Page 1

JAVA2-LP MANUAL

Cecilware sells value...

Worldwide

43-05 20th Avenue, Long Island City, 11105 718-932-1414

Fax: 718-932-7860

OPERATIONAL MANUAL

• Specifications...........................……………..

• Installation & Start Up

Procedure……………

• Programming...............................…………...

• Adjustments................................…………...

• Cleaning & Sanitizing...............………………

• Parts Identification..................………………

• Wiring Diagrams.....................………………..

LECTRICAL SPECIFICATIONS:

120 Volts

15 Amp Circuit

60 Hz

1 Heater

1,700 Watts

5-15R Receptacle

MECHANICAL SPECIFICATIONS:

Width: 8.5"

Depth: 20"+2" Clearance For Waterline.

Height: 21"+2.5" Legs.

Cup Clearance: 4.5"

Hopper Capacity: 1 Lb Dry Coffee.

Tank Capacity: 1 Us Gal.

Burst Rate: 120 Cups/Hr.

Recovery Time: 5 Min.

FACTORY SETTINGS:

Gram Throw Dial: 2.4

Coffee Gram Throw: 2.2 gr. Coffee /8 oz. Cup.

Water Flow Rate: 1 to 1.3 oz./sec.

1

2

3

3

5

10

11

Page 2

INSTALLATION

Water Inlet Connection:

This equipment is to be installed to comply with the applicable Federal, State, or local plumbing codes having jurisdiction. In

addition:

1. A quick disconnect water connection or enough ext

ra coiled tubing (at least 2x the depth of the unit) so that the machine

can be moved for cleaning underneath.

2. An approved back flow prevention device, such as a double check

valve to be installed between the machine and the water

supply.

The JAVA2-LP is equipped with a 1/4"

Flare Water Inlet Fitting, located on the lower left side in the back of the base.

HIGHLY RECOMMENDED:

A WATER SHUT-OFF VALVE and A WATER FILTER, pref

erably a combination Charcoal/Phosphate Filter, to remove odors and

inhibit lime and scale build up in the machine. Note: In areas with extremely hard water, a water softener must be installed

in order to prevent a malfunctioning of the equipment and in order not to void the warranty.

STARTUP PROCEDURE

Caution: Make sure that the Heater Switch, located behind right hopper with door opened,

1. Connect the 1/4" dia copper waterline to the 1/4" flare water inlet fitting of the valve.

2. Plug the power cord i

nto a proper receptacle.

3. Activate the Power Switch (Toggle Up). T

he door display panel and the green dispense buttons will light up and the tank

will start filling. Allow approximately 2 minutes for the tank to fill.

4. Activate the Heater Switch. Allow approximately 15 - 20 minutes for

the water to reach a preset temperature of

200°F. The heat up time will depend on the water inlet temperature, the input voltage and the wattage of the elements

in the machine.

5. Place cup under nozzle and press dispense switch. The machine will dispense wat

Repeat it several times for each dispen

se switch to check for consistent output.

er at the rate of 1-1.3 oz. per second.

6. While the tank is heating up, remove the hoppers, load them with products and reposition them back in the machine.

When the heater light goes OFF, t

he tank has reached its brew temperature and the machine is ready to dispense Coffee.

VOLUME AND DRINK SIZE ADJUSTMENTS:

2

is in the OFF position.

