C.B.S. Scientific DGGEK-4801 User Manual

Cipher DGGE Electrophoresis Systems

DGGEK-4001

DGGEK-4801

INSTRUCTION MANUAL

TABLE OF CONTENTS

Important User Information . . . . . . . . . . . . . . . . . . . . . . . .3-4

ENGLISH

IMPORTANT USER INFORMATION

Section 1: General Information

1.1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.2 Specications . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Section 2: DGGEK Unit Set-Up

2.1 Unpacking Instructions . . . . . . . . . . . . . . . . . . . . . . .6-7

2.2 Filling DGGEK Tank with Buffer . . . . . . . . . . . . . . . . . . . . 7

2.3 Heater/Stirrer/By-Pass Pump (Controller) Instructions . . . . . . . . . . 8-13

2.4 Setting Buffer Temperature . . . . . . . . . . . . . . . . . . . . . . 14

2.5 Connecting Power Supply . . . . . . . . . . . . . . . . . . . . . 14-15

Section 3: Gel Casting Options

3.1 Preparation of Glass Plates . . . . . . . . . . . . . . . . . . . . . . 16

3.2 Gel Casting Techniques . . . . . . . . . . . . . . . . . . . . . .16-20

3.3 Vertical Gradient Formation . . . . . . . . . . . . . . . . . . . 21

3.4 Perpendicular Gel Casting . . . . . . . . . . . . . . . . . . . 22-23

Section 4: Gel Running Preparations

4.1 Preparation of Cassettes . . . . . . . . . . . . . . . . . . . . . . 24

4.2 Buffer Cycling Set-Up . . . . . . . . . . . . . . . . . . . . . . 25-26

Section 5: Running Conditions

5.1 Running the Gels . . . . . . . . . . . . . . . . . . . . . . . . . 26

5.2 Removing the Gels . . . . . . . . . . . . . . . . . . . . . . . 27

5.3 Buffer Disposal . . . . . . . . . . . . . . . . . . . . . . . . . 27

Section 6: Recommended Buffers

6.1 Stock Solutions . . . . . . . . . . . . . . . . . . . . . . . . . 28

Section 7: Comb Specications . . . . . . . . . . . . . . . . . . . . . 29

Section 8: References . . . . . . . . . . . . . . . . . . . . . . . . . 30

Section 9: Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . 31

Section 10: Maintenance of Equipment

10.1 Care and Handling . . . . . . . . . . . . . . . . . . . . . . . . 32

10.2 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . 32

This Instruction Manual will explain how to use this product safely and effectively.

Please read and carefully follow the instruction manual in its entirety.

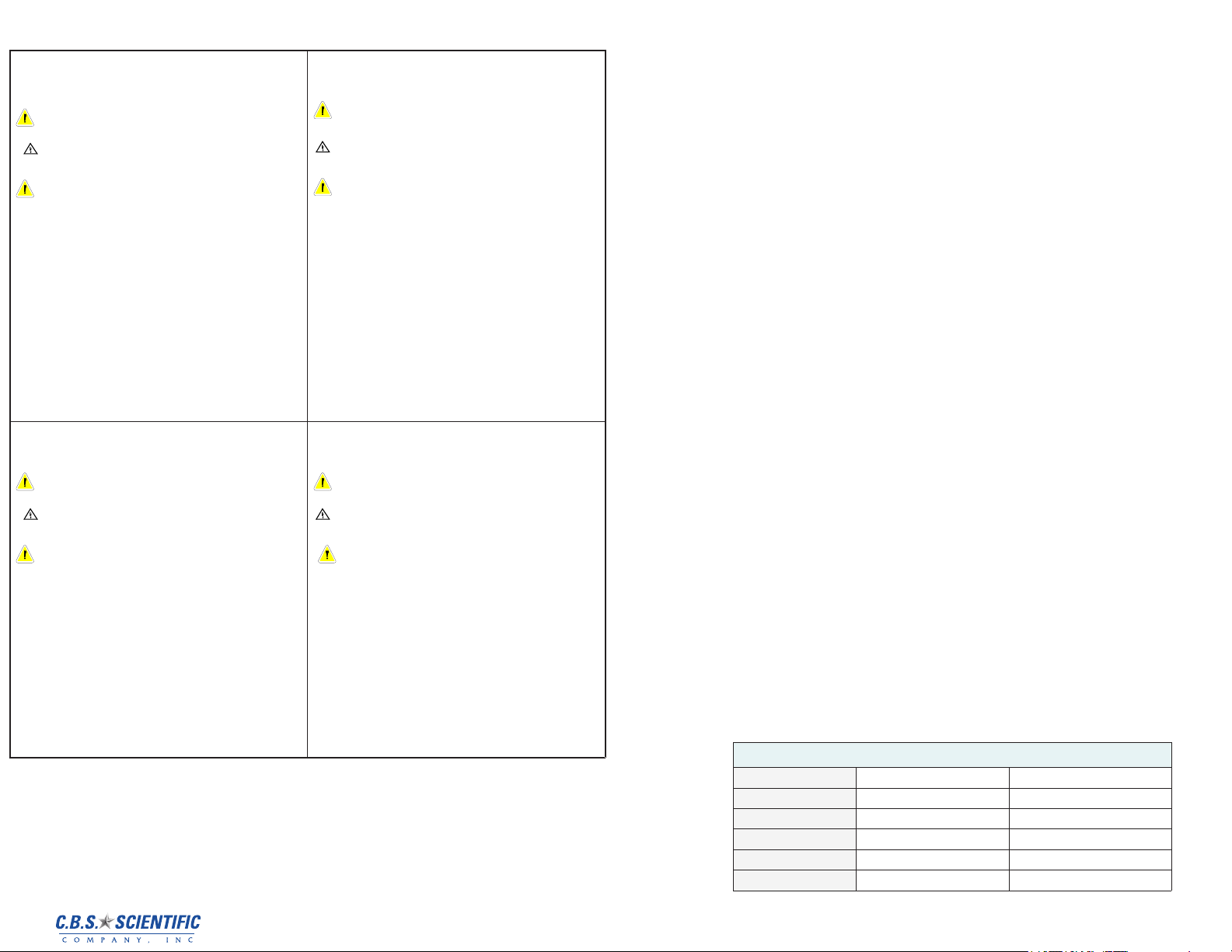

The triangle/exclamation mark symbol alerts the user of the product to important operational, maintenance, and/or warranty requirements.

