Page 1

INSTRUCTION MANUAL

Cipher GenetiC AnAlysis system

DTSK-2001-110

DTSK-2001-220

DTSK-2401-110

DTSK-2401-220

One System that Detects Mutations and Polymorphisms 4 different ways:

1) DGGE - Denaturing Gradient Gel Electrophoresis

2) TTGE - Temporal Temperature Gradient Electrophoresis

3) SSCP - Single Strand Conformational Polymorphisms

4) CDGE - Constant Denaturant Gel Electrophoresis

1

Cipher Genetic Analysis System

www.cbsscientic.com

DTSK Instruction Manual, version 8/30/2011

Page 2

TABLE OF CONTENTS

Important User Information 3-4

Section 1 General Information

1.1 Introduction 5

1.2 Specications 6

1.3 Safety 6

Section 2 Description of parts

2.1 Unpacking 7

2.2 Components/Assembly 7

Section 3 Instructions for Use

3.1 Unit Set-up and Unpacking 8-9

3.2 Heater/Stirrer General Set-Up 10-24

3.3 Heater/Stirrer Programming 25-34

3.3.1 Setting Operational Parameters and Functions 25

3.3.2Entering/ModifyingaTemperatureProgram 26-30

3.3.3 Running a Temperature Program 31-32

3.3.4 Setting Preferences 32

3.3.5 Heater/Stirrer Error Messages 33-34

3.4 Running the Heater/Stirrer 35

3.5 Preparation/Cleaning of Glass Plates 35

3.6 GelCastingTechniques 36-37

3.7 Vertical Gradient Formation 38-42

3.8 Preparation of the Cassettes 43

3.9 Buffer Cycling Connections 44

3.10 Running the Gels 45

3.11 RemovingtheGels 46

3.12 Perpendicular Gel Casting 47

3.13 Perpendicular Gradient Formation 48-49

3.14 Buffer Siphon Pump Instructions for use 50

3.15 Maximum Well/Comb Volumes 50

Section 4 Running Conditions 51

4.1 Recommended Power 51

4.2 Recommended Buffers 51

4.3 Recommended Running Conditions 52

4.4 SSCP Running Conditions 52

4.5 References 53

Section5 MaintenanceofEquipment

5.1 Care and Handling 54

5.2 Maintenance & Calibration 55

Section6 Heater/StirrerTroubleshooting 56-57

Section 7 Accessories 58

2

Page 3

IMPORTANT USER INFORMATION

This Instruction Manual will explain how to use this product safely and effectively. Please read and carefully follow the

instruction manual in its entirety.

The triangle/exclamation mark symbol alerts the user of the product to important operational, maintenance, and/

or warranty requirements.

The triangle/lighting bolt symbol alerts the user of the product to potentially hazardous electrical exposure.

Failure to adhere to the instructions could result in personal and/or laboratory hazards, as well as invalidate any

warranty. Always turn off the DC power source prior to disconnecting power cords from the product. Disconnect

power cords from the power source rst, and then from the product. For maximum safety, always operate this

system in an isolated, low trafc area, not accessible to unauthorized personnel. Never operate damaged or

leaking equipment.

WARRANTY AND LIABILITY

This product was produced utilizing the highest practical standards of materials, workmanship, and design. C.B.S. Scientic

warrants that the product has been tested and will meet or exceed published specications. This warranty is valid only if

the product has been operated and maintained according to the instructions provided.

C.B.S. Scientic warrants this product to be free from defects in materials and workmanship under normal service for one

year from date of shipment. If the product proves defective during this period, C.B.S. Scientic will repair or replace it at our

option, free of charge, if returned to us postage prepaid. This warranty does not cover: damage in transit, damage caused

by carelessness, misuse or neglect, normal wear through frequent use, damage caused by solvent corrosion, damage

caused by improper handling or user alteration, nor unsatisfactory performance as a result of conditions beyond our

control. C.B.S. Scientic shall in no event be liable for incidental nor consequential damages, including without limitation,

lost prots, loss of income, loss of business opportunities, loss of use and other related damages, however caused, nor any

damage arising from the incorrect use of the product.

www.cbsscientic.com

3

Cipher Genetic Analysis System

DTSK Instruction Manual, version 8/30/2011

Page 4

FRANÇAIS INFORMATION IMPORTANTE À L’USAGE DES UTILISATEURS

Le présent manuel d’utilisation explique la manière de se servir efcacement du produit en conditions

de sécurité. Il est recommandé de soigneusement lire la totalité du manuel, avec ses consignes

et ses instructions.

Le triangle avec point d’exclamation est un symbole destiné à avertir l’utilisateur du produit

de l’importance de certaines exigences relatives au fonctionnement, à l’entretien et/ou à

la garantie.

Le triangle avec èche en zigzag est un symbole destiné à avertir l’utilisateur du produit de la

possibilité d’exposition à des décharges avec danger de secousses électriques.

Tout manquement à l’observation des consignes et des instructions peut exposer les personnes

et les biens à des dommages corporels et/ou matériels et peut annuler toute garantie. Il faut toujours

interrompre l’alimentation de courant continu avant de déconnecter les cordons d’alimentation du produit.

Déconnecter d’abord les cordons d’alimentation branchés sur la source de tension (alimentation de

secteur) puis ceux branchés sur le produit. Pour une sécurité maximum, il faut toujours faire fonctionner

ce système dans un lieu isolé, peu fréquenté, où le personnel non autorisé n’a pas accès. Ne jamais faire

fonctionner un matériel endommagé ou affecté par des fuites.

GARANTIE ET RESPONSABILITÉ

Le produit a été fabriqué conformément aux normes applicables les plus exigentes en matière de

matériaux, de main d’oeuvre, de conception et d’ingéniérie. C.B.S. Scientic garantit que le produit a subi

des essais et que ses performances rempliront les conditions des spécications publiées ou luer seront

même supérieures. La présente garantie n’est valide que si le produit a fonctionné et a été entretenu

conformément aux consignes et instructions fournies.

C.B.S. Scientic garantit que le produit sera dépourvu de vices de matériaux et de main d’oeuvre, en

conditions de service normales, pendant un an à compter de la date d’expédition. Au cas où le produit

s’avérerait défectueux pendant cette période de garantie, C.B.S. Scientic réparera ou remplacera le

produit, à sa discrétion et gratuitement, si le produit lui est retourné port payé d’avance. La garantie

ne couvre pas les dommages de transport; les dommages causés par l’imprudence, le manque de

soins, l’abus ou la négligence; l’usure normale résultant d’une utilisation fréquente; les dommages

causés par la corrosion des solvants; et les dommages causés par la manipulation inadéquate ou

des changements apportés par l’utilisateur. La garantie ne couvre pas non plus les performances non

satisfaisantes résultant de conditions hors du contrôle de C.B.S. Scientic. C.B.S. Scientic ne pourra

en aucun cas être tenue responsable de dommages indirects, y compris, de manière non limitative, la

perte de bénéces, le manque à gagner, la perte d’occasions d’affaires, l’impossibilité d’usage ou tous

autres dommages associés, quelle qu’en soit la cause, ni de dommages résultant de l’usage incorrect

du produit.

DEUTSCH WICHTIGE INFORMATION FÜR DEN BENUTZER

Diese Bedienungsanleitung beschreibt wie man dieses Produkt sicher und wirksam benutzt. Bitte lesen

und befolgen Sie alle Anweisungen in dieser Anleitung.

ESPAÑOL INFORMACIÓN IMPORTANTE PARA EL USUARIO

El presente instructivo explica la manera de usar este producto en forma segura y efectiva. Sírvase

leerlo en su totalidad y seguir detenidamente las indicaciones que contiene.

El símbolo del triángulo con exclamación llama la atención del usuario a requisitos

importantes para el uso y mantenimiento del producto, así como para la validez de

la garantía.

El símbolo del triángulo con rayo llama la atención del usuario a la posibilidad de riesgos

eléctricos.

El incumplimiento de las instrucciones aquí señaladas podría dar lugar a riesgos a la persona, al

laboratorio o a ambos y podría anular toda garantía. Siempre apague la fuente de corriente continua

antes de desenchufar los cables eléctricos del producto. Primero desconecte los cables de la fuente de

energía y después del producto. Para mayor seguridad, siempre use este sistema en un área aislada,

de poco movimiento de personas e inaccesible a personal no autorizado. Jamás use equipo que

presenta algún daño o fuga.

GARANTÍA Y RESPONSABILIDAD

Este producto fue fabricado de acuerdo con las normas más estrictas que sean factibles en cuanto a

materiales, mano de obra y diseño. C.B.S Scientic garantiza que se sometió el producto a pruebas y

que cumplirá o excederá las especicaciones publicadas. Esta garantía será válida únicamente si se

usa y se da servicio de mantenimiento al producto de acuerdo con las instrucciones señaladas.