Page 3

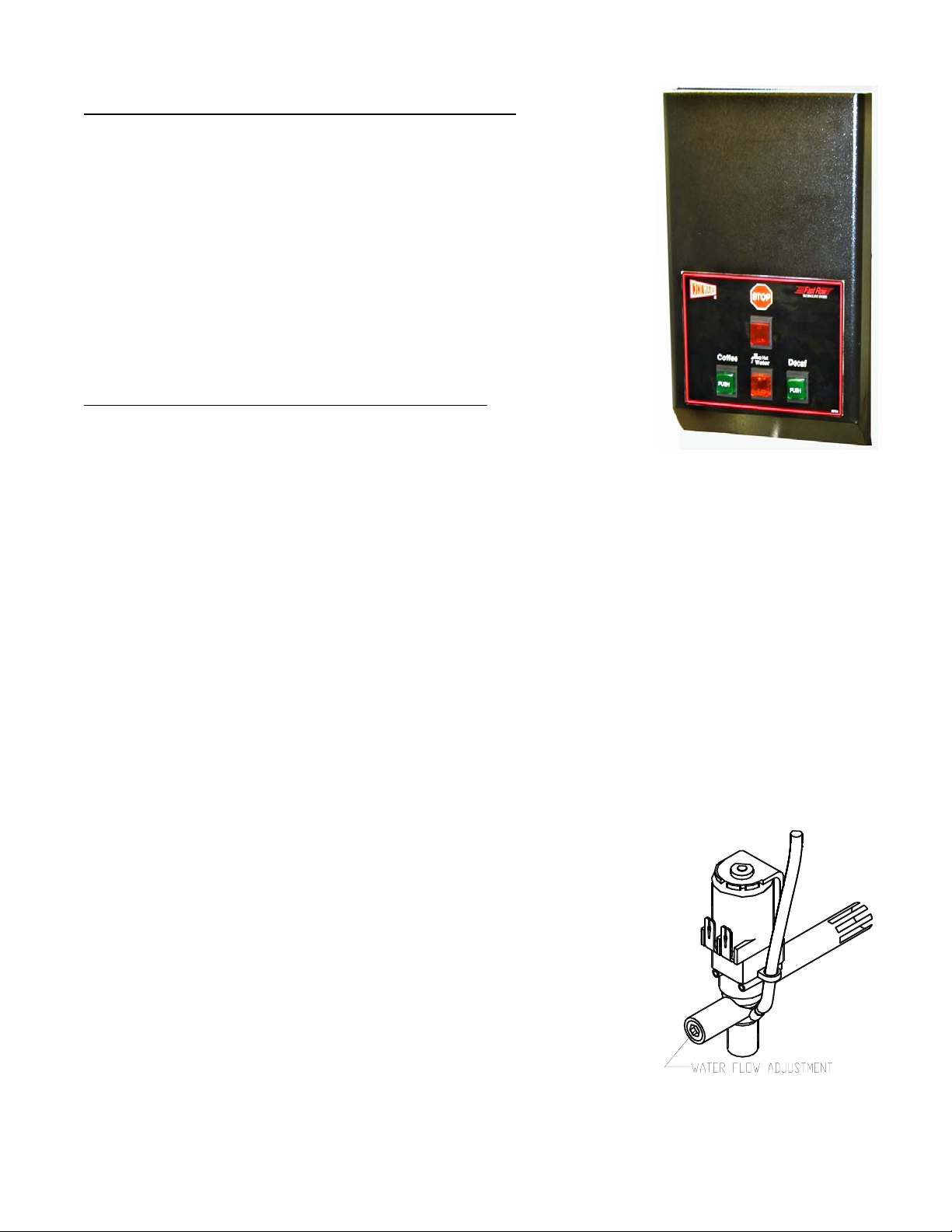

PROGRAMMING INSTRUCTIONS FOR AUTOMATIC DISPENSE

1. Turn Power Switch ON (toggle switch inside door).

2. PRESS and HOLD [red] STOP Button with one hand.

3. PRESS and HOLD [green] DISPENSE Button with other hand.

4. RELEASE [red] STOP Button ONLY.

5. Continue to HOLD [green] DISPENSE Button for 5 SECONDS, then RELEASE.

6. PRESS and RELEASE [green] DISPENSE Button. Product begins dispensing.

When it reaches the "DESIRED VOLUME",

7. PRESS and RELEASE [green] DISPENSE Button to SET "DESIRED VOLUME".

DISPENSE Button can be "jogged" to top off.

8. PRESS and RELEASE [red] STOP button to LOCK IN "DESIRED VOLUME".

Repeat steps 1 to 8 for each Dispense Button.

PROGRAMMING INSTRUCTIONS FOR MANUAL DISPENSE

1. PRESS AND HOLD STOP [red] BUTTON WITH ONE HAND.

2. PRESS AND HOLD DISPENSE [green] BUTTON WITH OTHER HAND.

3. RELEASE STOP [red] BUTTON.

4. RELEASE DISPENSE [green] BUTTON.

5. PRESS AND RELEASE STOP [red] BUTTON.

The Total Time The Water Is Running Is Accumulated And Saved Into Memory. For Normal Operation,

Press and Release Dispense Button.

The Automatic Dispense Buttons are factory programmed to dispense 8 oz. of Water per cup.

PRODUCT STRENGTH ADJUSTMENTS:

The JAVA units have variable speed control auger motors [CD151 with variable

speed of 10 to 130 RPM].

Drink or Product Strength can be changed by adjusting the Gram Throw Dial on inside door panel.

The Gram Throw is factory preset at approx. 2.4 (2.2 gr. per 8 oz. cup) for the JAVA2-LP machines.

The water flow rate adjustment for the dispense valve should remain fixed bet. 1 - 1.3.