The triangle/lighting bolt symbol alerts the user of the product to potentially hazardous

electrical exposure.

Failure to adhere to the instructions could result in personal and/or laboratory hazards,

as well as invalidate any warranty. Always turn off the DC power source prior to disconnecting power cords from the product. Disconnect power cords from the power source

rst and then from the product. For maximum safety, always operate this system in an

isolated, low trafc area, not accessible to unauthorized personnel. Never operate dam-

aged or leaking equipment.

WARRANTY AND LIABILITY

This product was produced utilizing the highest practical standards of materials, work-

manship, and design. C.B.S. Scientic warrants that the product has been tested and

will meet or exceed published specications. This warranty is valid only if the product

has been operated and maintained according to the instructions provided.

C.B.S. Scientic warrants this product to be free from defects in materials and workmanship under normal service for one year from date of shipment. If the product

proves defective during this period, C.B.S. Scientic will repair or replace it at our

option, free of charge, if returned to us postage prepaid. This warranty does not

cover: damage in transit, damage caused by carelessness, misuse or neglect, normal

wear through frequent use, damage caused by solvent corrosion, damage caused by

improper handling or user alteration, nor unsatisfactory performance as a result of con-

ditions beyond our control. C.B.S. Scientic shall in no event be liable for incidental nor

consequential damages, including without limitation, lost prots, loss of income, loss

of business opportunities, loss of use and other related damages, however caused, nor

any damage arising from the incorrect use of the product.

Section 11: Ordering Information . . . . . . . . . . . . . . . . . . . . 33

Section 12: Regulatory Compliance . . . . . . . . . . . . . . . . . . . . 34-35

2 3

Cipher DGGE Instructions 2/28/14

www.cbsscientic.com

FRANÇAIS INFORMATION IMPORTANTE À L’USAGE DES UTILISATEURS

Le présent manuel d’utilisation explique la manière de se servir efcacement du produit en conditions

de sécurité. Il est recommandé de soigneusement lire la totalité du manuel, avec ses consignes

et ses instructions.

Le triangle avec point d’exclamation est un symbole destiné à avertir l’utilisateur du produit

de l’importance de certaines exigences relatives au fonctionnement, à l’entretien et/ou à

la garantie.

Le triangle avec èche en zigzag est un symbole destiné à avertir l’utilisateur du produit de la

possibilité d’exposition à des décharges avec danger de secousses électriques.

Tout manquement à l’observation des consignes et des instructions peut exposer les personnes

et les biens à des dommages corporels et/ou matériels et peut annuler toute garantie. Il faut toujours

interrompre l’alimentation de courant continu avant de déconnecter les cordons d’alimentation du

produit. Déconnecter d’abord les cordons d’alimentation branchés sur la source de tension (alimentation

de secteur) puis ceux branchés sur le produit. Pour une sécurité maximum, il faut toujours faire

fonctionner ce système dans un lieu isolé, peu fréquenté, où le personnel non autorisé n’a pas accès. Ne

jamais faire fonctionner un matériel endommagé ou affecté par des fuites.

GARANTIE ET RESPONSABILITÉ

Le produit a été fabriqué conformément aux normes applicables les plus exigentes en matière de

matériaux, de main d’oeuvre, de conception et d’ingéniérie. C.B.S. Scientic garantit que le produit a subi

des essais et que ses performances rempliront les conditions des spécications publiées ou leur seront

même supérieures. La présente garantie n’est valide que si le produit a fonctionné et a été entretenu

conformément aux consignes et instructions fournies.

C.B.S. Scientic garantit que le produit sera dépourvu de vices de matériaux et de main d’oeuvre, en

conditions de service normales, pendant un an à compter de la date d’expédition. Au cas où le produit

s’avérerait défectueux pendant cette période de garantie, C.B.S. Scientic réparera ou remplacera le

produit, à sa discrétion et gratuitement, si le produit lui est retourné port payé d’avance. La garantie

ne couvre pas les dommages de transport; les dommages causés par l’imprudence, le manque de

soins, l’abus ou la négligence; l’usure normale résultant d’une utilisation fréquente; les dommages

causés par la corrosion des solvants; et les dommages causés par la manipulation inadéquate ou

des changements apportés par l’utilisateur. La garantie ne couvre pas non plus les performances non

satisfaisantes résultant de conditions hors du contrôle de C.B.S. Scientic. C.B.S. Scientic ne pourra

en aucun cas être tenue responsable de dommages indirects, y compris, de manière non limitative, la

perte de bénéces, le manque à gagner, la perte d’occasions d’affaires, l’impossibilité d’usage ou tous

autres dommages associés, quelle qu’en soit la cause, ni de dommages résultant de l’usage incorrect

du produit.

