Page 1

Coffee Urns

FE75N, FE100N, FE200, FE300,

CL75N, CL100N, CL200 Series

Operator Manual

Grindmaster-Cecilware

4003 Collins Lane, Louisville, KY 40245 USA

Phone: 502.425.4776 Toll Free: 800.695.4500

Fax: 502.425.4664

Web: gmcw.com Email: info@gmcw.com

Safety Information..................2

Rough-In Drawings .................3

Electrical Specifications...........5

Installation...............................5

Priming ....................................6

Operation ................................6

Cleaning...................................7

Adjustments ............................7

Maintenance ...........................9

Parts Diagram........................12

Parts List.................................15

Wiring Diagram.....................16

Thank you for purchasing this quality urn. For your safety and the safety of others, read all warnings and the

operator manual before installing or using the product. Properly instruct all operators. Keep training records. For

future reference, record serial number here:

Table of Contents

©2016 Grindmaster-Cecilware

Printed in USA

0516 Form # CW-326-01

Part # 390-00070

Grindmaster-Cecilware provides the

industry’s BEST warranty. Visit gmcw.com

for warranty terms and conditions.

Model FE300

Model CL100N

Page 2

GB Series Cecilware

®

2

For safe and proper operation, the appliance must be placed in a stable, vertical position.

To reduce risk of serious burns or scalding, do not place hand or other body parts under dispenser or container

while product is brewing.

Always unplug unit from power supply before servicing.

Hot liquid in brew basket could cause burns. Remove with care.

Surfaces are hot and can cause burns.

CAUTION

To reduce risk of electrical shock, do not remove or open cover. No user-serviceable parts inside. Repair should

be done by authorized service personnel only.

The appliance is not intended for outdoor use.

Do not clean with pressurized water or use in an area where pressurized water may be used.

Cleaning and maintenance shall be made only by properly trained persons with supervision.

This appliance is not intended for use by persons with reduced physical, sensory, or mental capabilities, or lack

of experience and knowledge, unless they have been given supervision or instruction concerning use of the

appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

Do not alter or deform the power cord or plug in any way! Altering or deforming the plug may cause electrical

shock, damage unit and will void warranty.

To reduce risk of explosion or fire, do not use near combustibles.

WARNING

Safety Information

2 Cecilware

®

Coffee Urns

Important Safety Information

This is the safety alert symbol. It is used to alert you to potential personal injury hazards. Obey all safety messages

that follow this symbol to avoid possible injury or death.

For your safety and the safety of others, read all warnings and the operator manual before installing or using

the product.

DANGER: This term warns the user of imminent hazard that will result in serious injury or death.

WARNING: This term refers to a potential hazard or unsafe practice, which could result in serious injury or death.

CAUTION: This term refers to a potential hazard or unsafe practice, which could result in minor or moderate

injury.

NOTICE: This term refers to information that needs special attention or must be fully understood.

Use only on a circuit that is properly protected and capable of the rated load.

Electronically ground the chassis.

Follow national and local electrical codes.

Do not use extension cord.

This equipment must be installed in compliance with applicable Federal, State, and/or Local plumbing codes

having jurisdiction. This product requires an approved back flow prevention water device, such as a double

check valve, to be installed between the machine and the water supply.

NOTICE

Page 3

Coffee Urns Cecilware

®

3

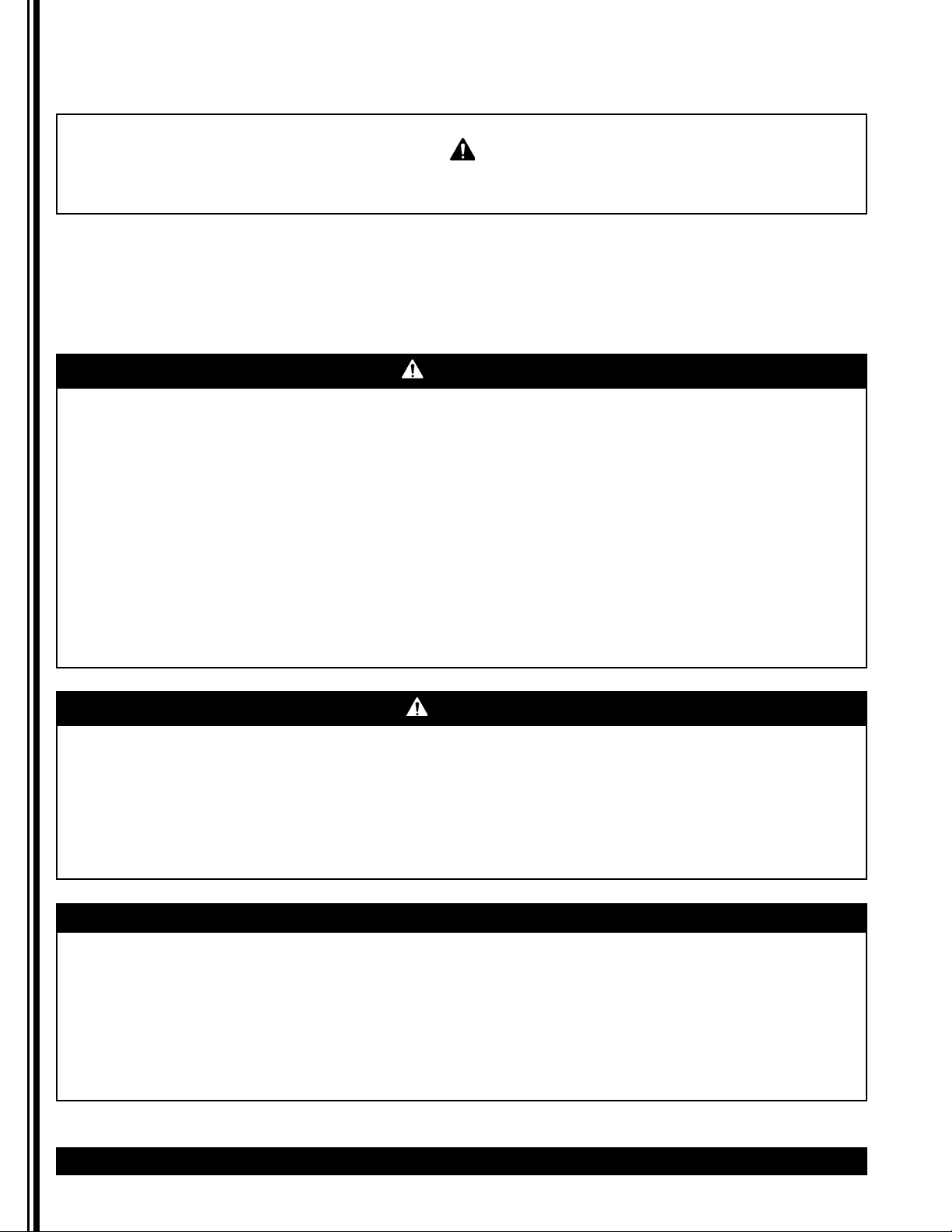

Rough-In Drawings

FE75N Single 3 Gallon Urn, Adjustable By-pass, Automatic Agitator, and Solid State Timer

CL75N Single 3 Gallon Urn, Adjustable By-pass, Push-Button Agitator, and Electro-Mechanical Timer

FE100N Twin 3 Gallon Urn, Adjustable By-pass, Automatic Agitator, and Solid State Timer

CL100N Twin 3 Gallon Urn, Adjustable By-pass, Push-Button Agitator, and Electro-Mechanical Timer

