MANUAL USUARIO Z auto-Z fresh 27/10/06 16:48 Pgina 17

• In order to avoid the accumulation of wax, the fruit feeder must be cleaned frequently

(Fig. 11).

• In the models with a base stand, always clean the hopper and inside of the base

stand, so that there are no peels or pulp remains.

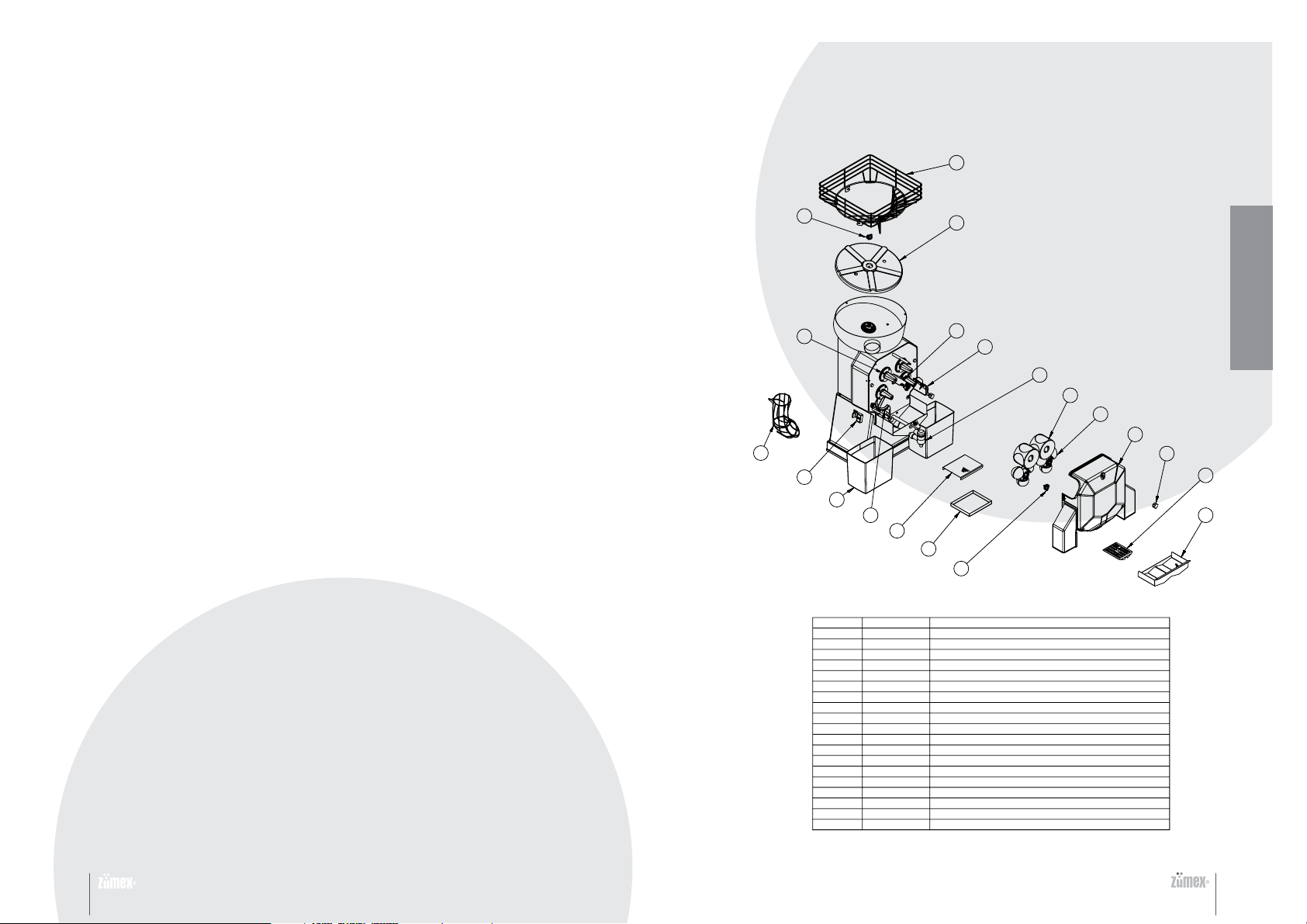

5. DIAGRAMS WITH PARTS AND LIST OF SPARE PARTS

19

17

8

18

10

12

9

11

14

15

16

17

Zumex Autoservicio Barra

7

6

5

4

EN

3

13

2

1

Description

REMEMBER:

• Do not place the front cover and the fresh

container in the dishwasher. It can be cleaned

with a soft cloth and soapy water. Do not use

abrasive products or lime protection products.