C.B.S. Scientic garantiza que este producto se encontrará libre de defectos de materiales y mano de

obra por un período de servicio normal de un año a partir de la fecha de embarque. Si el producto resulta

defectuoso durante este período, C.B.S. Scientic lo reparará o lo repondrá, a criterio de C.B.S., libre

de cargos, si se devuelve el producto a C.B.S. porte pagado. Esta garantía no cubre daños sufridos en

tránsito, daños provocados por descuido, mal uso o negligencia, desgaste normal como consecuencia

del uso excesivo, daños atribuibles a corrosión provocada por solventes, daños causados por el uso

indebido o alteraciones realizadas por el usuario ni rendimiento insatisfactorio atribuible a circunstancias

fuera del control de C.B.S. Scientic. C.B.S. Scientic en ningún caso asumirá responsabilidad por

daños incidentales o subsecuentes, incluyendo, en forma no limitativa, la pérdida de utilidades, de

ingresos, de oportunidades comerciales o del uso del producto y otros daños anes, fuere cual fuere su

origen, ni por daños derivados del uso incorrecto del producto.

ITALIANO INFORMAZIONI IMPORTANTI PER L’UTENTE

Questo manuale spiega come utilizzare questo prodotto in maniera sicura ed efciente. Si pregai di

leggere e seguire con cautela le istruzioni di ogni parte di questo manuale.

Das Dreieck mit Ausrufezeichen weist den Benutzer des Produktes darauf hin, daß

wichtige Bedienungs-, Wartungs- und/oder Garantievorschriften zu beachten sind.

Das Dreieck mit Zickzackblitz warnt den Benutzer des Produktes vor möglichen

Gefahren durch elektrische Spannungen.

Nichtbeachtung dieser Anweisungen kann zu persönlichen und/oder labortechnischen Schäden

führen und gleichzeitig alle Garantien als nichtig erklären. Die DC Stromzufuhr muß immer, vor dem

Entfernen der Stromkabel vom Produkt, abgeschaltet werden. Die Stromzufuhrkabel müssen zuerst von

der Steckdose und erst dann vom Produkt entfernt werden. Um höchste Sicherheit zu gewährleisten

sollte dieses System in einem abgesonderten und besonders ruhigen Bereich eingesetzt werden und

vor Unbefugten sicher sein.

GARANTIE UND HAFTUNG

Dieses Produkt wurde unter Anwendung von Produkten mit höchster Qualität und aus Materialien mit

bester Verarbeitung und modernstem Design hergestellt. C.B.S Scientic garantiert, daß das Produkt

getestet wurde und alle publizierten Spezikationen übertrifft. Diese Garantie ist jedoch nur gültig, wenn

das Produkt nach der beigefügten Bedienungsanleitung bedient und gewartet wurde.

C.B.S. Scientic garantiert, daß dieses Produkt bei normaler Bedienung aus fehlerfreiem Material

besteht und fehlerfrei in der Ausführung ist. Diese Garantie gilt für ein Jahr ab Lieferdatum. Sollte

das Produkt in diesem Zeiraum fehlerhaft werden, bietet C.B.S. Scientic eine kostenlose Reparatur

bzw. Kostenlosen Ersatz, einschließlich freiem Rückporto. Diese Garantie schließt folgendes aus:

Transportschaden, Schaden durch Nachlässigkeit, Mißbrauch oder Vernachlässigung, normale

Abnützung durch regelmäßigen Gebrauch, Schaden durch Säureangriff, Schaden durch falsche

Handhabung, Veränderung des Produktes durch den Benutzer, oder unzureichende Leistungen die

sich nicht im Verantwortungsbereich von C.B.S. Scientic benden. C.B.S. Scientic kommt unter

keinen Umständen für folgende Schäden auf: Sachschadensverlust, Einkommensverlust, Verlust

von Geschäftsmöglichkeiten, Verlust der Anwendung und andere damit verbundene Schäden die auf

irgend eine Art und Weise entstanden sind, oder Schäden die aus falscher Anwendung des Produktes

entstanden sind.

Il triangolo contenete il simbolo di un punto esclamativo avverte l’utente di importanti

requisiti relativi al funzionamento, manutenzione e/o garanzia del prodotto.

Il triangolo contenete il simbolo di un lampo avverte l’utente del prodotto della possibilità

di pericoli dovuti a corrente elettrica.

La mancata osservanza delle istruzioni può essere causa di pericolo alla propria persona ed

al laboratorio, oltre a poter annullare la garanzia. Prima di distaccare il cordone d’alimentazione dal

prodotto, spegnere sempre la sorgente di corrente continua. Distaccare i cordoni d’alimentazione prima

dal lato della sorgente di tensione e poi dal lato del prodotto. Per maggior sicurezza, mettere sempre

in funzione il prodotto in un’area isolata con poco trafco che non sia accessibile al personale non

autorizzato. Non mettere mai in funzione un’apparecchiatura che sia danneggiata o abbia perdite.

GARANZIA E RESPONSABILITÀ

Questo prodotto è stato fabbricato seguendo gli standard più elevati per i materiali, la manodopera e la

progettazione. La C.B.S. Scientic garantisce il prodotto è stato sottoposto a prova e raggiunge o supera

i valori pubblicati per i dati tecnici. Questa garanzia è valida solo se il prodotto è messo in esercizio e

soggetto a manutenzione secondo le istruzioni fornite.

La C.B.S. Scientic garantisce che questo prodotto è libero di difetti di materiali e manodopera, in normali

condizioni d’esercizio, per la durata di un anno dalla data di spedizione. Se, in questo periodo, il prodotto

si dimostrerà difettoso, la C.B.S. Scientic, a suo giudizio, lo riparerà o sostituirà. Questa garanzia non

copre danni in transito, danni causati da negligenza, uso improprio, trascuratezza, normale consumo

derivante da uso frequente, o danni causati da solventi corrosivi, danni causati da maltrattamento o da

modiche apportate dall’utente e non copre prestazioni insoddisfacenti che siano il risultato di condizioni

al di fuori del controllo del fabbricante. La C.B.S. Scientic non sarà in ogni caso responsabile per danni

incidentali o consequenziali, incluso, senza limitazioni, perdite di protto, perdita di entrate, perdita di

opportunità d’affari e altri danni relativi, comunque causati, e per danni risultati da uso incorretto del

prodotto.

4

Page 5

SECTION 1

General Information

1.1 Introduction

DESCRIPTION

The Cipher GenetiC AnAlysis systems (DTSK-2001 and DTSK-2401) allow the researcher to choose which technique

is most applicable to their investigation. Both DGGE and TTGE rely on establishing a gradient of either solvent

(Urea/Formamide) or temperature in which the target fragments will undergo conformational transition (melt). This

sequence dependent information will determine the theoretical melting behavior of the target fragment after PCR

amplication. If the sequence is known, then primer/probe design can be made using certain software design

programs (1). If not, the melting range can be revealed by running perpendicular DGGE/TTGE gels. The third

mutation detection technique, SSCP, differentiates between normal and mutant duplex DNA by denaturing the DNA

to form single stranded molecules of equal length. These molecules can re-anneal onto themselves and based on

the varying degree of intrastrand base pairing, form different three-dimensional structures. These structures, differ

in electrophoretic mobility and can be separated on a non-denaturing polyacrylamide gel.

C.B.S. SCIENTIFIC has designed two different Cipher GenetiC AnAlysis systems which are reliable and easy-to-use.

The DTSK-2001 is a 2 gel system and includes two single gel cassettes. The DTSK-2401 is a four gel system which

includes two dual gel cassettes. The systems feature: programmable heater/stirrer which can be programmed for

DGGE, TTGE and SSCP applications, a large diameter cooling coil for use with an external chiller, a simplied

method for casting perpendicular and vertical gels using Gel Wrap®, single or dual gel cassettes, an internal

impellor pump for buffer cycling, polypropylene spring clamps, and a safety cover with an electrical interlock which

helps maintain temperature, reduce evaporation, and protect against shock hazard.

DGGE & CDGE

Denaturing Gradient Gel Electrophoresis (DGGE) is a powerful genetic analysis technique that can be used for

detecting single base changes and polymorphisms in genomic (2,3), cloned, and PCR amplied DNA (3,4). Two

of the most valuable uses for DGGE in human, animal or microbial genetics are in directly detecting single base

changes that cause disease and in detecting polymorphisms with DNA probes for genetic-linkage analysis. In DGGE,

conformational transitions of multiple nucleic acid complexes are induced by an increasing concentration of solvent

(Urea/Formamide) at a constant temperature. Clinical applications of DGGE include a rapid and effective method

for screening samples for genetic mutations and variants. Also, DNA fragment melting points can be determined

using perpendicular DGGE (2). In contrast to DGGE, CDGE (Constant Denaturant Gel Electrophoresis) uses a

single solvent percentage to induce partial melting of DNA fragments as they enter the gel. The disadvantage of

CDGE is that only a single melting domain can be interrogated.

TTGE

Destabilization of nucleic acid complexes can also be studied using acrylamide gels which contain a uniform solvent

concentration (Urea/Formamide), but with an increasing temperature gradient (6). Since the temperature of the

entire gel is uniformly raised over a period of time, this technique has been termed ‘TTGE’, or Temporal Temperature

Gradient Electrophoresis (7). This technique incorporates many improvements over DGGE/CDGE especially when

studying multiple melting domains (8).

