Page 1

CAPPUCCINO, COFFEE, and SOUP DISPENSERS

GB POUROVER models:

•GB1P

•GB2P

•GB3P

•GB4P

OPERATION MANUAL

• Specifications...................................................…. 2

• Installation and Operating Instructions.............. 4

• Adjustments..........................................…............. 6

• Care and Maintenance.........................….............. 8

• Components Illustration.....…............................. 11

• Parts Identification...................…........................ 15

• Wiring Diagrams..........................…..................... 21

Cecilware sells value... Worldwide

45-05 20th Avenue, Long Island City, NY 11105 • 718-932-1414

FAX 718-932-7860

NH79A 11/99

Page 2

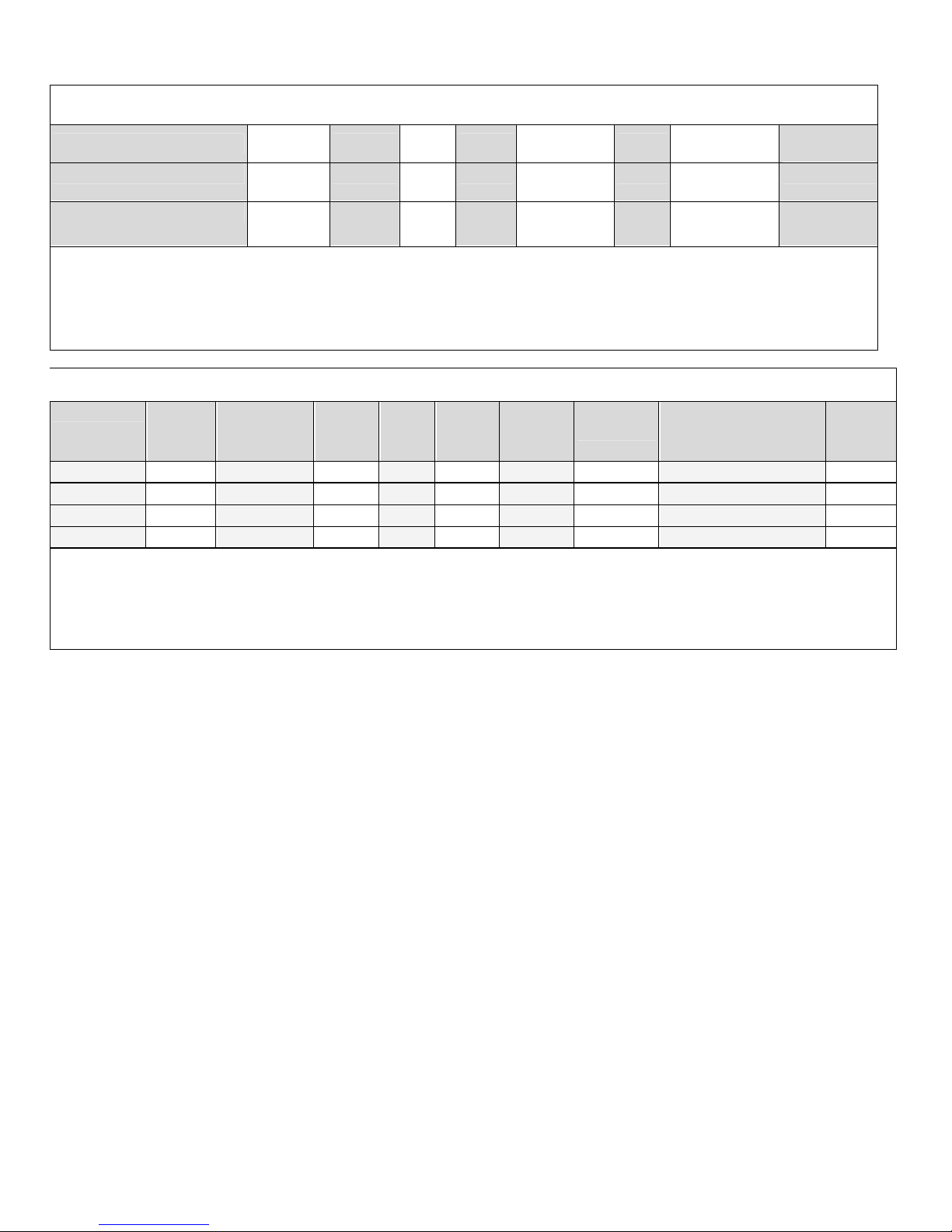

Electrical Specifications

Plumbing: ¼” water line required.

