Page 1

AUTOMATIC

COFFEE URNS

FE75

FE100

FE200

FE250

FE300

INS75

OPERATION MANUAL

Contents

Specifications

Unpacking and Inspection

Installation

Brewing Instructions

Maintenance Tips Repair

Parts List Wiring Diagrams

CRS3

CRS33

CRS66

CL75

CL100

CL200

INS100

ELECTRICAL SPECIFICATIONS

Kilowatts Amps

Model No. 1 Phase 3 Phase

Volts

7 6 120/240 29 15

FE75, INS75, CRS3, CL75

5.3 4.5 120/208 26 12

8 8 120/240 34 20

FE100, INS100, CRS33

6 6 120/208 29 17

7 8 120/240 29 20

CL100

5.3 6 120/208 26 17

1 Phase

(3 wire)

3 Phase

(4 wire)

FE200, FE250, CRS66, CL200

FE300

CECILWARE CORPORATION

43-05 20th AVENUE, LONG ISLAND CITY, N.Y. 11105 • 718-932-1414 • FAX 718-932-7860

10 10 120/240 42 24

7.5 7.5 120/208 38 22

— 15 120/240 — 37

— 11.3 120/208 — 33

N059A-8/99

Page 2

** UNPACKING AND INSPECTION **

SPECIFICATIONS

Steam Inlet Pressure

15-30

p.s.i. Steam Requirement

7-21

Ibs./hr.

Plumbing Connection

1/2n.p.t.

Electrical Connection

Plug line cord into any convenient 120V outlet

Input

Power

120

VAC, 6A,

50/60

HZ

UNPACKING INSTRUCTIONS: Carefully unpack urn and inspect immediately for shipping damage. Your automatic coffee urn was shipped in

a carton designed to give it maximum protection in normal handling. It was thoroughly inspected before leaving the factory and the carrier

accepted and signed for it. File any claims for shipping damage or irregularities directly with the carrier, not with the company.

ASSEMBLY (SEE Illustration 3): The four legs (38), faucets (36), vent cap drain (2) and water strainer assembly (23,24) are packed separately

with urn. Install legs by tilting urn on its side and screwing legs into urn leg supports until hand tight. Carefully right unit and install in its

permanent location, being sure to leave at least 6" on right side of urn for access to controls. Level urn by adjusting legs. Then attach faucets

and install vent cap drain. Cover(s) (3) are shipped with knob(s) on inside to prevent damage. Simply unscrew and reverse knob(s) and

hardware. Your urn comes with one brew basket (11) and an introductory filter pack. Additional Cecilware filters are available from your dealer.

** INSTALLATION INSTRUCTIONS **

FOR QUALIFIED SERVICE PERSONS ONLY

CAUTION: DO NOT TURN THERMOSTAT ON UNTIL ALL INSTALLATION INSTRUCTIONS HAVE BEEN FOLLOWED.

WATER HOOK -UP (See Illustration 3): Your urn comes supplied with a water strainer assembly (23,24). Connect copper tubing (24) to elbow

(22) at lower back of side box; then connect other end of water strainer to a suitable length of 1 /4" tubing with shut-off valve (plumber

supplied), connected to cold water supply.

The National Sanitation Foundation also requires an approved flowback prevention device such as a double check valve to be installed

between urn and water supply. Adjust water pressure to 20 p.s.i. for proper operation.

