Cee 1300CSX Operator User Manual

1

Cee

®

1300CSX

Thermal Debonder

Operator/User Manual

New users: Read this manual in its entirety before operating the equipment.

© 2019 Cost Effective Equipment, LLC

2

Contents

1. Products Covered in This Manual .................................................. 3

2. Confidentiality Statement, Warranty, and Instructions

for Returning Materials ......................................................................... 3

2.1 Confidentiality Statement ..................................................................................... 3

2.2 Warranty ............................................................................................................... 3

2.3 Instructions for Returning Materials ...................................................................... 4

3. Introduction to the Cee® 1300CSX Thermal Debonder ...... 5

3.1 Programmability ................................................................................................... 5

3.2 Precision .............................................................................................................. 5

3.3 Reliability .............................................................................................................. 5

3.4 Utilities .................................................................................................................. 6

3.5 Dimensions .......................................................................................................... 6

4. Software ......................................................................................................... 7

4.1 Startup and Run Screen ....................................................................................... 7

4.1.1 Startup with Passwords Enabled ............................................................... 7

4.1.2 Home Slide Button .................................................................................... 7

4.1.3 Run Screen ............................................................................................... 8

4.2 Debonding Process Screen .................................................................................. 9

4.2.1 Running a Debonding Process .................................................................. 11

4.2.2 Loading a Substrate .................................................................................. 12

4.2.3 Starting a Debonding Process ................................................................... 13

4.2.4 The Debonding Process Flow ................................................................... 13

4.2.5 Aborting a Process .................................................................................... 15

4.2.6 Continuing a Process ................................................................................ 15

4.3 Recipe Manager (Edit) Screen ............................................................................. 16

4.3.1 Writing a Recipe ........................................................................................ 18

4.3.2 Entering Data ............................................................................................ 18

4.3.3 Recipe Management ................................................................................. 19

4.3.4 Recipe Backup .......................................................................................... 20

4.4 Diagnostics Screen .............................................................................................. 21

4.4.1 Debonder Diagnostics Screen ................................................................... 22

4.5 User Configuration Screen ................................................................................... 30

4.5.1 Debonder User Configuration Screen ....................................................... 32

4.5.2 Password Configuration Screen ................................................................ 34

4.5.3 User Level Access ..................................................................................... 34

4.6 Navigation Bar ...................................................................................................... 35

3

1. Products Covered in This Manual

This manual covers the Cee® 1300CSX thermal slide debonder. This manual is to be

used to install, operate, and troubleshoot the 1300CSX debonder. New users should

read this manual in its entirety before operating the equipment.

2. Confidentiality Statement, Warranty, and Instructions for

Returning Materials

2.1 Confidentiality Statement

Information supplied is only for use during operation and/or maintenance of Cee®

equipment. Neither this document nor the information it contains shall be

disclosed to others for manufacturing or any other purpose without written

authorization from Cost Effective Equipment, LLC.

2.2 Warranty

Cost Effective Equipment, LLC (Cee), warrants to the original purchaser (Buyer) that the

equipment is free from defects in material and workmanship under normal use and

service in accordance with Cost Effective Equipment, LLC instructions and

specifications.

Buyer shall promptly notify Cost Effective Equipment, LLC of any claim against this

warranty, and any item to be returned to Cost Effective Equipment, LLC shall be sent

with transportation charges prepaid by Buyer, clearly marked with a Return Material

Authorization (RMA) number obtained from Cost Effective Equipment, LLC Customer

Support. (See section 2.3.)

Cee®’s obligation under this warranty is limited to the repair or replacement, at Cee

®

’s

option, of any equipment, component, or part that is determined by Cee® to be defective

in material or workmanship. This obligation shall expire one (1) year after the initial

shipment of the equipment from Cee®.

This warranty shall be void if:

a) Any failure is due to the misuse, neglect, or improper installation of or accident to

the equipment.

b) Any major repairs or alterations are made to equipment by anyone other than a

duly authorized representative of Cee®. Representatives of Buyer may be

authorized to make repairs to the equipment without voiding warranty upon

completion of the appropriate Cee® equipment training program.

c) Replacement parts are used other than those made or recommended by Cee®.

4

COST EFFECTIVE EQUIPMENT, LLC MAKES NO OTHER WARRANTIES,

EXPRESSED OR IMPLIED, WITH RESPECT TO EQUIPMENT. NO WARRANTY IS

MADE AS TO THE MERCHANTABILITY OF THE EQUIPMENT NOR ITS FITNESS

FOR ANY PARTICULAR PURPOSE. In no event shall Cee® be liable for consequential

loss or damages, however caused. No person or representative of Cee® is authorized to

assume for Cee® any liability in connection with Equipment nor to make any change to

this warranty unless such change or modification is put in writing and signed by an

authorized representative of Cee®.