10

9

F

8

29.1

19.3

F

O

7

6

5

1

4

2

3

3.5

NN10A

10.1

2.5

4.0

14.016.0 5.4

29.1

19.3

10

9

F

8

F

O

7

6

5

1

4

2

3

4.0

28.0

5.4

3.5

NN10A

10.1

2.5

14.0

Page 4

4 Cecilware

®

Coffee Urns

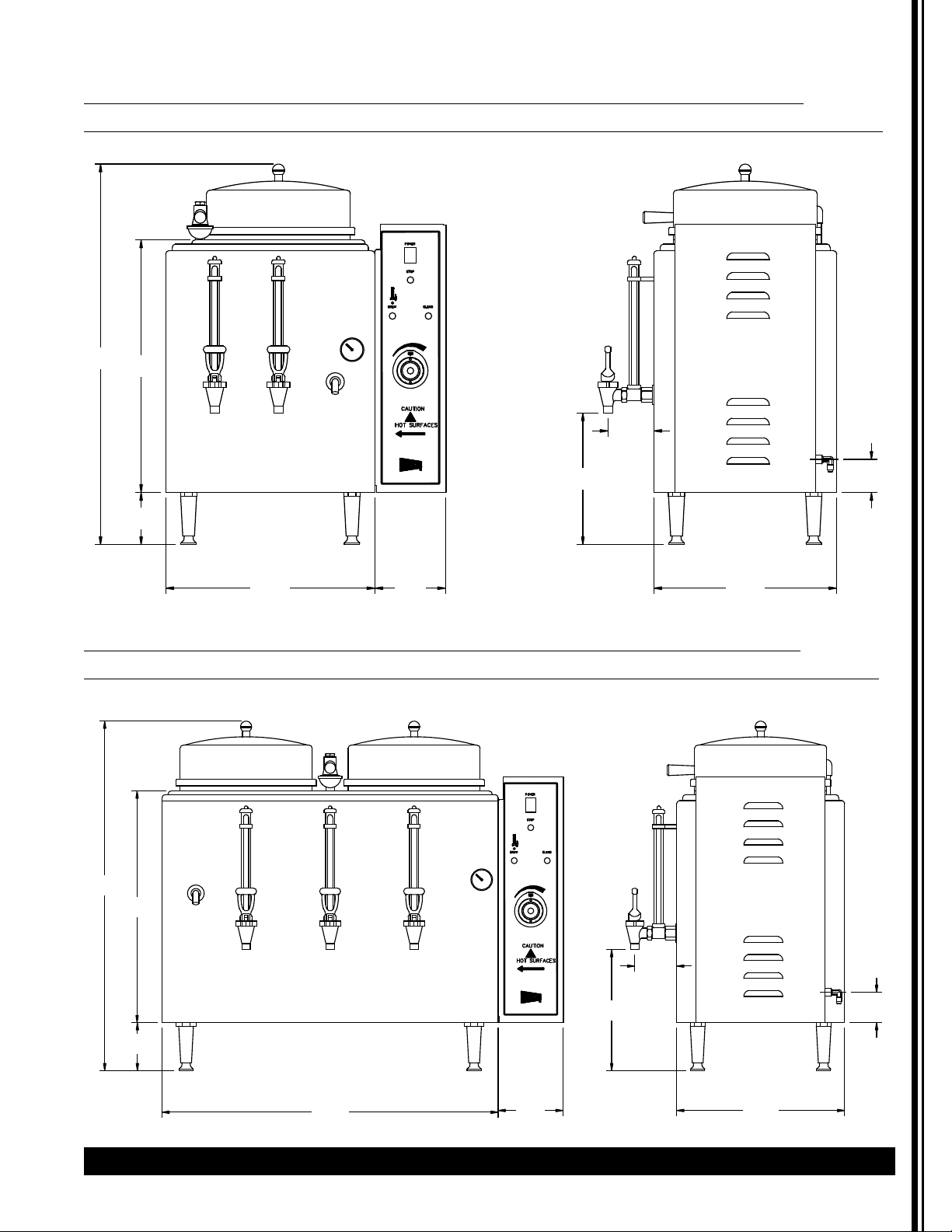

Rough-In Drawings (continued)

FE200N Single 6 Gallon Urn, Adjustable By-pass, Automatic Agitator, and Solid State Timer

CL200N Single 6 Gallon Urn, Adjustable By-pass, Push-Button Agitator, and Electro-Mechanical Timer

FE300N Twin 10 Gallon Urn, Adjustable By-pass, Automatic Agitator, and Solid State Timer

10

31.2

21.2

4.0

9

F

8

F

O

7

6

5

1

4

2

3

3.5

NN10A

10.1

2.5

32.0 5.4

16.0

10

9

F

8

F

O

34.5

23.4

7

6

5

1

4

2

3

4.0

36.1 5.4

NN10A

3.5

9.1

2.5

18.0

Page 5

Coffee Urns Cecilware

®

5

Installation

Unpacking Instructions

Carefully unpack the machine and inspect immediately

for shipping damage. The packaging may contain

unattached parts. Your machine was shipped in a carton

designed to give it maximum protection in normal

handling. It was thoroughly inspected before leaving

the factory. In case of damage, contact the shipper, not

Grindmaster-Cecilware.

NOTICE: The person installing this appliance is

responsible for ensuring that electric and water

connections meet the requirements of the national

electric code, national plumbing code, and any local

ordinances.

See Rough-in Drawings for approximate dimensions

and locations of electric and water input.

Mechanical Installation

NOTICE: Do not turn thermostat on until all

installation instructions have been followed.

1. Inspect unit to see if any damage occurred in

shipment.

2. Remove the urn from the packing material. The

four legs, faucets, and vent cap drain are packed

separately with urn.

3. Install legs by tilting urn on its side and screwing

legs into urn leg supports until hand tight.

4. Carefully right unit and install in its permanent

location, being sure to leave at least 6" on right side

of urn for access to controls. Position urn so that the

faucets drip into a drip trough or drain receptacle

of some type.

5. Level urn by adjusting legs. Then attach faucets and

install vent cap drain.

6. Cover(s) are shipped with knob(s) on inside to

prevent damage. Simply unscrew and reverse.

WARNING: ELECTRIC SHOCK HAZARD!

Installation of this appliance should be performed by

qualified service personnel only. Improper installation

could result in electrocution.

CAUTION

These urns are heavy pieces of equipment. It is

recommended that moving or lifting the unit be done

by two people to avoid injury.

MODEL VOLTS KILOWATTS AMPS

1 PHASE 3 PHASE 1 PHASE 3 PHASE

3 WIRE 4 WIRE

FE75N, CL75N

120/240

7

6

29

15

120/208 5.3 4.5 26 12

FE100N 120/240 6 8 34 20

120/208 8 6 29 17

CL100N 120/240 7 8 29 20

120/208 5.3 6 26 17

FE200N, CL200N 120/240 10 10 42 24

120/208 7.5 7.5 38 22

FE300N

120/240

-

15

-

37

120/208

-

11.3

-

33

MODEL WIRE SIZE

1 PHASE 3 PHASE

FE75N, CL75N, CL100N (2) 10 AWG + GND

(3) 10 AWG + GND

FE100-N (2) 8 AWG + GND (3) 8 AWG + GND

FE200-N, CL200-N (2) 6 AWG + GND (3) 8 AWG + GND

FE300-N - (3) 10 AWG + GND

Neutral and Ground Wires # 14 AWG min.

Note: Field wiring must be suitable for 75° C. Use copper wire only for power supply connections.

GROUNDING: ON ALL URNS, CONNECT A GROUND WIRE TO GROUNDING LUG TO COMPLY WITH LOCAL

ELECTRICAL CODES (14 AWG MIN. 75° C)

Recommended Wire Size For Field-Wiring Urns US models only. Consult factory for export model information..

