Page 1

AUTOMATIC

OPERATION MANUAL

Contents

MODEL No.

HOT WATER BOILER

Specifications

Installation

Maintenance Tips

Repair Parts List

ME-10E

ME-15E

ME-30E

Wiring Diagrams

ELECTRICAL SPECIFICATIONS

MODEL No.

ME-10E

ME-15E

ME-30E

NOTE: FIELD WIRING MUST BE SUITABLE FOR 75 DEGREES CELCIUS.

Every Cecilware product has been carefully inspected before shipment. The finest of materials and the highest

standards of workmanship have been but into the equipment.

Within 1 year of purchase, should any Cecilware product show defect in factory workmanship or material, we agree to

Repair, at our option or replace without cost to user such parts which prove upon factory inspection to have been so

defective. All equipment must be shipped transportation charges prepaid for acceptance. This warranty covers

replacement parts only, labor charges are covered for 90 days after installation.

This warranty does not apply under the following conditions:

Every Cecilware urn body is covered for three years. This warranty covers the stainless steel body and stainless steel

liners only.

Portable equipment such as Electric Fryers, Food Warmers, Electric Stoves, Dispensers, Plug-In Urns, Coffee

Brewers and Warmers must be returned to the factory or brought to an authorized service station for repair.

VOLTS WATTS AMPS PHASE

120 1,800 15.0 1 14AWG

240 7,000 29.2 1 10AWG

208 5,300 25.5 1 10AWG

240 10,500 25.0 3 10AWG

208 7,900 22.0 3 10AWG

USE COPPER WIRE ONLY FOR POWER SUPPLY CONNECTION.

COPPER WIRE: 14 AWG MINIMUM COPPER ONLY.

WARRANTY

• neglect or abuse of equipment

• excessive lime condition

• Improper installation

• any outside modification to equipment

UNPACKING INSTRUCTION: Carefully unpack the water boiler and inspect immediately for

shipping damages. Your automatic water boiler was shipped in a carton designed to give maximum

protection in normal handling. It was thoroughly inspected before leaving the factory and the carrier

accepted and signed for it. File any claims for shipping damage or irregularities directly with the

carrier.

FIELD

WIRING SIZE

CECILWARE CORPORATION

43-05 20th AVENUE, LONG ISLAND CITY, N.Y. 11105 • 718-932-1414 • FAX 718-932-7860

N796A-10/98

Page 2

ASSEMBLY: The four legs, faucet, float ball, and vent cap drain are packed

separately with the water boiler. Install legs by tilting the water boiler on its side

and screwing the legs into the leg supports until hand tight Carefully right the unit

and install it in its permanent location, being sure to leave at lest 6" on the right

side of the water boiler for access to the controls. Level the unit by adjusting the

bottom pad of the legs. Screw the ball float (36) onto the end of the water inlet

valve rod (35). Place the vent cap (30) into the recess in the top of the unit. Mount

the faucet assembly onto the shank (13).