Model No. Volts Phase Hz Watts

GB1P, GB2P, GB3P

GB1P, GB2P, GB3P, GB4P

120V, 1.8 KW, 15A, Nema 5-15R standard on ail models; 3.0 KW, 120/240V units available

** 120/240V, 3 pole, 4 wire grounding type Twist-Plug Receptacle.

For 240V units. Use L6-20R, 2 pole, 3 Wire Twist-Plug Receptacle. For Wiring, refer to Wiring Diagrams.

See Electrical Data Label attached to the back of the unit for proper voltages, breaker sizes and electrical outlet requirements for each model

number listed.

120V

120/240V

240

1

1

1

60

50/60

50/60

1.8KW

3.0KW

3.0KW

Number of

Heaters

1

1

1

Amps

15

15

15

Receptacle

Nema No.

5-15R

L14-20R**

L6-20R

Circuit

15A

20A

20A

Mechanical Specifications

Model# No. of

Hoppers

GB1P-LD 1 4 Ib. 8.5 22 31.5 1.5 15 (7X13)91 70

GB2P-LD 2 4 Ib. 8.5 22 31.5 1.5 15 (7X13)91 75

GB3P-LD 3 4 Ib. 11 22 31.5 2 22 (9.5X13) 123.5 90

GB4P-LD 4 4 Ib. 14.125 22 31.5 4.5 45 (12.375X13) 123.5 100

Height: Add an additional 4" when installing with 4" legs.

Add an additional 14" min for water bottle and additional height space to invert bottle over the top.

*Burst Capacities - Max. number of drinks dispensable with available hot water - based on 6 oz. cups.

** Add 2" for line cord and valve fitting clearance.

Hopper

Capacity

(lb.)

Width

(in.)

Dept.

(in.)

Height

(in.)

Tank

(gal.)

Burst

Capacity

Lit Display Area

(W x H) sq. in

Ship

Weight

(Ib.)

2

Page 3

START UP INSTRUCTIONS FOR GB POUROVER

CAPPUCCINO DISPENSER

(see illustration 9-3 for clarification)

I. INSTALLATION INSTRUCTIONS

This equipment is to be installed to comply with the applicable Federal, State, or local plumbing codes having jurisdiction.

In addition:

1. A quick disconnect water connection or enough extra coiled tubing (at least 2x the depth of the unit) so that the machine can be moved for

cleaning underneath.

2. An approved back flow prevention device, such as a double check valve to be installed between the machine and the water supply.

The GB beverage dispenser is equipped with a '/4" Flare Water Inlet Fitting which is located on the left side in the back of the base (when looking

at the machine from the front).

HIGHLY RECOMMENDED: A WATER SHUT-OFF VALVE and A WATER FILTER, preferably a combination Charcoal/ Phosphate Filter,

to remove odors and inhibit lime and scale build up in the machine.

Note: In areas with extremely hard water, a water softener must be installed in order to prevent a malfunctioning of the equipment and in order

not to void the warranty.

After the machine has been unpacked and placed on a counter, pull out the stainless steel drip tray. It should contain

the following: A Set of 4 Adjustable Leveling Legs & Water Inlet Fitting.

Connect the ¼” dia. copper waterline to the ¼” flare water inlet fitting of the valve.

Caution: Do not plug into power outlet yet.

Make sure the Heater Switch is OFF (Toggle Down) (see below door).