Electrical Specifications

Information below provided for US models only. Check rating marking on urn nameplate. Consult factory for

export model information.

Page 6

6 Cecilware

®

Coffee Urns

Water Hook-up

NOTICE:

This equipment must be installed in

compliance with applicable Federal, State, and/or Local

plumbing codes having jurisdiction. This product requires

an approved back flow prevention water device, such as

a double check valve, to be installed between the

machine and the water supply. Incoming pressure should

be greater than 30 psi and not more than 70 psi.

Urn should be connected to cold water supply

1. The automatic coffee urn is equipped with a ¼"

Flare water inlet fitting which is located on the back

of the unit.

2. Provide shut-off valve and union in supply line near

urn.

3. Minimum inlet pressure at urn should be 30 PSI.

4. Maximum inlet pressure recommended at 70 PSI.

5. Copper flex tubing should be used for valve

connections.

6. To ensure pressure at the urn of at least 30 PSI, use

3/8" OD tubing for short runs, 1/2" OD tubing for

longer runs, and larger size tubing for unusually

long runs. Be sure other appliances will not reduce

water pressure excessively.

7. Turn on the water supply line and check for leaks.

NOTE: For the best tasting coffee, add a filtering system

to the water supply line to eliminate any taste and/or

odor from the water.

NOTE: In areas with extremely hard water, a water

softener must be installed in order to prevent mineral

deposits that could result in malfunctioning of the

equipment and in order not to void the warranty.

Electrical Hook-up

NOTICE: This equipment must be installed in compliance

with applicable Federal, State and/or Local electrical codes

having jurisdiction. Do not use extension cords. Make sure

that the outlet the urn plugs into is grounded.

1. Check rating marking on urn nameplate to be sure

electric lines match voltage, phase, and amperage

requirements of urn. Select the proper cord and

cord grip for electrical rating of the urn.

2. Urn body MUST be grounded. A grounding

terminal is provided for this purpose.

3. Use only copper wire to connect this urn.

NOTE: THERMOSTAT MUST BE IN THE "OFF" POSITION.

1. Open water supply line valve to urn.

2. Turn on or plug in the power supply to the urn.

Water compartment will begin to fill automatically.

Do not power up the urn when the water line is off.

3. Wait until water is visible in center gauge glass (lefthand gauge glass on 3-gallon single urns). Then

turn thermostat knob to 10; thermostat pilot light

shows heater is on. Urn jacket will continue to fill

automatically until water reaches the proper level.

4. When indicator on dial thermometer approaches

the "W" in BREW zone, 195°F (92°C), urn is ready to

brew coffee.

5. In high altitude locations (over 5000 ft. above sea

level), thermostat may have to be lowered to

prevent boiling.

6. Brew and discard at least one batch of water into

each liner. Check that the fill level is correct. See the

Adjustments section if changes are needed.

Operation

1. Place filter paper in brew basket with designated

amount of coffee grounds. Coffee experts

recommend from 6 to 10 ounces of coffee per gallon

of water. Use fresh urn grind or drip grind coffee

spread evenly on filter for proper extraction. Make

certain you have a level bed of coffee. Consult your

coffee supplier for exact brewing specifications.

2. Water should be heated to 195°F (92°C) before

brewing coffee.

3. While brewing, leave cover on urn to preserve

aroma and prevent excessive steaming. Total contact

time for urn grind should be approximately 4-6

minutes. When the brew is finished, allow one to

two minutes for the coffee to drip from the basket.

4. When the drip period is complete, center the spray

arm and remove the basket to throw away the

grounds. Replace the liner cover to keep the coffee

hot. Never pour coffee back through spent grounds.

• Urns with automatic agitator (FE series), blend

coffee automatically at end of brewing cycle.

Press and hold agitator BLEND switch for

additional blending.

• If urn has a manual agitator (CL series), press

and hold agitator BLEND switch for 20 seconds

after brewing cycle to blend coffee.

5. Coffee is ready to serve.

6. Hold coffee at 185°-190°F (85°-88°C) (about 8 on

thermostat). Brewed coffee should not be held for

longer than one (1) hour and should never be

reheated.

WARNING: ELECTRIC SHOCK HAZARD!

Installation of this appliance should be performed by

qualified service personnel only. Improper installation

could result in electrocution.

Installation (continued) Priming

WARNING: ELECTROCUTION HAZARD!

Never use the ground conductor as a neutral. This

could cause electrocution.

CAUTION: BURN HAZARD

Water used for brewing coffee is very hot. Use

caution when brewing, pouring, or transporting

coffee. Accidental spills may result in severe burns.

Use caution when disposing grounds.

Page 7

Coffee Urns Cecilware

®

7

NOTICE: All sanitizing agents in the food zone must

comply with 21 CFR 178.1010. Sanitize all food

dispensing units periodically. All parts to be sanitized

must be cleaned first. Cleaning and sanitizing frequency

must follow state and local health department

regulations.

NOTICE: Do not use cleansers, bleach liquids,

powders, or any other substance containing chlorine.

These products promote corrosion and will pit the

stainless steel. USE OF THESE PRODUCTS WILL VOID THE

WARRANTY.

After Each Brew:

1. Dispose of grounds and rinse brew basket.

Every Day:

1. Drain the urn; then run a brew cycle of hot water.

After spraying hot water into the liner, thoroughly

brush the liner with a long handled brush.

2. Drain the water and repeat step one. Run another

brew cycle. Brush the liner and drain.

3. Wash the wire brew baskets with urn cleaner and

rinse thoroughly.

Weekly or Bi-Weekly, Depending on Use:

1. Fill the urn liners with several gallons of hot water.

2. Pour into the liner the recommended concentration

of urn cleaning compound. Set the thermostat to

high (NO. 10) and then run a brew cycle of hot

water.

3. Allow solution to remain in the liner for

approximately 30 minutes.

4. Scrub the inside of both the liner and the cover with

a long handled brush.

5. Drain the cleaning solution from the liner. Rinse by

running several brew cycles with the sprayhead

centered over the liner. Be sure to drain the rinse

water between cycles.

6. Thoroughly clean the faucets.

7. Use a long, thin gauge glass brush to clean the

coffee gauge glass. Use the same brush to clean the

fitting at the bottom of the liner and the pipe

connected to the coffee faucet.

8. Reassemble faucets. Fill the liners with hot water

and drain until the liner and all parts are completely

rinsed.

Adjustments

Thermostat Adjustment

The Thermostat is factory set for proper dispense

temperature of 200°F ± 3°F with the control knob set to

the maximum clockwise position. If field adjustments

are needed proceed as follows:

• To DECREASE temperature, turn the control knob

slightly in the COUNTERCLOCKWISE direction.

• To INCREASE the water temperature -

1. With the Thermostat Knob to its maximum

clockwise position, remove the knob and locate the

slotted adjustment screw inside the hollow

thermostat shaft.

2. Using a narrow-bladed screwdriver, engage slotted

adjustment screw and turn it 1/4 turn slowly

counter-clockwise.

(continued next page)

WARNING: SHOCK AND BURN HAZARD

To prevent electric shock and burn hazard, all tasks

described in this section are to be performed by a

trained and qualified service technician.

Thermostat Adjustment

CAUTION: BURN HAZARD

The urn surfaces and water inside jacket are very hot.

Use caution when cleaning this urn to prevent burns.

CAUTION: BURN HAZARD

Never remove the faucet when the liner has water or

coffee in it. Switch OFF the power to the unit at the

circuit breaker. Turn off the water line running to the

urn.