This warranty shall be governed by the laws of the state of Missouri, U.S.A.

2.3 Instructions for Returning Materials

Any materials, parts, or equipment returned to Cost Effective Equipment Customer

Support must be clearly labeled with a Return Material Authorization (RMA) number.

To obtain an RMA number, contact:

Cost Effective Equipment Customer Support

Telephone: (573) 466-4300

E-Mail: support@costeffectiveequipment.com

Web Address: http://www.

costeffectiveequipment

.com

Shipping information for use in returns with an RMA number:

Cost Effective Equipment, LLC

Attn: Equipment Customer Support

3703 HyPoint Blvd

Rolla, Missouri 65401

USA

5

3. Introduction to the 1300CSX Thermal Debonder

The Cee® 1300CSX thermal debonder enables high-temperature slide-off debonding of

thinned wafers in a laboratory setting. This tool permits development engineers to

complete the final step of thinned-full-wafer processing in a confidential developmental

setting. Internal small-scale prototyping capability may be used to accelerate product

development cycles and improve time to market for new ultrathin wafer technologies.

3.1 Programmability

• PC-controlled

• PC-based touch screen interface and display

• Full-color alphanumeric-capable graphical user interface (GUI)

• 250,000 process recipe programs onboard

• A virtually unlimited number of user-defined recipe program steps

• 0.1-second resolution for step times (max. step time: 9,999.9 seconds)

• Connectivity: USB/Ethernet port for communications for uploading/downloading

process parameters with offline firmware standard (offline recipe number and steps

unlimited)

• Security: Password protection option available at no charge

3.2 Precision

• Precision lower platen z-position control (closed-loop control/feedback): ± 0.5 µm

accuracy

• Substrate sizes: 2 inches to 200 mm round

• Temperature resolution: 0.1°C

• Temperature range: ambient to 300°C

3.3 Reliability

• Total throughput < 200 mm: est. 8-14 WPH

• Total throughput ≥ 200 mm: est. 4-8 WPH

• Wafer breakage: < 10% (≥ 90% process yield for compound semiconductor and

silicon)

• System uptime: > 90% over a 12-month period

• MTBF (hours/cycles): > 600 hours, 6,000 cycles

• MTTR: < 24 hours (critical spare parts, as defined by Cee®, to be kept at customer

site per Cee® field service standard working schedule)

6

3.4 Utilities

• Electrical: 208 V, single phase, 50/60 Hz, 6500 W

• Exhaust: 30 cfm

• Vacuum: 25 in Hg

• Nitrogen or CDA: 100 psi

3.5 Dimensions

• 49” W × 39.5” D × 52.5” H (125 cm W × 100 cm D × 133 cm H)

• Shipping weight: 187 kg

7

4. Software

4.1. Startup and Run Screen

4.1.1 Startup with Passwords Enabled

If the Cee® 1300CSX debonder tool has passwords enabled, the initial screen will only

contain login and logout buttons.

To log in, press the Login button, to view the touch screen keyboard, and then enter

your password. By default, the passwords for a Cee® 1300CSX tool are:

Super User Level: CEE

User Level: 1300CSX

Maintenance: DIAG

4.1.2 Home Slide Button

Once login is complete, or at startup if passwords are not enabled, the Home Slide

button is visible. Pressing this button will move the slide to the home sensor at a high

speed. Once the home sensor detects the bottom platen, the bottom platen will move off

of the sensor and then back onto the sensor at a very slow speed. Once the x-axis slide

has returned to its home position, the z-axis lift platform will return to its home position

by moving up to the end of its stroke and then back to the zero position. Once the

homing sequence is complete, the Run screen appears and a process may be run.

4.1.3 Run Screen

Once the slide has returned to its home position and the user has logged in (if enabled),

the Run screen will appear.

From this screen, the user can go directly to the Debonding Process screen by pressing

the Debonding Process button in the left-center of the screen. Navigating to other

windows is also possible by using the navigation bar at the bottom of the screen.