SSCP

Single Strand Conformational Polymorphism (SSCP) reveals differences in electrophoretic mobility between normal

and mutant single strands of DNA (9). In SSCP, normal and mutant duplex DNA are denatured to form single stranded

molecules of equal length. These molecules can re-anneal onto themselves and based on the varying degree of

intrastrand base pairing, form different three-dimensional structures. These structures, differ in electrophoretic

mobility and can be separated on a chilled non-denaturing polyacrylamide gel. The electrophoretic mobility of

these “conformers” change depending on temperature and buffer ionic strength. For accurate characterization

of mutations within these re-folded single strands, it is essential that the buffer temperature be tightly controlled

within each electrophoresis procedure, usually between 4º-25ºC. If the gel temperature is not precisely controlled,

the resolution will suffer because of the loss of intrastrand base pairing and change in the overall shape of the

3-dimensional conformer.

www.cbsscientic.com

5

Cipher Genetic Analysis System

DTSK Instruction Manual, version 8/30/2011

Page 6

1.2Specications

Constructions

DTSK Tank Sodalime glass, Kydex

DTSK Lid Sodalime glass, Kydex

Electrodes Platinum wire .012” diameter

Power cords FR Polypropylene/Silicone, rated 7500V, 200mA, 65° C

DTSK Cassette Acrylic

Cooling Coil brass, copper, PVC

Heater/Stirrer Buffer Cycler Stainless steel

Combs Teon/ Acrylic

Spacers Proprietary

Glass Plates Sodalime or Borosilicate

Gradient Maker Acrylic, teon, stainless steel

DTSK-2401

Gel Size

Distance between electrodes

Voltage limit

17.7cm x 22cm

20cm

250

1.3 Safety

Power to the DTSK Systems is to be supplied by an external DC voltage power supply that must be ground isolated

so that the DC voltage output oats with respect to ground. For any power supply used, the maximum specied

operating parameters for the units are:

Maximum Limits

250 VDC voltage

60 watts power

1600 mA current

70°C ambient temperature

Current to the unit, provided from the external power supply, must enter the unit through the lid assembly, providing

a safety interlock to the user. Current to the unit is broken when the lid is opened. Do not attempt to use the unit

without the safety lid. Always turn the power supply off before removing the lid, or when working with the

unitinanyway.Followsafetyprecautionsspeciedbythepowersupplymanufacturer.

6

Page 7

SECTION 2

Heater

Stirrer

Buffer Siphon

Pum p Assemb ly

TTG E

Tank

Dual

Cassette (2)

Com b (4 )

Spacers

(4 pairs)

Glass Plate

Assembly(4)

Clamps

Mini-Pump

(Optiona l)

GM-40

Gelwrap

®

(4)

Description of Parts

2.1 Unpacking

Please verify that your Cipher GenetiC AnAlysis system comes complete with the following components:

• Lower Reservoir/Glass tank/safety interlock/ with 2 black leads inside lid

• Heater/Stirrer/By-pass pump/Cooling Coil

• Two Dual Gel cassettes

• 1 Gradient maker, 20mls per side, Cat. # GM-40

• 8 each combs, 4 sets glass plates, 8 pair spacers and 8 each Gel Wrap gaskets

• White spring clamps, 12 each GPC-0002-177 and 16 each GPC-0001-177 (Number of clamps received with

system will vary depending on format of DGGE)

• Buffer siphon pump with tubing, Cat. # BSP-100

• EPS-300-II Power Supply

• Peristaltic Mini-Pump for gel casting

2.2 Components/Assembly

www.cbsscientic.com

7

Cooling coil is

situated inside tank

below heater/stirrer

Cipher Genetic Analysis System

DTSK Instruction Manual, version 8/30/2011

Page 8

SECTION 3

Instructions for Use

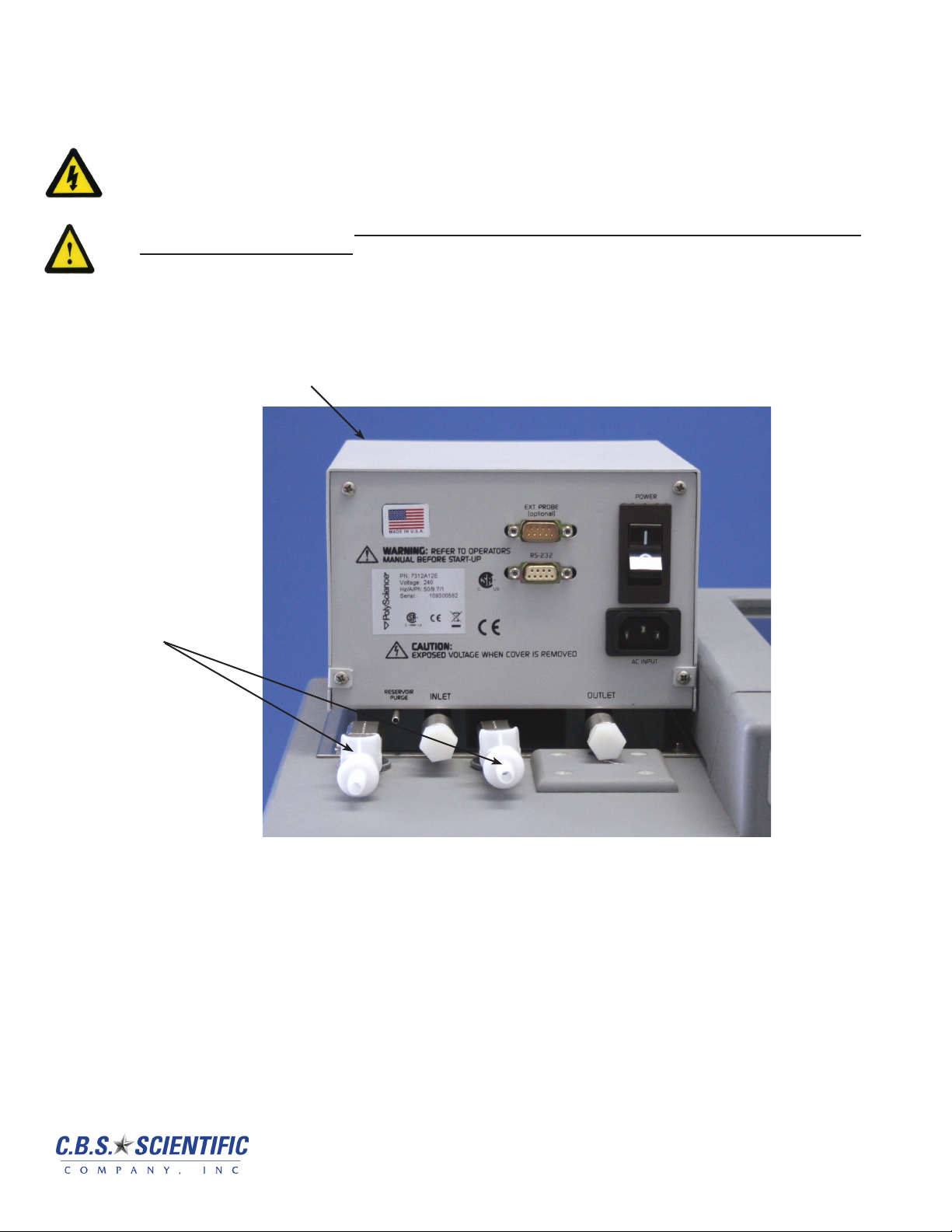

3.1 Unit Set-up and Unpacking Instructions

1. Unpack lower reservoir and place on level surface in an approved location.

2. WARNING:DoNOTturnonHeater/Stirreruntiltankhasbeenlledwithbuffer. The MINIMUM buffer

volume for heating is 23 liters. Turning Heater/Stirrer on with less than 23 liters of buffer will damage the

heating coil, and void warranty. If running two dual cassettes, the buffer volume is 24 liters.

3. Connect cooling coil to chiller using tubing adapters and 1/4th I.D. tubing (tubing is not supplied).

Fig. 3-1

cooling coil inlet

and outlet

heater/stirrer

8

Page 9

3.1 Unit Set-up and Unpacking Instructions-continued

4. Position an appropriate power supply on a shelf above the tank.

5. Fill the tank with running buffer. To obtain the correct level of buffer, place the cassettes in the tank and ll

the tank until the level of buffer reaches the underside of the upper reservoir. The upper reservoir holds only

50mls.

6. Attach the power supply to the safety interlock. (Fig 3-2-A)

7. Attach the safety interlock to a wall (mains) outlet. (Fig 3-2-B)

8. Plug the Heater/Stirrer into a wall (mains) outlet. Important: Do not plug the heater/stirrer into anything other

than a wall outlet.

9. Do NOT attach power leads (from power supply to safety interlock, Fig 3-2-C) until gels are loaded and

installed in the tank.