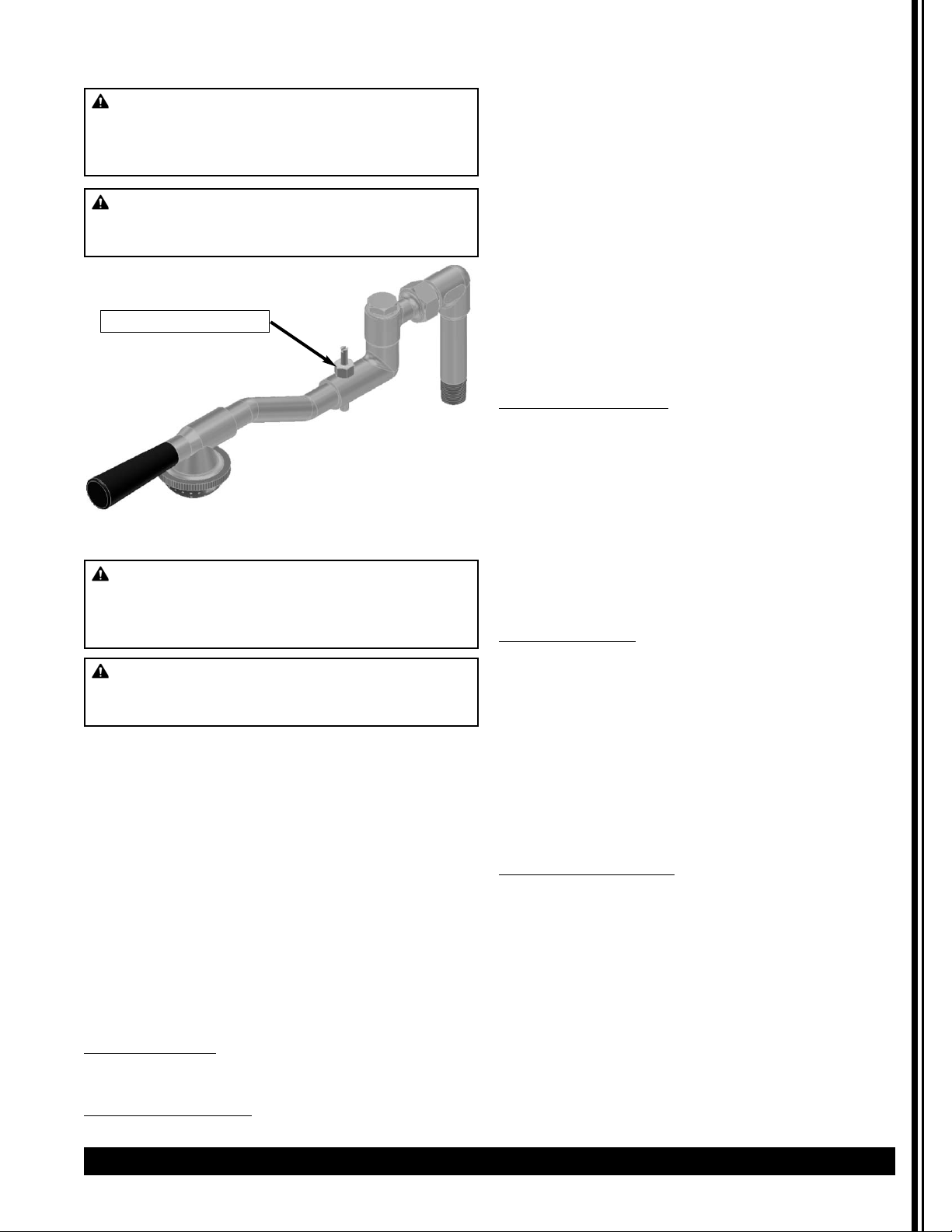

Faucet Body

Seat Cup

X014A

Bonnet

Faucet Handle

Faucet Assembly (D017A)

Cleaning

Page 8

8 Cecilware

®

Coffee Urns

Thermostat Adjustment (continued)

3. Allow a few minutes for the temperature to reach

set level. The Heater Light will go ON, indicating the

heating element is activated, wait for it to go OFF,

indicating that the water has reached new set

temperature.

4. Take a temperature reading and repeat if necessary.

Solid-State Timer Adjustment (FE models)

A factory pre-set electronic solid-state timer controls the

volume of water for each brew cycle. If more or less

water is desired, follow these instructions:

1. Turn knob of timer clockwise to increase volume of

water or counterclockwise to decrease it.

2. Run through a complete brew cycle after each

adjustment. Since timer cannot be readjusted in

mid-cycle, simply push cycle stop switch at bottom

right of side box if water gets too high.

3. If maximum setting of timer fails to deliver enough

water, check water pump and spray head and

follow instructions under Maintenance.

Mechanical Timer Adjustment

(CL models)

The factory pre-set mechanical timer can be adjusted

for more or less water by following these instructions:

1. Remove timer knob and loosen lock nut holding

stop pin.

2. To increase volume of water, rotate stop pin

clockwise.

3. To decrease, rotate counterclockwise. Tighten lock

nut and replace knob.

Spray Arm By-Pass Adjustment (All Urns )

Adjustable bypass allows proper brew extraction even

with variations caused by soft or treated water. If bypass

requires adjustment to correct for local water

conditions, proceed as follows:

1. Position spray head over center of coffee liner and

press BREW switch.

2. Turn by-pass adjustment screw clockwise to

decrease by-pass flow (for stronger coffee) or

counter-clockwise to increase by-pass flow (for

weaker coffee).

3. At end of brewing cycle, note volume of water in

coffee liner. Readjust timer if necessary to obtain

the correct volume of water.

WARNING: SHOCK HAZARD

Disconnect power before attempting any electrical

repairs.

Thermostat Bulb

Coupling

Nut

CCW - Decrease

Temperature

WARNING: SHOCK AND BURN HAZARD

To prevent electric shock and burn hazard, all tasks

described in this section are to be performed by a

trained and qualified service technician.

Adjustments (continued)

Single Timer

(120V - L205A)

(240V - L210A)

Dual Timer

(120V - L214A)

(240V - L216A)

Manual Timer

(L154A)

Thermostat Assy

(L780A)

Page 9

Coffee Urns Cecilware

®

9

Adjustments (continued)

Maintenance

The rest of this manual contains information to aid the

service technician who is maintaining this equipment.

This section has information on performing common

service tasks.

If you still need help after reading this section, call

Grindmaster-Cecilware Technical Service Department,

(502) 425-4776 or (800) 695-4500 (USA & Canada only)

(Monday through Friday 8 AM - 6 PM EST). Please have

the model and serial number ready so that accurate

information can be given.

Prior authorization must be obtained from

Grindmaster-Cecilware for all warranty claims.

Grindmaster-Cecilware provides the industry’s

BEST warranty. Visit our website at gmcw.com for

warranty terms and conditions.

To Move the Urn

The urn must be completely drained (jacket and liners)

and allowed to cool prior to moving this urn.

Spray Arm Assembly

The new improved spray head system was designed to

facilitate easier cleaning and maintenance. The swivel

valve has a larger flow opening and the spray head cap

is equipped with a stainless steel disc, used to control

the flow of water.

When ordering replacement parts, be sure to order the

correct disc and spray cap for each urn, as shown in

Parts Diagram Illustration.

• To prevent lime buildup, especially in hard water

areas, remove and clean spray head cap and spray head

disc frequently.

• To clean swivel valve loosen nut and remove spray arm

assembly from urn.

• Remove sediment by inserting a pipe cleaner through

small hole in valve.

• If maximum setting of timer fails to deliver enough

water, check water pump.

If Water Fails To Heat

1. Check line fuse or circuit breaker. Replace or reset

if necessary.