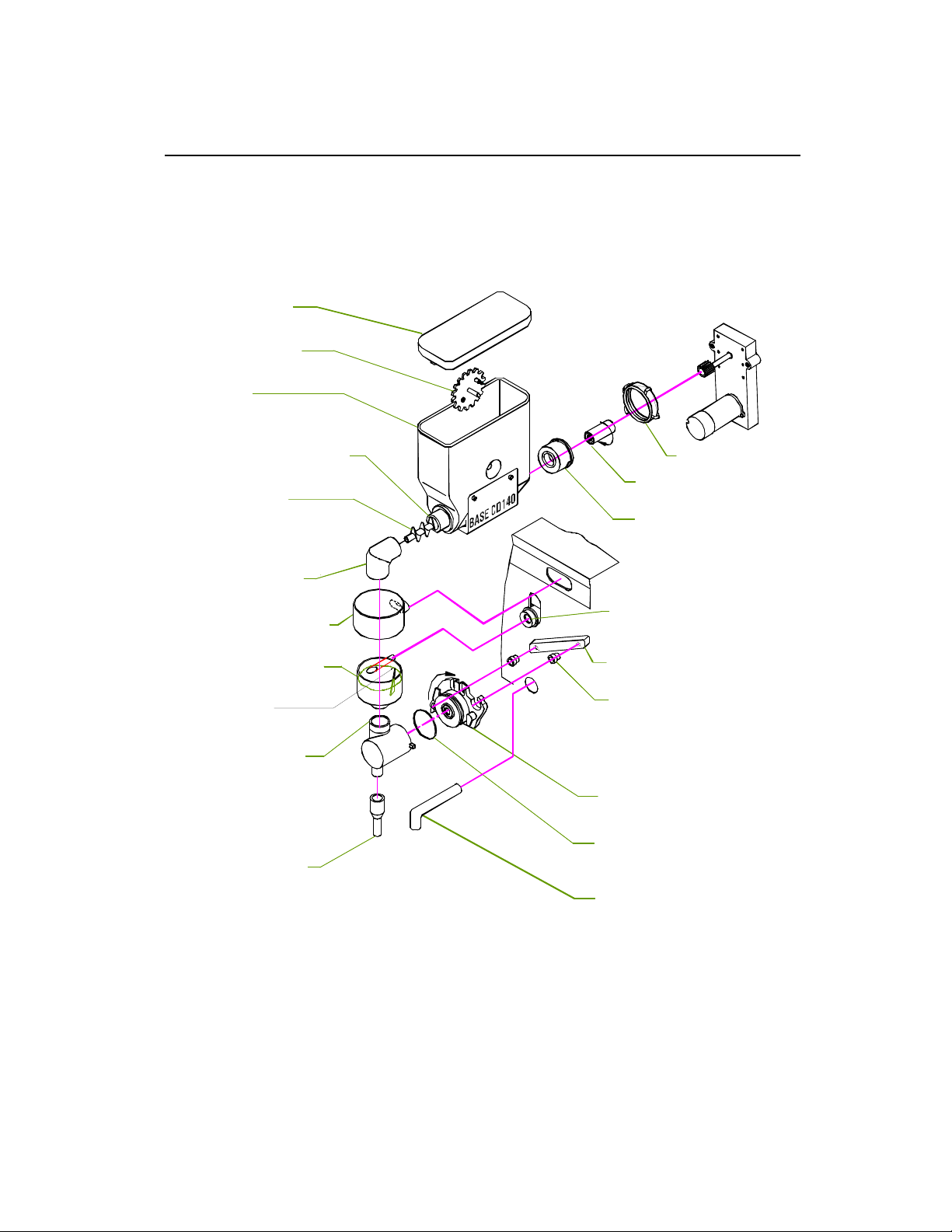

HOT WATER FLOW RATE ADJUSTMENTS:

Note: Remove right side panel to access the Water Dispense Valves, .

TO ADJUST HOT WATER FLOW RATE:

1. Remove right side panel to access the Water Dispense Valves, mounted on tank.

2. Locate adjustment screw on Dispense Valve.

3. Using Allen Key or flat screwdriver rotate, 1/4 turn at a time,

CLOCKWISE to decrease water flow, or COUNTERCLOCKWISE to increase water flow.