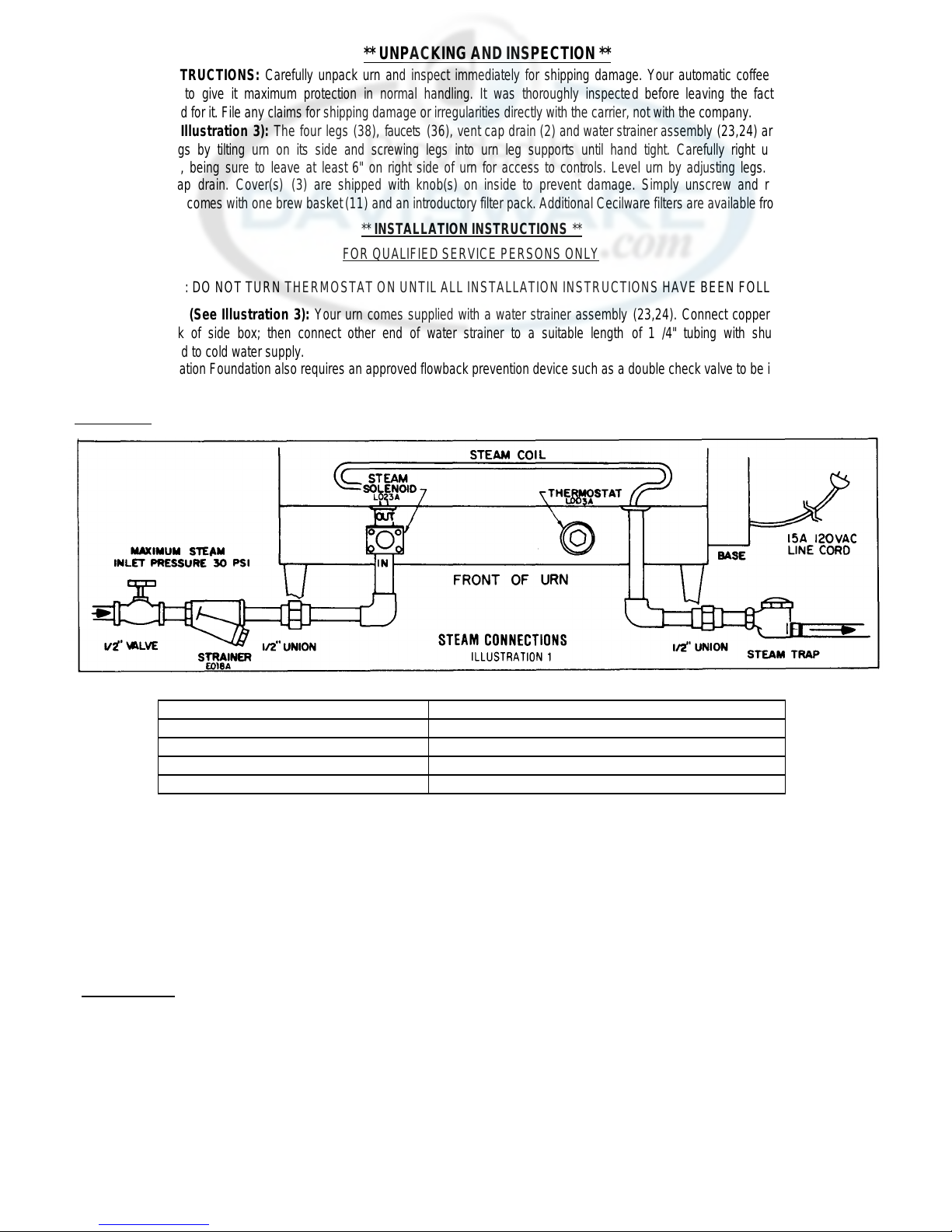

STEAM URNS

TO PRIME: CAUTION: THERMOSTAT MUST BE IN THE "OFF position. Turn on water supply and electrical power to urn and wait until water

is visible in center gauge glass (left-hand gauge glass on 3-gallon single urns). Priming can be accelerated by manual filling through vent cap

opening in top of urn, using a water hose. Then turn thermostat knob (33, III. 3) to 10; thermostat pilot light shows heater is on. Urn jacket will

continue to fill automatically until water reaches the proper level. When indicator on dial thermometer (32) approaches the "W" in BREW zone,

197°-205°F (92°-96°C), urn is ready to brew coffee. In high altitude locations (at least 5000 ft. above sea level), thermostat may have to be

lowered to prevent boiling.