II. PRIMING- MANUAL/BOTTLE POUROVER - Water Selection Switch -Toggle Up (See Back Panel)

1. Do NOT plug into power outlet yet.

2. Make sure Heater Switch is in the OFF position.

3. Fill reservoir tank (top) with 2 gallons of water, wait about 3 minutes for water to fill Heating Tank below. Refill Top Reservoir Tank with

another 2 gallons of water.

The unit will NOT dispense unless the Top Reservoir Tank is at least 1/2 full. So keep Reservoir Tank full.

Note: The unit has a Float-low water cutout switch (item 2, 111. h-1) inside the Reservoir Tank, which stops the machine from

dispensing when the Reservoir Tank is empty.

4. Plug into power outlet.

5. Turn Heater Switch ON.

6. Allow 10 to 15 minutes for water to reach dispense temperature of 185°F. Heater Indicator Light (red) goes ON when heater is on (see

lower front panel).

7. Fill hopper with product.

8. Place cup under dispenser.

9. Push and hold Dispense Button (green) until water flows from mixing chamber.

10. Machine is primed and ready to go.

3

Page 4

III. PRIMING - AUTOFILL - Water Selection Switch - Toggle Down (See Back Panel)

1. Plug into power outlet.

2. Turn Heater Switch ON.

3. Allow 10 to 15 minutes for water to reach dispense temperature of 185°F. Heater Indicator Light (red) goes ON when heater is on (see

lower front panel).

4. Fill hopper with product.

5. Place cup under dispenser.

6. Push and hold Dispense Button (green) until water flow s from mixing chamber

7. Machine is primed and ready to go.

IV. POUROVER-PORTABLE BOTTLE OPERATION (Water Selection Switch - toggle UP) UNIT CAN BE OPERATED WITH A

3 GALLONS CAPACITY FRESH WATER BOTTLE. TO OPERATE WITH PORTABLE BOTTLE, proceed AS FOLLOWS:

1. Remove Reservoir Tank Cover.

2. Make sure that Reservoir Tank is only 1/2 full or empty, to prevent water spillage. To remove excess water push dispense

button.

3. Fill bottle with water.

4. Invert bottle into reservoir tank in one motion to minimize spillage.

5. Remove and refill bottle when "REFILL" light is ON.

NOTE: REFILL LIGHT, ON THE FRONT DOOR PANEL, WILL GO ON, WHICH INDICATES THAT THE WATER TANK MUST

BE REFILLED. WHEN REFILL LIGHT GOES ON, THE UNIT WILL NOT DISPENSE UNTIL TANK IS FILLED WITH WATER.

REFILLING WITH HOT TAP WATER WILL SHORTEN HEAT UP TIME.

V. NORMAL OPERATION (POUROVER AND AUTOREFILL)

1. Place a 6 oz. or larger cup under the left dispense nozzle, then press and hold the left dispense switch for 6 seconds. The machine

will dispense water at the rate of 1 oz. per second. Repeat it several times to check for consistent output.

2. While the tank is heating up, remove the hopper, load with product and reposition it back in the machine. When Ready Light goes

ON. the tank has reached its brew temperature and the machine is ready to begin dispensing the first cup of Cappuccino.

VI. WATER FLOW ADJUSTMENTS

THE UNIT IS FACTORY ADJUSTED TO DISPENSE WATER AT THE RATE OF 4 oz/sec. TO INCREASE

OR DECREASE FLOW, PROCEED AS FOLLOWS:

1. Remove Left side panel and locate Dispense Valve mounted on tank, with Flow Adjuster facing up, underneath cold water reservoir.

2. Locate Flow Adjustment Screw (white) on Dispense Valve. Use Allan Key to reach Flow Adjuster.

3. Rotate Adjustment Screw Counterclockwise to INCREASE flow rate.

4. Rotate Clockwise to DECREASE flow rate.

When making adjustments, do not adjust by more than 1/4 turn at a time, without checking output flow or drink strength

(ratio of water to powder).

