Page 1

AUTOMATIC GAS WATER BOILER

ME10-GN ME15-GN

18 Gauge Type 304L

Stainless Steel

construction to resist

corrosion.

Solid State water level

control for automatic

refill

CONTENTS

Specifications

Start up Instructions

Trouble Shooting Guide

Parts List

Wiring Diagram

Operation Manual

NQ24A 12-2006

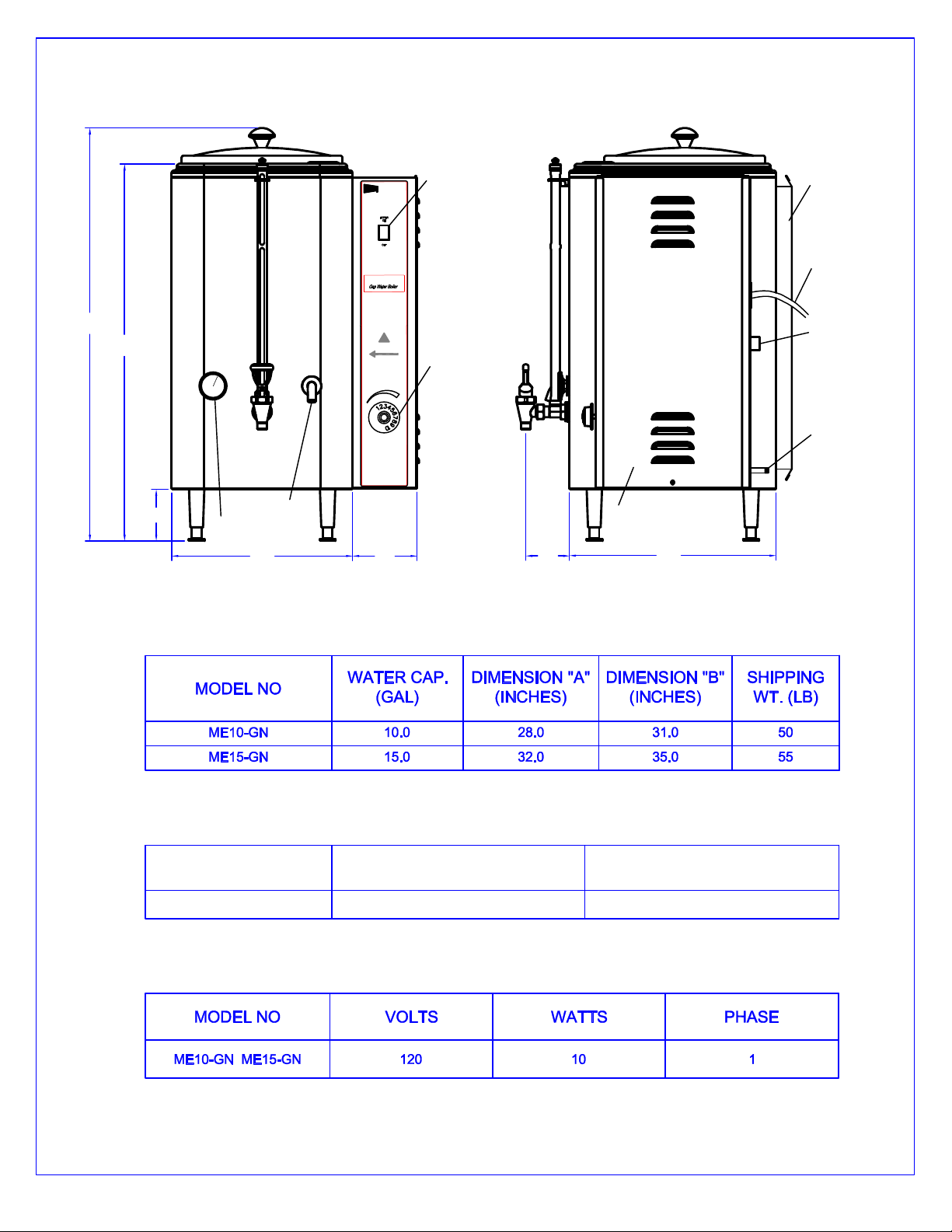

Page 2

POWER

SWITCH

GAS FLUE

"B"

