INSTRUCTION MANUAL

Adjustable Slab Gel Systems

Single Units

ASG-250

ASG-400

ASG-250-02

Dual Units

DASG-250

DASG-400

DASG-250-02

www.cbsscientific.com 2 Adjustable Slab Gel Manual 07/13

TABLE OF CONTENTS

Page

Important User Information 3-4

Section 1 General Information

1.1 Introduction 5

1.2 Specifications 5-6

1.3 Safety 7

Section 2 Description of parts

2.1 Unpacking-U.S. version 8

2.2 Components/Assembly-U.S. version 8

2.3 Unpacking-European version 9

2.4 Components/Assembly-European version 9

Section 3 Instructions for Use

3.1 Adjustable Slab Gel Unit Preparation 10

3.2 Preparation/Cleaning of glass plates 11

3.3 Gel Casting 11-12

3.4 Running the Gel 13-14

3.5 Removing the Gel 14

3.6 Maximum Well/Comb volumes 14

Section 4 Running Conditions

4.1 Recommended Power 15

4.2 Recommended Buffer & Reagents 15-16

4.3 References 16

Section 5 Maintenance of Equipment

5.1 Care and Handling 17

5.2 Maintenance 17

Section 6 Adjustable/Dual Adjustable Slab Gel

Kits and Accessories 18-21

www.cbsscientific.com 3 Adjustable Slab Gel Manual 07/13

IMPORTANT USER INFORMATION

This Instruction Manual will explain how to use this product safely and effectively. Please read and

carefully follow the instruction manual in its entirety.

The triangle/exclamation mark symbol alerts the user of the product to important

operational, maintenance, and/or warranty requirements.

The triangle/lighting bolt symbol alerts the user of the product to potentially hazardous

electrical exposure.

Failure to adhere to the instructions could result in personal and/or laboratory hazards, as well as

invalidate any warranty. Always turn off the DC power source prior to disconnecting power cords

from the product. Disconnect power cords from the power source first, and then from the product.

For maximum safety, always operate this system in an isolated, low traffic area, not accessible to

unauthorized personnel. Never operate damaged or leaking equipment.

WARRANTY AND LIABILITY

This product was produced utilizing the highest practical standards of materials, workmanship, and

design. C.B.S. Scientific warrants that the product has been tested and will meet or exceed published

specifications. This warranty is valid only if the product has been operated and maintained according to

the instructions provided.

C.B.S. Scientific warrants this product to be free from defects in materials and workmanship under normal

service for one year from date of shipment. If the product proves defective during this period, C.B.S.

Scientific will repair or replace it at our option, free of charge, if returned to us postage prepaid. This

warranty does not cover: damage in transit, damage caused by carelessness, misuse or neglect, normal

wear through frequent use, damage caused by solvent corrosion, damage caused by improper handling

or user alteration, nor unsatisfactory performance as a result of conditions beyond our control. C.B.S.

Scientific shall in no event be liable for incidental nor consequential damages, including without limitation,

lost profits, loss of income, loss of business opportunities, loss of use and other related damages,

however caused, nor any damage arising from the incorrect use of the product.

www.cbsscientific.com 4 Adjustable Slab Gel Manual 07/13

FRANÇAIS INFORMATION IMPORTANTE À L'USAGE DES UTILISATEURS

Le présent manuel d'utilisation explique la manière de se servir efficacement du produit en conditions

de sécurité. Il est recommandé de soigneusement lire la totalité du manuel, avec ses consignes

et ses instructions.

Le triangle avec poin t d'exclamation est un symbole destiné à avertir l'utilisateur du produit

de l'importance de certaines exigences relatives au fonctionnement, à l'entretien et/ou à la

garantie.

Le triangle avec flèche en zigzag est un symbole destiné à avertir l'utilisateur du produit de la

possibilité d'exposition à des décharges avec danger de secousses électriques.

Tout manquement à l'observation des consignes et des instructions peut exposer les personnes

et les biens à des dommages corporels et/ou matériels et peut annuler toute garantie. Il faut toujo urs

interrompre l'alim entation de coura nt continu avant de déconnecter les cordons d'alimen tation du

produit. Déconnecter d'abord les cordons d'alimentation branchés sur la source de tension

(alimentation de secteur) puis ceux branchés sur le produit. Pour une sécurité maximum, il faut

toujours faire fonctionner ce système dans un lieu isolé, peu fré quenté, où le pe rsonnel non autorisé

n'a pas accès. Ne jamais faire fonctionner un matériel endommagé ou affecté par des fuites.

GARANTIE ET RESPONSABILITÉ

Le produit a été fabriqué conformément aux normes applicables les plus exigentes en matière de

matériaux, de main d'oeuvre, de conception et d'ingéniérie. C.B.S. Scientific garantit que le produit a

subi des essa is et que ses performances rempliront les conditions des spécifications publiées ou leur

seront même supérieures. La présente garantie n'est valide que si le produit a fonctionné et a été

entretenu conformément aux consignes et instructions fournies.

C.B.S. Scientific garantit que le produit sera dépourvu de vices de matériaux et de main d'oeu vre, en

conditions de service normales, pendant un an à compter de la date d'expédition. Au ca s où le produit

s'avérerait défectueux pendant cette période de garantie, C.B.S. Scientific réparera ou remplacera le

produit, à sa discrétion et gratuitement, si le produit lui est retourné port payé d'avance. La garantie ne

couvre pas les dommages de transport; les dommages causés par l'imprudence, le manque de soins,

l'abus ou la négligence; l'usure normale résultant d'une utilisation fréquente; les dommages causés par

la cor rosion des so lvants; et les dom mages causés par la man ipulation inadéquate o u de s

changements apportés par l'utilisateur. La garantie ne couvre pas non plus les performances non

satisfaisantes résultant de conditions hors du contrôle de C.B.S. Scientific. C.B.S. Scientific ne pourra

en aucun cas être tenue responsable de dommages indirects, y compris, de manière non limitative, la

perte de bénéfices, le manque à gagner, la perte d'occas ions d'affaires, l'im possibilité d'usage ou tous

autres dommages associés, quelle qu'en soit la cause, ni de dommages résultant de l'usage incorrect

du produit.

ESPAÑOL INFORMACIÓN IMPORTANTE PARA EL USUARIO

El presente instructivo explica la manera de usar este producto en forma segura y efectiva. Sírvase

leerlo en su totalid ad y seguir detenidamente la s indicaciones q ue contiene.

El símbolo del triángulo con exclamación llama la atención del usuario a requisitos

importantes pa ra el uso y mantenimiento de l producto, así como para la validez de la

garantía.

El símbolo del triángulo con rayo llama la atención del usuario a la posibilidad de

riesgos eléctricos.

El incumplimiento de las instrucciones aquí señaladas podría dar lugar a riesgos a la persona, al

laboratorio o a ambos y podría an ular toda garantía. Siempre apague la fuente de corriente continua

antes de desenchufar los cables eléctricos del producto. Primero desconecte los cables de la fuente

de energía y después del prod ucto. Pa ra mayor seguridad, siempre use este sis tema en un área

aislada, de poco movimiento de personas e inaccesible a personal no autorizado. Jamás use equipo

que presenta algún daño o fuga.

GARANTÍA Y RESPONSABILIDAD

Este producto fue fabricado de acuerdo con las normas más estrictas que sean factibles en cuanto a

materiales, mano de obra y diseño. C.B.S Scientific garantiza que se sometió el producto a pruebas y

que cumplirá o excederá las especificaciones publicadas. E sta garantía será válida únicamente si se

usa y se da servicio de mantenimiento al producto de acuerdo con las instrucciones señaladas.

C.B.S. Scientific garantiza que este producto se encontrará libre de defectos de materiales y mano de

obra por un período de servicio normal de un año a partir de la fecha de embarque. Si el producto

resulta defectuoso durante este período, C.B.S. Scientific lo re parará o lo repondrá, a criterio de

C.B.S., libre de cargos, si se devuelve el producto a C.B.S. porte pagado. Esta garantía no cubre

daños sufridos en tránsito, daños provocados por descuido, mal uso o negligencia, desgaste normal

como con secuencia del uso excesivo, daños atribuibles a corrosión provocada por solventes, daños

causados por el uso indebido o alteraciones realizadas por el usuario ni rendimiento insatisfactorio

atribuible a circunstancias fuera del control de C.B.S. Scientific. C.B.S. Scientific en ningún caso

asumirá responsabilidad por daños incidentales o subsecuentes, incluyendo, en forma no limitativa, la

pérdida de utilidades, de ingresos, de oportunidades comerciales o del uso del producto y otros daños

afines, fuere cual fuere su origen, ni por daños derivados del uso incorrecto del producto.

DEUTSCH WICHTIGE INFORMATION FÜR DEN BENUTZER

Diese Bedienungsanleitung beschreibt wie man dieses Produkt sicher und wirksam benutzt. Bitte

lesen und befo lgen Sie alle An weisungen in d ieser Anleitung .