8

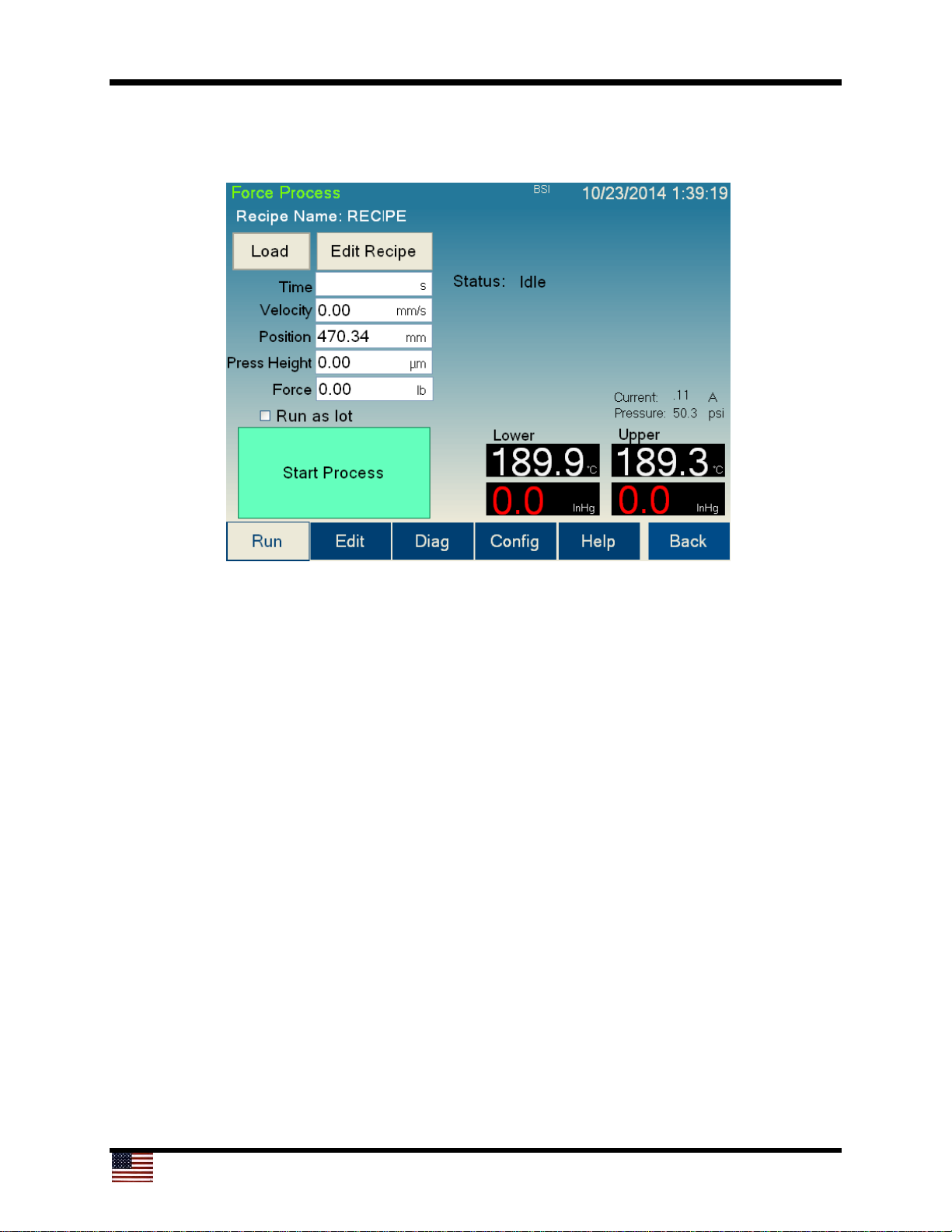

4.2 Debonding Process Screen

The Debonding Process screen is used to run and monitor debonding processes using

the Cee® 1300CSX tool’s software.

1

12

9

8

7

6

5

43

13

1411

10

2

The controls and indicators found on the Debonding Process screen are listed below:

1. Recipe Name: The name of the currently loaded recipe

2. Status: Describes the current status of the debonding process

3. Load button: Navigates to the recipe selection screen (section 4.2.1) to select the

process settings

4. Edit Recipe button: Navigates to the Debonding Process editor if a recipe is

loaded. If a recipe is not loaded, navigates to the recipe selection screen (section

4.2.1).

5. Time indicator: Displays the current time remaining of the current process step. Not

all process steps are time-based.

6. Velocity indicator: Shows the current speed of the lower platen

7. Position indicator: Shows the current position of the lower platen along the slide

8. Press Height indicator: Shows the current height of the bottom platen

9. Force indicator: Shows the current x-axis (lateral) force being applied at the bottom

platen

9

1

12

9

8

7

6

5

43

13

1411

10

2

10. Process button: The process button has three modes:

a. Start Process: Starts the debonding process. The user will be prompted to

load the substrate at the appropriate time.

b. Abort: Aborts a currently running process.

c. OK: Turns off the Process Complete alarm.

