Cecilware FE-100G Operation Manual

AUTOMATIC GAS

COFFEE URN

OPERATION MANUAL

MODEL:

FE-100G

SPECIFICATI ONS

I NSTALLATI ON

MAI NTENANCE TI PS

REPAIR PARTS LI ST

WI RING DI AGRAMS

GAS SPECI FI CATI ON S

MODEL NO. NATURAL GAS

BTU/ HR @ 3. 5” W.C.

FE- 100 G 32, 000 32, 000

PROPANE GAS

BTU/ HR @ 10 ” W.C.

FOR YOUR SAFETY

DO NOT STORE OR USE GASOLINE OR OTHER FLAMMABLE VAPORS AND

LIQUIDS IN THE VICINITY OF THIS OR ANY OTHER APPLIANCE.

THIS INSTALLATION MUST CONFORM WITH THE NATIONAL FUEL GAS CODE,

ANSI Z223.1 (LATEST EDITION).

WARNING: IMPROPER INSTALLATION, ADJUSTMENT, ALTERATION, SERVICE

OR MAINTENANCE CAN CAUSE PROPERTY DAMAGE, INJURY OR DEATH. READ

THE INSTALLATION, OPERATING AND MAINTENANCE INSTRUCTIONS

THOROUGHLY BEFORE INSTALLING OR SERVICING THIS EQUIPMENT.

CECILWARE CORPORATION

43-05 20TH AVENUE, LONG ISLAND CITY, NY 11105-1295

• 718 932-1414

N529A 08/99 DS

SAFETY PRECAUTI ON S

FOR Y OUR SAFETY, T HE FO LLO W I NG SAFETY PRECAU TI ON S SH O ULD

BE FOLLOW ED AN D EN FORCED .

I F YOU SMELL GAS:

• OPEN WI NDOWS

• DON’T TOUCH ELECTRI CAL SWI TCHES

• EXTI NGUI SH OPEN FLAMES

• I MMEDI ATELY CALL YOUR GAS SUPPLI ER

1. I nst r uct ions m ust be post ed in a pr om inent locat ion and all safet y

precaut ions tak en in t he event t h e u ser sm ells gas. Obt ain t his

in form at ion fr om y our local gas supplier .

2. LI GHTI NG:

Follow t he inst ruct ion on page 6 and label at t ached t o

right side of coffee ur n.

3. Do not place any t hing ov er t he flue opening.

4. Do not place com bust ibles or non- com bu st ible m at erials in t he

proxim it y of cof fee u rn as t his could cause fires or obst r uct air flow to

th e m ain bur ners.

5. This installation m ust con form wit h local codes, or in absence of local

codes w it h t he Nat ional Fuel Gas Code ANSI Z2 23. 1, lat est edit ion.

6. Provide adequat e air su pply and vent ilat ion.

7. Provide adequat e clear ance for air openings int o t he com bu st ion

cham ber.

8. Provide clear an ce for serv icing an d proper oper ation. Minim u m

clear an ce fr om com bust ible constr uction 8” fr om back and 6” fr om

side.

9. Boiler m ust be disconn ect ed from gas supply during any pressu re

test ing of pipelin es in excess of ½ psig, and isolat ed ( by t urn ing off

gas shut - off v alv e) d uring an y test ing less t han ½ psig.

10. Ret ain t his m anual for f ut ur e reference.

UNPACKI NG I NSTRUCTI ON:

Car ef ully un pack t he coffee ur n and inspect

im m ediat ely for sh ipping dam ages. Your au tom at ic coffee urn w as

shipped in a car t on designed t o giv e m axim u m pr ot ection in norm al

handlin g. I t was t horough ly inspect ed bef or e leav in g t he fact or y and t he

carr ier accept ed and sig ned for it . File any claim s for shippin g dam age or

ir r egu lar it ies wit h th e carr ier .