• To clean the inside of the tap, fill the container

with clean water and press the tap to eliminate

Index Reference

1

260.0208.002

2

260.0209.000 JUICE CONTAINER INTERIOR FILTER

3

33.013.001 FRONT COVER

33.0031.000

4

5

33.0024.000

13.125.001 STEEL FRONT TAP

6

7

33.0001.000

8

200.3364.000

33.0059.000

9

10

33.0013.000

13.115.002

11

12

225.0921.002 FEEDER TUBE D85

13

33.0004.000

14

33.0002.000

15

260.0214.001

16

260.0213.001

33.0003.001

17

33.0034.000 CLASIC FEEDER PLATE

18

260.0908.003

19

PLASTIC JUICE FILTER

LOWER PRESSING UNIT

UPPER PRESSING UNIT

RIGHT PEEL EJECTOR

FASTENER SUPPORT CAP

BUTTON RUBBER PROTECTION

BLADE HOLDER

PEEL BUCKET

RETAINING KNOB KIT

LEFT JUICE EXTRACTOR

DRAIN TRAY FIL TER

DRAIN TRAY

SECURING KNOB

FEEDER BASKET

the remains of juice and pulp inside the tap.

32 33

MANUAL USUARIO Z auto-Z fresh 27/10/06 16:48 Pgina 18

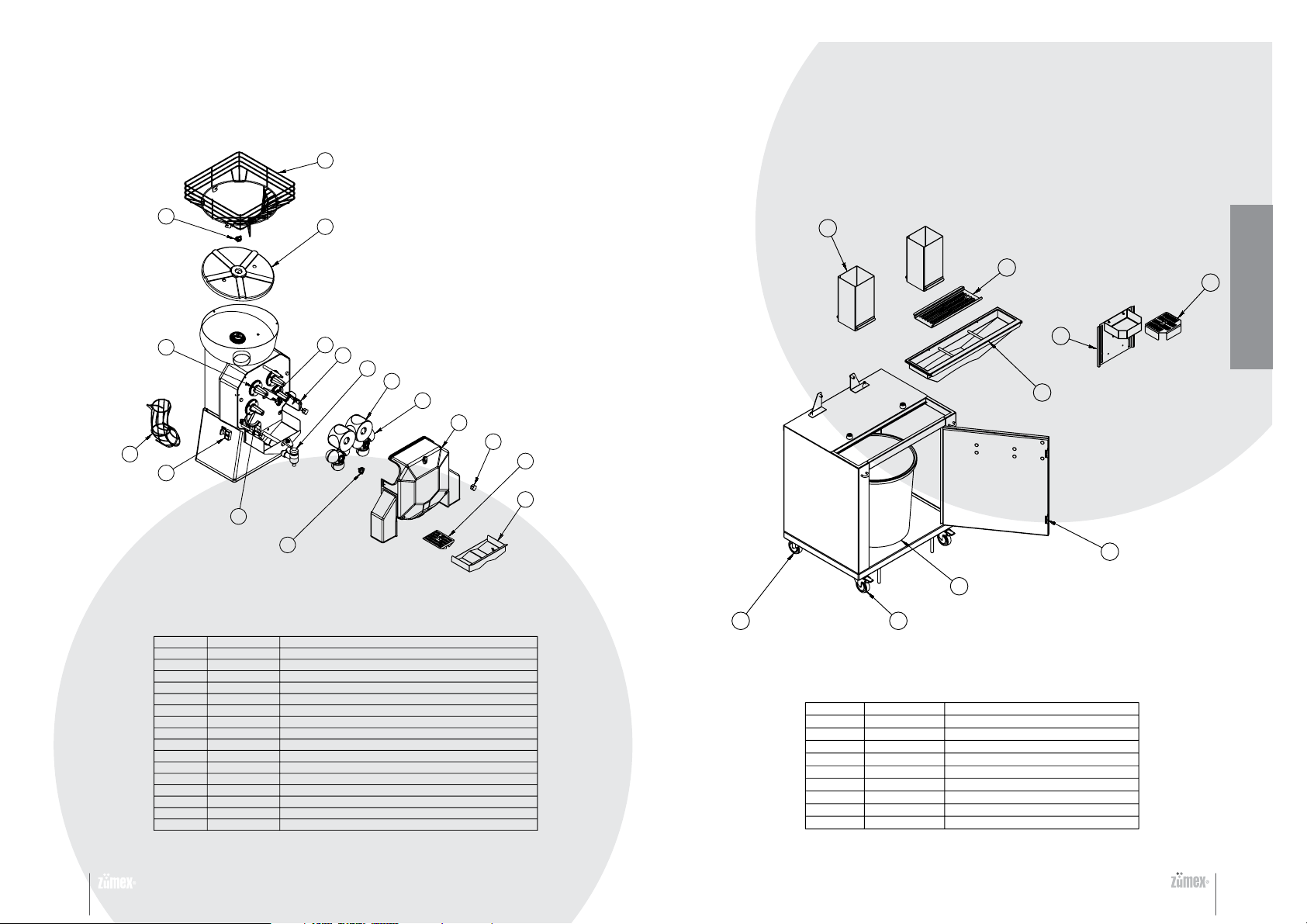

19

Zumex Autoservicio

Zumex Autoservicio:

base stand

17

8

12

9

14

18

6

7

9

10

7

6

5

4

3

13

2

1

17

8