Power Supply/Safety Interlock Connections

Fig. 3-2

www.cbsscientic.com

C

B

A

9

Cipher Genetic Analysis System

DTSK Instruction Manual, version 8/30/2011

Page 10

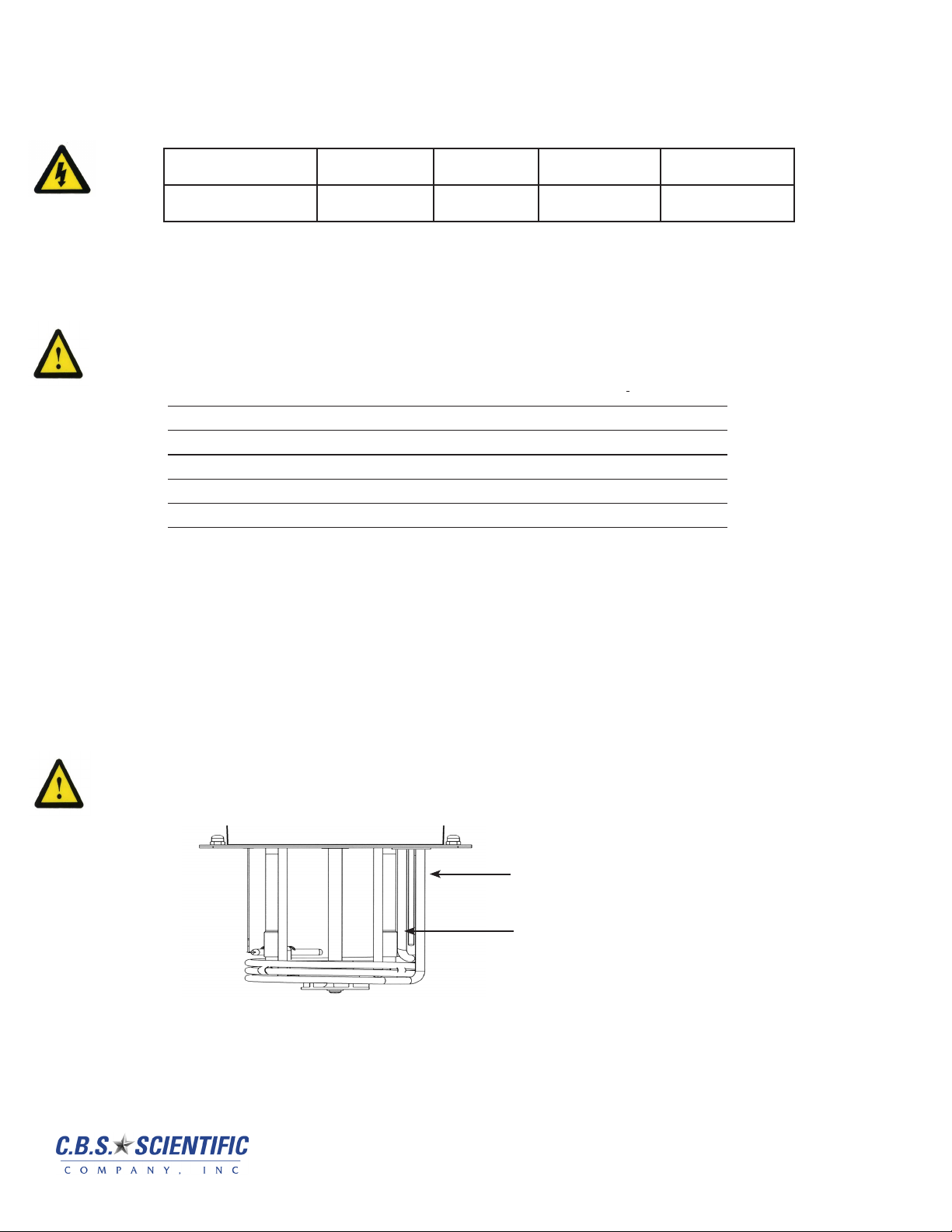

3.2 Heater/Stirrer Set-Up and Programming

3.2a General Information

Model Type Temperature

Heat Only

Immersion Circulator

Circulator Pump

Pump speed is selected via the Main Menu. The MINIMUM setting is used for DGGE applications.

MAXIMUM is recommended where temperature varies frequently and there is a need for fast recovery or when

pumping to multiple external units.

Speed Maximum Pump Outlet Ratings Maximum Pump Outlet Ratings

Selection Line Frequency = 60Hz Line Frequency = 50Hz

MAXIMUM 30 LPM / 5.0 PSI 22 LPM / 3.4 PSI

HIGH 24 LPM / 2.5 PSI 20 LPM / 1.7 PSI

MEDIUM 20 LPM / 1.7 PSI 17.5 LPM / 1.2 PSI

LOW 18 LPM / 1.2 PSI 15.8 LPM / 0.8 PSI

MINIMUM 15.7 LPM / 0.8 PSI 15 LPM / 0.7 PSI

Range

Ambient +5°C to

200°C*

Reservoir

Capacity

N/A 11A 9.7A

Amps @

120V,60Hz

Amps @

240V, 50Hz

The data in the table above are based on the following criteria:

a. Maximum pump outlet ow rate is measured in liters per minute (LPM) with no restriction on the pump outlet.

b. Maximum pump outlet pressure is measured in pounds per square inch (PSI) at no ow.

c. Water was used as the circulation uid. Water has a viscosity of one centistoke. High viscosity or low-density uids will change

these gures.

Filling the Reservoir

A liquid level that fully covers the heater coil, pump, over-temperature sensor, and at least one inch

(25mm) of the temperature sensor must be maintained. For heating applications, the DTSK tank must

have at least 23 liters of buffer. When running the system with two dual cassettes, buffer volume should

be 24 liters.

Temperature Sensor

minimum ll level

10

Page 11

3.2 Heater/Stirrer Set-Up and Programming – continued

3.2b Front and Rear Panels

2

3

4

Front View Rear View

1

5

6

8

9

7

10

11

12

1. Select / Set Knob 10. Identication Label

2. LCD Display 11. Reservoir Purge

3. Safety Set Indicator Knob 12. Pump Inlet (Do NOT open)

4. Safety Set Reset Button 13. Pump Outlet (Do NOT open)

5. Timer Button 14. AC Input

6. Escape Button 15. External Probe Connection

7. Power On/Off Button 16. RS232 Interface

8. Heating Light 17. Circuit Breaker / AC Power Switch

9. Cooling Light1

1

Active on Refrigerating/Heating Circulating Baths only

2

Functional on Programmable Controller only.

15

16

14

2

17

13

www.cbsscientic.com

Heater/Pump Assembly

1

2

3

1. Temperature Sensor

2. Pump Shaft and Impeller

3. Over-Temperature Sensor

4. Heater Coils

4

11

Cipher Genetic Analysis System

DTSK Instruction Manual, version 8/30/2011

Page 12

3.2 Heater/Stirrer Set-Up and Programming – continued

3.2cSpecications

Temperature Stability

Controller / RS232 Yes

External Temperature Probe Functional on Programmable models / optional external

Readout Accuracy Graphic LCD, °C or °F, ±0.25°C

Heater 1100W – 115V, 2200W – 240V

Pressure Flow Rate 15.7 to 30 LPM (60Hz); 15 to 22 LPM (50Hz)

Suction Flow Rate 11 to 22 (60Hz); 10 to 15 LPM (50Hz)

Over-Temperature Protection Yes, user-adjustable

Low-Liquid Protection Yes

Pump Speeds Five-speed adjustable

1. Temperature stability may vary depending on bath volume, surface area, insulation, and type of uid.

NOTE: Performance specications determined at ambient temperature of 20°C (68°F).

1

±0.01°C

probe required

Not functional on Digital models

Environmental Conditions:

• Indoor Use Only • Over Voltage: Category ll

• Maximum Altitude: 2000 meters • Operating Ambient: 5° to 30°C

• Relative Humidity: 80% for temperatures to 30°C • Pollution Degree: 2

• Class 1: Residential, Commercial, Light Industrial • Class 2: Heavy Industrial

12

Page 13

3.2 Heater/Stirrer Set-Up and Programming – continued

3.2d Circulator Location

Locate the Circulator on a level surface, free from drafts and out of direct sunlight. Do not place it where corrosive

fumes, excessive moisture, high room temperatures, or excessive dust are present.

Refrigerating/Heating Circulators must be a minimum of four inches (102mm) away from walls or vertical surfaces so

air ow around the unit is not restricted.

To help prevent voltage drops, position the Circulator as close as possible to the power distribution panel and a

properly grounded outlet. The use of an extension cord is not recommended.

Warning: These units are equipped with over-temperature protection (Safety Set). A low liquid level or failure to set

the Safety Set and properly immerse the heater may result in heater burnout and triac failure. While operating, do not

allow the heater to contact any potentially ammable materials, such as plastic racks or the sides of plastic tanks, as

a re hazard may result.

3.2eReservoirLiquidLevel

Fill the reservoir with the appropriate buffer. On circulating baths, the liquid level should be sufcient to cover the

heating coils, cooling coils (if applicable), pump, over-temperature sensor, and at least one inch (25mm) of the

temperature sensor. The level should be at the ll line indicator on the tank.

After lling the reservoir with uid, you must set the Safety Set and the Limit High value as well as your desired

control set point temperature.

3.2f External Temperature Probe

The Programmable Controller is designed to accommodate an optional remote temperature probe. The probe

attaches to the 9-pin male D-connector on the rear panel of the Controller.

NOTE: On Digital Controllers, this connection is present, but not functional.

The Controller will automatically sense the presence of the external probe when main power (rear panel circuit

breaker/power switch) is turned On. To control temperature using the external probe, “External” must be selected via

the Controller’s software. You must also set a Maximum Setpoint Differential value.

To attain better temperature uniformity when using the external temperature probe in a jacketed or air-lled vessel,

stirring the external uid with pumps or mixing air with fans is recommended. Expect only ±1.0°C stability with air or

any medium that does not conduct heat well. Insulate and cover the entire set-up to remove temperature gradients;

the Controller cannot compensate for external chamber or component temperature gradients.

