Page 1

CATEYE ERGOCISER

AUTOMATIC TYPE

Applicable Models: EC-1200/EC-1600/EC-3600/EC-3700

SERVICE MANUAL

Page 2

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

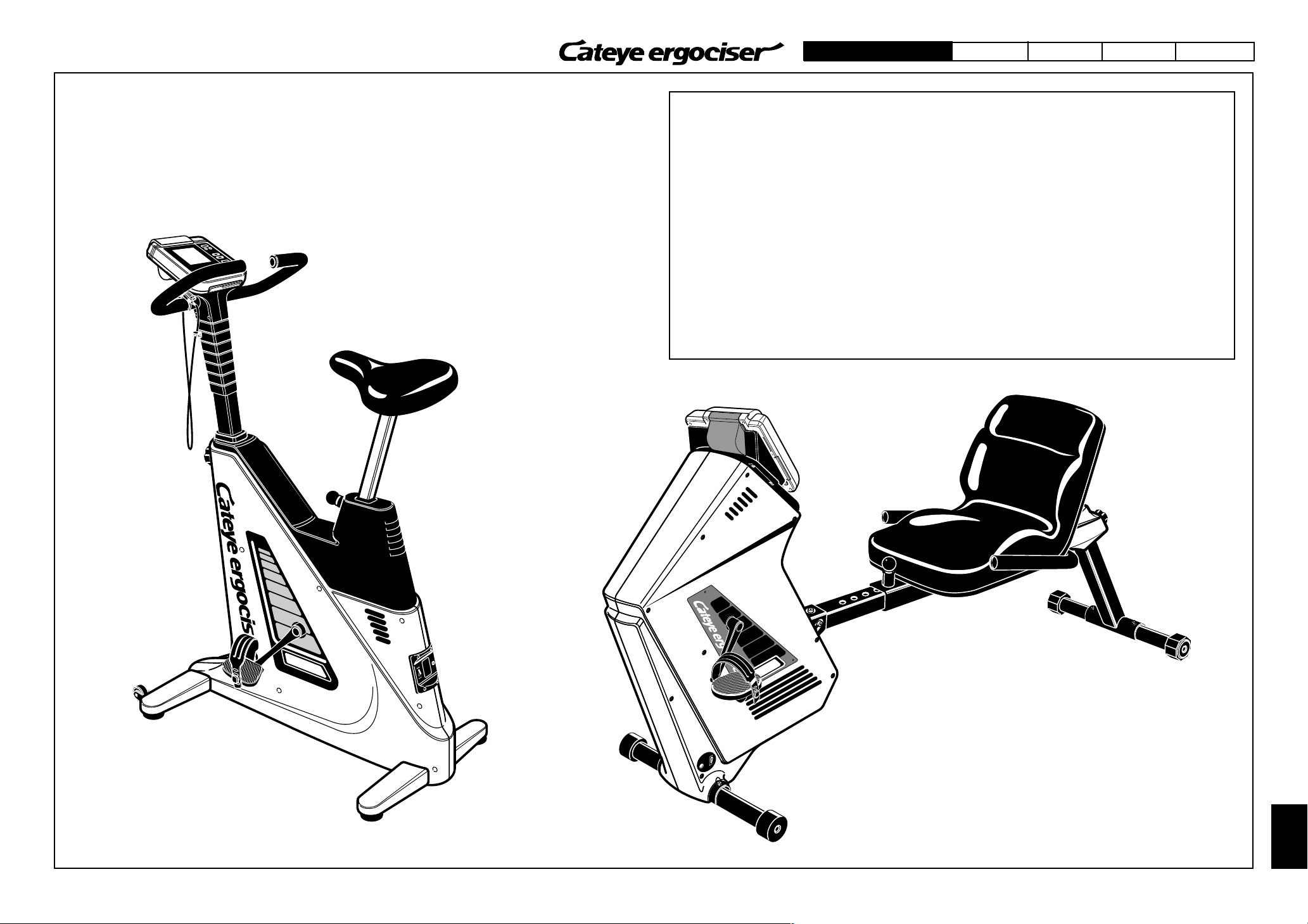

INDEX

INDEX

INTRODUCTION

• How to Use This Service Manual

• Name of Parts

1. Upright Type (w/o Flywheel)---------------------------------------------------------- 4~5

Upright Type (with Flywheel)--------------------------------------------------------- 6~7

2. Recumbent Type (EC-3600 & EC-3700) ------------------------------------------- 8~9

3. Belt Drive (EC-1200B, EC-1600B, EC-3600B & EC-3700B) ----------ADD.1~2

• Circuit Diagram----------------------------------------------------------------------------------10

Part A

Symptoms of Problems & Causes

T-1: No Display on Control Unit after Power ON-----------------------------------11~12

T-2: No Display of Cadence --------------------------------------------------------------------13

T-3: No Display of Pulse Rate ----------------------------------------------------------------- 14

T-4: No Printer Operation -----------------------------------------------------------------------15

T-5: No Loading -------------------------------------------------------------------------------16~17

T-6: No Pedal Rotation (Locked) -------------------------------------------------------------18

T-7: Unusual Noise

1. Continuous and Increasing. ------------------------------------------------------- 19

2. Periodical.--------------------------------------------------------------------------------20

3. Noise occurs when the pedal is rotated with a large loading. ---------21

Part B

Removing the Frame Covers

D-1: Upright Type (EC-1200 & EC-1600)----------------------------------------------------22

D-2: Recumbent Type (EC-3600 & EC-3700) ----------------------------------------------23

Repair & Adjustment Methods

EC-1200 EC-1600 EC-3600 EC-3700

ES-1: Replacing the Wiring within the Frame ----------------------- 24

ES-2: Replacing the 5P Cable ---------------------------------------25~26

ES-3: Replacing the Power Supply Board---------------------------- 27

ES-4: Correcting the Position of Solenoid Coil--------------------- 28

ES-5: Replacing the CDC Sensor --------------------------------------- 29

- - ES-6: Replacing the Panel Keyboard ---------------------------------- 30

- - ES-7: Replacing the Button Panel -------------------------------------- 31

- - ES-8: Replacing the Printer ----------------------------------------------- 32

- - ES-9: Adjusting the Printing Darkness-------------------------------- 33

- - ES-10: Paper Jamming in Printer -----------------------------------------24

- - MS-1: Replacing the Workload Unit (w/o Flywheel) ----------35~37

G MS-2: Replacing the Workload Unit (w/ Flywheel) --------------- 38

- - MS-3: Adjusting the Flywheel--------------------------------------------- 39

MS-4: Replacing the Chain------------------------------------------------- 40

MS-5: Replacing the Free Wheel Set ----------------------------------- 41

MS-6: Replacing the Derailleur Set-------------------------------------- 42

MS-7: Replacing the Idler Set --------------------------------------------- 43

MS-8: Replacing the Crank Set -------------------------------------- 44~45

MS-9: Replacing the BB Set ----------------------------------------------- 46

- - MS-10: Replacing the Post Spacer---------------------------------------- 47

- - MS-11: Adjusting the Spacer Spring ------------------------------------- 48

- - MS-12: Replacing the Inner Pipe Spacer-------------------------------- 49

- - MS-13: Replacing the Vertical Pipe Spacer ---------------------------- 50

- - MS-14: Replacing the Leg Cover ------------------------------------------ 51

- - MS-15: Replacing the Caster/Level Adjuster -------------------------- 52

- - MS-16: Replacing the Seat Post Knob----------------------------------- 53

- - MS-17: Replacing the Lock Pin -------------------------------------------- 54

MS-18: Replacing the Crank Cover --------------------------------------- 55

- - MS-19: Replacing the Center Cover of Upright Type --------------- 56

- - MS-20: Replacing the Center Cover of Recumbent Type --------- 57

MS-21: Replacing the Handlebar Grip ----------------------------------- 58

- - MS-22: Replacing the Printer Cover -------------------------------------- 59

- - MS-23: Replacing the Paper Cutter --------------------------------------- 60

PART C

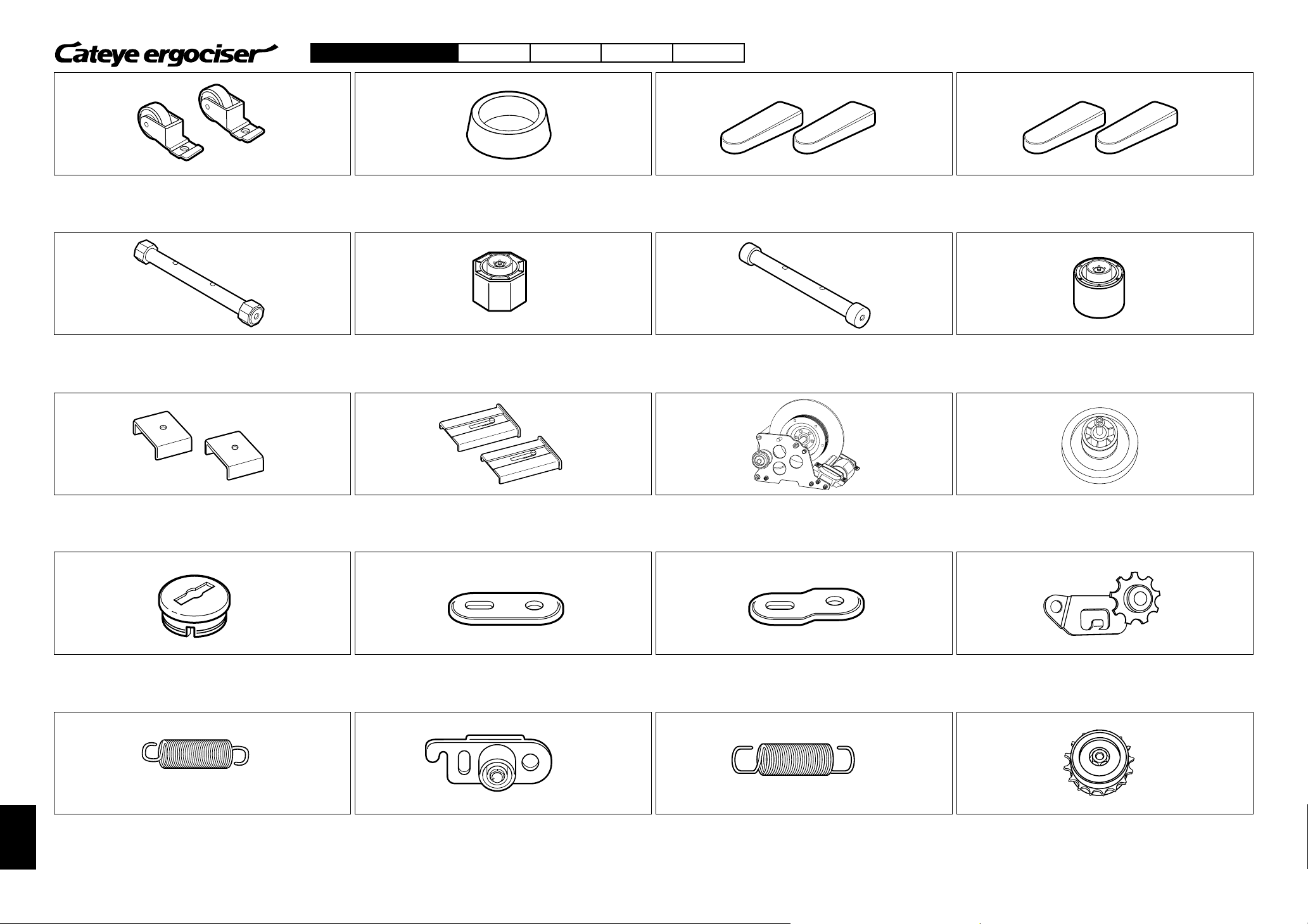

List of Genuine Parts -------------------------------------------------------------------------------------------- 61~65

Cateye Ergociser Series 1000 Service Manual

2

Page 3

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

How to Use This Service Manual

The manual consists of Part A, Part B and Part C. Part A refers to trouble-shooting which allows you

to identify the cause and areas to be fixed depending on typical symptoms. Part B shows how to

repair and/or adjust specific defects. This part consists of repair methods for electrical parts [ES]

and those for mechanical parts [MS].

Part C lists up all genuine parts and corresponding part numbers that will be necessary for

replacement or stock

T

E

S

E

R

E

D

O

M

V

D

A

Whenever any problem has occurred on the main unit, take the following actions to repair or adjust it.

1. Check and identify the cause by referring to Part A.

2. Identify the parts name by referring to Name of Parts.

3. Perform repair or adjustment in accordance with the instructions in Part B.

4. Replacement, if required, should be done by using genuine parts as specified in Part C.

EC-1600

N

O

F

F

O

00

7

R

EC-3

How to Use This Service Manual

Cateye Ergociser Series 1000 Service Manual

3

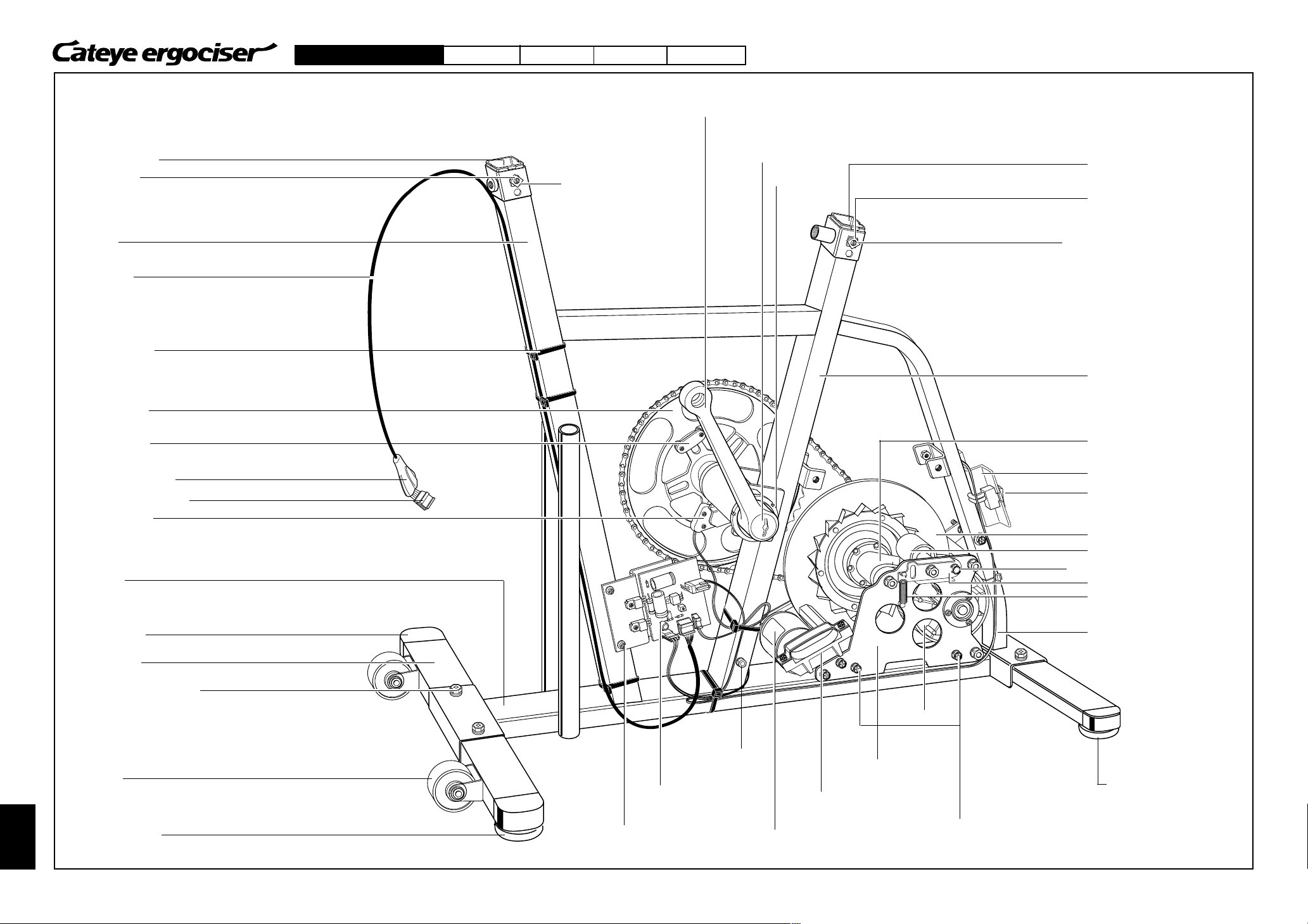

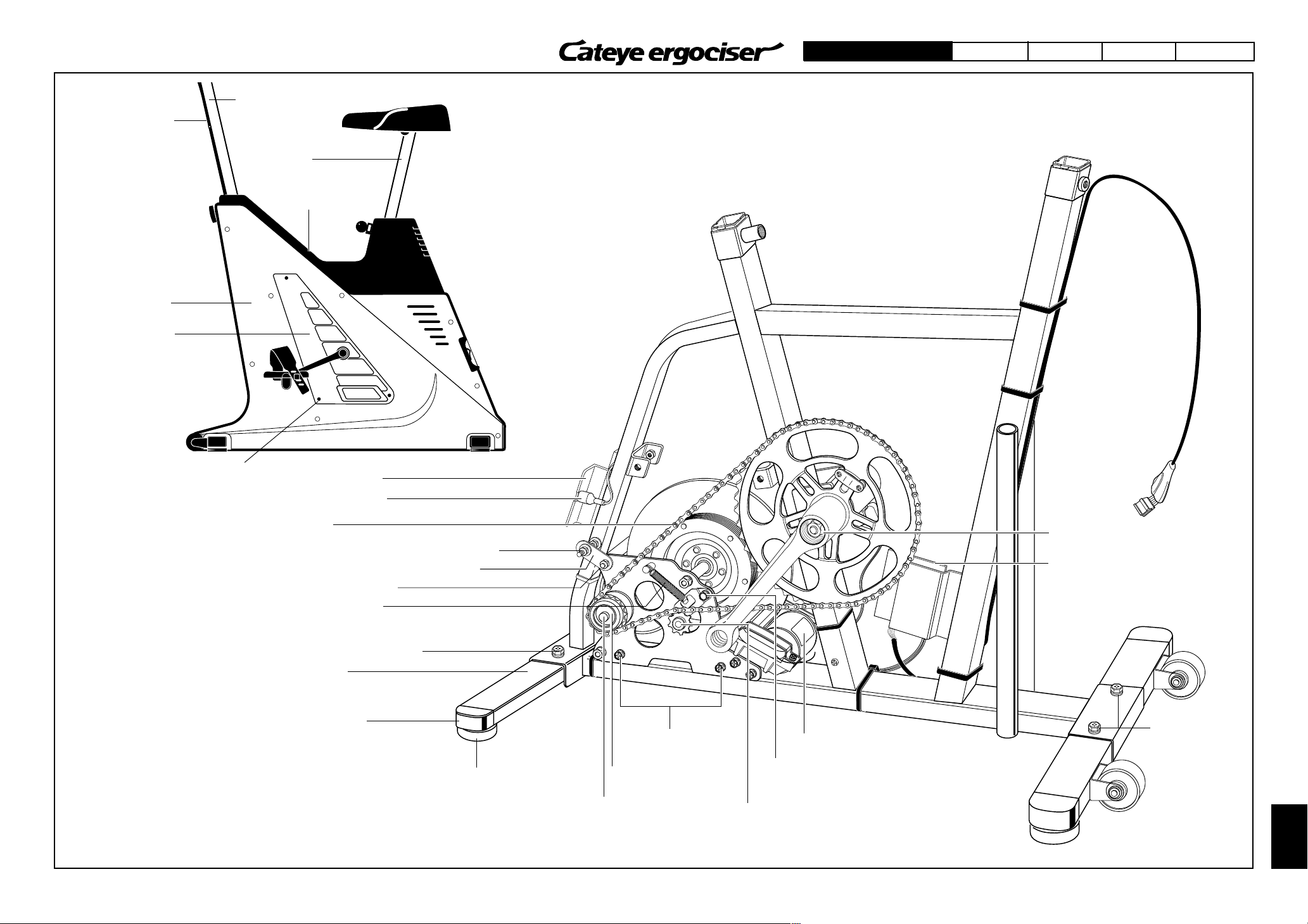

Page 4

Applicable Models:

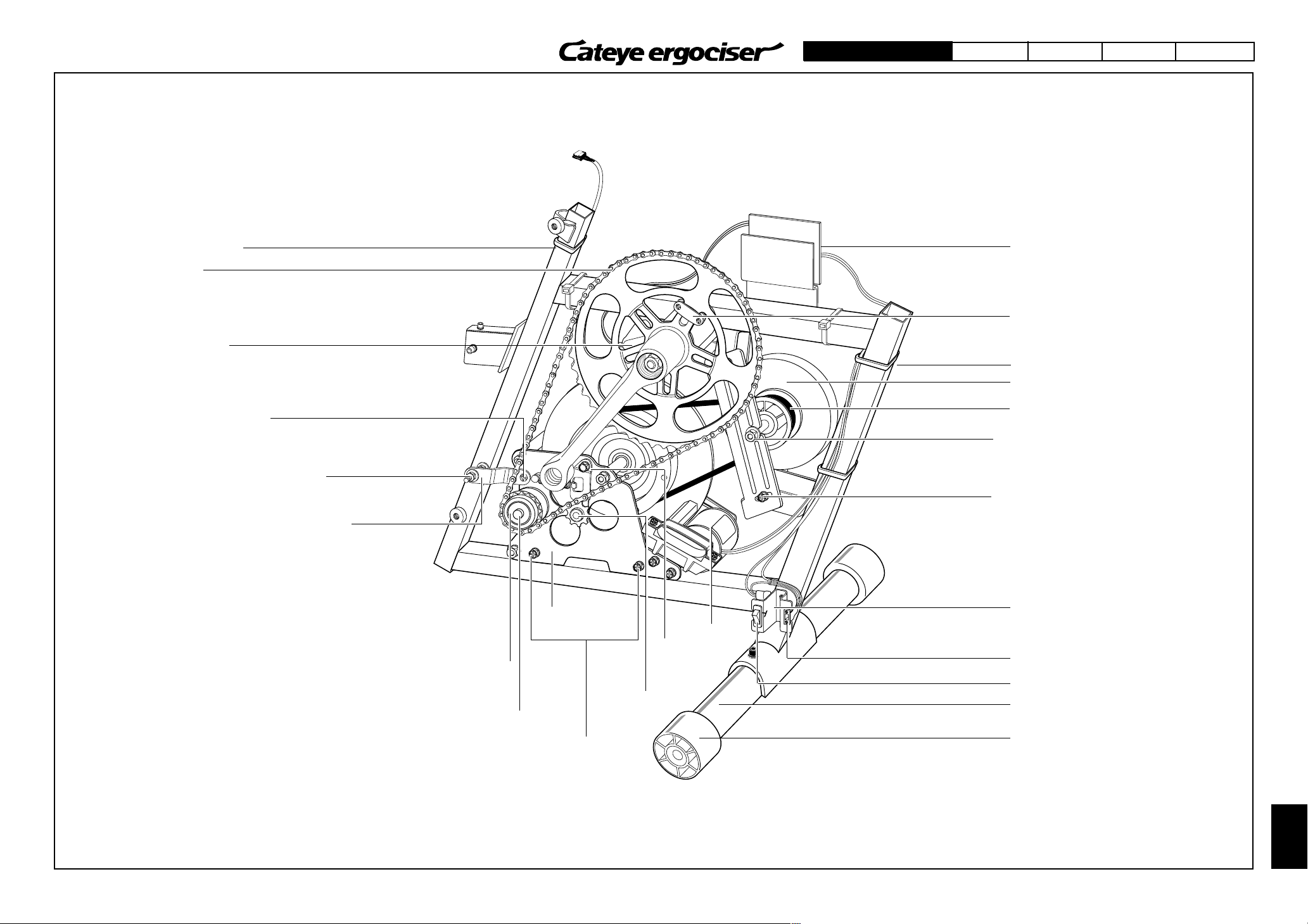

Name of Parts for Upright Type (w/o Flywheel)

EC-1200 EC-1600 EC-3600 EC-3700

Crank

Post Spacer

Lock Nut

Frame

5P Cable

Cable Holder

Large Gear

CDC Magnet

Connector Cover

5P Cable Connector

CDC Sensor

Frame

Adjust Screw

9

Spacer Spring

6

Crank Cap

BB Set

Post Spacer

Lock Nut

Adjust Screw

9

Spacer Spring

6

Seat Pipe

Timing Belt

Inlet Metal Base

Power Switch

Copper Plate

Idler

Idler Fixing Bolt [M6x16]

8

Idler Metal Base

Idler Spring

Leg Cover

Leg Pipe

Leg Pipe Fixing Screw

Caster

Name of Parts for Upright Type (w/o Flywheel)

Levelling Knob

Cateye Ergociser Series 1000 Service Manual

4

q

Power Supply Board

Power Supply Board Fixing Screw

0

[Tapping Screw(2) 4x12c]

SW Nut (M6)

Workload Unit

Solenoid Coil Mounting Base

Solenoid Coil

Plastic Pulley

Workload Unit Mounting Base

4

[Screw Set (+) (M6x16)]

Wiring within Frame

Levelling Knob

Page 5

Cable Holder

Frame Cover

Crank Cover

Handlebar Post

Seat Post

Center Cover

EC-1200

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

5

Tapping Screw (4x12) with Washer

Inlet Metal Base

AC Adapter Inlet

Chain

Workload Unit Reinforcing Metal Base Nut

2

Workload Unit Reinforcing Metal Base

Hexagon Nut (M8-3)

1

Derailleur Spring

Leg Pipe Fixing Screw

Leg Pipe

Lever Cover

Levelling Knob

4

Free Wheel Set

Hexagon Head U Nut

Workload Unit

Fixing Bolt

Derailleur Mounting Bolt

Thrust Washer (9x15.5x0.25)

3

Derailleur

Solenoid Coil

Crank Nut

9

Power Supply Board

4

Screw Set(+) (M6x16)

Name of Parts for Upright Type (w/o Flywheel)

Cateye Ergociser Series 1000 Service Manual

5

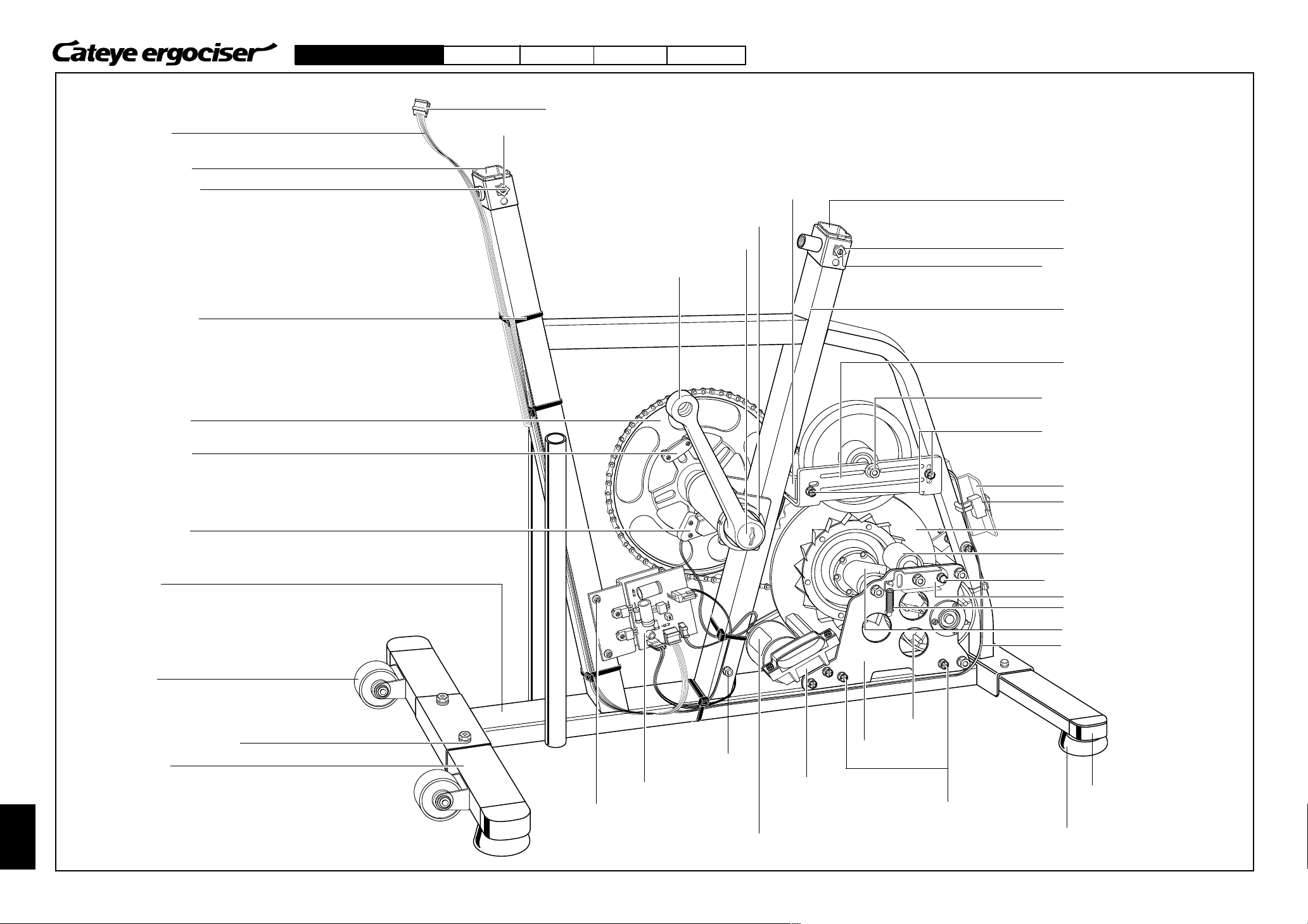

Page 6

Applicable Models:

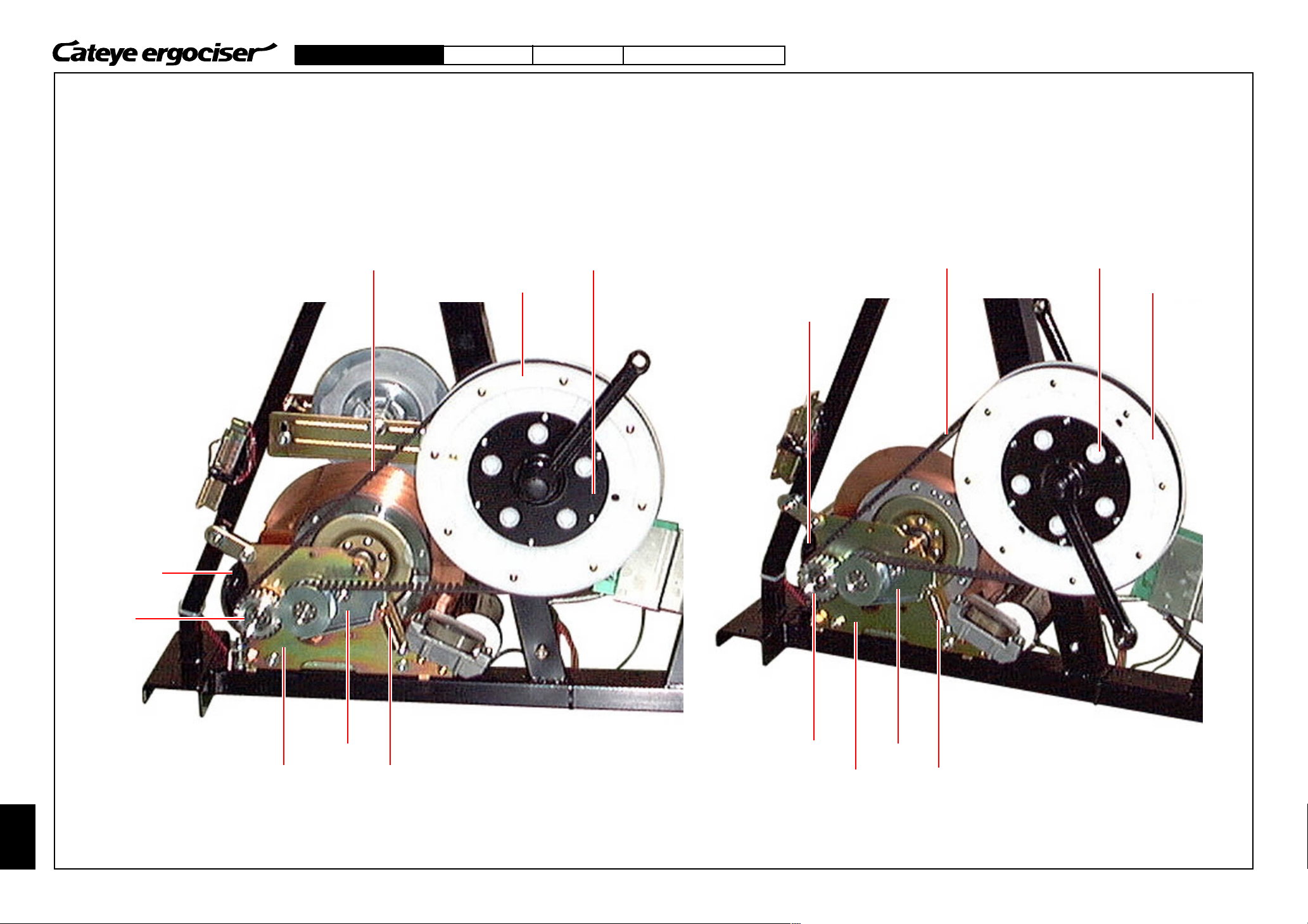

Name of Parts for Upright Type (w/ Flywheel)

5P Cable

Post Spacer

EC-1200 EC-1600 EC-3600 EC-3700

5P Cable Connector

Lock Nut

Adjust Screw

Cable Holder

Large Gear

CDC Magnet

CDC Sensor

Flywheel Mounting Metal Base

BB Set

Crank Cap

Crank

Post Spacer

Lock Nut

9

Adjust Screw [M8x10]

Spacer Spring

6

Seat Pipe

Flywheel Metal

Flywheel Fixing Screw [SW Nut(M6)]

q

Flywheel Metal Base Fixing Screw

4

[Screw Set (+) (M6x16)]

Inlet Metal Base

Power Switch

Copper Plate

Idler

Frame

Caster

Leg Pipe Fixing Screw

Leg Pipe

Name of Parts for Upright Type (w/ Flywheel)

Cateye Ergociser Series 1000 Service Manual

6

SW Nut (M6)

q

0

Power Supply Board Fixing Screw

[Tapping Screw(2) 4x12c]

Power Supply Board

Solenoid Coil Mounting Base

Solenoid Coil

Plastic Pulley

Workload Unit

Workload Unit Mounting Base

4

[Screw Set (+) (M6x16)]

Idler Mounting Bolt [M6x16]

4

Idler Metal Base

Idler Spring

Timing Belt

Wiring within Frame

Leg Pipe

Levelling Knob

Page 7

Flywheel

Flywheel Fixing Screw

Flywheel Mounting Metal Base

Power Supply Board

Applicable Models:

Frame Cover

Crank Cover

CDC Magnet

EC-1200 EC-1600 EC-3600 EC-3700

Handlebar Post Cover

Seat Post

Center Cover

Flywheel Metal Base Fixing Screw

Flywheel Metal Base

AC Adapter Inlet

Inlet Metal Base

Plain Belt

Chain

Workload Unit Reinforcing Nut

2

[Hexagon Nut (M6-3)]

Workload Unit Reinforcing Metal Base

Hexagon Nut (M8-3)

1

Hexagon Head U Nut

Free Wheel Set

Derailleur

Spring

Workload Unit

Workload Unit Mounting

4

Bolt (M6x16)

Derailleur

Solenoid Coil

Derailleur Mounting Bolt

Thrust Washer (9x15.5x0.25)

3

Crank Nut (M10x1.25)

7

5

Screw Set(+) (M6x16)

4

Tapping Screw (4x12) with Washer

Name of Parts for Upright Type (w/ Flywheel)