4

Page 5

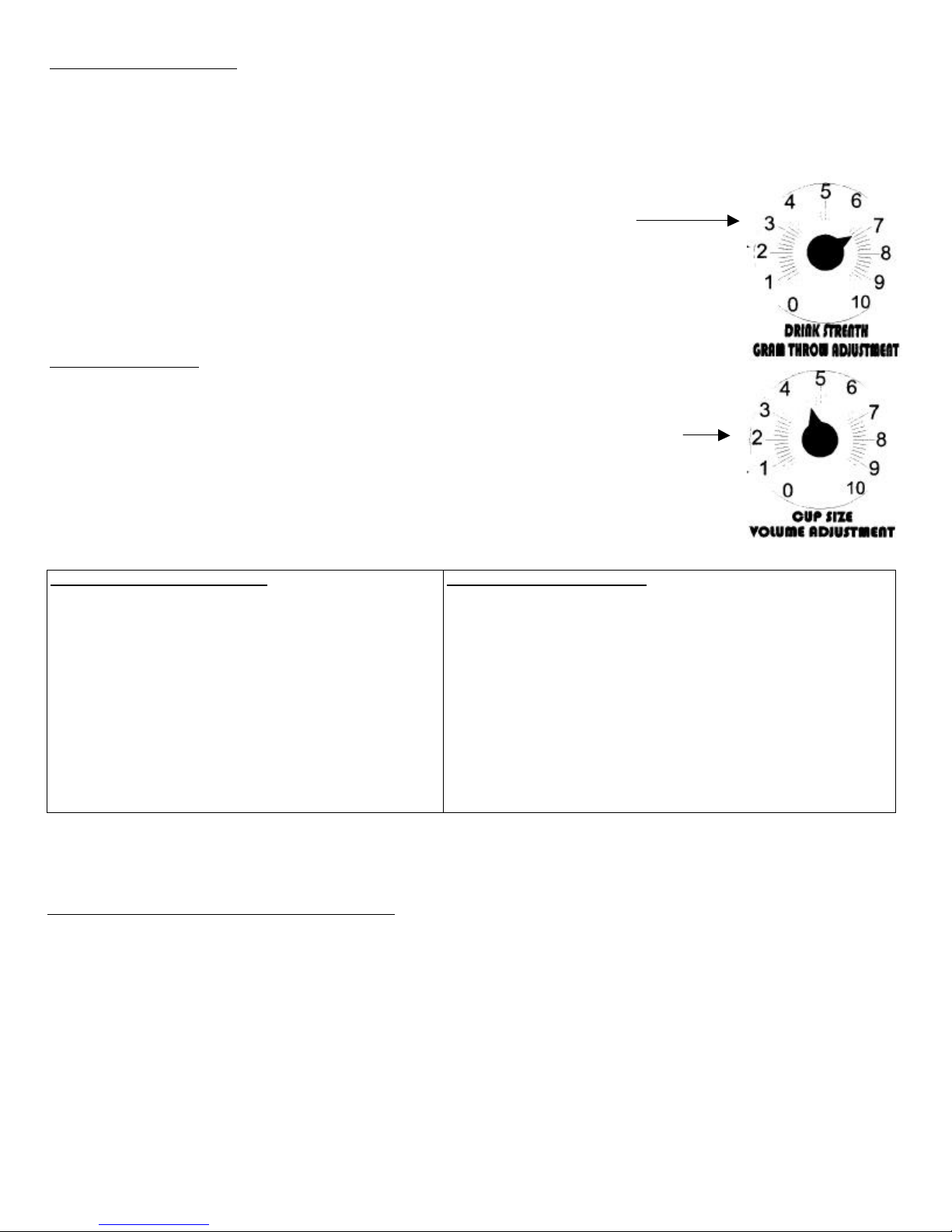

DRINK STRENGTH ADJUSTMENT - Adjusting the AUGER SPEED or the WATER FLOW RATE ON DISPENSE VALVE.

1.

3.

4.

6.

7.

8.

9.

I. UNITS WITH FIXED SPEED AUGER MOTORS-AC [CD150] • Fixed Auger Speed [95 RPM] and dispenses powder at a constant fixed rate.