DEUTSCH WICHTIGE INFORMATION FÜR DEN BENUTZER

Diese Bedienungsanleitung beschreibt wie man dieses Produkt sicher und wirksam benutzt. Bitte lesen

und befolgen Sie alle Anweisungen in dieser Anleitung.

Das Dreieck mit Ausrufezeichen weist den Benutzer des Produktes darauf hin, daß

wichtige Bedienungs-, Wartungs- und/oder Garantievorschriften zu beachten sind.

Das Dreieck mit Zickzackblitz warnt den Benutzer des Produktes vor möglichen

Gefahren durch elektrische Spannungen.

Nichtbeachtung dieser Anweisungen kann zu persönlichen und/oder labortechnischen Schäden

führen und gleichzeitig alle Garantien als nichtig erklären. Die DC Stromzufuhr muß immer, vor dem

Entfernen der Stromkabel vom Produkt, abgeschaltet werden. Die Stromzufuhrkabel müssen zuerst von

der Steckdose und erst dann vom Produkt entfernt werden. Um höchste Sicherheit zu gewährleisten

sollte dieses System in einem abgesonderten und besonders ruhigen Bereich eingesetzt werden und

vor Unbefugten sicher sein.

GARANTIE UND HAFTUNG

Dieses Produkt wurde unter Anwendung von Produkten mit höchster Qualität und aus Materialien mit

bester Verarbeitung und modernstem Design hergestellt. C.B.S Scientic garantiert, daß das Produkt

getestet wurde und alle publizierten Spezikationen übertrifft. Diese Garantie ist jedoch nur gültig, wenn

das Produkt nach der beigefügten Bedienungsanleitung bedient und gewartet wurde.

C.B.S. Scientic garantiert, daß dieses Produkt bei normaler Bedienung aus fehlerfreiem Material

besteht und fehlerfrei in der Ausführung ist. Diese Garantie gilt für ein Jahr ab Lieferdatum. Sollte

das Produkt in diesem Zeiraum fehlerhaft werden, bietet C.B.S. Scientic eine kostenlose Reparatur

bzw. kostenlosen Ersatz, einschließlich freiem Rückporto. Diese Garantie schließt folgendes aus:

Transportschaden, Schaden durch Nachlässigkeit, Mißbrauch oder Vernachlässigung, normale

Abnützung durch regelmäßigen Gebrauch, Schaden durch Säureangriff, Schaden durch falsche

Handhabung, Veränderung des Produktes durch den Benutzer, oder unzureichende Leistungen die

sich nicht im Verantwortungsbereich von C.B.S. Scientic benden. C.B.S. Scientic kommt unter

keinen Umständen für folgende Schäden auf: Sachschadensverlust, Einkommensverlust, Verlust

von Geschäftsmöglichkeiten, Verlust der Anwendung und andere damit verbundene Schäden die auf

irgend eine Art und Weise entstanden sind, oder Schäden die aus falscher Anwendung des Produktes

entstanden sind.

ESPAÑOL INFORMACIÓN IMPORTANTE PARA EL USUARIO

El presente instructivo explica la manera de usar este producto en forma segura y efectiva. Sírvase

leerlo en su totalidad y seguir detenidamente las indicaciones que contiene.

El símbolo del triángulo con exclamación llama la atención del usuario a requisitos

importantes para el uso y mantenimiento del producto, así como para la validez de

la garantía.

El símbolo del triángulo con rayo llama la atención del usuario a la posibilidad de riesgos

eléctricos.

El incumplimiento de las instrucciones aquí señaladas podría dar lugar a riesgos a la persona, al

laboratorio o a ambos y podría anular toda garantía. Siempre apague la fuente de corriente continua

antes de desenchufar los cables eléctricos del producto. Primero desconecte los cables de la fuente de

energía y después del producto. Para mayor seguridad, siempre use este sistema en un área aislada,

de poco movimiento de personas e inaccesible a personal no autorizado. Jamás use equipo que

presenta algún daño o fuga.

GARANTÍA Y RESPONSABILIDAD

Este producto fue fabricado de acuerdo con las normas más estrictas que sean factibles en cuanto a

materiales, mano de obra y diseño. C.B.S Scientic garantiza que se sometió el producto a pruebas

y que cumplirá o excederá las especicaciones publicadas. Esta garantía será válida únicamente si

se usa y se da servicio de mantenimiento al producto de acuerdo con las instrucciones señaladas.

C.B.S. Scientic garantiza que este producto se encontrará libre de defectos de materiales y mano de

obra por un período de servicio normal de un año a partir de la fecha de embarque. Si el producto resulta

defectuoso durante este período, C.B.S. Scientic lo reparará o lo repondrá, a criterio de C.B.S., libre

de cargos, si se devuelve el producto a C.B.S. porte pagado. Esta garantía no cubre daños sufridos en

tránsito, daños provocados por descuido, mal uso o negligencia, desgaste normal como consecuencia

del uso excesivo, daños atribuibles a corrosión provocada por solventes, daños causados por el uso

indebido o alteraciones realizadas por el usuario ni rendimiento insatisfactorio atribuible a circunstancias

fuera del control de C.B.S. Scientic. C.B.S. Scientic en ningún caso asumirá responsabilidad por

daños incidentales o subsecuentes, incluyendo, en forma no limitativa, la pérdida de utilidades, de

ingresos, de oportunidades comerciales o del uso del producto y otros daños anes, fuere cual fuere su

origen, ni por daños derivados del uso incorrecto del producto.

ITALIANO INFORMAZIONI IMPORTANTI PER L’UTENTE

Questo manuale spiega come utilizzare questo prodotto in maniera sicura ed efciente. Si pregai di

leggere e seguire con cautela le istruzioni di ogni parte di questo manuale.