Cateye Ergociser Series 1000 Service Manual

7

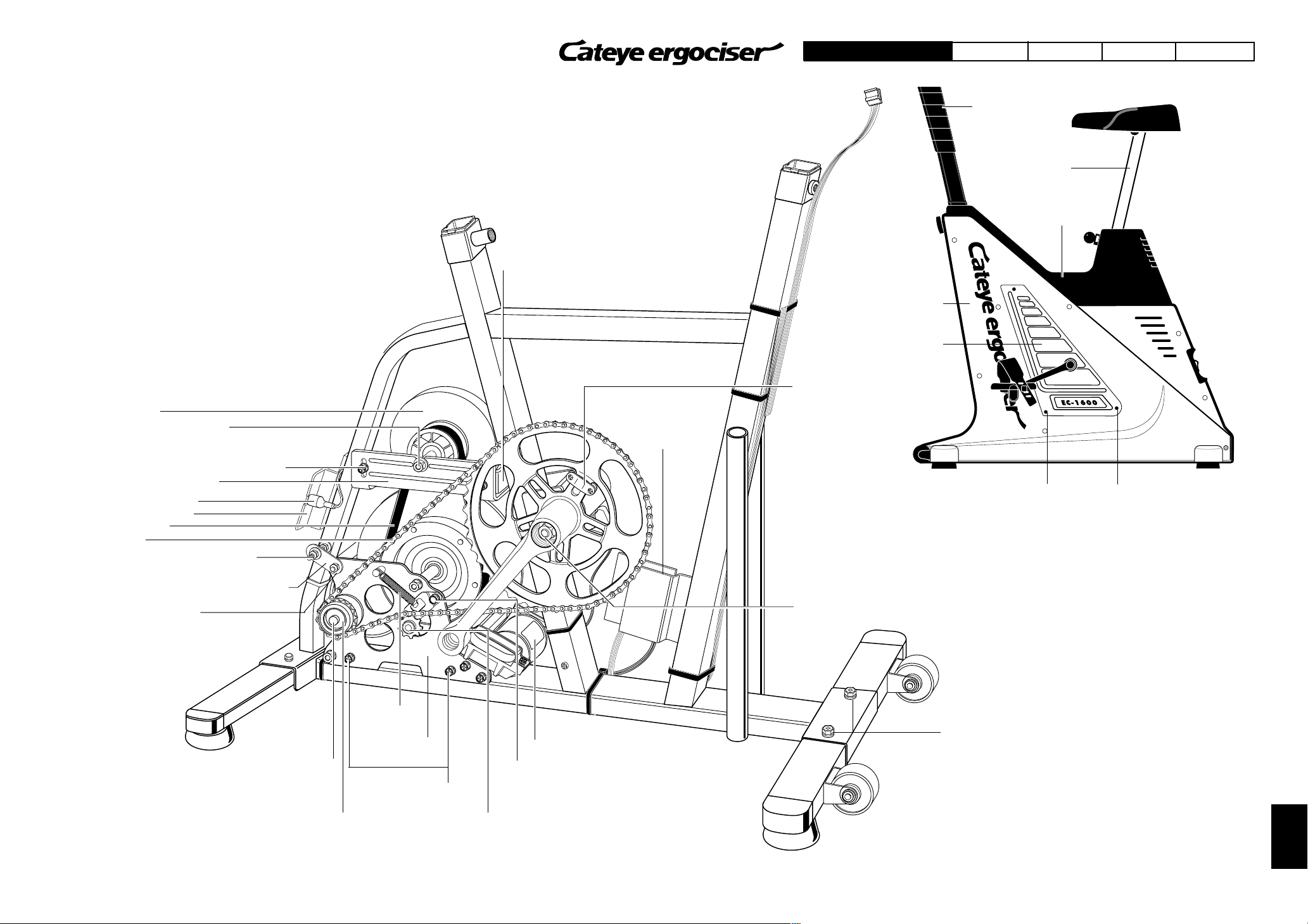

Page 8

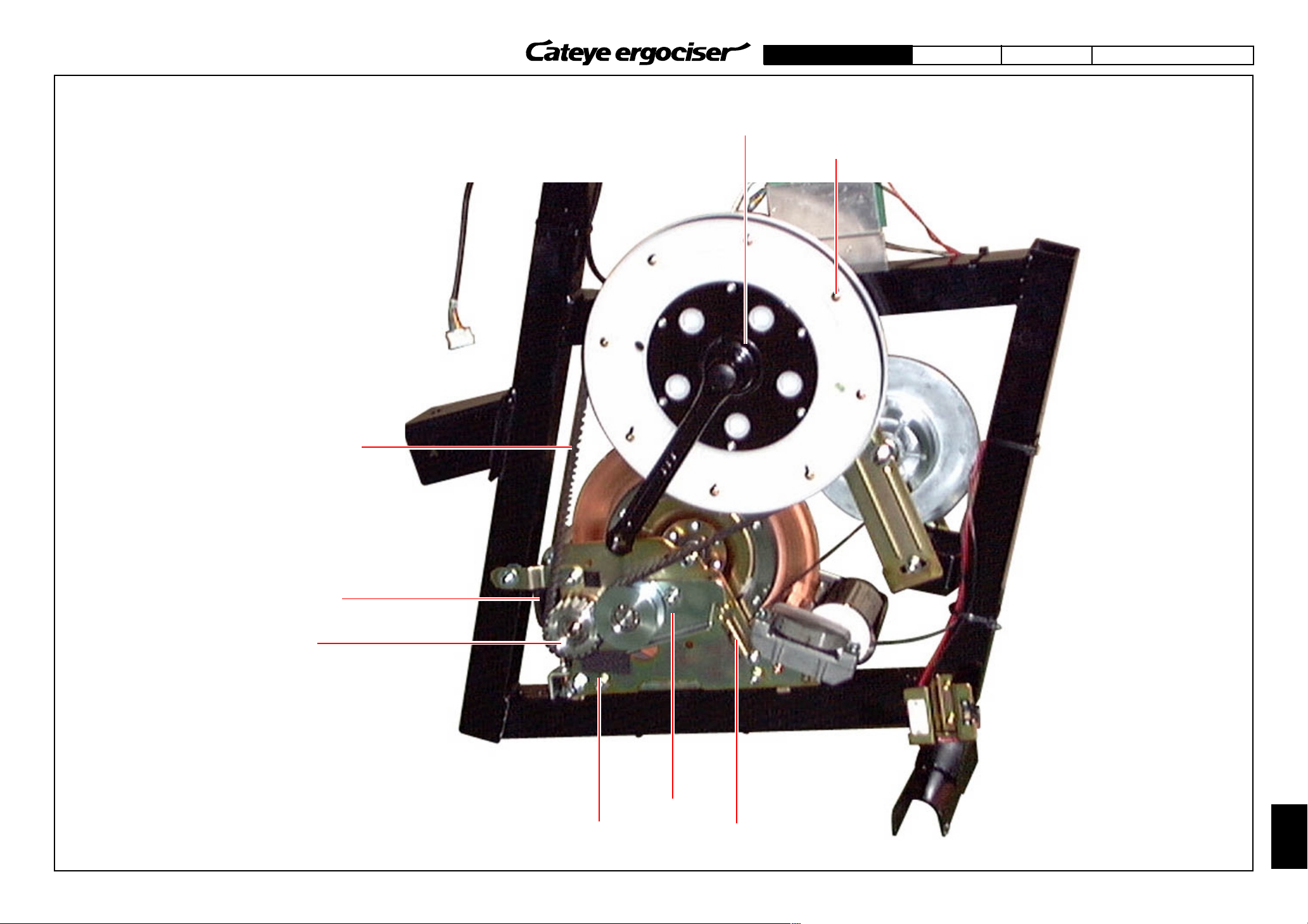

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

Name of Parts for Recumbent Type (EC-3600 & EC3700)

Wiring within Frame

Flywheel Metal Base Fixing Screw

4

Flywheel

Flywheel Fixing Screw

q

Flywheel Metal Base

Plain Belt

Power Supply Board Fixing Bolt

0

Power Supply Board

7

Crank

Crank Nut

5P Cable Connector

5P Cable Set

Cable Holder

Frame

BB Set

Copper Plate

Timing Belt

Idler

Idler Metal Base

Idler Fixing Bolt

8

Idler Spring

Frame Cover

Center Cover

Crank Cover

R

Name of Parts for Recumbent Type

Cateye Ergociser Series 1000 Service Manual

8

Inner Pipe

Seat Pipe

Rear Support Pipe

Leg Pipe Fixing Screw

Solenoid Coil

Mounting Base

Solenoid Coil

4

Workload Unit Mounting Base [Screw Set (+) (M6x16)]

Plastic Pulley

Workload Unit

Page 9

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

Cable Holder

Chain

CDC Sensor

Screw Set (+) [M6x16]

4

Workload Unit Reinforcing Nut

2

Workload Unit Reinforcing Metal Base

Workload Unit

Solenoid Coil

Power Supply Board

CDC Magnet

Cable Holder

Flywheel

Plain Belt

Flywheel Fixing Screw

q

Flywheel Metal Base Fixing Screw

4

O

N

O

F

F

Inlet Metal Base

Free Wheel Set

Hexagon Head U Nut

Workload Unit Mounting Base

4

[Screw Set (+) (M6x16)]

Derailleur

3

Derailleur

Mounting Bolt

AC Adapter Inlet

Power Switch

Front Leg with Casters

Caster

Name of Parts for Recumbent Type

Cateye Ergociser Series 1000 Service Manual

9

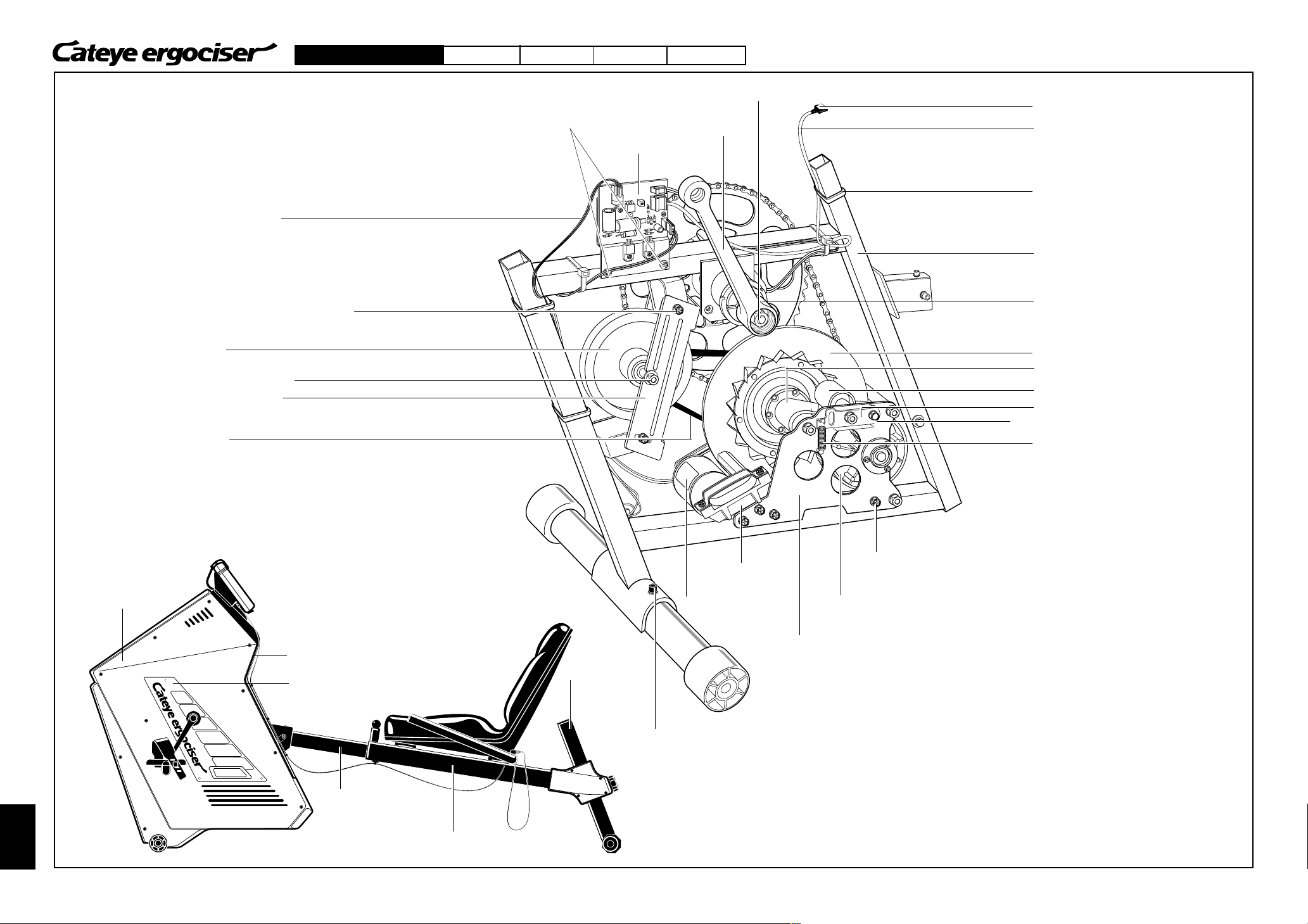

Page 10

Applicable Models:

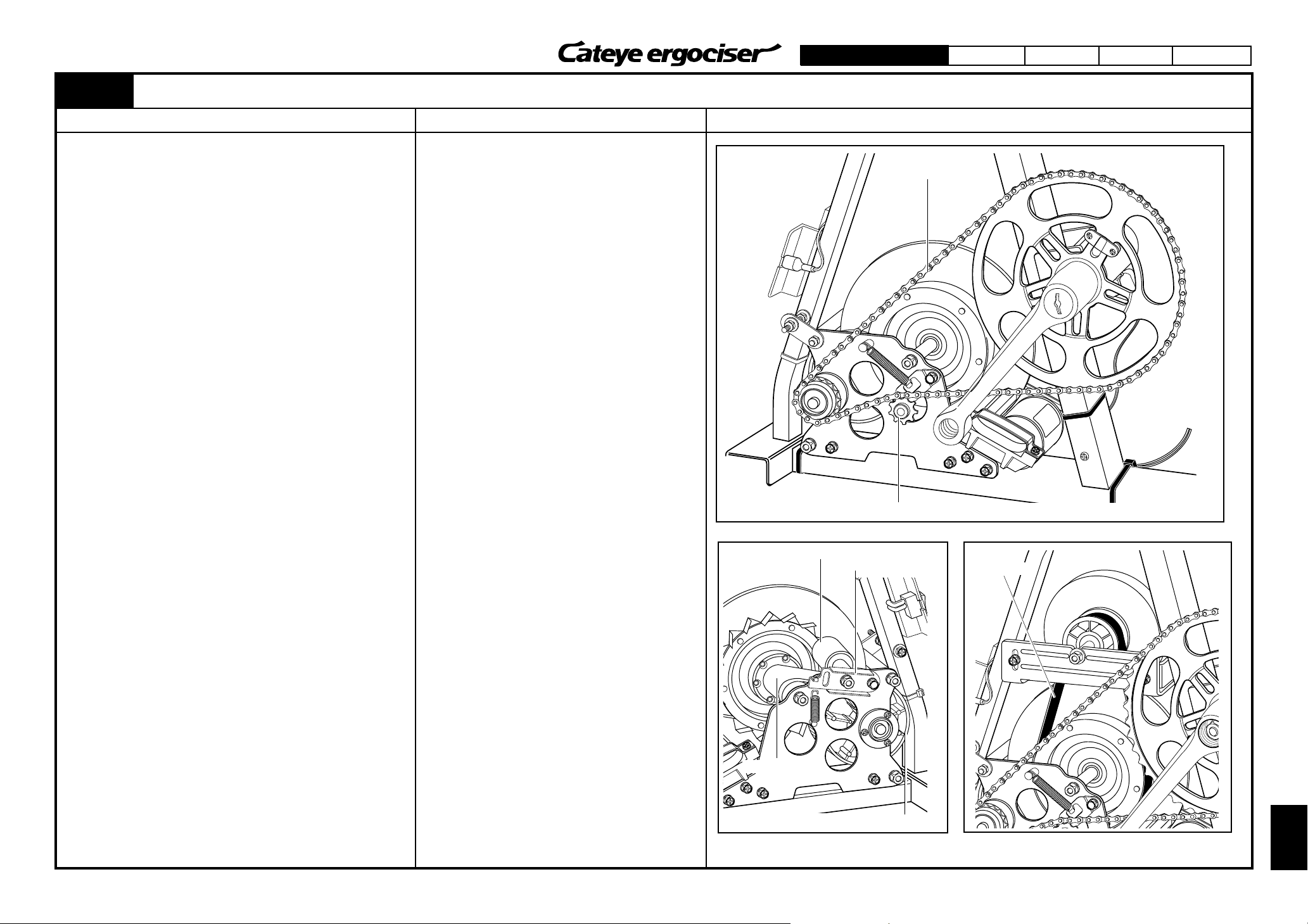

Belt Drive

EC-1600B EC-1200B

EC-1200B EC-1600B

Pulley 2-A Set

Pulley 1-B

Teethed Timing Belt (P8M15-1192)

Pulley 1-A Set

Pulley Flange

Pulley 2-A Set

Teethed Timing Belt (P8M15-1192)

Pulley 1-A Set

Pulley Flange

Workload Unit

Name of Parts for Belt Drive Type

Cateye Ergociser Series 1000 Service Manual

ADD. 1

Idler A Set

Idler Spring A

Pulley 1-B Idler A Set

Workload Unit Idler Spring A

Page 11

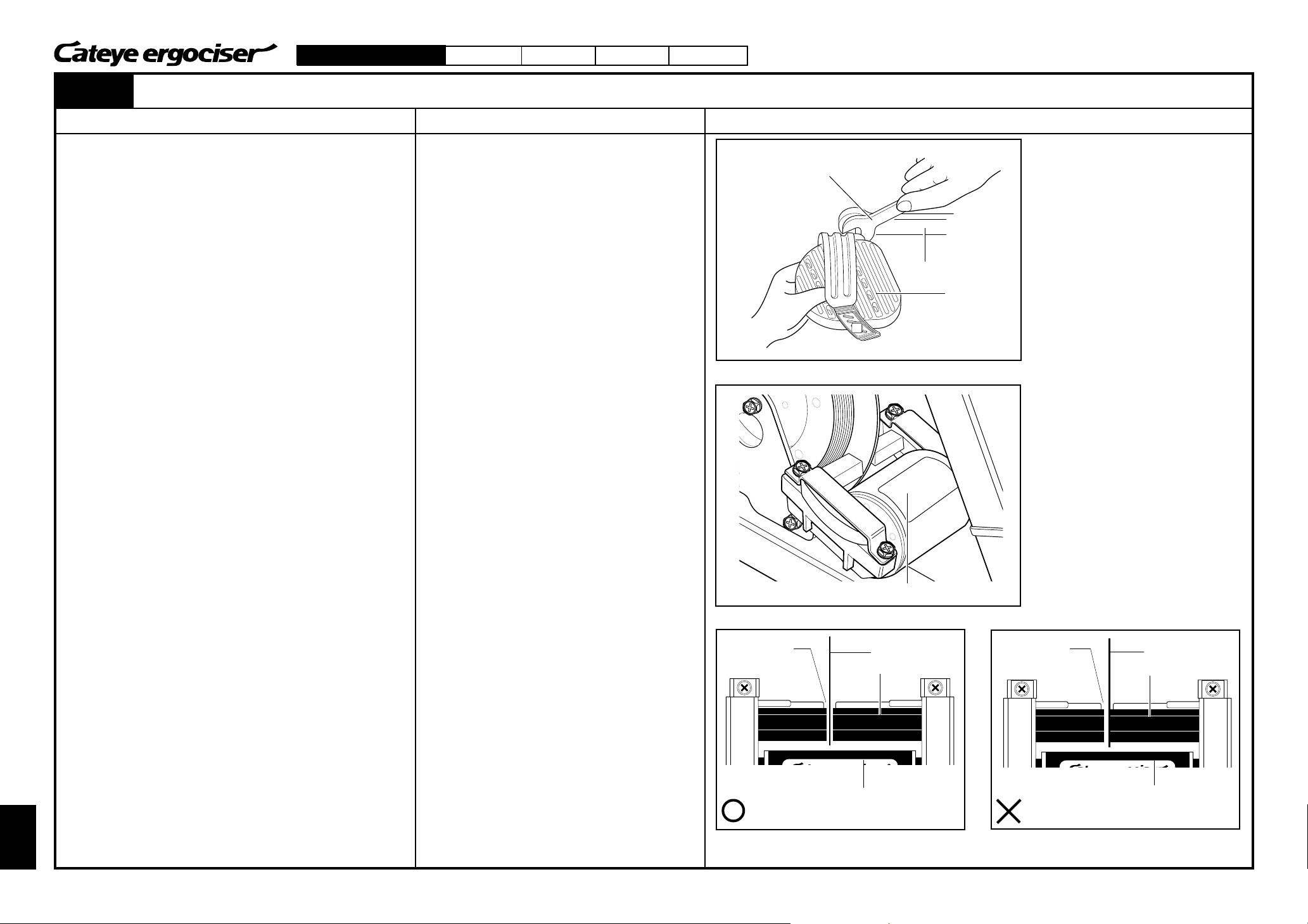

Belt Drive

EC-3600B/EC-3700B

Applicable Models:

Pulley 1-A Set

Pulley Flange

EC-3600B/EC-3700B

Teethed Timing Belt (P8M15-1080)

Pulley 2-A Set

Pulley 1-B

Workload Unit

Name of Parts for Belt Drive Type

Idler A Set

Idler Spring A

Cateye Ergociser Series 1000 Service Manual

ADD. 2

Page 12

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

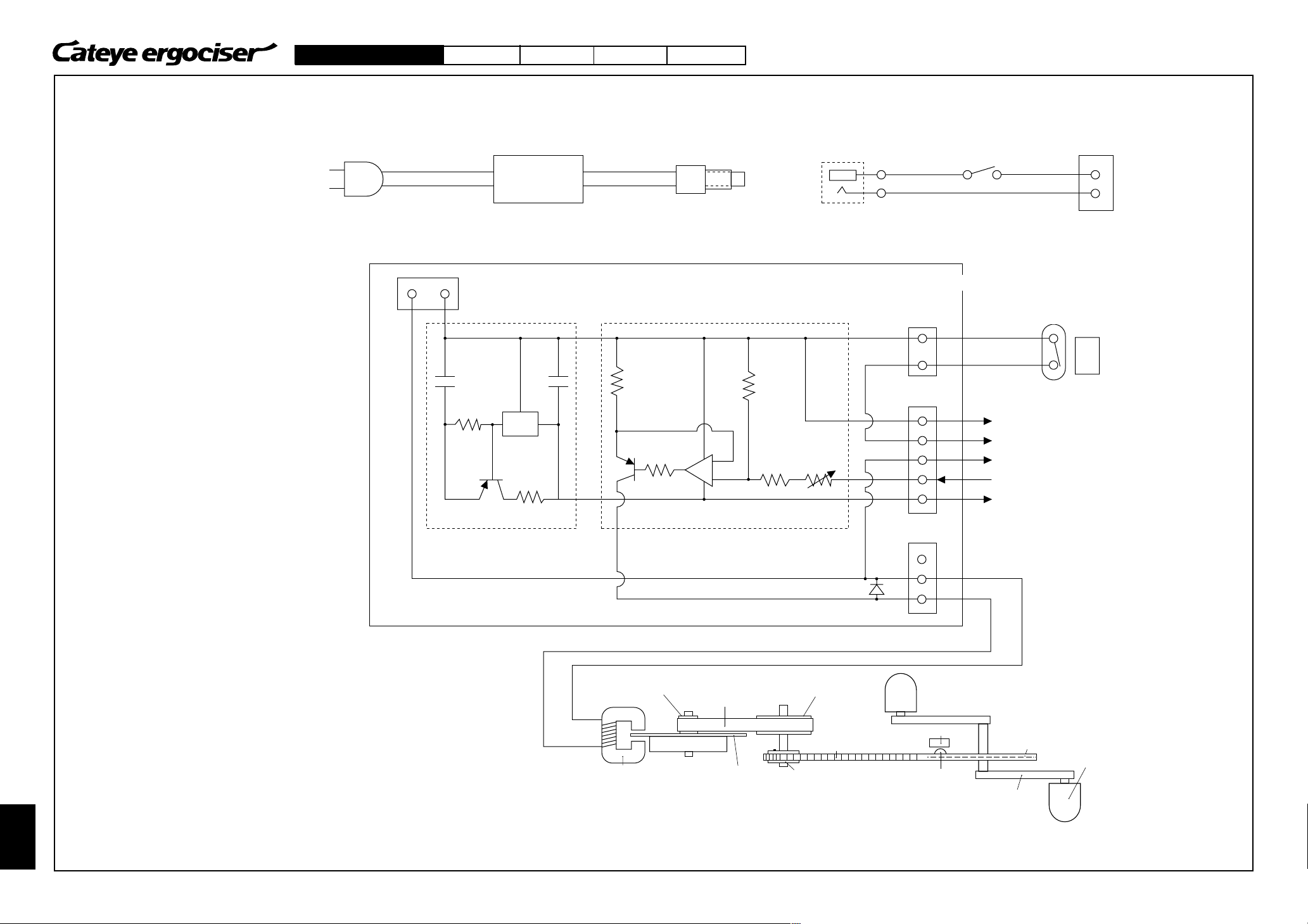

Circuit Diagram for Automatic Type Cateye Ergociser

AC Plug

100V AC

DC Power Supply

CN4

+ –

C1

Power Supply Control Circuit

for Printer

AC Adapter

12V DC*

*Fluctuate depending on the electric load

About 16V when the load is zero.

(Connector 4)

REG

R1

C2

–

+

TR2

–

+

R8

TR1

DC Connector

R2

R3

R7

IC1

Solenoid Coil Current Control Circuit

AC Adapter Inlet

VR1

Wiring within Frame

Black Cable (-)

Red Cable (+)

Power Supply Board

CN3

CN2

CN1

CN4 (Connector 4)

Switch

Cadence Sensor

5P Cable to Control Unit

Common Line

Cadence Signal

Control Unit Power Supply

Solenoid Coil Current Control Signal

Printer Power Supply (+5V)

–––

+

Magnet

Circuit Diagram

Cateye Ergociser Series 1000 Service Manual

10

Coil

Electromagnet

Metal Pulley

Timing Belt

Copper Disk Plate

Plastic Pulley

Chain

Free Wheel

D1

Cadence Sensor

Large Gear

Pedal

Magnet

Crank

Page 13

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

T-1

Check the power is available at the wall socket before proceeding to

checking of causes.

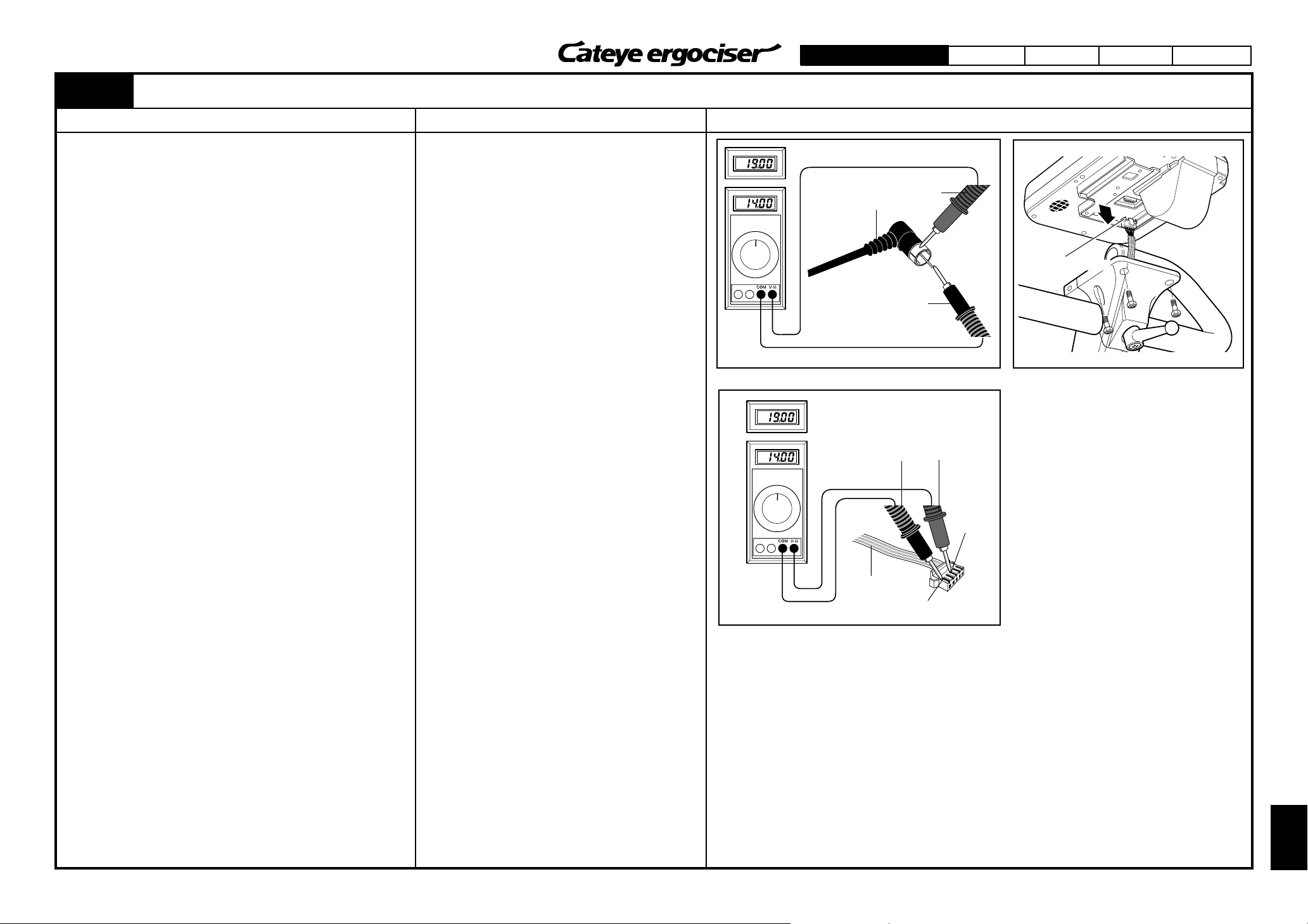

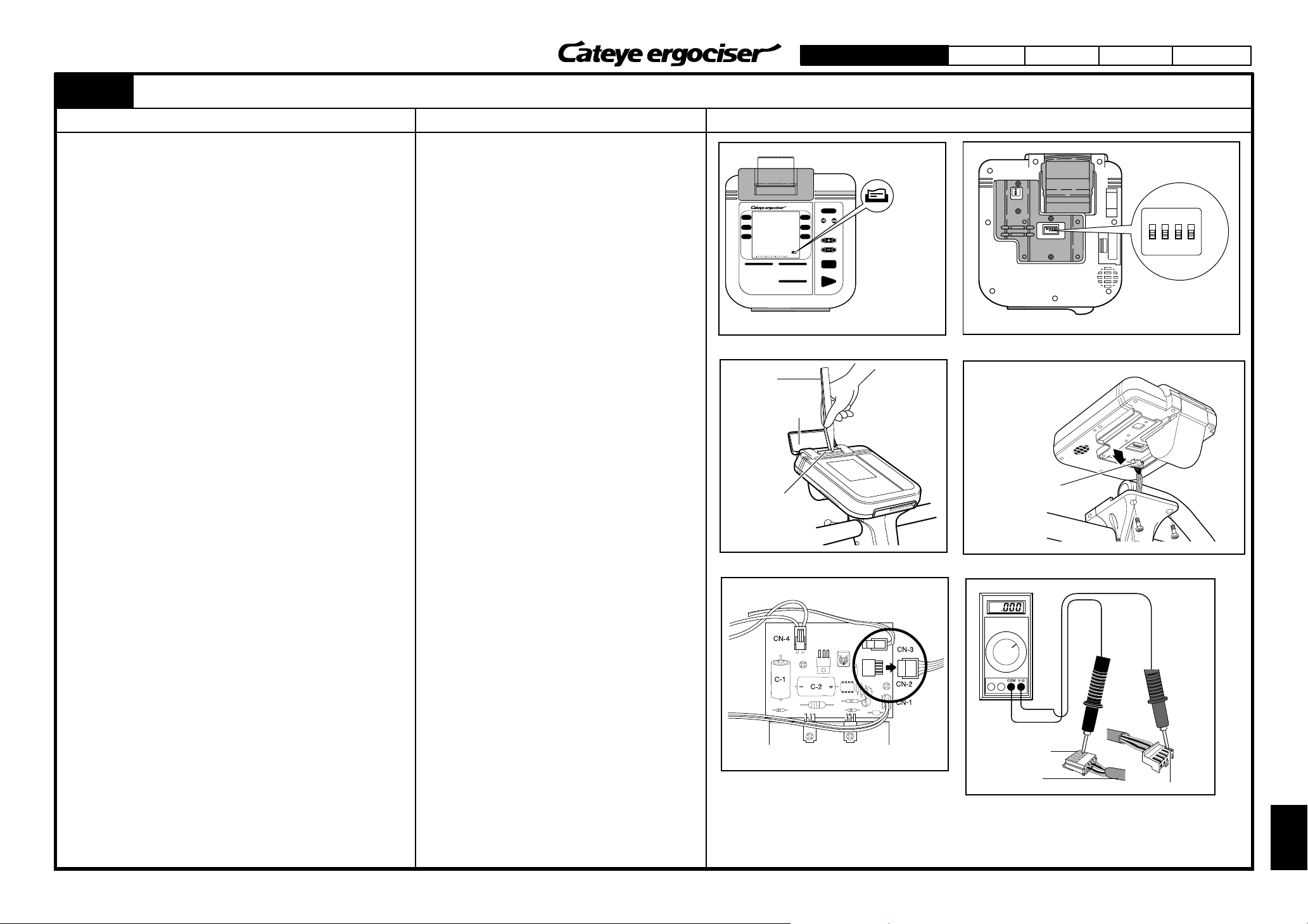

[1] Checking the AC Adapter

1. Detach the plug of AC adapter from the AC adapter inlet of the

main unit.

2. Connect the wall socket plug of the AC adapter to the wall

socket.

3. Using a tester, measure the voltage at the plug which will be

connected to the main unit. (Fig. 1)

t The AC adapter will be working fine, if the voltage is minus

t When the measured voltage is 0V, or less than 14V, the

Note: Never short-circuit the plug of AC adapter. This will

[2] Checking the Wiring within the Frame

1.When the AC adapter is found to be correct, proceed to

checking of wiring within the frame. Loosen the four screws

on the handlebar stem to remove the control unit. (Fig. 2)

2. Remove the 5P cable which is connected to the back of the

control unit. (Fig. 2)

3. Connect the AC adapter, and turn on the main unit.

4. Using a tester, measure the voltage across the terminals 1 (-)

and 3 (+) of the 5P cable. (Fig. 3)

t The main unit side will be working fine if the meter reading

No Display on Control Unit after Power ON. (1)

Check Method of Causes Repair Method Explanation Figures

(-) at the inner area and plus (+) at the outer area of the

connector and also the meter reading is in the range of 14V

and 19V.

AC adapter will be defective.

damage the AC adapter.

is in the range of 14V and 19V. This means the control unit

will be defective.

Replace the AC adapter.

Replace the control unit.

Fig. 1

Fig. 3

Normal for 14V thru 19V

Red Cable

DC Connector

Black Cable

Normal for 14V thru 19V

Black Cable

5P Cable

Terminal 1 (-)

Cable Connector

Fig. 2

Red Cable

Terminal

3 (+)

Cateye Ergociser Series 1000 Service Manual

11

No Display on Control Unit after Power ON. (1)

T-1

Page 14

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

T-1

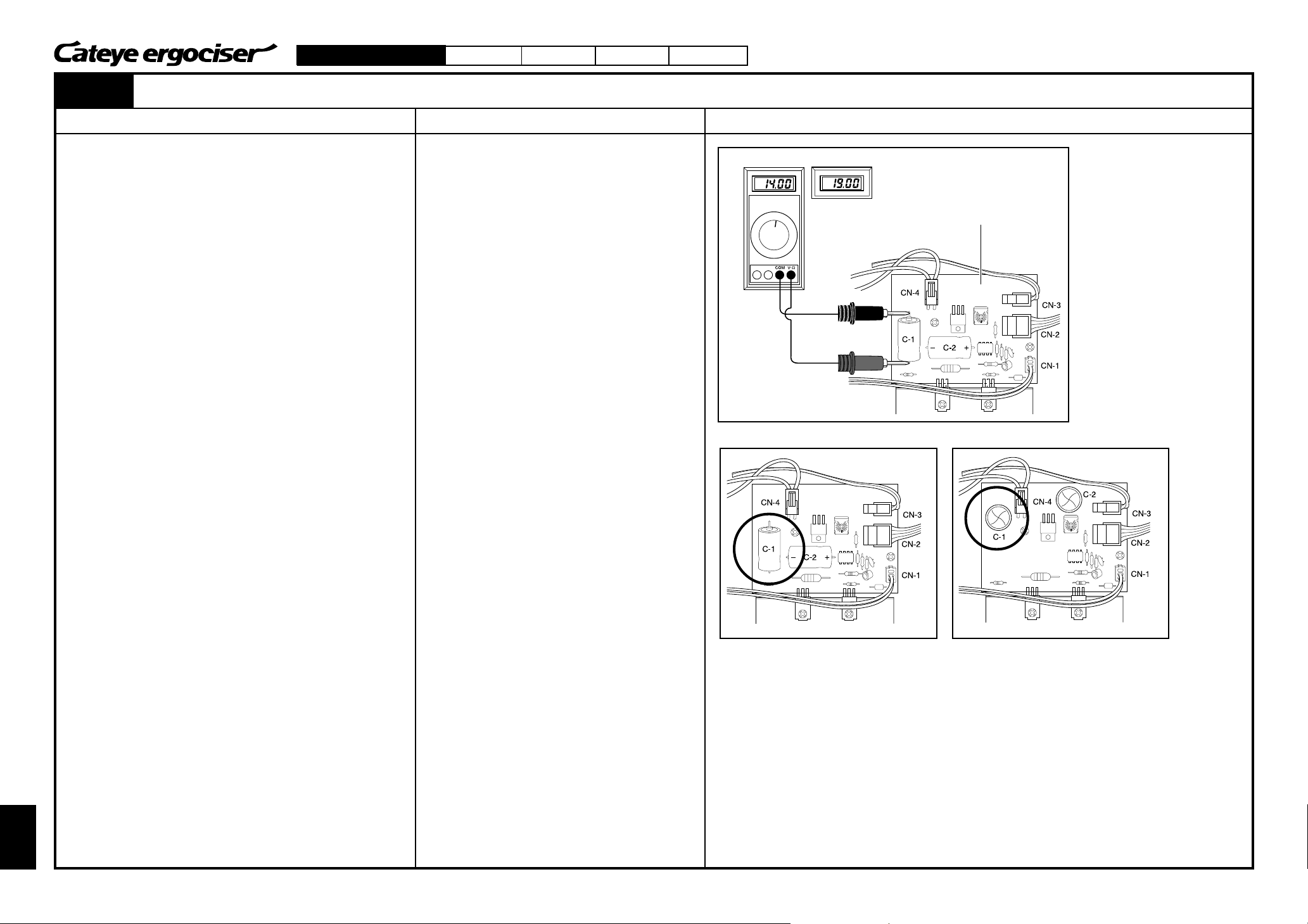

[3] When the meter reading at step 2. is 0V or less than 14V, check the

main unit in accordance with the following procedures:

1. Remove the frame cover. (See sections D-1 and D-2

"Removing the Frame Covers.")