"A"

OVERFLOW

4.0

GENERAL SPECIFICATIONS

THERMOMETER

14.0 5.0

TEMPERATURE CONTROL

NP87A

ME10-GN

CAUTION

HOT SURFACES

TEMPERATURE

CONTROL

LINE CORD

WITH PLUG

WATER INLET

(1/4 " FLARE)

GAS INLET

(3/8 " NPT)

SIDE ACCESS DOOR

(SLIDES UP)

3.4

16.0

GAS SPECIFICATIONS

MODEL NO.

ME10-GN ME15-GN

NATURAL GAS

BTU/ HR @ 3.5" W.C.

12,000

PROPANE GAS

BTU/ HR @ 10" W.C.

12,000

ELECTRICAL SPECIFICATIONS

NOTE: UNIT IS SUPPLIED WITH A GROUNDED 120V-15A LINE CORD AND PLUG (NEMA 5-15P).

1

Page 3

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND

LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

THIS INSTALLATION MUST CONFORM WITH THE NATIONAL FUEL GAS CODE,

ANSI Z223.1 (LATEST EDITION).

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE

OR MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH. READ

THE INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS

THOROUGHLY BEFORE INSTALLING OR SERVICING THIS EQUIPMENT.

SAFETY PRECAUTIONS

FOR YOUR SAFETY, THE FOLLOWING SAFETY PRECAUTIONS SHOULD

BE FOLLOWED AND ENFORCED.

IF YOU SMELL GAS:

• OPEN WINDOWS

• DON’T TOUCH ELECTRICAL SWITCHES

• EXTINGUISH OPEN FLAMES

• IMMEDIATELY CALL YOUR GAS SUPPLIER

1. Instructions must be posted in a prominent location and all safety precautions taken

in the event the user smells gas. Obtain this information from your local gas supplier.

2. LIGHTING: Follow the instruction on page 2 and label attached to right side of the

water boiler.

3. Do not place anything over the flue opening.

4. Do not place combustibles or non-combustible materials in the proximity of coffee

urn as this could cause fires or obstruct air flow to the main burners.

5. This installation must conform with local codes, or in absence of local codes with the

National Fuel Gas Code ANSI Z223.1, latest edition.

6. Provide adequate air supply and ventilation.

7. Provide adequate clearance for air openings into the combustion chamber.

8. Provide clearance for servicing and proper operation. Minimum clearance from

combustible construction 8” from back and 6” from side.

9. Boiler must be disconnected from gas supply during any pressure testing of

pipelines in excess of ½ psig, and isolated (by turning off gas shut-off valve) during

any testing less than ½ psig.

10. Retain this manual for future reference.

UNPACKING INSTRUCTION: Carefully unpack the water boiler and inspect immediately

for shipping damages. Your automatic water boiler was shipped in a carton designed to

give maximum protection in normal handling. It was thoroughly inspected before

leaving the factory and the carrier accepted and signed for it. File any claims for

shipping damage or irregularities with the carrier.

2

Page 4

ASSEMBLY: The four legs and vent cap drain are packed separately with the water

boiler. Install legs by tilting the water boiler on its side and screwing the legs into the

leg supports until hand tight. Carefully right the unit and install in its permanent

location, being sure to leave at least 6” on the right side of the water boiler for access

to the control box. Level the unit by adjusting the bottom pad of the legs. Place the

vent cap into the recess in the top of the unit. Mount the faucet assembly onto the

shank in upright position.

INSTALLATION AND OPERATING INSTRUCTION:

PRE-INSTALLATION INSTRUCTIONS: The installation of your water boiler must be made

by a licensed plumber and the installation must conform with State and Local Codes or

in absence of Local Codes, with the National Fuel Gas Code ANSI Z223.1 a latest

version.

AIR SUPPLY AND VENTILATION: Adequate ventilation and air supply must be provided

in order for the water boiler to operate properly and efficiently. The area in front of and

above the unit must be clear to avoid any obstruction of flow of combustion and

ventilation air. DO NOT under any circumstances, connect the water boiler flue directly

to a building exhaust system or place the flue outlet directly into the plenum of the

exhaust hood as it will adversely affect the gas combustion of the water boiler.