Das Dreieck mit Ausrufezeichen weist den Benutzer des Produktes darauf hin, daß

wichtige Bedienungs-, Wartungs- un d/oder Garantievo rschriften zu beachte n sind.

Das Dreieck mit Zickzackblitz warnt den Benutzer des Produktes vor möglichen

Gefahren durch elektrische Spannungen.

Nichtbeachtung dieser Anweisungen kann zu persönlichen und/oder labortechnischen Schäden

führen und g leichzeitig alle Ga rantien als nich tig erklä ren. Die DC Stromzufuhr muß immer, vor dem

Entfernen der Stromkabel vom Produkt, abgeschaltet werden. D ie Stromzufuhrkabel müssen zuerst

von der Steckdose und erst dann vom Produkt entfernt werden. Um höchste Sicherhe it zu

gewährleisten sollte dieses System in einem abgesonderten und besonders ruhigen Bereich eingesetzt

werden und vor Unbefugten sicher sein.

GARANTIE UND HAFTUNG

Dieses Produkt wurde unter Anwendung von Produkten mit höchster Qualität und aus Materialien mit

bester Verarbeitung und modernstem Design hergestellt. C.B.S Scientific garantiert, daß das Produkt

getestet w urde und alle publizierten Spezifikationen übertrifft. Diese Garantie ist jedoch nur gültig,

wenn das Produkt nach der beigefügten Bedienungsanleitung bedient und gewartet wurde.

C.B.S. Scientific garantiert, daß dieses Produkt bei normaler Bedienung aus fehlerfreiem Material

besteht und fehlerfrei in der Ausführung ist. Diese Garantie gilt für ein Jahr ab Lieferdatum. Sollte das

Produkt in diesem Zeiraum fehlerhaft werden, bietet C.B.S. Scientific eine kostenlose Reparatur bzw.

kostenlosen Ersatz, einschließlich freiem Rückporto. Diese Garantie schließt folgendes aus:

Transportschaden, Schaden durch Nachlässigkeit, Mißbrauch oder Vernachlässigung, normale

Abnützung durch regelmäßigen Gebrauch, Schaden durch Säureangriff, Schaden durch falsche

Handhabung, Veränderung des Produktes durch den Benutzer, oder unzureichende Leistungen die

sich nicht im Verantwortungsbereich von C.B.S. Scientific befinden. C.B.S. Scientific kommt unter

keinen Umständen für folgende Schäden auf: Sachschadensverlust, Einkommensverlust, Verlust von

Geschäftsmöglichkeiten, Verlust der Anwendung und andere damit verbundene Schäden die auf

irgend eine Art un d Weise entstanden sind, o der Schäden die aus falscher Anwen dung des Produkte s

entstanden sind.

ITALIANO INF ORMAZIONI IM PORTANTI PER L’UTENTE

Questo manuale spiega come utilizzare questo prodotto in maniera sicura ed efficiente. Si pregai di

leggere e segu ire con cautela le istruzioni di ogni parte di questo m anuale.

Il triangolo contenete il s imbolo di un punto esclamativo avver te l’utente di importanti

requisiti relativi al funzionamento, man utenzione e/o garanzia del prodotto.

Il triangolo contenete il s imbolo di un lampo avverte l’utente del p rodotto della

possibilità di pericoli dovuti a corrente elettrica.

La mancata osservanza delle istruzioni può essere causa di pericolo alla propria persona ed al

laboratorio, oltre a poter annullare la garanzia. Prima di distaccare il cordone d’alimentazione dal

prodotto, spegnere sempre la sorgente di corrente continua. Distaccare i cordoni d’alimentazione

prima dal lato della sorgente di tensione e poi dal lato del prodotto. Per maggior sicurezza, mettere

sempre in funzione il prodotto in un’area isolata con poco traffico che non sia accessibile al personale

non autorizzato. Non mettere mai in funzione un’apparecchiatura che sia danneggiata o abbia

perdite.

GARANZIA E RESPONSABILITA

Questo prodotto è stato fabbricato seguendo gli standard più elevati per i materiali, la manodopera e la

progettazione. La C.B.S. Scientific garantisce il prodotto è stato sottoposto a prova e raggiunge o

supera i valori pubblicati per i dati tecnici. Questa garanzia è valida solo se il prodotto è messo in

esercizio e soggetto a manutenzione secondo le istruzioni fornite.

La C.B.S. Scientific garantisce che questo prodotto è libero di difetti di materiali e manodopera, in

normali condizioni d’esercizio, per la durata di un anno dalla data di spedizione. Se, in questo periodo,

il p rodotto si dimostre rà difettoso, la C.B.S. S cientific, a suo giudizio, lo r iparerà o sostituirà. Questa

garanzia non copre danni in transito, danni causati da negligenza, uso improprio, trascuratezza,

normale consumo derivante da uso frequente, o danni causati da solventi corrosivi, danni causati da

maltrattamento o da modifiche apportate dall’utente e non copre prestazioni insoddisfacenti che siano il

risultato di cond izioni al di fuori del controllo del fab bricante. La C.B.S. Scientific non sarà in ogni caso

responsabile per da nni incidentali o cons equenziali, incluso, senz a limitazioni, perdite di p rofitto,

perdita di entrate, perdita di opportunità d’affari e altri danni relativi, comunque causati, e per danni

risultati da uso incorretto del prodotto.

www.cbsscientific.com 5 Adjustable Slab Gel Manual 07/13

SECTION 1

General Information

1.1 Introduction

The Adjustable Slab Gel Systems offered by C.B.S. Scientific are designed to meet a wide variety

of applications. These systems are designed for separating and characterizing protein and can

be adapted for short nucleic acid sequencing runs with the appropriate accessories. The Dual

systems allow two gels to be run simultaneously under identical buffer conditions and also

provides the flexibility of running gels from 145mm to 400mm (U.S. version, Cat. # DASG-250 or

DASG-400) or 160mm to 280mm (European version, Cat. # DASG-250-02). The single systems

provide the flexibility of running gels in lengths from 145mm to 400mm (U.S. version, Cat. # ASG250 or ASG-400) or 160mm to 280mm (European version, Cat. # ASG-250-02). Gel casting can

be accomplished using our convenient and unique Gel Wrap, or by using our multiple gel

casting chambers (see Section 6, Adjustable/Dual Adjustable Slab Gel Kits and Accessories).

Other applications include; mobility shift assays, antibody super shift assays, Rnase protection

assays, DNA footprinting, differential display, DNA paternity testing and forensic analysis.

1.2 Specifications

Constructions:

Buffer chamber, safety cover Acrylic

Electrodes Platinum wire .012" diameter

Power cords FR Urethane rated 7500VDC,

200mA, 65°C

Guide Rods Delrin

Combs Teflon

Glass plates Soda-lime float glass

Spacers PVC

Clamps Polypropylene, stainless steel

Safety Certification EN61010-1-1993 (IEC1010-1)