2. With the control unit removed, connect the AC adapter, and

turn on the power switch. Measure the voltage across the

electrolytic capacitor C1 on the power supply board (25V

1000µV). (Fig. 4)

Note: The layout of the power supply board may be different from

lot to lot. (Figs. 5 and 6)

t The wiring within the frame is correct when the measured

t When the measured voltage is 0V, the wiring within the

t When the problem cannot be remedied even if the 5P cable

No Display on Control Unit after Power ON. (2)

Check Method of Causes Repair Method Explanation Figures

voltage is in the range of 14V and 19V. When the voltage

across the electrolytic capacitor on the power supply board

is correct, the 5P cable, which connects the power supply

board and the control unit, may be defective.

frame is defective.

is replaced, the power supply board may be defective.

Replace the 5P cable. (See the Section ES-2

"Replacing the Frame.")

Replace the Inlet Metal Base Set. (See the Section

ES-1 "Replacing the Wiring within the Frame."

Replace the power supply board. (See the Section

ES-3 "Replacing the Power Supply Board. "Fig. 4

Fig. 4

Black Cable

Red Cable

Power Supply Board A

Correct for 14V thru 19V

Power Supply Board

Power Supply Board B

No Display on Control Unit after Power ON. (2)

T-1

Cateye Ergociser Series 1000 Service Manual

12

Fig. 5

Fig. 6

Page 15

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

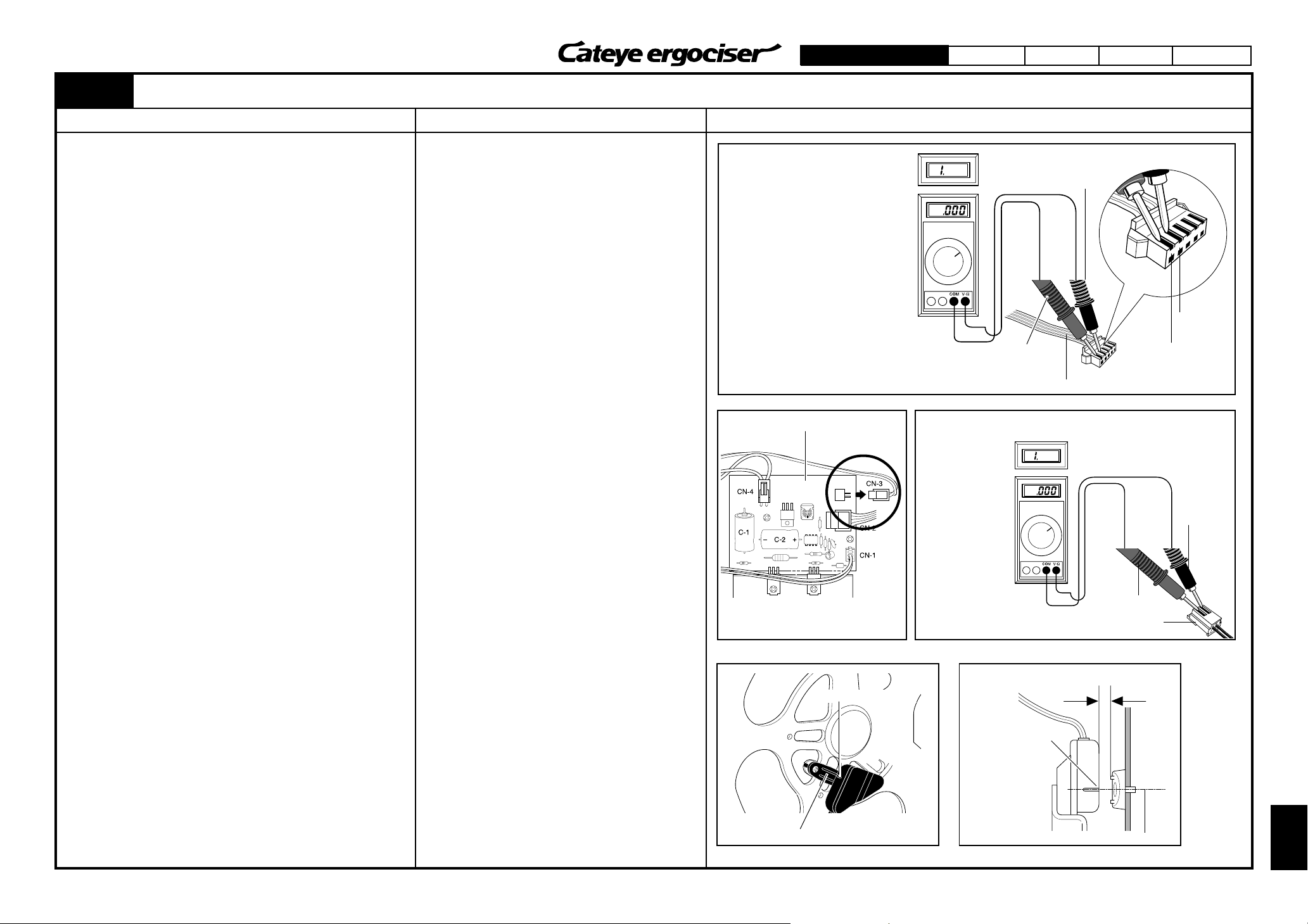

T-2

No Display of Cadence (The cadence remains at zero (0) and does not count when the pedal is rotated.)

Check Method of Causes Repair Method Explanation Figures

[1] Checking the Control Unit

1. Turn off the power. Loosen the four screws on the handlebar

stem to remove the control unit.

2. Remove the cable connector which is connected to the back of

control unit.

3. Slowly rotate the pedal while measuring the resistance across

the connector terminals 1 and 2 of the 5P cable. (Fig. 1)

t When there is one short-circuiting (resistance becomes

zero) during one rotation of the pedal, the control unit is

defective.

When there is no short-circuiting, proceed to the following check

procedures.

[2] Checking the Main Unit

1.Remove the frame cover. (See the Section D-1 and D-2

"Removing the Frame Covers.")

2. Remove the CN-3 connector on the power supply board. (Fig.

2)

3. Slowly rotate the pedal while checking shortcircuit across the

two terminals of the CN-3 connector by using a tester to see if

there is one short-circuiting during one rotation of the pedal.

(Fig. 3)

t If short-circuiting is found, the 5P cable which connects the

power supply board and the control unit is defective.

When there is no short-circuiting, proceed to the following check

procedures.

[3] Check the positional relation between the CDC sensor and the

magnet of the large gear. (Fig. 4)

1. Align the line on the CDC sensor with the center of the CDC

magnet. (Fig. 5)

2. Secure a gap of about 2mm between the surface of the CDC

sensor and that of the CDC magnet. (Fig. 5)

Check if there is any short-circuiting in the CN-3 connector again.

t When a short-circuiting is found, the positional relation

between the CDC sensor and the CDC magnet of the large

gear is incorrect.

t When there is no shortcircuit, the CDC sensor is defective.

Replace the control unit with a brand new one.

Replace the 5P cable. (See the Section ES-2

"Replacing the 5P Cable.")

Replace the CDC sensor. (See the Section ES-5

"Replacing the CDC Sensor".)

The case of no short-circuiting

The case a short-circuiting is found. One zero (0)

is detected during one rotation of the pedal.

Fig. 1

Power Supply Board

The case a short-circuiting is

found. One zero (0) is detected

during one rotation of the pedal.

Fig. 2

Line on CDC Sensor

Black Cable

Red Cable

5P Cable

The case of no shortcircuiting

CN-3 Connector

Fig. 3

Gap of 2mm between CDC Sensor and CDC

Magnet

Line on CDC Sensor

Red Cable

5

4

3

2

1

Terminal 2

Terminal 1

Black Cable

No Display of Cadence

Center of CDC Magnet

Fig. 4

Center of CDC Magnet

Fig. 5

Cateye Ergociser Series 1000 Service Manual

T-2

13

Page 16

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

T-3

1. Turn on the power to display the in-training screen (any

exercise program).

2. Install a brand new pulse sensor, and check if pulse rate will be

displayed.

t When the pulse rate can be displayed, the pulse sensor is

t When the pulse rate cannot be displayed, the control unit is

No Display of Pulse Rate

Check Method of Causes Repair Method Explanation Figures

defective.

defective.

Replace the pulse sensor with a brand new one.

Replace the control unit with a brand new one.

No Display of Pulse Rate

T-3

Cateye Ergociser Series 1000 Service Manual

14

Page 17

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

T-4

No Printer Operation

Check Method of Causes Repair Method Explanation Figures

In such cases as display of the LCD panel, etc. operate without

problem, but the printer does not operate, the following cases are

possible:

[1] Checking the Control Unit

1. Check that the printer symbol is displayed on the LCD panel

and the printer is in a working status. (Fig. 1)

2. Check if the setting of control unit is in the setting that the

printer is not used. (Check if the No.4 select switch on the

back of the control unit is in the "OFF" position.) (Fig. 2)

3 Check if the thermal paper is not jammed at the printer head.

t Remove the thermal paper if it is jammed. (Fig. 3)

4. When no other problems are found, replace the control unit

with a brand new one.

5. With the new control unit installed, check the printer operation.

t When the printer works fine, the control unit is defective.

When the printer does not operate after the above-stated checks,

proceed to the following procedures:

[2] Checking the Main Unit

1. Turn off the power, and loosen the four screws on the

handlebar stem to remove the control unit. (Fig. 4)

2. Remove the cable connector which is connected to the back of

the control unit. (Fig. 4)

3. Remove the frame cover. (See the Section D1 & D2

"Removing the Frame Covers.")

4. Remove the CN-2 connector on the power supply board. (Fig.

5)

5. Using a tester, check for any short-circuiting across Terminal

1s and Terminal 5s at both ends of the 5P cable which

connects the power supply board and the control unit. (Fig. 6)

t When there is no shortcircuit, the 5P cable is disconnected.

In case the printer symbol is not indicated on the LCD

panel, press the printer button to have the symbol

indicated.

Replace the control unit with a brand new one.

Replace the 5P cable. (See the Section ES-2

"Replacing the 5P Cable.")

Control Unit

Fig. 1

Tweezer

Printer Cover

Paper Cutter

Fig. 3

RESET

Printer Symbol

10 1

10 1

TIME

MODE

ADV

Back of Control Unit

123

Select Switch

ON

4

OFF

Fig. 2

Cable Connector

Fig. 4

Power Supply Board

Normal when zero (0)

t When it is short-circuited, the power supply board is

defective.

Replace the power supply board. (See the Section

ES-3 "Replacing the Power Supply Board.")

Fig. 5

Connector

Terminal 5

5P Cable

Connector Terminal 5

Fig. 6

Cateye Ergociser Series 1000 Service Manual

No Printer Operation

T-4

15

Page 18

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

T-5

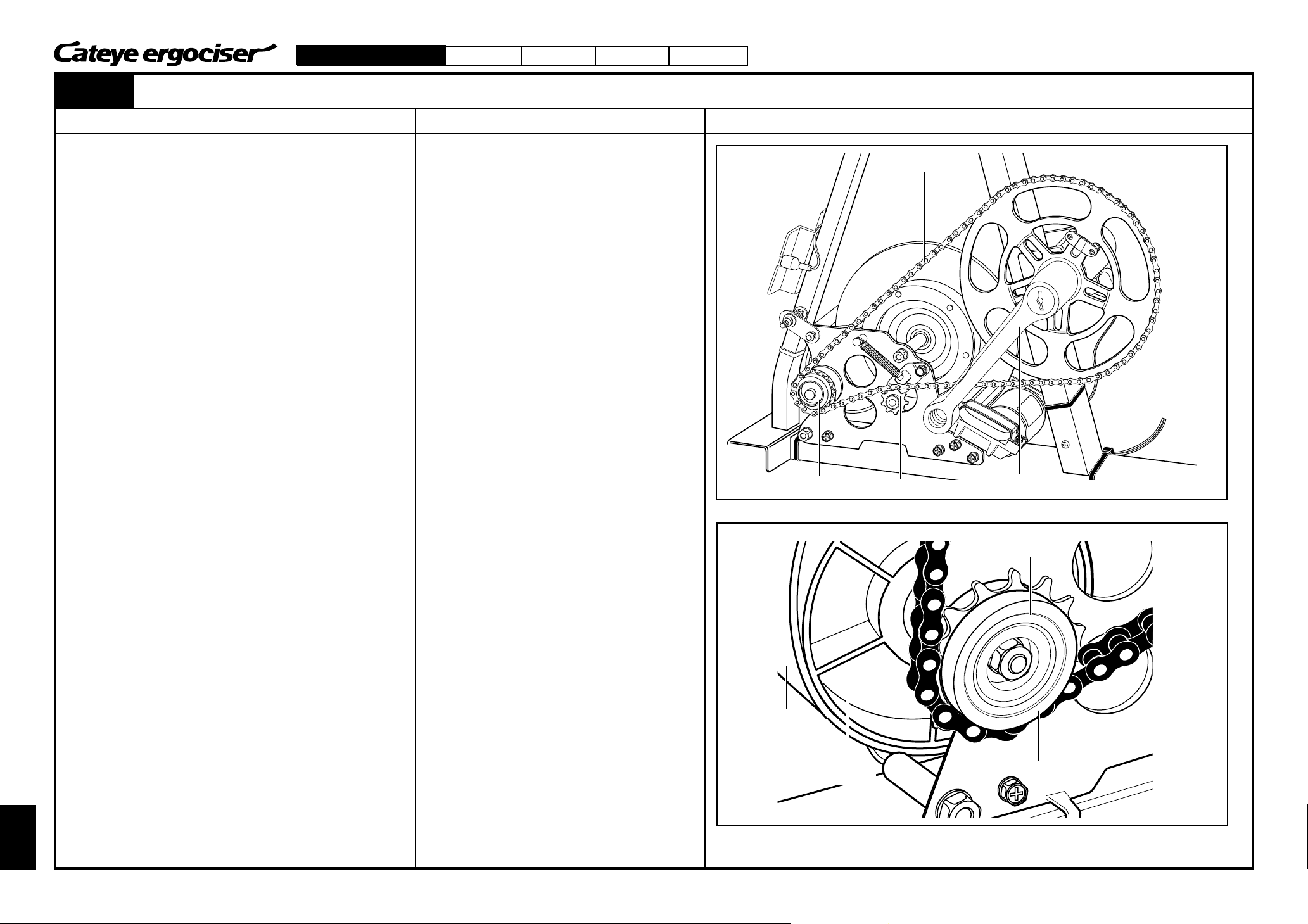

[1] Checking the Mechanical Systems

See the Section D1 & D2 "Removing the Frame Covers" to remove

the frame cover, and check the inside of frame.

1. Check if the chain has not been broken. (Fig. 1)

2. Rotate the crank and check if the belt of the workload unit will

rotate. (Fig. 2)

3. Check if the free wheel set is not idling. (Fig. 2)

4. Check if the belt (timing belt) of the workload unit has not been

broken. (Fig. 2)

5. Check if the plastic pulley of the workload unit has not been

broken. (Fig. 2)

No Loading (Check of mechanical systems)

Check Method of Causes Repair Method Explanation Figures

Chain

Replace the chain with a brand new one. (See the

Section MS-4 "Replacing the Chain.")

Replace the free wheel with a brand new one. (See

the Section MS-5 "Replacing the Free Wheel Set.")

Spray CRC into the gap as shown in Fig. 2, and rotate

the pedal in forward and backward directions.

Replace the workload unit. (See the Sections MS-1 &

MS-2 "Replacing the Workload Unit.")

Replace the workload unit. (See the Sections MS-1 &

MS-2 "Replacing the Workload Unit.")

No Loading (Check of Mechanical Systems)

T-5

Fig. 1

Fig. 2

Free Wheel

Timing Belt

Plastic Pulley

Derailleur

Crank

Gap

Free Wheel

Cateye Ergociser Series 1000 Service Manual

16

Page 19

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

T-5

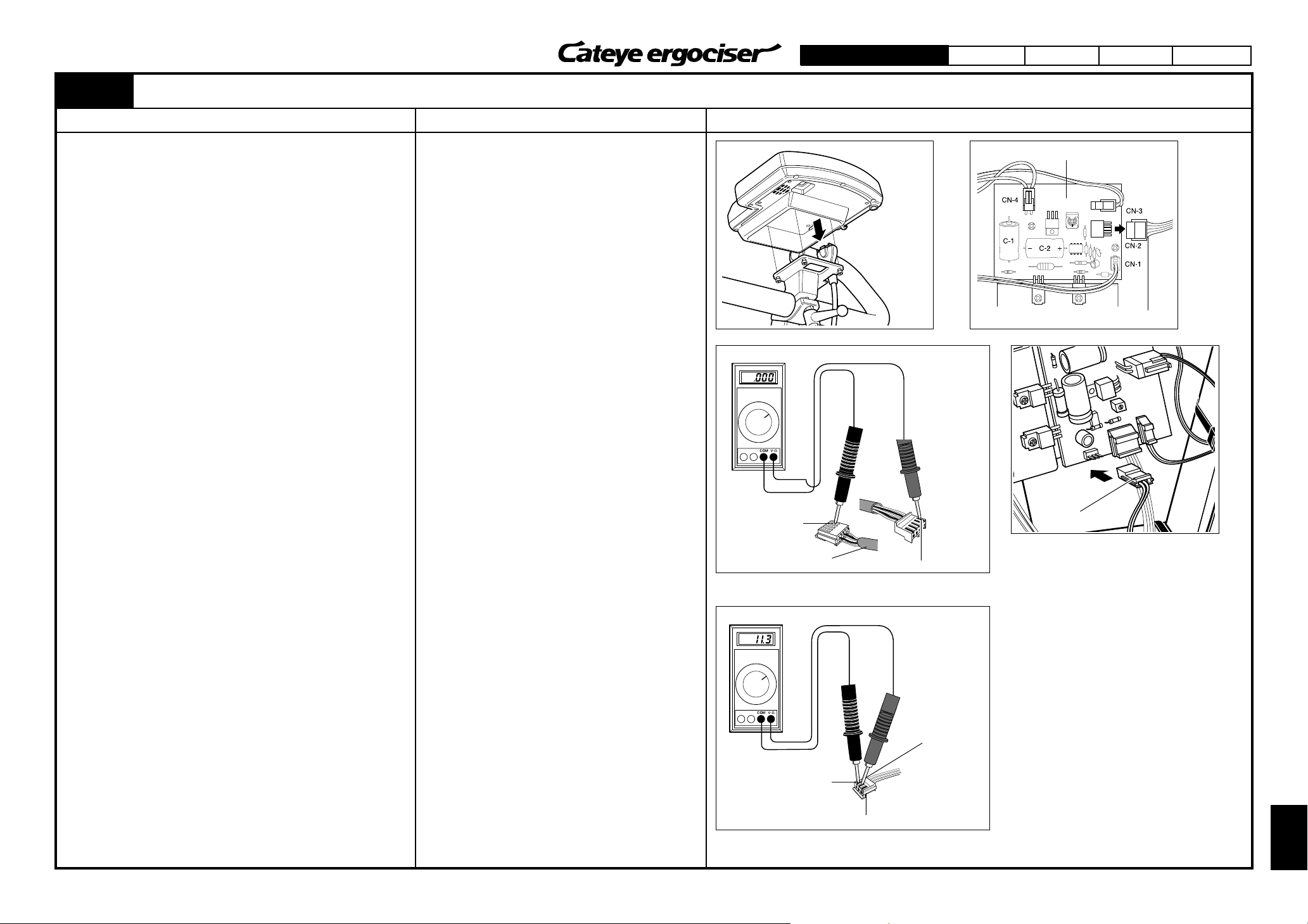

[2]Checking the Electrical Systems

1. Connect the AC adapter, and turn on the power of the main

unit.