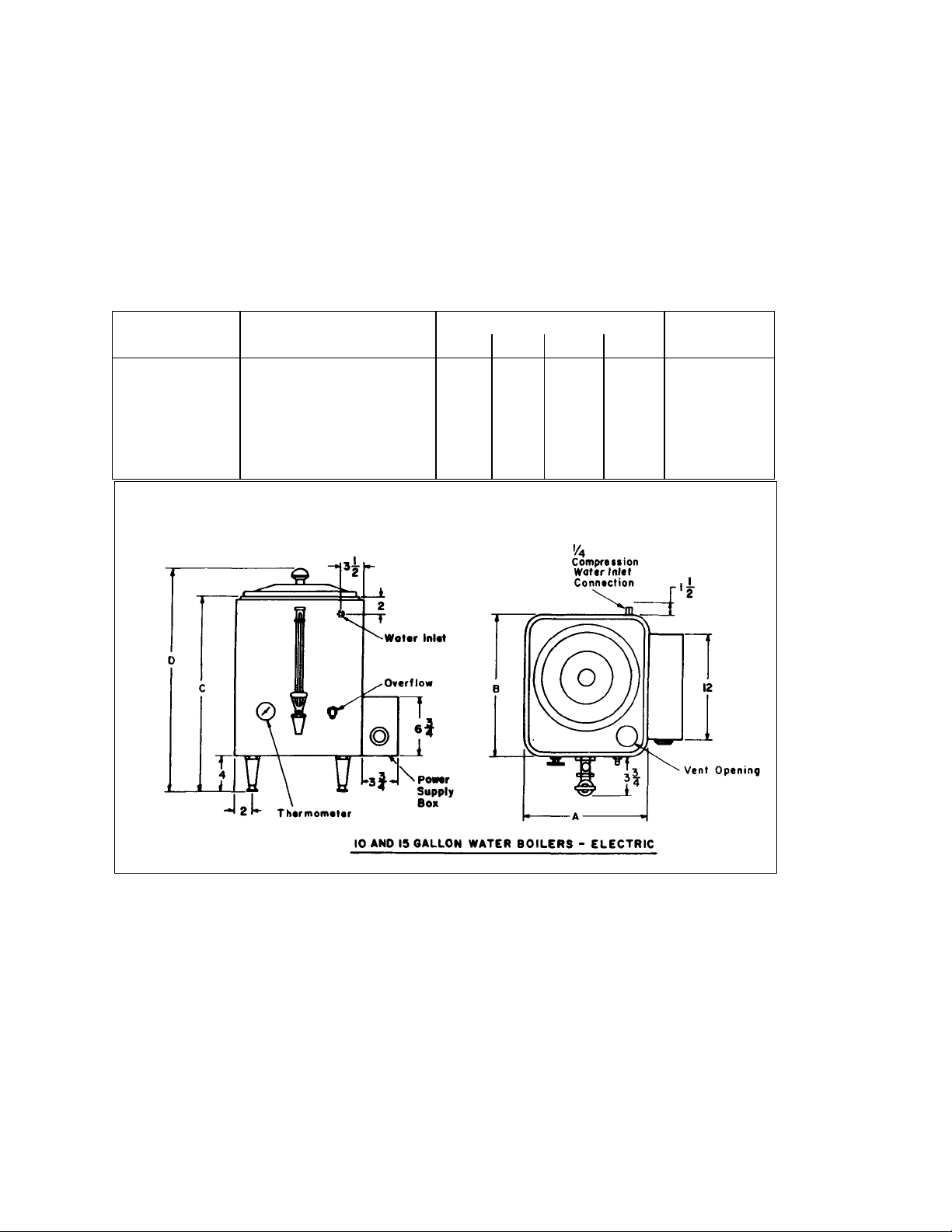

GENERAL SPECIFICATIONS

MODEL NO.

ME-10E 10.0 14 16 22.5 25.5 45

ME-15E 15.0 14 16 27.5 30.5 50

ME-30E 30.0 29 14 22.5 25.5 95

WATER CAP. IN

GALLONS

DIMENSIONS (INCH)

A B C D

SHIPP.

WT.(LB)

2

Page 3

CECILWARE CORPORATION

INSTALLATION INSTRUCTION FOR WATER BOILERS

Water boilers are shipped with the thermostats in the OFF position. Do not turn the thermostat

on before filling the water boiler with water.

NOTE: When positioning the unit, leave a minimum of 6" clearance on the right side of the

water boiler for ease of service.

WATER HOOK-UP PROCEDURE:

Use ¼” outside diameter copper tubing to connect the unit to the water supply line. The water

line must have a shut-off valve (supplied by a plumber). At the unit, connect the tubing to the

compression water inlet valve at the upper right hand side of the unit.

NOTE: Connecting the water boiler to a warm water supply will speed up heating and

recovery times.

ELECTRICAL HOOK-UP PROCEDURES:

NOTE: Always check the rating plate of the unit for proper voltage and current requirements.

1. 120V water boilers are provided with a 120V/15A grounded plug. Units must have a

separate 120V/15A outlet.

2. 208/240V water boilers are provided with a terminal block inside the control box. Field

wiring must be performed by a qualified serviceman.