www.cbsscientific.com 6 Adjustable Slab Gel Manual 07/13

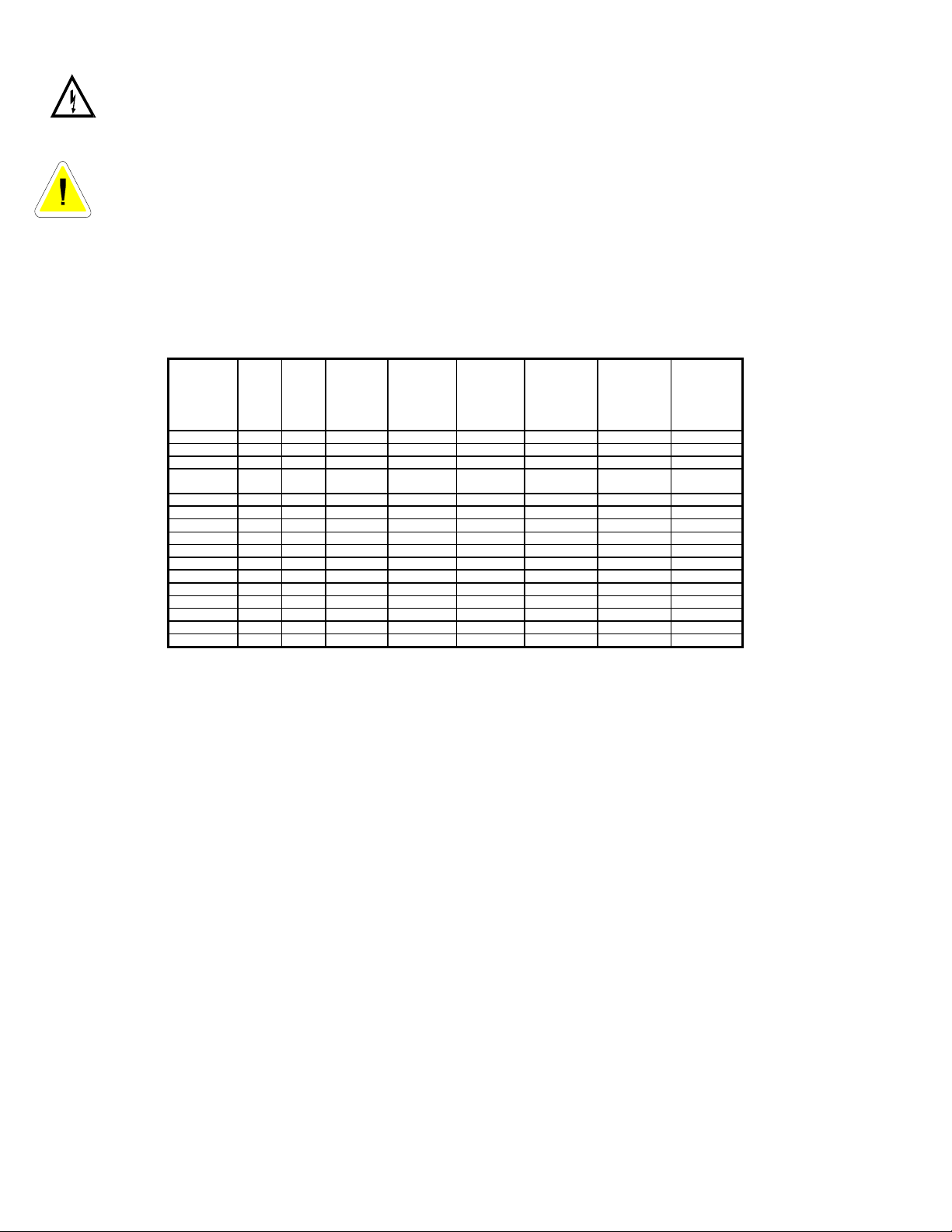

Table 1 Specifications

Single Adjustable

Unit

U.S. version

ASG-250/400

adjusted to:

Shipping

weight

Overall unit

size cm

(l) x (w) x (h)

Distance between

electrodes mm

Recommended

buffer volume mls

Reservoirs:

UPPER LOWER

Voltage Limit

VDC

145mm

7 lb.

24 x 19 x 21.91

250

310-375 150-350

725

160mm

7 lb.

24 x 19 x 31

265

310-375 150-350

800

170mm

7 lb.

24 x 19 x 31

275

310-375 150-350

850

190mm

7 lb.

24 x 19 x 31

295

310-375 150-350

950

220mm

7 lb.

24 x 19 x 31

325

310-375 150-350

1100

280mm

8 lb.

24 x 19 x 31

385

310-375 150-350

1400

400mm

10 lb.

24 x 19 x 41

505

310-375 150-350

2000

Single Adjustable

Unit

European version

ASG-250-02

adjusted to:

Shipping

weight

Overall unit

size cm

(l) x (w) x (h)

Distance between

electrodes mm

Recommended

buffer volume mls

Reservoirs:

UPPER LOWER

Voltage Limit

VDC

160mm

7 lb.

24 x 19 x 31

265

250-300 100-200

800

170mm

7 lb.

24 x 19 x 31

275

250-300 100-200

850

190mm

7 lb.

24 x 19 x 31

295

250-300 100-200

950

220mm

7 lb.

24 x 19 x 31

325

250-300 100-200

1100

280mm

8 lb.

24 x 19 x 31

385

250-300 100-200

1400

Dual Adjustable Unit

U.S. version

DASG-250/400

adjusted to:

Shipping

weight

Overall unit

size cm

(l) x (w) x (h)

Distance between

electrodes mm

Recommended

buffer volume mls

Reservoirs:

UPPER LOWER

Voltage Limit

VDC

145mm

12 lb.

24 x 19 x 21.91

250

375-475 150-350

725

160mm

12 lb.

24 x 19 x 31

265

375-475 150-350

800

170mm

12 lb.

24 x 19 x 31

275

375-475 150-350

850

190mm

12 lb.

24 x 19 x 31

295

375-475 150-350

950

220mm

12 lb.

24 x 19 x 31

325

375-475 150-350

1100

280mm

13 lb.

24 x 19 x 31

385

375-475 150-350

1400

400mm

14 lb.

24 x 19 x 41

505

375-475 150-350

2000

Dual Adjustable Unit

European version

DASG-250-02

adjusted to:

Shipping

weight

Overall unit

size cm

(l) x (w) x (h)

Distance between

electrodes mm

Recommended

buffer volume mls

Reservoirs:

UPPER LOWER

Voltage Limit

VDC

160mm

12 lb.

24 x 19 x 31

265

300-350 400-600

800

170mm

12 lb.

24 x 19 x 31

275

300-350 400-600

850

190mm

12 lb.

24 x 19 x 31

295

300-350 400-600

950

220mm

12 lb.

24 x 19 x 31

325

300-350 400-600

1100

280mm

13 lb.

24 x 19 x 31

385

300-350 400-600

1400

www.cbsscientific.com 7 Adjustable Slab Gel Manual 07/13

1.3 Safety

Power to the Adjustable Vertical units is to be supplied by an external DC voltage power supply

that must be ground isolated so that the DC voltage output floats with respect to ground. For any

power supply used, the maximum specified operating parameters for the units are:

Maximum Limits

50VDC/cm of gel

60 watts power

80mA current

55°C ambient temperature

Current to the unit, provided from the external power supply, must enter the unit through the lid

assembly, providing a safety interlock to the user. Current to the unit is broken when the lid is

removed. Do not attempt to use the unit without the safety lid, and always turn the power

supply off before removing the lid, or when working with the unit in any way. Follow

safety precautions specified by the power supply manufacturer.

www.cbsscientific.com 8 Adjustable Slab Gel Manual 07/13

SECTION 2

Description of Parts

2.1 Unpacking—U.S. version only

Please verify that your unit comes complete with the following components:

Single Adjustable Vertical Gel Kit

ASG-250/400:

Dual Adjustable Vertical Gel Kit

DASG-250/400:

• Adjustable electrophoresis unit

• Dual Adjustable electrophoresis unit

• Safety cover with attached DC power leads

• Safety cover with attached DC power leads

• Black guide rods with stainless screws

• Black guide rods with stainless screws

• 2ea GPC-0001, white spring clamps

• 4ea GPC-0001, white spring clamps

• 6ea GPC-0002, white spring clamps

• 12ea GPC-0002, white spring clamps

• 1ea comb

• 2ea combs

• 1 set glass plates

• 2 sets glass plates

• 1 set spacers

• 2 sets spacers

• 1ea Gel Wrap

• 2ea Gel Wrap

• Bubble level, attached to base

• Bubble level, attached to base

• 2ea black thumb screws

• 2ea black thumb screws

• 4ea leveling screws, nylon

• 4ea leveling screws, nylon

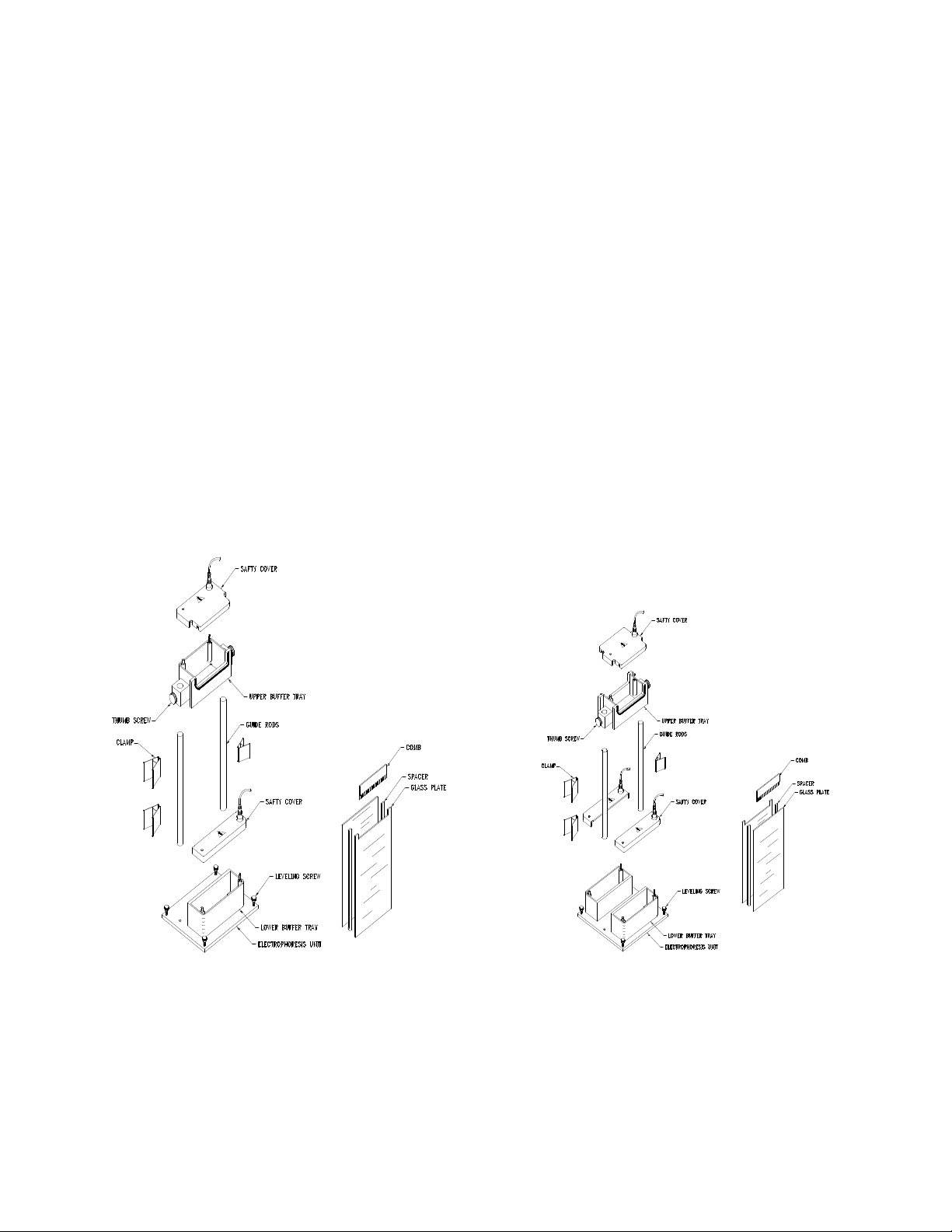

2.2 Components/Assembly-- U.S. version only

Single Adjustable Vertical Gel Kit Dual Adjustable Vertical Gel Kit

www.cbsscientific.com 9 Adjustable Slab Gel Manual 07/13

SECTION 2---continued

Description of Parts

2.3 Unpacking—European version only

Please verify that your unit comes complete with the following components:

Single Adjustable Vertical Gel Kit

ASG-250-02:

Dual Adjustable Vertical Gel Kit

DASG-250-02:

• Adjustable electrophoresis unit

• Dual Adjustable electrophoresis unit

• Safety cover with attached DC power leads

• Safety cover with attached DC power leads

• Black guide rods with stainless screws

• Black guide rods with stainless screws

• 2ea GPC-0001, white spring clamps

• 4ea GPC-0001, white spring clamps

• 6ea GPC-0002, white spring clamps

• 12ea GPC-0002, white spring clamps

• 1ea comb

• 2ea combs

• 1 set glass plates

• 2 sets glass plates

• 1 set spacers

• 2 sets spacers

• 1ea Gel Wrap

• 2ea Gel Wrap

• Bubble level, attached to base

• Bubble level, attached to base

• 2ea black thumb screws

• 2ea black thumb screws

• 4ea leveling screws

• 4ea leveling screws

2.4 Components/Assembly—European version only

Single Adjustable Vertical Gel Kit Dual Adjustable Vertical Gel Kit

www.cbsscientific.com 10 Adjustable Slab Gel Manual 07/13

Section 3

Instructions for Use

3.1 Adjustable Slab Gel Unit Preparation

A. Unit Set-Up

1. Place Adjustable Slab Gel unit on a level work surface in an authorized work area.

Attach each of the black guide rods to the flathead screws through the countersunk

holes on the bottom of the base. Thread the screws into the black guide rods and

hand tighten. Do not over tighten.

2. Slide the upper reservoir onto the guide rods. Be sure to unscrew the thumbscrews

slightly so that the ends of the screws are not protruding into the guide rod channels.

3. Adjust the upper reservoir so that the facia and glass notches are level, using a

notched plate as a guide. Tighten the two black thumbscrews to fix the height.

4. Level the unit by adjusting the four white nylon thumbscrews until the bubble is

centered in the level. Be sure that all four of the screws are touching the bench.

5. Verify that the comb, spacer set and Gel Wrap gasket are the same thickness by

assembling without gel casting.

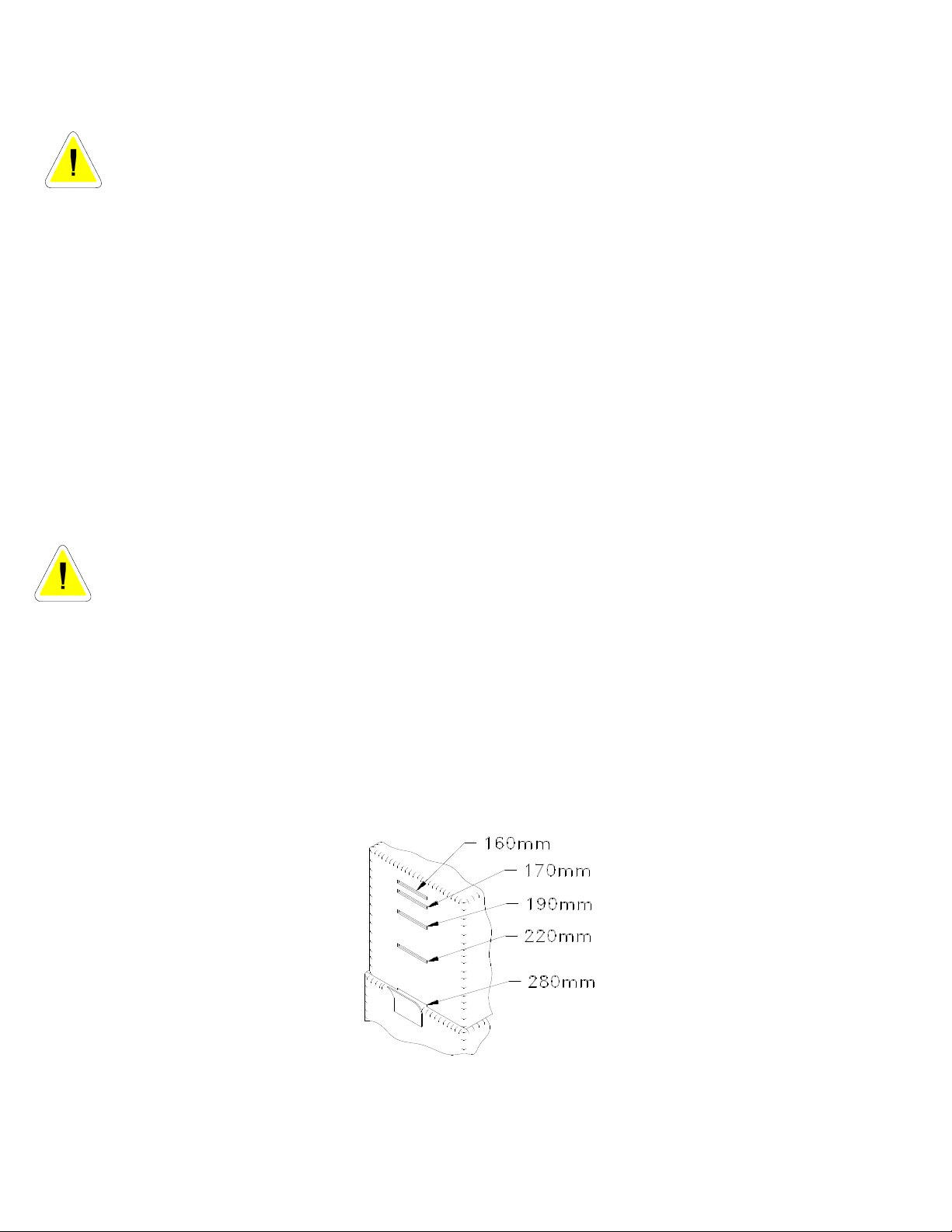

B. Adjustable-Height Safety Cover (European version only).

The safety cover is shipped set at a height corresponding to the 160mm glass plates. To

adjust the cover height:

1. Pull both white handles outward to release tabs.

2. Immediately push up on inner cover with index finger, to increase height, until tab

reaches desired slot. Alternatively, invert both section of the adjustable height safety

cover, pull both white handles outward to release tabs, allowing the inner section to

slide to desired height.

Reminder: For proper safety cover operation, height of upper reservoir notch

must align with the notch in the glass plates. Place a single notched glass

plate (or short plate if using unnothced sets) on to feet in lower reservoir and

adjust upper reservoir until glass and upper reservoir notch are even (see step

3 in Unit Set-up). Secure black thumbscrews. Test fit safety cover before using

system.

www.cbsscientific.com 11 Adjustable Slab Gel Manual 07/13

3.2 Preparation/Cleaning of Glass Plates

Hand wash both plates with a high quality lab detergent followed by a complete rinsing

with dH

2

O. Air dry or use a lint-free tissue. Spray/wipe the chosen inner surfaces of the

plate set with 95% ethanol and dry with lint-free tissue.

3.3 Gel Casting Using Gel Wrap Gasket Casting method

1. Start by holding the rectangular back plate with

the rounded bottom corners and start applying

the gasket around one side of the glass plate.

Note: one side of the “U” shaped gasket is flat,

and the other side has tubing that will act as a

seal around the spacers.