2.Obtain the manual training program, set the pedal torque

setting to 4.0kg·m, and rotate the pedal at the rate of 50 rpm. If

you can rotate it quite easily, no load will be applied.

3. Replace the control unit with a brand new one.

4.Again, check the torque status under the manual training

program.

t When the pedal torque is loaded, the control unit is

When no torque loading is possible, proceed to the following

procedures.

1. Turn off the power, and loosen the four screws on the

handlebar stem to remove the control unit. (Fig. 1)

2. Remove the cable connector which is connected to the back of

the control unit. (Fig. 1)

3. Remove the frame cover. (See the Sections D1 & D2

"Removing the Frame Covers.")

4. Remove the CN-2 connector on the power supply board. (Fig.

2)

5. Using a tester, check for any short-circuiting across Terminal

1s and Terminal 4s at both ends of the 5P cable which

connects the power supply board and the control unit. (Fig. 3)

t When there is no shortcircuit, the 5P cable is disconnected.

When it is short-circuited, proceed to the following procedures:

1. Remove the connector CN-1 from the power supply board,

and measure the resistance across Terminals 2 and 3 of the

connector. When the reading is in the range of 9Ω and 14Ω,

the connector is all right. (Figs. 4 & 5)

t When the meter reading is exceedingly large, the solenoid

t When the meter reading is in the acceptable range, the

No Loading (Check of Electrical Systems)

Check Method of Causes Repair Method Explanation Figures

defective.

coil is defective.

power supply board may be defective.

Replace the control unit with a brand new one.

Replace the 5P cable with a brand new one. (See the

Section ES-2 " Replacing the 5P Cable.")

Replace the workload unit. (See the Sections MS-1 &

MS-2 "Replacing the Workload Unit.")

Replace the power supply board. (See the Section

ES-3 "Replacing the Power Supply Board.")

Fig. 1

Normal when zero (0)

Connector

Terminal 4

5P Cable

Fig. 3

Normal for 14V thru 19V

Power Supply Board

CN-2 Connector

Fig. 2

CN-1 Connector

Fig. 4

Connector Terminal 4

Connector Terminal 3

Fig. 5

Connector

Terminal 2

To Solenoid Coil

No Loading (Check of Electrical Systems)

CN-1 Connector

T-5

Cateye Ergociser Series 1000 Service Manual

17

Page 20

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

T-6

1. Remove the frame cover, and check the inside of frame. (See

the Sections D1 & D2 "Removing the Frame Covers.")

2. Check if the plain belt of the flywheel has not been detached.

(Fig. 1)

t No damage on the plain belt

t The plain belt is damaged.

No Pedal Rotation (Locked)

Check Method of Causes Repair Method Explanation Figures

Apply the plain belt correctly. (See the Section MS-2

"Replacing the Workload Unit (w/ Flywheel).")

Replace the workload unit and free wheel with brand

new ones. (See the Section MS-2 "Replacing the

Workload Unit (w/ Flywheel).")

Plain Belt

No Pedal Rotation (Locked)

T-6

Fig. 1

Cateye Ergociser Series 1000 Service Manual

18

Page 21

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

T-7-1

The noise generating source will be different depending on the

cases whether it is of continuous noise or periodical noise (several

times per rotation of pedal).

[1] Noise is continuous and increasing.

1. Remove the frame cover. (See the Sections D-1 & D-2

"Removing the Frame Covers.")

Apply grease to the following points. (Figs 1 & 2)

· Chain

· Inner surface of the timing belt (mating surface with the

2. Check if the derailleur has been worn out. (Fig. 1)

3. Check if the idler has been worn out. (Fig. 2)

4. Check if the plain belt has been deviated in position, thus

causing friction.

Unusual Noise (Continuous and Increasing)

Check Method of Causes Repair Method Explanation Figures

plastic pulley)

When it has been worn out, replace it with a brand

new derailleur set. (See the Section MS-6 "Replacing

the Derailleur Set.")

When it has been worn out, replace it with a brand

new idler set. (See the Section MS-7 "Replacing the

Idler Set.")

When the plain belt is shifted and is going to be

damaged, replace both the workload unit and the

flywheel set with new ones.

Fig. 1

Idler

Derailleur

Idler Set

Chain

Plain Belt

Fig. 2

Timing Belt

Plastic Pulley

Fig. 3

Cateye Ergociser Series 1000 Service Manual

Unusual Noise

T-7-1

19

Page 22

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

T-7-2

[2] Noise is Periodical.

1. Noise occurs around once per rotation of the pedal.

t The pedal installation may not be perfect. (Fig. 1)

2. Sliding noise occurs around 17 times per rotation of the pedal.

Remove the frame cover, and check the inside of frame. (See the

Sections D-1 & D-2 "Removing the Frame Covers.")

t The copper disc plate of the workload unit may touch the

Unusual Noise (Periodical)

Check Method of Causes Repair Method Explanation Figures

solenoid coil. (Figs. 2 & 3)

Use a No.15 wrench and securely fasten the pedal to

the crank. (both sides)

See the Section ES-4 "Correcting the Position of

Solenoid Coil," and correct the position of the copper

disc plate.

[If the plate is warped and the position of solenoid coil

cannot be corrected, replace the workload unit. (See

the Sections MS-1 & MS-2 "Replacing the Workload

Unit.")]

No.15 Wrench

Crank

Pedal

Fig. 1

Unusual Noise

T-7-2

Cateye Ergociser Series 1000 Service Manual

20

Fig. 2

Fig. 3

Core Slit

Correct Position

Solenoid Coil

Copper Disc Plate

Core

Solenoid Coil

Core Slit

Copper disc plate is in contact with the core.

Fig. 4

Copper Disc Plate

Core

Solenoid Coil

Page 23

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

T-7-3

[3] Noise occurs when the pedal is rotated with a large torque.

A large sound "bang" occurs when the pedal is abruptly rotated with

a large torque.

Remove the frame cover, and check the inside of frame. (See the

Sections D-1 & D-2 "Removing the Frame Covers.")

1. Check if the idler spring is detached.

2. Check if the idler mounting bolt is detached or loosened.

Unusual Noise (Noise occurs when the pedal is rotated with a large torque.)

Check Method of Causes Repair Method Explanation Figures

Hook the idler spring on the pawl of the idler.

Securely fasten the idler mounting bolt.

Idler

Pawl

Idler Mounting Bolt

Idler Spring

dler Metal Base

Fig. 1

Cateye Ergociser Series 1000 Service Manual

21

Unusual Noise

T-7-3

Page 24

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

D-1

Removing the Frame Covers

Upright Type (EC-1200 & EC-1600)

When any repair or adjustment of parts within the frame is required,

remove the frame covers in the following procedures.

REMOVAL

1. Remove the pedals at both the left and right sides. (The right

side pedal can be removed by turning it in the clockwise

direction, and the left side pedal can be removed in the

counter-clockwise direction.) (Fig. 1)

2. Remove the crank cover fixing screws. The narrow-width area

of the crank cover should be positioned in between the frame

cover and the crank. (Fig. 2)

3. Remove the leg pipe fixing screws. (Fig. 3)

* You do not have to remove the leg pipe itself.

* For the model EC-1600, remove the leg pipe cover.

4. Shift the rubber base at the seat post lock knob away from the

center cover.

5. Loosen the center cover fixing screw a little, and lift the center

cover upward. (Do not remove it.) (Fig. 4)

6. Loosen the four screws on the inlet cover. (Fig. 5)

7. Remove the frame cover fixing screw with a screwdriver before

removing the frame cover. (Fig. 6)

ASSEMBLING

1. Place the frame covers onto the frame at both right and left

sides, paying attention to the position of the crank.

2.Fix the right and left frame covers with frame cover fixing

screws.

3. Mount the inlet cover with four screws. (Fig. 5)

4. Set the center cover to the frame cover correctly in position,

and fix it with the center cover fixing screws. (Fig. 4)

5. Pass the crank through the hole on the crank cover, and fix the

crank cover onto the frame cover with screws. (Fig. 2)

6.Set the rubber base for the seat post lock knob, and then

mount the right and left pedals.

7. Fix the leg pipe with the leg pipe fixing screws. (For the model

EC-1600, mount the leg pipe cover.)

Removing the Frame Covers

No. 15 Wrench

Fig. 1

Front

Crank

Leg Pipe Fixing Screw

Pedal

Crank Cover

Fig. 2

ON

OFF

Rear

Leg Pipe Fixing Screw

ON

OFF

Center Cover Fixing Screw

Fig. 3 Fig. 4

Frame Cover

ON

OFF

Inlet Cover

Four (4)

Screws

Lift upward.

Center Cover

D-1

Cateye Ergociser Series 1000 Service Manual

22

Fig. 5 Fig. 6

Page 25

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

D-2

Recumbent Type (EC-3600 & EC-3700)

When any repair or adjustment of parts within the frame is required,

remove the frame covers in the following procedures.

àREMOVAL

1. Remove the pedals at both the left and right sides. (The right

side pedal can be removed by turning it in the clockwise

direction, and the left side pedal can be removed in the

counter-clockwise direction.) (Fig. 1)

2. Remove the crank cover fixing screws. The narrow-width area

of the crank cover should be positioned in between the frame

cover and the crank. (Fig. 2)

3. Remove the leg pipe fixing screws. (Fig. 3)

* You do not have to remove the leg pipe itself.

4. Remove the frame cover fixing screw with a screwdriver before

removing the frame cover. (Fig. 4)

àASSEMBLING

1. Place the frame covers onto the frame at both right and left

sides, paying attention to the position of the crank. At the

same time, the center cover should be built in.

2.Fix the right and left frame covers with frame cover fixing

screws.

3. Pass the crank through the hole on the crank cover, and fix the

crank cover onto the frame cover with screws. (Fig. 2)

4. Fix the front leg with casters with the leg pipe fixing screws.

5. Mount the pedals.

Removing the Frame Covers

Fig. 1

Frame Cover

No. 15 Wrench

R

Crank

Pedal

Center Cover

Screw

Crank Cover

Fig. 2

Leg Pipe

Fixing Screw

Front Leg with

Casters

Fig. 3

Fig. 4

Removing the Frame Covers

D-2

Cateye Ergociser Series 1000 Service Manual

23

Page 26

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

ES-1

Replacing the Wiring within the Frame

[A]Removing the Wiring Parts

1.Remove the frame cover. (See the Sections D-1 & D-2

"Removing the Frame Covers.")

2. Loosen the two screws on the inlet metal base to remove

them. (Fig. 1)

3. With the stopper being held with fingers, pull the CN-4

connector off the power supply board. (Fig. 2)

4. Cut the cable holder with a nipper. (Fig. 3)

[B]Mounting the Brand New Wiring Parts

1. Mount the brand new inlet metal base to the frame with two

screws.

2. Pass the wiring cable from beneath the DC jack of the power

supply board along with the square pipe (21mm x 21mm) to

the left direction, and then pass it through the back of the inlet

metal base along with the square pipe toward the switch.

3. Connect the CN-4 connector to the power supply board.

4.Refer to the Section (2) "Checking the Wiring within the

Frame" of T-1 "No Display on the Control Unit after Power ON"

(1) , measure the voltage across the electrolytic capacitor C-1

to check that it is in the correct range of 14V and 19V.

5. Use the cable holder to fix the CDC sensor cable together with

the solenoid coil cable. (Fig. 3)

6. Provisionally connect the control unit, and check the unit works

fine after turning on the power. Then, completely assemble

the frame cover.

Power Supply Board

EC-1200 & EC-1600

Inlet Metal Base (for Upright Type)

ON

Screws

OFF

DC Jack

Inlet Metal Base

EC-3600 & EC-3700

Inlet Metal Base (for Recumbent Type)

Screws

ON

OFF

Inlet Metal Base

DC Jack

Power Supply

Board

ON

OFF

Replacing the Wiring within the Frame

ES-1

Cateye Ergociser Series 1000 Service Manual

24

Fig. 1

Hold the stopper.

Fig. 2

Power Supply Board

Cable Holders

Fig. 3

Page 27

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

ES-2

Procedures are different depending on the type of model as shown

below:

àUpright Type (EC-1200)

T Removing the Existing Cable

1. Loosen the four screws which fix the control unit to remove the

control unit. Also, remove the cable connector. (Fig. 1)

2.Remove the cable holder which fixes the 5P cable to the

handlebar post.

3. Remove the frame cover. (See the Section D-1 "Removing the

Frame Covers.")

4. Remove the CN-2 connector from the power supply board.

(Fig. 2)

5. Cut the cable holders which fix the 5P cable to the frame, and

remove the 5P cable.

T Mounting the Brand New Cable

1. Mark the 5P cable at a point approx. 87cm from the unit-side

cable connector (Fig. 3), and connect the leading end of the

CN-2 connector to the power supply board.

2. (1)Using cable holders, fix the 5P cable at the bottom of the

handlaber pipe of the main unit frame.(2)Fix the cable at the

marked point of the cable to the handlebar pipe just beneath

the horizontal frame.(3)Pass the 5P cable along with the

handlebar pipe, and the sagging portion should be binded with

a cable holder. (Fig. 4)

3. Connect the cable connector to the control unit, and apply the

connector cover.Then, fix the control unit to the handlebar post

by using four screws. (Fig. 1)

4. Provisionally turn on the power, and check if the control unit

works fine.

5.Fix the 5P connector to the handlebar post with the cable

holder.

6. Mount the frame cover. (See the Section D-1 "Removing the

Frame Covers.")

àUpright Type (EC-1600)

T Removing the Existing Cable

5P Cable Handleber Post

1. Loosen the four screws which fix the control unit to remove the

control unit. Also, remove the cable connector. (Fig. 4) Slide

the inner handlebar post cover upward, and unplug the cable

connector. (Fig. 5)

2. Remove the screws of both the handlebar stem and the outer

handlebar post cover to remove the 5P cable. (Fig. 6)

5P Cable within the Frame

1. Remove the frame cover. (See the Section D-1 "Removing the

Frame Covers.")

2. Remove the CN-2 connector at the end of the 5P cable from

the power supply board.

3. Cut the cable holders which fix the 5P cable to the handlebar

pipe, and remove the 5P cable.

To be continued on the next page.

Replacing the 5P Cable (1)

EC-1200

Fig. 1

Cable Holders

EC-1200

Fig. 4

Screws

(2)

Cable

Connector

Screws

Handlebar Pipe

Horizontal Frame

(3)

(1)

Handlebar Stem

Cover

Fig. 2

Power Supply Board

EC-1600

Fig. 5

Cable Connector

Cable Holder

Cable

Connector

Screws

5cm

Unit-Side Cable Connector

Mark this point.

87cm

Fig. 3

Inner Handlebar Post Cover

Unplug

Fig. 6

Replacing the 5P Cable (1)

Fig. 7

Fig. 8

ES-2

Cateye Ergociser Series 1000 Service Manual

25

Page 28

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

ES-2

T Mounting the Brand New Cable

5P Cable within the Handlebar Post

1. Using cable holders, bind the 5P cable, leaving approx. 5cm

portion from the control unit side cable connector, to the

handlebar post. (Fig. 7) Assemble the handlebar post cover

and the handlebar stem cover. (Fig. 6)

2. Connect the cable connector to the control unit, and fix the unit

to the handlebar post by using four screws. (Fig. 5)

5P Cable within the Frame

1. Connect the CN-2 Connector at the end of the 5P cable to the

power supply board.

2. (1)Using cable holders, fix the 5P cable to the frame, leaving

the extra portion of 10cm from the top of the handlebar pipe.(2)

Fix the 5P cable at the bottom of the handlebar pipe.(3)

Pass the 5P cable along the handlebar pipe, and bind the

sagging portion to the point (3) by using cable holders. (Fig. 8)

3. Provisionally connect the intermediate cable connector, and

turn on the power. Then, check if the control unit works fine.

4. Mount the frame cover to restore the original shape. (See the

Section D-1 "Removing the Frame Covers.")

àRecumbent Type (EC-3600 and EC-3700)

T Removing the Existing Cable

1. Loosen the four screws which fix the control unit to remove the

control unit. Also, remove the cable connector. (Fig. 10)

2. Remove the frame cover. (See the Section D-2 "Removing the

Frame Covers.")

3. Remove the 5P connector from the power supply board. (Fig.

2)

4. Cut the cable holders which fix the cable to remove the 5P

cable.

T Mounting the Brand New Cable

1. Leaving approx. 30cm from the end of the frame, fix the 5P

cable to the frame by using cable holders.

2. Connect the 5P cable to the power supply board, and bind the

sagging portion to the point (2) of the frame. (Fig. 11)

3. Provisionally turn on the power, and check if the control unit

works fine.

4. Mount the frame cover. (See the Section D-2 "Removing the

Frame Covers.")

Replacing the 5P Cable (2)

10cm

Cable Holders

EC-1600

Fig. 9

(1)

(3)

Power Supply Board

Control Unit

5P Cable

Screws

Fig. 10

(2)

30cm

Cable Holders

Replacing the 5P Cable (2)

ES-2

Cateye Ergociser Series 1000 Service Manual

26

Fig. 11

Page 29

Applicable Models:

K6020

I

mA

COIL

LOT No.

EC-1200 EC-1600 EC-3600 EC-3700

ES-3

[1] Replacing the Power Supply Board

1. Remove the frame cover. (See the Sections D-1 & D-2

"Removing the Frame Covers.")

2. Remove all connectors CN-1, CN-2, CN-3 and CN-4 which are

connected to the power supply board.

3. Loosen the two screws which fix the power supply board to

remove the board. (Fig. 1)

4. Securely fix the brand new power supply board by using two

fixing screws.

5. Connect three connectors, CN-2, CN-3 and CN-4.

[2] Adjustment of Coil Current Value

1. Connect the cables for measuring coil current between the

female connector of the solenoid coil and the male connector

(CN-1) on the power supply board, and then connect the

cables to an ammeter. (Fig. 2)

2. Turn on the power switch of the main unit, set the control unit

to the manual mode, set the load display to 4.0kg m, and start

the system.