Drink Strength adjustments can be made by adjusting the water flow rate on the Water Dispense Valves. [See ILL. C]

1. Remove Hoppers to access the Dispense Valve, located behind the hoppers.

2. Locate Flow Adjustment Screw on Dispense Valve. (See illustration C)

3. Rotate adjustment screw Counterclockwise to INCREASE Flow Rate, Clockwise to DECREASE Flow Rate.

(Note: the water flow rate should not exceed 1 to 1.3 oz./sec.)

Do not turn Adjustment Key more than 1/4 turn at a time without checking drink strength (ratio of water to powder).

II. UNITS WITH VARIABLE SPEED AUGER MOTORS-DO [CD151] • Variable Auger Speed [10 to 130 RPM]

Drink or Product Strength adjustments can be made by adjusting the Auger Motor RPM [knob on inside door panel], which

controls the amount of product being dispensed [gram throw]. The gram throw is factory preset at 7. Because the

consistency of each product varies, the customer can set the desired gram throw for each hopper.

The water flow rate on the Dispense Valves should remain fixed.

Note: the water flow rate should not exceed 1-1.3 oz./sec to avoid spillage from dispense chamber. [See ILL. C]

DRINK SIZE ADJUSTMENT

a. MANUAL MACHINES: Hold down the Dispense Button until desired amount is dispensed.

b. AUTOMATIC MACHINES WITH TIMER L493A ON INSIDE DOOR PANEL NOT PROGRAMMABLE] & SPEED CONTROL BOARD L556A

To increase the volume, turn the dial to the next increment. [0-1 is equivalent to 2 sec.]

c. AUTOMATIC MACHINES WITH PROGRAMMABLE "TEACH ME”-TIMERS [L576A OR L582A]:

These units do not have a cup size adjustment knob inside the door, since the timer is programmable from the dispense button.

PROGRAMMING INSTRUCTIONS FOR "TEACH ME" TIMERS; DISPENSE BUTTONS

PROGRAMMING FOR AUTOMATIC DISPENSE PROGRAMMING FOR MANUAL DISPENSE

1. Press and Hold STOP [red] Button with one hand.

2. Press and Hold DISPENSE [green] Button with other land. 2. PRESS AND HOLD DISPENSE [green] BUTTON WITH OTHER HAND.

3. Release STOP [red] Button only.

4. Release DISPENSE [green] Button.

5. Press and Release DISPENSE [green] Button to start time. 5. PRESS AND RELEASE STOP [red] BOTTON.

Product begins dispensing.

When it reaches the desired level in the cup,

Press and Release DISPENSE [green] Button to stop time.

Product stops dispensing.

DISPENSE Button can be jogged to top off cup.

Press and Release STOP [red] button, to lock in total dispense time.

Repeat steps 1 to 8 for each Dispense Button.

PRESS AND HOLD STOP [red] BUTTON WITH ONE HAND.

RELEASE STOP [red] BUTTON.

RELEASE DISPENSE [green] BUTTON.

The Total Time The Water Is Running Is Accumulated And Saved Into Memory. For Normal Operation, Press and Release Dispense Button.

The Timers Have Been Factory Preset for 6 oz. Cups for Coffee; For 8 oz. Cups for Soup and Cappuccino.

To Change To Larger Or Smaller Cup Sizes [Volumes] Repeat Steps 1 To 8 Above.

TO CHECK VOLUME AND GRAM THROW DISPENSED (RATIO):

1. Remove the product guide from the hopper and position a receptacle under the hopper nozzle to catch the gram throw of product. Also place a measuring cup under

extension tube to catch the water dispensed.

2. Push the dispense button and check the amount of product dispensed, amount of water dispensed, and time [use stop watch] to dispense that water.

3. The amount of water dispensed in the measuring cup divided by the amount of time to dispense that water is the Water Flow Rate from Dispense Valve.

FOR CAPPUCCINO: The machine is factory adjusted to dispense 4-4.5 gr./sec. per OZ. Cup. [32 grams Product per 8 oz. cup]

The recommended throw is 28-32 grams per 8 oz. cup for Cappuccino, with 80% fill.