Il triangolo contenete il simbolo di un punto esclamativo avverte l’utente di importanti

requisiti relativi al funzionamento, manutenzione e/o garanzia del prodotto.

Il triangolo contenete il simbolo di un lampo avverte l’utente del prodotto della possibilità

di pericoli dovuti a corrente elettrica.

La mancata osservanza delle istruzioni può essere causa di pericolo alla propria persona ed

al laboratorio, oltre a poter annullare la garanzia. Prima di distaccare il cordone d’alimentazione dal

prodotto, spegnere sempre la sorgente di corrente continua. Distaccare i cordoni d’alimentazione prima

dal lato della sorgente di tensione e poi dal lato del prodotto. Per maggior sicurezza, mettere sempre

in funzione il prodotto in un’area isolata con poco trafco che non sia accessibile al personale non

autorizzato. Non mettere mai in funzione un’apparecchiatura che sia danneggiata o abbia perdite.

GARANZIA E RESPONSABILITÀ

Questo prodotto è stato fabbricato seguendo gli standard più elevati per i materiali, la manodopera e la

progettazione. La C.B.S. Scientic garantisce il prodotto è stato sottoposto a prova e raggiunge o supera

i valori pubblicati per i dati tecnici. Questa garanzia è valida solo se il prodotto è messo in esercizio e

soggetto a manutenzione secondo le istruzioni fornite.

La C.B.S. Scientic garantisce che questo prodotto è libero di difetti di materiali e manodopera, in normali

condizioni d’esercizio, per la durata di un anno dalla data di spedizione. Se, in questo periodo, il prodotto

si dimostrerà difettoso, la C.B.S. Scientic, a suo giudizio, lo riparerà o sostituirà. Questa garanzia non

copre danni in transito, danni causati da negligenza, uso improprio, trascuratezza, normale consumo

derivante da uso frequente, o danni causati da solventi corrosivi, danni causati da maltrattamento o da

modiche apportate dall’utente e non copre prestazioni insoddisfacenti che siano il risultato di condizioni

al di fuori del controllo del fabbricante. La C.B.S. Scientic non sarà in ogni caso responsabile per danni

incidentali o consequenziali, incluso, senza limitazioni, perdite di protto, perdita di entrate, perdita di

opportunità d’affari e altri danni relativi, comunque causati, e per danni risultati da uso incorretto del

prodotto.

SECTION 1

General Information

1.1 Introduction

Denaturing Gradient Gel Electrophoresis (DGGE) is a powerful genetic analysis

technique that can be used for detecting single base changes and polymorphisms

in genomic (1, 2), cloned, and PCR amplied DNA (3,4). Two of the most valuable

uses for DGGE in human genetics are in directly detecting single base changes that

cause disease and in detecting polymorphisms with DNA probes for genetic-linkage

analysis. Also, DNA fragment melting points can be determined using Perpendicular

DGGE (1).

C.B.S. Scientic has designed four different Cipher DGGEK Systems, which are

reliable and easy-to-use. The DGGEK-1001 is a 2 gel system and features one dual

gel cassette. The DGGEK-2001 features two single gel cassettes. The DGGE-2401

has the same buffer tank as the DGGE-1001 and DGGE-2001 but features two dual

gel cassettes, for a capacity of 4 gels per run. Finally there are the DGGE-4001,

which features the larger buffer tank and four single cassettes and the DGGEK-4801

with 4 dual cassettes enabling the researcher to run up to 8 gels simultaneously.

Improvements to the technique include: a simplied method for casting perpendicular

and vertical gels using Gel Wrap™. Single or dual gel cassettes have been redesigned

eliminating the use of agarose plugs, the need for an external peristaltic pump for

buffer cycling has been eliminated, bulky screw clamps have been replaced with

polypropylene spring clamps, buffer tank dimensions have been changed to use

bench space more efciently, and a safety cover with an electrical interlock has been

added for protection to help maintain temperature and reduce evaporation.

1.2 Specications

Constructions

DGGE Tank Acrylic

DGGE Lid Sodalime glass, acrylic

Electrodes Platinum wire .010” diameter

Power cords FR Silicone rated 7500V, 200mA, 65° C

DGGE Cassette Acrylic

Heater/Stirrer Buffer Cycler Stainless steel

Combs Teon

Spacers UHMW-PE

Glass Plates Sodalime or Borosilicate

Gradient Maker Acrylic, teon, stainless steel

ADDITIONAL SPECIFICATIONS

Model Cat. #

# of cassettes

# of gels

gel dimensions 15cm(w) x 20cm(l) 15cm(w) x 20cm(l)

Buffer Volume Required

footprint (cm)

Cipher DGGEK-4001 Cipher DGGEK-4801

4 single cassettes 4 dual cassettes

4 gels 8 gels

32 Liters 32 Liters

25.4(w) x 74.9(l) x 34.3(h) 25.4(w) x 74.9(l) x 34.3(h)

4 5

Cipher DGGE Instructions 2/28/14

www.cbsscientic.com

Heater

Stirrer

Buffer Siphon

Pump Assembly

Vapor

Shield

Thermometer

DGGE

Tank

Single

Cassetes

Comb (2)

Spacers

(2 pairs)

Glass Plate

Assembly(2)

Clamps

Mini-Pump

(Optional)

GM-40

Gelwrap

®

(2)

1.3 Safety

Power to the DGGE systems is to be supplied by an external DC voltage power supply

that must be ground isolated so that the DC voltage output oats with respect to

ground. For any power supply used, the maximum specied operating parameters for

the units are: Maximum Limits

250 VDC voltage

30 watts power

80 mA current

70°C ambient temperature

Current to the unit, provided from the external power supply, must enter the unit

through the lid assembly, providing a safety interlock to the user. DC current to the unit

is broken when the lid is opened. Do not attempt to use the unit without the safety

lid. Always turn the power supply off before removing the lid, or when working

with the unit in any way. Follow safety precautions specied by the power supply

manufacturer.