EN

3

5

4

12

Index

1

2

3

4

5

6

7

8

9

10

12

13

14

17

18

19

Reference

260.0208.002

260.0209.000 INTERIOR FILTER JUICE CONTAINER

33.013.001 FRONT COVER

33.0031.000

33.0024.000

13.125.001 STEEL FRONT TAP

33.0001.000

200.3364.000

33.0059.000

33.0013.000

225.0921.002 FEEDER TUBE D85

33.0004.000

33.0002.000

33.0003.001

33.0034.000 CLASIC FEEDER PLATE

260.0908.003

PLASTIC JUICE FILTER

LOWER PRESSING UNIT

UPPER PRESSING UNIT

RIGHT PEEL EJECTOR

FASTENER SUPPORT CAP

BUTTON RUBBER PROTECTION

BLADE HOLDER

RETAINING KNOW KIT

LEFT JUICE EXTRACTOR

SECURING KNOB

FEEDER BASKET

Description

Index Reference

180.0008.000

1

180.0007.000

2

3

220.0219.001

165.0001.003

4

120.0014.001

5

220.0217.002

6

7

220.0218.001

33.0064.000

8

260.0233.002

9

ROTARY WHEEL, WITH BRAKE

ROTARY WHEEL, WITHOUT BRAKE

STAND PEEL HOPPER

43 LT. BUCKET

DOOR LOCK MAGNET

PEEL OUTLET

STAND FILTER

FRONT+ DRIP TRAY

DRIP TRAY FILTER

Description

34 35

MANUAL USUARIO Z auto-Z fresh 27/10/06 16:48 Pgina 19

19

Zumex Fresh Zumex Fresh:

base stand

17

18

8

10

7

6

EN

5

4

3

13

2

12

9

1

5

14

17

Index

10

12

13

14

17

18

19

1

2

3

4

5

7

8

9

Reference

260.0202.001

260.0203.000

33.013.001 FRONT COVER

33.0031.000

33.0024.000

33.0001.000

200.3364.000

33.0059.000

33.0013.000

225.0921.002 FEEDER TUBE D85

33.0004.000

33.0002.000

33.0003.001

33.0034.000 CLASIC FEEDER PLATE

260.0908.003

PLASTIC JUICE FILTER

INTERIOR FILTER JUICE CONTAINER

LOWER PRESSING UNIT

UPPER PRESSING UNIT

RIGHT PEEL EJECTOR

FASTENER SUPPORT CAP

BUTTON RUBBER PROTECTION

BLADE HOLDER

RETAINING KNOW KIT

LEFT JUICE EXTRACTOR

SECURING KNOB

FEEDER BASKET

Description

24

Index Reference

1

2

4

5

6

1

180.0008.000

180.0007.000

165.0003.000

120.0014.001

220.0217.002

ROTARY WHEEL, WITH BRAKE

Description

ROTARY WHEEL, WITHOUT BRAKE

30 LT. BUCKET

DOOR LOCK MAGNET

PEEL OUTLET

36 37

MANUAL USUARIO Z auto-Z fresh 27/10/06 16:48 Pgina 20

12

11

10

Index

10

11

12

Zumex Fresh Dispenser

6. DETECTING FAULTS AND PROBLEMS AND SECURITY ADVICES

• ALL MODELS

POSSIBLE CAUSE SOLUTIONFAULT

1

2

The machine does not start

3

4

5

6

7

8

9

1

2

3

4

5

6

7

8

9

Reference

13.020.000

260.0004.000

260.0005.000

260.0009.000

260.0010.000

260.0001.000

260.0011.000

260.0007.000

260.0008.000

260.0024.000

260.0003.000

260.0006.000

DEPOSIT COVER

FIXING PLATE

PUMP COVER

TAP PISTON

TAP JOINT

JUICE DEPOSIT

LEVER

DRIP TRAY FILTER

DRIP TRAY

BALANCE FOOT

DEPOSIT JOINT

PUMP TURBINE

Description

Machine blocks often when

juicing

Drums are blocked Oranges are blocked

Drums are not synchronized

Peel ejector is broken

Motor is running but drums are

not running

Tap is blocked

Machine stops after a short

period of time

• ONLY ZUMEX FRESH

The cooling group does not cool

the system

IMPORTANT SAFETY ADVICE

Always disconnect the machine before carrying out any action to unblock the unit.

To avoid accidents, do not start the machine without the safety detectors of the protective cover.

The cover acts on the safety detectors. The correct operation of the safety detectors must be tested periodically. Start

the machine and then remove the cover and check the machine to ensure that it stops. If the machine does not stop,

contact the Technical support service.

Do not start or use the machine if the power supply cable is damaged, contact the Technical support service.

When moving the machine and base stand (Zumex Self-Service and Zumex Fresh):

Unlock the front wheels of the base stand.

Never push the machine, only push the base stand. Never pull the base stand towards you.

Machine is not on Connect it

No voltage Check the socket

Top is not placed correctly Ensure it is placed correctly

Faulty safety detectors

Faulty ON/OFF switch

Faulty circuit

Not enough voltage

Faulty circuit

Internal fault

Peel ejectors are incorrectly placed

Internal fault

Juice has pulp or seeds

Not enough ventilation

Too much power

Contact the Technical support service

Contact the Technical support service

Contact the Technical support service

Check voltage and see if it matches

that described in the manual

Contact the Technical support service

Eliminate blockage

Contact the Technical support service

See the manual for correct placement

instructions (Fig. 7)

Contact the Technical support service

Clean the tap and ensure that both filters

of the container are placed correctly

Ensure the ventilation grids of the machine

are not blocked

Contact the Technical support service

POSSIBLE CAUSE SOLUTIONFAULT

Cooling group is disconnected

Cooling group is not on

Temperature regulation device is not

positioned correctly

Internal fault Contact the Technical support service

Level detector photocells are dirty

Deposit walls are dirty

Internal fault

Press the push-button placed on the left

of the deposit’s control lever

Check the internal connection on the

opening of the back cover of the base stand

Turn clockwise to increase cooling

Clean photocells

Clean the depositThe machine does not start

Contact the Technical support service

EN

38 39

Loading...

Loading...