CLEARANCES: Your water boiler is design certified to use on combustible floors. The

side and back clearances for combustible constructions are as follows: 6 inches from

side and 8 inches from back. The water boiler must be installed with 4 inch high legs

provided.

GAS CONNECTION: Before connecting the water boiler to the gas line Examine the gas

specification label attached to the right side panel to be certain that the type of gas for

which the unit is equipped is the same as the gas supply. A 3/8 NPT gas connection is

needed to connect the unit to the gas line. An accessible manual shut-off valve must be

installed in the gas supply line in case of an emergency. The gas supply pipe must be

sized to accommodate all the gas fired equipment that may be connected to it. Check

with your local Gas Company as to proper pipe size. Sealant on all pipe joints must be

resistive to propane gas. Before attempting to light the water boiler, check all joints for

gas tightness using a soap and water solution.

WATER CONNECTION: The unit is supplied with ¼” flare fitting. Connect the copper

tubing with the flare fitting to the water connection at the rear of the machine. The

water line must have a shut-off valve (supplied by a plumber) to a cold water supply.

Water pressure should be 20 lbs. minimum for proper operation.

NOTE: Connecting the unit to a warm water supply will speed by heating and recovery

time.

To turn on the water supply valve plug the line cord into a dedicated 120V grounded

receptacle (NEMA 5-15R). The water will start entering the unit and automatically fill it

to capacity.

PRIMING OR INITIAL FILLING: Turn on the water supply. The unit fills at the rate of 1

gallon per minute. When the water level becomes visible in the sight gauge, turn the

thermostat knob to the ON position. The boiler will now automatically fill to capacity

and heat the water.

LIGHTING AND ADJUSTMENT: Water must be visible in the sight glass before lighting to

pilot. Turn the thermostat knob to its lowest position. Turn gas cock dial to PILOT

position. Depress gas cock dial and light pilot with a long lighted match through the

opening located on the bottom of the urn. Hold in depressed position for approximately

30 sec. or until pilot remains lit when dial is released.

3

Page 5

NOTE: On the first lighting it may be necessary to hold the dial for a longer period to

allow trapped air to escape from the line.

DIAL SETTINGS AND CORRESPONDING WATER TEMPERATURES:

“1”= 50F, “10”=198F

RELIGHTING: Shut off all gas and wait approximately 5 minutes before relighting the

pilot.

SHUTTING DOWN: For temporary shut down, turn the thermostat to lowest or OFF

position, then turn gas cock dial to PILOT position. To shut boiler down completely,

partially depress and turn gas cock dial to OFF position.

MAINTENANCE OR REPAIR: The owner should contact the manufacturer or an approved

local service company for maintenance or repair of the unit.

CLEANING: The outside of the unit should be cleaned on a regular basis using a soap

solution and a soft cloth or sponge. Abrasive cleaners are not recommended. For

cleaning the burner see section on removal and cleaning.

FOR QUALIFIED SERVICE PERSONNEL ONLY

THERMOSTAT CALIBRATION:

To adjust the temperature of the water in the urn, turn the thermostat knob to “10”and

remove the knob without moving the thermostat shaft. Place narrow bladed screwdriver

(1/8”) into the hollow thermostat shaft and engage center adjustment screw. When

thermometer reading approaches 198F slowly turn the adjustment screw clockwise until

the burner goes out. Turning the screw counter-clockwise will increase the

temperature.

REPLACING SOLENOID VALVE:

1. Shut off water supply and disconnect power to the boiler.

2. Drain off approx. 1 gallon of water from the boiler.

3. Disconnect hose nut from solenoid inlet.

4. Disconnect wires from terminals on solenoid coil.

5. Remove solenoid from cabinet (2 screws).

6. Remove silicon hose from solenoid and slip onto new solenoid and assemble back in

reverse order.

SAFETY PILOT:

Remove pilot adjustment cap on the gas valve and turn adjustment screw to provide

properly sized flame (3/4 inch long).Replace the cap.

