goal is to place the

sensor 5.25 inches behind the rear flange of the EdgeHD 800, or 5.75 inches behind the rear flange of the EdgeHD 925, 1100,

and1400.

For those who wish to make images with a faster focal ratio

than EdgeHD 1100’s ƒ/10 or the EdgeHD 1400’s ƒ/11, we

designed a five-element 0.7× reducer lens for each of these

EdgeHD telescopes. (For more information, see Appendix B.)

The Reducer Lens 0.7× for the EdgeHD 1100 is item #94241;

for the 14-inch, item #94240. (The newly-released EdgeHD

800 Focal Reducer is item #94242.)

The reducer lens attaches directly to the 3.290×16 tpi threaded

baffle tube lock nut on the back of the telescope. Since the back

focus distance for the 1100 and 1400 reducer lens is 5.75 inches

(146.05mm), you can use the same T-Adapter and camera

T-Ring you would use for imaging at the ƒ/10 or ƒ/11 focus. The

linear field of view is still 42mm diameter, but the angular field is

43% larger, and exposure times drop by a factor of two.

For super-fast, super-wide imaging, the EdgeHD telescope

series supports Starizona’s Hyperstar lens. Mounted on the

corrector plate in place of the secondary mirror, the Hyperstar

provides an ƒ/1.9 focal ratio on the EdgeHD 1400, and ƒ/2.0 or

ƒ/2.1 on the 800, 925, and 1100. Covering a 27mm diameter

field of view, the Hyperstar is a perfect match for APS-C format

digital SLR cameras. Because of the short focal length and

fast focal ratio, sub-exposures are just a minutes. With a solid,

polar-aligned equatorial mount, guiding seldom necessary.

Of course, the focal length of any EdgeHD telescope can be

extended using a Barlow lens such as the Celestron 2x X-Cel

LX (item #93529) or 3x X-Cel LX (item #93428). Using a

Barlow, imagers can reach the desirable f/22 to f/32 range for

ultra-high-resolution lunar and planetary imaging.

In summary, the Celestron EdgeHD telescopes provide a flexible

platform for imaging. You can work at the normal ƒ/10 or ƒ/11

Cassegrain focus for seeing-limited deep-sky images or add

the reducer lens for wider fields and shorter exposure times.

With a Hyperstar, you can grab wide-field, deep-sky images

in mere minutes. And finally, you can extend the focus to capture

fine lunar and planetary images with a quality Barlow lens.

When you buy an EdgeHD telescope, you’re getting an imaging

platform that covers all the bases, from fast, wide-field imaging to

high-resolution imaging of the moon and planets.

14 I The Celestron EdgeHD

Page 15

10. CONCLUSION

The classic Schmidt-Cassegrain telescope introduced tens of

thousands of observers and imagers to astronomy and nurtured

their appreciation for the wonder of the night sky. Today, observers

and imagers want a more capable telescope, a telescope that

provides sharp close-ups as well as high-quality images all the

way across a wide, flat field of view. But, consumers want this

advanced optical technology at an affordable price.

Celestron has designed the EdgeHD to meet customers’ needs.

The EdgeHD is not only coma-free, but it also provides a flat

field so that stars are sharp to the very edge of the field of view.

In this brief technical white paper, we have shown you the inner

workings of our new design. We also demonstrated the care we

exert as we build and test each EdgeHD telescope. We trust that

we have proven that an EdgeHD is the right telescope for you.

You may find the following resources to be useful in

learning about optical design, fabrication, and testing:

11. REFERENCES

DeVany, Arthur S., Master Optical Techniques. John Wiley

and Sons, New York, 1981.

Fischer, Robert E.; Biljana Tadic-Galeb; and Paul R. Yoder,

Optical System Design. McGraw Hill, New York, 2008.

Geary, Joseph M., Introduction to Lens Design.

Willmann-Bell, Richmond, 2002.

Malacara, Daniel, ed., Optical Shop Testing. John Wiley

and Sons, New York, 1978.