11. Run as lot check box: Checking this box will cause the tool to begin the same

process as soon as the previous process was completed. Checking this box

eliminates the need for the user to press Start Process a second time. This check

box will only appear if the tool is set to Production Mode on the User Configuration

screen (section 4.5).

12. Temperature and Vacuum display: Shows the current temperature and vacuum

level of both platens.

13. Current display: Shows the current on the z-axis lift.

14. Pressure display: Shows the current system pressure.

10

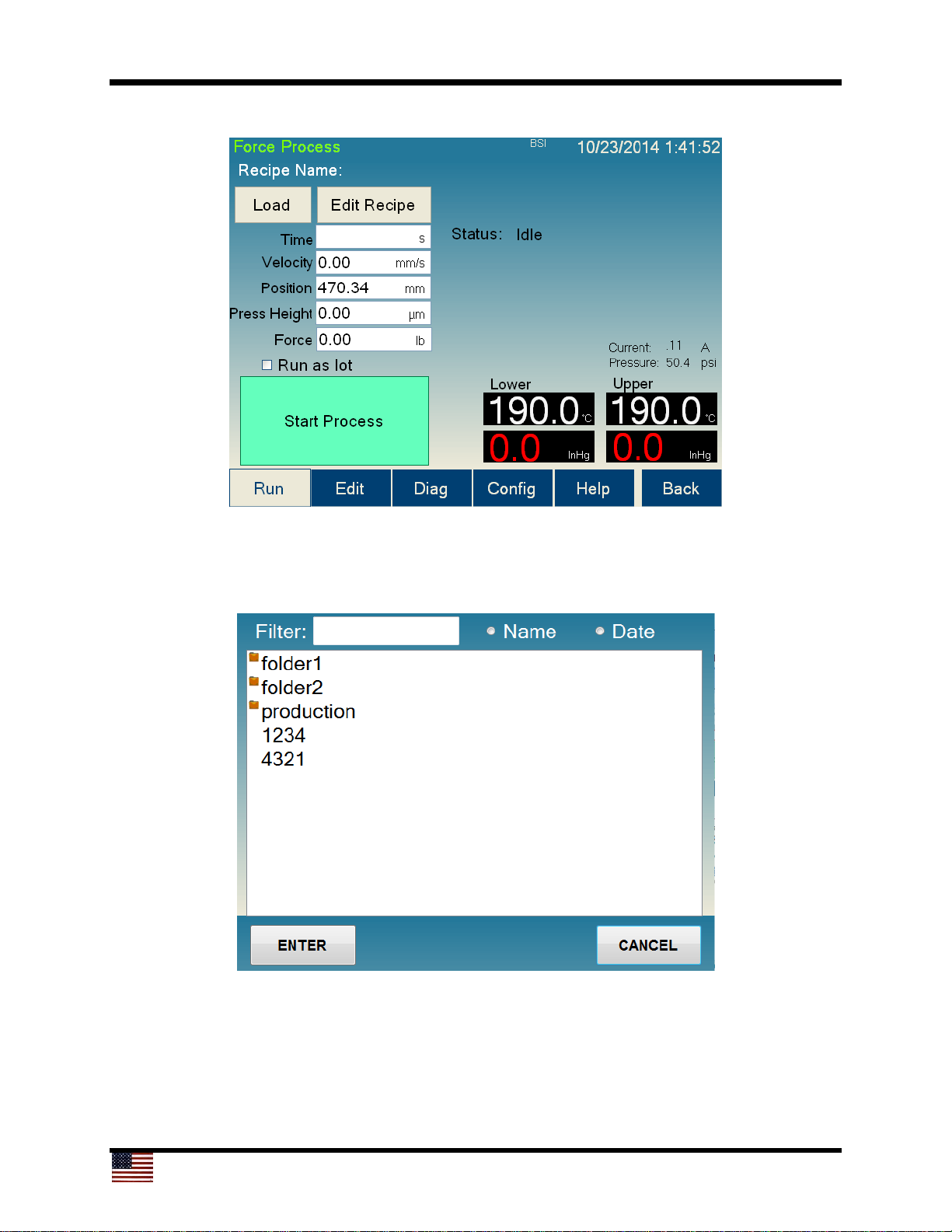

4.2.1 Running a Debonding Process

To run a debonding process, a recipe must first be loaded. Pressing the Load button will

bring up the recipe selection screen (see below). To select a recipe, double-press on

the desired recipe, or select the desired recipe and press Enter.