2. When applying the gasket over the rounded

corners of the back glass plate, make sure the

notches on the gasket align with the rounded

corners of the glass plate. Once the gasket is

pushed over the bottom edge and corners, work

it down the remaining side.

3. Place the gasketed plate on the lab bench with

the tubing side up, and extend the bottom of the

plate over the edge of the bench, approximately

¾ of an inch. Place the spacers along side the

inside edges of the gasket. Be sure the rounded

corner end of each spacer is facing the outside

bottom of the plate, following the radius of the

glass.

4. Place the notched plate on top of the bottom

assembly, starting from the bottom edge and

gently easing the plate down. Verify the gasket is

smooth around the edges and then clamp along

the bottom.

www.cbsscientific.com 12 Adjustable Slab Gel Manual 07/13

5. Lift the assembly and stand it on the base of the

clamps. For leveling, push glass plate assembly

down until it stops against clamp body. Clamp

the sides of the assembly with additional casting

clamps on either side. As each clamp is

attached, be sure the gasket is aligned between

the plates forming a seal.

6. Apply PAGE or agarose solution to gel plate sandwich using a syringe or pipette. If

using a stacking gel, pour desired height of running gel, then overlay a small amount

of dH

2

O or 0.1% SDS solution to top of gel. After polymerization, rinse with buffer,

add stacking gel solution and insert comb. For regular, unit percentage gels, add

polyacrylamide solution to correct height, and insert comb. Allow gel to set, usually

20 minutes. Extra gel solution in pipette or syringe can be monitored to test

polymerization of gel mix.

7. Disassembly. Hold the clamped plate

assembly with one hand. Remove the gasket

by starting at one of the top ends and pulling

up and out on the gasket until it releases from

the plate, up to the bottom of each of the

white clamps. When each clamp is reached

DO NOT remove it, instead feed the gasket

down through the clamp body and repeat

pulling up and out. Continue feeding until the

gasket is fully detached. If gel, is not to be

used immediately, wrap entire plate sandwich

with plastic wrap tightly to seal and store at

4°C for up to a month.

www.cbsscientific.com 13 Adjustable Slab Gel Manual 07/13

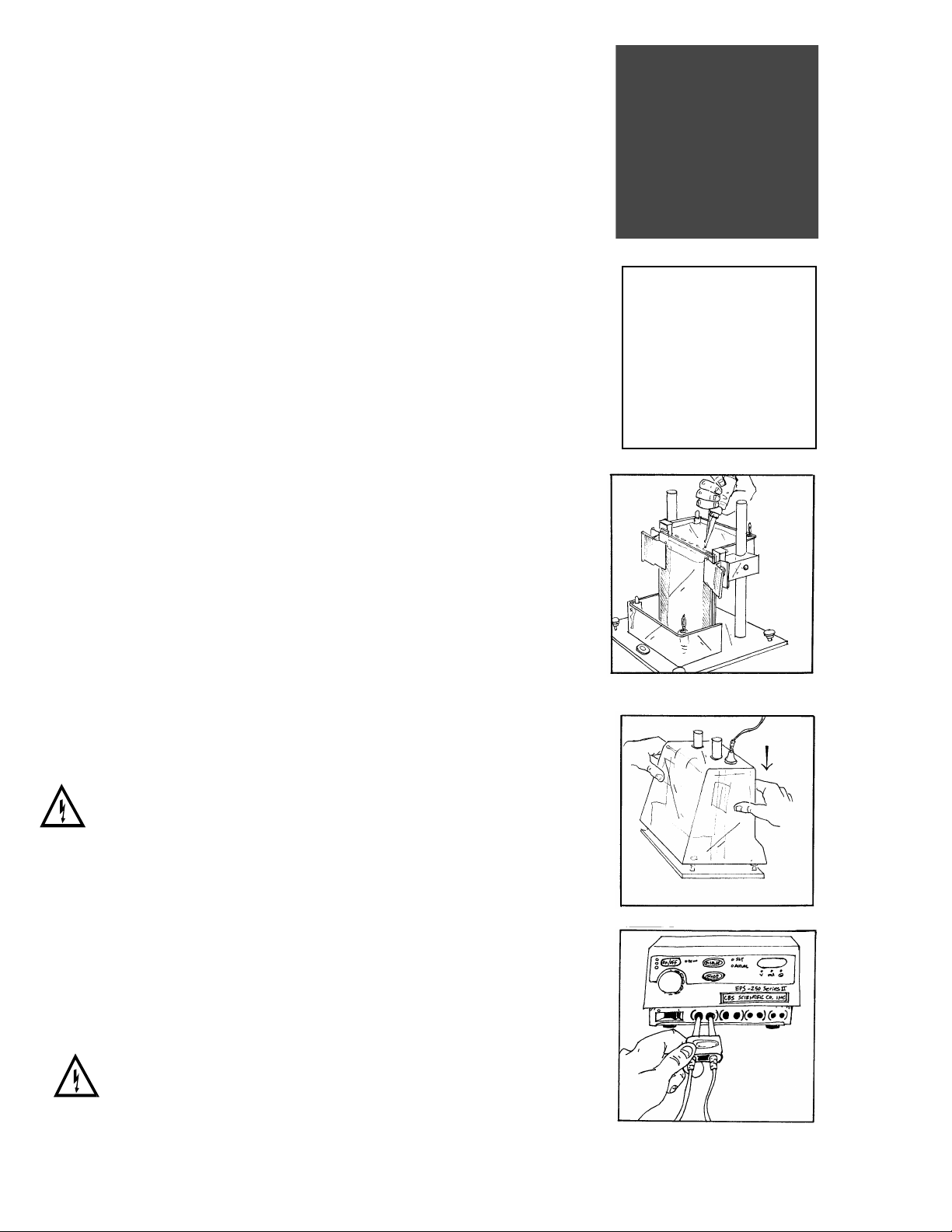

3.4 Running the Gel

1. Attach plate set(s) to unit with

smaller or notched plate facing

towards the upper buffer reservoir. If

using a pre-cast gel stored at 4°C,

allow to warm to room temperature.

Use white clamps with mouth open

(cat. # GPC-0001) to attach plate

set to unit, clamping each side to

the sandwich.

1b. Optional Cooling Plate

Instructions:

If using optional aluminum plate

during electrophoresis place behind

the unit shown in figure at right.

Secure in place with 2 each GPC0001 white clamps (ordered

separately).

2. Pour freshly prepared buffer in

upper and lower chamber. Using a

pipette or syringe, thoroughly flush

out the wells in the glass plate

sandwich with buffer from the upper

chamber. Boil or heat samples and

then place immediately on ice. Load

samples. If outer lanes do not

contain sample, it is recommended

that you run standards (Rainbow™

standards can be monitored easily

during run) and/or fill outer lanes

with loading buffer to reduce smiling

and wrap-around effects.

3. Attach safety cover.

4. Connect the leads to the power

supply, matching the color-coded red

to red and black to black. See

Section 4.1 for recommended

power conditions. Begin

separation by electrophoresis

3.5 Removing the Gel

1. Turn the power supply off and disconnect the leads from the power supply. Remove the

safety cover from the unit, by placing thumbs on white posts next to red & black connectors,

then pushing down while pulling up with fingers under lid. DO NOT pull on power cords.

2. Drain upper reservoir using a pipette or syringe. Detach side clamps and remove gel

sandwich. Carefully separate, making sure that the gel remains attached to one plate. Stain

and fix according to your preferred method. Dispose of buffer according to your institutions

safety requirements.

3.6 Maximum Well/Comb Volumes

NOTE: To calculate sample well volume expressed in millimeters (mm) of height divide

maximum volume by tooth depth.

TABLE 1---Combs

Overall

Length

13cm

Tooth

width/

mm

Tooth

Depth

Spacing

between

teeth

mm

0.75mm

thickness

volume per

tooth

microliters

(ul)

1.0mm

thickness

volume per

tooth

microliters

(ul)

1.5mm

thickness

volume per

tooth

microliters

(ul)

2.0mm

thickness

volume per

tooth

microliters

(ul)

3.0mm

thickness

volume per

tooth

microliters

(ul)

1

130.2

19.1

3.2

1865

2486

3729

4966

7458

2

63.5

19.1

3.2

909

1213

1819

2426

3639

3 equal

41.3

19.1

3.2

591

788

1182

1576

2364

2 w/middle

marker

59.8/

4.2

19.1

3.2

856

1142

1713

2284

3426

4

30.1

19.1

3.2

432

576

1151

1152

1728

5

23.5

19.1

3.2

336

449

673

898

1347

6

19.1

19.1

3.2

273

364

546

728

1092

8

13.5

19.1

3.2

193

257

386

514

771

10

10.1

19.1

3.2

145

194

291

388

582

12

7.9

19.1

3.2

113

151

227

302

453

14

6.4

19.1

3.2

91

121

182

242

363

15

5.7

19.1

3.2

82

109

163

218

327

16

5.2

19.1

3.2

74

98

147

196

294

20

4.2

17.7

2.4

55.72

74.3

111.45

148.7

222.9

29

2.9

17.7

1.6

38.5

51.33

77

102.66

154.0

30

2.8

17.7

1.6

37.2

49.6

74.4

99.12

148.8

www.cbsscientific.com 15 Adjustable Slab Gel Manual 07/13

SECTION 4

Running Conditions

4.1 Recommended Power

Precise electrophoresis conditions will vary according to the number and type of gels used, buffer

conditions employed, power input, and the general goal of the experiment. Refer to the reference

section for in depth discussions on practical and theoretical approaches to protein gel

electrophoresis.