Rutten, Harrie, and Martin van Venrooij, Telescope Optics:

A Comprehensive Manual for Amateur Astronomers.

Willmann-Bell, Richmond, 1999.

Smith, Gregory Hallock, Practical Computer-Aided Lens Design.

Willmann-Bell, Richmond, 1998.

Smith, Gregory Hallock; Roger Ceragioli; Richard Berry,

Telescopes, Eyepieces, and Astrographs: Design, Analysis, and

Performance of Modern Astronomical Optics. Willmann-Bell,

Richmond, 2012.

Wikipedia. Search references to specific topics.

See: http://en.wikipedia.org/wiki/Optical_lens_design

and many associated links.

Wikipedia. Search references to T-mount.

See: http://en.wikipedia.org/wiki/T-mount and associated

camera system links.

Wilson, R. N., Reflecting Telescope Optics I and II.

Springer-Verlag, Berlin, 1996.

®

ZEMAX

Optical Design Program, User’s Guide.

Radiant Zemax LLC, Tucson, 2012.

The Celestron EdgeHD 15

Page 16

Appendix A:

Airy Disk and Seeing Blurs

Technical Profiles of EdgeHD Telescopes

When evaluating astronomical telescopes, astroimagers must

bear in mind the many factors that influence image quality. The

major factors at play are:

• The image formed by the telescope

• The sampling by pixels of the image sensor

• The diffraction pattern of the telescope

• The “seeing” quality during exposure

• The guiding accuracy during exposure

To aid astroimagers, this Appendix presents a spot matrix plot

for each of the telescopes in the EdgeHD series. To determine

the size of the images that you observe in your exposures, these

must be compounded with the other factors that affect your images.

In the spot matrix plots we have provided, each large gray box

is 64µm on a side, and consists of a ten small boxes 6.4µm

representing a pixel in a “typical” modern CCD camera. The

black circle represents the diameter of the Airy disk to the first

dark ring. It is immediately clear that for each of the EdgeHDs,

two 6.4µm pixels roughly match the diameter of the Airy disk.

This means that under ideal conditions, a CCD camera with

pixels of this size will capture most of the detail present in the

telescopic image. Referring to Figure A1, the left column shows

the Airy disk for a telescope with a central obstruction of 34%.

Because the light in the Airy disk is concentrated into a smaller

area in the center, capturing all of the image detail in a planetary

or lunar image requires using a 2x or 3x Barlow lens to further

enlarge the Airy disk.

Unfortunately, ideal conditions are fleeting. During a typical CCD

exposure, atmospheric turbulence enlarges the image of all

stars, and furthermore, it causes the images to wander. On the

steadiest nights, the “seeing” effect may be as small as 1 arcsecond.

In Figure A1, the “superb seeing” column shows blurs with a

FWHM (full-width half-maximum) of 1 arcsecond. The next column

shows excellent seeing (1.5”), and the right column shows 2”

seeing blurs, typical of many nights at most observing sites. It

is important to note that as the focal length of the telescope

increases, the diameter of the seeing blur increases in proportion.

With a small telescope, seeing plays a smaller role. With the large

apertures and long focal lengths of the EdgeHD series, nights of

good seeing become particularly valuable.

14-inch 8-inch11-inch 9.25-inch

Airy

Disk

FIGURE A1. Shown at the same scale as the matrix spot

diagrams are the Airy disk and the point-spread-function

of seeing disks for average (2.0”), excellent (1.5”), and superb

(1.0”) seeing.

Superb

Seeing

Excellent

Seeing

Average

Seeing

16 I The Celestron EdgeHD

Page 17

Celestron EdgeHD 800

Celestron EdgeHD 800

On-axis, the spots show that the 8-inch EdgeHD is diffractionlimited in both green (for visual observing) and red (for imaging).

And because blue rays are strongly concentrated inside the

Airy disk, the 8-inch EdgeHD is diffraction-limited in blue light.

Off-axis, its images remain diffraction-limited over a field larger

than the full Moon.