ELECTRICAL CONNECTIONS:

Cord Type Plug- in

12 0 VAC, 15 AMP, 50/ 60 Hz

POWER REQUI REMENTS:

3 AMP @ 12 0 VAC, 50 / 60 Hz

2

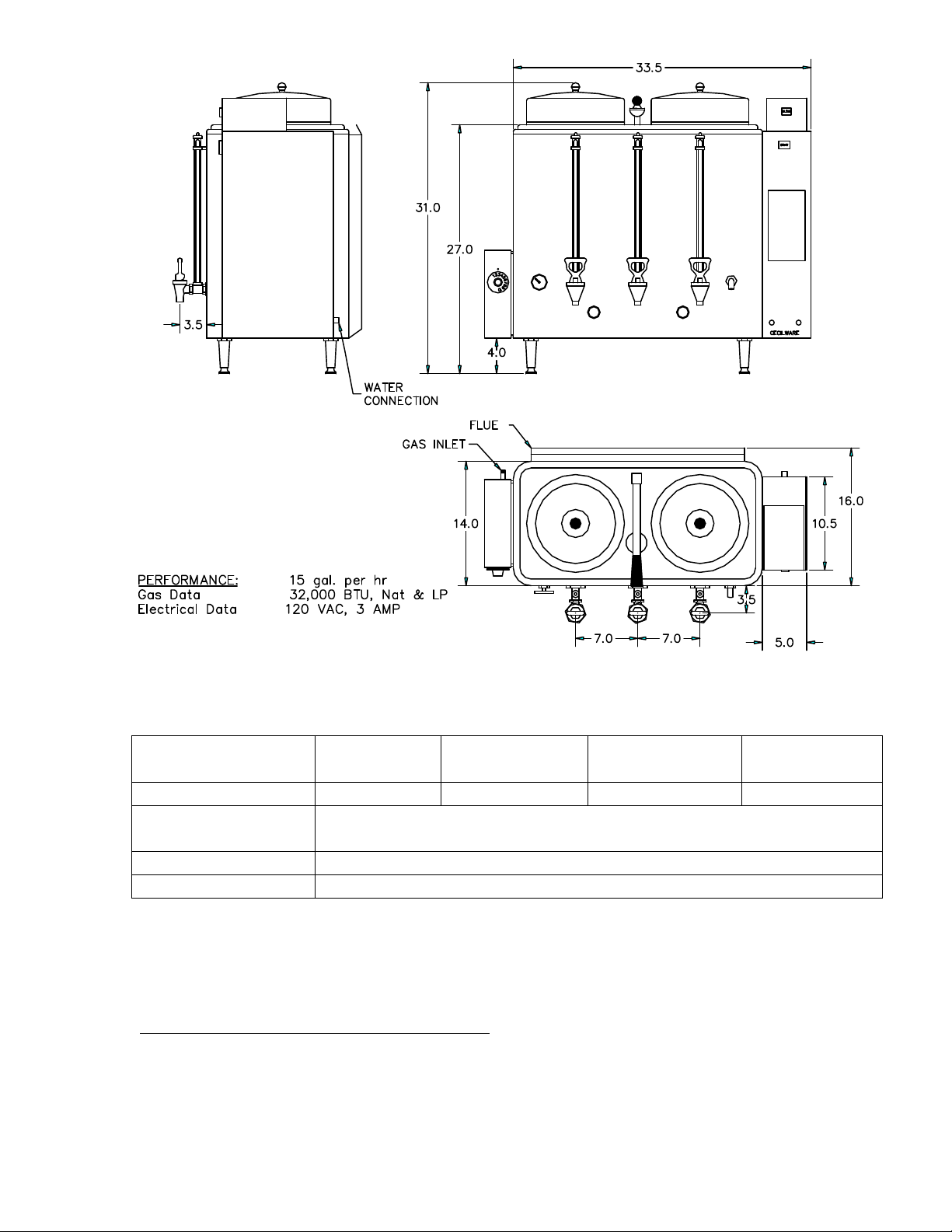

FE-100G

AUTOMATIC

COFFEE URN

FE- 1 0 0 G AUTOM ATI C CO FFEE U RN

Dim ensions

( in ch)

16 .0 19. 5 31. 0 3 7.0

Wat er

connect ion

Constr uct ion Type 30 4 18- 8 St ainless St eel

Shipping Wt . 1 25 lb.