4. Check water flow output, after each 1/4 turn.

3

Page 4

JAVA2-LP HOPPER ASS'Y CD313 & DISPENSE ASS'Y

CAPACITY- 1 LB COFFEE, 7.875"H w/cover x 3"W, W/NYLON AUGER

HOPPER COVER CD106

AGITATOR GEAR CD117

HOPPER CD313

AUGER BUSHING FRONT CD277

NYLON AUGER CD130

(22.5Øx18mmPT)

W/"O" RING CD139

PRODUCT GUIDE CD70A

DISPENSE CAP BLK - CD272

MIXING CHAM. BLK - CD275

8 mm dia. opening

NOTE WATER LEVEL

DC MOTOR CD151 90rpm

(Portion Control)

NUT [2] CD278

FLANGE/NUT CD136

AUGER BUSHING

BACK CD279

MIX BOWL SOCKET CD67A

W/O-RING M378A

BASE MOUNT BAR CD89A

BASE MOUNT GROMMET CD66A

WHIP CHAM. BLK-CD321

MOUNTING BASE BLK - CD322

EXTENSION TUBE M849A

M379A 'O'-RING #125

EXTENSION TUBE K682A

4

Page 5

CLEANING AND SANITIZING:

SANITIZING: All food dispensing units should be sanitized periodically. All parts to be sanitized must be cleaned first.

To prepare a sanitizing solution: ADD 2 TSP. OF LIQUID CLOROX BLEACH (5.25% CONCENTRATION) TO 1 GALLON OF

WATER AT ROOM TEMPERATURE (70° - 90°F).

Soak all parts for a minimum of 3 min. in the sanitizing solution. Note: Always start with a unopened bottle of Clorox Bleach

since the solution from an opened bottle has a short life span.

Let all sanitized parts drain and dry naturally. DO NOT WIPE THEM DRY. Before using the sanitized unit (or parts) with food

stuffs, rinse all parts thoroughly with water.

CARE FOR STAINLESS STEEL:

Stainless Steel surfaces that come in contact with food

substances, MUST BE CLEANED EVERY DAY.

WHEN CLEANING STAINLESS STEEL , ONLY A pH

NEUTRAL CLEANER IS TO BE USED.

Use nylon or brass brushes (not steel wire brushes) for

HOPPER

ASS’Y

removing food deposit.

Many food products contain acids,alkalies, or other

substances which corrode Stainless Steel.

RECOMMENDED DAILY CLEANING AND MAINTENANCE

1. Empty drip tray and wash with dish detergent.

2. Rinse Chamber:

PRODUCT

GUIDE

3. Flip RINSE SWITCH ON and press DISPENSE BUTTON.

4. Flip RINSE SWITCH OFF. Remove and refill Hopper.

5. Turn PRODUCT GUIDE UP to reduce spillage.

DISPENSE

CAP

CLEAN HOPPER (once a week)

a. Open cabinet door and top lid.

b. Turn the product guide up, to reduce spillage.

c. Empty out Hopper.

DISPENSE

CHAMBER

d. Pull off Product Guide.

e. Unscrew Agitator and remove.

f. Remove the auger by turning the hopper

horizontal, auger will fall out.

g. Wash parts with dish detergent.

MOUNTING

BASE

WHIPPER

CHAMBER

h. Rinse, dry, and re-assenble parts.

CLEAN DISPENSE CHAMBER (once a week)