2. Make sure thermostat is in ON position. If

thermostat pilot light does not come on, replace

thermostat. (Refer to instructions below.) If pilot

light is on, measure continuity between terminals l

and 2 of thermostat, and between terminals 3 and

4. If a resistance is measured, replace thermostat.

3. If thermostat is okay, check wiring and repair if

necessary: if wiring is okay, check heater resistance;

if high or infinite, replace as follows:

Replacing Heater

1. Shut off power and disconnect water supply at

elbow. Drain urn.

2. Remove one coffee gauge glass, faucet, shank, and

liner.

3. Tilt urn and disconnect wires to heater.

4. Remove socket head screw and heater flange and

lift heater out.

5. Install new heater and reassemble urn.

6. Repeat Priming instructions on page 6. NOTE: DO

NOT TURN ON THERMOSTAT UNTIL URN IS

PRIMED.

Replacing Thermostat

(All Models)

Thermostat is located in side box of urn. Lift off side box

door to gain access to thermostat; then follow

instructions below.

1. Shut off power, disconnect water supply, and drain

urn by opening hot water faucet. When faucet

stops running you are ready to remove the

thermostat bulb.

2. Remove thermostat knob and two screws holding

thermostat in place.

3. Disconnect wires from thermostat.

4. Pull out thermostat bulb.

5. Install new thermostat, push in the new thermostat

bulb. Tighten compression nut on thermostat fitting

to prevent leaking. (continued next page)

WARNING: SHOCK AND BURN HAZARD

To prevent electric shock and burn hazard, all tasks

described in this section are to be performed by a

trained and qualified service technician.

WARNING: SHOCK HAZARD

Disconnect power before attempting any electrical

repairs.

Bypass Adjustment

WARNING: SHOCK AND BURN HAZARD

To prevent electric shock and burn hazard, all tasks

described in this section are to be performed by a

trained and qualified service technician.

WARNING: SHOCK HAZARD

Disconnect power before attempting any electrical

repairs.

Page 10

6. Repeat Priming instructions on page 6. NOTE: DO

NOT TURN ON THERMOSTAT UNTIL URN IS

PRIMED.

If Water from Cold Water Supply Line Does Not

Enter Urn

1. Check water supply to external shut-off valve.

2. Check fuse on rear of side box and replace if

necessary.

3. If water supply and fuse are okay, remove fuse and

lift off side box door exposing terminal block and

electrical wiring.

4. Check dual probe liquid level controller. (See

Component Tests)

If Water Runs Out At Overflow Drain

1. Make sure urn is level and overflow tube is vertical.

2. Remove fuse from rear of side box.

3. If water continues to flow, solenoid valve is dirty or

not seating properly. Replace solenoid as described

below.

Replacing Solenoid

1. Shut off water supply, remove fuse, and lift off side

box door.

2. Disconnect wires from solenoid: then remove flare

nut and unscrew solenoid valve from bracket.

3. Install new solenoid and reinstall fuse and side box

door.

4. If necessary, follow Priming instructions on page 6.

No Water from Spray Head

1. Check fuse first.

2a For FE urns: Depress BREW switch and release. If

switch remains lit, water pump is probably not

operating. Lift off side box door and check if fan on

water pump is rotating. If not, replace pump as

described below.

2b. For CL urns: Turn brew timer knob clockwise.

Replace timer if it does not go on. If timer goes on

but pump doesn't, replace pump.

Replacing Water Pump

1. Shut off water supply and remove fuse. Drain urn

to level of water faucet.

2. Lift off side box door and disconnect the two pump

wires.

3. Loosen union fittings on pump and remove pump

from urn.

NOTICE: If your urn has older style

pump with copper connections, it is imperative

that you use a counter wrench when removing

and installing pump to avoid damaging copper

tubing. DO NOT OVERTIGHTEN.

4. Replace pump and follow Priming instructions on

page 6.

Checking Solid-State Timer (FE Urns)

1. Press and hold BREW switch for 10 seconds. Brew

cycle should start. If water stops coming from spray

head as soon as BREW switch is released, timer is

not operating. Replace it. (Instructions below.)

2. If no water comes from spray head when BREW

switch is pressed, replace switch.

NOTE: To check mechanical timer on CL urns, refer to

No Water from Spray Head.

Replacing Solid-State Timer

1. Remove fuse, lift off side box door, and remove

timer from bracket.

2. Carefully note locations of colored wires on timer

board and then remove wires.

3. Replace timer and reassemble unit in reverse order.

Blending - Automatic Type (FE Urns)

Operation:

The agitator pump circuit is programmed to operate

immediately after brewing cycle. The circuit pumps air

through the coffee gauge glass(es) into the coffee

liner(s). The complete cycle takes about 20 seconds. For

additional blending, simply press the BLEND switch.

Maintenance:

• If agitation is not sufficient to blend coffee, check

flexible tubing, and glasses and fittings, for possible air

leaks. Replace as necessary.

• If agitator pump does not operate immediately after

brewing cycle or when BLEND switch is pressed, replace

agitator pump or solid state agitator timer.

• If agitator pump comes on immediately after brewing

cycle, but does not operate when BLEND switch is

pressed, replace BLEND switch.

Blending - Manual Type (CL Urns)

Operation:

Immediately after brewing cycle, depress BLEND switch

and hold for about 20 seconds. Your coffee will be

completely blended and ready to serve.

Maintenance:

• If agitator pump does not operate when BLEND

switch is pressed, replace switch, if pump still does not

operate, replace pump.

10 Cecilware

®

Coffee Urns

WARNING: SHOCK AND BURN HAZARD

To prevent electric shock and burn hazard, all tasks

described in this section are to be performed by a

trained and qualified service technician.

WARNING: SHOCK HAZARD

Disconnect power before attempting any electrical

repairs.

Maintenance (continued)

Page 11

Coffee Urns Cecilware

®

11

Component Tests

Water Inlet Valve Test

1. Turn power OFF. If the water level rises inside a

partially filled tank, the Water Inlet Valve is leaking.

2. Disconnect wires from the Water Inlet Valve coil and

connect a 2 wire line cord to the terminals. Plug it

into a 115V outlet. If water flows in and stops when

you pull it out, the Valve is working fine. Repeat this

test a few times. The problem may be in the Probe

or Water Level Control Board.

3. If the water does not flow in when the cord is

plugged into an electrical outlet, the Solenoid coil

may be damaged, opened or the valve may have an

obstruction preventing the water from flowing in.

4. Clean or replace it.

Dual Probe Test

If lack of water persists, check the probe as follows:

1. Turn on the power and water supply. Check inside

the tank to make sure the water is below the Probe.

Pull the BLUE wire and terminal OFF the Probe rod.

2. If water still does not flow after the wire is

disconnected from the Probe, the problem may be

in the Solid State Dual Level Control Board.

3. If water starts flowing into the tank, the Probe may

be grounded, due to excessive liming. Check with

Ohm meter.

4. Clean or replace probe.

Dual Probe Liquid Level Controller Test

Check the Controller as follows:

1. Make sure there is power input to the Controller at

the terminals AC1 & AC2. Your voltmeter should

read 115 Volts. It should read the same at terminals

AC1 & FILL when the water level is low. This is the

output power to actuate the coil of the Solenoid

Valve to open it.

2. The lack of voltage at terminals AC1 & L-LEVEL or

H-LEVEL indicates that the Controller is not working

properly.

3. Make sure all wire connections are tight, including

ground.

4. If after this, the Controller is still failing to open the

Water Inlet Valve, replace it.

Maintenance (continued)

Hose Nut Assembly

Blue

WARNING: SHOCK AND BURN HAZARD

To prevent electric shock and burn hazard, all tasks

described in this section are to be performed by a

trained and qualified service technician.

WARNING: SHOCK HAZARD

Disconnect power before attempting any electrical

repairs.