I NSTALLATI ON AN D OPERATI N G I N STRUCTI ON :

PRE-I NSTALLATI ON I NSTRUCTI ONS:

m ust be m ade by a licensed plum ber an d t he inst allation m ust conform

wit h Stat e and Local Codes or in absence of Local Codes, w it h t he

Nat ion al Fuel Gas Code ANSI Z22 3.1 a lat est v ersion.

Body

Dept h

¼ ” Copper t ubing

Overall

Dept h

The installation of your coffee urn

Overall

Height

Overall

Widt h

3

AI R SUPPLY AND VENTI LATI ON:

Adequat e vent ilat ion and air supply

m ust be prov id ed in order for t he coffee urn t o operat e properly and

eff icien t ly . The area in fr ont of and above t he u nit m ust be clear t o avoid

an y obstr uct ion of flow of com b ust ion and vent ilat ion air. DO NOT under

an y circu m st ances, con nect t he coff ee ur n f lu e direct ly t o a bu ilding

ex haust syst em or place t he flue out let direct ly int o t he plen um of t he

ex haust hood as it w ill adv er sely affect t he gas com bust ion of t h e coffee

urn .

CLEARANCES:

Your coffee ur n is d esig n cer t if ied to u se on com bust ible

floor s. The side and b ack clearan ces for com b ust ible const r uctions are as

follow s: 6 in ches from side and 8 inches from back. The cof fee u rn m ust

be in st alled w it h 4 inch high legs pr ovided.

GAS CONNECTION:

Exam in e the gas specif ication label at tached t o t he

urn t o be cert ain t hat t he t y pe of gas for w hich the unit is equ ipped is

th e sam e as t he gas supply . A 3/ 8 NPT gas connect ion is n eeded t o

connect t h e u nit t o t he gas line. An accessible m an ual shu t- off valve

m ust be in st alled in t he gas su pply line in case of an em ergency. The gas

supply pipe m ust be sized t o accom m odate all t he gas fir ed equipm ent

th at m ay be con nect ed t o it . Check wit h your local Gas Com pan y as t o

proper p ip e size. Sealan t on all pipe j oin t s m ust be resist ive t o propane

gas. Befor e at t em pt ing t o lig ht t he coff ee ur n, ch eck all j oint s for gas

tigh t ness u sing a soap an d wat er solut ion .

WATER CONNECTION:

Unit is supplied wit h a wat er st rainer and a 19”

lengt h of ¼ ” copper t ubing w it h a flare fit t ing. Connect t he copp er t ubing

wit h t h e f lar e fit t in g t o t he w at er conn ection at th e rear of th e m achine.

The oth er end of t he st rainer is con nect ed wit h a suit able lengt h of ¼ ”

tu bing and a shut - off v alve ( sup plied by a plum ber ) t o a cold w at er

supply . Wat er pr essur e should be m inim um of 20 lbs. for proper

oper ation.

To t urn on t he w ater sup ply v alv e plug t he line cor d int o a 12 0 V

grounded ou t let . The w at er will st ar t en t er ing t he un it an d aut om at ically

fill it to capacit y.

LI GHTI NG AND ADJUSTMENT:

Wat er m ust be visible in t he sight glass

befor e light ing t o pilot . Tu rn t he t herm ost at k nob t o it s low est posit ion.

Turn gas cock d ial t o PILOT posit ion. Depress gas cock d ial and light pilot

wit h a long light ed m at ch t hrou gh t he opening locat ed on t he bot t om of

th e urn . Hold in depressed posit ion for approxim at ely 3 0 sec. or unt il

pilot r em ain s lit w hen dial is r eleased.

NOTE: On t he fir st ligh t in g it m ay be necessary t o hold t h e dial for a

longer period t o allow t r apped air t o escape fr om t he line.

DI AL SETTI NGS AND CORRESPONDI NG WATER TEMPERATURES:

“ 1” = 50F, “ 1 0” = 198F

4

Loading...

Loading...