NOTE: FOLLOW THE ABOVE INSTRUCTIONS FOR INITIAL PRIMING AND AFTER DRAINING URN FOR SERVICING.

TO BREW COFFEE: Follow instructions on front of urn.

ELECTRIC URNS

All electric urns come wired single (1) or three (3) phase, except for the FE300 which is 3 phase only. See wiring diagrams,

Illustration 6.

1 Phase Hookup. Remove screws and lift off side box door. Terminal block (20, III. 3) is located on rear wall of side box. Install a

suitable conduit through knockout in rear of side box and connect No. 14 neutral wire to the center connection of terminal block

(20). Then connect the remaining 2 wires to terminals L1 and L2. 3 Phase Hookup. 3 phase units have a 4-wire terminal block.

Connect No. 14 neutral wire to end terminal marked NEUT and connect remaining wires to terminal L1, L2 and L3.

2

Page 3

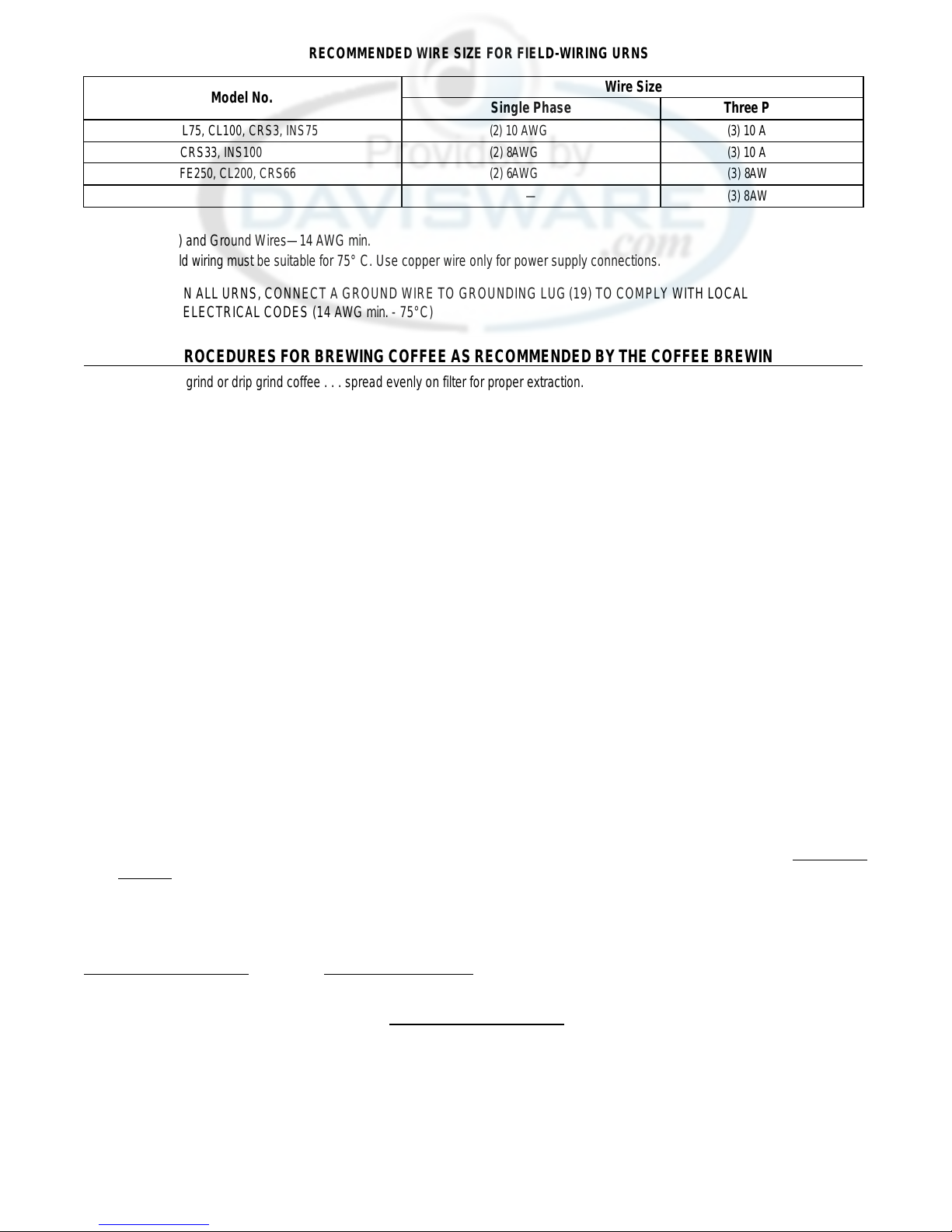

RECOMMENDED WIRE SIZE FOR FIELD-WIRING URNS

Model No.

FE75, CL75, CL100, CRS3, INS75 (2) 10 AWG (3) 10 AWG

FE100, CRS33, INS100 (2) 8AWG (3) 10 AWG

FE200, FE250, CL200, CRS66 (2) 6AWG (3) 8AWG

FE300 — (3) 8AWG

Single Phase Three Phase

Wire Size

Neutral (N) and Ground Wires—14 AWG min.

NOTE: Field wiring must be suitable for 75° C. Use copper wire only for power supply connections.

GROUNDING: ON ALL URNS, CONNECT A GROUND WIRE TO GROUNDING LUG (19) TO COMPLY WITH LOCAL

ELECTRICAL CODES (14 AWG min. - 75°C)

** CORRECT PROCEDURES FOR BREWING COFFEE AS RECOMMENDED BY THE COFFEE BREWING CENTER **

1. Use fresh urn grind or drip grind coffee . . . spread evenly on filter for proper extraction.

2. Urn should be connected to cold water supply and water heated to 197°-205°F (92°-96°C) before brewing coffee.

3. While brewing, leave cover on urn to preserve aroma and prevent excessive steaming. Total contact time for urn grind should be

approximately 4-6 minutes.