3. Adjust the potentiometer (as shown in Figs. 3 and 4) on the

power supply board with a blade-head screwdriver so that the

coil current will be the value indicated on the workload unit

solenoid coil. (A clockwise turn will increase the current, while

a counter-clockwise turn will reduce the current.)

Example: When the indication is 630 as shown in Fig. 5,

4.Upon completion of the adjustment, detach the cable for

measuring coil current, and connect the CN-1 connector

directly to the power supply board.

Replacing the Power Supply Board

adjust the potentiometer so that the coil current

value will be 630mA.

Fixing Screws

Fig. 1

Power Supply Board

Power Supply Board

Power Supply Board A

EC-1200 & EC-1600

Cable for Measuring

Coil Current

Fig. 2

Power Supply

Board

Power Supply Board B

EC-3600 & EC-3700

Solenoid

Coil

Fig. 3

Fig. 4

Replacing the Power Supply Board

Location of Coil Current Value Indication

Fig. 5

ES-3

Cateye Ergociser Series 1000 Service Manual

27

Page 30

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

ES-4

Correcting the Position of Solenoid Coil

Perform the positional correction of the core slit section after

detaching the frame cover and turning off the power. (See the

Sections D-1 & D-2 "Removing the Frame Covers.")

[1] Correction with Nuts of Workload Unit Reinforcing Metal Base

This correction is a minor correction method which allows

adjustment by the fastening force of the frame-side nuts of the

workload unit reinforcing metal base.

1. Check the contacting area by slowly rotating the copper disk

plate with your hands.

2. Adjust the two frame-side nuts of the workload unit reinforcing

metal base in the following procedures. (Fig. 1)

A.Loosen the nut on the workload unit side, and the nut on the

frame side (Fig. 1).

B.If the right side of the copper disk plate contacts the core,

when the main unit is viewed from the direction as depicted

in Fig. 3, fasten the frame-side nut.

C. Then, fasten the frame-side nut on the other side until the

copper disk plate comes close to the center of the core slit

(Fig. 2). [ Rotate the copper disk plate slowly, and check for

any contacts on the entire area of the plate.

D.Fasten the nuts which had been tightened in the above step

A.

[2] In case correction is not possible by the method stated in [1].

Replace the whole workload unit. (See the Section MS-2 "Replacing

the Workload Unit (w/ Flywheel).")

Workload Unit

Reinforcing Metal

Base

EC-1200 & EC-1600

Workload Unit Reinforcing

Metal Base

Frame-Side Nut

Fig. 1

Solenoid Coil

Workload-UnitSide Nut

Core Slit

I

mA

Correct Position

Workload Unit

Reinforcing

Metal Base

EC-3600 & EC-3700

Copper Disk Plate

Core

Solenoid Coil

ON

Solenoid Coil

Core Slit

Copper disk plate contacts the core.

OFF

Copper Disk Plate

Core

I

mA

Solenoid Coil

Correcting the Position of Solenoid Coil

ES-4

Cateye Ergociser Series 1000 Service Manual

28

Fig. 2

Fig. 3

Page 31

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

ES-5

1. Remove the frame cover. (See the Sections D-1 & D-2

"Removing the Frame Covers.")

2. Detach the CN-3 connector from the power supply board. (Fig.

1)

3. Cut the cable holders which fix the CDC sensor cable to the

frame.

4. Remove the defective CDC sensor set by loosening the

screws, and mount and fix the brandnew CDC sensor set.

(Fig. 2)

5. Perform the following adjustments. (Figs. 3 and 4)

T Align the line on the CDC sensor with the center of the line

T Adjust the gap between the surface of CDC sensor and the

* If the gap is inadequate, bend the metal base to secure the

6. Securely connect the CN-3 connector to the power supply

board. (Fig. 1)

7.Rotate the crank, and check if the pedal cadence will be

displayed on the control unit.

8. Fix the CDC sensor cable to the frame by using cable holders.

(Fig. 5)

9.Assemble the frame cover. (See the Sections D-1 & D-2

"Removing the Frame Covers.")

Replacing the CDC Sensor

on the CDC magnet. (Fig. 3)

surface of CDC magnet to be approx. 2mm. (Fig. 4)

specified gap.

CDC Sensor

EC-1200 & EC-1600

Power Supply Board

CN-3 Connector

Power Supply Board

EC-3600 & EC-3700

CDC Sensor

CDC Sensor

Power Supply

Board

ON

OFF

Fig. 1

Line on CDC Sensor

Center of CDC Magnet

Fig. 3

Fig. 2

Approx. 2mm gap between CDC sensor and

CDC magnet

Center of CDC

Magnet

Line on CDC Sensor

Fig. 4

Cable Holders

Replacing the CDC Sensor

Fig. 5

ES-5

Cateye Ergociser Series 1000 Service Manual

29

Page 32

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

ES-6

1.Remove the control unit by loosening four screws. Also

remove the cable connector from the control unit. (Fig. 1)

2. The control unit can be separated into upper and lower parts

when the eight screws on the bottom of the lower body of the

unit are removed (Fig. 2). Be careful to separate them slowly

since the upper and lower bodies are connected with a flat

cable.

3. Remove the connector on the panel keyboard which is located

at the upper body side, loosen the nine screws on the

substrate, and remove them from the upper body. (Fig. 3)

4.Since the panel keyboard is fixed to the control unit with

silicon, cut the silicon with a sharp cutter (Fig. 4). Peel the

panel keyboard off the surface of upper body. (Fig. 5)

5. If the silicon remains at the upper body, remove it thoroughly.

6. Place the brandnew panel keyboard. The cable from the

keyboard should be pulled in through the hole on the upper

body. Press and adhere the panel keyboard in position.

7. Apply silicon at two depicted areas to prevent intrusion of

sweat. (Figs. 4 and 6)

8. Mount the substrate and fix it with nine screws, and insert the

connector of the panel keyboard. (Fig. 3)

9. Put the upper and lower body together, and fix them with eight

screws.

10.Connect the cable connector to the control unit, and mount the

unit to the main unit.

Replacing the Panel Keyboard

Control Unit

Fig. 1

Fig. 4

Cable Connector

Silicon

Fig. 2

Screw

Control Unit

Upper Body

Fig. 5

Control Unit

Panel Keyboard

Substrate

Fixing Screw

Fig. 3

Substrate

Connector

Replacing the Panel Keyboard

ES-6

Cateye Ergociser Series 1000 Service Manual

30

Silicon

Fig. 6

Page 33

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

ES-7

1. Insert a thin cutting knife, while paying cautions not to damage

the control unit, in between the button panel and the body, and

carefully peel off the button panel. (Fig. 1)

2. Clean the adhesive agent, if any, on the control unit before

placing a brandnew button panel.

* Sufficiently press the button panel thus placed.

Replacing the Button Panel

Control Unit

Fig. 1

Button Panel

Cateye Ergociser Series 1000 Service Manual

31

Replacing the Button Panel

ES-7

Page 34

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

ES-8

1. Open the control unit into upper and lower bodies by referring

to the Section ES-6 "Replacing the Panel Keyboard (1) & (2)."

2. unit is fixed to the lower body with two screws. Remove these

two screws. (Fig. 1)

3. The printer unit can be removed after detaching cable

connectors CN-2 and CN-3 of the printer unit. To remove the

connector CN-3, just pull it, while to remove connector CN-2,

the use of tweezer will be recommended. (Fig. 2)

4.Connect the connector CN-2 of the brandnew printer unit.

Then, connect CN-3. For the connection, press it while moving

it to right and left side alternatively.

5. Fix the printer unit with two screws. (Fig. 1)

6. Put the upper and lower bodies together, and fix them with

eight screws.

7. Adjust the printing darkness by referring to the Section ES-9

"Adjusting the Printing Darkness."

8. Mount the control unit to the main unit.

Replacing the Printer

Fig. 1

Printer Unit

Printer Fixing Screws

CN-2 Connector

CN-3 Connector

Fig. 2

Replacing the Printer

ES-8

Cateye Ergociser Series 1000 Service Manual

32

Page 35

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

ES-9

1. Remove the control unit from the main unit. (Fig. 1)

2.Loosen four screws on the bottom of the control unit, and

remove the cable connector from the unit. (Fig. 1)

3. Remove the black metal base on the bottom of the control unit.

(Fig. 2)

4. Provisionally connect the 5P connector on the bottom of the

control unit to the main unit.

5. Turn on the power. Check if the printer symbol appears on the

LCD panel and the printer is in the operating condition.

6. Check if the thermal paper is set in position.

7. Adjustment should be done with the control unit positioned

horizontally. Press the ADV button on the control panel twice

to perform a test printing. A counter-clockwise turn of the

potentiometer PR on the bottom of the control unit will

decrease the darkness, while a clockwise turn will increase it

(Fig. 2). Set it to an appropriate darkness level. (An extreme

clockwise turn of the potentiometer may distort the printed

characters.)

NOTE: Never touch the potentiometer DCV.

Adjusting the Printing Darkness

Upright Type

Control Unit

Cable Connector

Recumbent Type

Fig. 2Fig. 1

DCV

PR

Control Unit

Cable Connector

Fig. 3

Potentiometer PR

Adjusting the Printing Darkness

ES-9

Cateye Ergociser Series 1000 Service Manual

33

Page 36

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

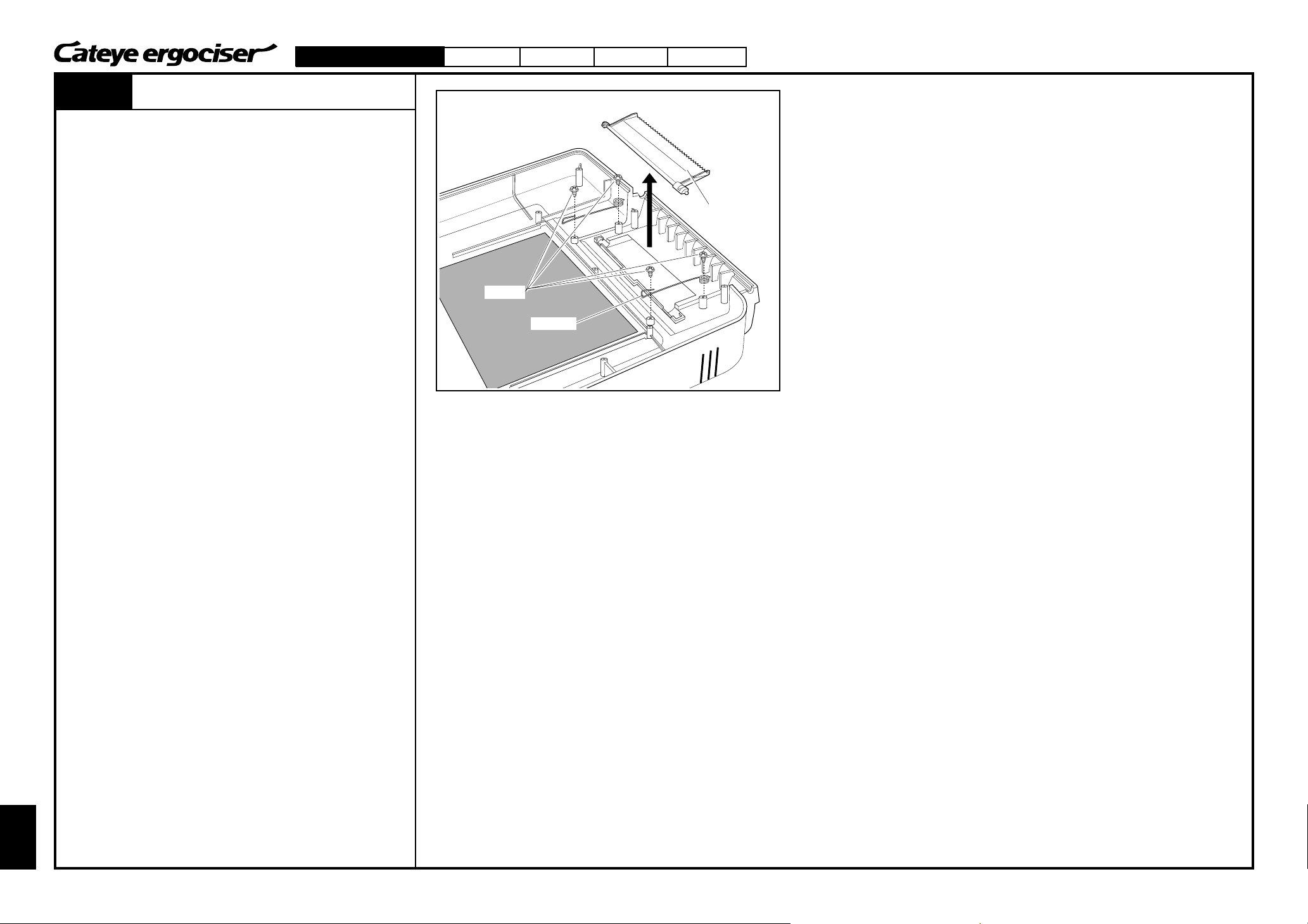

ES-10

1. Open the control unit into upper and lower bodies by referring

to the Section ES-6 "Replacing the Panel Keyboard (1) & (2)."

2. Remove the jammed paper with a tweezer or the like. (Fig. 1)

3. Assemble the control unit by referring to the Section ES-6

"Replacing the Panel Keyboard (9) & (10)."

4. Set the printer paper. (See the Operation Manual.)

Paper Jamming in Printer

Pincette

Printer Unit

Fig. 1

Paper Jamming in Printer

ES-10

Cateye Ergociser Series 1000 Service Manual

34

Page 37

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

MS-1

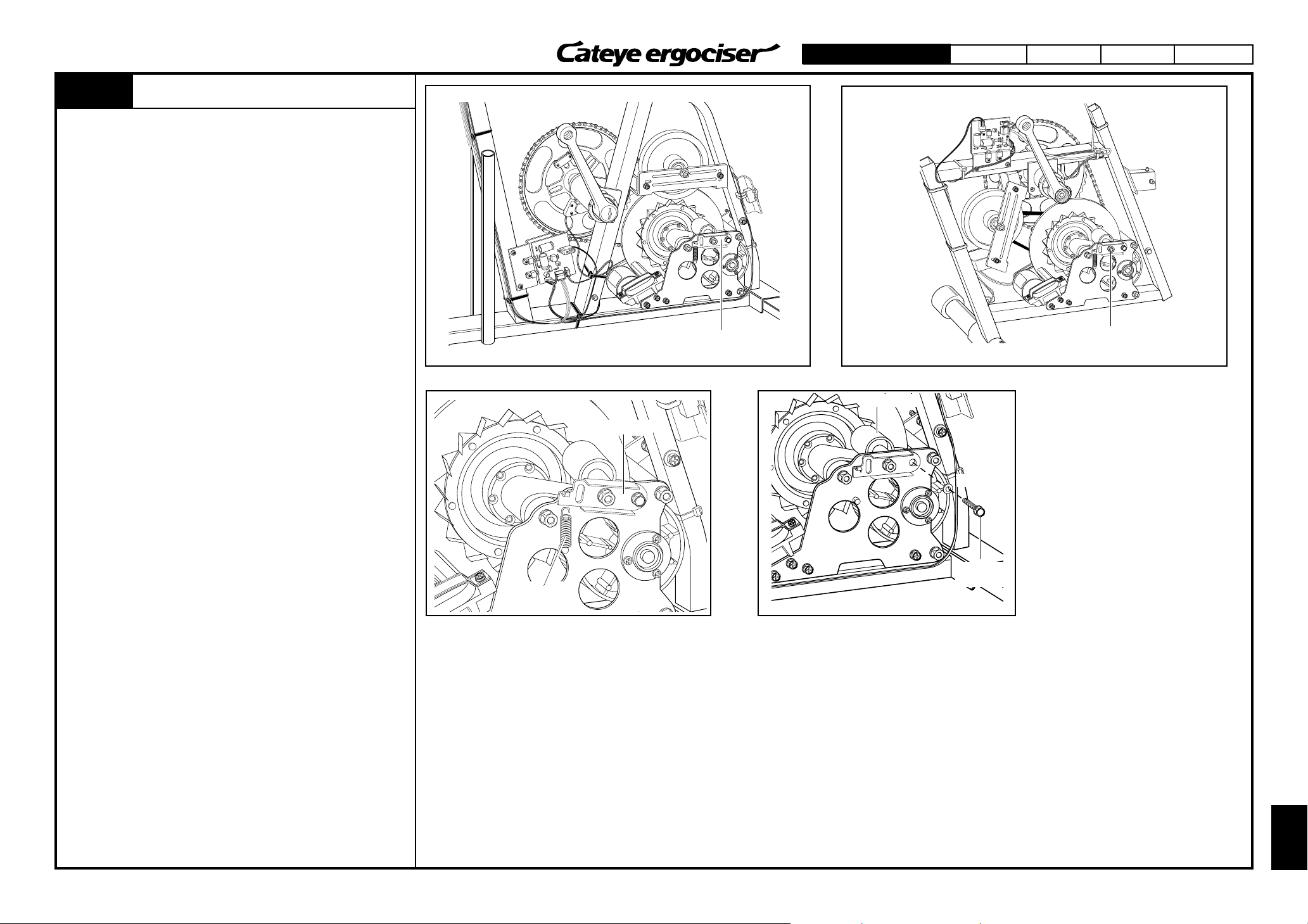

àRemoving the Workload Unit

1. Remove the frame cover, by referring to the Sections D-1 & D2 "Removing the Frame Covers."

2. Detach the CN-1 connector on the power supply board.

3. Using a nipper or the like, cut the cable holder which fixes the

CN-1 connector, while paying attention not to damage the

cable. (Fig. 2)

4.Remove the gear crank, by referring to the Section MS-8

"Replacing the Crank Set." Also, remove the chain together

with the gear crank.

5. Using a wrench, loosen the nuts, which fix the workload unit

reinforcing metal base, on both the workload unit side and the

frame side, and remove the metal base. (Fig. 3)

6. Remove the hexagon head bolts which fix the workload unit

(two bolts on either right and left sides). Lift the entire workload

unit upward until it comes off the workload unit fixing metal

base, and remove the unit by shifting it either in the right or left

side (Fig. 4). Be careful that the copper disk plate does not

touch the frame.

Replacing the Workload Unit (w/o Flywheel) (1)

EC-1200

Workload Unit

Power Supply Board

Power Supply

Board

CN-1 Connector

Fig. 1

Wrench

Workload Unit

Reinforcing Metal Base

Fig. 2

Workload Unit

Fig. 4

Cable Holder

Fig. 3

Replacing the Workload Unit (w/o Flywheel) (1)

Workload Unit Fixing Hexagon Head Bolt

MS-1

Cateye Ergociser Series 1000 Service Manual

35

Page 38

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

MS-1

àMounting the Brandnew Workload Unit

1. Assemble the brandnew workload unit so that it will engage

with the workload unit mounting metal base of the frame (Fig.