3.2g RS232 Interface

Programmable and Digital Controllers incorporate an RS232 interface to provide remote data-logging and control

capability. Remote control capability is available on the Programmable Controllers only. The 9-pin female RS232

connector is located on the rear panel of the Controller.

The RS232 interface should be connected to a serial communication port on a remote PC using an appropriate cable.

Communications software compatible with Microsoft® Excel and National Instruments LabView™ are provided with

Programmable Controllers. Contact Technical Service at C.B.S. Scientic technicalservice@cbssci.com

www.cbsscientic.com

13

Cipher Genetic Analysis System

DTSK Instruction Manual, version 8/30/2011

Page 14

3.2 Heater/Stirrer Set-Up and Programming – continued

3.2h Power

An IEC power cord is provided with the Circulator. This power cord should be plugged into the IEC receptacle on the

rear of the Controller and then plugged into a properly grounded outlet. Make sure that the power outlet is the same

voltage and frequency indicated on the identication label on the back of the Controller.

The use of an extension cord is not recommended. However, if one is necessary, it must be properly grounded and

capable of handling the total wattage of the unit. The extension cord must not cause more than a 10% drop in voltage

to the Circulator.

Once the unit has been connected to an appropriate electrical outlet, place the Circuit Breaker/Power Switch on the

rear of the Controller in the ON position. The unit will run through a self-test.

The rst time power is applied to the Controller, the following display will appear. This display allows you to select

the language that will be used for all subsequent displays. The instructions for selecting a language will be briey

displayed in each available language.

NOTE: The language selection display only appears the rst time the Controller is powered up.

When the language selection display appears, rotate the Select/Set Knob until the desired language is highlighted

and then press the Select/Set Knob. The Controller will continue with the start-up sequence and then display

“Standby” on the LCD.

DO NOT place the Power Switch on the front of the Controller ON until the Safety Set has been adjusted to the

desired temperature.

3.2i Setting the Safety Set Point

The Safety Set feature automatically disconnects Controller power to the heater and pump in the event that the

reservoir liquid level drops too low or the sensed temperature exceeds the Safety Set temperature. The Safety Set

is user-adjustable between approximately 40° and 210°C. It should be set at least 5°C higher than the desired bath

temperature.

Use a at blade screwdriver to rotate the Safety Set Indicator Knob to the desired temperature.

Do not force the knob beyond the stops at either end of the temperature value range.

If the Safety Set temperature is exceeded during normal operation, a fault message will ash on

the display and power to the heater and pump will be disrupted. To reset the fault, correct the problem (low liquid

level, incorrect Safety Set temperature, etc.), press the Safety Set Reset Button, and then the ESC Button. Normal

operation will resume.

3.2j Power On

Once the Safety Set temperature has been set, turn power to the Controller ON by pressing the Power Switch on the

front of the Controller. The following message will appear briey on the display:

14

Page 15

3.2 Heater/Stirrer Set-Up and Programming – continued

The pump will begin operating; the display will show the current bath temperature and the set point temperature

(Setpoint). If an external probe (Programmable Controllers only) is connected, both the internal and external bath

temperatures will be displayed. The temperature probe selected to control bath temperature (internal or external) will

be displayed in larger numerals.

NOTE: If the external temperature probe is selected to control bath temperature, but the temperature difference

between the set point temperature and the internal bath temperature exceeds the Maximum Setpoint Differential

setting, the heating rate will be controlled using the internal bath temperature until the set point/internal bath

temperature difference is within the Maximum Setpoint Differential value. The word Internal will be highlighted on the

display to indicate that the internal sensor is controlling bath temperature.

3.2k Local Lockout

This enables the user to lock all controls on the controller. While the feature is activated, the unit will remain running

at the current settings.

To activate the local lockout feature, press and hold the Select/Set Knob for 10 seconds. Once locked, “LocalLock”

will appear in the upper left corner of the display. The controller menus may still be viewed when Local Lockout is

active, but no changes may be made.

Press and hold the Select/Set Knob again for 10 seconds to unlock the controls. Once unlocked, “LocalLock” will

disappear and the menu settings can once again be modied.

LocalLock

3.2l Setting the Bath Temperature Set Point

Press and release the Select/Set Knob. The “whole” numbers in the set point temperature will be

highlighted. Rotate the Select/Set Knob clockwise to increase the displayed value; rotate the knob

counter-clockwise to decrease the displayed value.

Press the Select/Set Knob to accept the new value. The decimal value in the set point temperature digits

will be highlighted. Rotate the Select/Set Knob clockwise to increase the displayed value; rotate the knob

counter-clockwise to decrease the displayed value. Press the Select /Set Knob to accept the new value.

NOTE: Increasing/decreasing the decimal value past “0” will cause a corresponding change in the “whole”

number value. For example, if the current set point value is 24.8 and the desired value is 25.2, it is not

necessary to change the 24 to a 25; increasing the decimal value from .8 to .2 will automatically increase

the 24 to 25.

The Controller will not allow you to enter a set point value above the Limit High setting or below the Limit

Low setting. Should you attempt to do so, the set point value will stop increasing/decreasing when the

Limit value is reached and a Warning message will appear on the display. You must either change the set

point or change the Limit value. Reference the Heater/Stirrer instruction manual for detailed information.

www.cbsscientic.com

15

Cipher Genetic Analysis System

DTSK Instruction Manual, version 8/30/2011

Page 16

3.2 Heater/Stirrer Set-Up and Programming – continued

3.2m Menu Navigation

Main Menu — To view the Main Menu items, rotate the Select/Set Knob. Continue turning the Select/Set Knob to

scroll through the Main Menu displays.

To begin programming or view the options available in a Main Menu item, press the Select/Set Knob. The rst

available sub-menu item (or the last item in that sub-menu which was selected) will be highlighted like

To de-select an item, press the ESC Button. To return to the main operational display, press the ESC Button a second

time or allow the display to timeout.

Sub-Menu Selections — To select an item in a sub-menu, press the Select/Set Knob. The rst available item (or the

last item in that sub-menu which was selected) will be highlighted. Rotate the Select/Set Knob clockwise to advance

to the next sub-menu item; rotate the knob counter-clockwise to go back to the previous item. Press the Select/Set

Knob to select the highlighted item; the highlighting will change from to , indicating that the

displayed value or choice may be changed.

Entering and/or Changing Sub-Menu Values — Once the desired sub-menu item has been selected (as described

above), the displayed value is changed by rotating the Select/Set Knob. The change is accepted by pressing the

Select/Set Knob. On sub-menu items requiring multiple entries, such as hours/minutes/seconds, an underline will

appear under the rst value in that sequence which can be changed. (Example: 01:23:00 ) To accept the displayed

value and/or advance to the next value in the sequence, press the Select/Set Knob. To return to the previous cursor

position, such as from minutes back to hours, press the ESC Button. Once a value has been entered and accepted,

the highlighting box around the value will disappear. If you do not wish to accept the displayed value, press the ESC

Button or allow the display to timeout before pressing the Select/Set Knob.

THIS

THIS

THIS

16

Page 17

3.2 Heater/Stirrer Set-Up and Programming – continued

3.2n Menu Structure

Main Menu Item

Timer

Program

Run Program

1

1

Preferences

Limits / Alarms

Associated

Sub-Menu Items

Set

Beep

Program #

Program Steps

Program Loops

Step #

Step Setpoint

Minutes/Seconds

View Prole

Program #

Program Status

Readout

Units

Sound

Language

Program

1

Limit High

Alarm High

Alarm Low

Limit Low

Choices / Ranges / Comments

00:00:00 to 99:59:59

On or Off

1 to 10

1 to 50

1 to 99

1 to 50

–50° to 200°C (-50° to 392°F)

0 second to 999 minutes, 59 seconds

Displays temperature prole of program.

1 to 10

Start, Starting, Running, Paused, or Completed

#, #.#, or #.## (0, 1, or 2 decimal places)

°C or °F

1 to 100

English / French / German / Spanish

Time / Temperature

-50° to 200°C (-58° to 392°F)

-50° to 200°C (-58° to 392°F)

-50° to 200°C (-58° to 392°F)

-50° to 200°C (-58° to 392°F)

Pump/AutoTune

Temperature

Trend

1

Probe

Instrument

Pump speed

AutoTune

No sub-menu; displays

temperature prole

Internal / External

Maximum Setpoint

Differential

Contrast

Timeout

Baud Rate

Maximum / Fast / Medium / Slow / Minimum

Displays status of AutoTune procedure

2 minutes to 48 hours

Probe currently selected is shown

Only displayed when External is selected

1° to 10°C range

00 to 30

5 to 60 seconds

110 / 300 / 600 / 1200 / 2400 /4800 / 9600 /

14400 / 19200 / 38400 / 57600

1. These Main Menu items are present on Programmable Controllers only.

2. This Main Menu item is present on Refrigerating/Heating Circulators only.

NOTE: There are additional displays after “Instrument “ in the Main Menu. However, there are no user-settable

functions on these displays.