4. Remove grounds and filter as soon as coffee has dripped through. Never pour coffee back through spent grounds.

5a. Urns with automatic agitator (FE and INS series) blend coffee automatically at end of brewing cycle. Press and hold agitator ON switch

(31) for additional blending.

b. If urn has a manual agitator (CL series), press and hold agitator ON switch (31) for 15 seconds after brewing cycle to blend coffee.

c. On urns without agitator (CRS series), blend coffee by drawing off about half of batch and pouring back into brew (after removing

grounds and filter).

6. Hold coffee at 185°-190°F (85°-88°C) (about 8 on thermostat). Brewed coffee should not be held for longer than one (1) hour

and should never be reheated.

SOLID-STATE TIMER ADJUSTMENT (ALL FE's, INS's and CRS's): A factory pre-set electronic solid-state timer controls the volume of

water for each brew cycle. If more or less water is desired, follow these instructions:

Turn knob of timer (18, III.3) clockwise to increase volume of water or counterclockwise to decrease it. Run through a complete brew

cycle after each adjustment. Since timer cannot be readjusted in mid-cycle, simply push cycle stop switch (25) at bottom right of side

box if water gets too high. If maximum setting of timer fails to deliver enough water, check water pump and spray head and follow

instructions under maintenance.

NDTE: The FE200 features a dual timer. The upper knob is factory-adjusted for a 11b. brew, the lower knob for the full 2 Ib. brew.

MECHANICAL TIMER ADJUSTMENT (ALL CL's): The factory pre-set mechanical timer can be adjusted for more or less water by

following these instructions:

Remove timer knob and loosen lock nut holding stop pin. To increase volume of water, rotate stop pin clockwise. To decrease, rotate

counterclockwise. Tighten lock nut and replace knob.