FOR COFFEE: The machine is factory adjusted to dispense 0.3 gr./sec per OZ. Cup. [1.5 grams of coffee product per 5 oz. of liquid (in a 6 oz. cup).

The recommended throw is 1.5 to 1.8 grams per 6 oz. cup of Coffee, with 80% fill.

FOR SOUP: The machine is factory preset to specified customer requirements, because the gram throw for each soup flavor and type varies

considerably with the consistency of each product. Adjustments can be made by the customer, as shown above.

For customer specified/special settings see inserts I, II, III, etc.

5

Page 6

GB3P (POUROVER) PARTS IDENTIFICATION

Page 7

DESCRIPTION AND LOCATION OF COMPONENTS

GB3P (POUROVER)

Page 8

ITEM DESCRIPTION

GB1P GB2P GB3P 1 WATER BOTTLE

3

gal /

OR 6 gal M518A /M519A

M518A

/M519A

M518A/M519A

2

RESERVOIR ICOVER

97128 97128 97128 3 RESERVOIR ASSY

01740 Q174Q

01740 4 SILICONE HOSE

- RESERVOIR TO TANK

M540A

M540A

M540A

5

SILICONE HOSE

- BREATHER TUBE TO BREATHER TUBE

M541A

M541A

M541A

6

SILICONE HOSE

- HOSE BARB TO RESERVOIR

M542A

M542A

M542A

7

HOSE BARB,REOUCER

K534A K534A K534A 8 SILICONE HOSE

- WATER INLET VALVE TO HOSE BARB

M543A

M543A

M543A

9

TANK WELDMENT ASS'Y, (for

1

Heater) (HOT WATER)

? ?

RL40H

10

SWITCH, WATER SELECTION

– POUROVER/AUTOFILL

L069A L069A L069A 11 POWER/ ELECTRICAL CORO

C035A C035A C035A 12 WATER LEVEL SENSOR (CCA)

L398A L398A L398A 13 TERMINAL BLOCK 120V

f OR 240V

B117A/B116A

B117A/B116A

B117A/B116A

14

BRACKET, TERMINAL BRACKET

RE18A

RE18A

RE18A

15

BALLAST

CE221 CE221 CE221

16 RELAY, (NORMALLY OPEN) OR I RELAY, (NORMALLY OPEN, NORMALLY CLOSED) B129A (1)/B138A (1) B129A(2)/B138A (1) B129A(3)/B138A

17 LEGS (SET OF

4) M172A

M172A

M172A

18

HOSE NUT ASS'Y

K178A K178A K178A 19 WATER INLET VALVE

L462A L462A L462A

21 POWER SWITCH (120V) OR f (120/240V)

L069A I

L299A

L069A I

L299A

L069A/ L299A

22

RINSE SWITCH

L446A L446A L446A 23 HEATER SWITCH, 30ASPST (

120V) OR; |120/240V)

L069A I

L299A

L069A

/1299A

L069A

/

L299A

24

HEATER INDICATOR LIGHT (amber)

C002A C002A C002A 25 DRIP TRAY PAN metal

R111A R111A R112A 26 DRIP TRAY GRILL

R123A R118A R119A 27 DOOR HARNESS ASSY

CF19A

CF19A

CF19A

28

WHIPPER MOTOR sho

rt shaft CD75A

C075A CD75A

29

SLINGER DISC

CD 126 C0126 CD

126 30 CHAMBER MOUNTING GROMMET

CD66A

CD66A

CD66A

31

CHAMBER MOUNT

CD65A

CD65A

CD65A

32

"0"

RING #125

(used w/ grommet)

M379A

M379A

M379A

33

WHIP BLADE

CD64A

CD64A

CD64A

34

EXTENSION TUBE

M467A

M467A

M467A

35

WHIP CHAMBER

CD63A

CD63A

CD63A

36

MIXING CHAMBER

CD62A

CD62A

CD62A

37

DISPENSE CUP

CD61A

CD61A

CD61A

38

"0"

RING WHO) (used w

/ socket CD67A)