Input Power: Mains to safety interlock

Depending on country of destination, input voltage from mains electrical supply are as

follows: 110-120VAC @ 50/60Hz/5 Amps or 200-240VAC @ 50/60Hz/5 Amps. Country

specic power cords or CE approved adapter kits are supplied with each system.

Warning: Do NOT turn on Heater/Stirrer until tank has been lled with buffer!

SECTION 2

# of

Sample

Well

Combs

# of

1-well

Combs

# of Gel

Wrap ™

Spacer

Sets

6 7

Cipher DGGE Instructions 2/28/14

DGGEK Unit Set-Up

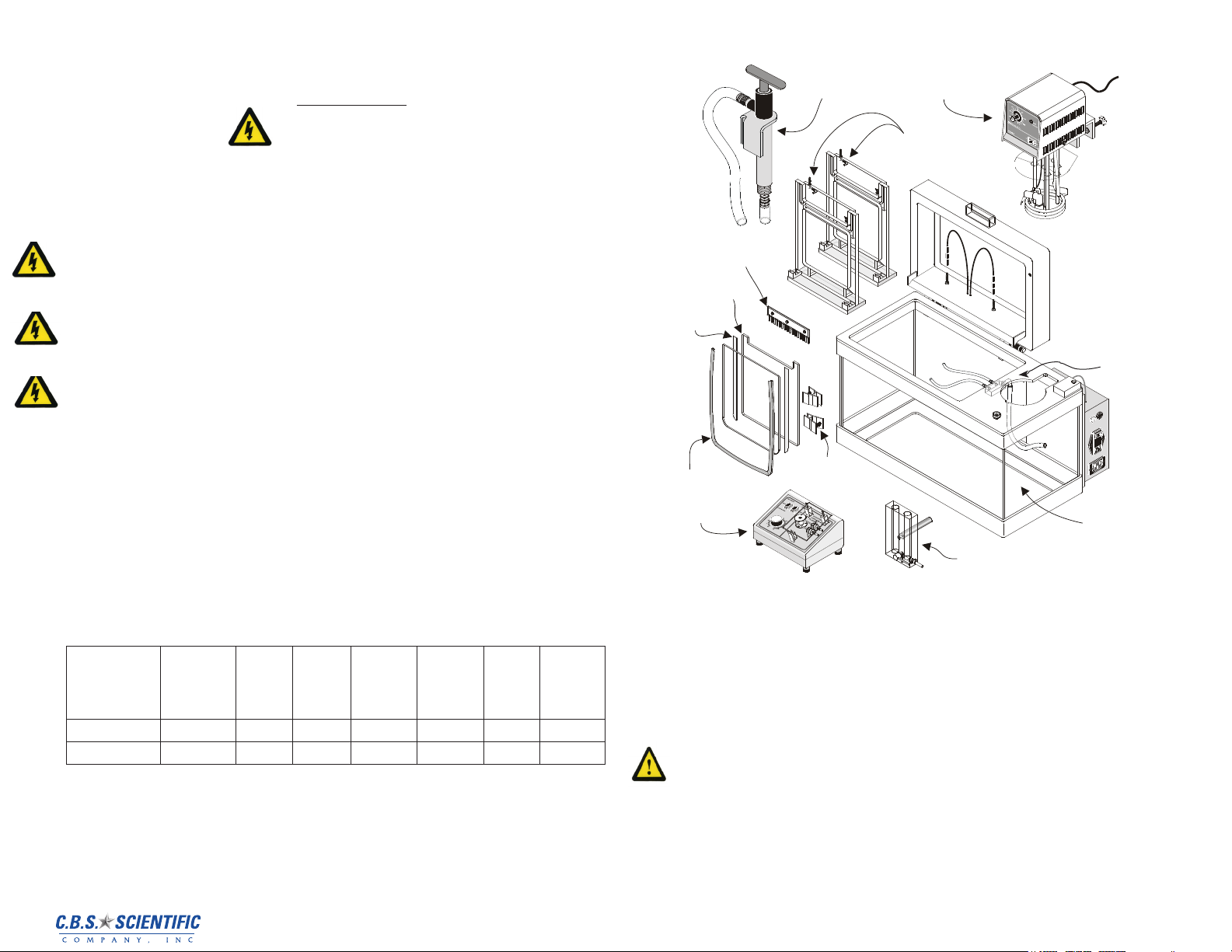

2.1 Unpacking Instructions

1) Unpack the DGGE Tank Assembly and place on level surface in an approved location.

Using gure 2-1 verify that your DGGEK-4001 or DGGEK-4801 System comes

complete with the following components:

• EPS-300 X Power Supply (not pictured)

• Peristaltic Mini-Pump for gel casting

• Lower Reservoir/Acrylic tank/safety interlock/ with 2 black leads inside lid

• Heater/Stirrer/By-pass pump (Controller) - factory-mounted onto DGGE tank

• Gel cassette(s), combs, spacer sets, Gel Wrap™ gaskets, and glass plates sets as

specied in chart below:

Type of Gel

Cassette(s)

DGGEK-4001 4 single 4 4 4 4 8 4

DGGEK-4801 4 dual 8 8 8 8 16 8

• 1 Gradient maker, 20mls per side, Cat. # GM-40

• White spring clamps

• Buffer siphon pump with tubing, Cat# BSP-1000

DGGEK-4801 only)

• 2 Conversion Plates (not shown) for running 1 gel at a time on dual cassette (for

# of Perpendicular

Spacer

Sets

# Gel

Wrap™

Gaskets

# glass

Plate Sets

Figure 2-1

Buffer recycling

manifold

2. Open the lid and conrm the following:

a) Two lengths of small bore silicone tubing for buffer cycling are already attached

to the buffer recycling manifold outlets

b) A single length of large bore tubing from the By-Pass Pump is connected to the

barb-tting on the plastic manifold.