For an imager using an APS-C digital SLR camera, relative

illumination falls to 84% at the extreme corners of the image.

Although for bright subjects this minor falloff would pass

unnoticed, for imaging faint objects we recommend making and

applying flat-field images for the best results. For CCD imaging,

we always recommend making flat field images.

Portability and affordability are the hallmarks of the EdgeHD

800. Although the 8-inch covers a 42mm image circle, we

optimized its optics for the central 28mm area, the size of an

APS-C chip in many popular digital SLR cameras.

The Celestron EdgeHD 17

Page 18

Celestron EdgeHD 925

.

Celestron EdgeHD 925

The spot matrix shows that on-axis images are diffraction

limited at all three wavelengths, and remain diffraction-limited

over the central 15mm. While blue and red are slightly enlarged,

in green light images are fully diffraction-limited over a 38mm

image circle. The size of the off-axis blue and red spots remain

nicely balanced.

On a night of average seeing, stars will display a FWHM of

23µm, comparable in size to the spot pattern at the very edge

18 I The Celestron EdgeHD

of a 42mm field. Relative illumination in the EdgeHD 925 is

excellent. The central 12mm is completely free of vignetting,

while field edges receive 90% relative illumination. For most

imaging applications, flat fielding would be optional.

For full-field imaging on a tight budget, the EdgeHD 925 is an

excellent choice. It offers nearperfect on-axis performance and

outstanding images over a full 42mm image circle.

Page 19

Celestron EdgeHD 1100

Celestron EdgeHD 1100

The 11-inch EdgeHD is optimized to produce its sharpest

images in green and red; at these wavelengths it is diffractionlimited over roughly two-thirds of the full 42mm image circle.

The relative illumination remains 100% across the central

16mm, then falls slowly to 83% at the very edge of a 42mm

image circle.

For pictorial images with an APS-C digital SLR camera, flats are

unnecessary. For monochrome imaging with an astronomical

CCD camera, we always recommend making flat-field images.

On nights when the seeing achieves 1.5 arcseconds FWHM,

star images shrink to 18µm at the focal plane. On such nights,

the EdgeHD 1100 delivers fine images over a 30mm image

circle, and well-defined stars over the full 42mm field.

The EdgeHD 1100 is a serious telescope. Its long focal length

and large image scale give it the ability to capture stunning

wide-field images of deep-sky objects with a large-format

CCD camera.

The Celestron EdgeHD 19

Page 20

Celestron EdgeHD 1400

Celestron EdgeHD 1400

In the matrix spot diagrams, note the tight cluster of rays in

green light, and the well balanced spherochromatism in the

blue and red. These spots are far better than spots from a fine

apochromatic refractor of the same aperture.

In green light, the EdgeHD 1400 is diffraction-limited over a

28mm image circle, although atmospheric seeing enables it

to display its full resolution only on the finest nights. Relative

illumination is 100% across the central 16mm, and falls

slowly to 83% in the extreme corners of a full-frame 35mm

20 I The Celestron EdgeHD

image sensor. We have seen excellent results when the

14-inch EdgeHD is used with a KAF-16803 CCD camera over

a 50mm circle.

The EdgeHD 1400 is a massive telescope, well suited to

a backyard observatory or well-planned away-from-home

expeditions. Its long focal length and large image scale offer

skilled imagers the opportunity to make images not possible

with smaller, less capable telescopes.

Page 21

Appendix B:

The EdgeHD 0.7× Focal Reducer

TECHNICAL PROFILE OF THE EDGEHD

0.7× FOCAL REDUCER LENS

Perhaps the most useful accessory you can get for an EdgeHD

telescope is a focal reducer. Although the long focal length

is a great advantage in capturing detailed images of nebulae,

galaxies, and especially of planetary nebulae, it also means the

field of view is sometimes smaller than desirable. The relatively

slow focal ratio also means rather long exposure times. We

designed our 0.7× Focal Reducer to provide a field of view

1.4× larger in angular diameter, giving you twice the sky area

coverage and halving the exposure time required to reach a

given signal-to-noise ratio. If your passion is imaging large

deep-sky objects, imaging in Hα, SII, and OIII narrowband,

capturing the faint reflection nebulae often found around

Barnard’s dark objects, or just cutting your exposure (and

guiding) times down, the focal reducer is a “must-have” item.