11

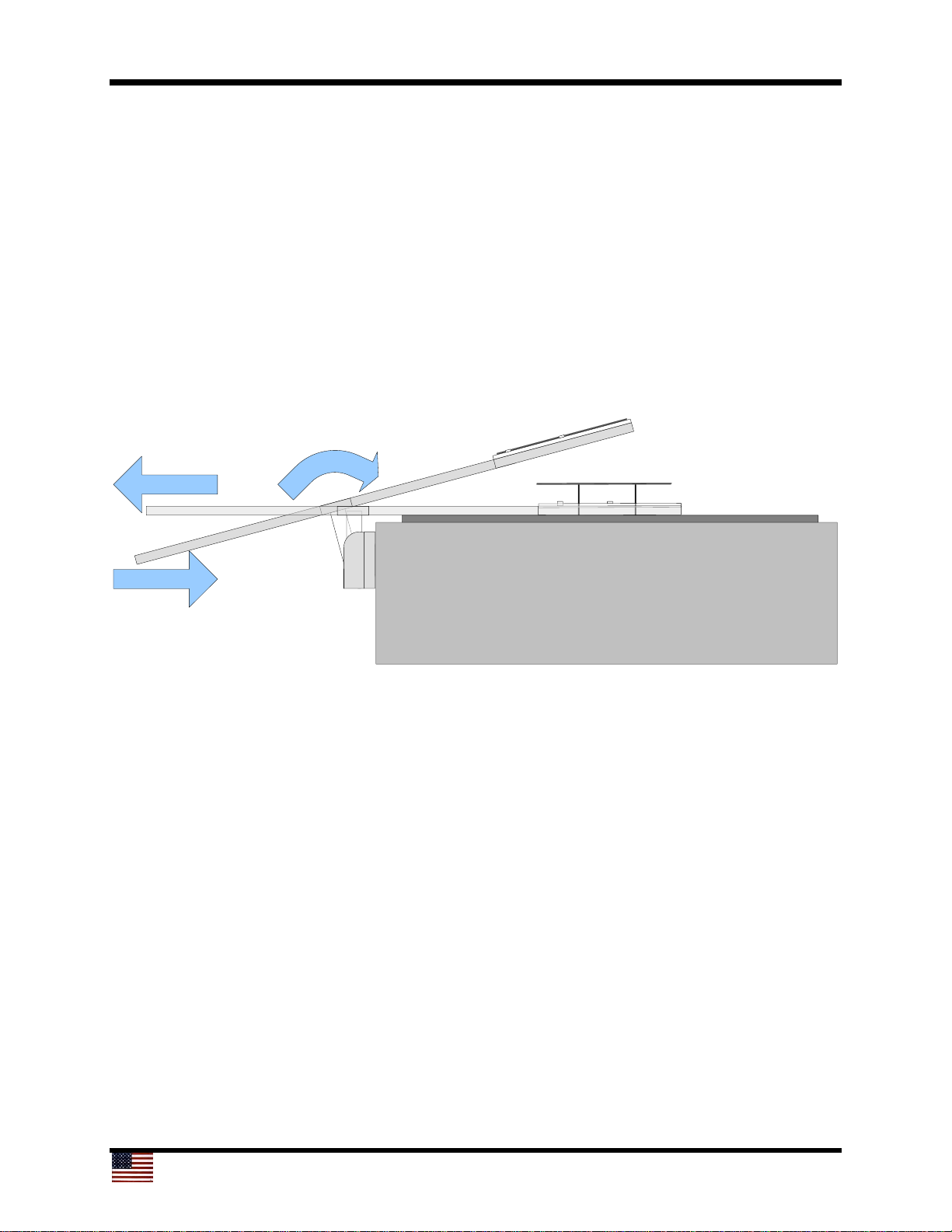

4.2.2 Loading a Substrate

The Cee® 1300CSX tool will prompt the user to load a substrate at the appropriate time

after the Start Process button is pressed. The process to load a substrate is as follows:

1. Place substrate on proper loading arm with the notch or flat to the right.

2. Insert loading arm with substrate into the alignment pocket on the lower platen at

the angle shown below. Be sure the substrate does not move on the loading arm.

3. Rotate the arm forward until the substrate is lifted off the loading arm.

4. Carefully pull out loading arm without bumping the substrate.

5. Visually check that the substrate is centered.

6. Press Continue at the user prompt.

2

4

3

Loading...

Loading...