17

www.cbsscientic.com

Cipher Genetic Analysis System

DTSK Instruction Manual, version 8/30/2011

Page 18

3.2 Heater/Stirrer Set-Up and Programming – continued

3.2o Fluid Type

Located in the Fluid Type screen are two adjustable parameters: Specic Heat and Volume. By adjusting the Specic

Heat you will be optimizing the circulator’s temperature control based on the uid being used. The table below lists a

few common uids. You can also refer to the MSDS sheets for your specic uid.

The other parameter, Volume, is strictly for diagnostic purposes and does not affect the performance of the unit.

When the Specic Heat of the uid and the Volume are entered correctly, the circulator will display the amount of

energy the unit is putting into the system (in Watts). When the unit is stable this will display 0+/-25 Watts.

FLUID DESCRIPTION SPECIFIC HEAT @25ºC

Distilled Water 1.00

Ethylene Glycol 30% / Water 70% 0.90

Ethylene Glycol 50% / Water 50% 0.82

3.2p Setting Operational Parameters and Functions

All operational parameters and functions are programmed and controlled via the Controller’s software settings. Most

are user-adjustable and easily accessed via the Main Menu. The Main Menu is accessed by rotating the Select/Set

Knob. A particular Main Menu item is selected by pressing the Select/Set Knob when that item is highlighted.

3.2qSettingandStartingtheTimer

The Timer sub-menu allows you to program the Controller’s timer to alert you once a specic period of time has

elapsed. It should be used as you would an external timer.

IMPORTANT: The Timer is independent of temperature control. It does not start or stop heating/cooling. The

Controller continues maintaining temperature at the set point even though the designated time period has elapsed.

To set the timer, access Timer on the Main Menu, select Set, and then enter the desired period of time. The timer’s

audible signal can be turned On and Off via the selection named Beep on the Timer sub-menu.

To start the timer, press the Timer button on the Controller’s front panel. A timer icon and Beep icon (indicating either

On – • or Off – the icon with an X through it), along with a countdown timer, will appear on the bottom of the LCD. The

Timer LED will light continuously.

Once the designated time period has elapsed, the audible signal (if enabled) will sound and the countdown timer will

display the amount of time which has elapsed since the designated time period ended. The timer LED will ash.

To silence the audible signal and/or clear the timer display from the LCD, press the Timer Button.

The timer may also be paused at any time during the countdown period by pressing the Timer Button. When this

occurs, the Timer LED will ash and the word “Paused” will appear on the display adjacent to the countdown timer.

18

Page 19

.2 Heater/Stirrer Set-Up and Programming – continued

3.2r Setting Preferences

The Preferences sub-menu allows you program global preferences regarding instrument operation.

Readout — This is the number of decimal places to which temperatures will be displayed (0, 1, or 2).

Units — This is the unit in which temperatures will be displayed (°C or °F)

Sound — This is the volume level for the unit’s audible signal. When it is selected, the volume of the audible signal

changes as the Select/Set Knob is rotated. You must press the Select/Set Knob to accept the displayed volume

value; if you press the ESC Button or allow the display to timeout without pressing the Select/Set Knob, the sound

level will remain where it was previously set.

Language — This is the language used for displays. When this is selected, a sub-menu appears with the available

languages.

Program — This menu item appears only on the Programmable Controller. It is used to select whether programs are

run using Time or Temperature as the priority.

When Time is selected, the program begins running when the bath temperature reaches the programmed set point

for step one and continues until the total programmed period of time has elapsed. The set point target for any given

step (except step one) may or may not be reached before the program advances to the next step.

When Temperature is selected as the priority, the program begins running when the bath temperature reaches

the programmed set point for step one. Each subsequent step runs until the programmed set point for that step is

reached, regardless of how much time has elapsed.

www.cbsscientic.com

19

Cipher Genetic Analysis System

DTSK Instruction Manual, version 8/30/2011

Page 20

3.2 Heater/Stirrer Set-Up and Programming – continued

3.2s Setting High/Low Temperature and Alarms

The Limits/Alarms sub-menu allows you to establish temperatures at which either power to the temperature control

components (heater/condenser) will be disconnected (Limits) or which Controller’s audible alarm will sound (Alarms).

Limit High Temperature — This feature provides additional safety and protection by allowing a selectable upper

temperature limit set point. To avoid an unwanted shutdown during regular operation, the high limit value should be

set at least 5°C higher than the selected control temperature. It should never be set higher than the Safety Set Set

Point temperature

If you attempt to enter a set point value that exceeds the Limit High value, the audible alarm will sound and a Warning

message will ash on the display when the Limit High value is reached. You will also be prevented from increasing

the set point value any further.

To clear a Limit High warning, enter a higher value for the Limit High or reduce the control temperature set point.

If the Limit High value is exceeded during operation (due to a Controller fault, excessive heat load, etc.), a Fault

message will appear on the display and power to the heater and compressor will be disconnected. The pump will

continue to run.

Alarm High Temperature — This feature is useful if you are using the bath to cool an external device. It alerts you

when bath temperature exceeds your programmed alarm high temperature setting (due to insufcient cooling,

blocked lines, etc.).

When the Alarm High value is exceeded, a Warning message ashes on this display and the audible alarm sounds.

Heater, compressor, and pump operation continue.

To clear an Alarm High warning, correct the problem or increase the Alarm High temperature value.

Alarm Low Temperature — This feature is useful if you are using the bath to warm an external device or need to

maintain the bath at a minimum temperature. It alerts you when bath temperature falls below your programmed alarm

low temperature setting.

When bath temperature falls below the Alarm Low value, a warning message ashes on the display and the audible

alarm sounds. Heater, condenser, and pump operation continue.

20

Page 21

3.2 Heater/Stirrer Set-Up and Programming – continued

To clear an Alarm Low warning, correct the problem or decrease the Alarm Low temperature value.

Limit Low Temperature — This feature provides additional safety and protection by allowing a selectable lower

temperature limit set point.

If you attempt to enter a set point value that exceeds the Limit Low value, the audible alarm will sound and a Warning

message will ash on the display when the Limit Low value is reached. You will also be prevented from decreasing

the set point value any further.

To clear a Limit Low warning, enter a lower value for the Limit High or increase the control temperature set point.

If the Limit Low value is exceeded during operation (due to a Controller fault, excessive cooling load, etc.), a Fault

message will appear on the display and power to the heater and condenser will be disconnected. The pump will

continue to run.

Limits/Alarms Example

Initial Bath Temperature = 20°C

Bath Temperature Set Point = 37°C

Limit High Temperature = 60°C

Alarm High Temperature = 40°C

Alarm Low Temperature = 35°C

Limit Low Temperature = 11°C

Limit High Set Point. Bath set point

temperature cannot be raised above this value.

High Temperature Alarm Set Point. Alarm activates if bath

temperature rises to this value.

Degrees

Low Temperature Alarm disabled

until bath temperature rises above

Low Temperature Alarm set point

value.

10 20 30 40 50 60 70 80 90

Limit Low Set Point. Bath set

point temperature cannot be

lowered below this value.

3.2t Selecting the Pump Speed

If bath temperature moves above

or below Limit values, alarm

activates and power to the heater

and condenser is disconnected.

Low Temperature Alarm Set

Point. Alarm activates if bath

temperature falls to this value.

Minutes

Pump speed is selected from the Pump/AutoTune menu. This display shows the current pump speed setting. Five

pump speed settings are available – Maximum, Fast, Medium, Slow, and Minimum. Select Minimum for DGGE

applications.

www.cbsscientic.com

21

Cipher Genetic Analysis System

DTSK Instruction Manual, version 8/30/2011

Page 22

3.2 Heater/Stirrer Set-Up and Programming – continued

3.2u Displaying the Bath Temperature Trend

The Controller can store up to 48 hours of bath temperature data. The data can be viewed by selecting Temperature

Trend from the Main Menu.

To view the temperature trend data, rotate the Select/Set Knob until the Temperature Trend display appears, showing

the most recent temperature data. The time period which the displayed trend line covers appears in the lower left

corner of the display. It will range from two minutes to 48 hours.

To view a different period of time, press the Select/Set Knob and then rotate it until the desired time period appears.

The temperature trend display will not timeout. To return to the main operational screen, press the ESC Button.

NOTE: If main power is turned off or power is accidentally lost, temperature trend data will be lost. If the Controller is

put in “Standby” (main power On, Controller power Off), the data will be retained.

22

Page 23

3.2 Heater/Stirrer Set-Up and Programming – continued

3.2v Selecting the Temperature Probe (Internal or External)

The Probe sub-menu allows you to designate whether to control temperature using the internal bath temperature or

the uid temperature at an external device. It is available on the Programmable Controller only and requires the use

of an optional external temperature probe.

NOTE: If an external temperature probe is not connected to the Controller, only “Internal” will be available for

selection. For information on connecting an external temperature probe.

When External is selected as the primary temperature probe, the Maximum Setpoint Differential setting becomes

available.

This allows you to set the maximum allowable difference between the set point temperature and the internal bath

temperature. It is intended as a safety feature to protect the internal bath from over-heating or over-cooling in the

event that the external temperature control set point cannot be achieved. The Maximum Setpoint Differential value

may be set from 1° to 10°C. The factory default value is 10°C.