Page 12

12 Cecilware

®

Coffee Urns

Parts Diagram

9

E

L

C

F

AUTOMATIC COFFEE URNS

17

Page 13

Coffee Urns Cecilware

®

13

Parts Diagram (continued)

E20

0

N

,

C

L

0

0

N

y

FAUCET, HOT WATER

FAUCET, COFFEE

SPRAY ARM ASSEMBLY

AUTOMATIC COFFEE URNS

FE300-N

of timer fails to deliver enough water, check water pump.

To prevent lime buildup, especially in hard water areas, remove and clean spra

remove spray arm assembly from urn.

head cap and spray head disc frequently. To clean swivel valve, loosen nut and

Remove sediment by inserting a pipe cleaner through small hole in valve.

If maximum setting

Page 14

14 Cecilware

®

Coffee Urns

Parts Diagram (continued)

Page 15

Coffee Urns Cecilware

®

15

Parts List

ITEM PART DESCRIPTION QUANTITY

# FE75N FE75N CL75N FE100N FE100N CL100N FE200N CL200N FE300N

DUAL DUAL DUAL

BREW BREW BREW

1 B157A TERMINAL BLOCK 4 WIRE 1 1 1 1 1 1 1 1 1

2 C036AL CONTACTOR, 3 POLE, 50 AMP - (240V) - - - - - - - - -

CG12AL CONTACTOR, 3 POLE, 50 AMP - 120V 1 1 1 1 1 1 1 1 1

3 C395AL FUSE 6A SC-6 1 1 1 1 1 1 1 1 1

4 C396AL FUSEHOLDER, SC-6 1 1 1 1 1 1 1 1 1

5 C511A AIR PUMP, AGITATOR (120V ONLY) 1 1 1 1 1 1 1 1 1

C512A AIR PUMP, AGITATOR (220V) - - - - - - - - -

6 CD318 WATER INLET VALVE (120V ONLY), .70 GPM - - - - - - - - 1

CD319 WATER INLET VALVE (240V), .70 GPM - - - - - - - - CD417 WATER INLET VALVE (120V ONLY), .35 GPM 1 1 1 1 1 1 - - CD418 WATER INLET VALVE (240V), .35 GPM - - - - - - - - CD423 WATER INLET VALVE (120V ONLY), .50 GPM - - - - - - 1 1 CD424 WATER INLET VALVE (240V), .50 GPM - - - - - - - - -

7 CH362 WIRING HARNESS 1 1 - 1 1 - 1 - 1

CH387 WIRING HARNESS (MECH. TIMER) - - 1 - - 1 - 1 -

8 D001B SIGHT GLASS ASSEMBLY (COFFEE) 1 1 1 2 2 2 - - -

D020B SIGHT GLASS ASSEMBLY (COFFEE) - - - - - - 3 3 D031B SIGHT GLASS ASSEMBLY (COFFEE) - - - - - - - - 2

9 D017Q FAUCET, SHANK ASSEMBLY (COFFEE) 1 1 1 2 2 2 2 2 2

10 D022Q FAUCET, SHANK, VALVE ASSEMBLY (WATER) 1 1 1 1 1 1 1 1 1

11 D024A SIGHT GLASS ASSEMBLY (WATER) 1 1 1 1 1 1 - - -

D032A SIGHT GLASS ASSEMBLY (WATER) - - - - - - - - 1

12 E000A WATER PUMP (120V ONLY) (Prior to 3/2014) 1 1 1 1 1 1 1 1 1

E070A WATER PUMP (240V) (Prior to 3/2014) - - - - - - - - A533-033 WATER PUMP (120V ONLY) (After 3/2014) 1 1 1 1 1 1 1 1 1

A533-034 WATER PUMP (240V) (After 3/2014) - - - - - - - - -

13 E009A OVERFLOW FITTING W/ NUT 1 1 1 1 1 1 1 1 1

14 235-00008 COMPLETE SPRAY ARM ASSY W/ BYPASS - - - - - - - - 1

235-00009 COMPLETE SPRAY ARM ASSY W/ BYPASS 1 1 1 1 1 1 - - 235-00010 COMPLETE SPRAY ARM ASSY W/ BYPASS - - - - - - 1 1 -

15 320-00015 HEATER ELEMENT 5KW 240V 1PH - - - - - - 2 2 3

16 320-00016 HEATER ELEMENT 8KW 240V 1PH - - - 1 1 - - - -

17 320-00020 HEATER ELEMENT 7KW 240V 1PH 1 1 1 - - 1 - - -

18 H429Q TUBE, OVERFLOW 1 1 1 1 1 1 - - -

19 K491B HOSE NUT ASSEMBLY (BRITISH THREAD) 1 1 1 1 1 1 1 1 1

20 H416A WATER INLET TUBE (Prior to 3/2014) 1 1 1 1 1 1 1 1 1

20 H416A WATER INLET TUBE (After 3/2014) 1 1 1 1 1 1 1 1 1

21 K808A RETAINER MOUNTING BLOCK 2 2 2 3 3 3 3 3 3

22 K810Q LEVEL SENSOR, DUAL PROBE 1 1 1 1 1 1 1 1 1

23 L007A THERMOMETER, BREW DIAL 1 1 1 1 1 1 1 1 1

24 L154A TIMER, MECHANICAL (0 - 15 MINUTES) - - 1 - - 1 - 1 -

25 L205A TIMER, SINGLE (120V) 1 - - 1 - - - - 1

L210A TIMER, SINGLE (240V) - - - - - - - - L214A TIMER, DUAL (120V) - 1 - - 1 - 1 - L216A TIMER, DUAL (240V) - - - - - - - - -