DGGEK-2001

2.2 Filling DGGE tank with Buffer

1) Fill the tank with running buffer (see Section 6 for buffer formulations) to minimum

level. This requires 32 liters of buffer. Use distilled or RO water when making

buffer.

www.cbsscientic.com

17

14

16

15

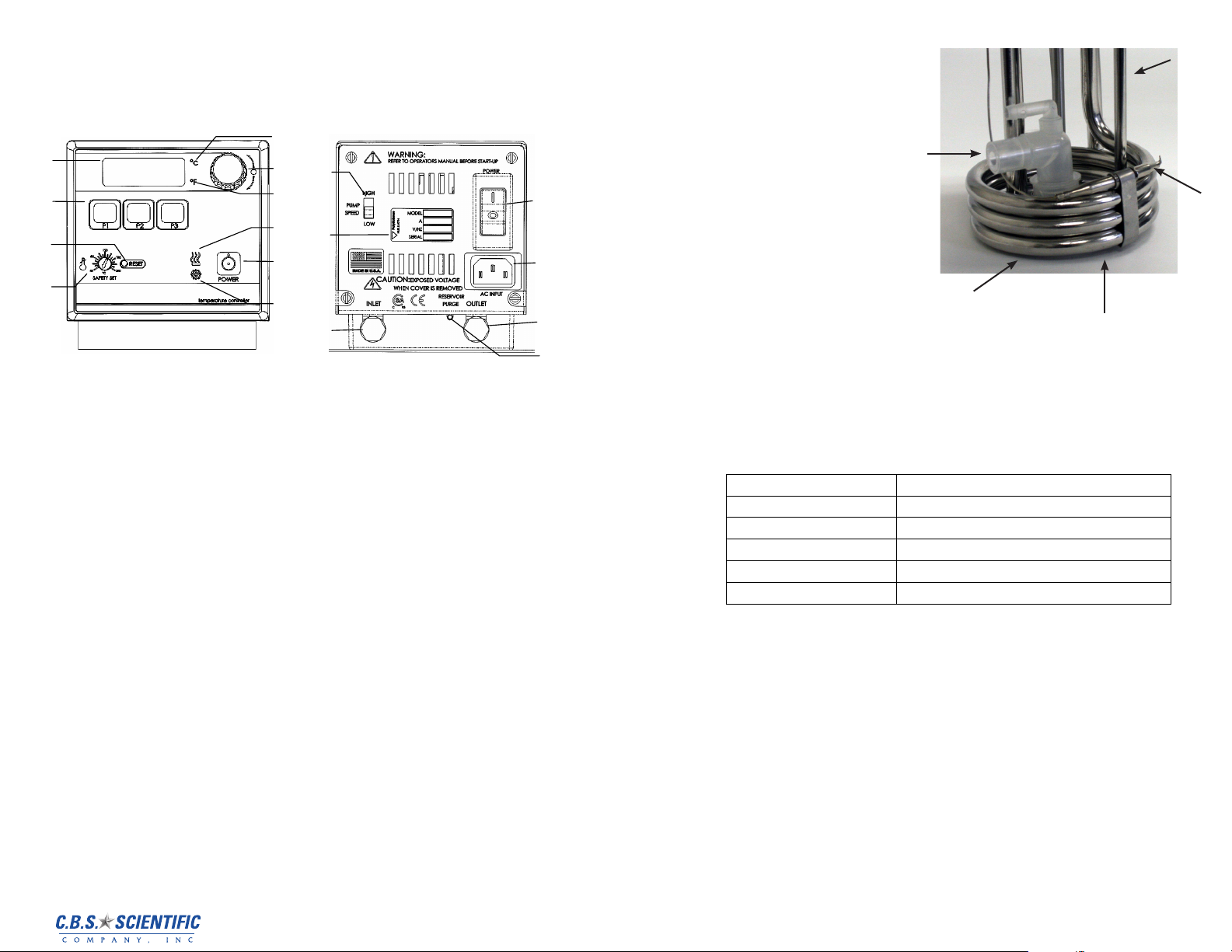

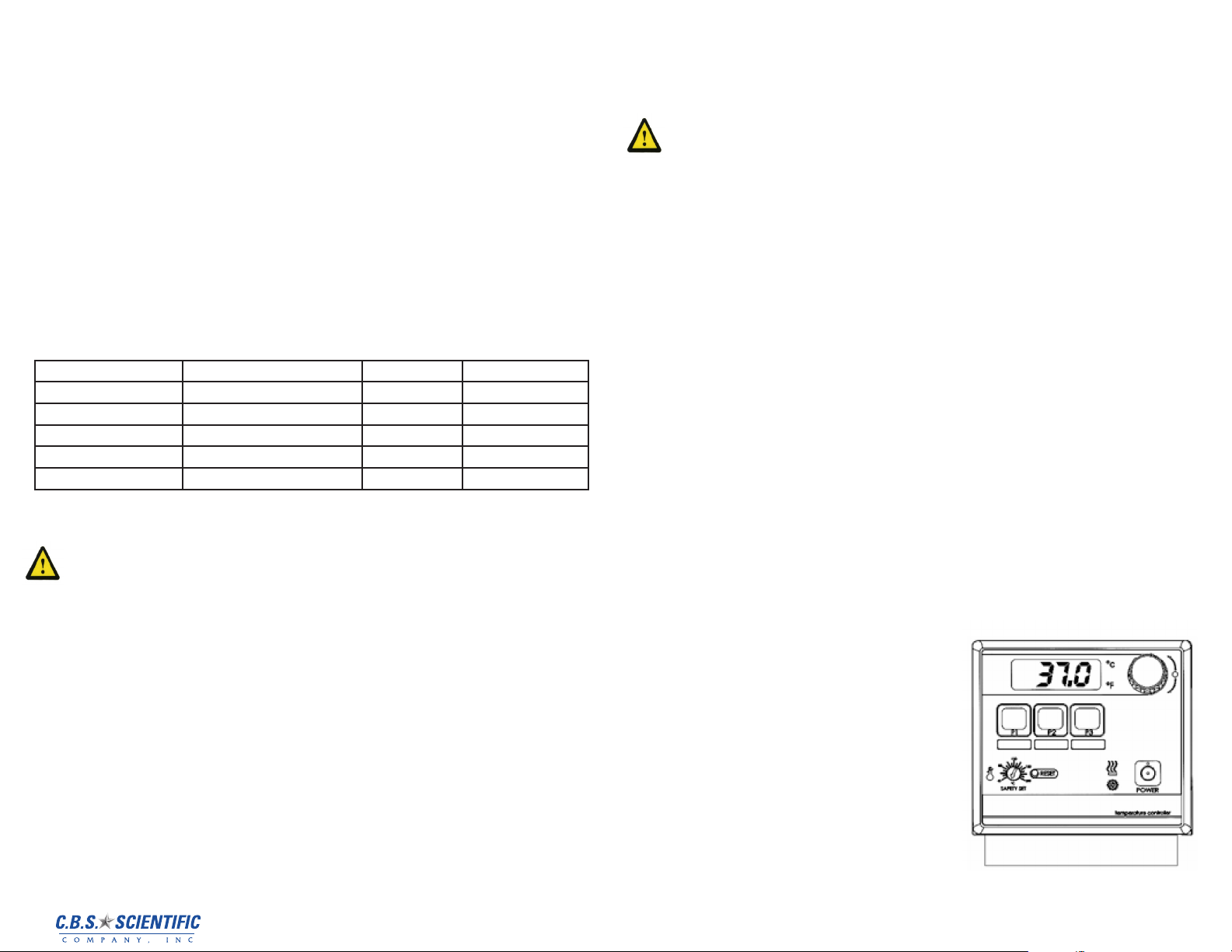

2.3 Operating Heater/Stirrer/By-Pass Pump (Controller)

1. Temperature Sens or

2. Pump Shaft and Impeller

3. Pump Outlet Nozzle

1

4. Over-Temperatur e Sensor

5. Heater Coils

1

Rotates on Immersion C irculators

5

3

1

2

4

1) Attach power cord to heater/stirrer and plug into wall outlet.

(comes factory-mounted onto DGGE tank)

2.3.2 Controller Assembly

1.

2.3.1 Front and Rear Panels

1

2

3

4

10

11

9

8

7

12

6

5

13

Front View Rear View

1. Display 11. Pump Speed Switch

2. Preset Temperature Buttons 12. Identification Label

3. Safety Set Reset Button 13. Pump Inlet

4. Safety Set Indicator Knob 14. Reservoir Purge

5. Cooling Light

6. Power ON / OFF Button 16. AC Input

7. Heating Light 17. Circuit Breaker / AC Power Switch

8. °F Light

9. Select/Set Knob (Push to set, turn to adjust)

10. °C Light

1

Present on R efrigerating/Heat ing models on ly

2

Built in on reservoir models only

1

15. Pump Outlet 2