M378A

M378A

M378A

39

MIXING BOWL SOCKET

CD67A

CD67A

CD67A

40

READY DISPENSER INDICATOR LIG

HT (green)

C072A C072A C072A 41 POWER INOICATOR LIGHT (red)

C165A C165A C165A 42 OISPENSE BUTTON

/ SWITCH

L455A L455A L455A 43 STARTER BASE (for lamp inside door)

B128A B128A B128A 44 STARTER, TYPE FS

- 5, 5-6-8

WATT L396A L396A L396A 45 BULB, TYPE F8

T5/CW

CE76A

CE76A

CE76A

46

DDOR LATCH

M367A

M367A

M367A

47

LAMP HOLOER

CE220 CE220 CE220 48 DOOR WELDMENT ASSEMBLY, less components

RD030

RD03Q

RD02H

49

TOP COVER! LID HINGE

P402A P402A P402A 50 MAINTANANCE INSTRUCTIONS

N978A N978A N978A 51 TOP COVER

/LID, FRONT

RC96A

RC96A

RC80A

52

PRODUCT GUIDE

C070A CD70A

CD70A

53

NYLON AUGER

C0130 CD130

C0130 54 AUGER BUSHING, FRONT

C0102 CD102

CD102

55

HOPPER ASS'Y

CD68A

CD68A

CD68A

56

AGITATOR GEAR

CD117

CD117

CD117

57

HOPPER COVER

CD106

CD106

CD106

58

AUG

ER BUSHING, BACK

CD138

C0138 CD138

59

NUT (FLANGE)

CD136

CD136

CD136

60

SCREW, FOR AUGER MOTOR

P443A P443A P443A 61 AUGER MOTOR

(90

RPM) CD

150 CD

150 CD

150 62 SIDE PANELS

RH91A

RH91A

RH91A

* Recommended spare parts

8

TIMER 120V-OPTIONAL 58017 58017 (1)

58017

20 BLOWER ORYER CD56A CD56A CD56A

MOUNTING CLIP (VENT. MOTOR) RA67A RA67A RA67A

BLOWER CUP CD57A CD57A C057A

ELBOW INSERT CD 108 CD108 CD108

BLOWER DUCT HOSE 16" x (1 “ DIA) C0107 C0107 C0107

Page 9

PARTS IDENTIFICATION LIST GB3P (POUROVER) RESERVOIR

RL40Q HOT WATER TANK ASSEMBLY

1

1

1

1

3

1

1

1

1

1

1

1

1

AND TANK ASSEMBLY

Q174Q RESERVOIR ASSEMBLY

ITEM

1 P.O-LINE TANK(CB3M/ICAP) Q174A 1

2 FLOAT SWITCH 70-V-A L499A 1

3 DIRECT MOUNTING SEAL (?0.466 ID) H46IA 3

4 LEVEL CONTROL PROBE SEAL K402A 1

5 LEVEL CONTROL PROBE P410A 1

6 ELBOV ASS'Y. K5ZSQ |

7 ½” OD S.S. 90 ELBOW K525A 1

8 UPPER TANK MOUNTING BRACKET R171C 1

DESCRIPTION PART NO QTY

ITEM DESCRIPTION PART NO OTY

8 DIRECT MOUNTING SEAL (?0.466 ID) H46IA 5

9 1/4-20x5/8 S.S. SL HEX WASHER HD SCR P446A 4

10 HEATER 120V. 1700W G267A

11 GASKET. TANK HEATER M018A

12 INLET TUBE, 1/2" 0D S.S. 8" LONG K537A

15 BREATHER FITTINGS K492A

14 DISPENSE/DUMP VALVE L467A

15 TANK BODY WELDED ASS'Y RK54Q

16 TANK INSULATION M534A

17 HI-LIMIT L269A

18 DRAIN TUBE K525A

19 SILICONE HOSE. DRAIN LINE MS45A

20 END PLUG. DRAIN LINE M391A

21 THERMOSTAT KNOB M008A

22 THERMOSTAT L029A

Page 10

Page 11

Page 12

Page 13

Page 14

Page 15

Loading...

Loading...