26 L155A ROCKER SWITCH, POWER ON-OFF 1 1 1 1 1 1 1 1 1

27 L238A DELAY TIMER-SOLID STATE (120V) 1 1 1 1 1 1 1 1 1

L253A DELAY TIMER-SOLID STATE (240V) - - - - - - - - -

28 L780A THERMOSTAT 25A, URNS 1 1 1 1 1 1 1 1 1

29 L584A SWITCH, PUSHBUTTON 3 4 - 3 4 - 4 - 3

30 L775A DUAL LEVEL CONTROL HI-LO (120V) 1 1 1 1 1 1 1 1 1

L776A DUAL LEVEL CONTROL HI-LO (220V ONLY) - - - - - - - - -

31 M005S LEGS (4" ADJ) (4 PER BAG) 1 1 1 1 1 1 1 1 1

32 M008A KNOB THERMOSTAT 1 1 1 1 1 1 1 1 1

33 M016A THERMOSTAT BEZEL 1 1 1 1 1 1 1 1 1

34 M027A KNOB, URN COVER 1 1 1 2 2 2 2 2 2

35 M326A WATER INLET HOSE 3/8 x 5/8 x 8" 1 1 1 1 1 1 1 1 1

36 M461A SILICONE GROMMET 12mm 3 3 3 3 3 3 3 3 3

37 M462A SILICONE GROMMET 15mm - - - - - - - - -

38 M876A BLUE BUTTON (BLEND) 1 1 1 1 1 1 1 1 1

39 M877A GREEN BUTTON (BREW) 2 2 - 2 2 - 2 - 2

40 MA15A COPPER GASKET, TEFLON FILLED 6 6 6 7 7 7 7 7 7

41 Q027Q LINER ASSY & COVER (FE75/ FE100) 1 1 1 2 2 2 - - -

Q094Q LINER (FE300) - - - - - - - - 2

Q204Q LINER ASSY & COVER (FE200) - - - - - - 2 2 -

42 UB17A SIGHT GLASS RETAINER 2 2 2 3 3 3 3 3 3

43 V002A BREW BASKET, FE75 / FE100 1 1 1 1 1 1 - - -

V003A BREW BASKET, FE200 - - - - - - 1 1 V081A BREW BASKET, FE300 - - - - - - - - 1

44 32004 INDICATOR LIGHT W/ RED LENS 2 3 - 2 3 - 3 - 2

45 ABB3WP FILTER PAPER (FE75N/FE100N) 1 1 1 2 2 2 - - -

ABB6WP FILTER PAPER (FE200N) - - - - - - 2 2 ABB810WP FILTER PAPER (FE300N) - - - - - - - - 2

Page 16

16 Cecilware

®

Coffee Urns

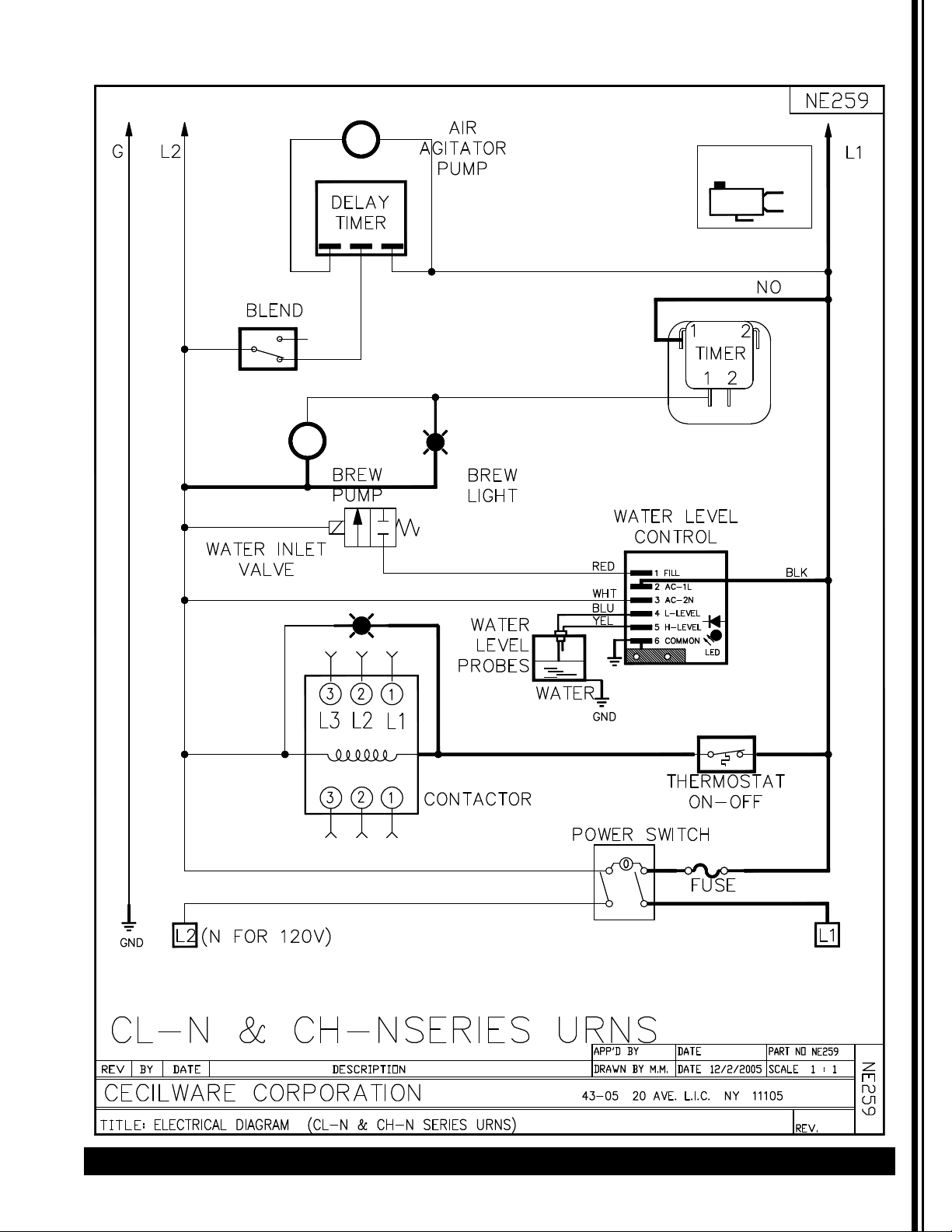

Wiring Diagram

GND

L2

FE-N SERIES W/ SINGLE TIMER

AIR AGITATOR PUMP

L1

SWITCH

CONFIGURATION

NC

C

BLEND

Yel

NO

NC

Yel

BREW

PUMP

DELAY

TIMER

Blue

Wht

Yel

Blue

Yel

BREW

LIGHT

WATER

INLET

VALVE

Gray

Wht

WATER

LEVEL

PROBES

SINGLE

TIMER

Yel

C

Red

NO

Red

NC

BREW

SWITCH

WATER LEVEL CONTROL

RED

WHT

BLU

YEL

1 FILL

2 AC-1L

3 AC-2N

4 L-LEVEL

5 H-LEVEL

6 COMMON

C

NO

STOP

NO

C

NC

LED

CONTACTOR

(N FOR 120V)