Using standard SDS-PAGE buffer systems apply 1-10 VDC/cm of gel. For sequencing

applications use 50 VDC/cm. If running two gels in the Dual Units, keep the volts the same but

double the mA. It is also true that if the thickness of gel increases, increase the mA

proportionally.

At constant voltage, the proteins will migrate at a constant rate during electrophoresis with

adequate heating appropriate for denaturing gels. Increasing the voltage/mA (for a single gel

thickness and percentage) will speed mobility but increase the risk of overheating.

The sample migration rate can be increased by raising the input power. This can be done son

systems which employ “active” temperature control such as Dual Slab Gel Units and Dual MiniVertical Gel Units. The joule heating generated by the higher input power is offset by the cooling

effect of the water jacket between the gels. Exact conditions should be determined empirically

but could be increased at least in the 20% range.

4.2 Recommended Buffers and Reagents

Pre-mixed acrylamide stock solutions are the method of choice. Use according to manufacturer’s

instructions.

Typical ‘scratch’ recipe for a 4% acrylamide gel:

10mls 40% acrylamide

6.6mls 2% Bis-acrylamide stock

5mls 10X TBE

78.4mls dH

2

0

750ul 10% APS

50ul TEMED

1. Make up 0.5X TBE buffer

2. After gel apparatus is set-up and ready for the gel to be poured, add 750ul

fresh 10% APS solution to the acrylamide solution.

3. Add 5 to 10 ul TEMED and using a 10 to 25ml pipette, quickly “pour” the gel.

4. Allow the gel to polymerize at least 60 minutes.

5. Remove the comb after polymerization and wash out wells with 0.5X TBE

(acrylamide will seep into the wells).

6. Fill upper and lower chambers with 0.5X TBE

7. Pre-electrophorese gel, if needed, 20-30 minutes.

8. Load wells with samples.

9. Monitor migration with dye markers.

www.cbsscientific.com 16 Adjustable Slab Gel Manual 07/13

4.2 Recommended Buffers and Reagents-continued

BUFFERS:

Agarose Page/Agarose Slab

TBE (1X solution):

TAE (1X):

0.089M Tris base 0.04M Tris-acetate

0.89M Boric acid 0.001M EDTA

0.002M EDTA pH 8.0

pH 8.3

Protein Denaturing Denaturing/Non-Denaturing/

TG-SDS(1X):

Nylon Blotting

0.025M Tris base TT (Tris-Taurine( (1X):

TT-SDS (1X):

0.192M Glycine 0.1M Tris base 0.1M Tris base

0.1%(w/v) SDS 0.1M Tricine 0.1M Tricine

pH3 0.1%(w/v) SDS

DNA Sequencing

TTE (Tris/Taurine/EDTA)(1X):

1.78M Tris

0.57M Taurine

0.01M EDTA Na2-2H

2

0

4.3 References

Hames, B.D., Rickwoood, D. (ed.) (1990). Gel Electrophoresis of Proteins. A Practical Approach.

2

nd

edn. IRL Press, Oxford. Ch.1 & 3.

Sambrook, J., Fritsch, E.F., Maniatis, T. (1989). Molecular Cloning. A Laboratory Manual. 2

nd

edn.

Cold Spring Harbor Laboratory Press, Cold Spring Harbor, New

York. 18.47-18.61.

Ausubel, F.M., Brent, R., Kingston, R.E., Moore, D.D., Seidman, J.G., Smith, J.A.,

Struhl, K. (ed)

(1993). Current Protocols in Molecular Biology. Vol. 2, Greene Publishing Associates,

Inc. and John Wiley & Sons, Inc., Ch.10.

www.cbsscientific.com 17 Adjustable Slab Gel Manual 07/13

SECTION 5

Maintenance of Equipment

5.1 Care and Handling

The plastic components of the Adjustable Slab Gel units are fabricated from acrylic, delrin and

polycarbonate. Electrodes and connectors are made from pure platinum, stainless steel, and

chrome plated brass. As with any laboratory instrument, adequate care ensures consistent and

reliable performance.

After each use, rinse buffer chamber, glass plate, spacers and combs with de-ionized water.

Wipe dry with a soft cloth or paper towel, or allow to air dry. Whenever necessary, all

components may be washed gently with water and a non-abrasive detergent, and rinsed and

dried as above. Never use abrasive cleaners, glass cleaning sprays or scouring pads to clean

the components, as these will damage the unit and components.

Additional precautions:

• Do not autoclave or dry-heat sterilize the apparatus or components.

• Do not expose the apparatus or components to phenol, acetone, benzene, halogenated

hydrocarbon solvents or undiluted alcohols.

• Avoid prolonged exposure of the apparatus or components to UV light.

• Do NOT treat with diethylpyrocarbonate (DEPC)-treated water for extended periods at

37°C. A brief rinse with DEPC-water is sufficient after a thorough wash.

5.2 Maintenance

The following inspection and maintenance procedures will help maintain the safety and reliable

performance of the Adjustable Slab Gel systems. Replacement parts can be ordered by calling

1-858-755-4959 or by contacting your local distributor.

• Banana plugs and power cords should be inspected regularly. If the banana plugs

become loose or do not feel friction tight replace the plugs or power cords.

• Should power cord assemblies (connectors, wire or shrouds) show any signs of wear or

damage (e.g. cracks, nicks, abrasions, or melted insulation), replace them immediately.

• The platinum wire is secured to the banana jack by compression between a stainless

washer and the jack nut. The nut/washer interface should be tight and free of corrosion.

www.cbsscientific.com 18 Adjustable Slab Gel Manual 07/13

SECTION 6

Adjustable/Dual Adjustable Slab Gel Kits and Accessories

Cat. # Item

ASG-250 Adjustable Slab Gel Kit, U.S. only. Adjusts from 145mm to 280mm. Includes 1 comb, 1 Gel Wrap

spacer set, 1 Gel Wrap Glass plate set, 1 each Gel Wrap and 8 clamps.

ASG-250-02 Adjustable Slab Gel Kit-CE, adjusts from 160mm to 280mm. Includes 1 comb, 1 Gel Wrap spacer

set, 1 Gel Wrap Glass plate set, 1 each Gel Wrap and 8 clamps.

ASG-400 Adjustable Slab Gel Kit, U.S. only. Adjusts from 145mm to 400mm. Includes 1 comb, 1 Gel Wrap

spacer set, 1 Gel Wrap Glass plate set, 1 each Gel Wrap and 8 clamps..

DASG-250 Dual Adjustable Slab Gel Kit, U.S. only. Adjusts from 145mm to 280mm. Includes 2 combs, 2

Gel Wrap spacer sets, 2 Gel Wrap Glass plate sets, 2 each Gel Wrap and 16 clamps.

DASG-250-02 Dual Adjustable Slab Gel Kit-CE, adjusts from 160mm to 280mm. Includes 2 combs, 2 Gel Wrap

spacer sets, 2 Gel Wrap Glass plate sets, 2 each Gel Wrap and 16 clamps.

DASG-400 Dual Adjustable Slab Gel Kit, U.S. only. Adjusts from 145mm to 400mm. Includes 2 combs, 2

Gel Wrap spacer sets, 2 Gel Wrap Glass plate sets, 2 each Gel Wrap and 16 clamps.