Pilot Adjustment Screw

4

Page 6

BURNER:

The burner is factory set for maximum performance. Should further adjustments be

required loosen slotted hex screw on side of venturi and rotate air shutter until flame

with soft blue inner core is obtained.

BURNER REMOVAL:

The burner can be removed with the unit standing in operating position. Turn off the

gas flow to the unit. Allow the burner to cool off. Remove the wing nut holding the

burner to the frame. Pull down the free burner end, enough to clear the threaded stud

and pull the burner horizontally away from the manifold orifice. The burner can now be

cleaned or replaced. To reinstall, reverse the above procedure.

Hex Screw

Air Shutter

BURNER MAITENANCE:

The burner should be cleaned both inside the venturi portion and on the outside using a

soft bristle brush. The burner must be replaced into the same position as prior to

removal. Once a year, a qualified service agency should be contacted to inspect the

appliance for safe and proper operation.

5

Page 7

Page 8

Page 9

PARTS LIST

No. PART # DESCRIPTION ME10-GN ME15-GN

1

B012A

2

B033A TERMINAL BLOCK 3 POSITION 1 1

3

C032S LINE CORD W/ PLUG 120V 15A 1 1

HEYCO BUSHING STRAIGHT, SMALL

1 1

4 CD257 WATER INLET VALVE 120V 1 1

5 CH32A THERMOSTAT HARNESS ASSEMBLY 1 1

6

CH415 WIRING HARNESS ASSEMBLY 1 1

7

D022Q FAUCET, SHANK W/ VALVE 1 1

8

D031A GUAGE SHIELD, 14 1/2" 1 0

9

D066A GUAGE SHIELD, 18" 0 1

10

E009A OVERFLOW FITTING W/ NUT 1 1

11

F091A

12

F124A

13

F136A PILOT HOUSING 1 1

14

F178A THERMOPILE 24" 1 1

15

G052A T-BURNER 1 1

16

H080A TUBING, OVERFLOW - CU 5/8 X 16.5 0 1

17

H081A TUBING, OVERFLOW - CU 5/8 X 13.5 1 0

18

H345A PILOT TUBE 1/4" ALUMINUM 1 1

19

H346A GAS VALVE TUBE 3/8" ALUMINUM 1 1

20

J015A NIPPLE 3/8NPT x 4" BLACK STEEL 1 1

21

J040A STREET ELBOW 3/8NPT BLACK STEEL 1 1

22

J041A REDUCING COUPLING 3/8 x 1/8 1 1

23

K039A 1/4 x 1/8 COMPRESSION FITTING 1 1

24

K088A ORIFICE BODY 3305 R 1 1

25

K110A NUT, 3/8 NPT CHROMIUM PLATED 1 1

26

K192A

27

K193A FTG 1/8 NPT x 1/4 ANGLE 1 1

28

K491A HOSE NUT ASSEMBLY (AMERICAN THREADS) 1 1

29

K525A 90 DEGREE ELBOW 1/2" TUBE 1 1

30

K549A

31

K635A ELBOW COMPRESSION FITTING 3/8 x 3/8 BRASS 2 2

32

K636A HEX REDUCING BUSHING 1 1

33

K810Q LEVEL SENSOR, DUAL PROBE 1 1

34

L007A THERMOMETER BREW DIAL 1 1

35

L299A ON - OFF SWITCH 20 AMP 1 1

36

L621A

37

L622A THERMOSTAT 1 1

38

L690A DUAL LEVEL CONTROL BOARD 120V 1 1

39

L347P

40

M005S LEGS, 4" ADJUSTABLE, (4/ SET) 1 1

41

M028A KNOB, COVER 1 1

42

M326A HOSE, WATER INLET 3/8 ID x 5/8 OD 15" LONG (FEET) 2 2

43

M461A SEAL, SILICONE 12mm 1 1

44

M462A SEAL, SILICONE 15mm 1 1

45

M607A CLEAR GASKET 1 1

46

MA85A BLACK KNOB, THERMOSTAT 1 1

47

P264A SCREW, 10-24 X 1/2" PAN HEAD, PHILLIPS SST 2 2

48

P528A WASHER 1 1

49

P810A WING NUT, 10-24, SST 1 1

50

P813A WASHER, S.S. (0.382 ID x 0.642 OD x .028 THK) 2 2

51

Q102A COVER 1 1

52

U019A VENT CAP DRAIN 1 1

53

U160A GAUGE SHIELD MOUNTING BRACKET 1 1

ORIFICE, LP (LP UNITS ONLY)