1. Temperature Sensor

2. Pump Shaft and Impeller

3. Buffer By-Pass Tubing Adapter

4. Over-Temperature Sensor

3.

5. Heater Coils

4.

2.

5.

2

2

2.3.3 Controller Specications

Temperatur e Stabilit y ±0.05°C

Readout Acc uracy ±0.5°C

Over-Tem perature Pr otection Yes, user- adjustable

Low-Liquid Protection Yes

Heater 1100W – 115V, 1600 W – 240V

Pump Speeds 2-speed, 9 liters per minute or 15 liters per minute

Environmental Conditions:

Indoor Use Only Over Voltage: Category ll

Maximum Altitude: 2000 meters Operating Ambient: 5° to 30°C

Relative Humidity: 80% for temperatures to 30°C Pollution Degree: 2

Class 1: Residenti al, Com merci al, Light Industrial Class 2: Heavy Industrial

8 9

Cipher DGGE Instructions 2/28/14

www.cbsscientic.com

2.3.4 Controller Operation

2.3.4.a Reservoir Liquid Level

Fill the reservoir with the appropriate buffer. The DGGEK Systems are designed to be used

with reagent buffers such as 1xTAE or 1xTBE. On Circulating Baths, the liquid level should

be sufcient to cover the heating coils, pump, over-temperature sensor, and at least one inch

(25mm) of the temperature sensor. On Immersion Circulators, the liquid level should be suf-

cient to fully immerse the heater coils, over-temperature sensor, and pump outlet nozzle.