SPRAY ARM BY-PASS ADJUSTMENT (ALL FE's, INS's, CL2DD and CRS661 (See III. 2).: Adjustable bypass allows proper brew

extraction even with variations caused by soft or treated water. If bypass requires adjustment to correct for local water conditions, proceed

as follows:

Position spray head over center of coffee liner and press BREW switch. Turn by-pass adjustment screw clockwise to decrease by pass flow (for stronger coffee) or counter-clockwise to increase it (for less strong coffee). At end of brewing cycle, note volume of

water in coffee liner. Readjust timer if necessary to obtain the correct volume of water.

THERMOSTAT ADJUSTMENT: To adjust temperature of water in urn jacket (205°F or 96°C), turn thermostat knob (33, III. 3) to 10

(maximum clockwise position). Pull off knob and insert a small screwdriver into adjusting screw in center of shaft when temperature on dial

thermometer (32) approaches the "W" in the word BREW. Slowly rotate screw clockwise until thermostat pilot light goes out. Turning screw

clockwise lowers temperature and turning counter-clockwise raises it. Apply a sealer (glyptol or fingernail polish) to screw after adjustment

has been made.

SPRAY ARM ASSEMBLY: The new improved spray head system was designed to facilitate easier cleaning and maintenance. The swivel

valve has a larger flow opening and the spray head cap is equipped with a stainless steel disc, used to control the flow of water.

When ordering replacement parts, be sure to order the correct disc and spray cap for each urn, as shown in Illustration 2.

** MAINTENANCE TIPS **

3

Page 4

To prevent lime buildup, especially in hard water areas, remove and clean spray head cap and spray head disc frequently. To clean swivel

valve (see III. 2) loosen nut and remove spray arm assembly from urn. Remove sediment by inserting a pipe cleaner through small hole in

valve. If maximum setting of timer (18. III. 3) fails to deliver enough water, check water pump (28).

FOR QUALIFIED SERVICE PERSONS ONLY

CAUTION: DISCONNECT POWER BEFORE ATTEMPTING ANY ELECTRICAL REPAIRS.

IF WATER FAILS TO HEAT:

1. Check line fuse or circuit breaker. Replace or reset if necessary.

2. Make sure thermostat is in ON position. If thermostat pilot light does not come on, replace thermostat (21, III. 3). (Refer to instructions

below.) If pilot light is on, measure continuity between terminals 1 and 2 of thermostat, and between terminals 3 and 4. (See III. 6) If a

resistance Is measured, replace thermostat.

3. If thermostat is okay, check wiring and repair if necessary; if wiring is okay, check heater resistance; if high or infinite, replace as follows:

REPLACING HEATER (See III. 3):

1. Shut off power and disconnect water supply at elbow (22,111.3). Drain urn.

2. Remove one coffee gauge glass (37), faucet (36), shank (37), and liner (12).

3. Tilt urn and disconnect wires to heater (34).

4. Remove socket head screw and heater flange and lift heater out.

5. Install new heater and reassemble urn.

6. Repeat priming instructions on page 2. CAUTION: DO NOT TURN ON THERMOSTAT UNTIL URN IS PRIMED.

REPLACING THERMOSTAT (FE200, FE250, FE300):

1. Shut off power, disconnect water supply, and drain urn.

2. Tilt urn and check wiring underneath before removing thermostat. If wiring seems to be in good condition, proceed as follows:

3. Remove thermostat knob (33, III. 3) and two screws holding thermostat in place.

4. Disconnect wires from thermostat.

5. Unscrew packing nut and pull out thermostat bulb.

6. Install new thermostat.

7. Repeat priming instructions on page 2. CAUTION: DO NOT TURN ON THERMOSTAT UNTIL URN IS PRIMED.

REPLACING THERMOSTAT (All Other Models): Thermostat is located in side box instead of skirt of urn. Lift off side box door to gain

access to thermostat; then follow instructions above.

IF WATER FROM COLD WATER SUPPLY LINE DOES NOT ENTER URN:

1. Check water supply to external shut-off valve and water strainer (23, III. 3).

2. Check fuse (30) on front of side box and replace if necessary.

3. If water supply and fuse are okay, remove fuse and lift off side box door. Remove timer (18), exposing terminal block (16) (see III. 5)

and electrical wiring.