1 and 3 phase hook-up:

Remove the fasteners on the cover and slide off cover. Install a suitable conduit and

connect copper wires to terminal L1 and L2 (and L3 for 3 phase unit only) and a #14

AWG ground wire to the ground lug.

PRIMING AND FILLING A UNIT:

Connect unit to power line (plug cord into line for 120V unit or turn on switch for the 208/ 240V

units). Turn on the water supply. The unit fills at the rate of 1 gallon/minute. When the water

level becomes visible in the sight gage turn the thermostat clockwise to maximum position.

The unit will now automatically fill to capacity and heat the water.

CLEANING INSTRUCTIONS:

DAILY: Wipe the outside of the unit with a damp cloth, using soap solution or a non-abrasive

compound when required.

SANITIZING THE UNIT:

With power to the unit disconnected, fill unit to capacity. Add 1 ounce of CLOROX BLEACH

(5.25%) for every gallon of water in the unit (400 PPM). Let the solution stand in the unit for 15

minutes, then drain all water from the unit slowly. If the unit is not to be used again

immediately after sanitizing — do not rinse with water. If the unit is to be used immediately

after sanitizing — rinse with water before refilling the unit for further use.

3

Page 4

SERVICE PROCEDURES

FOR QUALIFIED SERVICE PERSONNEL ONLY

TO REPLACE HEATING ELEMENT

1. Shut off electrical power to unit.

2. Shut off water supply to unit.

3. Drain water from unit by tilting the unit toward at the end of the drain cycle.

4. Remove control box cover and disconnect electric wire from electrical connection to the

heating element(s).

5. Remove (4) screws and pull out heating element(s) with gasket.

6. Install new heating element(s) with gasket.

7. Connect electrical wires to elements).

8. Repeat priming instructions.

TO REPLACE THERMOSTAT

1. Shut off electrical power to unit.

2. Remove control box cover and thermostat knob.

3. Disconnect electrical wires from thermostat.

4. Loosen small capillary nut, then the packing nut from boiler.

5. Remove (2) screws holding thermostat to side box.

6. Remove thermostat and pull out thermostat bulb from boiler. Note position of compression

ring on capillary tube.

7. Install new thermostat. Position capillary end of thermostat bulb two (2) inches from inside

wall.

8. Tighten large packing nut, then small capillary nut — DO NOT over tighten since this could

damage the controls.

9. Remount thermostat to control box side.

10. Re-connect electrical wires to thermostat.

11. Replace thermostat knob.

12. Repeat priming instruction.

13. Recalibrate control if required. Water temperature should be 195 to 205 degree F

maximum.

TO REPLACE HI-LIMIT CONTROL

1. Shut off electrical power to unit.

2. Remove control box cover and disconnect (4) electrical wires form control.

3. Loosen and remove (2) retaining nuts.

4. Install new control in reverse order.

REPLACING WATER INLET CONTROL VALVE

1. Shut off water supply to unit.

2. Disconnect water line from control valve.

3. Unscrew floatball.

4. Remove hex nut and washer while holding the valve/float arm assembly with the other

hand.

5. Install replacement valve in reverse order.

REPLACING FLOATBALL

1. Shut off water supply to unit.

2. Unscrew float ball. Check for water leaks by shaking the ball.

3. Replace defective float ball.

4

Page 5

TROUBLE SHOOTING PROCEDURES FOR QUALIFIED

of

eplace

If

depress red button. Still no

SERVICE PERSONNEL ONLY

PROBLEM POSSIBLE CAUSES SOLUTIONS OR REMEDIES

Water fails to heat

Line Fuse

or

Circuit Breaker

Hi-Limit Switch If Hi-Limit switch opens when water temp.

No voltage reading at

element

a. Defective

thermostat

b. Defective Hi-

Limit switch

Thermostat Pilot light should be on when thermostat

Check for circuit overload before resetting

breaker or replacing fuse.

reaches 200 degree F, replace switch.

Check voltage across terminals 1 and 3

Hi-Limit switch. If no reading r

thermostat.

Check voltage across terminals 2 and 4.

no reading —

reading — replace Hi-Limit switch.

is in the full on position (#5 position). If

not — replace thermostat and recalibrate

(see calibration). Power supply should

meet or exceed power requirements of

water boiler. Check data label on control

box for power requirements.