Back in the days of film astrophotography, focal reducers

came to be poorly regarded. Although they would shorten the

focal length, they also produced fuzzy star images, had bad

field curvature, and suffered from severe vignetting. But the

days of film and ersatz focal reducers are over. The modern

EdgeHD focal reducer is the product of optical engineering

and precision manufacturing on a par with the design and

production of wide- and ultra-wide-field eyepieces.

We designed three EdgeHD 0.7x focal reducers, each

specifically tailored to the EdgeHD 1400, 1100, and 800,

respectively. The 1400 and 1100 reducers contain five

precision optical elements, while the 800 contains four

elements. To attain a level of performance worthy of the

EdgeHD, the designs employ low-dispersion lanthanum

rare-earth glass to control both chromatic and geometric

aberrations. All optical surfaces are multi-layer anti-reflection

coated to maximize light transmission, provide high-contrast

images, and minimize image ghosting.

FIGURE B1. The EdgeHD 0.7x Focal Reducer shortens the

focal ratio of the of the EdgeHD 1400, 1100 and 800 while

maintaining sharp images across the full field. This enables CCD

imagers to reach the same signal-to-noise ratio on extended

objects in half the exposure time, and brings even the faintest

deep-sky objects within the range of your high-end digital SLR

camera.

The matrix spot diagram shows that star images on-axis are

diffraction-limited in green light, while rays at all wavelengths

concentrated near the Airy disk. Even at the outer edge of the

42mm image circle, green and blue rays are clustered tightly,

while red shows only a weak flare.

Both physically and mechanically, the 0.7× Reducer Lens is

more than comparable to a top-of-the-line wide-field eyepiece.

The CNC-machined housing easily supports the full weight

of your CCD camera or digital SLR camera without sag or

movement. And for safe storage, each unit is provided with

threaded metal covers for both the front and the back.

The Celestron EdgeHD 21

Page 22

Celestron EdgeHD 0.7× Reducer

EdgeH

1100 and

14

Celestron EdgeHD 0.7× Reducer

D

Large T-Adapter

T-Ring Adapter

Digital SLR

00

5.75 inches

146.05±0.5 mm

0.7× Reducer

Large T-Adapter

T-system Spacer

CCD Camera

The matrix spot diagrams show that the bulk of rays cluster

tightly in or near the Airy disk, with a diffuse scatter most strongly

seen in the red light. Plotted at the same scale as those for the

EdgeHD, the spots demonstrate that the focal reducer’s star

images are even smaller than those of the telescopes.

22 I The Celestron EdgeHD

For observers who wish to pursue faint nebulae in RGB or in

narrowband, the 0.7× Focal Reducer is a valuable accessory that

halves the necessary exposure time with no sacrifice in resolution

or image quality.

Page 23

Image by André Paquette

Imagine the thrill of seeing the first images from your Celestron

EdgeHD! A quick glance at the whole image shows that you have

captured your target’s faint outer extensions. Across the field, from

one side to the other, star images are sharp, crisp, and round. As you

process your image, fine details in the target object reveal themselves.

Star clouds, delicate dust lanes, subtle HII regions—it’s all there, credit

to your skill and the design of your EdgeHD telescope. The image

shown here is a single monochrome 10-minute exposure taken with

an Apogee U16 camera (KAF-16803 CCD chip) and a Celestron

EdgeHD 1400 telescope on a CGE Pro mount.

The Celestron EdgeHD 23

Page 24

The Celestron EdgeHD • ©2013 by Celestron • All rights reserved.

Torrance, CA 90503 U.S.A. • www.celestron.com

Loading...

Loading...