4

Page 5

4. Place wire jumper across terminals 8 and 9 of terminal block (III. 5). Reinstall fuse. If water enters urn, replace float switch (3), as

explained below. If no water enters urn, solenoid (27) or small relay (14) is not functioning. To check solenoid, remove fuse and

disconnect leads from coil; then reinstall fuse. If solenoid makes buzzing sound, replace relay. If no sound, replace solenoid.

REPLACING SOLENOID (27. III. 3):

1. Shut off water supply, remove fuse (30), and lift off side box door.

2. Disconnect wires from solenoid; then remove flare nut and unscrew solenoid valve from bracket.

3. Install new solenoid and reinstall fuse and side box door.

4. If necessary, follow priming instructions on page 2.

REPLACING FLOAT SWITCH (17, III. 3):

1. Remove fuse (30), lift off side box door, and remove timer (18) from bracket, exposing terminal block (16) and electrical wiring.

2. Disconnect float switch wires from terminals 8 and 9 on terminal block (see III. 5).

3. Unscrew packing nut from bottom of float can (13) and remove float switch (17) by pulling on wires.

4. Replace with new float switch and reassemble unit in reverse order.

CLEANING FLOAT CAN ASSEMBLY (13, III. 3): Periodically it may become necessary to clean float can (13, III. 3) to keep float switch (17)

operating properly.

1. Remove float can cover (10) and lift float (9) from stem.

2. Clean container and float, replace float on stem and reinstall cover.

IF WATER RUNS OUT AT OVERFLOW DRAIN (40. III. 3):

1. Make sure urn is level and overflow tube (45) is vertical.

2. Remove fuse (30) from front of side box. If water stops, replace float switch (instructions above).

3. If water continues to flow, solenoid valve is dirty or not seating properly. Replace solenoid as described above.

NO WATER FROM SPRAY HEAD (1, III. 3):

1. Check fuse (30) first.

2a. For all urns except CL's: Depress BREW switch (29) and release. If switch remains lit, water pump (28) is probably not operating. Lift

off side box door and check if fan on water pump is rotating. If not, replace pump as described below.

b. For CL urns: Turn brew timer knob clockwise. Replace timer if it does not go on. If timer goes on but pump doesn't, replace pump.

(See bottom left box of III. 5.)

REPLACING WATER PUMP (28. III. 3);

1. Shut off water supply and remove fuse (30). Drain urn to level of water faucet.

2. Lift off side box door and disconnect the two pump wires (see III. 5).

3. Loosen union fittings on pump and remove pump from urn.

4. Replace pump and follow priming instructions on page 2.

CHECKING SOLID-STATE TIMER (18. III. 3) (ALL URNS EXCEPT CL's): Press and hold BREW switch (29) for 10 seconds. Brew cycle should

start. If water stops coming from spray head as soon as BREW switch is released, timer is not operating. Replace it. (Instructions below.)

If no water comes from spray head when BREW switch is pressed, replace switch.

NOTE: To check mechanical timer on CL urns. refer to NO WATER FROM SPRAY HEAD, (see para. 2b above).

REPLACING SOLID-STATE TIMER (See III. 5):

1. Remove fuse (30, III. 3), lift off side box door. and remove timer from bracket.

2. Carefully note locations of colored wires on timer board, then remove wires.

3. Replace timer and reassemble unit in reverse order.

AGITATOR - AUTOMATIC TYPE (ALL FE AND INS URNS]:

OPERATION:

The agitator pump circuit is programmed to operate immediately after brewing cycle. The circuit pumps air through the coffee gauge

glass(es) into the coffee liner(s). The complete cycle takes about 20 seconds. For additional blending, simply press the agitator ON

switch (31, III. 3).