1). Be careful that the copper disk plate will not touch the

frame.

2. Tighten the crank nut by using a cotterless gear crank

removing/ fastening tool and a wrench (Figs. 2 and 3).

Tightening torque should be 350kg cm to 400kg·cm, and

tighten the nut until the end of the crank shaft can level with the

end surface of the nut. Then, put the crank cap with a coin or

the like. (Fig. 4)

3. Assemble the chain. Chain should first be set on the free

wheel before setting it to the upper part of the large gear.

Then, a forward rotation of the crank will enable the complete

setting on the large gear. (Fig. 5)

4. Set the derailleur spring to the pawl of the derailleur to give

tension to the chain. (Fig. 6)

5. Adjust the position of the workload unit so that the tension of

the chain at the workload unit can be adequate. Move the

workload unit back and forth so that the longer edge of the

derailleur fixing metal base can be positioned at a right angle

to the derailleur spring. (Fig. 6)

6. Tighten the workload unit fixing screw (two screws on either

right and left sides). (Fig. 7) The tightening torque is 90kg·cm

to 120kg·cm.

7. Assemble the workload reinforcing metal base in between the

bolts at the workload side and the frame side, and tighten the

bolts with nuts. (Fig. 8)

* In case the nut is screwed in at the position where the

workload-unit-side workload unit metal base is supposed to be

mounted, remove the nut.

* The tightening torque at the workload unit side should be

90kg·cm to 120kg·cm, and the nut at the frame side should be

provisionally tightened.

Replacing the Workload Unit (w/o Flywheel) (2)

Workload Unit

Fig. 1

Coin

Fig. 4

Workload Unit Fixing Metal Base

Crank Cap

Workload Unit Fixing Screw

Fig. 5

Wrench

Cotterless Gear Crank

Removing/Fastening Tool

Fig. 2

Upper Part of Large Gear

Chain

Workload Unit Reinforcing Metal

Base

Frame-Side Bolt

Wrench

Cotterless Gear Crank Removing/

Fastening Tool

Fig. 3

Derailleur

Spring

Derailleur

Fig. 6

Workload-UnitSide Bolt

Replacing the Workload Unit (w/o Flywheel) (2)

MS-1

Cateye Ergociser Series 1000 Service Manual

36

Fig. 7

Fig. 8

Page 39

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

MS-1

à Checking the Positions of Copper Disk Plate and Solenoid Coil

Core Slit

T Regarding the workload unit, positions of copper disk plate

T Rotate the copper disk plate slowly to check if it does not

Correction Method

Correction can be made by tightening the frame-side nuts of the

workload reinforcing metal base. Tighten the metal base toward the

direction in which the positional correction of the copper disk plate

should be made, until the plate comes close to the center of the core

slit (Fig. 1). (See the Section ES-4 "Correcting the Position of

Solenoid Coil.")

1. After checking the correction direction, use a wrench to tighten

the frame-side nut of the workload unit reinforcing metal base.

Give the even tightening to both right and left sides.

2. As shown in Fig. 2, set a cable for measuring coil current in

between the CN-1 female connector and the CN-1 male

connector at the side of power supply board, and connect the

cable to an ammeter.

3. Turn on the power switch of the main unit, set the control unit

to the manual mode, select the torque at 4.0kg·m, and start the

system.

4. Using a blade-head screwdriver, adjust the potentiometer on

the power supply board so that the meter reading shows the

coil current which is specified on the solenoid coil of the

workload unit.

Example:As shown in Fig. 3, when 630 is indicated, adjust the

potentiometer so that the coil current will be 630mA.

5. After having adjusted the coil current, remove the measuring

cable, and connect the female connector of the CN-1 cable

directly to the male connector at the power supply board side.

6. Fix the cable onto the seat pipe with cable holders.

Replacing the Workload Unit (w/o Flywheel) (3)

and solenoid coil core slit have been adjusted before

mounting the frame so that they will not touch each other

while the plate is rotating. However, due to positional

distortion caused by tightening the bolts while the frame is

being mounted, the copper disk plate may touch the core.

(Fig. 1)

touch the core. If it does, it is necessary to eliminate the

positional distortion caused by the tightening.

Correct Position

Core Slit

Fig. 1

CN-1 Female

Connector

Fig. 3

Copper Disk Plate

Core

Cable for Measuring

Coil Current

Frame-Side Nut

Fig. 2

Power Supply Board

CN-1 Connector

Workload Unit

Reinforcing Metal Base

Workload-Unit-Side Nut

I

LOT No.

Fig. 4

mA

COIL

K6020

àAdjusting the Flywheel

1. Adjust the flywheel by referring to the Section MS-3 "Adjusting

the Flywheel."

Replacing the Workload Unit (w/o Flywheel) (3)

MS-1

Cateye Ergociser Series 1000 Service Manual

37

Page 40

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

MS-2

àRemoving the Workload Unit

1. Remove the gear crank and the chain by referring to Items 1

through 4 of the Section MS-1 "Replacing the Workload Unit

(w/o Flywheel) (1)."

2. Loosen the flywheel fixing nut which is fixed to the flywheel

metal base. (Fig. 1)

3. Remove the four bolts which fix the flywheel metal base, and

remove the plain belt. (Fig. 2)

4. Remove the workload unit by referring to Items 5 and 6 of the

Section MS-1 "Replacing the Workload Unit (w/o flywheel)

(1)."

àMounting the Brandnew Workload Unit

1. Assemble the brandnew workload unit so that it will engage

with the workload unit mounting metal base of the frame (Fig.

1). [See the Item 1 of the Section MS-1 "Replacing the

Workload Unit (w/o flywheel) (2)."]

2. Hang the plain belt on the flywheel, and fix it to the flywheel

metal base with the flywheel fixing nut.

3. Provisionally fasten the metal base fixing screw (4 pieces) to

the flywheel fixing metal base and the frame respectively. (Fig.

2)

4. Mount the workload unit by referring to Items 2 to 6 of the

Section MS-1 "Replacing the Workload Unit (w/o flywheel)

(2)."

àAdjusting the Flywheel

1. Adjust the flywheel by referring to the Section MS-3 "Adjusting

the Flywheel."

Replacing the Workload Unit (w/ Flywheel)

Fig. 1

Flywheel

Workload Unit

Flywheel Fixing Nut

Flywheel

EC-1600

Workload Unit

Flywheel Fixing Nut

Flywheel Metal Base

Metal Base Fixing

Screw

Fig. 2

Flywheel

ON

EC-3600 & EC-3700

Plain Belt

Flywheel Fixing Metal Base

Replacing the Workload Unit (w/ Flywheel)

MS-2

Cateye Ergociser Series 1000 Service Manual

38

Page 41

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

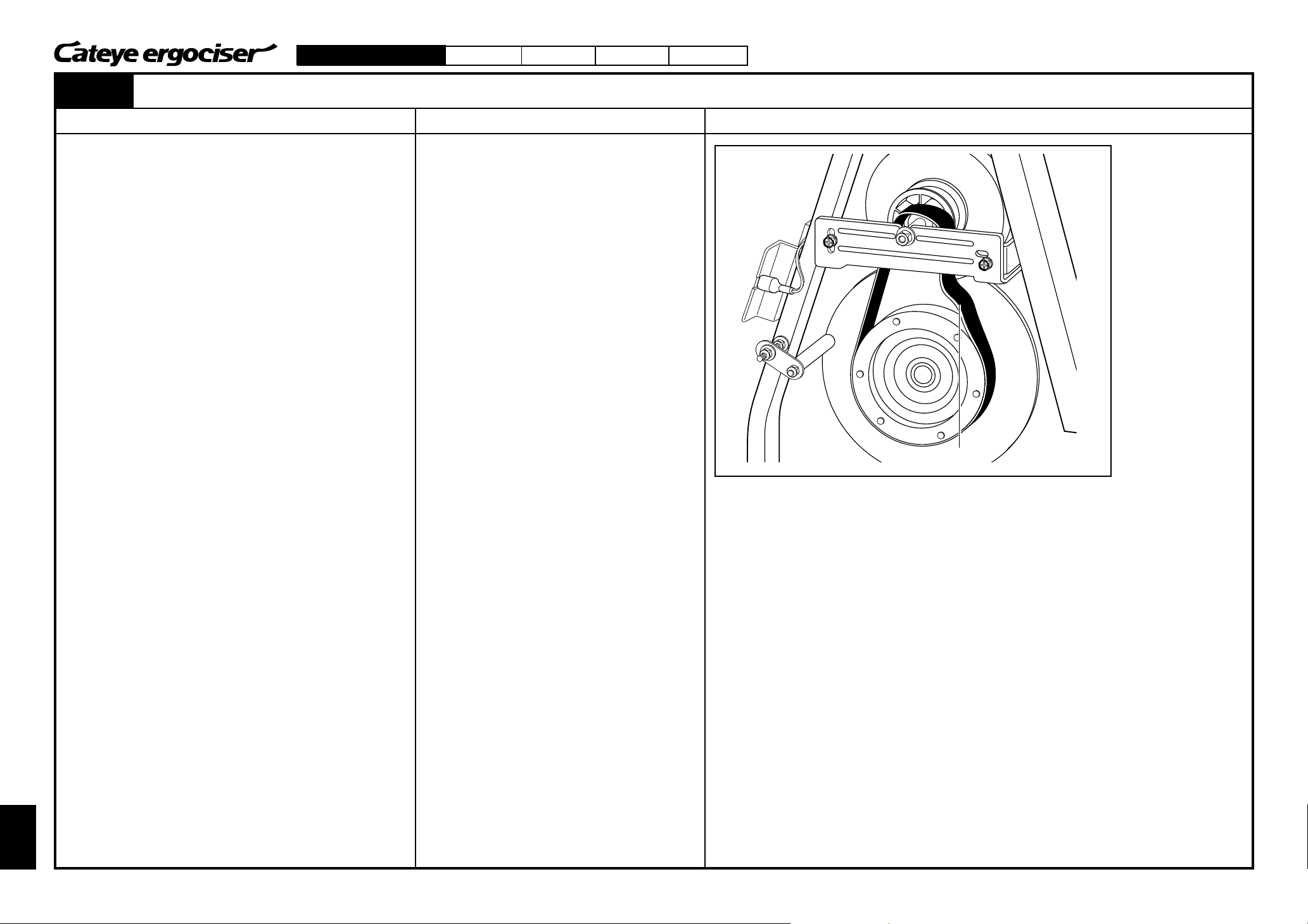

MS-3

àAdjustment Method of Flywheel

Since the plain belt which delivers the rotation of both the workload

unit and flywheel requires an adequate tension, a specified tension

should be given to the plain belt in the following adjustment

procedures. For this adjustment, use commercial tools, since no

purpose-designed tool is not prepared.

1.Set a commercial wire around the flywheel metal base as

depicted in Fig. 1, and tie up the both ends outside the frame.

2. Hang a commercial spring scale at the top of the wire thus tied

up, and lift the scale upward with a pulling force of 5 to 6 kg.

3. Keeping this status, fully tighten the four metal base fixing

screws which had been fastened provisionally. (Fig. 2)

Adjusting the Flywheel

Spring Scale

Wire

Metal Base Fixing Screws

Flywheel Metal Base

Flywheel Metal Base

Flywheel

Metal Base Fixing Screw

Fig. 2

Fig. 1

Adjusting the Flywheel

MS-3

Cateye Ergociser Series 1000 Service Manual

39

Page 42

Applicable Models:

ON

OFF

EC-1200 EC-1600 EC-3600 EC-3700

MS-4

1. Remove the frame cover by referring to the Sections D-1 & D2 "Removing the Frame Covers."

2. Use a screwdriver or the like to remove the derailleur spring

which is hung on the derailleur metal base, thus loosening the

chain.

3. First detach the chain at the upper part of the large gear, and

then rotate the crank forward to detach the entire chain. (Fig.

2)

4. The brandnew chain should be hung firstly on the free wheel,

and then hang it over the upper part of the large gear. A

forward rotation of the crank will allow complete setting of the

entire chain. (Fig. 3)

5. Adjust the tension of chain. Hang the spring on the derailleur,

loosen the workload fixing screw, and adjust the tension while

sliding the workload unit back and forth. (Fig. 4)

* Be careful not to give excessive tension to the chain.

6. Assemble the frame cover by referring to the Sections D-1 &

D-2 "Removing the Frame Covers."

Replacing the Chain

EC-1200 & EC-1600

Derailleur Spring

Chain

Chain

EC-3600 & EC-3700

Crank

Large Gear

Replacing the Chain

MS-4

Cateye Ergociser Series 1000 Service Manual

40

Fig. 1

Large Gear

Fig. 3

Derailleur

Fig. 2

Crank

Approx. 3 to 7mm of slack

Free Wheel

Fig. 4

Page 43

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

MS-5

1.Detach the chain. (See the Section MS-4 "Replacing the

Chain.")

2. Hold the D-cut section on the free wheel shaft with a No.13

wrench, and remove the hexagon U-nut. Then, pull off the free

wheel set by using a free wheel remover. (Figs. 1 & 2)

3. Mount the brandnew free wheel set, and firmly tighten the

hexagon nut. Tightening should be done while holding the Dcut section with a No.13 wrench. (Fig. 1)

4. Set the chain by referring to the Section MS-4 "Replacing the

Chain."

Replacing the Free Wheel Set

Free Wheel Set

EC-1200 & EC-1600

Idler

Free Wheel Set

EC-3600 & EC-3700

ON

OFF

Free Wheel

D-Cut Section

Fig. 1

Timing Belt

Hexagon U-Nut

Free Wheel

Fig. 2

Replacing the Free Wheel Set

MS-5

Cateye Ergociser Series 1000 Service Manual

41

Page 44

Applicable Models:

ON

EC-1200 EC-1600 EC-3600 EC-3700

MS-6

1. Detach the derailleur spring from the pawl of the derailleur

metal base. (Fig. 1)

2. Loosen the derailleur fixing bolt with a No.10 socket wrench,

and remove the derailleur set. (Fig. 2)

3. Mount the brandnew derailleur set with fixing screws.

4. Set the derailleur spring on the pawl of the metal base to give

tension to the chain.

Replacing the Derailleur Set

Derailleur Set

EC-1200 & EC-1600

Derailleur Set

EC-3600 & EC-3700

Replacing the Derailleur Set

MS-6

Derailleur Spring

Fig. 1

Derailleur

Fig. 2

Derailleur Fixing Bolt

Derailleur

Cateye Ergociser Series 1000 Service Manual

42

Page 45

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

MS-7

1. Remove the frame cover by referring to the Sections D-1 & D2 "Removing the Frame Covers."

2. Remove the idler spring from the pawl of the idler metal base.

(Fig. 1)

3. Loosen the idler mounting bolts, and detach the idler set. (Fig.

2)

4. Mount a brandnew idler set by using an idler mounting bolt.

5. Hang the idler spring on the pawl of the idler to give tension to

the belt.

Replacing the Idler Set

EC-1200 & EC-1600

Idler

Idler Set

Idler Set

EC-3600 & EC-3700

Idler

Fig. 1

Idler Fixing

Bolt

Idler Spring

Fig. 2

Replacing the Idler Set

MS-7

Cateye Ergociser Series 1000 Service Manual

43

Page 46

Applicable Models:

ON

OFF

EC-1200 EC-1600 EC-3600 EC-3700

MS-8

àRemoving the Gear Crank (Crank)

1. Remove the frame cover by referring to the Sections D-1 & D2 "Removing the Frame Covers."

2. Detach the chain by referring to the Section MS-4 "Replacing

the Chain." (Fig. 1)

3. Detach the crank cap with a coin or the like. (Fig. 2)

4. Use a cotterless gear crank removing/fastening tool and a

wrench, rotate the crank nut to remove it. (Fig. 3)

5. Change the sides of a cotterless gear crank removing/

fastening tool, and rotate it clockwise to remove the gear crank

(crank) from the crank shaft. (Fig. 4)

- to be continued to the next page -

Replacing the Crank Set (1)

EC-1200 & EC-1600

Crank Set

Crank Set

EC-3600 & EC-3700

Upper Part of Large Gear

Coin

Replacing the Crank Set (1)

MS-8

Cateye Ergociser Series 1000 Service Manual

44

Fig. 1

Cotterless Gear Crank

Removing/Fastening Tool

Fig. 3

Chain

Crank Cap

Fig. 2

Wrench

Wrench

Cotterless Gear Crank

Removing/Fastening Tool

Fig. 4

Page 47

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

MS-8

àAssembling the Gear Crank (Crank)

1. Mount the gear crank (crank) to the crank shaft.

2. Securely fasten the crank nut by using a socket wrench (or by

a cotterless gear crank removing/fastening tool and a wrench).

(Figs. 1 & 2)

* Respective cranks should be positioned each other to from

3. Fasten the crank cap by using a coin, etc. (Fig. 4)

4. The chain should be first set on the free wheel, and then on the

upper part of the large gear. A forward rotation of the crank will

enable the complete setting of the gear. (Fig. 5)

5. Adjust the tension of chain. Loosen the workload fixing screw

[two screws at each right and left side (Fig. 6)], and adjust the

tension while sliding the workload unit. The tension of chain

should be adjusted as illustrated in Fig. 7.

* Be careful not to give excessive tensioning to the chain.

6. Adjust the clearance between the magnet mounted on the

large gear and the CDC sensor, and also adjust the positions

of the indication lines, by referring to Item (5) Section ES-5

"Replacing the CDC Sensor."

7. Provisionally turn on the power, and check if the pedal

cadence is displayed on the control unit.

8. Assemble the frame cover by referring to the Sections D-1 & D2 "Removing the Frame Covers."

Replacing the Crank Set (2)

an angle of 180° against the gear.(Fig.3)

Wrench

Cotterless Gear Crank Removing/Fastening Tool

Fig. 1

Coin

Crank Cap

Fig. 4

Wrench

Cotterless Gear Crank

Removing/Fastening Tool

Fig. 2

Fig. 5

Right-Side

Crank

Left-Side Crank

Fig. 3

Upper Part of Large Gear

Chain

Workload Unit Fixing Screw

Fig. 6

Approx. 3 to 7mm of Slack

Replacing the Crank Set (2)

Fig. 7

MS-8

Cateye Ergociser Series 1000 Service Manual

45

Page 48

Applicable Models:

EC-1200 EC-1600 EC-3600 EC-3700

MS-9

àREMOVAL

1. Remove the frame cover, by referring to the Sections D-1 & D2 "Removing the Frame Covers."

2. Remove the gear crank/crank from the crank shaft(BB axle),

by referring to the Section MS-8 "Replacing the Crank Set."

3. Remove the BB cup locking with a hanger rotating jig. (Fig. 1)

4. Remove the BB adjusting cup, by using a pin face wrench.

(Fig. 2)

5. Remove the crank shaft(BB axle).

6. Remove the BB fixing cup, by using the hanger rotating jig.

(Fig. 3) The CDC sensor metal base will be removed at the

same time.

àASSEMBLING

1. Check if no retainer remains within the hanger, and mount the

BB fixing cup. Be sure that the CDC sensor metal base should