Accessories:

COMBS (Teflon) COMBS (Teflon)

Cat. # Comb dimensions

Cat. # Comb dimensions

VGC-7501 0.75mm x 1 well VGC-2001 2.0mm x 1 well

VGC-7502 0.75mm x 2 well VGC-2002 2.0mm x 2 well

VGC-7503E 0.75mm x 3 equal wells VGC-2003E 2.0mm x 3 equal wells

VGC-7503M 0.75mm x 2 well + middle marker VGC-2003M 2.0mm x 2 well + middle marker

VGC-7504 0.75mm x 4 well VGC-2004 2.0mm x 4 well

VGC-7505 0.75mm x 5 well VGC-2005 2.0mm x 5 well

VGC-7506 0.75mm x 6 well VGC-2006 2.0mm x 6 well

VGC-7508 0.75mm x 8 well VGC-2008 2.0mm x 8 well

VGC-7510 0.75mm x 10 well VGC-2010 2.0mm x 10 well

VGC-7512 0.75mm x 12 well VGC-2012 2.0mm x 12 well

VGC-7514* 0.75mm x 14 well VGC-2014* 2.0mm x 14 well

VGC-7515 0.75mm x 15 well VGC-2015 2.0mm x 15 well

VGC-7516 0.75mm x 16 well VGC-2016 2.0mm x 16 well

VGC-7520 0.75mm x 20 well VGC-2020 2.0mm x 20 well

VGC-7529* 0.75mm x 29 well VGC-2029* 2.0mm x 29 well

VGC-7530 0.75mm x 30 well VGC-2030 2.0mm x 30 well

VGC-1001 1.0mm x 1 well VGC-3001 3.0mm x 1 well

VGC-1002 1.0mm x 2 well VGC-3002 3.0mm x 2 well

VGC-1003E 1.0mm x 3 equal wells VGC-3003E 3.0mm x 3 equal wells

VGC-1003M 1.0mm x 2 well + middle marker VGC-3003M 3.0mm x 2 well + middle marker

VGC-1004 1.0mm x 4 well VGC-3004 3.0mm x 4 well

VGC-1005 1.0mm x 5 well VGC-3005 3.0mm x 5 well

VGC-1006 1.0mm x 6 well VGC-3006 3.0mm x 6 well

VGC-1008 1.0mm x 8 well VGC-3008 3.0mm x 8 well

VGC-1010

1.0mm x 10 well VG

C-3010 3.0mm x 10 well

VGC-1012 1.0mm x 12 well VGC-3012 3.0mm x 12 well

VGC-1014* 1.0mm x 14 well VGC-3014* 3.0mm x 14 well

VGC-1015 1.0mm x 15 well VGC-3015 3.0mm x 15 well

VGC-1016 1.0mm x 16 well VGC-3016 3.0mm x 16 well

VGC-1020 1.0mm x 20 well VGC-3020 3.0mm x 20 well

VGC-1029* 1.0mm x 29 well VGC-3029* 3.0mm x 29 well

VGC-1030 1.0mm x 30 well VGC-3030 3.0mm x 30 well

VGC-1501 1.5mm x 1 well VGC-6001 6.0mm x 1 well

VGC-1502 1.5mm x 2 well VGC-6002 6.0mm x 2 well

VGC-1503E 1.5mm x 3 equal wells VGC-6003E 6.0mm x 3 equal wells

VGC-1503M 1.5mm x 2 well + middle marker VGC-6003M 6.0mm x 2 well + middle marker

VGC-1504 1.5mm x 4 well VGC-6004 6.0mm x 4 well

VGC-1505 1.5mm x 5 well VGC-6005 6.0mm x 5 well

VGC-1506 1.5mm x 6 well VGC-6006 6.0mm x 6 well

VGC-1508 1.5mm x 8 well VGC-6008 6.0mm x 8 well

VGC-1510 1.5mm x 10 well VGC-6010 6.0mm x 10 well

VGC-1512 1.5mm x 12 well VGC-6012 6.0mm x 12 well

VGC-1514* 1.5mm x 14 well VGC-6014 * 6.0mm x 14 well

VGC-1515 1.5mm x 15 well VGC-6015 6.0mm x 15 well

VGC-1516 1.5mm x 16 well VGC-6016 6.0mm x 16 well

VGC-1520 1.5mm x 20 well VGC-6020 6.0mm x 20 well

VGC-1529* 1.5mm x 29 well VGC-6029* 6.0mm x 29 well

VGC-1530 1.5mm x 30 well VGC-6030 6.0mm x 30 well

* Designed for multi-channel pipettor loading.

www.cbsscientific.com 19 Adjustable Slab Gel Manual 07/13

SPACERS for GEL WRAP (PVC) GEL WRAP GASKET

Cat. # Spacer dimensions

Cat. # Gasket thickness x plate size

VGS-0512R 0.50mm x 145mm VGE-0512 0.50mm thick x 145mm

VGS-0516R 0.50mm x 160mm VGE-0516 0.50mm thick x 160mm

VGS-0517R 0.50mm x 170mm VGE-0517 0.50mm thick x 170mm

VGS-0519R 0.50mm x 190mm VGE-0519 0.50mm thick x 190mm

VGS-0520R 0.50mm x 220mm VGE-0520 0.50mm thick x 220mm

VGS-0525R 0.50mm x 280mm VGE-0525 0.50mm thick x 280mm

VGS-0540R 0.50mm x 387mm VGE-0540 0.50mm thick x 387mm

VGS-7512R 0.75mm x 145mm VGE-7512 0.75mm thick x 145mm

VGS-7516R 0.75mm x 160mm VGE-7516 0.75mm thick x 160mm

VGS-7517R 0.75mm x 170mm VGE-7517 0.75mm thick x 170mm

VGS-7519R 0.75mm x 190mm VGE-7519 0.75mm thick x 190mm

VGS-7520R 0.75mm x 220mm VGE-7520 0.75mm thick x 220mm

VGS-7525R 0.75mm x 280mm VGE-7525 0.75mm thick x 280mm

VGS-7540R 0.75mm x 387mm VGE-7540 0.75mm thick x 387mm

VGS-1012R 1.0mm x 145mm VGE-1012 1.0mm thick x 145mm

VGS-1016R 1.0mm x 160mm VGE-1016 1.0mm thick x 160mm

VGS-1017R 1.0mm x 170mm VGE-1017 1.0mm thick x 170mm

VGS-1019R 1.0mm x 190mm VGE-1019 1.0mm thick x 190mm

VGS-1020R 1.0mm x 220mm VGE-1020 1.0mm thick x 220mm

VGS-1040R 1.0mm x 387mm VGE-1040 1.0mm thick x 387mm

VGS-1512R 1.5mm x 145mm VGE-1512 1.5mm thick x 145mm

VGS-1516R 1.5mm x 160mm VGE-1516 1.5mm thick x 160mm

VGS-1517R 1.5mm x 170mm VGE-1517 1.5mm thick x 170mm

VGS-1519R 1.5mm x 190mm VGE-1519 1.5mm thick x 190mm

VGS-1520R 1.5mm x 220mm VGE-

1520 1.

5mm thick x 220mm

VGS-1525R 1.5mm x 280mm VGE-1525 1.5mm thick x 280mm

VGS-1540R 1.5mm x 387mm VGE-1540 1.5mm thick x 387mm

VGS-2012R 2.0mm x 145mm VGE-2012 2.0mm thick x 145mm

VGS-2016R 2.0mm x 160mm VGE-2016 2.0mm thick x 160mm

VGS-2017R 2.0mm x 170mm VGE-2017 2.0mm thick x 170mm

VGS-2019R 2.0mm x 190mm VGE-2019 2.0mm thick x 190mm

VGS-2020R 2.0mm x 220mm VGE-2020 2.0mm thick x 220mm

VGS-2025R 2.0mm x 280mm VGE-2025 2.0mm thick x 280mm

VGS-2040R 2.0mm x 387mm VGE-2040 2.0mm thick x 387mm

VGS-3012R 3.0mm x 145mm VGE-3012 3.0mm thick x 145mm

VGS-3016R 3.0mm x 160mm VGE-3016 3.0mm thick x 160mm

VGS-3017R 3.0mm x 170mm VGE-3017 3.0mm thick x 170mm

VGS-3019R 3.0mm x 190mm VGE-3019 3.0mm thick x 190mm

VGS-3020R 3.0mm x 220mm VGE-3020 3.0mm thick x 220mm

VGS-3025R 3.0mm x 280mm VGE-3025 3.0mm thick x 280mm

VGS-3040R 3.0mm x 387mm VGE-3040 3.0mm thick x 400mm

VGS-6012R 6.0mm x 145mm VGE-6012 6.0mm thick x 145mm

VGS-6016R 6.0mm x 160mm

VGS-6017R 6.0mm x 170mm

VGS-6019R 6.0mm x 190mm

VGS-6020R 6.0mm x 220mm

VGS-6025R 6.0mm x 280mm

VGS-6040R 6.0mm x 387mm

(2 sides with rounded corners, no bottom)

SILICONE TUBING* BULK GEL WRAP GASKET*

Cat. # Gel Thickness

Cat. # Gel Thickness

ST-0500 0.5mm VGE-05XX 0.5mm thick - yellow

ST-7500 0.75mm VGE-75XX 0.75mm thick - yellow

ST-1000 1.0mm VGE-10XX 1.0mm thick - red

ST-1500 1.5mm VGE-15XX 1.5mm thick - blue

ST-2000 2.0mm VGE-20XX 2.0mm thick - purple

ST-3000 3.0mm VGE-30XX 3.0mm thick - white

*Order by the foot *Order by the foot

GEL WRAP GLASS PLATE SETS, NOTCHED* GLASS PLATE SETS, NOTCHED & BEVELED*

(1/8” back plate with rounded corners) (1/8” back plate with rounded corners)

Cat. # Glass Plate dimensions (w x h)

Cat. # Glass Plate dimensions (w x h)