ORIFICE, NAT (NATURAL GAS UNITS ONLY)

FITTING ALUMINUM INLET (NATURAL GAS UNITS ONLY)

FITTING ALUMINUM INLET (LP UNITS ONLY)

GAS VALVE NAT. (NATURAL GAS UNITS)

GAS VALVE LP. (LP UNITS ONLY)

1 1

1 1

1 1

1 1

1 1

1 1

Page 10

COMPONENT TESTS

A) Thermostat Adjustments:

The Thermostat is factory set for proper dispense temperature of 200°F ± 3°F with

the control knob set to the maximum clockwise position. If field adjustments are

needed proceed as follows:

To DECREASE temperature, turn the control knob slightly counter-clockwise.

For qualified technicians ONLY:

To INCREASE the water temperature - With the Thermostat Knob to its maximum

clockwise position, remove the knob and locate the slotted adjustment screw

inside the hollow thermostat shaft, Note: glyptal may need to be removed to gain

access, then using a narrow-bladed screwdriver, engage slotted adjustment

screw and turn it ¼ turn slowly counter-clockwise.

Allow a few minutes for the temperature to reach set level. The Heater Light will

go ON, indicating the heating element is activated, wait for it to go OFF, indicating

that the water has reached new set temperature. Take a temperature reading and

repeat if necessary.

B) Water Inlet Valve Test

- CCW - DECREASES

TEMPERATURE

ADJUSTMENT

SCREW

THERMOSTAT

Turn power OFF. If the water level rises inside a partially filled tank, the

Water Inlet Valve is leaking. Disconnect wires from the Water Inlet

Valve coil and connect a 2 wire line cord to the terminals. Plug it into a

115V outlet. If water flows in and stops when you pull it out, the Valve

is working fine. Repeat this test a few times. The problem may be in

the Probe or Water Level Control Board. If the water does not flow in

when the cord is plugged into an electrical outlet, the Solenoid coil may

be damaged, opened or the valve may have an obstruction preventing

the water from flowing in. Clean or replace it.

C) Dual Probe Test

If lack of water persists, check the probe as follows:

Turn on the power and water supply. Check inside the tank to make

sure the water is below the Probe. Pull the BLUE wire and terminal

OFF the Probe rod. If water still does not flow after the wire is

disconnected from the Probe, the problem may be in the Solid State

Dual Level Control Board.

If water starts flowing into the tank, the Probe may be grounded, due to

excessive liming. Check with Ohm meter. Clean or replace probe.

D) Dual Probe Liquid Level Controller Test

HOSE NUT ASSY

WATER INLET VALVE

BLUE

DUAL PROBE

Check the Controller as follows:

1. Make sure there is power input to the Controller at the terminals AC1

& AC2

Your voltmeter should read 115 Volts. It should read the same at

terminals AC1 & FILL when the water level is low. This is the output

power to actuate the coil of the Solenoid Valve to open it. The lack of

voltage at terminals AC1 & L-LEVEL or H-LEVEL indicates that the

Controller is not working properly.

2. Make sure all wire connections are tight, including ground.

3. If after this, the Controller is still failing to open the Water Inlet Valve,

replace it.

DUAL PROBE CONTROLLER

Page 11

ELECTRICAL DIAGRAM ME10G-N, ME15G-N

120/ 240 VOLTS

GND

N

WATER LEVEL CONTROL

WATER INLET

VALVE

WATER LEVEL

PROBES

WATER

POWER LIGHT

RED

WHT

BLU

YEL

GRN

GND

1 FILL

2 AC-1L

3 AC-2N

4 L-LEVEL

5 H-LEVEL

6 COMMON

LED

L1

POWER SWITCH

N

L1

CECILWARE CORPORATION

Loading...

Loading...