2.3.4.b Power

An IEC power cord is provided with the Circulator. This power cord should be plugged into

the IEC receptacle on the rear of the Controller and then plugged into a properly grounded

outlet. Make sure that the power outlet is the same voltage and frequency indicated on the

identication label on the back of the Controller. The use of an extension cord is not recommended. However, if one is necessary, it must be properly grounded and capable of handling

the total wattage of the unit. The extension cord must not cause more than a 10% drop

in voltage to the Circulator. Once the unit has been connected to an appropriate electrical

outlet, place the Circuit Breaker/Power Switch on the rear of the Controller in the ON position.

Four decimal points (….) will appear on the digital display. DO NOT place the Power Switch

on the front of the Controller ON until the Safety Set has been adjusted to the desired tem-

perature (see 3.6 below).

Indicated Voltage:

Volts/Phase/Frequency Operational Voltage Range Phase Frequency

100/ 1 / 60 90 to 110 Volts single 60 Hz

100/ 1 / 50 90 to 110 Volts single 50 Hz

120/ 1 / 60 110 to 130 Volts single 60 Hz

230/ 1 / 60 208 to 230 Volts single 60 Hz

240/ 1 / 50 220 to 240 Volts single 50 Hz

2.3.4.c Setting the Safety Set Set Point - NOTE: DGGEK is factory set to 80ºC

The Safety Set feature automatically disconnects Controller power to the heater and pump in

the event that the reservoir liquid level drops too low or the Controller fails. The Safety Set is

user-adjustable between approximately 40° and 210°C. It should be set at least 5°C higher

than the Software High Limit temperature. Use a at blade screwdriver to rotate the Safety

Set Indicator Knob to the desired temperature. Do not force the knob beyond the stops at either end of the temperature value range. Once the Safety Set temperature has been set, turn

power to the Controller ON by pressing the Power Switch on the front of the Controller. The

pump will begin operating, the display will ash the current temperature set point (tx.xx), the

°C LED will light, and the current bath temperature will appear on this display. Pump speed

selection is made using the Pump Speed Selection Switch on the rear of the Controller (see

Section 2.3 or 3.3). If power is disrupted because the Safety Set temperature was exceeded,

place the Circuit Breaker/Power Switch in the OFF position, press the Safety Set Reset Button, correct the problem (low liquid level, incorrect Safety Set temperature, etc.), and then

restore power. Activation of the Safety Set during normal operation will display a fault (FLt 3)

on the readout.

2.3.4.d Selecting Temperature Units

The control set point and actual bath temperatures may be displayed in either °C or °F. The

factory-default is °C. To change from °C to °F, place the Circuit Breaker/Power Switch on the

rear of the Controller in the OFF position and then press and hold the P2 Button while turning

the power back ON.

To change from °F to °C, place the Circuit Breaker/Power Switch in the OFF position and then

press and hold the P3 Button while turning the power back ON.

NOTE: When the temperature display units are changed, the Software High Limit value and all

temperature presets revert to the factory-default values. If a calibration value has been entered,

the value will be retained.

2.3.4.e Setting the Software High Limit - NOTE: DGGEK is factory set to 75ºC

This feature provides additional safety and protection by allowing a selectable upper temperature limit set point. To avoid an unwanted shutdown during regular operation, the high

limit value should be set at least 5°C higher than the selected control temperature To set the

Software High Limit temperature set point, press the P2 and P3 keys simultaneously and repeat

until (Hxxx) appears on the display. This is the current Software High Limit value. It is factory set

at 75°C. To change the displayed value, press and turn the Select/Set Knob until the desired

Software High Limit set point value is displayed. A clockwise rotation increases the value; a

counterclockwise rotation decreases the value. Press the Select/Set Knob a second time to

accept the new value and return to normal operation. If the Software High Limit value meets or

exceeds the control temperature set point, (E-H1) will ash on the display. If this occurs, enter

a higher value for the Software High Limit or reduce the control temperature set point. If the

actual bath temperature reaches the Software High Limit setpoint, (FLt1) will ash on the display. Should this occur, the Controller will automatically remove power from the heater and, in

Refrigerating/Heating units, the compressor as well. The pump will continue to operate. Once

the problem is corrected (bath temperature reduced or Software High Limit value increased),

press the Power button to clear the message.

2.3.4.f Setting the Set Point Temperature

Press and release the Select/Set Knob. The decimal point ashes to indicate that the set point

temperature can be changed. Turn the Select/Set Knob until the desired temperature set point

is displayed. A clockwise rotation increases the setting; a counterclockwise rotation decreases

the setting. Press the Select/Set Knob a second time to accept the displayed value. The deci-

mal point stops ashing and the display will indicate the actual bath temperature. Allow sufcient time for the bath to stabilize at the desired temperature before making any adjustments

to set point temperature. NOTE: The unit will automatically accept the displayed set point after

approximately 10 seconds of inactivity, even if the Select/Set Knob was not pressed. The set

point temperature may be checked at any time by pressing the Select/Set Knob. If the set

point temperature cannot be raised, it is possible that the Software High Limit value is set lower

than the desired control temperature set point. Reset the Software High Limit value to 5°C or

more above the desired set point temperature.

2.3.4.g User-Denied Preset Temperatures

With the unit on, press the desired Preset Button —

P1, P2, or P3. The LED associated with the selected

Preset Button will begin to ash. Rotate the Select/

Set Knob to the desired temperature set point. Press

the selected Preset Button a second time to enter the

new set point. The new set point temperature will not

be saved unless the Preset Button is pressed. The

LED associated with Preset Button lights continuously whenever that preset value is controlling bath

temperature. If more than one Preset Button is set

at a given temperature set point, the LED associated

with all Preset Buttons with that set point will light.

10 11

Cipher DGGE Instructions 2/28/14

www.cbsscientic.com

Loading...

Loading...