MAINTENANCE:

If agitation is not sufficient to blend coffee, check flexible tubing (6 and 44), and glasses and fittings, for possible air leaks. Replace

as necessary.

If agitator pump (5) does not operate immediately after brewing cycle or when agitator ON switch (31) is pressed, replace agitator

pump or solid state agitator timer (8).

If agitator pump comes on immediately after brewing cycle, but does not operate when agitator ON switch is pressed, replace

agitator ON switch.

5

Page 6

AGITATOR

•

MANUAL TYPE

(

CL URNS

)

OPERATION:

REPAIR PARTS LIST

(See Illustration

3)

ITEM NO.

STOCK NO.

DESCRIPTION

MODEL NO.

1 E045A

Complete spray arm assm. w/bypass

FE/INS/CL75,

100

1 E011A

Complete spray arm assembly

CRS3,

33 1 E038A

Complete spray arm assm. w/bypass

FE/CL200: FE250: CRS66

1

E039A

Complete spray arm assm. w/bypass

FE300

2

U019A

Vent cap drain

All (except INS's)

2

E072A

Vent cap drain

All INS's

3

Q024A

Cover with

knob

FE/INS/CL75, 100; CRS3. 33

3

0011 A

Cover with knob

FE/CL200: FE250: CRS66

3

Q092A

Cover with knob

FE300

4

E023A

3" Nipple union assembly

All (except

FE300)

4

E036A

3" Nipple union assembly

FE300

5

C511A

Agitator pump assembly

All (e

xcept CRS's)

6

H050A

9 ½” Agitator tubing

All (except CRS's)

7

U152A

Agitator box cover

All (except CRS's)

7

L249A Agitator assm. (solid state aut.)

All FE's and INS's

7

L251A Agitator assembly (manual)

All CL's

8

L238A Solid state agitator ti

mer

All (except CRS's)

9

E040A

Float

All 10 U022A

Float can cover

All 11 V002A

Brew basket (s/s)

FE/INS75,

100; CRS3, 33

11

V003A

Brew basket (s/s0

FE/CL200; FE250: CRS66

11

V081A

Brew basket (s/s)

FE300

11

V113A

Brew basket (polypropylen

e)

CL75,

100 12 00820 Liner - 3 gallon

FE/INS/CL75,

100:CRS3,

33 12 Q094Q

Left liner

- 9

gallon

FE300

12

0095Q

Right liner

- 9

gallon

FE300

12

Q096Q

Left liner

- 6

gallon

FE/CL200; FE250; CRS66

12

Q097Q

Right liner

- 6

gallon

FE/CL200; FE2

50; CRS66

13

U023Q

Float can assembly

All 14 L018A Relay

All 15 C008A

Capacitor

&

resistor assm.

All 16 B034A

Terminal block

All 17 L019A Float switch

All 18 L205A Solid state timer 120V

All (except FE200 and CL's)

18

L210A Solid state t

imer 220V

All (except

FE200

and CL's)

18

L214A Dual solid state timer 120V

FE200

18

L216A Dual solid state timer 220V

FE200

18

L154A Mechanical timer (Not shown)

All CL'S

19

B039A

Grounding lug

All 19 C034A

Contactor (Not shown)

FE300

20

BOOOA

Terminal block

All single phase

20

B017A

Terminal block

All three phase

21

L029A Thermostat

All 22 K028A

Elbow

All 23 E002A

Water strainer

All 24 H016Q

19"

Copper tubing

All 25 C396A

Fuse holder, SC

-

6 type

All 25 C142A

Fuse holde

r, FN type (Canadian)

All 26 L017A Cycle stop switch

All (except CL's)

27

L022A Solenoid

.28

GPM

FE/INS/CL75, 100; CRS3, 33

27

L010A Solenoid

.50

GPM

FE/CL200; FE250; CRS66

27

L080A Solenoid

.75

GPM

FE300

27

X008A Solenoid coil

All 27 X033A

Solenoid diaphragm repair kit

All 27 X035A Solenoid flow washer (Not shown)