NGP-125NR 16.5cm x 145mm NGP-125BR 16.5cm x 145mm

NGP-160NR 16.5cm x 160mm NGP-160BR 16.5cm x 160mm

NGP-170NR 16.5cm x 170mm NGP-170BR 16.5cm x 170mm

NGP-190NR 16.5cm x 190mm NGP-190BR 16.5cm x 190mm

NGP-200NR 16.5cm x 220mm NGP-200BR 16.5cm x 220mm

NGP-250NR 16.5cm x 280mm NGP-250BR 16.5cm x 280mm

NGP-400NR 16.5cm x 387mm NGP-400BR 16.5cm x 400mm

* Glass plate ordering options: To order an unnotched plate set and add a “UN” to the end of the catalog # (rubber ears included). Note: Although

glass plates are listed as sets, individual pieces can be ordered. To order a notched only plate, add a “-NO” to the end of the cat. #. To order a back

only (rectangular) plate, add a “-BO” to the end of the cat. #. To order Low fluorescence borosilicate plate sets add “-LFP” to end of cat. #.

www.cbsscientific.com 20 Adjustable Slab Gel Manual 07/13

STANDARD GLASS PLATE SETS, NOTCHED* GLASS PLATE SETS, NOTCHED & BEVELED*

For 2-dimensional gels

Cat. # Glass Plate dimensions (w x h) Cat. # Glass Plate dimensions (w x h)

NGP-125N 16.5cm x 145mm NGP-125B 16.5cm x 145mm

NGP-160N 16.5cm x 160mm NGP-160B 16.5cm x 160mm

NGP-170N 16.5cm x 170mm NGP-170B 16.5cm x 170mm

NGP-190N 16.5cm x 190mm NGP-190B 16.5cm x 190mm

NGP-200N 16.5cm x 220mm NGP-200B 16.5cm x 220mm

NGP-250N 16.5cm x 280mm NGP-250B 16.5cm x 280mm

NGP-400N 16.5cm x 387mm NGP-400B 16.5cm x 387mm

* Glass plate ordering options: To order an unnotched plate set and add a “UN” to the end of the catalog # (rubber ears included). Note: Although

glass plates are listed as sets, individual pieces can be ordered. To order a notched only plate, add a “-NO” to the end of the cat. #. To order a back

only (rectangular) plate, add a “-BO” to the end of the cat. #. To order Low fluorescence borosilicate plate sets add “-LFP” to end of cat. #.

ALUMINUM HEAT DISPERSION PLATES

Cat. # Plate Dimensions

CPA165-200 For use with NGP-200

CPA165-250 For use with NGP-250

CPA165-400 For use with NGP-400

COMBS (Polycarbonate) COMBS (Polycarbonate)

Cat. # Comb dimensions

Cat. # Comb dimensions

VGC-0201 0.2mm x 1 well VGC-0401 0.4mm x 1 well

VGC-0202 0.2mm x 2 well VGC-0402 0.4mm x 2 well

VGC-0203E 0.2mm x 3 equal wells VGC-0403E 0.4mm x 3 equal wells

VGC-0203M 0.2mm x 2 well + middle marker VGC-0403M 0.4mm x 2 well + middle marker

VGC-0204 0.2mm x 4 well VGC-0404 0.4mm x 4 well

VGC-0205 0.2m x 5 well VGC-0405 0.4mm x 5 well

VGC-0206 0.2mm x 6 well VGC-0406 0.4mm x 6 well

VGC-0208 0.2mm x 8 well VGC-0408 0.4mm x 8 well

VGC-0210 0.2mm x 10 well VGC-0410 0.4mm x 10 well

VGC-0212 0.2mm x 12 well VGC-0412 0.4mm x 12 well

VGC-0214* 0.2mm x 14 well VGC-0414* 0.4mm x 14 well

VGC-0215 0.2mm x 15 well VGC-0415 0.4mm x 15 well

VGC-0216 0.2mm x 16 well VGC-0416 0.4mm x 16 well

VGC-0220 0.2mm x 20 well VGC-0420 0.4mm x 20 well

VGC-0229* 0.2mm x 29 well VGC-0429* 0.4mm x 29 well

VGC-0230 0.2mm x 30 well VGC-0430 0.4mm x 30 well

VGC-0501 0.5mm x 1 well

VGC-0502 0.5mm x 2 well

VGC-0503E 0.5mm x 3 equal wells

VGC-0503M 0.5mm x 2 well + middle marker

VGC-0504 0.5mm x 4 well

VGC-0505 0.5mm x 5 well

VGC-0506 0.5mm x 6 well

VGC-0508 0.5mm x 8 well

VGC-0510 0.5mm x 10 well

VGC-0512 0.5mm x 12 well

VGC-0514 * 0.5mm x 14 well

VGC-0515 0.5mm x 15 well

VGC-0516 0.5mm x 16 well

VGC-0520 0.5mm x 20 well

VG

C-0529* 0.5mm x 29 well

VGC-0530 0.5mm x 30 well

SHARKTOOTH COMBS SEQUENCING SPACER SETS (Polycarbonate)

Cat. # Comb dimensions

Cat. # Comb dimensions

SK16.5-0201 0.2mm x 1 well VGS-0216 0.2mm x 160mm

SK16.5-0220 0.2mm x 20 well VGS-0217 0.2mm x 170mm

SK16.5-0226* 0.2mm x 26 well VGS-0219 0.2mm x 190mm

SK16.5-0230 0.2mm x 30 well VGS-0220 0.2mm x 220mm

SK16.5-0242* 0.2mm x 42 well VGS-0225 0.2mm x 280mm

SK16.5-0258* 0.2mm x 58 well VGS-0240 0.2mm x 387mm

SK16.5-0401 0.4mm x 1 well VGS-0416 0.4mm x 160mm

SK16.5-0420 0.4mm x 20 well VGS-0417 0.4mm x 170mm

SK16.5-0426* 0.4mm x 26 well VGS-0419 0.4mm x 190mm

SK16.5-0430 0.4mm x 30 well VGS-0420 0.4mm x 220mm

SK16.5-0442* 0.4mm x 42 well VGS-0425 0.4mm x 280mm

SK16.5-0458* 0.4mm x 58 well VGS-0440 0.4mm x 387mm

SK16.5-0501 0.5mm x 1 well VGS-0516 0.5mm x 160mm

SK16.5-0520 0.5mm x 20 well VGS-0517 0.5mm x 170mm

SK16.5-0526* 0.5mm x 26 well VGS-0519 0.5mm x 190mm

SK16.5-0530 0.5mm x 30 well VGS-0520 0.5mm x 220mm

SK16.5-0542* 0.5mm x 42 well VGS-0525 0.5mm x 280mm

SK16.5-0558* 0.5mm x 58 well VGS-0540 0.5mm x 387mm

*Designed for multi-channel pipettor loading

www.cbsscientific.com 21 Adjustable Slab Gel Manual 07/13

ADDITIONAL VERTICAL GEL ACCESSORIES:

BAR CLAMP SILICONE CORD REPAIR KIT

Cat. # Item Cat. # Item

GPC-1650 Bar clamp for 16.5cm wide units SCK-500 Kit for Sequencing and Slab Gel Units

MULTIPLE GEL CASTING CHAMBERS

Cat. # Item

GCC-404 Multiple Vertical Gel Casting chamber, casts up to 4 gels simultaneously

GCC-410 Multiple Vertical Gel Casting chamber, casts up to 10 gels simultaneously

GEL CASTING STAND

Cat. # Item

GCS-250 Gel Casting Stand, includes stand with leveling base and 4 clamps

RUBBER EARS

Cat. # Item

VFR-1000 Adhesive rubber ears for unnotched glass plate sets

WHITE CLAMPS

Cat. # Item

GPC-0004 Large capacity, multi-task white clamp

GPC-0002 Casting clamp, jaws closed in resting position

GPC-0001 Large white clamp, jaws slightly open in resting position

POWER SUPPLY

Cat. # Item

EPS-300-II Mini Power Supply, with timer, CV or CC, 10-300V, 110V/60Hz, current range:4-500mA, 90 watts

EPS-300-IIV Mini Power Supply, with timer, CV or CC, 10-300V, 220V/50Hz, current range:4-500mA, 90 watts

EPS-3000-III Constant Power Supply, 0-3000 Volt, 110V/60Hz, Series II

EPS-3000-IIV Constant Power Supply, 0-3000 Volt, 220V/50Hz, Series II

NOTES

NOTES

CONTACT US

Telephone:

Local or International

858-755-4959

Toll Free: 800-243-4959

Fax: 858-755-0733

Check out our new and

improved online ordering!

www.cbsscientific.com

E-mail address:

sales@cbssci.com

Mailing address:

C.B.S. Scientific Company

P.O. Box 856

Del Mar, CA 92014

Shipping address:

C.B.S. Scientific Company

10805 Vista Sorrento Pkwy

Suite 100

San Diego, CA 92121

Credit Card Options:

Visa/Mastercard

Discover/American Express

Loading...

Loading...