Temperature Control / Display When Using an External Probe

When the difference between the set point temperature and internal bath temperature exceeds the programmed

Maximum Setpoint Differential value, heating is controlled using the internal bath temperature. “Internal” is highlighted

on the temperature display.

Control of the bath heating rate will be based on the internal bath temperature until the difference between the set

point and the internal bath temperature is at the Maximum Setpoint Differential value. When the heating rate is being

controlled using the external bath temperature, the word “External” is highlighted on the display.

NOTE: When the external temperature probe is in use, external bath temperature is displayed in large numerals,

regardless of whether temperature control is based on the internal or external bath temperature.

www.cbsscientic.com

23

Cipher Genetic Analysis System

DTSK Instruction Manual, version 8/30/2011

Page 24

3.2 Heater/Stirrer Set-Up – continued

3.2w Setting the Display Contrast and Timeout

Display Contrast and Display Timeout appear as sub-menu items under Instrument in the Main Menu. These menu

items allow you to change the readability of the LCD and set the length of time, which can pass without menu activity

before the display will revert to the main operational display.

NOTE: When Contrast is selected, the display contrast will change as the Select/Set Knob is rotated. You must

press the Select/Set Knob to accept the displayed contrast value; if you press the ESC Button or allow the display to

timeout without pressing the Select/Set Knob, the display contrast value will remain where it was previously set.

3.2x Setting the Baud Rate

This sub-menu selection also appears under Instrument in the Main Menu. It allows you to set the baud rate at which

data will be transmitted over the RS232 interface.

24

Page 25

3.3 Heater/Stirrer Programming

3.3.1 Setting Operational Parameters and Functions

All operational parameters and functions are programmed and controlled via the Controller’s software settings. Most are

user-adjustable and easily accessed via the Main Menu. The Main Menu is accessed by rotating the Select/Set Knob. A

particular Main Menu item is selected by pressing the Select/Set Knob when that item is highlighted.

1. Setting and Starting the Timer

The Timer sub-menu allows you to program the Controller’s timer to alert you once a specic period of time has

elapsed. It should be used as you would an external timer.

IMPORTANT: The Timer is independent of temperature control. It does not start or stop heating/cooling. The Controller

continues maintaining temperature at the set point even though the designated time period has elapsed.

To set the timer, access Timer on the Main Menu, select Set, and then enter the desired period of time. The timer’s

audible signal can be turned On and Off via the selection named Beep on the Timer sub-menu.

To start the timer, press the Timer button on the Controller’s front panel. A timer icon and Beep icon (indicating either On

– • or Off – the icon with an X through it), along with a countdown timer, will appear on the bottom of the LCD. The Timer

LED will light continuously.

Once the designated time period has elapsed, the audible signal (if enabled) will sound and the countdown timer will

display the amount of time which has elapsed since the designated time period ended. The timer LED will ash.

To silence the audible signal and/or clear the timer display from the LCD, press the Timer Button.

The timer may also be paused at any time during the countdown period by pressing the Timer Button. When this occurs,

the Timer LED will ash and the word “Paused” will appear on the display adjacent to the countdown timer.

www.cbsscientic.com

25

Cipher Genetic Analysis System

DTSK Instruction Manual, version 8/30/2011

Page 26

3.3 Heater/Stirrer Programming- con’t.

3.3.2 Entering/Modifying a Temperature Program

NOTE: This function is available on Programmable Controllers only. See Writing a Temperature Program below for

information on creating a time/temperature prole.

This menu selection allows you to program and store up to ten individual time/temperature proles. Each program

can have up to 50 steps and 99 program loops. Once a program has been entered, any portion of it may be modied.

Program # — This is the identication number assigned to the program. It is used to select/run the program (see

Running a Temperature Program below). You may enter a number from 1 to 10. If you enter a number that has been

assigned previously, any changes made overwrite the prior program.

Program Steps — This is the number of steps in the program. A program can have from 1 to 50 different steps.

NOTE: If you are modifying a program and change the number of steps (e.g., reduce the number of steps from 25

to 10), steps 11 through 25 will no longer appear. However, if you later increase the number of steps in that program

(e.g., from 10 to 15), the original programming for steps 11 through 15 will reappear.

Program Loops — This is the number of times the program will run before stopping. A program may be repeated up

to 99 times.

Step #, Set, MMM/SS — This is the temperature set point and time for the selected step in the program.

To enter the set point and time for the step, rotate the Select/Set Knob until a Step number is highlighted like THIS.

Press the Select/Set Knob again; the highlighting will now look like THIS. Rotate the Select/Set Knob to scroll to the

desired Step number and press the Select/Set Knob. The boxed highlighting will move to the temperature set point

eld associated with that step.

Rotate the Select/Set Knob until the desired temperature set point is displayed. You may advance the cursor

(underline) to the next number in the set point eld by pressing the Select/Set Knob. Press the ESC Button to return

to the previous cursor position.

26

Page 27

3.3 Heater/Stirrer Programming- con’t.

Once the temperature set point has been entered, press the Select/Set Knob to advance to the time (minutes/

seconds) eld. Time information is entered the same way as the temperature set point information.

When you press the Select/Set Knob to accept the time displayed time information, the highlighted box will

automatically advance to the set point temperature eld associated with the next step of the program.

IMPORTANT: The time eld establishes the amount of time the Controller should take to reach the temperature set

point for the next step (i.e., the ramp rate).

View Prole — This allows you to view the programmed time/temperature prole step-by-step. Rotate the Select/Set

Knob to move through the various steps in the program. When the cursor (a vertical line) reaches the beginning of a

step, a message box will appear displaying the step number, set point, and time.

To return to the main operational display, press the ESC Button or allow the display to timeout.

Writing a Temperature Program

Programmable Controllers permit the user to create up to 10 different time/temperature programs, each of which can

have as many as 50 steps and be repeated up to 99 times. The following information is intended to provide you with

some guidelines for creating useful programs.

1. Circulating baths are designed primarily to hold temperatures constant rather than change temperatures rapidly.

Do not underestimate the amount of time the circulator needs to heat or cool a uid to a given temperature.

Larger baths or circulators being used in closed or open loops will need more time to reach a programmed set

point.

2. Programs may be run using either a Time- or Temperature-based priority. If achieving successive temperature

set points is critical, Temperature should be selected as the priority. If completing a program in a xed amount of

time is essential, Time should be selected as the priority. See Section 5.12.4 – Preferences for more information.

3. If a program must run within a set period of time (Time priority), have the bath temperature at or very close to

the initial set point before starting the program. The program will not start running until the set point temperature

programmed for the rst step is achieved.

4. To incorporate a “soak” period in the program, enter the same set point for two adjacent steps in the program.

The time duration programmed for the rst step should equal the desired “soak” period; the time duration for

the second step should be short (e.g., 1 second). The temperature set point for the last step in a program also

functions as an indenite “soak”. The Controller maintains temperature at the last programmed set point until a

new set point is entered.

5. The step time in a program establishes the ramp rate that will be used to reach the programmed set point for the

next step. If you want to increase/decrease temperature slowly, set a lengthy step time. If you want to increase/

decrease as fast as possible, set a short step time. Keep the heating/cooling capabilities of your instrument

in mind, however. If you are running a program using Time-based priority, uid temperature may not reach a

desired set point temperature if the time allotted is too short.

www.cbsscientic.com

27

Cipher Genetic Analysis System

DTSK Instruction Manual, version 8/30/2011

Page 28

3.3 Heater/Stirrer Programming- con’t.

Programming Examples

Example A

Initial Bath Temperature = 25°C

Program Priority = Temperature

Desired Profile: Cool bath temperature to 20°C and hold it there for 25 minutes.

Increase bath temperature to 30°C and hold it there for 15 minutes.

Increase bath temperature to 50°C over a 45 minutes period.

Decrease bath temperature to 5°C and hold.

This example requires a 6-step program:

55

50

45

40

35

30

25

20

Degrees C

15

10

5

0

0 5 15 30 45 60 75 90 105 120 135 150 165

Step 2

Step

Step 4

Step 1

Step

Step

Step 3

Step

Step 5

Step

Step 6

Step

Minutes

Program

Step

1 20°C 25 minutes

2 20°C 1 second

3 30°C 15 minutes Fluid temperature is maintained at 30°C for 15 minutes.

4 30°C 45 minutes

5 50°C 1 second

6 5°C 1 second

Step Set

Point

Step

Duration

Controller Operation

Controller cools fluid to 20°C as fast as possible. Until

20°C temperature set point is achieved, “Starting”

appears on the display. When fluid temperature reaches

20°C, “Running” appears on the display.

Fluid temperature maintained at 20°C for 25 minutes.

Controller heats fluid as fast as possible until the 30°C set

point programmed for Step 3 is reached.

Controller slowly heats fluid until 50°C set point

programmed for Step 5 is reached. Ramp rate is based

on the 45 minute step duration.

Controller then cools fluid as fast as possible until 5°C set

point programmed for Step 6 is reached.

“Complete” appears on display. 5°C fluid temperature is

maintained until set point is changed.

28

Page 29

3.3 Heater/Stirrer Programming- con’t.

Example B

Initial Bath Temperature = 25°C

Program Priority = Temperature

Desired Profile: Cool bath temperature to 20°C and hold it there for 10 minutes.

Decrease bath temperature to 10°C over 15 minutes.