FE/INS/CL75, 100; CRS3, 33

27

X036A Solenoid flow washer (Not shown)

.5

FE/CL200; FE250; CRS66

27

X038A Solenoid flow washer (Not shown)

FE300

28

EOOOA

G-

wat

er pump

All 28 EOOOT

Rebuilt G

-

water pump

All 28 U070A

G-

water pump fan

All 28 E069A

H-

water pump

All 28 X032A Seal kit for G

-

water pump

All 29 L012A BREW switch

All (except CL's)

30

C395A

Fuse 6A SC

-6 All 30 C141A

Fuse, 5AFN (Canadian

)

All 31 L236A Agitator

All (except CRS's and CL's)

31

L052A Agitator

All CL's

32

L007A Dial thermometer

Alt (except INS's)

32

L323A Dial thermometer

All INS's

33

M008A

Thermostat knob

All 34 Q013A

Water heater 8kw

-

240V-1Ph

FE/INS100; C

RS33 33 G031A

Water heater 7kw

-

240V-1Ph

FE/INS/CL75; CRS3;

CL100

34

G011A

Water heater 5kw

-

240V-1Ph

FE/CL200; FE250; CRS66; FE300

34

G026A

Water heater 8kw

-

240V-3Ph

FE/INS/CL100;

CRS33

34

G024A

Water heater 6kw

-

240V-3Ph

FE/INS/CL75; CRS3

34 G018A Water heater 5kw

-

240V-3Ph

FE/CL200; FE250; CRS66

34 G040A

Water heater 5kw

-

480V-3Ph

FE/CL200; CRS66; FE250, 300

Immediately after brewing cycle, depress agitator ON switch and hold for about 20 seconds. Your coffee will be completely

blended and ready to serve.

MAINTENANCE:

If agitator pump does not operate when agitator ON switch is pressed, replace switch. If pump still does not operate,

replace pump.

6

Page 7

ITEM NO.

STOCK NO.

DESCRIPTION

MODEL NO.

34

G043A

Water heater 8kw

-

480V-3Ph

FE/INS/CL75,

100;

CRS3,

33

35

D021A

Shank for coffee gauge

All (except INS's)

35 D045A

Shank for gauges

All INS's

36 D017A

Water and coffee faucet

All 37

X005A

Coffee gauge glass

FE/INS/CL75, 100: CRS3, 33

37 X004A

Coffee gauge glass

FE/CL200; FE250; CRS66

37 X044A

Coffee gauge glass

FE300

38 M005S

Legs, chrome

All (except CL's)

38 M172S

L

egs, black

All CL's

39 D022A

Shank for water gauge

All (except INS's)

40 E009A

Overflow drain

All (except INS's)

40 E071A

Overflow drain

All INS's

41 X006A

Water gauge glass

FE/INS/CL75, 100; CRS3, 33

41 X030A

Water gauge

glass

FE/CL200; FE250; CRS66

41 X043A

Water gauge glass

FE300

42 D024A

8"

or 81/2

"

Water gauge shield

FE/INS/CL75, 100; CRS3, 33

42 D001A

9"

Water gauge shield

FE7CL200;

FE250; CRS66

42 D032A

12"

Water gauge shield

FE300

43 D001A

9"

Coffee gauge shield

FE/INS/CL75, 100; CRS3, 33

43 D020A

10-%"

Coffee gauge shield

FE/CL200; FE250; CRS66

43 D031A

14%"

Coffee gauge shield

FE300

44 H051A

5"

Agitator Tubing

All (except CRS's)

45 H0250

Overflow tube

All 46

K108A

Vent cap assembly

All (except CRS's)

718

Filter pack (Not shown)

FE/INS/CL75, 100; CRS3, 33

820 Filter pack (Not shown)

FE/CL200; FE250; CRS66

923 Filter Pack (Not Shown)

FE300

923

Filter pack (Not shown)

FE300

7

Page 8

8

Loading...

Loading...