L2

GND

WATER

GND

THERMOSTAT

FUSE

POWER SWITCH

L1

Page 17

Coffee Urns Cecilware

®

17

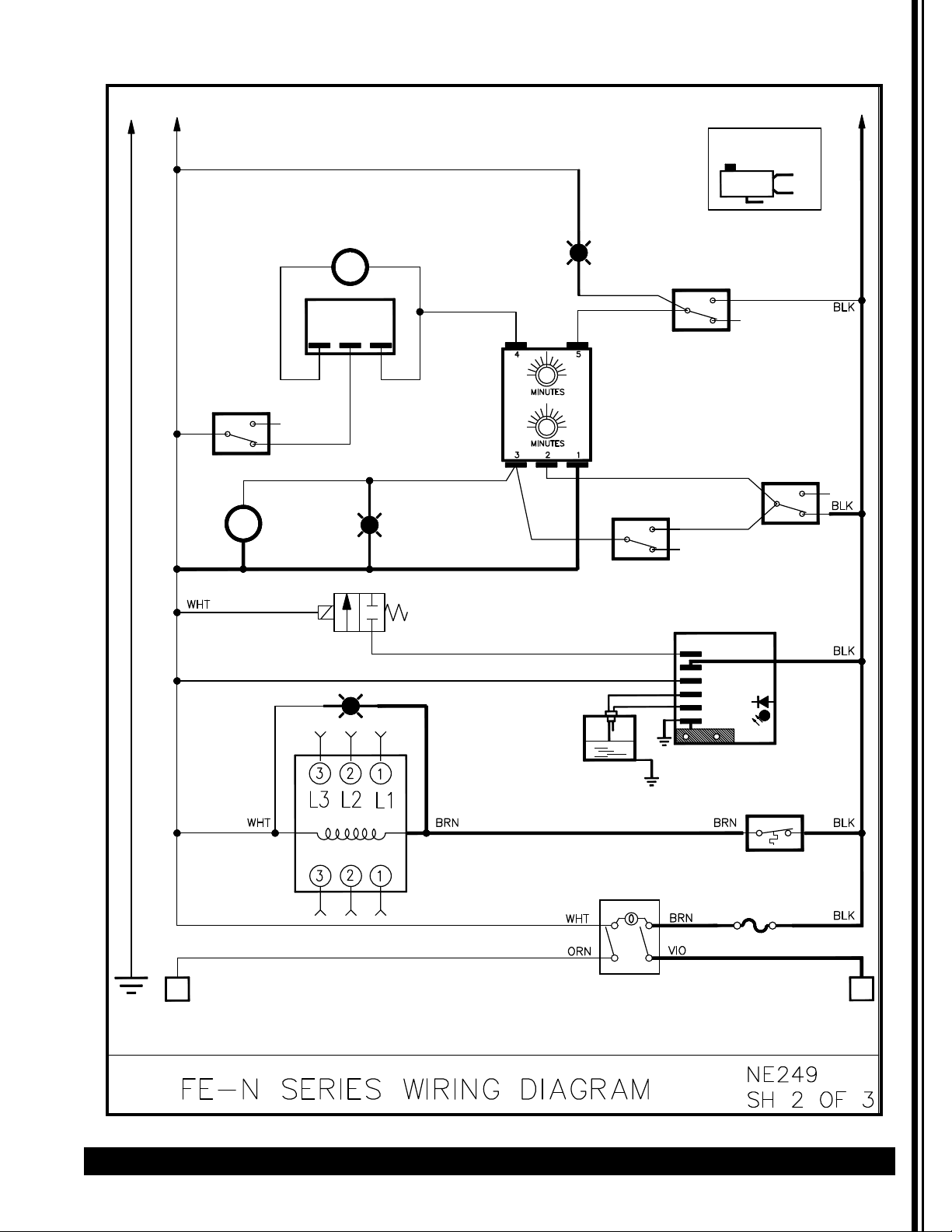

Wiring Diagram (continued)

FE-N SERIES W/ DUAL TIMER

L2

GND

Wht

AIR AGITATOR PUMP

DELAY

TIMER

Gray

Wht

BREW

LIGHT

Purple

Purple

BREW

SWITCH

C

SWITCH

CONFIGURATION

NC

C

NO

NO

NC

L1

Wht

BLEND

C

Yel

NO

NC

Yel

BREW

PUMP

Blue

Yel

Wht

Blue

Yel

HALF

BREW

LIGHT

WATER

INLET

VALVE

Wht

WATER

LEVEL

PROBES

DUAL

TIMER

HALF BREW

SWITCH

Yel

C

WATER

Red

STOP

C

NO

Red

NC

WATER LEVEL CONTROL

RED

WHT

BLU

YEL

GND

1 FILL

2 AC-1L

3 AC-2N

4 L-LEVEL

5 H-LEVEL

6 COMMON

LED

NO

NC

CONTACTOR

(N FOR 120V)

L2

GND

THERMOSTAT

FUSE

POWER SWITCH

L1

Page 18

18 Cecilware

®

Coffee Urns

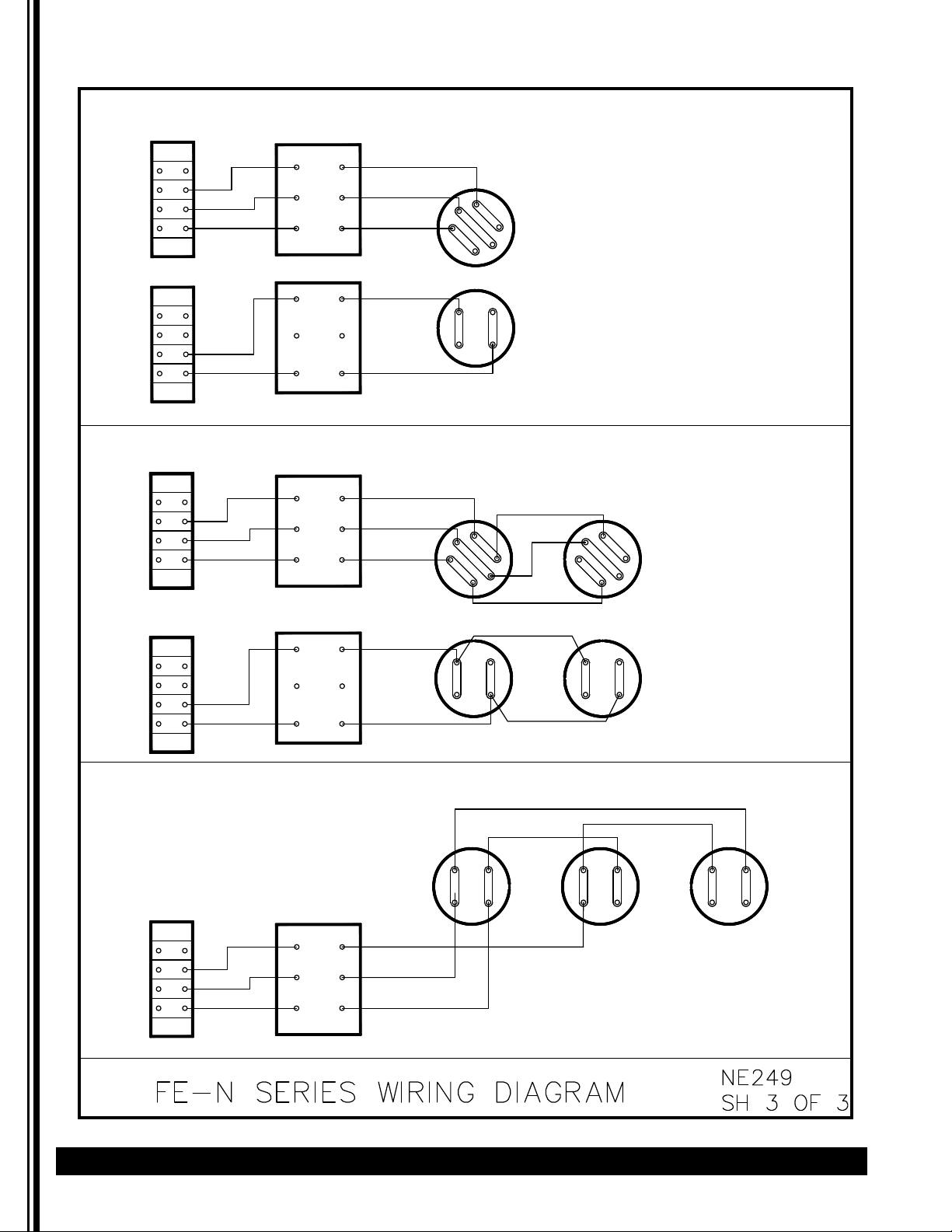

Wiring Diagram (continued)

3 GALLON - SINGLES & TWINS

TERMINAL

BLOCK

TERMINAL

BLOCK

TERMINAL

BLOCK

CONTACTOR

CONTACTOR

L1 L2 L3 N L1 L2 L3 N

3

2

1

3 PHASE

HEATER

1 PHASE

HEATER

G026A (8 KW)

G024A (6 KW)

G013A (8 KW)

G031A (7 KW)

6 GALLON TWINS

CONTACTOR

3

2

1

3

2

1

3 PHASE

HEATER

3 PHASE HEATERS

G018A (5 KW EACH)

TERMINAL

BLOCK

TERMINAL

BLOCK

CONTACTOR

L1 L2 L3 N L1 L2 L3 N

1 PHASE

HEATER

1 PHASE HEATERS

G011A (5 KW EACH)

9 GALLON TWINS

1 PHASE HEATERS

G011A (5 KW EACH)

CONTACTOR

L1 L2 L3 N

15 KW, 3 PHASE

Page 19

Coffee Urns Cecilware

®

19

Wiring Diagram (continued)

SWITCH

CONFIGURATION

NC

C

NO

NO

C

NC

Page 20

Grindmaster-Cecilware

4003 Collins Lane, Louisville, KY 40245 USA

Phone: 502.425.4776 Toll Free: 800.695.4500

Fax: 502.425.4664

Web: gmcw.com Email: info@gmcw.com

©2016 Grindmaster-Cecilware

Printed in USA

0516 Form # CW-326-01

Part # 390-00070

Loading...

Loading...