1. Twist CW and pull off STEAM DEFLECTOR.

2. Pull off DISPENSE CHAMBER.

PRODUCT

NOZZLE

6. Wash components with dish detergent.

7. Rinse, dry, and re-assenble parts.

5

Page 6

FRONT OPEN VIEW

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

23 24

22

20

19

18

17

25

26

27

28

21

6

Page 7

RIGHT SIDE OPEN VIEW

2 1 3

7

Page 8

LEFT SIDE OPEN VIEW

3 2 1

12

11

10

9

8

7

6

5

4

8

Page 9

TANK TOP ASS’Y

2

3 1

4

5 6 7 8 9

9

Page 10

FRONT OPEN VIEW

ITEM P/N QTY DESCRIPTION

1 RX67A 1 TOP COVER, CABINET

2 SF79A 2 SIDE PANELS

3 CD313 1 HOPPER ASS'Y

4 M705A 1 DOOR LATCH

5 RV57Q 1 TROUGHT DRAWER ASS'Y

6 CD272 1 STEAM DEFLECTOR

7 CD67A 1 SOCKET F/ MIXING BOWL

8 L299A 1 RINSE SWITCH

9 CD275 1 DISPENSE CHAMBER [8mm dia.]

10 CD321 1 WHIPPER CHAMBER

CD322

M848A

11

CD66A

CD89A

12 L069A 1 POWER SWITCH

M849A

13

K682A 1 1

14 NA91A 1 CAUTION LABEL

15 SF84A 1 GRILL

16 SF83A 1 TRAY

17 SF23A 1 FACIA BOTTOM CAP

18 C002A 1 HEATER LIGHT

19 CH93A 1 DOOR HARNESS

20 K618A 1 HIDDEN HINGES [1 SET]

NF17A

21

NF58A

N978A

22 SF19Q 1 DOOR FRAME ASS'Y

SF21A

SF22A

23

L576A

L557A

24 L567A 1 HEATER SWITCH

25 Ni70A 1 SWITCH PANEL LABEL

26 L574A 1 STOP SWITCH RED

27 L457A 1 HOT WATER SWITCH AMBER

28 L455A 2 DISPENSE SWITCH GREEN

1

BASE MOUNT CLOSED

PLUG F/ BASE MOUNT

1

GROMMETS

2

MOUNTING BAR

1

COFFEE SPOUT, WHITE TEFLON 1.75” L

HOT WATER SPOUT [1.5”L X 4”L]

1

START UP PROCEDURE INSIDE DOOR

1

PROGRAMMING INSTRUCTIONS

1

CLEANING AND SANITIZING INSTRUCTIONS

1

INSIDE DOOR PANEL

1

KNOBS COVER

3

TEACH ME TIMERS

2

POTENTIOMETERS

F/ WHIP. CHAMBER

RIGHT SIDE OPEN VIEW

ITEM P/N QTY DESCRIPTION

1 L556A 2 SPEED CONTROL BOARD F/AUGER MOTOR

2 CD151 2 AUGER MOTOR

3 CD56A 1 BLOWER

LEFT SIDE OPEN VIEW

ITEM P/N QTY DESCRIPTION

1 L566A 1 LEVEL CONTROL BOARD

2 B129A 2 RELAYS, SAFETY

3 CF29A 2 TRANSFORMERS

4 CD257 1 WATER INLET VALVE

5 M830A 1 HOSE - inlet valve to tank .375 Id x 9"L

6 M829A 1 HOSE - drain .375 IDx12"L

7 K525A 1 ELBOW

8 M832A 1 HOSE - Disp. Valve, Nozzle .375 Id x 11"L

9 M831A 1 HOSE - Disp. Valve–Chamber .375 Id x3.5"L

10 L467A 2 DISPENSE VALVE [1-Product, 1-Hot Water]

11 M494A

M461A 1 6

12 SG06Q

M600A 1 1

GROMMET PLUG [ F/ TESTING ]

GROMMET [ 0.466 DIA ]

TANK BODY ASS’Y

SPLICED GASKET,

CUT FROM 21.75” TO 21”

10

Page 11

ITEM P/N QTY DESCRIPTION

1 L573A 1 HI-LIMIT, SURFACE MOUNT

2 P465A 2 SCREW, TANK TOP 1/4-20x5/8

3 M461A 6 GROMMET [.446 ID]

4 L681A 1 THERMOSTAT

5 K402Q 1 LEVEL CONTROL PROBE

6 K525A

M787A 6

7 M 1 HOSE, BREATHER TUBE

8 G296A

03051

07059

M730A

9 L499A 1 FLOAT SWICH

TANK TOP ASS’Y SG08A

ELBOW TUBE, SS OR

ELBOW SILICON TUBE, BREATHER

1

HEATER 120V, 1500W

2

NUT F/ HEATER

2

WASHER F/ HEATER OUTSIDE

2

WASHER F/ HEATER INSIDE

11

Page 12

N

TEACH-ME

TIMER

2

314

TEACH-ME

TIMER

1

423

TEACH-ME

TIMER

231

4

L1

STOP

COFFEE DECAFF

HOT WATER

..

SPEED

CONTROL

D.C.

AUGER

MOTOR

COFFEE &

DECAFF

DISPENSE VALVE

WATER LEVEL PROBE - IN TANK

.

WATER INLET VALVE

FLOAT SWITCH

1 PROBE

3 N

2 L1

1 LOAD

HOT WATER

DISPENSE

VALVE

LEVEL

CONTROL

SPEED

CONTROL

DOOR UNIT

D.C.

AUGER

MOTOR

MAIN UNIT

FAN/BLOWER

HEATER LIGHT

N

.

THERMOSTAT

.

HEATER SWITCH

5-15P

5-15R

15A-1.7KW

POWER

SWITCH

L1

.

.

HI-LIMIT

CG 1 : 1

12

Loading...

Loading...