Hold bath temperature at 10°C for 15 minutes.

Increase bath temperature to 50°C over a 1-hour period.

This example requires a 5-step program:

55

50

45

40

35

Step 1

Step

30

25

20

Degrees C

Step

15

10

Step

5

Step 2

0

0 5 15 30 45 60 75 90 105 120 135 150 165

Step 3

Step 4

Step

Step 5

Step

Minutes

Program

Step

1 20°C 10 minutes

2 20°C 15 minutes

3 10°C 15 minutes Fluid temperature is maintained at 10°C for 15 minutes.

4 10°C 1 hour

5 50°C 1 second

Step Set

Point

Step

Duration

Controller Operation

Controller cools fluid to 20°C as fast as possible. Until

20°C temperature set point is achieved, “Starting”

appears on the display. When fluid temperature reaches

20°C, “Running” appears on the display.

Fluid temperature is maintained at 20°C for 10 minutes.

Controller cools fluid to 10°C set point programmed for

Step 3. Ramp rate is based on the 15 minute step

duration.

Controller slowly heats fluid until 50°C set point

programmed for Step 5 is reached. Ramp rate is based

on the 1 hour step duration.

“Complete” appears on the display. 50°C fluid

temperature is maintained until set point is changed.

www.cbsscientic.com

29

Cipher Genetic Analysis System

DTSK Instruction Manual, version 8/30/2011

Page 30

3.3 Heater/Stirrer Programming- con’t.

Example C

s

Initial Bath Temperature = 25°C

Program Priority = Temperature

Desired Profile: Cool bath temperature to 20°C as fast as possible.

Increase bath temperature to 55°C as fast as possible.

Repeat 7 times.

This example requires a 2-step program with the number of loops set to 8:

60

55

50

45

40

35

30

25

Degrees C

20

15

Step 1

10

Step

5

0

0 5 15 30 45 60 75 90 105 120 135 150 165

Program

Step

1 20°C 1 second

2 55°C 1 second

Step Set

Point

Step

Step 2

Step

Duration

Minute

Controller Operation

Controller cools fluid to 20°C as fast as possible. Until

20°C temperature set point is achieved, “Starting”

appears on the display.

When fluid temperature reaches 20°C, “Running” appears

on the display.

Controller applies heat until 55°C set point for Step 2 is

reached.

Controller loops back to Step 1, applying cooling until

20°C set point is reached.

Steps 1 and 2 repeat seven more times. When the last

loop has been completed, “Complete” appears on the

display. Fluid temperature is maintained at 55°C until the

set point is changed.

30

Page 31

3.3 Heater/Stirrer Programming- con’t.

3.3.3 Running a Temperature Program

NOTE: This function is available on Programmable Controllers only.

The Programmable Controller can store up to 10 user-dened time/temperature programs, which can later be run with

just a few simple commands. See Entering/Modifying a Temperature Program above for more information.

Programs may be run using either a Time- or Temperature-based priority. This priority is selected under Program in the

Preferences menu (see Setting Preferences below).

When Time is used, the program begins running when the bath temperature reaches the programmed set point for step

one. It continues running until the total programmed length of time for all steps has elapsed, regardless of whether the

set point temperatures for steps two and above have been achieved.

When Temperature is selected as the priority, the program begins running when the bath temperature reaches the

programmed set point for step one. Each subsequent step is run until the programmed set point for that step is reached,

regardless of how much time has elapsed.

Selecting a Program— To select a temperature program, rotate the Select/Set Knob until the Run Program menu

appears and then press the Select/Set Knob.

If the Program # eld is highlighted as shown above, press the Select/Set Knob and then rotate the Select/Set Knob

until the number of the program you wish to run is displayed.

Press the Select/Set Knob a second time to accept the displayed program number. If the word Start is highlighted,

rotate the Select/Set Knob one click counter-clockwise to highlight the program number.

Running a Program — Once you have selected and accepted the program number, rotate the Select/Set Knob until

Start is highlighted. Press the Select/Set Knob; the program will automatically begin running. The word “Starting” will

appear at the lower left of the Run Program menu and will remain there until the bath temperature reaches the set point

programmed for step one. It will then be replaced by the word “Running.”

While a program is running, the Run Program and main operational displays will alternate on the LCD. The Run

Program display shows the current step number, the target set point for the next step, time at the current step, loop

number, program status, and total elapsed time. The main operational display shows bath temperature, set point, and

program status.

Pausing or Stopping a Program — A program that is running may be paused or stopped at any time. To do so, press the

Select/Set Knob until Starting or Running is highlighted and then press the Select/Set Knob again. Rotate the Select/

Set Knob until the desired function (Pause / Stop) is highlighted and then press the Select/Set Knob. If you do not wish

to pause or stop the program, select and enter Escape.

If the program has been paused, “Paused” will appear on the lower left of the display. If the program has been stopped,

“Start” will appear on the lower left of the display.

To resume running a program that has been paused, press the Select/Set Knob, select Resume, and then press the

Select/Set Knob a second time. The program will resume operation from the point of disruption. Select Stop if you wish

to stop the program or Escape if you want to keep the program paused.

www.cbsscientic.com

31

Cipher Genetic Analysis System

DTSK Instruction Manual, version 8/30/2011

Page 32

3.3 Heater/Stirrer Programming- con’t.

If a program is stopped or paused, the Controller will control temperature using the set point value that was active when

the program was interrupted.

NOTE: If you select the Temperature Trend display while running a program, that display will remain on screen until the

ESC Button is pressed.

End of Program — Once the selected program has run, “Completed” will appear in the lower left of the Run Program

display. The Controller will keep the bath liquid at the last temperature set point until a new program is started or Run

Program has been exited and a new set point entered.

Exiting Run Program — Once a program has been completed, “Completed” will appear at the lower left of the Run

Program sub-menu. Highlight “Completed” and then press the Select/Set Knob. “Start” will appear. You may now return to

manual set point control, run another program, or turn Controller power Off.

Loss of Power — If the Controller is placed in Standby (front panel power turned Off), the Controller will resume running

the program when Controller power is restored. If main power (rear panel circuit breaker/power switch) is turned Off or

electrical power is lost while a program is running, paused, or completed (but not exited), the appropriate Fault message

will be displayed upon restoration of power (see Section 5.13 – Controller Messages). Press the ESC Button to clear the

Fault message; the Controller will resume operation at the set point at which power was lost. If the program was running

or paused, it will not resume. If it was completed, it must be exited before a new program can be run.

3.3.4 Setting Preferences

The Preferences sub-menu allows you program global preferences regarding instrument operation.

Readout: This is the number of decimal places to which temperatures will be displayed (0, 1, 2, or 3).

Units: This is the unit in which temperatures will be displayed (°C or °F)

Sound: This is the volume level for the unit’s audible signal. When it is selected, the volume of the audible signal

changes as the Select/Set Knob is rotated. You must press the Select/Set Knob to accept the displayed volume value;

if you press the ESC Button or allow the display to timeout without pressing the Select/Set Knob, the sound level will

remain where it was previously set.

Language: This is the language used for displays. When this is selected, a sub-menu appears with the available

languages.

Program: This menu item appears only on the Programmable Controller. It is used to select whether programs are run

using Time or Temperature as the priority.

When Time is selected, the program begins running when the bath temperature reaches the programmed set point for

step one and continues until the total programmed period of time has elapsed. The set point target for any given step

(except step one) may or may not be reached before the program advances to the next step.

When Temperature is selected as the priority, the program begins running when the bath temperature reaches within

±0.1°C of the programmed set point for step one. Each subsequent step runs until the programmed set point for that step

is reached, within ±0.1°C, regardless of how much time has elapsed.

Display Temperature Filter: This sets the rate at which the temperature display is updated. The default setting is 4.

Higher settings will result in less display uctuation; a setting of 0 displays real-time temperature probe data. The display

temperature lter can be set from 0 to 60.

32

Page 33

3.3 Heater/Stirrer Programming – continued

3.3.5 Controller Messages

Message Display Description ActionRequired

Standby mode

An attempt has been made

to set the temperature set

point higher than the Limit

High setting

Fluid temperature is higher

than the Alarm High setting

Fluid temperature is lower

than the Alarm Low setting

An attempt has been made

to set the temperature set

point lower than the Limit

Low setting

Safety Set temperature

exceeded

Normal — Indicates that the Circuit Breaker/Power Switch

is ON and the Controller Power Switch is OFF

Error — Decrease temperature set point or increase Limit

High setting

High Temperature Warning — Decrease temperature set

point, increase Alarm High setting, or correct condition

causing high uid temperature. Pump, heater, and

compressor operation continue.

Low Temperature Warning— Increase temperature set

point, decrease Alarm Low setting, or correct condition

causing low uid temperature. Pump, heater, and

compressor operation continue.

Error — Increase temperature set point or decrease Limit

Low setting

Safety Fault — Power to heater, compressor, and pump

automatically disconnected. Correct problem and then

press Safety Set Reset Button and ESC Button to clear

fault message and restore operation.

www.cbsscientic.com

Fluid temperature is higher

than the Limit High setting

Fluid temperature is lower

than the Limit Low setting

Indicates main power was

lost while a program was

running

Indicates main power

was lost while a program

paused

Indicates main power was

lost after a program was

completed, but before it