Water does not

stop filling

Water does not fill

Stuck valve Replace valve

Worn valve seat Replace valve

Float ball filled

with water due to

leak

Stuck filling

valve

Hung up float If float ball linkage does not move freely,

Water line

clogged

5

Replace float ball

Check float ball. It should move easily up

and down. If not — replace valve.

replace valve

Shut off water supply. Disconnect inlet

line. Clean or replace.

Page 6

ME 10E / 15E WATER BOILER

ME10E/15E

ME10E/15E

120V

ME10E/15E 120

V/1

Wiring diagrams

Schematic

diagrams

Electrical data

208/240 V/3 phase

VOLTS: 208/240

50/60 HZ

WATTS: 7900/10500

AMPS: 22/25

PHASE: 3

208/240 V/1 phase

VOLTS: 208/240

50/60 HZ

WATTS: 5300/7000

AMPS: 25.5/29.2

PHASE: 1

120 Volt Hook Up

VOLTS: 120

50/60 HZ

WATTS: 1750

AMPS: 14.6

PHASE: 1

phase

VOLTS: 120

50/60 HZ

WATTS: 1750

AMPS: 14.6

PHASE: 1

6

Page 7

J11.1

ME 10/15 E WATER BOILER

PARTS ILLUSTRATION

7

Page 8

PARTS LIST ME 10/15E

ME

10E/15E

120V

No. Description ME-10E ME-15E No. Description ME-10E ME-15E

1 Gauge Shield Mounting Bracket U160A U160A 20 Thermostat Bezel M016A M016A

2 Vent Cap Assembly K108A K108A 21 Control Box R484A R484A

3 Gauge Shield Washer KH X012A X012A 22A High-Limit Control 120V L224A L224A

4 Water Gauge Glass X030A X043A 22B High-Limit Control 240V M0602 M0602

5 Water Gauge Shield D020A D031A 23 Flange U013A U103A

6 Handle X007A X007A 24 Heater Gasket M0680 M0680

7 Plastic Bonnet X010A X010A 25A Heater 120V G199A G199A

8 Faucet Spring, S.S. X019A X019A 25B Heater 240V G197A G197A

9 Stem X058A X058A 26 Control Box Cover R485A R485A

10 Cup Seat X014A X014A 27 Thermostat L029A L029A

11 Silicon Gasket M256A M256A 28 Terminal Block BOOOA BOOOA

12 Faucet Assembly 0017A D017A 29 Overflow Tube H084Q H059Q

13 Shank D021A D021A 30 Vent Cap Drain U019A U019A

14 Dial Thermometer L007A L007A 34 Stem Valve M0251 M0251

15 Chrome Plated Nut, %" NPT K110A K110A 35 Adapter, % - 20 M0589 M0589

16 Body R479A R480A 36 S.S. Float, 3" M0892 M0892

17 Legs,set of 4 M005S M005S

18 Overflow Drain E071A E071A 38 Cover Q102H Q102H

19 Thermostat Knob M008A M008A

37 Knob M027A M027A

ME 10E / 15E WATER BOILER

Wiring diagrams

Schematic

Electrical data

diagrams

208/240 V/1 phase

VOLTS: 208/240

50/60 HZ

WATTS: 5300/7000

AMPS: 25.5/29.2

PHASE: 1

120 Volt Hook Up

VOLTS: 120

50/60 HZ

WATTS: 1750

AMPS: 14.6

PHASE: 1

CONVERSION INSTRUCTIONS FOR ME-10E and ME-15E WATER BOILERS

Conversion from 208 volts or 240 volts to 120 volts

To convert to 120 volt 15 amp outlet application simply connect a 120 volt 15 amp line cord equipped with 2 prong grounding cap to

terminal as follows.

1. Connect white lead to terminal block marked (L1).

2. Connect black lead to terminal block marked (L2).

3. Connect green lead to copper ground terminal marked GND.

4. Secure cord to terminal box with a strain relief clamp.

5. Change Marketings on Rating Label to reflect the voltage change.

8

Loading...

Loading...